Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Commitment to Food Safety and Quality interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Commitment to Food Safety and Quality Interview

Q 1. Describe your experience implementing HACCP principles.

Implementing HACCP (Hazard Analysis and Critical Control Points) involves a systematic, preventative approach to food safety. It’s not just about reacting to problems; it’s about identifying and controlling potential hazards *before* they cause harm. My experience includes developing and implementing HACCP plans for various food processing facilities, ranging from small-scale bakeries to large-scale meat processing plants. This involved conducting hazard analyses, identifying critical control points (CCPs), establishing critical limits for each CCP, establishing monitoring procedures, corrective actions, verification procedures, and record-keeping systems. For example, in a bakery, a CCP might be the baking temperature, with a critical limit set to ensure pathogens are eliminated. Deviation from this limit triggers a corrective action, like discarding the batch. I’ve also overseen the training of employees on HACCP principles and ensured compliance with regulatory requirements.

In one specific instance, I helped a small-scale jam producer identify a critical control point related to the acidity level of their product, a crucial factor in preventing Clostridium botulinum growth. By implementing strict monitoring and corrective actions, we significantly reduced the risk of botulism, leading to a safer product and improved consumer confidence.

Q 2. Explain the difference between GMPs and HACCP.

While both Good Manufacturing Practices (GMPs) and HACCP are crucial for food safety, they address different aspects. GMPs are the foundational hygiene and sanitation practices that create a clean and controlled environment. Think of them as the basic rules of the game, covering things like handwashing, proper sanitation of equipment, pest control, and employee hygiene. They are preventative measures aimed at reducing the general risk of contamination.

HACCP, on the other hand, is a more systematic and science-based approach. It builds upon GMPs by specifically identifying and controlling hazards that could cause illness or injury. It’s a proactive strategy focusing on preventing specific problems, rather than just reacting to them. Think of HACCP as the advanced strategy built upon the foundation of GMPs, targeting specific risks using data and analysis. For example, while GMPs would cover general cleaning procedures, HACCP would define the specific temperature and time needed to sanitize equipment to eliminate E. coli.

Q 3. How do you conduct a food safety audit?

Conducting a food safety audit involves a systematic evaluation of a food business’s practices to identify strengths and weaknesses in its food safety management system. It’s a multi-step process. First, I review relevant documentation, such as the HACCP plan, GMPs, and standard operating procedures. Then, I conduct a thorough on-site inspection, observing processes, checking equipment, reviewing records, and interviewing staff. This involves checking temperature logs, inspecting storage areas for proper sanitation, verifying employee training records, and observing the handling and preparation of food.

During the audit, I use checklists and standardized procedures to ensure consistency and objectivity. I document all findings, both positive and negative, with photographic evidence where appropriate. Finally, I prepare a comprehensive report summarizing the audit findings, identifying areas of compliance and non-compliance, and making recommendations for improvements. I’ll also follow up to ensure corrective actions are implemented and effective.

Consider a scenario where I audit a restaurant. I might find that the handwashing sink isn’t properly stocked with soap and paper towels (a GMP failure). Separately, I might find that the temperature of the refrigerator isn’t being properly monitored, and there’s a lack of procedures for handling temperature deviations at the critical control point (a HACCP failure).

Q 4. What are the key indicators of food spoilage?

Key indicators of food spoilage vary depending on the type of food, but common signs include:

- Off-odors: Sour, putrid, or unusual smells.

- Changes in appearance: Discoloration, mold growth, slimy texture, unusual gas production.

- Changes in texture: Softening, hardening, unusual stickiness.

- Off-flavors: Sour, bitter, or rancid taste.

- Abnormal gas production: Bulging cans or packaging.

For example, milk going sour develops a noticeable sour smell and taste, and its texture may thicken. Meat might develop a slimy texture and an unpleasant odor as it spoils. These changes are due to microbial growth and enzymatic activity breaking down the food’s components.

Q 5. How would you handle a food safety incident?

Handling a food safety incident requires a swift, systematic response to minimize harm and prevent further problems. My first step is to contain the situation, identifying and isolating any potentially contaminated food. Then, I initiate a thorough investigation to determine the root cause of the incident, gathering all relevant information, interviewing witnesses, and reviewing records. This might include checking temperature logs, examining food samples, and reviewing employee practices.

Based on the investigation, I implement corrective actions, which could range from discarding contaminated food to retraining employees or modifying processes. I also collaborate with relevant authorities, such as public health officials, and notify affected customers if necessary. Comprehensive documentation of the entire incident, including the corrective actions and preventative measures, is critical for preventing future incidents. Transparent communication throughout the process is key to maintaining trust with consumers and stakeholders.

Q 6. What are your methods for preventing cross-contamination?

Preventing cross-contamination is vital to food safety. My methods involve a multi-pronged approach. First, I implement strict separation procedures. Raw and cooked foods are stored and prepared in separate areas using designated equipment. Secondly, I enforce thorough cleaning and sanitizing protocols for equipment and surfaces between handling different food items. Thirdly, I mandate proper handwashing techniques and the use of gloves to prevent transfer of microorganisms. Finally, I establish clear procedures for handling waste and cleaning spills to avoid spreading contaminants.

For instance, in a restaurant kitchen, raw meat would be stored on the bottom shelves of a refrigerator to avoid dripping onto ready-to-eat foods. Cutting boards used for raw meat would be thoroughly cleaned and sanitized before using them for vegetables. All of these measures reduce the risk of pathogens spreading from one food item to another.

Q 7. Describe your experience with allergen control programs.

Allergen control programs are critical for protecting consumers with allergies. My experience includes developing and implementing allergen control programs across various food establishments. This involves identifying all potential allergens present in the facility, developing procedures to prevent cross-contamination, clearly labeling products, and training employees on safe handling procedures. This includes creating a system for segregating allergen-containing ingredients and equipment during preparation, cleaning and sanitation procedures specifically targeted at allergen removal, and the implementation of effective recall procedures in the event of an allergen contamination.

For example, in a bakery, we established a dedicated area for baking products containing nuts, with separate equipment, utensils, and work surfaces. We also implemented strict cleaning protocols to eliminate any traces of nuts before handling other products. We use clear labeling to identify products containing allergens, ensuring consumers can make informed choices. Employee training covers the significance of allergen control and the consequences of cross-contamination.

Q 8. How do you ensure traceability throughout the food production process?

Traceability in food production is like a detective’s case file, meticulously documenting the journey of a food product from farm to table. It ensures we can identify the source of any problem and prevent wider contamination. This is achieved through a robust system of record-keeping at every stage.

- Lot Numbers and Batch Codes: Each batch of ingredients and finished products receives a unique identifier, allowing us to pinpoint its origin and processing history. Imagine a unique serial number for every box of cereal.

- Supplier Documentation: We meticulously track our suppliers, demanding certifications and verifying their own food safety practices. It’s like checking references for a new employee – you want to know their background.

- Electronic Tracking Systems: Modern technology plays a huge role. Software and RFID tags can automatically record movement, temperature, and other vital data throughout the supply chain. Think of it as a GPS for your food.

- Internal Audits and Inspections: Regularly scheduled checks and audits ensure our traceability system is functioning correctly. This is like a regular check-up for your system’s health.

A complete traceability system allows for rapid responses to recalls, investigations into contamination, and continuous improvement of safety procedures. Without it, contamination outbreaks become significantly harder to manage.

Q 9. What are the critical control points (CCPs) in a specific food production process (e.g., canning, meat processing)?

Critical Control Points (CCPs) are steps in a food process where control can prevent or eliminate a food safety hazard. Let’s look at meat processing and canning as examples:

Meat Processing:

- Receiving and Inspection: Checking meat for defects, ensuring proper temperature, and verifying supplier certifications are crucial first steps to prevent contamination.

- Grinding/Mixing: Maintaining proper temperatures and sanitation during these stages is vital to inhibit bacterial growth. Any contamination here can quickly spread.

- Cooking: Reaching and maintaining a specific internal temperature for sufficient time to kill pathogens like E. coli and Salmonella is a CCP. Failure here directly affects product safety.

- Cooling: Rapid cooling after cooking is critical to prevent bacterial proliferation. The longer it takes, the higher the risk of spoilage and pathogen growth.

- Packaging and Storage: Ensuring the proper temperature and sealing methods to prevent recontamination is vital for the final product’s safety.

Canning:

- Cleaning and Sanitizing: Thoroughly cleaning cans and equipment is vital to prevent bacterial introduction.

- Filling and Sealing: Properly filled cans with appropriate seals prevent contamination and spoilage. Improper sealing leads to botulism, a severe foodborne illness.

- Heat Processing: Achieving the required pressure and temperature to inactivate all microorganisms (including Clostridium botulinum spores) is the most critical CCP in canning.

- Cooling: Gradual cooling after heat processing is crucial to avoid can damage and bacterial regrowth.

Identifying CCPs requires a thorough Hazard Analysis and Critical Control Point (HACCP) plan. This structured approach ensures all potential hazards are identified and controlled.

Q 10. Explain your understanding of foodborne illness prevention.

Foodborne illness prevention is a multi-faceted approach aimed at minimizing the risk of contamination and protecting consumers’ health. It begins long before the food reaches the consumer’s plate.

- Good Agricultural Practices (GAPs): Ensuring safe farming practices, from soil management to pest control, forms the foundation of safe food production.

- Proper Handling and Storage: Maintaining appropriate temperatures throughout the supply chain prevents bacterial growth. Think of the ‘danger zone’ (40-140°F or 4-60°C) as enemy territory for food safety.

- Sanitation and Hygiene: Rigorous cleaning and sanitizing procedures are essential to eliminate pathogens. Proper handwashing is the cornerstone of hygiene.

- Employee Training: Educating workers about proper hygiene, food handling, and safety procedures is paramount. Well-trained staff are your best line of defense.

- Hazard Analysis and Critical Control Points (HACCP): Implementing a robust HACCP system allows for proactive identification and management of hazards at critical points in the food production process.

- Allergen Control: Preventing cross-contamination of allergens (e.g., nuts, dairy) is crucial for consumers with allergies.

Foodborne illness prevention is a shared responsibility, demanding rigorous practices at all stages of the food supply chain, from farm to fork.

Q 11. What are the regulations governing food safety in your region?

(Please note: The specific regulations governing food safety vary widely by region. This answer will provide a general overview, and you should replace this section with the specifics for your region. For example, instead of mentioning ‘the FDA’ you may refer to your national food safety authority.)

In many jurisdictions, food safety regulations are extensive and cover various aspects, often incorporating international standards. Key aspects usually include:

- Food Safety Modernization Act (FSMA) or equivalent: This legislation shifts the focus from reacting to contamination to proactively preventing it. It includes rules on preventive controls for human food, produce safety, and sanitary transportation.

- Good Manufacturing Practices (GMPs): These guidelines establish minimum standards for facility sanitation, equipment maintenance, and employee training. They are the bedrock of food safety in many countries.

- Hazard Analysis and Critical Control Point (HACCP): Many regulations mandate or strongly encourage the implementation of HACCP systems. It’s a science-based approach to controlling food safety hazards.

- Labeling Requirements: Clear and accurate labeling of ingredients, allergens, and nutritional information is mandatory to ensure consumer awareness and safety.

- Food Recall Procedures: Clear and efficient procedures are established for handling food recalls to minimize consumer harm.

These regulations are continually updated to reflect scientific advancements and emerging risks. Keeping up-to-date with these changes is crucial for any food safety professional.

Q 12. How do you interpret and implement food safety regulations?

Interpreting and implementing food safety regulations requires a multi-step approach:

- Understanding the Regulations: This is the first and most crucial step. It involves carefully reviewing all relevant regulations, guidelines, and interpretations.

- Gap Analysis: Comparing current practices with regulatory requirements to identify areas needing improvement.

- Developing and Implementing Corrective Actions: Creating and implementing specific plans to address any identified gaps. This often involves procedural changes, employee training, or equipment upgrades.

- Documentation: Maintaining detailed records of all compliance activities, including training records, inspections, and corrective actions. Thorough documentation is essential for audits and inspections.

- Regular Audits and Reviews: Regularly reviewing and updating the food safety management system to ensure ongoing compliance. This proactive approach helps stay ahead of potential problems.

It’s not enough to simply read the regulations; one must understand the ‘why’ behind them. This understanding allows for more effective implementation and minimizes the risk of non-compliance.

Q 13. What are your skills in using food safety management systems (e.g., ISO 22000)?

My experience with food safety management systems, particularly ISO 22000, is extensive. ISO 22000 is an internationally recognized standard that provides a framework for establishing, implementing, maintaining, and improving a food safety management system. My skills encompass:

- Implementing ISO 22000: I have led successful ISO 22000 implementation projects, guiding organizations through the process from gap analysis to certification. This includes developing detailed procedures, training staff, and managing the documentation process.

- Internal Audits: I regularly conduct internal audits to assess compliance with ISO 22000 requirements and identify areas for improvement. This is critical for maintaining certification and continuous improvement.

- Management Review: I participate in management reviews, providing valuable insights and recommendations to senior management on the performance of the food safety management system.

- HACCP System Development: I possess a thorough understanding of HACCP principles and have developed and implemented HACCP plans for various food processing environments.

- Corrective Actions: I’m adept at identifying the root causes of non-conformances and developing and implementing effective corrective and preventive actions. This prevents problems from recurring.

My expertise extends beyond just certification; I understand how to use ISO 22000 as a tool to enhance food safety culture and build a proactive approach to safety.

Q 14. How do you maintain accurate records and documentation for food safety?

Maintaining accurate records and documentation for food safety is crucial for traceability, compliance, and continuous improvement. Think of it as maintaining a detailed diary for your food safety journey.

- Electronic Record Keeping Systems: Utilizing software designed specifically for food safety record-keeping offers improved efficiency and data management. These systems often provide features like automated reporting and alerts.

- Standard Operating Procedures (SOPs): Detailed written procedures for every critical step in the food process should be available to all staff and followed consistently. These are your instruction manual for food safety.

- Calibration Records: Maintaining records of calibrations for all equipment that impacts food safety (e.g., thermometers, scales) ensures accuracy and reliability.

- Training Records: Keeping a comprehensive record of all employee training on food safety practices is crucial to ensure competence and compliance.

- Pest Control Records: Maintaining logs of pest control activities and inspections provides evidence of proactive measures to prevent contamination.

- Supplier Documentation: Storing certifications and other relevant documents from suppliers ensures verification of their food safety practices.

All records should be easily accessible, well-organized, and properly archived. Regular checks ensure data integrity and completeness.

Q 15. Describe your experience with food safety training and education.

My food safety training and education is extensive and spans various aspects of the field. I hold a certification in HACCP (Hazard Analysis and Critical Control Points), a globally recognized food safety management system. I’ve also completed numerous courses on GMPs (Good Manufacturing Practices), allergen control, sanitation procedures, and various microbiological testing techniques. My background includes practical experience in food processing facilities, giving me hands-on familiarity with applying these principles. For example, I’ve directly implemented and audited HACCP plans, ensuring compliance with regulatory requirements like FDA regulations. Furthermore, I’ve participated in several advanced workshops focusing on emerging food safety challenges, such as the detection and management of foodborne pathogens and the handling of new food technologies.

Career Expert Tips:

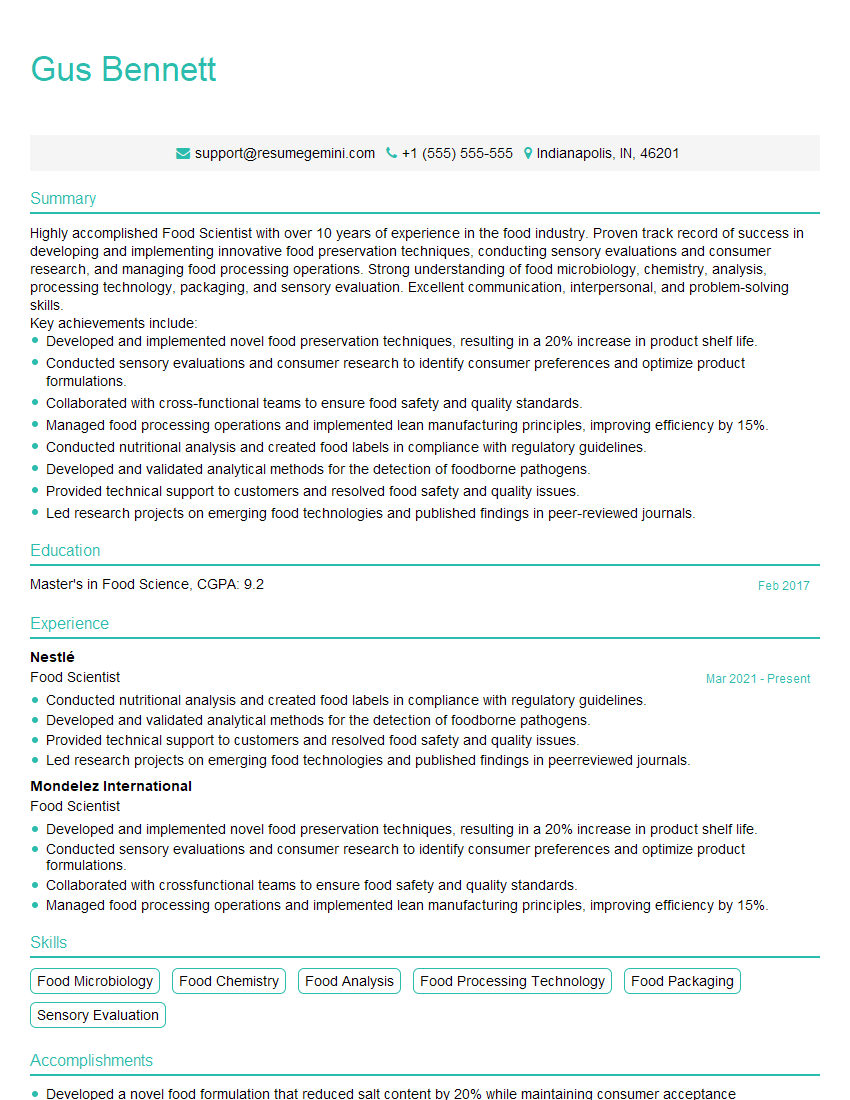

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay updated on current food safety trends and best practices?

Staying current in food safety requires continuous learning. I subscribe to industry journals like Food Technology and Journal of Food Science, and I actively participate in webinars and conferences organized by organizations like the FDA and the Food Safety Preventive Controls Alliance (FSPCA). Professional memberships in organizations like the Institute of Food Technologists (IFT) provide access to the latest research and best practices. I also regularly review updated regulatory guidelines and standards from relevant governing bodies. Furthermore, I actively network with other professionals in the food safety field to share insights and learn from their experiences. Following industry influencers and experts on social media platforms is another effective method I utilize.

Q 17. Explain your experience with pest control in a food production environment.

Effective pest control is crucial for maintaining food safety. In my experience, a multi-pronged approach is essential. This starts with rigorous sanitation – regularly cleaning and removing debris that attracts pests. We also use physical barriers like screens on windows and doors, and we implement a robust integrated pest management (IPM) program. This involves identifying pest entry points, monitoring pest activity using traps and visual inspections, and only using approved pest control methods. For example, I’ve overseen the implementation of an IPM program in a large-scale bakery, where we successfully reduced pest infestations by over 80% through a combination of proactive sanitation, preventative measures, and targeted pest control interventions. Documentation is key; we maintain detailed records of pest sightings, treatments, and control measures to ensure traceability and compliance with regulations.

Q 18. What are your methods for verifying the effectiveness of sanitation procedures?

Verifying sanitation effectiveness involves a combination of visual inspections, environmental monitoring, and ATP testing. Visual inspections ensure cleanliness of surfaces and equipment. Environmental monitoring includes collecting samples from surfaces to check for microbial contamination. ATP testing (Adenosine Triphosphate) measures the presence of organic matter, indicating cleanliness. A high ATP reading suggests inadequate cleaning. For example, in a meat processing plant, I would visually inspect equipment for residue after cleaning, take swabs from critical control points for microbial analysis, and use ATP meters to quantify the cleanliness of surfaces. Documented results, including photographs and test data, are essential for demonstrating sanitation effectiveness and maintaining a record for audits.

Q 19. How would you address employee non-compliance with food safety protocols?

Addressing employee non-compliance starts with a clear understanding of the root cause. Is it a lack of training, unclear procedures, or a lack of motivation? I utilize a multi-step approach: First, I provide clear and thorough training using various methods such as videos, hands-on demonstrations and written materials. Secondly, I ensure clear communication of food safety protocols, making them easily accessible and understandable. Thirdly, if non-compliance persists, I implement corrective actions, ranging from retraining to disciplinary measures. It’s crucial to approach this with a focus on education and support, while still enforcing standards. For instance, I would document the non-compliance, provide retraining, and then conduct follow-up observations to monitor for improvement. In serious cases, disciplinary action might be necessary, but it is always preceded by attempts to understand and address the underlying causes.

Q 20. What are your techniques for identifying and addressing food safety risks?

Identifying and addressing food safety risks uses a systematic approach based on HACCP principles. This involves conducting a hazard analysis to identify potential biological, chemical, and physical hazards at each step of the production process. Critical Control Points (CCPs) are identified – steps where control can prevent or eliminate hazards. Critical limits are then established for each CCP, and monitoring procedures are put in place to ensure these limits are met. Corrective actions are defined for deviations, and verification procedures ensure the overall system is effective. For example, in a canning operation, the CCP might be the heat treatment process. The critical limit would be a specific temperature and time combination to ensure pathogen inactivation. Monitoring involves regularly measuring temperature and time during the process, and corrective actions are in place if these limits are not met. Regular reviews and updates of the HACCP plan ensure its continued effectiveness.

Q 21. Describe your proficiency in microbiological testing and analysis.

My proficiency in microbiological testing and analysis includes performing various tests like aerobic plate counts, coliform counts, E. coli detection, Salmonella detection, and Listeria detection using standard microbiological techniques. I am familiar with different media and incubation conditions for each test, and I understand the interpretation of results. I have experience using both traditional culture methods and rapid detection methods like ELISA and PCR. I am adept at interpreting results and reporting them accurately. I also understand the importance of proper sample collection and handling to ensure accurate and reliable results. For example, I’ve been involved in implementing a robust testing program for a dairy processing facility, ensuring compliance with regulatory standards for microbial contamination. My experience includes troubleshooting issues related to testing methodologies and interpreting data to inform process improvements and corrective actions.

Q 22. How do you ensure the quality of incoming raw materials?

Ensuring the quality of incoming raw materials is paramount to producing safe and high-quality food products. It’s a multi-step process that begins even before the materials arrive at our facility. We utilize a robust system incorporating supplier approval, specification setting, and rigorous testing.

- Supplier Approval: We meticulously vet our suppliers, auditing their facilities to verify their adherence to food safety standards, such as HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices). This involves reviewing their own quality control processes, documentation, and traceability systems.

- Specification Setting: Clear specifications are established for each raw material, outlining acceptable levels of quality attributes such as microbial load, physical characteristics (size, color, texture), and chemical composition. These specifications act as a benchmark against which incoming materials are measured.

- Testing and Inspection: Upon arrival, a sample of each raw material batch undergoes rigorous testing. This can involve microbiological analysis (checking for pathogens like Salmonella or E. coli), physical and chemical analysis (to verify composition and detect contaminants), and sensory evaluation (assessing aspects like smell, taste, and texture). Any batch failing to meet specifications is rejected and returned to the supplier.

For example, if we’re receiving tomatoes, we’ll specify acceptable levels of Brix (sugar content), pH, and microbial counts. Any batch falling outside these parameters would be rejected, preventing potential quality and safety issues downstream.

Q 23. What is your experience with food recall procedures?

Food recall procedures are a critical component of any robust food safety management system. My experience spans multiple recalls, ranging from minor issues to more significant events. The process is always systematic and prioritizes consumer safety above all else.

- Immediate Action: Upon identifying a potential hazard, whether through internal monitoring or external notification, the first step is immediate containment. This includes isolating the affected product and halting its distribution. A crisis management team is activated, typically involving representatives from production, quality assurance, legal, and public relations.

- Traceability: Effective traceability is essential for determining the scope of the problem. We utilize comprehensive tracking systems to identify all potentially affected batches, their distribution channels (wholesalers, retailers, etc.), and ultimately the consumers who may have received them. This information is vital for the effectiveness of the recall.

- Notification and Communication: We work closely with regulatory agencies to implement a swift and transparent recall. Consumers are notified through various channels, such as public announcements, social media, and press releases. Clear and accurate information regarding the hazard and necessary actions (return, disposal) is provided.

- Root Cause Analysis: Post-recall, a comprehensive root cause analysis is performed to determine the factors that contributed to the incident. This analysis helps to prevent future occurrences by identifying weaknesses in our systems and implementing corrective actions.

In one instance, a recall was initiated due to a packaging error involving mislabeling. Through our traceability system, we rapidly identified the affected batches and initiated a recall, minimizing consumer risk and protecting our brand reputation.

Q 24. How do you ensure proper labeling and packaging for food products?

Proper labeling and packaging are crucial aspects of food safety and consumer protection. Accurate and complete labeling provides consumers with the necessary information to make informed choices, while effective packaging maintains product integrity and protects against contamination.

- Compliance with Regulations: All labeling adheres strictly to all relevant regulations, including those related to ingredients, nutritional information, allergen declarations, and country-specific labeling requirements. This involves meticulous attention to detail and maintaining updated knowledge of ever-evolving regulations.

- Accuracy and Clarity: The information presented on the label must be accurate, unambiguous, and easily understood by the consumer. This includes using clear language, appropriate font sizes, and avoiding misleading or deceptive statements.

- Packaging Integrity: The packaging material should be chosen to protect the product from contamination, damage, and spoilage. This includes considerations of material strength, barrier properties (against oxygen, moisture, etc.), and seal integrity. Tamper-evident packaging helps to further ensure product security.

- Traceability: Packaging also plays a vital role in product traceability. Batch codes and other identifiers are included to allow for easy tracking of the product from origin to consumer. This is critical in the event of a recall or quality issue.

We regularly conduct internal audits to ensure our labeling and packaging practices meet the highest standards, and we employ a quality control team dedicated to verifying labeling accuracy prior to release.

Q 25. What are the key elements of a successful food safety program?

A successful food safety program is built on several key pillars, working in synergy to minimize risks and ensure product safety.

- Hazard Analysis and Critical Control Points (HACCP): This systematic, preventative approach identifies potential hazards at each stage of the food production process and establishes critical control points (CCPs) to manage these risks. Monitoring these CCPs ensures that the food safety system remains effective.

- Good Manufacturing Practices (GMP): GMPs cover a broad range of operational practices designed to minimize contamination, maintain product quality, and ensure the overall cleanliness and hygiene of the food production environment.

- Preventive Controls for Human Food (PCFH): PCFH is a set of regulations that addresses hazards that may not be fully addressed by HACCP alone. This includes focusing on preventing intentional adulteration, allergen control, supply-chain program, and recall plan.

- Staff Training and Education: A well-trained workforce is essential. Regular training programs ensure that all personnel understand their roles in maintaining food safety, from proper hygiene practices to the correct use of equipment.

- Record Keeping and Documentation: Meticulous record-keeping is crucial for traceability and demonstrating compliance with regulations. All aspects of the food safety system, including testing results, training records, and corrective actions, must be thoroughly documented.

- Regular Audits and Inspections: Regular internal audits and external inspections (by regulatory bodies) help to identify potential weaknesses and ensure ongoing compliance.

Think of it like a well-oiled machine; each element contributes to the overall effectiveness and efficiency of the system.

Q 26. Describe your experience with continuous improvement in food safety practices.

Continuous improvement in food safety is not a one-time endeavor; it’s an ongoing process of refinement and enhancement. My approach to this involves several key strategies:

- Data Analysis: We regularly analyze data from various sources, including microbiological testing results, customer complaints, and internal audit reports, to identify trends and areas for improvement. This data-driven approach allows for targeted interventions rather than relying on guesswork.

- Benchmarking: Comparing our practices to industry best practices and those of leading competitors helps to identify areas where we can improve. This might involve adopting new technologies, implementing best-in-class procedures, or enhancing training programs.

- Process Optimization: Continuous improvement also involves evaluating and optimizing existing processes to eliminate inefficiencies and reduce the potential for errors. This could involve streamlining workflows, improving equipment design, or enhancing training programs.

- Technology Adoption: Embracing new technologies such as automated sanitation systems, real-time temperature monitoring, and advanced traceability systems can significantly enhance food safety and efficiency.

- Employee Involvement: Involving employees at all levels in the continuous improvement process fosters a culture of food safety awareness and facilitates the identification of potential issues before they escalate.

For example, by analyzing data on sanitation procedures, we identified a potential gap in our cleaning protocols, leading to a revised protocol that has significantly reduced the risk of microbial contamination.

Q 27. How do you manage conflicts related to food safety and production efficiency?

Balancing food safety and production efficiency is a common challenge. Conflicts can arise when efficiency measures seem to compromise safety or vice versa. Managing these conflicts effectively requires a collaborative approach.

- Prioritize Food Safety: Food safety should always take precedence. No efficiency gains are worth compromising the safety of the product or the consumer.

- Open Communication: Creating a culture of open communication between production and food safety teams is essential. This ensures that potential conflicts are identified early and addressed proactively. Regular meetings and clear communication channels help foster this collaboration.

- Risk Assessment: When conflicts arise, a systematic risk assessment is conducted to evaluate the potential risks associated with various options. This allows for informed decision-making based on a thorough understanding of the potential consequences.

- Innovative Solutions: Often, creative problem-solving can identify solutions that enhance both food safety and production efficiency. This might involve investing in new technologies or redesigning processes to optimize both safety and output.

- Documentation and Training: Decisions made regarding food safety and production trade-offs must be documented clearly and transparently. Training is provided to ensure everyone understands the rationale behind the chosen approach.

For example, a conflict might arise between a desire to increase production speed and the time required for thorough sanitation. By carefully evaluating the risks associated with reduced sanitation time and investing in automated cleaning systems, we can achieve both efficiency improvements and maintain impeccable food safety standards.

Key Topics to Learn for Commitment to Food Safety and Quality Interview

- Hazard Analysis and Critical Control Points (HACCP): Understanding the principles of HACCP, including hazard identification, critical control point determination, and monitoring procedures. Practical application: Describe how you would implement HACCP in a specific food production environment.

- Good Manufacturing Practices (GMP): Knowledge of GMP principles and their application in maintaining a sanitary food production environment. Practical application: Explain your experience with sanitation procedures and preventative maintenance to minimize contamination risks.

- Foodborne Illness Prevention: Understanding common foodborne pathogens, their sources, and prevention strategies. Practical application: Discuss how you would handle a suspected foodborne illness outbreak.

- Food Allergen Management: Knowledge of common food allergens and strategies for preventing cross-contamination and allergen labeling compliance. Practical application: Describe your experience with managing allergens in a food service or production setting.

- Food Quality Management Systems (e.g., ISO 22000): Familiarity with internationally recognized food safety management systems and their implementation. Practical application: Explain the benefits of implementing a food safety management system and how it improves operational efficiency.

- Food Traceability and Recall Procedures: Understanding the importance of traceability systems and the procedures to follow in the event of a product recall. Practical application: Detail your experience with tracking ingredients or products through the supply chain.

- Regulatory Compliance (e.g., FDA regulations): Knowledge of relevant food safety regulations and compliance procedures. Practical application: Describe how you ensure compliance with food safety regulations in your work.

- Personal Hygiene and Sanitation Practices: Understanding the importance of personal hygiene in preventing food contamination. Practical application: Describe your experience enforcing and maintaining high hygiene standards within a team.

Next Steps

Mastering Commitment to Food Safety and Quality demonstrates a crucial skillset highly valued across the food industry, significantly enhancing your career prospects and opening doors to leadership roles. To maximize your job search success, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a compelling and effective resume that showcases your qualifications. ResumeGemini provides examples of resumes tailored to Commitment to Food Safety and Quality, guiding you in presenting your skills and experience in the best possible light. Invest time in crafting a professional resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good