Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Understanding of Produce Handling and Storage Practices interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Understanding of Produce Handling and Storage Practices Interview

Q 1. What are the optimal temperature and humidity levels for storing different types of produce?

Optimal storage temperatures and humidity levels for produce vary significantly depending on the type of fruit or vegetable. Think of it like this: each produce item has its own Goldilocks zone – not too cold, not too warm, not too dry, not too humid. Getting it right maximizes shelf life and quality.

- Leafy Greens (Lettuce, Spinach): Just above freezing (32-36°F or 0-2°C) with 95-100% relative humidity. These delicate items need high humidity to prevent wilting.

- Fruits (Apples, Pears): 30-34°F (-1-1°C) with 90-95% relative humidity. Cooler temperatures slow down ripening.

- Root Vegetables (Carrots, Potatoes): 32-40°F (0-4°C) with 90-95% relative humidity. These store well at slightly warmer temperatures than some fruits.

- Tomatoes: 55-60°F (13-16°C) with 85-90% relative humidity. Tomatoes are particularly sensitive to cold damage.

- Tropical Fruits (Bananas, Mangoes): 55-60°F (13-16°C) with 90-95% relative humidity. These require warmer conditions and higher humidity to prevent chilling injury.

These are general guidelines; specific recommendations might vary based on the variety of produce and its maturity level. Consulting reliable resources such as USDA guidelines is crucial for precise temperature and humidity settings.

Q 2. Explain the importance of proper ventilation in produce storage.

Proper ventilation is absolutely vital in produce storage. It’s like providing fresh air for your produce. Without it, you create a stagnant atmosphere, fostering the growth of spoilage organisms and the accumulation of ethylene gas (a natural plant hormone that accelerates ripening and decay).

Ventilation removes excess moisture, preventing condensation that can lead to rot. It also helps to disperse ethylene, slowing down the ripening process and extending shelf life. A well-ventilated storage area maintains consistent temperature and humidity levels, creating a more stable environment for produce. Think of it as providing a comfortable and breathable space for your produce to stay fresh for longer.

Poor ventilation can lead to rapid spoilage, increased losses, and reduced quality.

Q 3. Describe common methods used to prevent produce spoilage and extend shelf life.

Several methods help prevent produce spoilage and extend its shelf life. These methods build upon each other for best results.

- Temperature Control: Storing produce at optimal temperatures slows down respiration and enzymatic activity, thereby delaying spoilage.

- Humidity Control: Maintaining proper humidity levels prevents wilting and shriveling in fruits and vegetables.

- Modified Atmosphere Packaging (MAP): This involves altering the gas composition inside packaging to reduce respiration rates and slow down spoilage. For example, reducing oxygen and increasing carbon dioxide levels can significantly extend shelf life.

- Controlled Atmosphere Storage (CAS): This sophisticated method is used for longer-term storage, primarily in large-scale operations. It involves precisely controlling the atmosphere (oxygen, carbon dioxide, and nitrogen levels) within a storage chamber to dramatically slow ripening and spoilage.

- Ethylene Removal: Ethylene scrubbing systems are used to remove ethylene gas from storage areas, preventing its acceleration of ripening and decay.

- Pre-cooling: Rapidly cooling harvested produce to its ideal storage temperature immediately after harvest is essential to slow enzymatic activity and microbial growth.

- Proper Cleaning and Sanitization: Maintaining clean storage areas prevents contamination and cross-contamination.

The most effective approach often combines multiple methods, tailored to the specific produce and storage conditions.

Q 4. How do you identify and handle produce that is spoiled or damaged?

Identifying and handling spoiled produce is crucial to prevent contamination and maintain product quality and safety. Spoilage signs vary widely, depending on the produce type.

- Visual Inspection: Look for signs like discoloration, wilting, soft spots, mold growth, bruising, or unusual textures.

- Smell Test: Spoiled produce often has an off-putting odor.

- Touch Test: Check for unusual softness or firmness.

Once spoiled produce is identified, it should be immediately separated from fresh produce and discarded appropriately, ideally following food safety guidelines.

For example, if a crate of apples has a few rotten ones, those rotten apples should be removed immediately to prevent ethylene gas released by the spoiled apples from affecting the rest.

Q 5. What are the key principles of First-In, First-Out (FIFO) inventory management for produce?

First-In, First-Out (FIFO) is a fundamental inventory management principle that ensures the oldest produce is used or sold before the newest. It’s like managing a queue – the first one in line is the first one served.

In practice, FIFO involves carefully rotating produce stock. Older items should be placed at the front of shelves or in easily accessible areas, while newer items are placed behind them. This prevents older items from spoiling before being used, minimizing waste and maintaining product quality.

Regular stock checks and appropriate labeling with dates (either harvest dates or arrival dates at the storage facility) are essential for effective FIFO implementation. This systematic approach ensures freshness and minimizes losses due to spoilage.

Q 6. What are the risks associated with improper produce handling and storage?

Improper produce handling and storage carries significant risks:

- Increased Spoilage and Waste: Leading to financial losses.

- Reduced Product Quality: Affecting appearance, texture, flavor, and nutritional value.

- Foodborne Illness: Improper storage can promote the growth of harmful bacteria, leading to illness.

- Reputational Damage: Spoiled produce can damage a company’s reputation and customer trust.

- Compliance Issues: Violations of food safety regulations can lead to penalties and legal repercussions.

The consequences can range from minor financial setbacks to serious health risks and legal liabilities.

Q 7. Explain the role of sanitation and hygiene in maintaining produce quality.

Sanitation and hygiene are paramount in maintaining produce quality and safety. It’s all about preventing contamination at every stage of the handling process.

This involves thorough cleaning and sanitization of storage areas, equipment (such as conveyor belts and crates), and work surfaces. Workers should practice good personal hygiene, including handwashing, using protective clothing, and maintaining cleanliness of their work environment.

Regular pest control is also essential to prevent infestation. A clean and sanitized environment significantly reduces the risk of spoilage, microbial growth, and foodborne illnesses. It safeguards product quality and protects consumer health.

Q 8. Describe different types of produce packaging and their suitability for various products.

Produce packaging plays a crucial role in maintaining quality and extending shelf life. The choice of packaging depends heavily on the product’s characteristics, its intended shelf life, and the distribution channels involved.

- Modified Atmosphere Packaging (MAP): This involves altering the gas composition within the packaging (reducing oxygen, increasing nitrogen or carbon dioxide) to slow down respiration and microbial growth. It’s ideal for highly perishable items like leafy greens and berries.

- Vacuum Packaging: Air is removed from the packaging, minimizing oxidation and enzymatic activity. Suitable for products like mushrooms and certain types of cheeses, although it may affect texture in some cases.

- Rigid Containers (e.g., plastic clamshells, punnets): These offer good protection against physical damage and are commonly used for fruits and vegetables that need robust containment. They are widely used for tomatoes, grapes, and other delicate items. However, breathability needs consideration.

- Flexible Packaging (e.g., bags, pouches): Cost-effective and suitable for a wide range of produce, from root vegetables (potatoes) to fruits (apples and bananas), these are versatile but can be more prone to damage.

- Ethylene-absorbing Packaging: This type utilizes materials that absorb ethylene, a ripening hormone, extending the shelf life of ethylene-sensitive produce like lettuce and broccoli.

For example, a delicate berry would benefit from MAP in a clamshell to maintain its freshness and visual appeal while preventing bruising, whereas potatoes might be perfectly suited for storage in a breathable, flexible bag.

Q 9. How do you ensure the traceability of produce throughout the supply chain?

Traceability is paramount in ensuring food safety and maintaining consumer trust. It’s the ability to track produce from its origin (farm) to the point of sale (retail store or restaurant). This is achieved through a robust system of record-keeping and identification at each stage.

- Unique Identifiers: Each batch of produce should have a unique identifier, often a lot number or code, linked to specific information about its origin, handling, and processing.

- Electronic Data Capture: Utilizing barcodes, RFID tags, or other technologies allows for efficient data collection and tracking throughout the supply chain.

- Integrated Software Systems: These systems enable seamless data exchange between different parties involved (growers, packers, distributors, retailers).

- Blockchain Technology: This emerging technology provides a secure and transparent record of every transaction and step in the supply chain, enhancing traceability and reducing the risk of fraud.

Imagine a scenario where a foodborne illness outbreak is traced back to a specific batch of lettuce. With a comprehensive traceability system, the implicated produce can be quickly identified and removed from the market, limiting the impact of the outbreak.

Q 10. What are the key aspects of a successful cold chain management system for produce?

Successful cold chain management for produce involves maintaining a consistently low temperature throughout the entire supply chain, from harvest to consumption. This is critical for slowing down respiration and microbial growth, preserving quality and extending shelf life.

- Pre-cooling: Immediately after harvest, rapid cooling is vital to reduce the temperature of produce to its ideal storage range. Methods include hydrocooling, forced-air cooling, or vacuum cooling.

- Transportation: Refrigerated trucks or containers are essential for maintaining low temperatures during transportation. Temperature monitoring devices should be used to ensure consistent cold chain integrity.

- Storage: Warehouses and retail spaces must maintain appropriate temperatures and humidity levels. Regular equipment maintenance and calibration are critical to prevent temperature fluctuations.

- Temperature Monitoring and Recording: Accurate temperature logging throughout the supply chain is crucial for identifying potential cold chain breaches. Data loggers provide detailed temperature records.

A failure in cold chain management can lead to rapid deterioration of produce quality, resulting in substantial economic losses and potential food safety hazards. For example, if a shipment of berries experiences a temperature spike during transportation, its quality will drastically decrease.

Q 11. What are the common pests and diseases that affect produce, and how can they be controlled?

Produce is susceptible to a wide range of pests and diseases that can significantly impact yield and quality. Effective pest and disease management strategies are critical for maintaining produce safety and marketability.

- Common Pests: Aphids, whiteflies, mites, thrips, and various insects can cause damage to plants and transmit diseases.

- Common Diseases: Fungal diseases (e.g., blight, mold, rot), bacterial diseases (e.g., soft rot), and viral diseases can severely affect plant health and produce quality.

- Control Measures: Integrated pest management (IPM) is a holistic approach combining various techniques: Good Agricultural Practices (GAPs), proper sanitation, resistant varieties, biological control (using beneficial insects or microorganisms), and judicious application of pesticides only when necessary.

For example, a farmer might use pheromone traps to monitor and control insect populations, along with crop rotation and the introduction of beneficial insects like ladybugs to reduce reliance on chemical pesticides.

Q 12. How do you handle potential contamination during produce handling and storage?

Contamination can occur at various points in the produce handling and storage process. A multi-faceted approach is necessary to minimize risks.

- Good Agricultural Practices (GAPs): These practices emphasize sanitation, worker hygiene, and proper handling procedures in the field and during harvest.

- Proper Cleaning and Sanitization: Equipment and facilities should be regularly cleaned and sanitized to prevent the spread of microorganisms. This includes washing and sanitizing harvesting equipment and storage containers.

- Pest Control: Effective pest management helps minimize contamination risks associated with insects and rodents.

- Temperature Control: Maintaining appropriate temperatures throughout the supply chain inhibits microbial growth and reduces contamination risk.

- Hazard Analysis and Critical Control Points (HACCP): This systematic approach identifies potential hazards and implements critical control points to prevent or eliminate contamination.

For instance, ensuring workers wash their hands regularly and wear clean gloves during harvesting minimizes the risk of transferring pathogens from their hands to the produce. Regular cleaning of packing facilities is equally important.

Q 13. Explain the importance of proper labeling and documentation for produce.

Proper labeling and documentation are crucial for ensuring traceability, facilitating trade, and providing consumers with essential product information.

- Product Identification: Clear and unambiguous identification of the product, including its name, variety, and origin.

- Lot Number or Code: A unique identifier linking the product to specific production and handling information.

- Weight or Count: Accurate indication of the quantity of produce.

- Storage Instructions: Guidance on proper storage conditions (temperature, humidity) to maintain quality and extend shelf life.

- Expiry Date or Best Before Date: Provides consumers with information about the product’s optimal consumption period.

- Country of Origin: Important for transparency and regulatory compliance.

Accurate labeling allows consumers to make informed choices and prevents confusion. Furthermore, detailed documentation supports traceability and helps to identify the source of any problems that might arise.

Q 14. What is your experience with various produce ripening methods and technologies?

I have extensive experience with various produce ripening methods and technologies, understanding that optimal ripening is essential for achieving peak flavor, texture, and aroma.

- Controlled Atmosphere (CA) Storage: Modifying the atmosphere within storage facilities (reducing oxygen, increasing carbon dioxide and nitrogen) slows down ripening and extends shelf life for many fruits. This is commonly used for apples and pears.

- Ethylene Treatment: Applying ethylene gas can accelerate ripening in some fruits like bananas and tomatoes. This is carefully controlled to avoid over-ripening.

- 1-Methylcyclopropene (1-MCP) Treatment: This compound inhibits ethylene action, slowing down ripening and extending shelf life. Effective for fruits like apples, pears, and berries.

- Temperature Management: Careful control of temperature plays a crucial role in ripening. Different fruits have different optimal temperature ranges for ripening.

- Sensor Technologies: Utilizing sensors to monitor ethylene production, temperature, and other parameters allows for precise control of the ripening process, leading to greater efficiency and consistency.

For example, I’ve worked with projects optimizing CA storage for apples, adjusting the gas composition to maintain optimal quality and extend shelf life by several months. This requires precise monitoring and control to prevent spoilage or uneven ripening.

Q 15. How do you manage inventory levels to minimize waste and spoilage?

Minimizing waste and spoilage in produce handling requires a proactive, multi-pronged approach focusing on accurate forecasting, efficient inventory management systems, and strict adherence to quality control protocols. It’s like running a finely tuned orchestra – every section needs to be in perfect harmony.

First, accurate demand forecasting is crucial. We utilize historical sales data, seasonal trends, and anticipated market fluctuations to predict future demand. This allows us to order the appropriate quantities, avoiding overstocking that leads to spoilage. For example, during peak watermelon season, we’ll adjust our orders significantly upward, knowing demand will be high, but during the off-season, we’ll order much more conservatively.

Secondly, we employ a First In, First Out (FIFO) inventory management system. This ensures that the oldest produce is used or sold first, preventing spoilage of items that have been sitting in storage for extended periods. Imagine a bakery – they always sell the oldest bread first to maintain freshness.

Finally, regular quality checks and inspections are vital. This includes visual inspections for bruising, discoloration, and signs of decay, alongside temperature monitoring to ensure proper storage conditions. Discarding damaged or substandard produce immediately prevents it from affecting the quality of the rest of the inventory.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of produce storage facilities (e.g., refrigerated warehouses, controlled atmosphere storage).

My experience encompasses a variety of produce storage facilities, each with its own advantages and challenges. Refrigerated warehouses are the most common, providing controlled temperatures to slow down the respiration rate of produce and extend shelf life. I’ve worked extensively with facilities employing various cooling technologies, from forced-air systems to hydrocooling, each suited to specific types of produce.

Beyond refrigerated warehouses, I have experience with controlled atmosphere (CA) storage. CA storage modifies the atmosphere within the storage area by reducing oxygen levels and increasing nitrogen or carbon dioxide levels. This dramatically slows down the ripening and respiration processes, extending the storage life of highly perishable items like apples and pears. It’s like putting the produce into a state of suspended animation. For example, I managed a CA facility that successfully stored apples for up to a year while maintaining their quality.

Furthermore, I’m familiar with the operation and maintenance of various climate control systems in these facilities and understand the importance of regular calibration and maintenance to ensure optimal storage conditions.

Q 17. What are your experiences with different produce handling equipment (e.g., forklifts, conveyors)?

Safe and efficient handling of produce relies heavily on specialized equipment. My experience includes the operation and supervision of various types of equipment including forklifts, conveyors, and palletizers. Safety is paramount, so all operators receive thorough training and adhere to strict safety protocols.

Forklifts are essential for moving large quantities of produce efficiently within warehouses. Proper training and certification of operators, alongside regular maintenance checks, are critical to prevent accidents and damage to the produce. For instance, we use specialized forklifts with cushioned forks for delicate items to minimize bruising.

Conveyors are vital for streamlining the processing and packaging lines, minimizing manual handling, and improving efficiency. I have experience working with both belt conveyors and roller conveyors, ensuring proper speed and alignment to prevent damage. For example, we optimize conveyor speeds to handle delicate greens without damaging them.

Palletizers automate the stacking of produce onto pallets, which is essential for efficient storage and transportation. These machines require careful programming and regular maintenance to ensure proper functioning and produce integrity.

Q 18. How do you ensure compliance with food safety regulations (e.g., HACCP, GMP)?

Food safety is my top priority. We strictly adhere to Hazard Analysis and Critical Control Points (HACCP) principles and Good Manufacturing Practices (GMP) guidelines throughout the entire produce handling process. This is not merely compliance, it’s a fundamental aspect of our operation.

Our HACCP plan identifies potential hazards at each stage of the process – from receiving to storage, processing, and distribution – and establishes critical control points to prevent or mitigate these hazards. This includes regular sanitation of facilities and equipment, temperature monitoring, and employee training on proper hygiene practices. For example, our HACCP plan includes specific procedures for cleaning and sanitizing conveyor belts to prevent cross-contamination.

GMP guidelines cover all aspects of production, including employee hygiene, facility cleanliness, equipment maintenance, and pest control. Regular audits and internal inspections help us maintain compliance and identify any areas needing improvement. We meticulously document all procedures and maintain detailed records for traceability.

Q 19. Describe your experience with conducting quality checks and inspections on produce.

Quality checks and inspections are integral to maintaining produce quality and meeting customer expectations. My experience involves visual inspections, sensory evaluations, and, where necessary, laboratory testing. It’s like being a produce detective, identifying even subtle signs of deterioration.

Visual inspections are performed at various stages: upon receipt, during storage, and prior to shipment. We check for signs of damage (bruising, cuts, discoloration), disease, and pest infestation. This helps us identify and segregate substandard produce to prevent it from affecting the rest of the batch.

Sensory evaluations involve checking for ripeness, texture, and aroma. For example, we assess the firmness of tomatoes or the sweetness of melons. We also test for off-flavors or odors, which could indicate spoilage or contamination.

When necessary, we utilize laboratory testing to analyze the microbiological quality of the produce. This is especially important for products that are subject to high levels of contamination. For example, we do regular microbiological testing to confirm that our leafy greens are safe for consumption.

Q 20. Explain your understanding of the different stages in the produce supply chain.

The produce supply chain is a complex network involving several stages. Understanding each step is critical for maintaining quality and efficiency. It’s like a relay race, where each team member needs to perform their role flawlessly.

- Production/Farming: This initial stage involves planting, cultivation, and harvesting of produce. Factors such as soil quality, climate, and farming practices greatly influence the quality of the final product.

- Harvesting and Pre-Cooling: Careful harvesting techniques minimize damage to the produce. Pre-cooling, often through hydrocooling or forced-air cooling, immediately reduces the temperature of the produce after harvest, slowing down respiration and extending shelf life.

- Grading and Sorting: This stage involves separating produce based on size, quality, and appearance. This ensures consistent product quality and efficient packaging.

- Packaging: Proper packaging protects the produce during transportation and storage, preventing damage and spoilage. Appropriate packaging materials and techniques are crucial for different types of produce.

- Transportation and Storage: Maintaining the cold chain throughout transportation and storage is crucial to prevent spoilage. Refrigerated trucks and appropriate storage facilities are essential.

- Distribution and Retail: The final stages involve delivering the produce to distribution centers and retailers, where it is finally sold to consumers.

Q 21. How do you manage the transportation and logistics of produce to maintain its quality?

Maintaining produce quality during transportation and logistics is critical. It demands meticulous planning and execution. Think of it like a delicate balancing act – ensuring the produce arrives in perfect condition is crucial.

We use refrigerated trucks equipped with temperature monitoring systems to maintain the cold chain throughout transit. The trucks are regularly inspected and maintained to ensure they are functioning correctly. Moreover, we optimize transportation routes to minimize transit times, reducing the risk of spoilage. The selection of appropriate packaging materials plays a significant role in protecting the produce from damage during transit. For example, we use cushioned containers for particularly delicate fruits to minimize bruising during transportation.

Real-time tracking of shipments allows us to monitor temperature and location throughout transit, enabling proactive intervention if any issues arise. Effective communication with transportation providers ensures that the produce is handled with care and arrives at its destination in optimal condition.

Q 22. Describe your experience with different types of produce storage containers.

My experience encompasses a wide range of produce storage containers, each chosen based on the specific needs of the produce and the storage environment. For example, I’ve extensively used:

- Reusable plastic crates: These are versatile, stackable, and easy to clean, ideal for transporting and storing a variety of fruits and vegetables. Their durability minimizes damage and spoilage.

- Cardboard boxes: While less durable than plastic crates, cardboard boxes are cost-effective and suitable for shorter-term storage, especially for delicate produce requiring ventilation. I’ve used different types, from single-wall to double-wall, depending on the produce weight and journey length.

- Modified Atmosphere Packaging (MAP): This involves packaging produce in containers with a controlled atmosphere (reduced oxygen, increased carbon dioxide and/or nitrogen) to extend shelf life significantly. I have experience with both pre-packaged MAP and implementing MAP systems at a packing facility. This is particularly crucial for long-distance transportation of highly perishable items like berries and leafy greens.

- Refrigerated containers: For long-distance transportation, refrigerated containers (reefers) are essential for maintaining the cold chain. Monitoring the temperature and humidity within these containers is critical to prevent spoilage. I’m proficient in managing the settings and addressing any malfunction.

The choice of container often depends on factors such as the type of produce, its fragility, transportation distance, and storage duration. For instance, delicate strawberries might require smaller, ventilated containers cushioned with inserts, while robust root vegetables may be stored in larger bulk bins.

Q 23. How do you deal with temperature fluctuations during produce transportation?

Temperature fluctuations during transportation are a major threat to produce quality. To mitigate this, we employ several strategies:

- Pre-cooling: Before loading, produce is rapidly cooled to its optimal temperature. Hydro-cooling and forced-air cooling are common methods. This minimizes temperature shock during the journey.

- Insulated Transportation: We use refrigerated trucks or containers equipped with reliable temperature monitoring systems. This helps maintain consistent temperatures throughout transit. Regular checks and temperature logs are crucial.

- Route Planning: The transportation route is carefully planned to minimize exposure to extreme temperatures, avoiding prolonged stops in direct sunlight. Faster routes, even if slightly more expensive, are sometimes preferred to reduce transit time and temperature fluctuations.

- Temperature Monitoring Devices: Data loggers are placed inside the shipments to continuously record temperature data. This provides a comprehensive record of temperature throughout transportation, enabling us to identify and address potential issues proactively. This data is crucial for traceability and quality assurance.

Imagine transporting bananas. A sudden temperature spike can lead to rapid ripening and bruising, drastically reducing their shelf life. By meticulously controlling the temperature, we ensure that the bananas reach the consumer in optimal condition.

Q 24. What are some common challenges in maintaining produce quality during long-distance transportation?

Maintaining produce quality during long-distance transportation poses several significant challenges:

- Temperature Fluctuations: As discussed earlier, these lead to spoilage, ripening, and damage.

- Mechanical Damage: Rough handling during loading, unloading, and transit can cause bruising, cuts, and other physical damage, reducing shelf life and market value.

- Pathogen Growth: Warm temperatures and high humidity can accelerate the growth of microorganisms, leading to rotting and spoilage. This is particularly concerning for high-moisture produce.

- Dehydration: Loss of moisture during transport can lead to wilting and shriveling, affecting the appearance and quality of produce. This is a problem with leafy greens and many fruits.

- Ethylene Production: Many fruits and vegetables produce ethylene gas, which accelerates ripening. If not managed properly (through ventilation or the use of ethylene absorption filters), this can lead to premature ripening and spoilage.

For example, transporting avocados across continents requires careful temperature management to prevent them from becoming overripe. Addressing these challenges requires a multi-faceted approach that considers every step of the process, from harvesting and pre-cooling to transport and storage.

Q 25. What is your experience with implementing and monitoring a pest control program in a produce facility?

Implementing and monitoring a pest control program is crucial for maintaining produce safety and quality. My experience involves:

- Regular Inspections: Conducting routine inspections of the facility to identify potential pest infestations early on. This includes visual checks and using monitoring traps.

- Integrated Pest Management (IPM): Employing IPM strategies, which prioritize prevention and minimize the use of pesticides. This involves sanitation, proper storage practices, and targeted pest control methods only when necessary.

- Pesticide Application: When chemical control is necessary, using approved pesticides following strict safety protocols and adhering to label instructions. Careful documentation of all applications is essential for traceability.

- Monitoring and Record-Keeping: Maintaining detailed records of pest sightings, control measures, and pesticide applications. This data is crucial for tracking pest activity and evaluating the effectiveness of the control program.

- Employee Training: Educating staff on proper sanitation practices, pest identification, and reporting procedures. A well-informed workforce is essential for successful pest control.

In one instance, we identified a weevil infestation in a stored grain shipment. We immediately implemented a combination of sanitation, targeted pesticide application (after thorough risk assessment), and enhanced monitoring to successfully eradicate the infestation without compromising produce safety.

Q 26. How do you address customer complaints related to the quality or condition of produce?

Addressing customer complaints related to produce quality is a critical aspect of maintaining customer satisfaction. My approach involves:

- Prompt Acknowledgement: Responding to complaints promptly and acknowledging the customer’s concerns.

- Thorough Investigation: Conducting a thorough investigation to determine the root cause of the complaint. This may involve reviewing records, inspecting the affected produce, and contacting relevant parties in the supply chain.

- Appropriate Compensation: Offering appropriate compensation, such as a refund or replacement product, to satisfy the customer.

- Preventive Measures: Implementing corrective actions to prevent similar complaints in the future. This may involve changes to handling, storage, or transportation practices.

- Documentation: Maintaining thorough documentation of the complaint, investigation, and resolution.

For instance, if a customer complains about bruised apples, I would investigate whether the damage occurred during harvesting, packaging, or transportation. Depending on the finding, I would either provide a refund or adjust our handling procedures to avoid similar incidents.

Q 27. How would you respond to a situation where a large quantity of produce has spoiled?

A situation involving significant produce spoilage requires swift and decisive action:

- Immediate Assessment: Determine the extent of the spoilage, identifying the affected products and the likely cause.

- Containment: Isolating the spoiled produce to prevent cross-contamination.

- Waste Disposal: Safely disposing of the spoiled produce in accordance with relevant regulations. This might involve composting or other environmentally sound methods.

- Root Cause Analysis: Conducting a thorough investigation to identify the reasons behind the spoilage, such as temperature issues, pest infestation, or improper handling.

- Corrective Actions: Implementing corrective actions to prevent future spoilage. This might involve adjusting storage temperatures, improving sanitation practices, or implementing better quality control measures.

- Inventory Management Review: Reviewing inventory management practices to minimize future losses.

For example, if a large shipment of lettuce spoils due to a refrigeration unit malfunction, we would immediately initiate disposal and launch an investigation into the malfunction, potentially replacing the refrigeration system and retraining staff on maintenance procedures.

Q 28. Describe your experience with using technology to improve produce handling and storage practices (e.g., inventory management software, temperature monitoring systems).

Technology plays a vital role in enhancing produce handling and storage practices. My experience includes:

- Inventory Management Software: Utilizing software to track produce inventory levels, monitor stock rotation (FIFO – First In, First Out), and predict demand. This helps reduce waste and ensure optimal stock levels.

- Temperature Monitoring Systems: Employing wireless sensors and data loggers to monitor temperatures in storage facilities and during transportation. This provides real-time data and alerts for temperature excursions, enabling timely interventions.

- Cold Chain Management Software: Integrating software that manages the entire cold chain, from harvesting to delivery, providing complete traceability and visibility into temperature control throughout the process.

- Predictive Analytics: Using data analytics to predict potential quality issues and optimize storage and transportation strategies. This allows proactive adjustments to reduce spoilage and improve efficiency.

For instance, using temperature monitoring sensors in refrigerated trucks allows for immediate alerts if the temperature rises above the threshold for a particular product. This allows for intervention before significant spoilage occurs, preventing substantial financial losses.

Key Topics to Learn for Understanding of Produce Handling and Storage Practices Interview

- Pre-harvest Considerations: Understanding factors influencing produce quality before harvesting, including growing practices, pest management, and harvesting techniques.

- Harvesting and Handling: Proper techniques for harvesting, minimizing damage, and efficient post-harvest handling to maintain freshness and quality.

- Cleaning and Sanitization: Methods for effectively cleaning and sanitizing produce to remove soil, contaminants, and reduce microbial growth.

- Storage Conditions: Optimizing temperature, humidity, and atmosphere (e.g., modified atmosphere packaging) for different types of produce to extend shelf life and maintain quality.

- Packaging and Transportation: Selecting appropriate packaging materials and methods to protect produce during transportation and minimize damage and spoilage.

- Quality Control and Assurance: Implementing procedures to monitor and assess produce quality throughout the handling and storage process, including visual inspection and quality testing.

- Waste Reduction Strategies: Implementing practices to minimize waste at each stage of the handling and storage process, from harvesting to consumption.

- Food Safety Regulations: Understanding and adhering to relevant food safety regulations and best practices to ensure product safety and prevent contamination.

- Technological Advancements: Familiarity with emerging technologies impacting produce handling and storage, such as automated sorting systems and advanced preservation techniques.

- Problem-Solving and Troubleshooting: Ability to identify and address common issues related to produce quality, spoilage, and storage challenges.

Next Steps

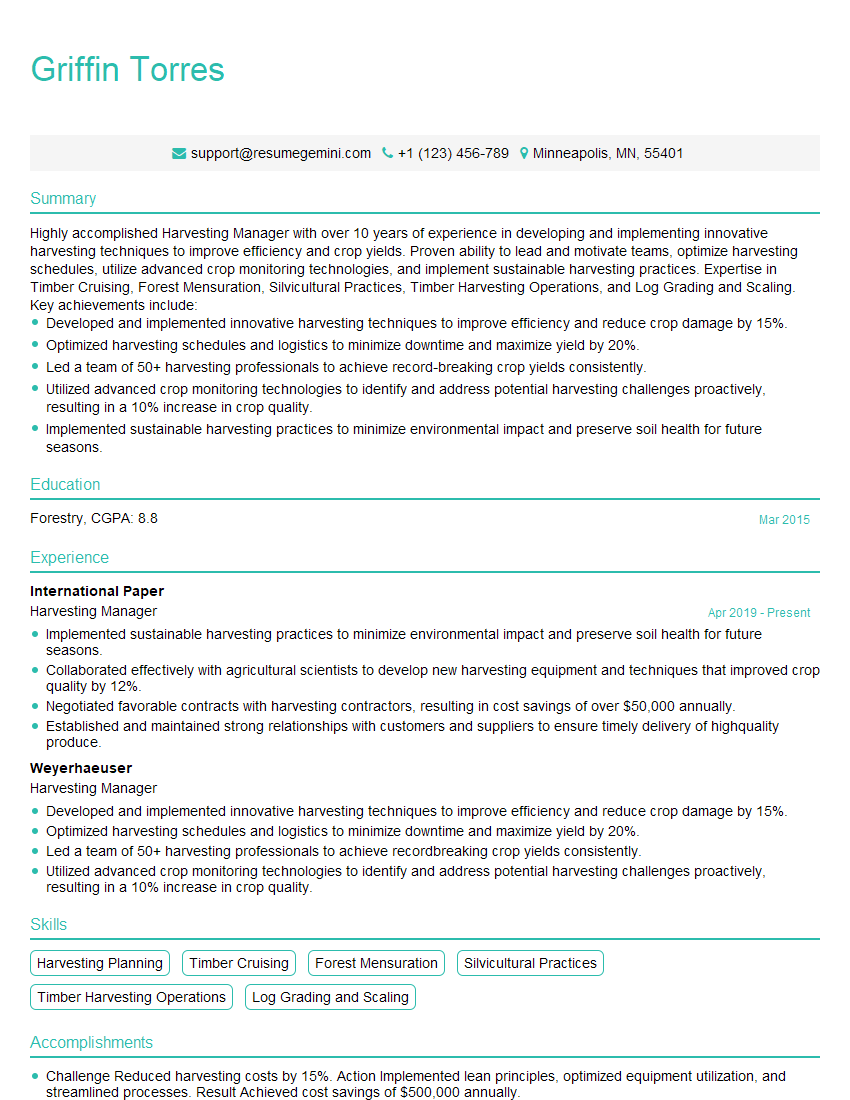

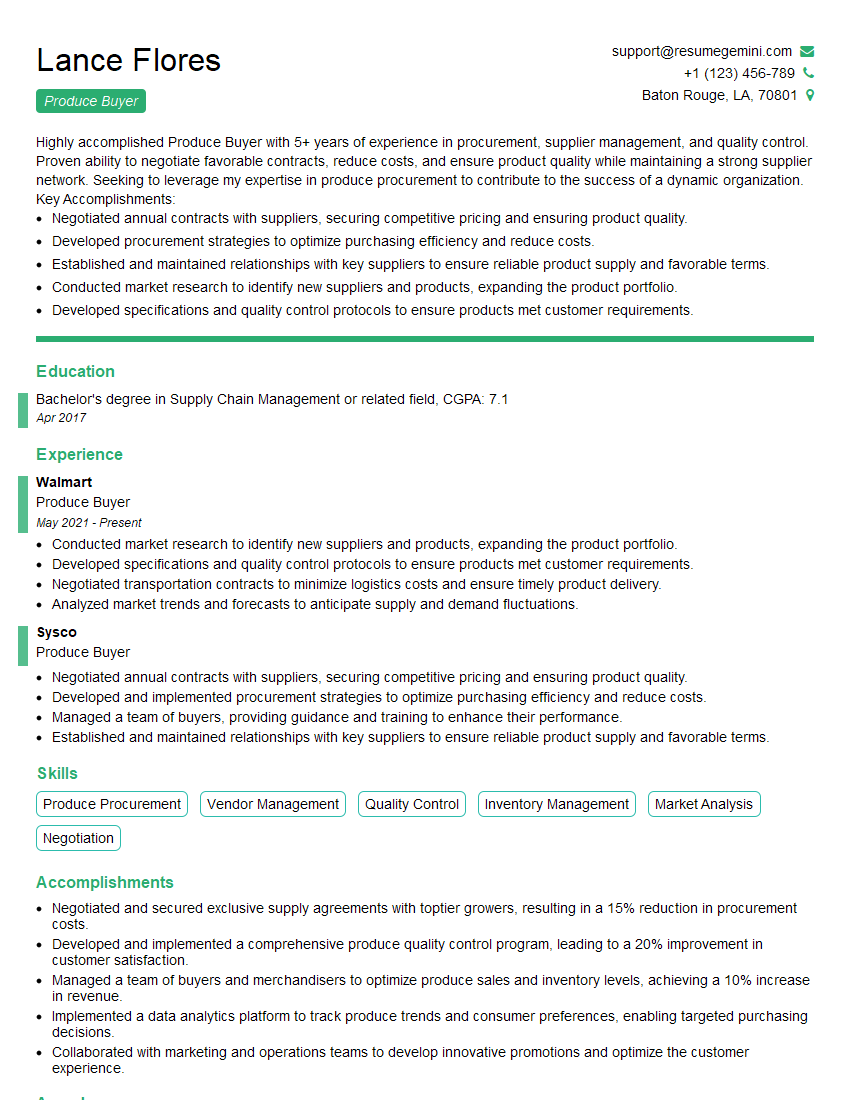

Mastering Understanding of Produce Handling and Storage Practices is crucial for career advancement in the food industry, opening doors to specialized roles and increased earning potential. A strong resume is your key to unlocking these opportunities. Create an ATS-friendly resume that highlights your skills and experience effectively. To build a professional and impactful resume, we recommend using ResumeGemini, a trusted resource for creating resumes tailored to specific industries. Examples of resumes tailored to Understanding of Produce Handling and Storage Practices are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good