Preparation is the key to success in any interview. In this post, we’ll explore crucial Solid Solution Strengthening interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Solid Solution Strengthening Interview

Q 1. Explain the mechanism of solid solution strengthening.

Solid solution strengthening, also known as substitutional strengthening, is a crucial mechanism for enhancing the mechanical properties of metals. It involves increasing the strength and hardness of a metal by alloying it with another element, which dissolves into the metal’s crystal lattice to form a solid solution. The solute atoms disrupt the regular arrangement of the solvent atoms, hindering the movement of dislocations—the primary carriers of plastic deformation. This resistance to dislocation motion results in a significant increase in the material’s yield strength.

Imagine trying to push a box across a smooth floor versus pushing it across a floor covered in small obstacles. The obstacles represent the solute atoms, and the box is the dislocation. The obstacles make it much harder to move the box, just as the solute atoms make it harder for dislocations to move through the crystal structure.

Q 2. What are the factors affecting the magnitude of solid solution strengthening?

Several factors influence the magnitude of solid solution strengthening. The most prominent are:

- Solute atom size difference: Larger differences between the solute and solvent atom radii lead to greater strengthening.

- Solute atom concentration: Higher concentrations of solute atoms generally result in increased strengthening, up to a certain limit.

- Modulus difference: A larger difference in the elastic moduli of the solute and solvent atoms enhances strengthening.

- Valence difference: Significant differences in the valence (number of electrons in the outer shell) of the solute and solvent atoms can cause considerable strengthening.

- Temperature: Solid solution strengthening is usually more effective at lower temperatures because thermal energy can assist dislocation movement.

For instance, adding a small amount of carbon to iron (steel) drastically increases its strength because the carbon atoms, significantly smaller than iron atoms, impede dislocation motion.

Q 3. Differentiate between substitutional and interstitial solid solutions.

Solid solutions are categorized into substitutional and interstitial solutions based on how the solute atoms are incorporated into the solvent’s crystal lattice:

- Substitutional solid solutions: The solute atoms replace the solvent atoms in the crystal lattice. This typically occurs when the solute and solvent atoms have similar atomic radii and crystal structures. Example: Nickel (Ni) dissolving in copper (Cu) to form a Cu-Ni alloy. Both have FCC crystal structures and similar atomic radii.

- Interstitial solid solutions: The solute atoms occupy the interstitial sites—the spaces between the solvent atoms—in the crystal lattice. This is common when the solute atoms are much smaller than the solvent atoms. Example: Carbon (C) dissolving in iron (Fe) to form steel. Carbon atoms are much smaller than iron atoms and fit into the interstitial spaces.

Q 4. Describe Hume-Rothery rules and their relevance to solid solution strengthening.

Hume-Rothery rules are empirical guidelines that predict the likelihood of a complete solid solution forming between two elements. They are crucial because extensive solid solution formation is essential for achieving significant solid solution strengthening. The rules are:

- Atomic size factor: The difference in atomic radii between the solute and solvent should be less than 15%. Larger differences hinder solubility and limit strengthening.

- Crystal structure: The solute and solvent should have the same crystal structure for complete solid solubility. Different structures limit the extent of dissolution.

- Valence: The solute and solvent should have similar valences. Significant valence differences can result in stronger interatomic bonding in the solute-solvent interaction, creating precipitates rather than a solid solution.

- Electronegativity: The solute and solvent should have similar electronegativities. Large differences in electronegativity can lead to the formation of intermetallic compounds instead of a solid solution.

Meeting these rules increases the chance of forming a solid solution, promoting solid solution strengthening. If the rules are not met, the solute might form precipitates or intermetallic compounds, leading to different strengthening mechanisms (e.g., precipitation hardening).

Q 5. How does solute atom size affect solid solution strengthening?

The size difference between solute and solvent atoms is a critical factor in solid solution strengthening. Larger size differences lead to more significant lattice distortion, which hinders dislocation movement. This increased resistance to dislocation motion translates to a greater increase in yield strength. Imagine trying to move through a crowded room—the larger the size difference (representing the atom size difference), the more difficult it is to navigate.

For example, a small amount of tungsten (W) added to steel significantly improves its high-temperature strength due to the substantial size difference between tungsten and iron atoms.

Q 6. How does solute atom valence affect solid solution strengthening?

The valence difference between the solute and solvent atoms significantly affects the strength of the interaction between them. This difference leads to charge imbalances within the lattice, creating regions of localized stress and strain fields that impede dislocation motion. This effect is often more pronounced than size misfit alone. The stronger the interactions due to the valence difference, the stronger the strengthening effect.

For instance, adding elements like chromium (Cr) or molybdenum (Mo) to steel (iron) increases the strength substantially, partially due to their higher valence than iron, which causes stronger interactions with the iron lattice.

Q 7. Explain the role of dislocations in solid solution strengthening.

Dislocations are linear defects in the crystal structure that act as planes of weakness. They are the primary mechanism for plastic deformation in metals. In solid solution strengthening, the solute atoms interact with dislocations, increasing the energy required to move them. This interaction occurs in several ways:

- Size misfit interactions: Solute atoms of a different size create local strain fields around them. Dislocations are attracted to these strain fields, reducing their mobility.

- Modulus misfit interactions: Differences in elastic modulus between solute and solvent atoms also create strain fields that interact with dislocations.

The presence of solute atoms effectively ‘pins’ or ‘impedes’ the movement of dislocations, increasing the resistance to plastic deformation and hence the strength and hardness of the material.

Q 8. Describe the effect of temperature on solid solution strengthening.

Temperature significantly impacts solid solution strengthening. At lower temperatures, the solute atoms are less mobile, leading to more effective impediment of dislocation movement and thus greater strengthening. As temperature increases, the solute atoms become more mobile, reducing their ability to hinder dislocations. Think of it like trying to navigate a crowded room: at low temperatures (low mobility), the solute atoms are like immovable obstacles, making it hard to move through. At high temperatures (high mobility), the obstacles become more easily moved aside, allowing for easier passage.

This effect is often described by a decreasing strengthening effect with increasing temperature, typically following an Arrhenius-type relationship. This means that the strengthening effect exponentially decreases with increasing temperature. Beyond a certain critical temperature, the strengthening effect becomes negligible, as the solute atoms diffuse rapidly, losing their ability to impede dislocations. This is important in applications where materials are subjected to high temperatures, like turbine blades in jet engines.

Q 9. How does solid solution strengthening influence yield strength?

Solid solution strengthening directly increases the yield strength of a material. Yield strength represents the stress required to initiate plastic deformation. By introducing solute atoms into a metal lattice, we create lattice distortions that impede the movement of dislocations – the primary mechanism for plastic deformation. These dislocations need to overcome the extra energy associated with moving through the distorted lattice, requiring a higher applied stress to initiate plastic flow. This is why alloys generally exhibit much higher yield strengths than their pure metal counterparts. For example, adding carbon to iron (creating steel) significantly increases its yield strength compared to pure iron.

The extent of the increase in yield strength depends on several factors: the concentration of the solute atoms, the size difference between solute and solvent atoms, and the temperature. The higher the solute concentration and the larger the size difference, the greater the increase in yield strength. This relationship is often described by empirical rules, such as those developed by strengthening laws in material science, that show how strengthening from different mechanisms additively contribute to yield strength.

Q 10. How does solid solution strengthening influence ductility?

Solid solution strengthening generally reduces ductility. Ductility refers to a material’s ability to deform plastically before fracture. Since solid solution strengthening hinders dislocation movement, it makes plastic deformation more difficult. This means that the material will be stronger but less able to deform before failure. Imagine trying to bend a piece of stiff wire (high strength, low ductility) compared to a more pliable wire (lower strength, higher ductility). The stiff wire may not bend as much before breaking.

The decrease in ductility is a trade-off for increased strength. The extent of ductility reduction depends on several factors, including the type and amount of solute added, the matrix material, and the temperature. Careful alloy design aims to find a balance between strength and ductility to meet specific application needs. For example, in aerospace applications, high strength is crucial but some degree of ductility is essential to prevent brittle fracture.

Q 11. How does solid solution strengthening influence hardness?

Solid solution strengthening increases hardness. Hardness is a measure of a material’s resistance to indentation or scratching. Because it’s harder for dislocations to move in a solid solution strengthened material, it becomes more difficult to indent or scratch the material’s surface. This increased resistance to plastic deformation directly translates into higher hardness. Think of it like trying to scratch a hardened steel surface compared to a softer aluminum surface – the steel requires significantly more force.

Hardness testing methods, like Rockwell or Brinell hardness tests, are often used to quantify this increase in hardness. The increase in hardness is directly related to the increase in yield strength, as both properties reflect the material’s resistance to plastic deformation. High hardness is desirable in many applications, such as cutting tools, where resistance to wear is essential.

Q 12. How does solid solution strengthening influence toughness?

The effect of solid solution strengthening on toughness is complex and not always straightforward. Toughness is a material’s ability to absorb energy before fracture, encompassing both strength and ductility. While solid solution strengthening increases strength, it generally decreases ductility, leading to a potentially reduced toughness, especially in brittle materials. However, in some cases, a moderate increase in strength with a relatively small decrease in ductility can lead to an overall increase in toughness. This is because increased strength can sometimes compensate for slightly reduced ductility.

The net effect on toughness depends on the specific alloy system and the balance between increased strength and reduced ductility. The interaction between these properties needs to be considered during material selection. In applications where toughness is critical, like structural components, a balance between strength and ductility needs to be carefully managed during alloy design. Toughness testing, often involving impact tests (like Charpy or Izod tests), is vital in assessing the material’s ability to withstand impact loading.

Q 13. Explain the difference between solution hardening and precipitation hardening.

Both solution hardening and precipitation hardening are strengthening mechanisms that involve solute atoms, but they differ significantly in their microstructural features and strengthening mechanisms. Solution hardening involves dissolving a solute atom into the solid solution of the matrix. The solute atoms disrupt the crystal lattice, impeding dislocation motion and thereby strengthening the material. This strengthening is directly related to the concentration of the solute atoms in the matrix.

Precipitation hardening, on the other hand, involves the formation of fine, dispersed precipitates within the matrix. These precipitates act as obstacles to dislocation motion. The strengthening effect is significantly larger than in solution hardening due to the coherent strain fields developed around the precipitate particles. The particles are usually formed by heat treatments that cause the solute atoms to precipitate out of the solid solution at a controlled rate. An example is the aging of aluminum alloys (like 2024 or 7075 aluminum) to increase their strength through the precipitation of intermetallic phases.

Q 14. Describe how to determine the strengthening effect of a particular solute in a given matrix.

Determining the strengthening effect of a particular solute in a given matrix involves a combination of experimental and theoretical approaches. Experimentally, tensile testing can measure the increase in yield strength resulting from adding various concentrations of the solute. This data can then be used to develop empirical relationships between solute concentration and yield strength, often described by strengthening models which consider both solid solution and other strengthening mechanisms.

Theoretically, computational methods like Density Functional Theory (DFT) can provide atomistic insights into the interaction between solute atoms and dislocations. These calculations can help predict the strength of the solute-dislocation interaction and estimate the strengthening effect. Combining experimental measurements with theoretical modeling often gives a more comprehensive understanding. The strengthening contribution from a particular solute element can be isolated through careful experimentation and analysis, separating it from the contributions of grain boundary strengthening, work hardening and other mechanisms.

Q 15. What are some common alloying elements used for solid solution strengthening in steels?

Solid solution strengthening in steels involves adding alloying elements that dissolve substitutionally or interstitially into the iron lattice. This creates lattice distortions, hindering dislocation movement and thus increasing the material’s strength and hardness.

- Interstitial elements: Carbon (C), Nitrogen (N) are small atoms that fit between iron atoms, causing significant lattice strain.

- Substitutional elements: Nickel (Ni), Manganese (Mn), Chromium (Cr), Molybdenum (Mo), Tungsten (W) replace iron atoms. The size difference between the solute and solvent atoms leads to lattice distortion. Larger atoms cause tensile stresses, smaller atoms cause compressive stresses.

The effect of each element depends on its concentration and its atomic radius difference with iron. For example, a small amount of carbon significantly strengthens steel, while nickel’s effect is more moderate due to its similar atomic size to iron.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common alloying elements used for solid solution strengthening in aluminum alloys?

Solid solution strengthening in aluminum alloys uses alloying elements that dissolve into the aluminum lattice, similarly to steels. However, the choice of elements differs due to aluminum’s different crystal structure and properties.

- Copper (Cu): A common alloying element that forms a substitutional solid solution and significantly increases strength. It’s key in many 2xxx and 6xxx series aluminum alloys.

- Magnesium (Mg): Another important substitutional element that improves strength and corrosion resistance, found in 5xxx and 6xxx series alloys.

- Zinc (Zn): Often used in conjunction with other elements like magnesium and copper to enhance strength and other properties (7xxx series alloys).

- Silicon (Si): Can act as both a substitutional and a precipitate-forming element. In solid solution, it increases strength and castability.

The choice of element and its concentration depend on the desired combination of properties. For example, 7075 aluminum alloy (Zn, Mg, Cu) exhibits high strength, while 5052 (Mg) offers excellent corrosion resistance.

Q 17. How can you quantify solid solution strengthening using experimental techniques?

The quantification of solid solution strengthening relies primarily on experimental measurements of the yield strength (σy) or tensile strength as a function of solute concentration. Techniques include:

- Tensile testing: The most common method to determine the yield strength. Specimens with different solute concentrations are tested, and the increase in yield strength is attributed to solid solution strengthening.

- Hardness testing: Methods like Rockwell or Vickers hardness testing provide a rapid and relatively inexpensive way to assess strength changes. Hardness is directly related to strength, though not a precise measure of yield strength.

- Microstructural analysis: Techniques like transmission electron microscopy (TEM) can be used to study the interaction between dislocations and solute atoms, giving insights into the strengthening mechanism, though not a direct measure of strength.

By plotting the yield strength against the solute concentration, an empirical relationship can be established, often using a linear or power-law equation. This relationship can then be used to predict the yield strength for different solute concentrations.

Q 18. What are the limitations of solid solution strengthening?

While solid solution strengthening is a powerful technique, it has limitations:

- Limited strengthening potential: The increase in strength obtained through solid solution strengthening is generally less than that achieved through other strengthening mechanisms like precipitation hardening or work hardening. The amount of strengthening is limited by the solubility limit of the alloying element.

- Reduction in ductility: Increased strength often comes at the cost of reduced ductility, making the material more brittle. The increased lattice distortion restricts dislocation movement which hinders plastic deformation.

- Potential for undesirable effects: Some alloying elements can negatively affect other material properties such as corrosion resistance, weldability, or machinability.

- Temperature dependence: The effectiveness of solid solution strengthening decreases at elevated temperatures as thermal energy assists dislocation movement.

Therefore, the choice of alloying elements and their concentrations involves careful trade-offs between strength, ductility, and other essential properties.

Q 19. How can you predict the solid solution strengthening effect using computational methods?

Computational methods, particularly density functional theory (DFT) and molecular dynamics (MD), are increasingly used to predict solid solution strengthening.

- DFT calculations: Can be used to determine the interaction energy between solute atoms and dislocations, providing insights into the energy barrier for dislocation movement. This information can then be used in conjunction with dislocation dynamics models to predict yield strength.

- Molecular dynamics simulations: Allow for the simulation of the behavior of dislocations in the presence of solute atoms at the atomic scale. These simulations can provide detailed information on dislocation motion and yield strength, though they’re computationally expensive.

These computational methods are particularly useful in the early stages of alloy design, where they can help identify promising alloying elements and compositions before expensive experimental testing. However, accurately predicting strengthening requires careful consideration of various factors such as solute atom clustering and the interactions between different solute atoms.

Q 20. Describe a case study where solid solution strengthening played a crucial role in material selection.

The selection of 304 stainless steel for the construction of nuclear reactor components illustrates the crucial role of solid solution strengthening.

304 stainless steel (approximately 18% Cr, 8% Ni) benefits from the solid solution strengthening provided by chromium and nickel. Chromium enhances corrosion resistance and contributes to strength, while nickel improves ductility and weldability. This specific alloying combination provides excellent corrosion resistance in the highly corrosive environment of the nuclear reactor while retaining sufficient strength and ductility to withstand operational stresses. Alternative materials might offer better strength but lack the crucial corrosion resistance necessary for a safe and efficient nuclear power generation.

Q 21. Explain how solid solution strengthening contributes to creep resistance.

Solid solution strengthening enhances creep resistance by impeding dislocation climb, a major mechanism of creep deformation at high temperatures.

Creep occurs when dislocations move and climb through the material under sustained stress. Solute atoms interact with dislocations, pinning them and making it more difficult for them to climb. This increased resistance to dislocation climb leads to improved creep resistance and higher strength at elevated temperatures. The effectiveness of this strengthening mechanism depends on several factors such as the size and concentration of solute atoms, the temperature and applied stress.

Q 22. Discuss the effect of solid solution strengthening on fatigue properties.

Solid solution strengthening generally improves a material’s fatigue resistance, but the effect is complex and depends on several factors. Fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Solid solution strengthening increases the yield strength and the flow stress, making it more difficult for dislocations – the defects responsible for plastic deformation – to move and propagate fatigue cracks. This leads to increased fatigue life and fatigue strength. However, it’s important to note that excessive solute additions can sometimes lead to a reduction in fatigue ductility, making the material more brittle and susceptible to crack propagation under cyclic loading. The optimal solute concentration for maximizing fatigue life must be determined experimentally.

Example: Alloying steel with elements like chromium and molybdenum significantly improves its fatigue resistance by solid solution strengthening. The improved strength delays the initiation and propagation of fatigue cracks, leading to longer service life in applications such as bridges and aircraft components.

Q 23. How does grain size influence the effectiveness of solid solution strengthening?

Grain size significantly impacts the effectiveness of solid solution strengthening. Smaller grains generally lead to a more pronounced strengthening effect because they hinder dislocation movement. Dislocations pile up at grain boundaries, creating back stress that makes further dislocation motion more difficult. This effect, known as Hall-Petch strengthening, is additive to the strengthening provided by solute atoms. In materials with larger grains, the solute strengthening effect is somewhat diminished because the dislocations have more space to move before encountering a grain boundary. The solute atoms still impede dislocation movement, but the influence of grain boundaries is reduced, leading to less overall strengthening.

Think of it this way: Imagine trying to navigate a crowded room (small grains) versus a wide-open field (large grains). In the crowded room, even with obstacles (solute atoms) it’s harder to move freely; in the open field, the obstacles have less effect on your overall movement.

Q 24. What are the trade-offs between solid solution strengthening and other strengthening mechanisms?

Solid solution strengthening is just one of several strengthening mechanisms available. Others include work hardening (strain hardening), precipitation hardening, and grain boundary strengthening. Each mechanism has its own advantages and disadvantages, resulting in important trade-offs.

- Solid solution strengthening vs. work hardening: Solid solution strengthening improves strength with minimal ductility loss but has a limit on the amount of strengthening achievable. Work hardening increases strength significantly but reduces ductility substantially.

- Solid solution strengthening vs. precipitation hardening: Precipitation hardening offers higher strength than solid solution strengthening but requires a more complex heat treatment process. Solid solution strengthening is simpler to implement.

- Solid solution strengthening vs. grain boundary strengthening: Grain boundary strengthening is easier and less expensive than solid solution strengthening but usually results in lower strength levels.

Choosing the best strengthening method depends on the specific application and the desired balance between strength, ductility, and cost.

Q 25. Explain the concept of solute drag.

Solute drag is a phenomenon where solute atoms interact with moving grain boundaries or dislocations, impeding their movement. It’s particularly relevant during high-temperature processes such as grain growth or creep. The solute atoms diffuse and accumulate in the region ahead of a moving grain boundary or dislocation. This accumulation creates a concentration gradient that slows the boundary or dislocation’s motion because the solute atoms exert a drag force, opposing its movement. The stronger the solute-solvent interaction, the greater the drag effect.

Analogy: Imagine trying to push a heavy object (grain boundary) through a crowd of people (solute atoms). The people will push back, creating drag and making your task more difficult.

Q 26. Describe the difference between solid solution strengthening and work hardening.

Solid solution strengthening and work hardening are distinct strengthening mechanisms that operate at different scales and involve different microstructural changes.

- Solid solution strengthening is achieved by adding alloying elements to a base metal. The solute atoms create lattice distortions that impede dislocation motion, thus increasing strength. This is an inherent property of the alloy’s composition.

- Work hardening (strain hardening) is achieved by plastically deforming the material. This introduces dislocations into the crystal lattice, which then interact and hinder each other’s motion. This increases strength but reduces ductility as the material becomes more brittle.

Key Difference: Solid solution strengthening involves changes in the atomic scale, while work hardening involves changes at a macroscopic scale.

Q 27. How does solid solution strengthening affect the electrical conductivity of metals?

Solid solution strengthening generally decreases the electrical conductivity of metals. The addition of solute atoms introduces lattice distortions and scattering centers for electrons, thereby increasing the electrical resistivity. The greater the difference in atomic size or valency between the solute and solvent atoms, the more pronounced the reduction in conductivity.

Example: Pure copper has high electrical conductivity. Adding elements such as zinc (to form brass) reduces its conductivity because zinc atoms disrupt the regular copper lattice structure, thereby scattering electrons and increasing resistance.

Q 28. How does solid solution strengthening affect the magnetic properties of metals?

The effect of solid solution strengthening on magnetic properties is complex and depends on the specific solute and solvent atoms. Some solute atoms may enhance the magnetic properties (e.g., increasing saturation magnetization or Curie temperature), while others can decrease them. The effect is related to factors such as the solute’s atomic size, electronic structure, and interaction with the magnetic moments of the solvent atoms. Detailed analysis often requires considering the magnetic anisotropy and exchange interactions within the alloy.

Example: Adding carbon to iron (steel) can have a complex effect on magnetic properties. While small additions of carbon can improve certain magnetic characteristics, larger additions can eventually reduce the overall magnetism due to changes in the crystal structure and magnetic domain interactions.

Key Topics to Learn for Solid Solution Strengthening Interview

- Fundamental Concepts: Understand the definition of solid solution strengthening, including substitutional and interstitial solutes. Grasp the role of solute atom size and its effect on dislocation movement.

- Strengthening Mechanisms: Delve into the detailed mechanisms behind increased yield strength, such as solute atom-dislocation interactions (e.g., size mismatch, modulus mismatch). Explore the concept of lattice distortion and its impact on dislocation motion.

- Practical Applications: Discuss real-world examples of alloy design based on solid solution strengthening. Consider specific material systems and how their properties are tailored through solute additions (e.g., alloying elements in steels, aluminum alloys). Be prepared to discuss case studies.

- Quantitative Aspects: Familiarize yourself with relevant equations and models used to predict the increase in yield strength due to solid solution strengthening. This may include understanding the limitations of these models.

- Microstructural Considerations: Understand how microstructural features (grain size, precipitation) can interact with solid solution strengthening. Be prepared to discuss how these interactions affect the overall mechanical properties.

- Limitations and Challenges: Discuss the limitations of solid solution strengthening. For example, consider the trade-off between strength and ductility, or the potential for embrittlement.

- Advanced Topics (Optional): Explore more advanced concepts such as order strengthening, clustering effects, and the influence of temperature on solid solution strengthening. These may be beneficial for senior-level positions.

Next Steps

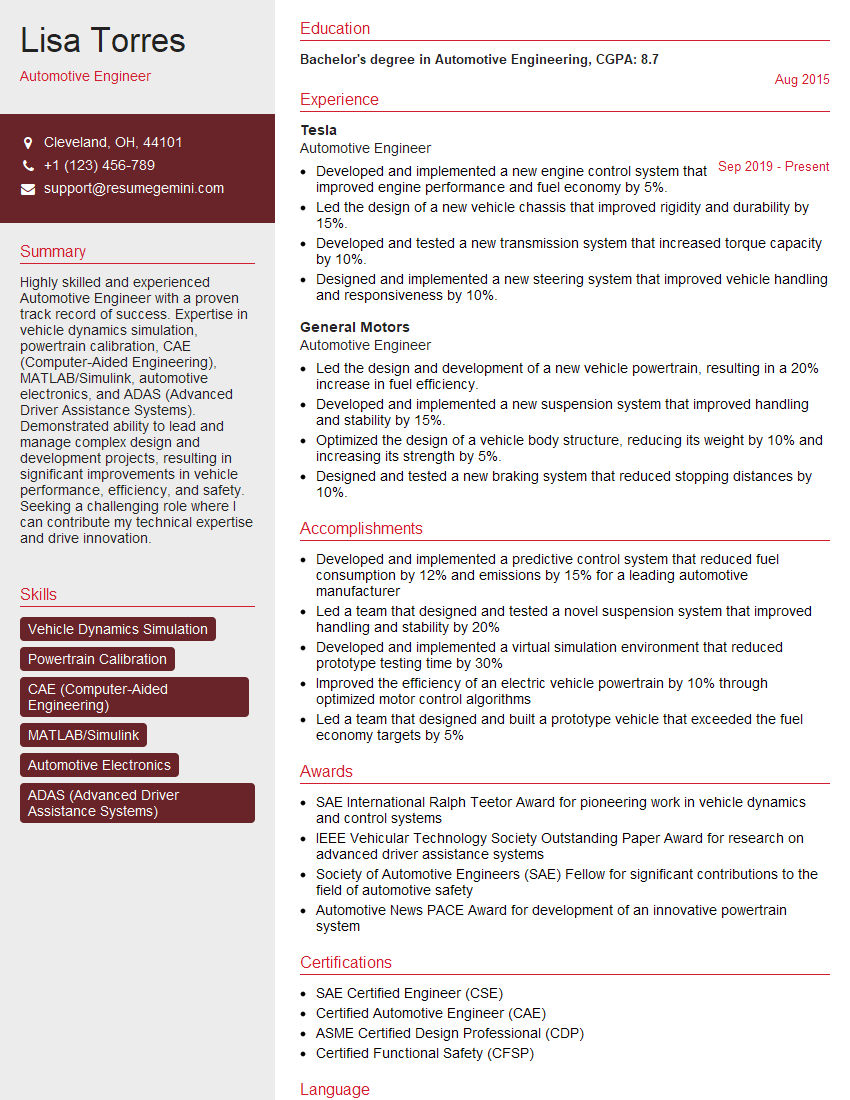

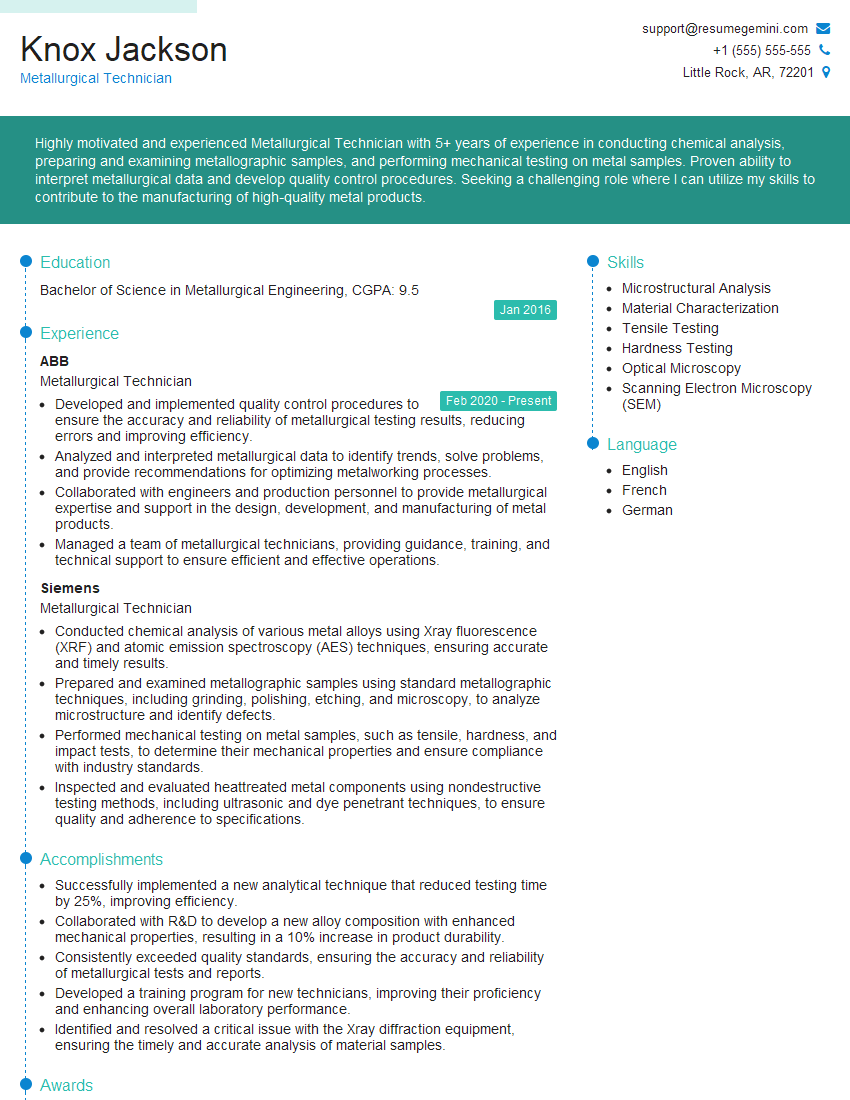

Mastering Solid Solution Strengthening demonstrates a strong foundation in materials science and engineering, significantly enhancing your career prospects in research, development, or manufacturing. A well-crafted resume is crucial for showcasing this expertise to potential employers. Building an ATS-friendly resume is key to maximizing your chances of getting noticed. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to your specific skills and experience. Examples of resumes tailored to Solid Solution Strengthening are available to provide you with inspiration and guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good