The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Commercial painting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Commercial painting Interview

Q 1. What types of surface preparation techniques are you familiar with?

Surface preparation is the cornerstone of any successful painting project. It ensures the paint adheres properly and lasts for years. My experience encompasses a range of techniques, tailored to the specific surface and paint type.

- Cleaning: This involves removing dust, dirt, grease, and any loose or flaking paint using pressure washing, scraping, sanding, or chemical cleaning agents. For instance, on a brick wall, I’d use a pressure washer followed by a thorough brushing to remove any remaining debris. On a delicate surface like drywall, a careful sanding and wiping might be necessary.

- Priming: Priming is crucial for providing a uniform surface for the topcoat and improving adhesion. Different primers are chosen depending on the substrate; for instance, an oil-based primer on wood helps to seal tannins and prevent bleeding through, whereas an alkali-resistant primer is vital on concrete to prevent chemical reactions.

- Repairing: Before painting, any damage such as holes, cracks, or imperfections need to be addressed. This involves filling holes with spackle or patching compound, allowing it to dry, and then sanding smooth for a flawless finish. I’ve worked extensively with various patching compounds and understand the drying times and sanding requirements for each.

- Caulking: Caulking is essential for sealing gaps and cracks, preventing drafts and water damage. I meticulously choose appropriate caulking compounds, applying them neatly and smoothing them to achieve a professional finish.

Q 2. Describe your experience with different paint types (e.g., latex, epoxy, oil-based).

My experience spans a wide variety of paint types, each suited to different applications and environments.

- Latex Paints: These are water-based, low-odor, easy to clean up, and dry quickly. They’re my go-to for most interior and exterior projects, offering a good balance of durability, color range, and ease of application. I’ve successfully used numerous brands, knowing the specific characteristics of each — for example, some are better for high-traffic areas while others excel in weather resistance.

- Epoxy Paints: Epoxy paints are highly durable, chemical-resistant, and excellent for flooring, garages, or other areas requiring exceptional protection. I’ve worked with epoxy coatings in commercial settings, such as industrial kitchens or chemical plants, understanding the critical need for precise application and proper ventilation.

- Oil-Based Paints: While less common now due to VOC concerns, oil-based paints offer excellent durability and gloss retention, making them suitable for specific applications like trim work or when a very hard-wearing finish is crucial. I understand their longer drying times and the importance of proper ventilation during application and drying.

Q 3. How do you determine the appropriate amount of paint needed for a project?

Accurately estimating paint quantity is key to preventing costly material waste and project delays. I use a combination of methods for this:

- Surface Area Calculation: I meticulously measure the area to be painted (length x width x height for walls, length x width for ceilings). I always add extra for overlaps, corners, and potential unforeseen issues.

- Manufacturer’s Guidelines: Paint cans specify the coverage per gallon or liter. I refer to these guidelines and always round up, accounting for variations in surface texture and absorption rates.

- Experience and Judgement: Years of experience allows me to judge the likely paint consumption based on the substrate and the desired number of coats. This often means factoring in the porosity of the surface, whether there’s a need for priming, and the type of paint being used.

- Example: A 10ft x 12ft wall needing two coats of paint, with a coverage of 350 sq ft per gallon, would require roughly 1 gallon. However, I’d always add an extra half-gallon to account for wastage, uneven surfaces and additional coats due to imperfections.

Q 4. Explain your experience with different painting methods (e.g., brush, roller, spray).

I’m proficient in various painting methods, each offering unique advantages:

- Brushes: Brushes are ideal for detailed work, trim, and corners, offering precise control. I use different brush sizes and bristle types depending on the project’s requirements.

- Rollers: Rollers are efficient for large surfaces, providing a relatively smooth finish. I use appropriate nap rollers (thickness of the nap) depending on the surface texture— for example, a thicker nap for textured walls, and a thinner nap for smooth surfaces.

- Sprayers: Sprayers are excellent for large, even coatings, minimizing brush strokes and offering speed, particularly on exterior surfaces. However, careful preparation and safety measures are crucial, as well as consideration for overspray. I use both airless and HVLP (High Volume Low Pressure) sprayers depending on the project.

The choice of method often depends on the project scope, surface type, and desired finish. I often combine methods for optimal results.

Q 5. How do you ensure a consistent paint finish across large surfaces?

Achieving a consistent finish across large surfaces requires meticulous planning and execution.

- Consistent Technique: Maintaining a consistent wet edge, overlapping strokes, and applying even pressure are crucial, regardless of the method used. I train my team to apply these techniques consistently.

- Proper Lighting: Good lighting helps to identify inconsistencies and ensures even application. I often work with good lighting and periodically re-assess the work to ensure even coverage.

- Multiple Thin Coats: Applying multiple thin coats is preferred to one thick coat, preventing runs, drips, and ensuring a consistent level of coverage and color saturation. I always opt for multiple thin coats instead of fewer thick coats.

- Careful Preparation: A thoroughly prepared surface is essential for a uniform finish. This includes addressing imperfections and ensuring the surface is clean and primed. I emphasize a meticulous preparation phase before any painting begins.

Q 6. What safety precautions do you take when working at heights?

Safety is my utmost priority, especially when working at heights. My safety procedures adhere strictly to OSHA regulations:

- Fall Protection: I always use appropriate fall protection equipment, such as harnesses, lanyards, and anchor points. I ensure all equipment is properly inspected and certified before each job.

- Scaffolding: When needed, I use properly erected and secured scaffolding, ensuring it meets all safety standards. I inspect scaffolding before use and ensure it’s stable and correctly positioned.

- Proper Training: All team members receive thorough training on safe work practices at heights, including equipment usage and emergency procedures.

- Regular Inspections: I conduct regular safety inspections of the work area, equipment, and personnel to ensure adherence to safety protocols.

Q 7. How do you handle unexpected problems or delays on a painting project?

Unexpected problems are part of the painting business. My approach involves:

- Problem Identification: I thoroughly assess the problem—is it material-related, weather-related, or a design flaw?

- Solution Development: Based on the problem’s nature, I develop a solution, whether it involves material substitution, schedule adjustment, or consulting with the client.

- Communication: I proactively communicate with clients, keeping them informed of any delays or changes. Transparency helps to manage expectations.

- Contingency Planning: I always have a contingency plan. This includes having backup materials, flexible scheduling, and an understanding of alternative approaches. For example, if bad weather delays an exterior project, I might shift focus to interior work until the weather improves.

My focus is on finding solutions while maintaining quality and client satisfaction. I view unexpected issues as opportunities to showcase problem-solving skills and professional adaptability.

Q 8. What is your experience with color matching and matching existing paint?

Color matching is crucial for achieving a seamless and professional finish in commercial painting. My experience involves using a variety of methods, from utilizing colorimeters and spectrophotometers for precise digital matching to relying on my trained eye and experience with paint formulations. I’m proficient in interpreting color codes (e.g., Pantone, RAL) and translating them into the correct paint mixtures using various brands and finishes.

For matching existing paint, I typically start by obtaining a sample of the existing paint. I then use a colorimeter to capture the color data, which I subsequently use to find the closest match in our extensive paint library. In cases where a perfect match is impossible due to fading or age, I’ll work with the client to choose a color that blends seamlessly, often providing multiple options and explaining the subtle differences. For example, I recently matched a faded shade of Benjamin Moore’s “Balboa Mist” on a large office building. The original paint had significant sun damage, so I presented three options – slight variations to account for the inevitable aging process – and discussed the pros and cons of each with the client before settling on a final choice.

Q 9. Describe your experience with managing a painting crew.

Managing a painting crew requires a blend of leadership, organization, and technical expertise. My approach centers around clear communication, delegation, and fostering a collaborative environment. I’ve successfully led teams ranging from three to ten individuals, ensuring each crew member understands their role, responsibilities, and safety protocols. Before commencing a project, I hold thorough briefings to discuss the project scope, timeline, safety procedures, and expected quality standards.

I delegate tasks based on individual skill sets and experience, regularly monitoring progress and providing guidance and feedback. I strongly believe in teamwork and encourage open communication among team members. For instance, on a recent large-scale retail store renovation, I divided the team into smaller, specialized units – surface preparation, priming, painting, and finishing – and assigned experienced team members to act as supervisors for each unit. This approach ensured efficiency, enhanced quality control, and minimized potential issues. I also emphasize the importance of safety, conducting regular safety checks and enforcing strict adherence to industry best practices.

Q 10. How do you ensure project completion within budget and timeframe?

Ensuring projects are completed on time and within budget involves meticulous planning, efficient resource allocation, and proactive problem-solving. This starts with a comprehensive project estimate, considering all aspects including labor costs, materials, equipment rentals, and potential unforeseen expenses. I utilize detailed checklists and timelines to track progress and identify potential delays early.

Regular communication with clients keeps them informed of progress and addresses any potential concerns. Should challenges arise, I employ a problem-solving approach focused on finding cost-effective solutions that don’t compromise the quality of the work. For example, if we encounter unexpected damage during surface preparation, I immediately assess the situation, develop a revised scope of work, and discuss the necessary adjustments with the client. By having a contingency plan for potential delays and cost overruns, and maintaining open communication, I can ensure projects are delivered on time and within the agreed-upon budget.

Q 11. What software or tools do you use for estimating and project management?

For estimating and project management, I leverage a combination of software and tools. I use specialized construction estimating software, like [Name of Software – replace with a real software name], to create detailed estimates, manage material costs, and track labor hours. This software allows for precise calculations and helps in preparing comprehensive proposals for clients.

I also use project management tools like [Name of Software – replace with a real software name] for scheduling, task assignment, progress tracking, and communication with team members. This allows for real-time monitoring of the project’s progress, ensuring we stay on schedule and identify any potential bottlenecks early on. For example, using a Gantt chart feature in this software helps visualize project dependencies and potential conflicts, letting me adjust the schedule as needed and prevent delays.

Q 12. Explain your experience with different types of paint application equipment.

My experience encompasses a wide range of paint application equipment. I’m proficient in using airless sprayers for large-scale projects, ensuring a consistent and efficient finish. I also have extensive experience with conventional brushes and rollers for detailed work and areas where spraying isn’t suitable.

I understand the nuances of each tool and select the appropriate equipment based on the project’s requirements, paint type, and surface texture. For example, I might use airless sprayers for painting large walls and ceilings in an office building, while utilizing brushes and rollers for trim work and intricate details. My expertise extends to specialized equipment like HVLP (High Volume Low Pressure) sprayers for finer finishes and texture rollers for achieving specific surface effects. I prioritize safety and always ensure proper training and use of protective equipment for all tools used.

Q 13. Describe your understanding of VOC regulations and environmental compliance.

VOC (Volatile Organic Compound) regulations and environmental compliance are paramount in my work. I am well-versed in local, state, and federal regulations concerning VOC emissions from paints and coatings. I prioritize the use of low-VOC or zero-VOC paints whenever possible to minimize environmental impact and ensure compliance with all relevant regulations.

This includes proper disposal of paint waste, ensuring adherence to hazardous waste handling procedures, and using appropriate safety equipment during application to prevent exposure to both myself and the clients. I regularly stay updated on changes to environmental regulations and incorporate the latest best practices into our work processes. For instance, I make sure all our suppliers provide certifications demonstrating their products meet environmental standards, and I maintain detailed records of all materials used on each project to demonstrate compliance for potential audits.

Q 14. How do you handle client communication and address concerns?

Effective client communication is key to successful project delivery. I maintain open and consistent communication throughout the entire project lifecycle, starting with initial consultations and continuing through completion. I actively listen to client needs, answer questions thoroughly, and provide regular updates on progress, addressing concerns proactively.

I use a variety of communication methods, including in-person meetings, phone calls, emails, and project management software updates, ensuring that the client is always informed and involved. Should issues arise, I address them promptly and transparently, working collaboratively with the client to find mutually acceptable solutions. For example, if a client expresses concern about a particular aspect of the project, I’ll schedule a meeting to discuss their concerns, explain the situation, and propose solutions. My aim is to build trust and foster a strong, collaborative relationship that ensures client satisfaction.

Q 15. What is your experience working with different substrates (e.g., wood, drywall, metal)?

My experience spans a wide range of substrates commonly encountered in commercial painting. Understanding the unique properties of each material is crucial for achieving a high-quality, durable finish.

- Wood: I’m proficient in prepping various wood types, from the smooth surface of hardwood trim to the more textured grain of exterior siding. This includes addressing issues like knots, imperfections, and previous finishes. Proper priming is key for adhesion and preventing bleed-through.

- Drywall: Drywall is a staple in commercial settings. My experience includes working with different drywall types, handling joint compound application and sanding for a smooth, even surface before painting. I’m adept at repairing minor damage and ensuring a flawless final coat.

- Metal: Metal substrates, like steel or aluminum, require specific preparation techniques. This involves cleaning to remove rust, grease, or other contaminants, followed by the application of a suitable primer to prevent corrosion and ensure paint adhesion. I’m experienced with both interior and exterior metal applications.

For example, on a recent project involving a historic building with intricate wood paneling, I carefully assessed the condition of the wood, repaired any damaged sections, and applied a specialized primer designed for optimal adhesion and stain blocking before applying the final coat of paint to preserve the wood’s integrity and beauty.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with surface cleaning and preparation before painting.

Surface preparation is arguably the most crucial step in the painting process; a poor prep job will inevitably lead to poor results regardless of the quality of the paint. My process typically involves:

- Inspection: A thorough assessment of the surface to identify imperfections, damage, or existing coatings.

- Cleaning: Using appropriate methods to remove dirt, dust, grease, mildew, or any other contaminants. This might involve washing, scraping, or pressure washing depending on the substrate and level of soiling. For example, using a TSP (trisodium phosphate) solution for thorough cleaning of walls before painting.

- Repair: Addressing any imperfections such as cracks, holes, or damaged areas using appropriate patching compounds, fillers, or caulking.

- Sanding: Smoothing out repaired areas and creating an even surface for painting using various grits of sandpaper.

- Priming: Applying a primer to ensure proper adhesion, improve paint coverage, and block stains or bleeding from the substrate.

In a recent project involving a large office space, meticulous surface preparation – including extensive cleaning, patching, and priming – was essential to achieve the seamless, professional look our client required. We followed this process diligently, which resulted in a high-quality finish that lasted many years.

Q 17. How do you maintain quality control throughout the painting process?

Maintaining quality control is an ongoing process throughout the project lifecycle. It starts with clear communication with the client, meticulous planning, and careful execution of each step. Here’s my approach:

- Regular Inspections: Frequent checks throughout the process – from surface preparation to the final coat – to ensure adherence to standards and promptly address any issues.

- Color Matching: Using calibrated tools and methods to ensure consistent and accurate color application across all areas.

- Sample Boards: Creating sample boards showing different color options before committing to a final decision on colour and sheen.

- Team Training and Oversight: Ensuring my team is well-trained and equipped to follow established procedures. I provide regular feedback and guidance to maintain consistency.

- Final Walkthrough: A thorough inspection with the client at the end of the project to review the completed work and address any concerns.

Think of it like baking a cake. You have to follow the recipe precisely, using quality ingredients, and check on the progress regularly to ensure it’s baking correctly. The same applies to painting.

Q 18. Explain your experience with various masking and protection techniques.

Effective masking and protection are vital to protecting surfaces not being painted and achieving clean, crisp lines. I utilize a variety of techniques depending on the project’s needs:

- Painter’s Tape: For precise masking of edges and details. Different tape types are used for various substrates and paint types.

- Drop Cloths: Protecting floors and furniture using drop cloths of varying thickness and materials, ensuring complete coverage.

- Plastic Sheeting: Covering larger areas like windows, fixtures, or adjacent walls to prevent overspray and splatters.

- Masking Film: For more delicate surfaces, using masking film provides a superior protective layer that can be easily removed.

- Caulk: Using caulk to seal gaps and cracks before painting, preventing paint from bleeding through and ensuring a clean, professional finish.

For example, during a recent project in a high-end retail space, we meticulously masked delicate fixtures, glass display cases, and flooring using a combination of painter’s tape, drop cloths, and masking film, ensuring a perfect paint job without any damage or imperfections.

Q 19. How do you manage waste disposal and environmental impact?

Environmental responsibility is paramount in my operations. We adhere to strict waste disposal procedures and prioritize environmentally friendly practices:

- Proper Disposal: We segregate paint waste according to local regulations, often utilizing hazardous waste disposal services for solvents and other chemicals.

- Recycling: We recycle whenever possible, including paint cans, plastic sheeting, and cardboard.

- Low-VOC Paints: We use low-VOC (volatile organic compound) paints whenever feasible, minimizing harmful emissions.

- Spill Prevention: Employing appropriate containment procedures and cleanup methods to minimize accidental spills and protect the environment.

We aim to minimize our environmental footprint while maintaining the highest standards of workmanship. This includes proper cleanup at each job site, leaving it cleaner than we found it.

Q 20. Describe your experience with working with different types of paint sprayers.

My experience encompasses a variety of paint sprayers, each with its strengths and weaknesses, which allows me to select the best tool for the job:

- Airless Sprayers: Excellent for large surface areas, offering high-speed application. Ideal for exterior projects or large interior spaces.

- HVLP (High-Volume, Low-Pressure) Sprayers: Produce a finer finish with less overspray, suitable for detailed work and delicate surfaces.

- Air-Assisted Airless Sprayers: Combine the speed of airless spraying with a finer finish. A versatile option for various projects.

Choosing the right sprayer is crucial for efficiency and quality. For instance, an airless sprayer is perfect for quickly painting a large warehouse, while an HVLP sprayer may be preferred for painting detailed trim in a luxury apartment. I am comfortable and proficient with all three types.

Q 21. How do you ensure the safety of your crew and the work environment?

Safety is paramount. We prioritize a safe work environment for our crew and anyone on the job site. Our safety protocols include:

- PPE (Personal Protective Equipment): Mandatory use of safety glasses, respirators, gloves, and appropriate clothing to protect against hazards.

- Fall Protection: Implementing fall protection measures, such as harnesses and guardrails, when working at heights.

- Hazard Communication: Clearly communicating potential hazards and providing proper training on safe work practices.

- Proper Ventilation: Adequate ventilation, particularly when using solvents or spray equipment, to minimize exposure to harmful fumes.

- Emergency Preparedness: Having a well-defined plan for handling emergencies, including first aid and communication procedures.

Safety isn’t just a checklist; it’s a culture. Regular safety meetings, thorough training, and a commitment to following safety protocols ensure that everyone on the job site returns home safely.

Q 22. What is your experience with caulking, patching and surface repair?

Caulking, patching, and surface repair are fundamental to a quality paint job. They ensure a smooth, even surface for optimal paint adhesion and a professional finish. My experience encompasses a wide range of techniques for addressing various defects.

Caulking: I’m proficient in using various caulking materials, from silicone to acrylic latex, to seal gaps and cracks around windows, doors, and trim. Proper caulking prevents drafts, water damage, and ensures a clean aesthetic line. For example, I recently worked on a project where improperly caulked windows were causing drafts. After carefully removing the old caulk, cleaning the surface, and applying fresh, appropriately matched caulk, the drafts were eliminated, and the client was delighted.

Patching: I’m skilled in patching holes and imperfections in drywall, plaster, and other surfaces. This involves selecting the appropriate patching compound – spackle, joint compound, or patching plaster – based on the size and nature of the damage. After patching, careful sanding is crucial to ensure a seamless transition to the surrounding surface. I remember one project where there were significant holes left from removed plumbing fixtures. After patching and sanding, the walls were ready for painting, and you couldn’t even tell where the holes once were.

Surface Repair: This often involves addressing more extensive damage, like water stains or significant imperfections. I use a combination of techniques – patching, sanding, priming – to restore the surface to a paintable condition. For instance, I’ve repaired water-damaged drywall by cutting out the affected section, replacing it with new drywall, and then blending the repair seamlessly with the existing wall.

Q 23. How do you deal with challenging surfaces like textured walls or intricate trim work?

Textured walls and intricate trim work present unique challenges, requiring specialized techniques and attention to detail. I approach these surfaces strategically:

Textured Walls: The key here is using the right tools and techniques to ensure even paint coverage without obscuring the texture. I often use a high-quality brush or roller specifically designed for textured surfaces, adjusting my technique to ensure thorough coverage in all crevices and valleys. I might even use a slightly thicker coat for more textured walls to prevent unevenness.

Intricate Trim Work: Precise application is paramount. I use brushes of various sizes – from small detail brushes to larger sash brushes – depending on the intricacy of the trim. Masking tape plays a crucial role in protecting adjacent surfaces and ensuring crisp, clean lines. I also utilize various painting techniques, such as cutting in with a brush before rolling larger areas, to achieve a flawless result. For example, I carefully cut in the edges before rolling to maintain a clean look around the windows and doors.

In both cases, preparation is key – cleaning and priming the surface before painting is essential for optimal adhesion and a superior finish.

Q 24. What is your understanding of different paint sheen levels and their application?

Understanding paint sheen levels is vital for achieving the desired aesthetic and functional outcome. Different sheens offer varying levels of durability, washability, and light reflection.

Flat/Matte: Offers excellent hiding power and minimizes imperfections, but it is less durable and washable.

Eggshell: Provides a slightly more durable and washable finish than flat, with a subtle sheen. It is a popular choice for walls and ceilings.

Satin: More durable and washable than eggshell, with a soft luster. It’s a good choice for areas prone to moisture, such as kitchens or bathrooms.

Semi-Gloss: Very durable and highly washable, with a noticeable sheen. Often used for trim work, doors, and cabinetry.

High-Gloss: The most durable and washable option, with a very high sheen. It’s best suited for areas requiring maximum durability, but it tends to highlight imperfections.

Choosing the correct sheen depends on the specific needs of the project. For example, a high-gloss finish might be appropriate for kitchen cabinets but would be inappropriate for a living room wall because it shows imperfections more easily.

Q 25. How do you read and interpret blueprints and specifications?

Reading and interpreting blueprints and specifications are essential for ensuring that the painting project aligns with the client’s vision and the building codes. I meticulously review the plans to understand:

Scope of Work: The exact areas to be painted, including walls, ceilings, trim, and any other specified surfaces.

Surface Preparation Requirements: Any necessary repairs, patching, or priming before painting commences.

Paint Specifications: The required paint type, sheen level, and color codes.

Safety Considerations: Any potential hazards or safety protocols that need to be followed.

I often use a combination of software and traditional methods (like highlighting relevant sections on the blueprints with color-coded sticky notes) to aid in the interpretation process. This ensures I am perfectly prepared to execute the project as per the specifications.

Q 26. Explain your experience with managing and maintaining painting equipment.

Maintaining painting equipment is crucial for efficiency and longevity. My experience includes proper cleaning, storage, and repair of various tools.

Cleaning: After each use, I thoroughly clean rollers, brushes, spray guns, and other equipment to remove paint and prevent clogging. I use appropriate solvents for different paint types.

Storage: Tools are stored properly to prevent damage and ensure their readiness for future use. Brushes are cleaned and stored in protective sleeves; rollers are wrapped in plastic; and spray guns are thoroughly cleaned and stored in appropriate cases.

Repair and Maintenance: I perform minor repairs, such as replacing worn brush bristles or cleaning clogged spray nozzles. I also regularly check equipment for wear and tear and replace components as needed. I understand that regular maintenance saves money in the long run by extending the equipment’s lifespan.

This approach minimizes downtime, reduces material waste, and maintains the quality of my work.

Q 27. Describe your approach to problem-solving in a fast-paced environment.

In a fast-paced environment, effective problem-solving is crucial. My approach is systematic and proactive:

Identify the Problem: Clearly define the issue, gathering all relevant information.

Analyze the Situation: Evaluate possible causes and their impact on the project timeline and budget.

Develop Solutions: Brainstorm multiple solutions, considering their feasibility and potential consequences.

Implement the Best Solution: Choose the most effective solution and implement it efficiently.

Evaluate the Results: Assess the effectiveness of the solution and make adjustments as needed.

For instance, if a delivery of paint is delayed, I would immediately communicate this to the client and explore alternative solutions, such as using a substitute paint from my inventory or adjusting the work schedule. Flexibility and proactive communication are vital.

Q 28. What is your experience with using personal protective equipment (PPE)?

Safety is my top priority. I’m highly experienced in using personal protective equipment (PPE) to mitigate risks associated with painting. This includes:

Eye Protection: Safety glasses or goggles to prevent paint splashes or dust from entering my eyes.

Respiratory Protection: Respirators or dust masks to prevent inhalation of paint fumes or dust particles, especially when working with spray paint or sanding.

Hand Protection: Gloves to protect my hands from paint and solvents.

Protective Clothing: Coveralls or long-sleeved shirts and pants to protect my skin from paint and other chemicals. Also, wearing appropriate footwear to prevent slips and falls.

I ensure all PPE is in good condition and properly used according to manufacturer instructions. I regularly inspect my equipment and replace it when needed. Safety training is something I take very seriously and always stay up-to-date on best practices.

Key Topics to Learn for Your Commercial Painting Interview

- Surface Preparation: Understanding different surface types (wood, metal, drywall, etc.), appropriate cleaning methods, and the importance of proper priming for adhesion and long-lasting results. Practical application: Describing your experience with various priming techniques and troubleshooting adhesion problems.

- Paint Selection & Application: Knowledge of different paint types (latex, oil-based, epoxy), their properties, and suitability for various substrates and environments. Practical application: Explaining your decision-making process when selecting paints for specific projects, considering factors like durability, cost, and aesthetic requirements.

- Safety Procedures & Regulations: Familiarity with OSHA standards, proper use of safety equipment (PPE), and handling of hazardous materials. Practical application: Describing your experience implementing safety protocols on a job site and addressing potential safety hazards.

- Estimating & Project Management: Ability to accurately estimate project costs, materials, and labor, along with experience managing project timelines and budgets. Practical application: Detailing your experience creating detailed project plans and effectively managing resources.

- Color Theory & Matching: Understanding color mixing, matching existing colors, and interpreting color specifications. Practical application: Describing your experience with color matching techniques and resolving discrepancies between color samples and the final result.

- Tools & Equipment: Familiarity with various painting tools (brushes, rollers, sprayers) and their appropriate use for different applications. Practical application: Explaining your experience maintaining and troubleshooting painting equipment.

- Troubleshooting & Problem-Solving: Ability to identify and resolve common painting issues such as blistering, peeling, and uneven finishes. Practical application: Describing your problem-solving approach when encountering unexpected challenges during a project.

Next Steps

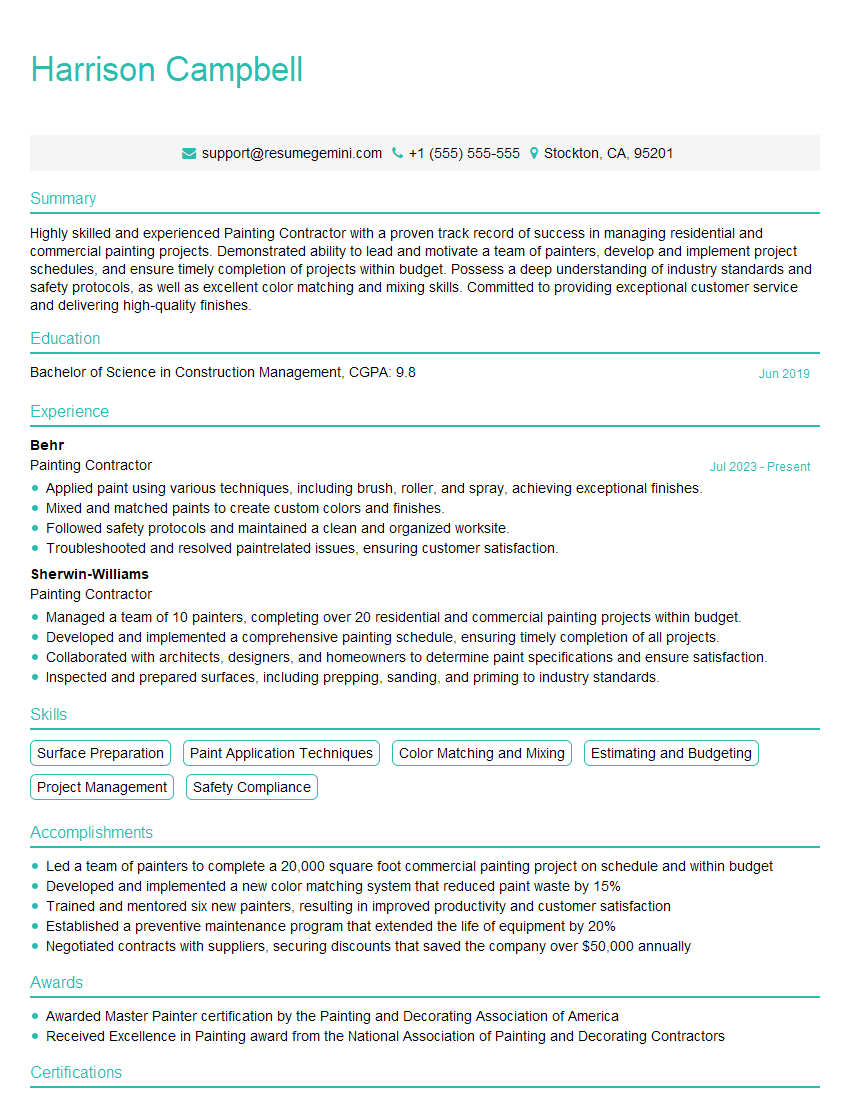

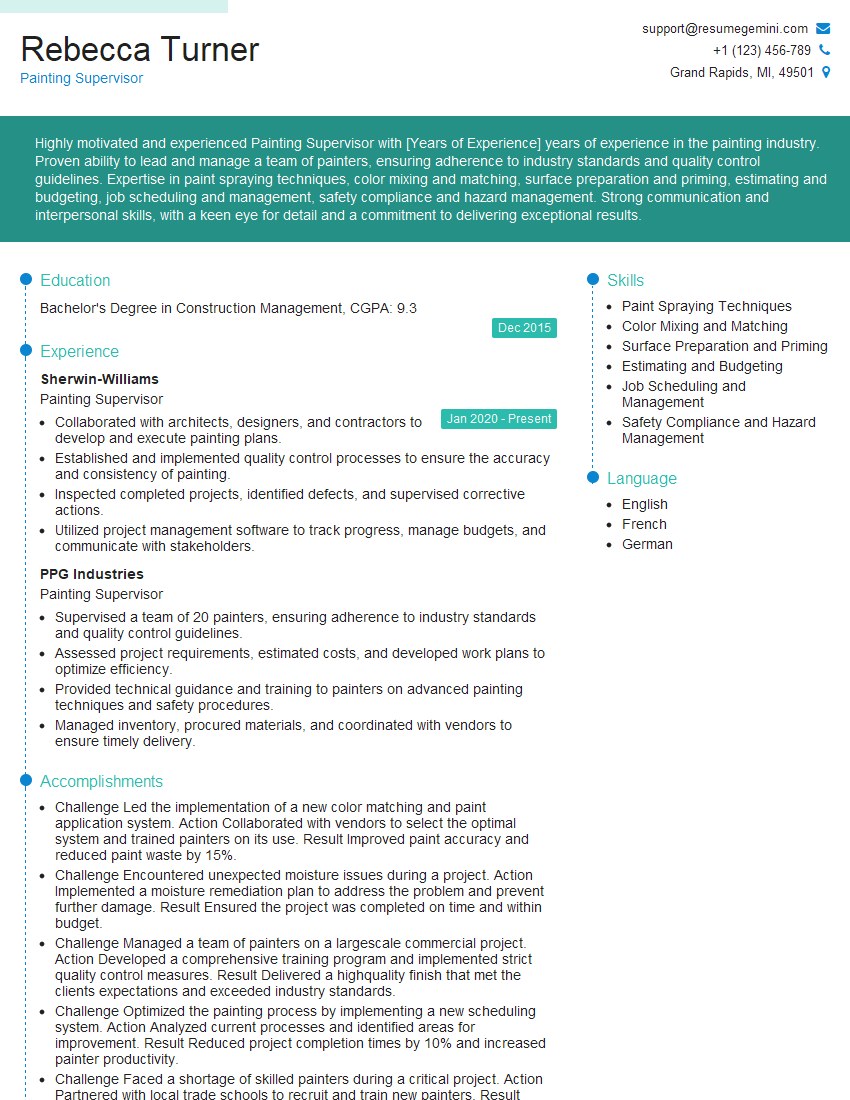

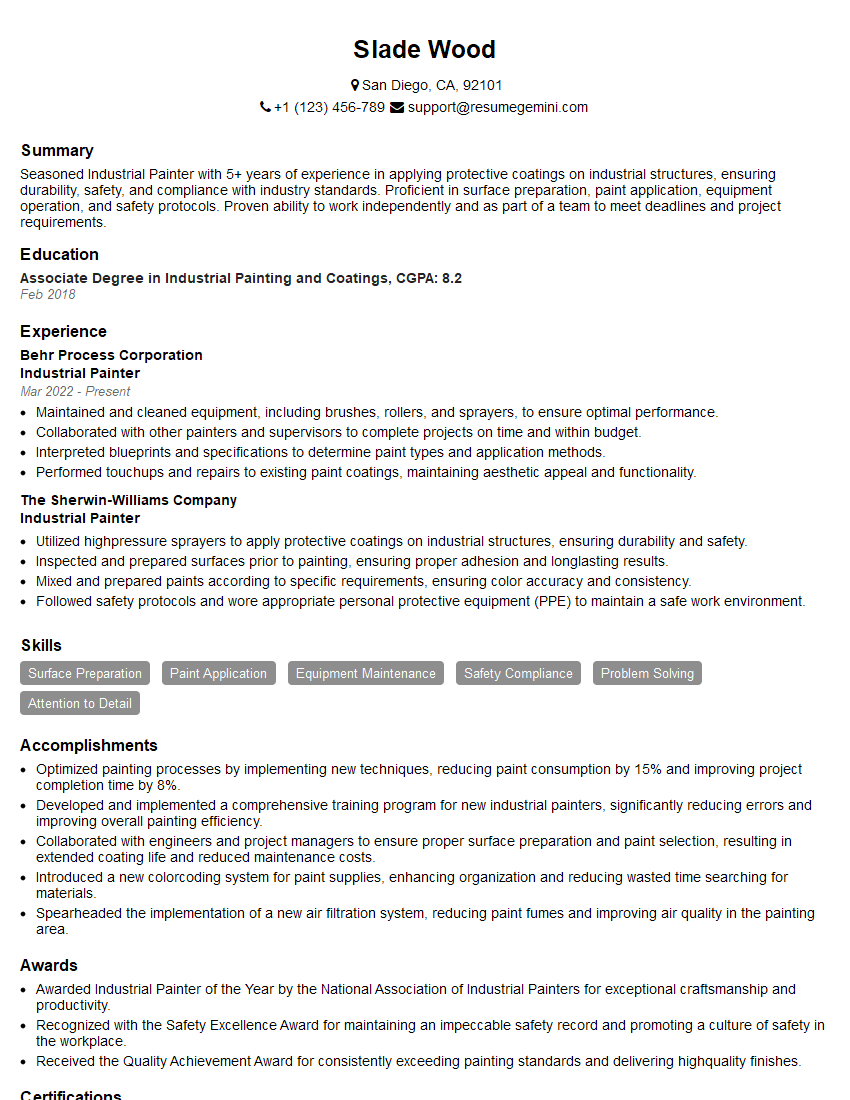

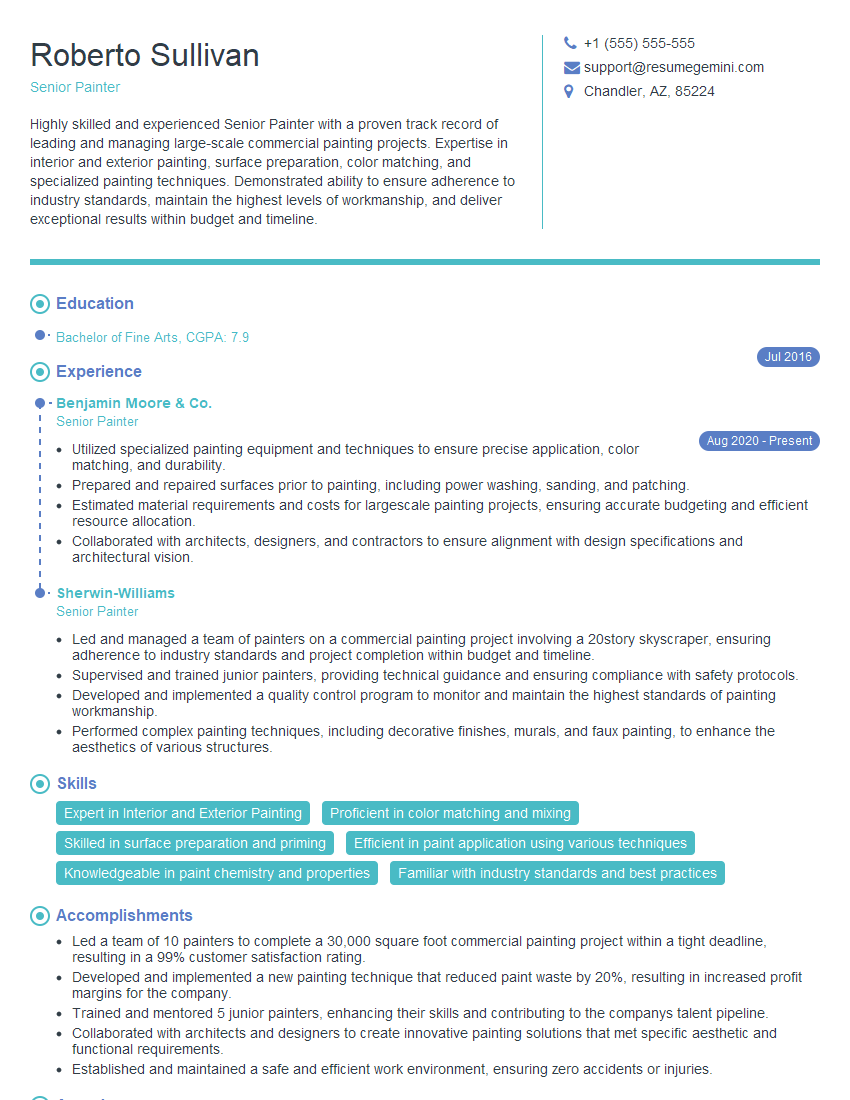

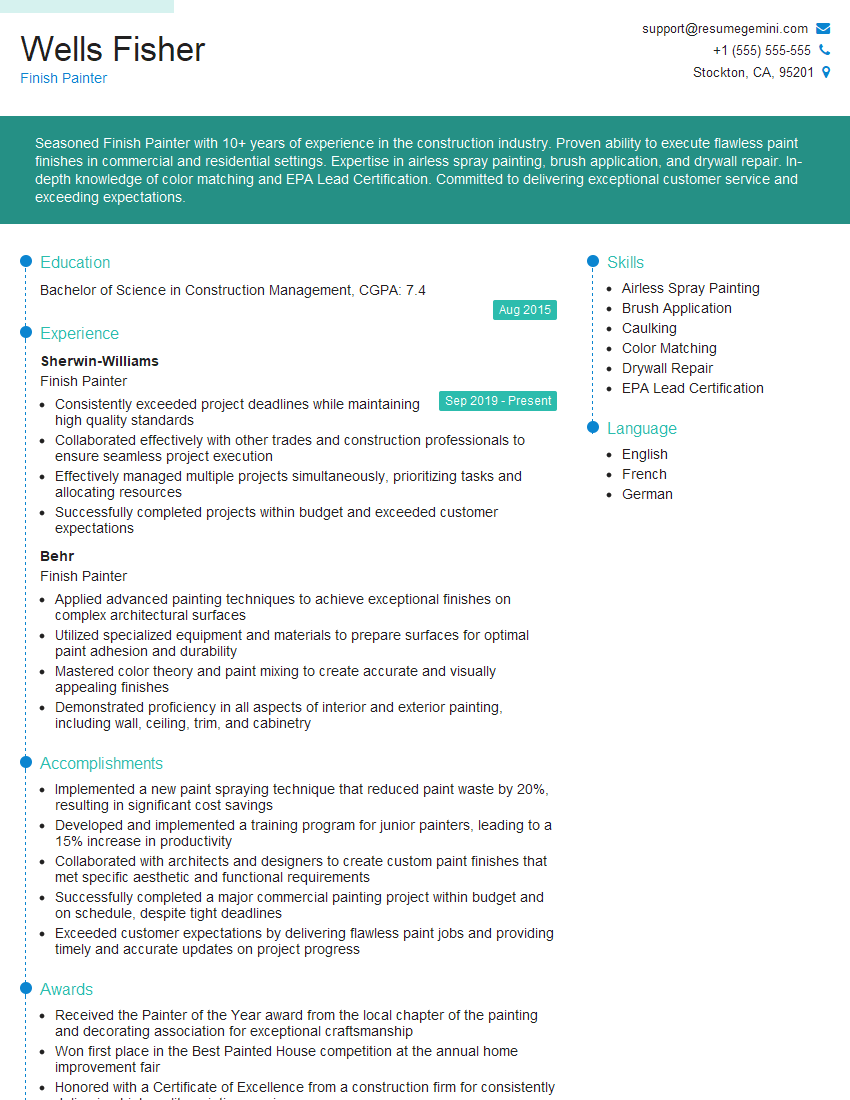

Mastering the art of commercial painting opens doors to a rewarding and potentially lucrative career path with opportunities for growth and specialization. To maximize your job prospects, focus on creating a professional and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the commercial painting industry. We provide examples of resumes specifically designed for commercial painting professionals to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good