Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Animal Hide Evaluation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Animal Hide Evaluation Interview

Q 1. Describe the different grades of animal hides and their characteristics.

Animal hide grading is crucial in determining its suitability for various leather products. Grades are assigned based on several factors including the hide’s overall condition, thickness, and the presence of defects. Generally, hides are categorized into several grades, though the specific naming conventions can vary between tanneries and regions.

- Grade A: Represents the highest quality. These hides are virtually flawless, with minimal blemishes or imperfections. They possess uniform thickness and are ideal for high-end leather goods requiring superior quality and consistency.

- Grade B: These hides have some minor imperfections, such as small scars or brand marks that don’t significantly affect the overall quality. They are still suitable for many applications but might be used for less visible parts of a product.

- Grade C: This grade encompasses hides with more pronounced defects, like larger scars or patches of damage. While usable, they are typically suited for less demanding applications or items where the defects can be easily hidden.

- Grade D (or lower): These hides show significant damage, making them less desirable for leather production. They may have extensive scarring, holes, or other imperfections that severely compromise their structural integrity and appearance. They might be used for non-leather applications or discarded entirely.

Think of it like grading gemstones: A flawless diamond is Grade A, a diamond with a tiny inclusion is Grade B, and so on. The grading system ensures transparency and helps determine the appropriate price and application for each hide.

Q 2. Explain the process of assessing hide damage, such as scars and insect damage.

Assessing hide damage requires a keen eye and detailed examination. We look for a variety of defects, employing visual inspection, sometimes aided by tools like magnifying glasses.

- Scars: We evaluate the size, depth, and location of scars. Small, superficial scars have less impact than deep, extensive ones that penetrate the hide’s grain. The location also matters; a scar on a less visible area of a garment is less impactful than one in a prominent location.

- Insect Damage: We check for holes, pitting, or other signs of insect infestation. The extent and type of damage are noted. Small holes may be acceptable, but extensive damage renders the hide unsuitable for many applications. We assess whether the damage is consistent with insect activity or something else such as animal bites.

- Other Damages: This includes cuts, gouges, brand marks, and other forms of physical damage. We meticulously document the type, size, and severity of each defect.

Imagine a detective investigating a crime scene – we meticulously examine every aspect of the hide to understand its history and its suitability for its intended purpose. Detailed records are kept for traceability and transparency.

Q 3. How do you determine the suitability of a hide for specific leather types?

The suitability of a hide for a specific leather type depends on several factors, including the hide’s thickness, grain characteristics, and the presence or absence of defects.

- Full-Grain Leather: Requires hides with a flawless or nearly flawless top grain layer. Any significant scars or imperfections will show through in the finished product. This is because full-grain retains the top layer of the hide, offering superior durability and character.

- Top-Grain Leather: The top grain layer is sanded to remove minor imperfections before finishing. Therefore, hides with minor blemishes are suitable. This is a more cost-effective option, and still offers good durability.

- Genuine Leather: This term is often used for leather made from the lower layers of the hide, after the top layer has been removed for other types of leather. Therefore, it is less demanding in terms of the hide quality and can accommodate more imperfections.

It’s a matching game – a flawless hide is perfect for full-grain leather, while hides with minor imperfections can still be utilized for top-grain and genuine leather types. The choice of leather type dictates the allowable level of hide defects.

Q 4. What are the key factors influencing hide quality and price?

Hide quality and price are interconnected, influenced by multiple factors. A premium hide commands a higher price because of its superior characteristics, while lower grades are cheaper due to defects or imperfections.

- Thickness and Area: Larger and thicker hides are more valuable because they yield more leather.

- Grain Quality: A fine, uniform grain is valued over coarse, uneven grains.

- Fiber Structure: Dense, tightly packed fibers indicate strength and durability. Loosely packed fibers result in weaker leather.

- Presence of Defects: Scars, insect damage, and other imperfections reduce the value of a hide, which results in lower prices.

- Animal Breed and Age: Certain breeds are known for producing higher quality hides than others. The age of the animal also plays a role; younger animals often produce thinner and softer hides compared to older animals.

Think of it like real estate – location, size, and condition determine the price. The same logic applies to hides; a large, flawless hide from a prized animal breed will command top dollar.

Q 5. What are the common defects found in animal hides and how are they assessed?

Many defects can affect animal hides. Their assessment involves a systematic approach to identify and quantify the impact of these imperfections on the final leather quality.

- Scars: These are caused by injuries and are assessed based on their size, depth, and location. Deep, large scars significantly affect hide value.

- Insect Damage: Holes, pitting, and other damage caused by insects are carefully documented. The extent of infestation and the area affected are critical assessment points.

- Brand Marks: These are often intentional markings made on livestock, and their presence and location affect the hide’s grade.

- Cuts and Gouges: These are accidental injuries, and their size, depth, and location dictate their influence on the hide’s value.

- Grain Damage: Damage to the hide’s grain structure, such as wrinkles or unevenness, affects the final appearance of the leather.

A thorough inspection helps assign an appropriate grade, ensuring the hide is used for the most suitable application. Imagine a tailor carefully inspecting fabric for flaws before starting a project; this is a comparable level of scrutiny we apply to hides.

Q 6. Explain the difference between full-grain, top-grain, and genuine leather.

These terms refer to different levels of leather processing and the resulting quality and characteristics.

- Full-Grain Leather: This is the highest quality leather. The top layer of the hide (the grain) is left untouched, retaining its natural texture and markings. This results in durable, breathable leather with a unique character. It shows the animal’s natural markings.

- Top-Grain Leather: The topmost layer of the hide is sanded to remove imperfections, creating a smoother surface. A finishing layer is usually applied for uniformity and protection. It lacks the natural texture and markings of full-grain leather.

- Genuine Leather: This term often refers to leather made from the lower layers of the hide (splits), after the top layer is used for full-grain or top-grain leather. These layers are less durable and often have a more artificial finish.

Think of it like cutting a cake: Full-grain is like the top layer, smooth and beautiful, while top-grain is like the next layer down, still delicious but perhaps a bit less impressive, while genuine represents the scraps, still edible but less refined. Each type offers different qualities, suited to various needs.

Q 7. How do you identify and measure hide thickness and area?

Measuring hide thickness and area is crucial for grading and pricing. Specialized tools and techniques are employed for accurate measurements.

- Thickness: A hide’s thickness is typically measured using a hide thickness gauge, usually at multiple points across the hide. This ensures a representative measurement as thickness can vary across the hide. Measurements are often recorded in millimeters or fractions of an inch.

- Area: The area of the hide is typically measured by laying it flat and carefully measuring its length and width using a measuring tape. The area is then calculated as length x width. Complex shapes might require more advanced measuring techniques.

Accuracy is paramount. Think of a tailor precisely measuring fabric for a garment; similar precision is required when measuring hides to ensure accurate assessments and pricing.

Q 8. Describe the process of evaluating hide wet-blue and its significance.

Evaluating wet-blue hides is crucial for determining their suitability for leather production. Wet-blue is the stage after tanning where the hide is still damp and has a bluish tint. The evaluation process involves a meticulous assessment of several key characteristics.

- Visual Inspection: This involves checking for any defects like holes, cuts, brands, insect damage, or uneven thickness. We look for the overall consistency of the hide’s surface and its uniformity in color. Think of it like inspecting a piece of fabric for flaws before tailoring it.

- Measurement: The area (usually in square feet) and thickness are precisely measured. Larger hides, with consistent thickness, are generally preferred as they yield more usable leather.

- Texture and Feel: Experienced evaluators can assess the hide’s texture (firm, soft, etc.) and feel to judge its grain characteristics and potential quality. It’s akin to a skilled tailor judging the quality of fabric by its drape and texture.

- Smell: A trained eye and nose can detect any undesirable odors indicative of spoilage, improper curing, or underlying problems within the hide itself. A musty smell, for example, signals potential issues.

The significance of this evaluation lies in ensuring that only hides meeting specified quality standards proceed to the next stages of leather production, ultimately affecting the final product’s quality, cost, and marketability.

Q 9. What are the standard industry measurements used for hide evaluation?

The standard industry measurements for hide evaluation primarily focus on:

- Area: Measured in square feet (sq ft) or square meters (sq m), this determines the amount of leather that can be produced from a single hide. Accurate measurements are vital for pricing and yield calculations.

- Thickness: Measured in millimeters (mm) or fractions of an inch, using tools like a hide thickness gauge. Consistent thickness is key; variations can lead to uneven leather. We look for an ideal thickness suitable for the intended leather type, for example, a thinner hide might be better for clothing leather, while a thicker one is better for upholstery.

- Weight: The weight, often expressed in kilograms or pounds, is often less important than area and thickness, but can give a rough indicator of hide density.

- Stretch/Shrinkage: Although not a direct measurement, the hide’s ability to stretch during the tanning and finishing process and subsequent shrinkage is vital for determining its suitability for different leather goods. This is assessed by comparing measurements before and after certain stages.

Q 10. How do you assess hide fiber structure and density?

Assessing hide fiber structure and density is crucial because it directly impacts the leather’s final quality – its strength, softness, and overall feel. We employ various methods:

- Visual Inspection (Microscopic): Using a microscope or magnifying glass, we examine a cross-section of the hide to analyze fiber arrangement, diameter, and the space between fibers. Tightly packed, well-organized fibers indicate a denser hide with potentially superior strength and durability.

- Physical Tests: Mechanical testing methods are used to measure hide strength and elasticity. These tests give quantitative data that complements visual assessment, providing a more comprehensive understanding of the fiber structure. Tensile strength tests measure the maximum load the hide can withstand before breaking, an important indicator of the future leather’s resilience.

- Density Measurement: Although not a direct measure of fiber density, we can calculate hide density by comparing the weight and volume. Higher density generally implies denser fiber packing, but it’s essential to consider other factors too.

Think of it like comparing different types of wood: dense wood like oak is stronger than less dense wood like balsa. Similarly, hide with well-organized, dense fiber structure will yield superior quality leather.

Q 11. How do you identify different animal hide types (e.g., cow, sheep, goat)?

Identifying animal hide types relies on a combination of experience, visual examination, and sometimes even DNA testing. Key features considered include:

- Size and Shape: Cow hides are typically large and rectangular, sheep hides are smaller and more irregular, and goat hides are smaller still, with a more distinct grain pattern.

- Grain Structure: The grain is the surface texture of the hide. Cow hides have a characteristic open grain, while sheep and goat hides have finer, tighter grains.

- Thickness and Texture: Cow hides are generally thicker than sheep or goat hides, and the thickness varies across the hide. Sheep and goat hides are relatively thinner and softer.

- Hair Follicle Density: The density and arrangement of hair follicles can provide clues. Cow hides have a comparatively more widely spaced hair follicle arrangement.

- Fiber Structure (Microscopic): Microscopic examination can reveal specific differences in fiber structure and organization which can help differentiate between various animal hide types.

Experienced hide evaluators can typically identify the hide type with high accuracy through visual inspection alone. However, for ambiguous cases, DNA testing provides definitive confirmation.

Q 12. Explain the impact of animal age and breed on hide quality.

The age and breed of the animal significantly impact hide quality.

- Age: Younger animals generally have finer, softer hides with less pronounced grain structure. Older animals have thicker, tougher hides with more pronounced grain patterns, which can sometimes be preferred for certain leather goods. However, overly old hides may have reduced elasticity and increased scarring.

- Breed: Different breeds have varying hide characteristics. Some breeds are known for producing high-quality hides with desirable texture and thickness. For instance, certain cattle breeds are prized for their robust, thick hides ideal for full-grain leather.

Imagine comparing the skin of a young calf to an adult cow; the calfskin will be thinner, softer, and more delicate. Similarly, different breeds of cows could yield hides of different thicknesses, grain patterns, and qualities.

Q 13. How do you determine the presence of diseases or imperfections in a hide?

Identifying diseases or imperfections requires careful visual inspection and sometimes laboratory tests. Common imperfections include:

- Scars: These can significantly reduce hide value, depending on their size and location.

- Holes and Cuts: These reduce usable leather area and can affect the hide’s strength.

- Insect Damage: Holes and discoloration from insect activity diminish the hide’s quality.

- Brand Marks: These can significantly impact the value, particularly if located in highly visible or usable areas.

- Disease-Related Defects: Certain diseases can cause discoloration, weakening, or structural damage to the hide. Laboratory tests might be needed for accurate identification.

Identifying disease requires both visual inspection and potentially chemical or microbiological analysis to identify specific pathogens or their impact on the hide’s structure. A hide with prevalent disease-related defects may be rejected entirely for processing.

Q 14. Describe the different methods used for hide preservation.

Hide preservation is critical to maintain quality before tanning. Methods include:

- Salting: Dry salting or wet salting is used to inhibit bacterial growth and prevent spoilage. This is a common and effective method that dehydrates the hide and draws out moisture which bacteria need to thrive.

- Freezing: Freezing at low temperatures slows down or stops bacterial and enzymatic activity. This is often used for short-term preservation in locations where salting isn’t immediately feasible.

- Chemical Preservation: Certain chemicals, including specific preservatives, can be used to inhibit bacterial growth and maintain hide integrity. This approach is sometimes used in conjunction with other methods.

The choice of preservation method depends on factors like climate, storage conditions, transportation time, and cost. The goal is to prevent deterioration and keep the hide in optimal condition for processing.

Q 15. What are the critical quality control checks during hide processing?

Critical quality control checks during hide processing are crucial for ensuring the final product meets the required standards. These checks begin at the point of receiving the hides and continue throughout the various stages of processing, including curing, fleshing, salting, and tanning.

- Initial Inspection: This involves assessing the hide for damage like cuts, holes, brands, and insect bites. We also check for the hide’s overall cleanliness and the presence of any disease. A hide with significant damage or disease contamination will likely be downgraded or rejected.

- Salt Content and Moisture: Proper salting is vital for preserving the hide. We use salt meters to ensure the salt concentration is optimal to prevent microbial growth while avoiding excessive salt that can damage the fibers. Moisture content is measured to determine if the hide is adequately cured and ready for the next stages.

- Fleshing and Trimming: This step involves removing excess fat and flesh. We visually inspect the hide after fleshing to ensure completeness and identify any remaining imperfections. Improper fleshing can lead to defects in the final leather.

- Tanning and Finishing: Regular quality checks throughout the tanning process ensure consistent leather quality, including examining the hide’s softness, tensile strength, and uniformity of color. Defect tracking and analysis are critical here, guiding adjustments to improve consistency across batches.

Think of it like baking a cake – you need to check the ingredients, the mixing process, and the baking time to guarantee a delicious result. Similarly, every step in hide processing demands careful monitoring to create high-quality leather.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy and consistency of your hide evaluations?

Accuracy and consistency in hide evaluations are paramount. We achieve this through a combination of standardized procedures, regular training, and the use of precise measuring instruments.

- Standardized Grading Protocols: We adhere to established grading systems (like those by the American Leather Chemists Association) and develop internal standards to maintain consistency across our evaluations. This ensures that different evaluators produce similar results for the same hide.

- Regular Calibration and Training: Our measuring instruments (discussed in detail later) are regularly calibrated to ensure accurate readings. Our evaluators undergo continuous training, including practical sessions and proficiency tests, to maintain their skill and consistency in assessment. This ensures everyone interprets the grading standards in the same way.

- Blind Testing and Audits: Periodic blind testing is employed, where evaluators assess hides without prior knowledge of their origin or previous assessments. This helps identify and rectify any biases or inconsistencies in individual evaluations. Internal audits further ensure compliance with established procedures.

Imagine a team of chefs following a precise recipe; consistency is guaranteed through standardized procedures and regular skill honing. Similarly, consistent training and procedures help us achieve accurate and repeatable hide assessments.

Q 17. Explain your experience with different hide grading systems.

My experience encompasses several hide grading systems, each with its own nuances and criteria. The most common systems I’ve worked with include:

- The American Leather Chemists Association (ALCA) system: This system uses numerical grades to represent the quality of the hide based on factors like area, thickness, and the presence of defects. It’s widely recognized and used across the industry.

- International standards (ISO): Though not as specific to hide grading, ISO standards often provide guidelines for quality control and testing methods. We use aspects of these standards to complement our existing grading procedures.

- Company-specific systems: Many tanneries and manufacturers develop their own grading systems tailored to their specific needs and product lines. I’ve been involved in developing and refining these custom systems, ensuring they align with broader industry standards while catering to particular requirements like desired leather thickness or finishing techniques.

Each system has its own strengths and weaknesses. For example, the ALCA system provides a widely understood scale, but company-specific systems can incorporate more detailed criteria relating to the final application of the leather, leading to more accurate evaluations from the standpoint of its use. Understanding these differences is key to providing efficient and effective evaluations for diverse clients.

Q 18. Describe your experience with using measuring instruments for hide evaluation.

Measuring instruments play a crucial role in objective hide evaluation. We routinely use a variety of tools to ensure accuracy and detail in our assessments.

- Hide Area Measurers: These tools, ranging from simple planimeters to sophisticated digital area scanners, provide precise measurements of the hide’s surface area. Accurate area measurement is crucial for determining pricing and yield.

- Thickness Gauges: Various gauges, including dial gauges and electronic thickness meters, measure the hide’s thickness at multiple points. Thickness is a critical factor affecting leather quality and its final use. Inconsistent thickness leads to downgrading.

- Tensile Strength Testers: These machines measure the hide’s resistance to stretching and tearing, which is a significant indicator of its overall strength and quality. The resulting data helps determine the suitability of the hide for different applications, such as upholstery or garment making.

- Digital Cameras and Imaging Software: High-resolution photography coupled with image analysis software allows for the detailed documentation of defects and assists in the objective assessment of hide quality. This supports both grading and the identification of processing errors.

Just as a carpenter uses a variety of tools for precise measurements and construction, we use a suite of instruments to gather objective data for an accurate and comprehensive evaluation of each hide.

Q 19. How do you handle discrepancies or disagreements on hide assessments?

Discrepancies in hide assessments are addressed through a structured process that emphasizes collaboration and objective evaluation.

- Review Process: When disagreements arise, a senior evaluator reviews the assessment, examining the hide in question and comparing the initial evaluations with the established standards. This often involves revisiting the raw data from the measuring instruments.

- Calibration Check: If the discrepancy persists, the measuring instruments are recalibrated to rule out any equipment malfunction as the source of the problem.

- Team Discussion: In cases of significant disagreement, a team meeting is convened to discuss the conflicting assessments. This collaborative approach provides an opportunity to identify any misunderstandings in the grading standards or differences in interpretation of specific defects.

- Third-Party Arbitration (Rare): In exceptional cases where a resolution cannot be reached internally, a third-party expert in hide evaluation may be consulted for an independent assessment.

Transparency and collaborative problem-solving are key to resolving disagreements fairly and ensuring accurate assessments. This helps to maintain trust and consistency in our evaluation process.

Q 20. How do you maintain accurate records and documentation of hide evaluations?

Maintaining accurate records and documentation is crucial for traceability, quality control, and legal compliance. We use a combination of digital and physical records.

- Digital Database: All hide evaluations are entered into a secure digital database, including detailed information like hide identification number, date of evaluation, assessor’s name, measurements (area, thickness, tensile strength), photographs of defects, and the final grade assigned. This allows for easy retrieval of data and analysis over time.

- Physical Records: Hard copies of evaluation forms, along with physical samples (if necessary), are archived for long-term storage. This serves as a backup for our digital data and helps to comply with regulatory requirements for record retention.

- Chain of Custody: We maintain a detailed chain of custody, tracking the hide from the point of receipt to its final processing stage. This ensures complete traceability and accountability throughout the entire process.

Think of it like meticulously documenting a scientific experiment. Precise and detailed records are paramount for reproducibility, verification, and legal compliance. Similarly, we meticulously document all our assessments to ensure accuracy and accountability.

Q 21. What are the legal and ethical considerations related to animal hide sourcing?

Legal and ethical considerations related to animal hide sourcing are significant and we adhere strictly to all applicable regulations.

- Traceability and Legality: We only source hides from suppliers who can provide verifiable proof of legal and ethical sourcing. This involves documentation confirming compliance with national and international regulations against illegal hunting, poaching, and the use of endangered species.

- Animal Welfare: We actively support and promote humane animal treatment throughout the supply chain. This involves due diligence in selecting suppliers with a strong commitment to animal welfare and ethical practices.

- Environmental Regulations: We ensure compliance with environmental regulations related to hide processing, minimizing waste and pollution throughout the process. This includes proper disposal of by-products and the use of environmentally friendly chemicals.

- Transparency: Maintaining transparency across the supply chain is crucial. This involves openly sharing information about our sourcing practices with our clients and stakeholders.

Ethical and legal compliance is not merely a regulatory obligation; it’s a fundamental part of our business ethos. We believe in responsible and sustainable practices throughout our operations.

Q 22. Describe your experience with different types of tanning processes and their effects on hide quality.

My experience encompasses a wide range of tanning processes, from traditional vegetable tanning to modern chrome tanning and the emerging techniques like aldehydes and zirconium tanning. Each method significantly impacts the final hide quality.

Vegetable Tanning: This ancient method uses plant extracts like tannins from bark or leaves. It produces a strong, durable leather with a natural look and feel, but it’s slower and less consistent than other methods. The resulting leather is often more susceptible to water damage and requires careful conditioning. For example, a vegetable-tanned leather briefcase will develop a beautiful patina over time, but requires regular oiling.

Chrome Tanning: This is the most widely used method, employing chromium salts to achieve rapid and consistent tanning. Chrome-tanned leather is soft, supple, and relatively water-resistant, making it ideal for clothing and upholstery. However, the chromium used can be a concern environmentally, and the leather may not age as gracefully as vegetable-tanned leather. Imagine the difference between a pair of inexpensive chrome-tanned leather shoes versus higher-quality, vegetable-tanned boots.

Aldehyde and Zirconium Tanning: These newer methods offer advantages in terms of environmental impact and specific leather characteristics. Aldehyde tanning, for example, produces leathers with excellent softness and fullness. Zirconium tanning creates leathers that are often more durable and resistant to shrinkage. These are less common but are rapidly gaining popularity for their unique properties and reduced environmental impact.

Understanding the specific characteristics of each tanning method is crucial for selecting the appropriate hide for a given application and predicting its long-term performance. My expertise allows me to assess the quality of a tanned hide based on its look, feel, and its response to various tests, and trace those qualities back to the specific tanning process used.

Q 23. How do you communicate your findings and recommendations to stakeholders?

Communicating findings and recommendations effectively is paramount. I tailor my approach to the audience, using a combination of clear, concise written reports, visual aids such as photographs and charts, and verbal presentations.

For technical audiences, such as fellow hide evaluators or tannery specialists, I use precise terminology and detailed data analysis, perhaps including specific measurements of tensile strength or water absorption.

For non-technical stakeholders, like clients or management, I focus on conveying the key findings in a simplified, accessible way, focusing on the impact on quality, cost, and the overall project goals. I use analogies and examples to help them understand complex concepts, for instance, explaining the difference between tanning methods with reference to the wear and tear expected from a car seat versus a handbag.

I always ensure my reports and presentations are well-organized, visually appealing, and readily understandable, making sure to emphasize actionable insights that lead to improvements in the process or product.

Q 24. What are the challenges you anticipate in this role, and how would you address them?

The main challenges I anticipate are managing the large volume of hide data efficiently, keeping abreast of evolving industry standards and regulations, and addressing potential conflicts that may arise from differing interpretations of hide quality.

Data Management: I plan to address this by leveraging my familiarity with relevant software and tools for efficient data storage, analysis, and reporting, as well as implementing robust quality control measures.

Industry Standards and Regulations: I will actively participate in professional development activities, stay updated with industry publications, and attend conferences to ensure my expertise remains current. This proactive approach will ensure my work aligns with the latest standards and regulations.

Conflict Resolution: My approach to conflict resolution involves open communication, active listening, and a focus on finding mutually acceptable solutions. I believe in a collaborative approach, prioritizing objectivity and data-driven decision making. This can involve mediation or even bringing in an independent third party to reach a consensus.

Q 25. What software or tools are you familiar with for managing hide data?

I am proficient in several software packages commonly used for managing hide data. This includes:

Spreadsheet software (Excel, Google Sheets): For organizing and analyzing large datasets, tracking key quality metrics, and creating reports.

Database management systems (SQL, Access): For establishing structured databases to store and retrieve hide information efficiently.

Statistical software (R, SPSS): For performing complex statistical analysis on the data, helping to identify trends and correlations.

Specialized leather industry software: While specific software varies across manufacturers and tanneries, I have experience adapting to new systems and quickly learning their functionalities.

My ability to integrate and interpret data from various sources, coupled with my proficiency in these tools, ensures accurate and comprehensive assessment and reporting.

Q 26. Describe a time you had to resolve a conflict related to hide quality or assessment.

In a previous role, a dispute arose regarding the quality of a large batch of hides. The client claimed that a significant portion of the hides were substandard, resulting in a financial loss due to the rework required. My initial assessment confirmed some quality issues, but not to the extent claimed by the client.

To resolve this, I employed a systematic approach:

Detailed Re-evaluation: I performed a thorough re-evaluation of the hides, documenting my findings with detailed photographs and measurements, focusing on both the client’s concerns and those I detected.

Data Analysis: I compared my findings with historical data and industry standards. This quantitative analysis helped to objectively determine the extent of the quality issues.

Open Communication: I presented my findings and data analysis to both parties, clearly explaining my methodology and conclusions. I facilitated open dialogue to address their concerns and dispel any misconceptions.

Negotiated Settlement: Based on the objective data, we negotiated a mutually acceptable settlement that addressed both the financial impact and prevented similar issues in the future. This involved agreed-upon quality control measures for subsequent deliveries.

This situation highlighted the importance of clear communication, detailed documentation, and the use of objective data in resolving conflicts related to hide quality assessment.

Q 27. How do you stay current with industry best practices and regulations regarding hide evaluation?

Staying updated on industry best practices and regulations is crucial. I achieve this through a multi-pronged approach:

Professional Organizations: I actively participate in relevant professional organizations, attending conferences and workshops to stay informed about the latest advancements in tanning technology, quality control methodologies, and environmental regulations.

Industry Publications: I regularly read industry journals and publications to stay abreast of research findings, best practices, and new regulations.

Online Resources: I leverage online resources, including reputable websites, webinars, and online courses, to expand my knowledge and understanding of emerging trends in the field.

Networking: I maintain a strong professional network through collaborations and partnerships with fellow experts in the industry. This networking provides opportunities for sharing knowledge and staying current.

This continuous learning ensures I maintain a high level of expertise and deliver consistent, high-quality work.

Q 28. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and expertise in animal hide evaluation, and are in line with the industry standard for similar roles. I am open to discussing a specific salary range based on the complete details of the position and the associated responsibilities. I am confident that my contributions will significantly benefit your organization and create a positive return on investment.

Key Topics to Learn for Animal Hide Evaluation Interview

- Hide Quality Assessment: Understanding factors influencing hide quality such as breed, age, health, and processing methods. This includes visual inspection techniques and the ability to identify defects.

- Defect Identification and Classification: Learn to accurately identify and categorize various hide defects (e.g., scars, brands, holes, insect damage) and their impact on value.

- Grading and Standardization: Familiarize yourself with industry standards and grading systems used to assess hide quality and value. Understand the practical application of these systems in real-world scenarios.

- Measurement and Calculation: Mastering techniques for accurate measurement of hide area and weight, and understanding how these measurements contribute to pricing and yield calculations.

- Leather Manufacturing Processes: Gain a basic understanding of how hides are processed into leather, as this knowledge helps in assessing the potential of a hide and predicting final product quality.

- Market Trends and Pricing: Develop an understanding of current market trends and price fluctuations for different types of hides. This involves analyzing supply and demand factors and their effect on valuation.

- Problem-Solving in Hide Evaluation: Develop skills in analyzing complex scenarios, troubleshooting issues, and making informed decisions based on incomplete or ambiguous data.

- Ethical and Sustainable Sourcing: Understand the ethical and environmental considerations related to hide sourcing and processing. This demonstrates your commitment to responsible practices.

Next Steps

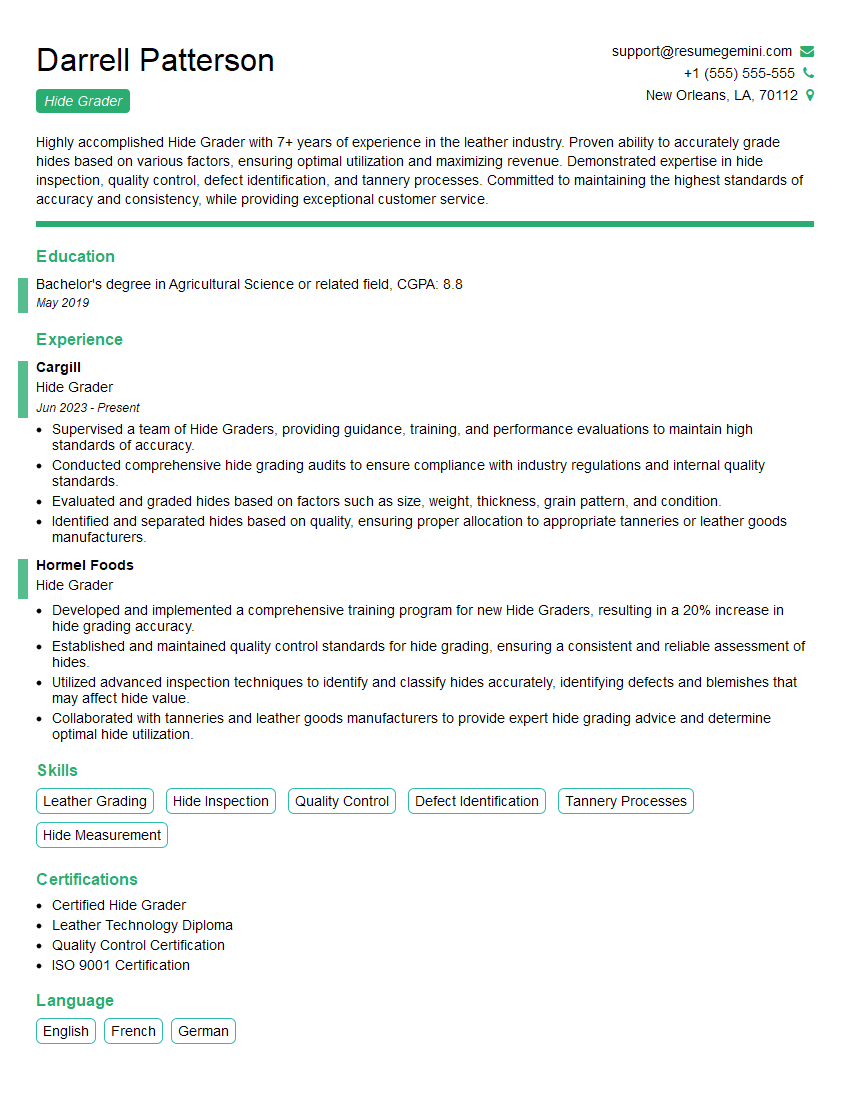

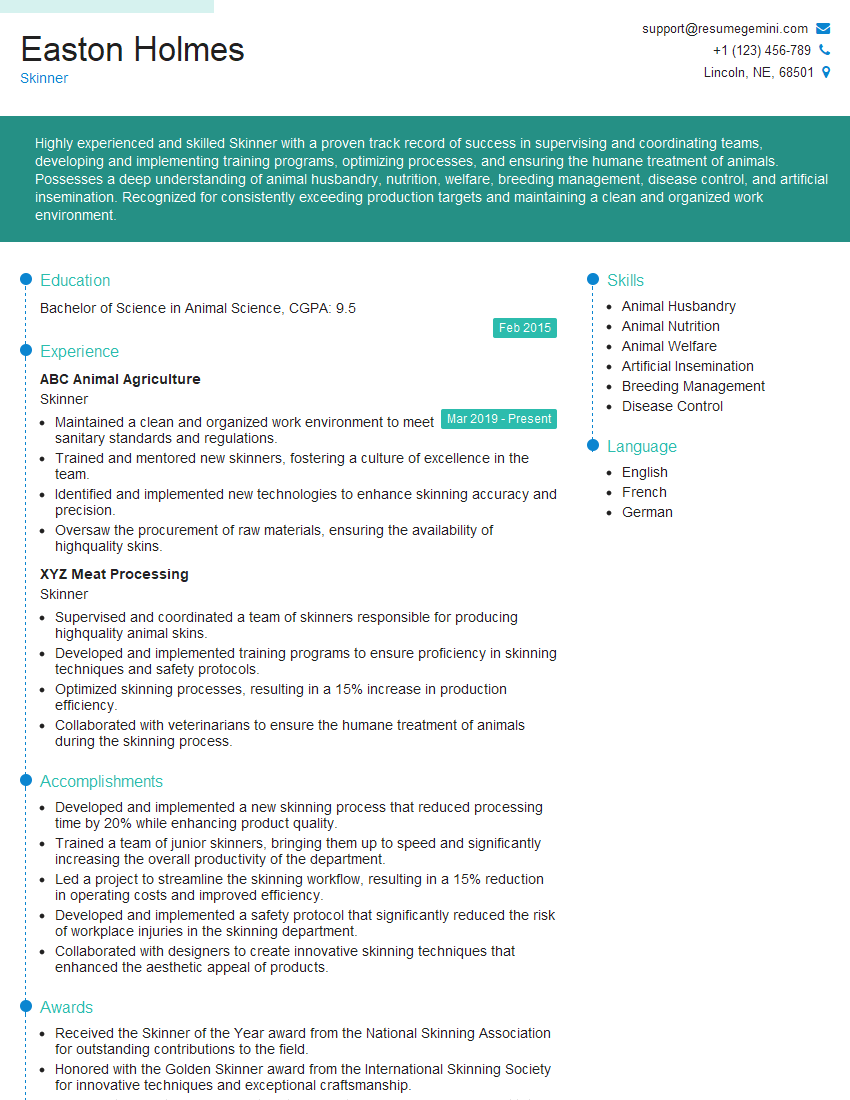

Mastering Animal Hide Evaluation opens doors to exciting career opportunities in the leather industry, offering specialization in quality control, procurement, or even research and development. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. We offer examples of resumes tailored to Animal Hide Evaluation to give you a head start. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good