The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Welding Robot Operation and Maintenance interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Welding Robot Operation and Maintenance Interview

Q 1. Describe your experience with different types of welding robots (e.g., arc welding, spot welding).

My experience encompasses a wide range of welding robots, primarily focusing on arc welding and spot welding applications. I’ve worked extensively with six-axis robots from various manufacturers like FANUC, ABB, and KUKA. Arc welding robots, which utilize a consumable electrode, are incredibly versatile for joining various metals, from thin sheet metal to thick structural steel. I’ve used these in applications ranging from automotive body assembly to the fabrication of large industrial components. Spot welding robots, on the other hand, are specialized for creating localized welds by applying pressure and electric current. My experience includes programming and maintaining these robots for high-volume production lines, often in automotive and appliance manufacturing. I’m familiar with the nuances of each process, including the selection of appropriate welding parameters (current, voltage, travel speed) and the implications for weld quality.

For example, in one project, I transitioned a production line from manual arc welding to an automated system using FANUC arc welding robots. This significantly improved consistency and throughput, reducing production time by almost 30%. In another project involving spot welding robots, I optimized the robot programs and weld schedules to reduce cycle time by 15% and minimize electrode wear, resulting in substantial cost savings.

Q 2. Explain the process of programming a welding robot for a specific task.

Programming a welding robot involves several key steps. First, you need to create a detailed process plan, outlining the welding path, parameters, and other essential variables. This often involves using CAD models of the parts being welded to create a precise digital representation of the weld seams. Next, you’ll use robot programming software to define the robot’s movements. This can be done using various methods, including teach pendants (manual guiding of the robot arm), offline programming (using simulations), or a combination of both. The software allows you to create programs using a combination of commands to control the robot’s movements and the welding parameters. Finally, thorough testing and refinement of the program are crucial to ensure the weld quality meets the specified requirements.

For instance, in one project involving a KUKA robot, I used offline programming to simulate the welding process before deploying it on the actual robot. This allowed me to identify and rectify potential issues early on, saving time and resources. Offline programming tools often allow simulation of robot movement and collision detection, critical for maximizing efficiency and safety.

Example code snippet (pseudocode):MOVE_TO(start_point)SET_WELDING_PARAMETERS(current, voltage)WHILE (weld_seam_not_completed) ARC_WELDING() MOVE_ALONG_SEAM()ENDWHILEMOVE_TO(end_point)Q 3. What safety precautions are essential when operating and maintaining welding robots?

Safety is paramount when working with welding robots. Before operating a robot, it’s vital to ensure all safety interlocks and light curtains are functional. These systems create physical barriers to prevent accidental contact between humans and the moving robot arm. Proper personal protective equipment (PPE) is also crucial; this includes welding helmets with appropriate filters, flame-resistant clothing, and hearing protection. Regular safety inspections of the robot’s mechanical components, electrical systems, and welding equipment are necessary to identify and address any potential hazards. Furthermore, operators should be properly trained on emergency stop procedures and lockout/tagout protocols to prevent accidental operation. Restricted access zones should be established and clearly marked around the robot work cell.

For example, I always make it a practice to visually inspect the robot’s cabling and connections before starting any operation. I also regularly check the emergency stop buttons and light curtains, ensuring their responsiveness. It’s better to take a few extra minutes to prevent a serious accident.

Q 4. How do you troubleshoot common welding robot malfunctions?

Troubleshooting welding robot malfunctions requires a systematic approach. First, I’d thoroughly review the error messages displayed by the robot controller, which provide valuable clues. Then, I’d systematically check the robot’s mechanical components, such as the motors, gears, and sensors, for any signs of wear or damage. I’d also inspect the welding equipment, such as the welding torch, power supply, and wire feeder, for any issues. If the problem persists, I’d further analyze the robot program, looking for any errors in the logic or the welding parameters. The use of diagnostic tools and software can also be very helpful in identifying specific problems.

For example, if a robot is exhibiting erratic movements, I would first check the robot’s encoder feedback to see if there is any problem with the position sensing system. If a weld is inconsistent, I might review the welding parameters (e.g. current, voltage, speed) to optimize the process or identify possible problems with the torch or wire feed.

Q 5. Describe your experience with robot programming languages (e.g., RAPID, KRL).

I have extensive experience with several robot programming languages, including RAPID (ABB robots) and KRL (KUKA robots). RAPID is known for its structured approach and powerful features for managing complex robot applications. I’ve used RAPID to develop programs for high-precision welding tasks requiring intricate path planning and precise control of welding parameters. KRL, on the other hand, is characterized by its relatively straightforward syntax and well-defined functions. I’ve utilized KRL for programming robotic spot welding applications, leveraging its capabilities to efficiently manage the coordination of multiple robots and other automation components. My experience spans both basic and advanced programming techniques within these languages, allowing me to adapt to different robot models and welding applications effectively.

For example, using RAPID, I developed a program for a robotic arc welding system that automatically adjusted welding parameters based on real-time feedback from sensors monitoring the weld pool. This adaptive control greatly enhanced weld quality and consistency.

Q 6. How do you perform preventative maintenance on a welding robot?

Preventative maintenance is crucial for ensuring the reliability and longevity of a welding robot. A comprehensive preventative maintenance program should include regular inspections of all mechanical components for wear and tear, lubrication of moving parts as specified in the manufacturer’s manual, and cleaning of the robot’s exterior and internal components to prevent debris buildup. Regular checks of the electrical systems, including wiring, connectors, and sensors, are equally vital. Additionally, software checks should be performed to identify and address any potential software bugs or glitches. The frequency of these inspections and maintenance tasks will vary depending on the robot’s usage and the manufacturer’s recommendations.

I generally follow a checklist-based approach for preventative maintenance, ensuring no aspect is overlooked. Thorough documentation of each maintenance activity is crucial for tracking the overall health of the robot and for identifying potential problems early on.

Q 7. Explain the concept of robot calibration and its importance.

Robot calibration is the process of precisely aligning the robot’s internal coordinate system with the real-world coordinate system. This is crucial for accurate and repeatable robot movements. Over time, wear and tear on the robot’s mechanical components, as well as environmental factors, can lead to deviations between the robot’s perceived position and its actual position. Calibration ensures that the robot’s movements are accurate, preventing welding inaccuracies or collisions. The calibration process typically involves using specialized tools and software to measure the robot’s actual positions and make adjustments to its internal model. The frequency of calibration depends on several factors, including the robot’s usage and the level of accuracy required.

Imagine a painter using a robotic arm to paint intricate designs; without proper calibration, the robot may deviate from the intended path, resulting in an imperfect paint job. Similarly, in welding, inaccurate calibration can lead to inconsistent weld quality, weak welds, or even damage to the workpieces.

Q 8. What are the different types of sensors used in welding robots, and how do they function?

Welding robots utilize a variety of sensors to ensure accurate and consistent welds. These sensors provide feedback to the robot controller, allowing it to adapt to changing conditions and maintain weld quality. Common sensor types include:

- Arc Sensors: These sensors monitor the welding arc, providing information about arc length, voltage, and current. This data is crucial for maintaining a stable arc and preventing defects like porosity or incomplete fusion. For example, if the arc length becomes too long, the sensor signals the robot to adjust its position to maintain the optimal distance.

- Seam Tracking Sensors: These sensors, often using vision or laser technology, follow the weld seam, compensating for variations in the workpiece’s geometry. This ensures consistent weld placement even on uneven or irregularly shaped parts. Think of it like staying precisely on the line when painting a complex shape.

- Contact Sensors: Used to detect contact between the welding torch and the workpiece, allowing for precise positioning and triggering of the welding process. This is particularly important for applications requiring exact starting points for welds.

- Temperature Sensors: These measure the temperature of the weld pool or surrounding area. This data can be used to control preheating or post-weld cooling, optimizing weld quality and minimizing distortion.

The specific sensor selection depends on the welding process, material properties, and desired weld quality. A sophisticated robot system might integrate several sensor types for optimal performance.

Q 9. How do you handle robot errors and alarms?

Handling robot errors and alarms requires a systematic approach. My first step is always safety – ensuring the robot is stopped and the area is secure. I then carefully analyze the error message or alarm code. The robot’s control system typically provides detailed diagnostic information, often pinpointing the source of the problem. This could range from a simple sensor malfunction to a more complex issue with the robot’s mechanics or software.

I follow a troubleshooting process:

- Consult the robot’s manual: The manual provides detailed explanations of error codes and suggested troubleshooting steps.

- Inspect the system: I visually check all components, looking for any obvious issues such as loose connections, damaged wires, or obstructions.

- Check sensor readings: Verifying sensor data helps identify if a sensor malfunction is the root cause. Sometimes a quick cleaning or recalibration solves the problem.

- Test actuators and motors: If the issue involves movement, I check for mechanical faults like binding or motor issues.

- Review the program: In some cases, the problem might stem from a programming error. I carefully review the robot’s program logic to find and rectify potential mistakes.

- Contact support: If the problem persists, contacting the robot manufacturer’s technical support is essential. Their expertise can be crucial in diagnosing and resolving complex issues.

Effective documentation is crucial in managing errors. I maintain detailed logs of all alarms, troubleshooting steps, and solutions. This creates a valuable database for future reference and aids in preventative maintenance.

Q 10. Describe your experience with different types of welding processes (e.g., MIG, TIG, GMAW).

My experience encompasses several welding processes, each demanding a different approach in robot programming and parameter selection.

- MIG (Gas Metal Arc Welding): I have extensive experience with MIG welding, particularly in high-volume production environments. This involves optimizing parameters like wire feed speed, voltage, and shielding gas flow for consistent weld penetration and bead appearance. Robot programming for MIG welding requires precise control of arc length and travel speed to achieve consistent welds.

- TIG (Gas Tungsten Arc Welding): TIG welding requires a higher level of skill and precision. Robot programming for TIG focuses on accurate path control to maintain a consistent arc length and avoid defects. I have experience with both pulsed and DC TIG welding, adapting the robot programs to the specific application needs.

- GMAW (Gas Metal Arc Welding): GMAW is essentially the same as MIG welding, and I’ve worked extensively with both pulsed and standard GMAW processes, optimizing parameters for different materials and thicknesses.

In each case, I have adapted the robot’s parameters and programming to optimize weld quality, speed, and efficiency. For example, I’ve developed robot programs that automatically adjust welding parameters based on real-time feedback from arc sensors to compensate for variations in material thickness or weld joint geometry.

Q 11. Explain your understanding of robot kinematics and dynamics.

Robot kinematics and dynamics are fundamental to understanding and controlling a welding robot’s movements. Kinematics deals with the robot’s geometry and motion without considering forces and torques. It involves calculating the robot’s joint angles to achieve a desired position and orientation of the welding torch (end-effector) in three-dimensional space. This typically involves using forward and inverse kinematics equations.

Forward Kinematics: Joint angles -> End-effector position/orientation

Inverse Kinematics: End-effector position/orientation -> Joint angles

Dynamics, on the other hand, considers the forces and torques acting on the robot during movement. This is crucial for optimizing robot speed and trajectory, minimizing vibrations, and preventing damage to the robot itself. Factors like inertia, gravity, and friction affect the robot’s dynamic behavior. A well-designed robot control system takes these dynamic considerations into account to produce smooth, accurate, and efficient movements.

Understanding both kinematics and dynamics is crucial for programming welding robots efficiently. For example, by considering dynamic effects, you can optimize the robot’s path to minimize acceleration and deceleration, leading to faster cycle times and reduced wear and tear on the mechanical components.

Q 12. How do you ensure the accuracy and precision of a welding robot?

Ensuring the accuracy and precision of a welding robot involves a multifaceted approach encompassing calibration, maintenance, and programming:

- Calibration: Regular calibration is vital. This involves precisely positioning the robot’s joints to match their programmed values. Errors accumulate over time due to wear and tear, so periodic calibration using specialized equipment and procedures is necessary.

- Maintenance: Preventative maintenance is essential to minimizing wear and tear. This includes lubricating moving parts, inspecting cables and wiring, and regularly checking the condition of the robot’s mechanical components. Prompt attention to minor issues prevents them from becoming major problems impacting accuracy.

- Programming: The robot’s program is crucial. Precisely defining the welding path and parameters – including speed, current, and voltage – directly impacts weld quality. Simulations and offline programming allow for testing and fine-tuning before deployment, minimizing the risk of errors on the actual workpiece.

- Sensor Integration: As mentioned before, sensors play a significant role. Real-time feedback from arc sensors and seam tracking sensors allows the robot to automatically compensate for minor variations in workpiece geometry or welding conditions.

In practice, I regularly use specialized software to monitor the robot’s performance, identifying any deviations from expected behavior and addressing them promptly. This proactive approach minimizes errors and maintains consistent weld quality over time. Think of it as regular checkups for the robot, ensuring it’s always in top shape.

Q 13. What are the common causes of welding defects, and how can they be prevented?

Welding defects can significantly impact the structural integrity and performance of welded joints. Common causes include:

- Porosity: Caused by gas entrapment in the weld metal. This can result from inadequate shielding gas coverage, moisture contamination, or incorrect welding parameters.

- Incomplete Fusion: Occurs when the weld metal does not fully fuse with the base metal. This typically results from insufficient heat input, poor joint fit-up, or incorrect welding speed.

- Undercutting: Characterized by grooves along the edges of the weld bead. This is often caused by excessive welding current, improper travel speed, or insufficient shielding gas.

- Spatter: Weld spatter are small molten metal droplets that are ejected from the weld pool. Excessive spatter can be caused by high welding current, poor shielding gas coverage, or incorrect wire feed speed.

- Lack of Penetration: The weld doesn’t reach the required depth into the base material, weakening the joint. This is usually due to insufficient current, improper welding speed or excessive travel speed.

Prevention strategies focus on meticulous attention to detail across various stages:

- Proper Joint Preparation: Clean and properly fit-up joints are fundamental.

- Accurate Parameter Selection: Correct current, voltage, and travel speed are crucial.

- Appropriate Shielding Gas: Ensures proper protection of the weld pool from atmospheric contamination.

- Regular Maintenance: Keeping the welding equipment in good condition minimizes defects.

- Robot Programming & Calibration: Precise and calibrated robot programs ensure consistent welding parameters.

A rigorous quality control process, including regular inspection and testing of welded joints, is essential to identify and address any defects before they affect the final product.

Q 14. Describe your experience with robotic vision systems and their integration with welding robots.

Robotic vision systems are increasingly integrated with welding robots to enhance accuracy and adaptability. These systems use cameras and image processing algorithms to provide real-time information about the workpiece, allowing for adjustments to the welding process based on what the system “sees”.

My experience includes integrating vision systems for various tasks:

- Seam Tracking: Vision systems can accurately track irregular or complex weld seams, compensating for variations in workpiece geometry. This is crucial for automating the welding of parts with varying shapes or tolerances.

- Part Recognition and Positioning: Vision systems can identify and locate parts, ensuring accurate robot placement before welding begins. This is particularly useful in high-mix, low-volume applications where part variations are common.

- Weld Quality Inspection: Vision systems can be used to inspect the finished weld, automatically detecting defects such as porosity or incomplete fusion. This enhances quality control and reduces the need for manual inspection.

Integration typically involves several steps:

- Camera Selection and Placement: Choosing the appropriate camera and positioning it to provide optimal views of the workpiece.

- Image Processing: Using algorithms to identify features of interest, such as the weld seam or part edges.

- Robot Control Integration: Connecting the vision system to the robot controller, allowing the robot to adjust its movements based on the vision system’s feedback.

- Calibration: Precise calibration ensures that the vision system’s measurements accurately correspond to the robot’s coordinate system.

I’ve successfully integrated vision systems into various welding applications, significantly improving the accuracy, flexibility, and quality of the welding process. This has allowed for automation of tasks previously requiring significant manual intervention, increasing efficiency and productivity.

Q 15. How do you manage and interpret robot data for process optimization?

Managing and interpreting robot data for process optimization is crucial for maximizing efficiency and minimizing defects in welding. This involves collecting data from various sources, analyzing it to identify trends and anomalies, and then using those insights to adjust the welding parameters and robot programming.

For example, we might collect data on weld bead geometry (width, height, penetration), weld speed, current, voltage, and even the position of the robot arm throughout the welding process. This data often comes from sensors embedded in the welding torch, the robot controller, and even external vision systems. We use statistical process control (SPC) methods to analyze this data, looking for patterns indicating problems like inconsistent weld quality or excessive wear on the welding consumables.

Let’s say we observe a consistent increase in weld bead width. This could point to a problem with the wire feed speed, or potentially a worn contact tip on the welding torch. By analyzing the data over time, we can pinpoint the exact cause and implement the necessary correction, such as adjusting the wire feed settings or replacing the contact tip. This proactive approach ensures consistent, high-quality welds and prevents costly rework or scrap.

Specialized software packages are frequently used to visualize and analyze this data. Some packages even offer predictive modeling capabilities, allowing us to anticipate potential issues before they impact production.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of replacing worn parts on a welding robot.

Replacing worn parts on a welding robot is a routine maintenance procedure that’s essential for ensuring safety and maintaining consistent weld quality. The process varies depending on the specific part and robot manufacturer, but it generally involves a series of steps that prioritize safety and precision.

First, we always ensure the robot is in a safe, powered-down state. This is crucial for preventing accidental injury or damage. Next, we consult the robot’s maintenance manual to identify the specific steps and tools needed for the part replacement. The manual provides detailed diagrams and procedures.

Let’s say we need to replace a worn-out welding torch. We would first disconnect the power and gas supplies to the torch. Then, using the appropriate tools (often specialized wrenches or sockets), we carefully remove the worn torch and install the new one, ensuring all connections are secure and properly tightened. After installation, we test the new torch by conducting a series of welds under controlled conditions to ensure it’s functioning correctly.

Throughout the entire process, we meticulously document each step, noting the date, time, and the part that was replaced. This documentation is crucial for tracking maintenance history and for preventative maintenance scheduling.

Q 17. How do you ensure the safety and integrity of welding robot end effectors?

Ensuring the safety and integrity of welding robot end effectors (the tools at the end of the robot arm, like the welding torch) is paramount for both worker safety and consistent weld quality. This involves regular inspections, preventative maintenance, and appropriate safety protocols.

Regular inspections should check for wear and tear on the components, including the nozzle, contact tip, and gas diffuser. We look for signs of damage like cracks, excessive wear, or build-up of spatter. We also verify that all gas connections are leak-free.

Preventative maintenance includes regular cleaning of the end effector to remove spatter and debris, which can affect weld quality and even cause malfunctions. Replacing worn parts proactively, before they cause significant problems, is also key. For instance, a worn contact tip can lead to inconsistent weld arcs and poor weld quality. A cracked gas diffuser can lead to gas leaks.

Safety protocols are crucial. We must always power down the robot before working on the end effector to prevent accidental activation. We also use appropriate personal protective equipment (PPE) like safety glasses and gloves to protect ourselves from potential hazards such as hot metal or sparks.

Q 18. What experience do you have with different robot manufacturers (e.g., Fanuc, ABB, Kuka)?

My experience encompasses a wide range of robot manufacturers, including Fanuc, ABB, and KUKA. I’ve worked extensively with Fanuc robots, particularly their R-2000 series, programming and maintaining them for various high-volume welding applications in automotive manufacturing. I’m proficient in their Karel programming language and familiar with their controller interfaces.

With ABB robots, my experience includes working with their IRB 1410 and IRB 2600 models, primarily for precision welding in aerospace components. I’ve programmed and maintained these robots, troubleshooting issues related to path planning and arc stability. I’m familiar with their RAPID programming language and various arc sensing techniques.

My experience with KUKA robots includes the KR 16 and KR C4 controllers. I’ve worked on projects involving large-scale welding applications and integrating them with vision systems for automated seam tracking. I’m proficient in KUKA’s KRL programming language and have experience with their various safety features and functionalities. This broad experience across different manufacturers allows me to adapt quickly to new challenges and integrate various systems seamlessly.

Q 19. Explain your understanding of PLC programming in the context of welding robots.

PLC (Programmable Logic Controller) programming plays a vital role in the control and automation of welding robots. The PLC acts as the brain of the overall system, coordinating the robot’s actions with other peripheral devices, such as material handling systems, safety interlocks, and part sensors.

In a typical welding cell, the PLC handles functions like initiating the welding process, controlling the flow of gas and electricity to the welding torch, monitoring safety sensors (e.g., light curtains, emergency stops), managing parts movement through the cell using conveyors or other systems, and collecting data on the welding process for analysis. The PLC communicates with the robot controller via various communication protocols, such as Ethernet/IP or Profinet.

For example, I have programmed PLCs to coordinate the movement of a robotic arm with a conveyor belt, ensuring the robot picks up parts only when they are correctly positioned. I’ve also incorporated safety features into PLC programs that halt the robot’s operation if a safety sensor is triggered. This ensures a robust and safe welding operation, minimizing the risk of accidents and maximizing productivity.

My proficiency in various PLC programming languages, such as Ladder Logic and Structured Text, enables me to efficiently design, program, troubleshoot and maintain these control systems.

Q 20. How do you handle unexpected downtime or equipment failure?

Handling unexpected downtime or equipment failure requires a systematic approach that prioritizes safety, efficiency, and minimizing production disruption. My approach involves a structured troubleshooting process:

- Safety First: The first step is always to ensure the safety of personnel and equipment. We power down the robot and isolate any potential hazards.

- Identify the Problem: We systematically diagnose the problem by checking error logs, examining sensor readings, and visually inspecting the equipment. This often involves checking power supplies, communication links, and the robot’s mechanical components.

- Troubleshooting: We consult the robot’s maintenance manual, troubleshooting guides, and technical documentation to determine the likely cause. We might check for loose connections, faulty sensors, or problems with the control software.

- Repair or Replacement: Based on the diagnosis, we either repair the faulty component or replace it. This might involve replacing a worn-out part, repairing a malfunctioning sensor, or updating the robot’s software.

- Verification: After the repair or replacement, we thoroughly test the system to ensure it is functioning correctly and safely before resuming operation.

- Documentation: We meticulously document the entire process, including the problem, the solution, and any preventative measures taken to prevent future occurrences. This documentation is crucial for continuous improvement and future troubleshooting.

In some cases, we might need to escalate the issue to the robot manufacturer’s technical support team for assistance.

Q 21. What are the key performance indicators (KPIs) you monitor for welding robots?

Key Performance Indicators (KPIs) for welding robots are crucial for monitoring efficiency, quality, and overall performance. The specific KPIs chosen will depend on the application and priorities, but some common ones include:

- Uptime: The percentage of time the robot is operational. High uptime is crucial for maximizing productivity.

- Weld Quality: Measured through various methods, such as visual inspection, destructive testing, and non-destructive testing (NDT). This ensures consistency and reliability of welds.

- Cycle Time: The time it takes to complete a single weld cycle. Reducing cycle time directly increases production rate.

- Throughput: The total number of welds completed per unit time. This indicator reflects overall production volume.

- Defect Rate: The percentage of welds that fail to meet quality standards. A low defect rate signifies high-quality production.

- Maintenance Costs: Tracking maintenance expenses helps in managing costs and optimizing maintenance schedules.

- Scrap Rate: Percentage of parts scrapped due to welding defects. Minimizing scrap reduces material waste and production costs.

Regularly monitoring these KPIs allows for data-driven decision-making, optimizing processes, identifying areas for improvement, and ensuring consistent high-quality welds.

Q 22. Describe your experience with robot simulation software.

My experience with robot simulation software is extensive. I’ve worked extensively with software packages like RoboDK, ABB RobotStudio, and FANUC ROBOGUIDE. These tools are invaluable for offline programming (OLP), allowing us to program and test robot welding programs virtually before deploying them on the actual robot. This significantly reduces downtime and minimizes the risk of errors on the production floor. For example, using RoboDK, I was able to optimize a complex welding path for a large automotive part, reducing weld time by 15% and improving weld quality by minimizing heat input variations. Simulation also allows for collision detection and reach analysis, ensuring safe and efficient robot operation. The ability to visualize the entire welding process before execution, including toolpath adjustments and interference checks, makes these simulations a cornerstone of efficient robot programming and maintenance.

Q 23. How do you maintain a clean and organized work environment around welding robots?

Maintaining a clean and organized workspace around welding robots is paramount for safety and efficiency. Think of it like a surgeon’s operating room – precision and cleanliness are essential. Our approach involves a multi-pronged strategy:

- Regular Cleaning: Daily cleaning of the robot cell includes removing weld spatter, chips, and debris using appropriate tools and cleaning agents. This prevents build-up that could interfere with robot movement or cause electrical issues.

- Designated Storage: All tools, consumables (like welding wire and shielding gas), and spare parts have designated storage areas, preventing clutter and ensuring easy access during maintenance. We use clearly labeled containers and shelves.

- Floor Marking: Clear floor markings delineate safe zones for personnel and robot operation, minimizing the risk of accidents. These markings help enforce safe working distances from the robot’s operational area.

- 5S Methodology: We implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to create a sustainable system of organization and cleanliness, making maintenance and troubleshooting more efficient.

Q 24. What are your methods for documenting maintenance procedures and repairs?

Meticulous documentation is crucial for efficient maintenance and repair. We maintain a comprehensive digital system using a computerized maintenance management system (CMMS). Each maintenance task, from routine inspections to major repairs, is documented with details including:

- Date and time of the procedure

- Description of the work performed

- Parts replaced (with serial numbers if applicable)

- Technician responsible

- Photos or videos documenting the issue and the repair process

- Observations and any corrective actions taken

Q 25. Describe your experience with different types of welding power sources.

My experience encompasses various welding power sources, including Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Shielded Metal Arc Welding (SMAW) power supplies. I’m familiar with both constant current and constant voltage systems, understanding the differences in their application based on the material being welded and the desired weld quality. For instance, I’ve extensively used Miller and Lincoln Electric power sources, and I’m comfortable troubleshooting issues like voltage fluctuations, arc instability, and wire feed problems. My knowledge extends to understanding the parameters like amperage, voltage, and wire feed speed to achieve optimal weld penetration and bead appearance. I am also experienced with adjusting parameters based on material thickness and joint design.

Q 26. How familiar are you with robot safety standards and regulations (e.g., ISO 10218)?

I’m very familiar with robot safety standards and regulations, particularly ISO 10218-1 and ISO 10218-2, which cover industrial robots and robot systems. I understand the importance of risk assessment, safeguarding measures (like light curtains, pressure mats, and emergency stops), and the requirements for robot programming and operation to ensure personnel safety. My experience includes implementing and maintaining safety protocols, including regular safety inspections, operator training, and compliance audits. Understanding these standards is not just a matter of compliance; it’s about creating a safe working environment to prevent accidents and injuries.

Q 27. How would you train a new employee on operating and maintaining welding robots?

Training a new employee involves a structured approach incorporating both theoretical and practical learning. This begins with a comprehensive safety briefing covering all aspects of robot operation and maintenance, emphasizing ISO 10218 compliance. The training then progresses to:

- Classroom Training: Theoretical instruction on robot kinematics, programming principles, welding processes, and maintenance procedures.

- Hands-on Training: Supervised practical sessions on robot operation, programming using the relevant software, and performing basic maintenance tasks.

- Simulated Environments: Utilizing simulation software to familiarize the trainee with robot programming and troubleshooting in a risk-free environment.

- On-the-Job Training: Gradual introduction to real-world applications under the guidance of an experienced technician.

- Ongoing Evaluation and Feedback: Regular assessments to monitor progress and provide feedback, ensuring proficiency in all aspects of robot operation and maintenance.

Q 28. Describe a challenging welding robot maintenance issue you faced and how you resolved it.

One challenging issue I faced involved a recurring robot arc fault during a high-volume production run. The robot would intermittently stop welding, throwing an arc fault error. Initial troubleshooting, including checking the power source, welding wire, and shielding gas supply, yielded no results. After meticulously reviewing the robot’s operational logs and conducting a thorough inspection, I noticed a slight misalignment in the robot’s wrist joint. This subtle misalignment caused the welding torch to come into contact with the workpiece at an unpredictable angle, resulting in short circuits and arc faults. By carefully adjusting the wrist joint alignment using the robot’s teach pendant and verifying the alignment with a laser alignment tool, we were able to resolve the issue completely. This experience highlighted the importance of meticulous attention to detail, even in seemingly minor mechanical aspects of the robot system. It also demonstrated the importance of robust logging and data analysis in identifying and resolving complex issues.

Key Topics to Learn for Welding Robot Operation and Maintenance Interview

- Robot Programming and Control Systems: Understanding different programming languages (e.g., RAPID, KRL), path planning, and troubleshooting control system errors. Practical application: Modifying existing welding programs to adapt to new materials or weld parameters.

- Welding Processes and Parameters: Deep knowledge of various welding techniques (e.g., MIG, TIG, spot welding) used with robots, and how to optimize welding parameters (voltage, current, speed) for different materials and applications. Practical application: Diagnosing weld defects and adjusting parameters to achieve consistent weld quality.

- Robot Maintenance and Troubleshooting: Regular maintenance procedures (lubrication, cleaning, sensor calibration), diagnosing mechanical and electrical malfunctions, understanding safety protocols, and preventative maintenance strategies. Practical application: Identifying and resolving issues like sensor failures, faulty actuators, or communication errors.

- Safety Procedures and Regulations: Comprehensive understanding of relevant safety regulations, emergency procedures, lockout/tagout procedures, and risk assessment related to robot operation and maintenance. Practical application: Ensuring a safe working environment and preventing accidents.

- Sensor Technology and Integration: Knowledge of various sensors used in robotic welding (e.g., arc sensors, vision systems), their functionality, and integration with the robot control system. Practical application: Troubleshooting sensor-related issues and ensuring accurate weld positioning.

- Preventive Maintenance and Predictive Analytics: Implementing strategies for preventative maintenance to minimize downtime and extend the lifespan of the welding robots. Understanding and applying predictive analytics techniques based on sensor data to anticipate potential failures. Practical application: Creating and implementing a robust preventative maintenance schedule.

Next Steps

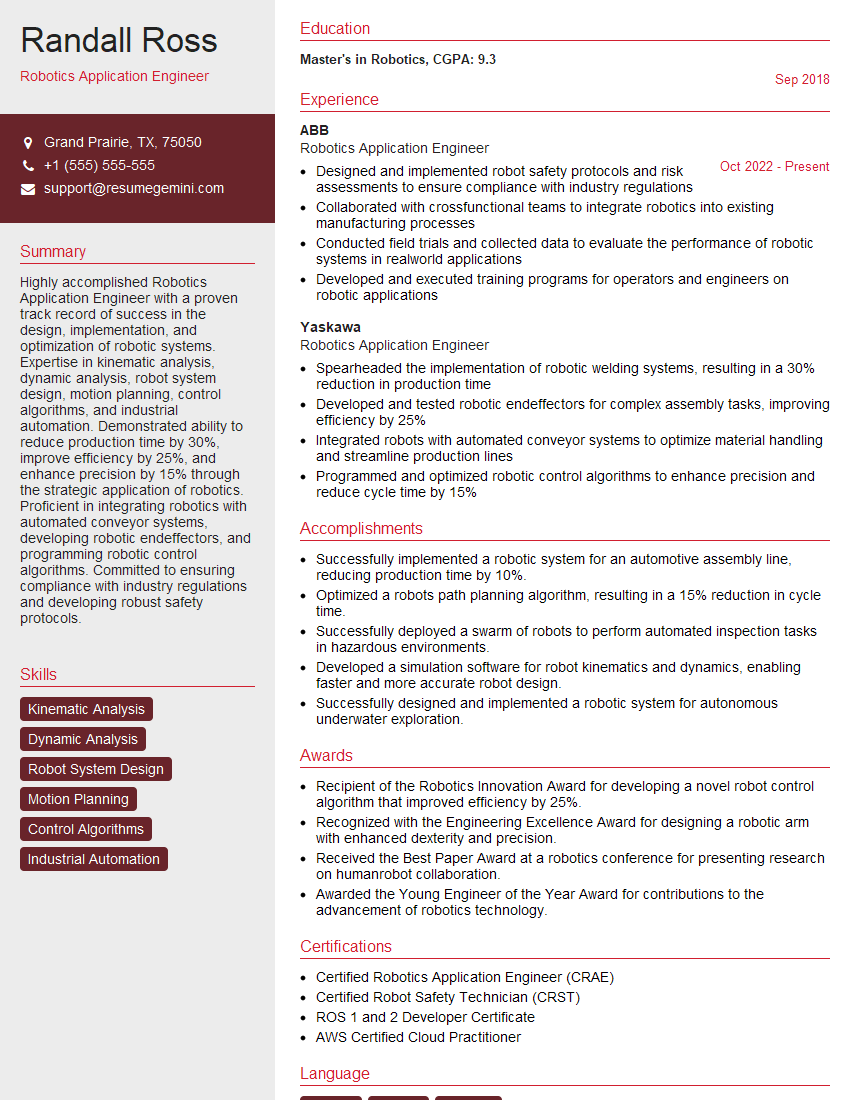

Mastering Welding Robot Operation and Maintenance opens doors to exciting career opportunities with excellent growth potential in advanced manufacturing and automation. To maximize your job prospects, invest time in crafting a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They offer examples of resumes tailored to the Welding Robot Operation and Maintenance field, ensuring your application stands out from the competition. Take the next step towards your dream career – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good