Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fish Cutting and Processing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fish Cutting and Processing Interview

Q 1. Describe your experience with different fish filleting techniques.

Filleting fish involves removing the fillets—the edible side portions—from the backbone. Different techniques exist depending on the fish type and desired outcome. For instance, the ‘butterfly’ method involves cutting the fish along the belly and then down the backbone, creating two large, connected fillets. This is great for presentation or grilling. The ‘single fillet’ method involves cutting along one side of the backbone and removing the fillet in one piece. This is ideal for portion control and certain cooking methods. Then there’s the ‘pin-bone removal’ technique, crucial for fish like salmon, where small bones need careful extraction after filleting. My experience spans all these, with a particular focus on adapting techniques based on the species. For example, filleting a delicate sole demands a much lighter touch and sharper knife than working with a robust tuna. I’ve also worked with many different kinds of equipment, from simple fillet knives to automated filleting machines, adapting my skills accordingly.

For example, when I was working on a salmon processing line, we used a combination of manual and semi-automated techniques. Skilled workers would fillet the fish using specialized knives, while automated machinery removed the pin bones. This process ensured both speed and precision.

Q 2. What are the common safety hazards associated with fish cutting and how do you mitigate them?

Fish cutting poses several safety hazards. Sharp knives are the obvious risk, leading to cuts and lacerations. To mitigate this, I always use sharp, well-maintained knives—a dull knife is more dangerous than a sharp one—and ensure a safe, clutter-free workspace. We wear cut-resistant gloves whenever possible. Another concern is slips and falls, especially when dealing with wet surfaces and fish slime. Good workplace hygiene and proper flooring are key here. Additionally, handling potentially contaminated fish carries a risk of bacterial infection. This necessitates strict adherence to hygiene protocols—hand washing, sanitization of equipment and surfaces, and proper cold storage.

Furthermore, some species contain venomous spines (like lionfish) or sharp scales, which necessitate cautious handling and protective gear. Regular safety training and awareness are vital in mitigating these risks. In my experience, proactive safety measures and a commitment to a clean workspace have always been prioritized, reducing incidents to a minimum.

Q 3. Explain the process of scaling and gutting different types of fish.

Scaling and gutting vary slightly across species. Generally, scaling involves using a scaling tool or even the back of a knife to remove scales from the fish’s skin. The process involves holding the fish firmly and scraping against the scales in a direction away from your hand. For fish with thicker scales, a more robust scraping action might be required. Gutting involves making an incision along the fish’s belly, from the vent to the gills, carefully removing the internal organs (gills, intestines, etc.). It’s vital to be careful not to puncture the gall bladder, as its contents can leave a bitter taste. Different sizes and shapes of fish necessitate adjusting the incision and removal process. For smaller fish, a single incision and gentle removal suffice. Larger fish may require additional care to ensure complete removal of the organs. The whole process must be done quickly and efficiently to ensure freshness.

For instance, scaling a salmon is quite different from scaling a trout, due to the differences in scale size and structure. Similarly, gutting a large tuna involves a larger incision and more precise removal of the organs compared to a small herring. Consistent practice and an understanding of fish anatomy are paramount for efficient and safe scaling and gutting.

Q 4. How do you ensure the quality and freshness of fish during processing?

Maintaining fish quality and freshness throughout processing requires a multifaceted approach. Immediate chilling after catch is crucial to slow down enzymatic and bacterial degradation. We maintain a consistent cold chain, from the fishing vessel to processing and storage. Proper hygiene is paramount—clean surfaces, tools, and hands prevent contamination. Rapid processing minimizes the time the fish spends at room temperature. We often use ice slurry or refrigerated storage to keep the fish at temperatures below 4°C (39°F) throughout the process. Regular monitoring of temperatures is also essential.

Visual inspection is critical. We check for signs of spoilage like discoloration, unpleasant odors, or slimy texture. In my experience, a well-maintained cold chain and strict hygiene protocols are the best guarantees of consistently high-quality and fresh fish products.

Q 5. What are the different types of knives used in fish cutting and their applications?

A variety of knives are used in fish cutting, each tailored to a specific task. The fillet knife, with its long, thin, flexible blade, is essential for filleting and separating fish fillets from the bone. Its flexibility allows for navigating the fish’s curves and bones precisely. The boning knife, similar but often slightly stiffer, is useful for removing bones from fillets. A scaling knife, with a sharp, rough edge, facilitates efficient scale removal. A gutting knife, typically shorter and sturdier, helps in the removal of internal organs. Finally, specialized knives exist for specific tasks like pin bone removal.

The choice of knife depends heavily on the type of fish and the specific operation. A delicate sole requires a slender fillet knife, while a sturdy tuna may be better handled with a somewhat stronger boning knife. Knife maintenance, including sharpening and regular cleaning, is vital for safety and efficiency.

Q 6. How do you identify and handle spoiled or damaged fish?

Identifying spoiled or damaged fish is crucial for food safety. Key indicators include a strong, ammonia-like odor, slimy texture, dull or discolored eyes, and sunken or soft flesh. Internal changes can also be evident, with damaged organs or discoloration within the flesh. Also, look for any physical damage, such as bruises or cuts. In some cases, parasites or unusual discoloration can signal problems.

Damaged or spoiled fish must be immediately discarded to prevent contamination of other fish or equipment. Strict protocols exist for proper disposal, including separating them from other fish and disposing of them appropriately, often according to local regulations.

Q 7. What are your strategies for maximizing yield while minimizing waste during filleting?

Maximizing yield and minimizing waste during filleting requires skill, precision, and an understanding of fish anatomy. Precise cuts, avoiding unnecessary trimming, are key. Proper use of the fillet knife ensures that we get the maximum amount of usable fillet from each fish. We train our staff to identify the precise location of the backbone and use a smooth, controlled cutting motion to avoid waste. Careful attention to bone removal also minimizes the amount of edible flesh lost in the process. We utilize any remaining trimmings—heads, tails, bones—for other products like fish stock or pet food. Innovative techniques, like using different filleting methods for specific species, also help maximize yield. Some waste can also be minimized by creating different value added products.

In my years of experience, continuous training and improvement in filleting techniques have shown a significant impact on yield. This involves a holistic approach to processing, encompassing both the skill of the individual filleting and efficient organization of the process.

Q 8. Describe your experience with different types of fish processing equipment.

My experience encompasses a wide range of fish processing equipment, from basic hand tools to sophisticated automated systems. I’m proficient with various types of:

- Filleting machines: These automate the process of removing fillets from whole fish, increasing efficiency and consistency. I’ve worked with both high-speed, industrial machines and smaller, more compact models suitable for smaller-scale operations. Understanding their maintenance and calibration is crucial for optimal performance and preventing product damage.

- Skinning machines: These machines efficiently remove fish skin, crucial for certain products like fillets. Different machines cater to different fish sizes and types; selecting the right one is vital for quality and yield.

- Portioning and cutting machines: These allow for precise cutting of fillets into uniform portions, steaks, or other desired shapes. I have experience with both manual and automated systems, recognizing their strengths and limitations in terms of precision, speed, and suitability for different fish types and sizes.

- Freezing equipment: This includes blast freezers for rapid freezing, vital for preserving the quality and texture of the fish. Experience with different freezing methods (IQF, block freezing) and their impact on final product quality is essential. I’m also familiar with various freezing technologies, such as cryogenic freezing.

- Canning equipment: This involves retort systems for sterilizing canned fish products. Safety and regulatory compliance are paramount here, and I have a detailed understanding of the processes and equipment involved.

Understanding the capabilities and limitations of each piece of equipment is vital for optimizing the processing line and ensuring product quality. This includes regular maintenance and calibration to maximize efficiency and minimize waste.

Q 9. How do you maintain sanitation and hygiene standards in a fish processing environment?

Maintaining sanitation and hygiene in fish processing is paramount to prevent contamination and ensure food safety. It’s a multi-faceted approach involving:

- Proper cleaning and sanitizing protocols: This includes regular cleaning and sanitizing of all equipment and surfaces using approved food-grade chemicals. We follow strict procedures, often involving a three-compartment sink system for cleaning, rinsing, and sanitizing. All personnel are thoroughly trained in these protocols.

- Personal hygiene practices: Employees are required to wear protective clothing, including gloves, aprons, and hairnets. Handwashing is mandatory at regular intervals, and strict rules against eating, drinking, or smoking in processing areas are enforced. Regular health checks are also implemented.

- Pest control: A comprehensive pest control program is vital to prevent contamination. Regular inspections and preventative measures are crucial.

- Waste management: Proper disposal of waste materials is critical to prevent cross-contamination and maintain a clean environment. This includes separate collection systems for different types of waste, ensuring they are disposed of according to regulatory guidelines.

- Temperature control: Maintaining the correct temperature throughout the processing environment is essential for preventing bacterial growth. Cold storage areas are monitored regularly, and equipment is maintained to ensure optimal performance.

Regular audits and inspections are carried out to ensure compliance with all sanitation and hygiene standards. A documented system of checks and balances guarantees consistent high standards throughout the processing operation. For example, we use color-coded cutting boards to reduce the chance of cross-contamination.

Q 10. Explain the importance of proper temperature control during fish processing.

Proper temperature control is crucial throughout the fish processing chain to maintain quality and safety. Fish are highly perishable; bacterial growth accelerates rapidly at higher temperatures.

- Immediately after catch: Fish should be chilled quickly to slow down enzymatic and microbial activity. Ice or refrigerated seawater is commonly used for this purpose. The temperature needs to be maintained at below 4°C (39°F).

- During processing: Maintaining low temperatures during all processing stages, from filleting to packaging, is critical. Equipment should be regularly calibrated to ensure proper temperatures are maintained.

- Storage and transportation: Cold storage facilities are essential to prevent spoilage. The cold chain must be maintained throughout the entire process from the point of catch to the consumer. Regular temperature monitoring of storage and transportation units is vital.

Failure to maintain proper temperature control can lead to spoilage, bacterial growth, and ultimately, unsafe products. A comprehensive temperature monitoring and control system is essential in any fish processing facility. Think of it like this: maintaining the correct temperature is like preserving the ‘freshness’ of the fish – the longer we keep it cold, the better the quality.

Q 11. How do you ensure compliance with food safety regulations?

Ensuring compliance with food safety regulations is a top priority. This involves:

- HACCP (Hazard Analysis and Critical Control Points): Implementing a HACCP plan identifies potential hazards and establishes critical control points to manage them. This involves regular monitoring and record-keeping. I have extensive experience in developing and implementing HACCP plans.

- GMP (Good Manufacturing Practices): Following GMP guidelines ensures a clean, safe, and controlled processing environment. This encompasses all aspects of the operation, from employee hygiene to equipment maintenance.

- Regulatory compliance: Staying up-to-date with all relevant food safety regulations and legislation is vital. This involves regularly reviewing and updating our procedures to ensure compliance with local, national, and international standards. We also participate in regular audits by regulatory bodies.

- Traceability: Maintaining complete traceability throughout the processing chain is essential for identifying the source of any potential problems. This includes thorough record-keeping of all aspects of the process, from raw material sourcing to finished product distribution.

Food safety is not just a matter of compliance; it is integral to maintaining consumer trust and protecting public health. Proactive measures and a strong commitment to quality are essential aspects of my professional practice.

Q 12. Describe your experience with different fish preservation methods (e.g., freezing, canning).

I have extensive experience with various fish preservation methods:

- Freezing: This is the most common method, preserving fish quality for extended periods. I’m familiar with different freezing techniques, including blast freezing, plate freezing, and individually quick frozen (IQF) methods. The choice of method depends on factors such as the type of fish, desired product form, and storage capacity. Understanding the impact of freezing rate on product quality is critical.

- Canning: Canning involves heat sterilization to eliminate microorganisms, allowing for long-term storage. I have experience with various canning processes and understanding the critical parameters, such as retort time and temperature, for achieving sterility without compromising product quality. This is a highly regulated process demanding meticulous attention to detail.

- Smoking: Smoking adds flavour and extends shelf life, although it’s not as effective as freezing or canning for long-term preservation. Different smoking techniques and wood types can influence the flavour and appearance of the finished product.

- Salting and curing: Traditional methods like salting and curing can extend shelf life, altering the texture and flavor. These are suitable for specific types of fish and require precise control of salt levels and curing times.

- Drying: Drying, another traditional method, is effective for certain types of fish, removing moisture to inhibit microbial growth. The drying process requires careful control of temperature and humidity to maintain quality.

The selection of the appropriate preservation method depends on various factors, including the type of fish, desired shelf life, and target market.

Q 13. How do you handle different cuts of fish (e.g., fillets, steaks, portions)?

Handling different cuts of fish requires precision and knowledge of fish anatomy. Different cuts are suitable for various culinary applications:

- Fillets: These are boneless side portions of fish, ideal for baking, grilling, or pan-frying. I’m skilled in precise filleting techniques, ensuring minimal waste and high-quality fillets. Different fish species require varying filleting approaches, considering bone structures and skin attachment.

- Steaks: These are cross-section cuts from a whole fish, containing the bone structure. Proper steak cutting ensures an aesthetically pleasing and evenly cooked product. I understand the optimal thickness for different fish types and cooking methods.

- Portions: Portioning involves cutting fillets into uniform sizes for convenience and consistency. This is often done using automated portioning equipment, requiring knowledge of its operation and maintenance to ensure accurate portion sizes and minimal waste.

- Other cuts: Depending on the species, other cuts like butterfly cuts, cube cuts, and loins are created. The type of cut often dictates how it’s best used, whether it is for sushi, fish cakes or other dishes.

My skill in handling different cuts ensures minimal waste, maximized yield, and uniformly sized products ready for packaging and sale.

Q 14. What is your experience with quality control checks during fish processing?

Quality control is an ongoing process throughout the entire fish processing operation. It ensures consistent product quality and safety. The checks involve:

- Raw material inspection: Inspecting the quality of the incoming fish, assessing freshness, and checking for damage or defects before processing. Sensory evaluations – including looking at appearance, checking for smell, and feeling texture – are paramount.

- Process monitoring: Monitoring critical control points during processing, such as temperature and time, ensuring compliance with established parameters. This involves regular data logging and documentation.

- Product inspection: Inspecting the final product for quality attributes, including size, weight, appearance, and absence of defects. Sensory evaluation is also done on the final product to guarantee quality.

- Microbiological testing: Regular microbiological testing to ensure compliance with safety standards. Sampling throughout the process and finished product testing are common procedures. We regularly utilize accredited laboratories for this purpose.

- Metal detection: Employing metal detectors to prevent metallic contamination, essential for ensuring product safety.

Thorough record-keeping and documentation are essential for effective quality control. A detailed traceability system allows quick identification of potential issues and ensures prompt corrective actions.

Q 15. Describe your experience with HACCP principles in a fish processing facility.

HACCP, or Hazard Analysis and Critical Control Points, is a systematic preventive approach to food safety. In a fish processing facility, its implementation is crucial to minimize biological, chemical, and physical hazards. My experience involves developing and implementing HACCP plans, including identifying critical control points (CCPs) such as temperature control during storage and processing, sanitation procedures, and monitoring of critical limits. For example, we established a CCP for chilling fish immediately after catching to prevent bacterial growth. We used temperature data loggers and regular checks to monitor compliance. Any deviation from the established limits triggered corrective actions, documented meticulously, allowing for traceability and quality assurance. I’ve also been involved in conducting regular HACCP audits, staff training, and implementing corrective actions to maintain compliance with food safety regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of seafood and their unique processing requirements?

Seafood encompasses a vast array of species, each with unique processing requirements. For instance, fatty fish like salmon require careful handling to prevent rancidity, often necessitating faster processing and lower storage temperatures compared to leaner fish like cod. Shellfish processing demands different techniques; oysters, for example, require careful shucking to prevent contamination, while shrimp need meticulous cleaning and deveining. Then there’s the consideration of different processing methods: filleting, skinning, freezing, canning, smoking—all tailored to specific species and market demands. For example, sushi-grade tuna requires stringent hygiene and temperature control throughout the entire process, from catching to packaging.

Q 17. How do you identify different types of fish by their appearance?

Identifying fish relies on a combination of visual cues. Shape and size are basic indicators – a long, slender body might suggest a mackerel, while a rounder body could indicate a snapper. Fin characteristics are critical; the number, placement, and shape of dorsal, anal, and pectoral fins are key identifiers. Coloration varies depending on the species and even the environment, but patterns and markings are crucial clues. Consider the mouth and teeth; a large mouth with sharp teeth points toward a predatory species, while a small mouth with blunt teeth indicates a different feeding habit. The scales can provide additional information; their size, shape, and arrangement are species-specific. Experience with many species and access to field guides or online resources are indispensable for accurate fish identification.

Q 18. Describe your experience with training new employees in fish cutting techniques.

Training new employees involves a structured approach. I start with basic safety procedures, emphasizing hygiene, knife safety, and the importance of adhering to HACCP guidelines. Then I move onto practical fish cutting techniques, starting with simpler cuts like filleting and progressing to more complex ones like portioning and trimming. Hands-on training is essential. I demonstrate the techniques, and then the employees practice under my supervision, receiving individual feedback and corrections. We use a variety of fish species to expose them to different textures and challenges. I encourage them to ask questions and emphasize the importance of precision and consistency in their work. Regular assessments help monitor their progress and identify areas requiring further training. A good training program helps reduce errors, improve efficiency, and ensure product quality.

Q 19. How do you manage your time effectively in a fast-paced fish processing environment?

Time management in a fast-paced fish processing environment is crucial. Prioritization is key: I focus on urgent tasks and high-volume processes. Effective workflow organization helps streamline operations. I often collaborate with team members, assigning tasks based on individual strengths and ensuring a balanced workload. Using checklists and time-tracking tools can help maintain efficiency and identify bottlenecks. Furthermore, anticipating potential delays and having contingency plans in place minimizes disruptions. For instance, ensuring sufficient supplies and maintaining equipment in good working order reduces downtime. Clear communication and a team-oriented approach contribute to effective time management in a demanding setting.

Q 20. How do you deal with unexpected problems or equipment malfunctions?

Dealing with unexpected problems or equipment malfunctions requires a quick-thinking, systematic approach. The first step is to assess the situation and identify the root cause of the problem. If it’s a minor issue, like a jammed blade, I try to fix it myself using basic troubleshooting skills. For more complex problems, I call for maintenance support or a qualified technician, depending on the severity and safety implications. In case of equipment malfunctions, I implement contingency plans; for example, having backup equipment or shifting workflow to minimize production disruption. Thorough documentation of the issue, repair process, and any corrective actions ensures future prevention. Safety is always the top priority; any situation posing a risk to personnel necessitates immediate action to ensure safety.

Q 21. What are the different methods for packaging and labeling fish products?

Fish product packaging and labeling are critical for product safety and marketability. Packaging methods vary depending on the type of product and intended shelf life. Common methods include Modified Atmosphere Packaging (MAP) which extends shelf life by controlling the atmosphere inside the package, Vacuum Packaging to remove air and prevent oxidation, and freezing for long-term storage. Labeling is regulated and must clearly indicate the product name, species, weight, processing date, storage instructions, and any relevant allergen information. Traceability is paramount, often achieved through batch numbers linking the product to its origin and processing history. Consumer appeal is important too; attractive packaging and clear labeling create a positive customer experience and influence purchasing decisions.

Q 22. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace in a fish processing facility is paramount for food safety, efficiency, and worker well-being. It’s not just about tidiness; it’s about preventing cross-contamination and ensuring a safe working environment.

- Pre-shift preparation: Before starting work, I always ensure my designated area is thoroughly cleaned. This includes wiping down all surfaces, including cutting boards, tables, and equipment, with appropriate sanitizers. Tools are inspected and sharpened.

- Ongoing maintenance: During processing, I immediately clean up any spills or debris. Used knives and tools are cleaned and stored properly. Waste is disposed of according to regulations.

- Post-shift cleanup: At the end of the shift, a more thorough cleaning takes place. This includes a deep clean of equipment and surrounding areas. Floors are swept and mopped. Equipment is disinfected and stored correctly.

- Designated areas: Maintaining designated areas for raw and processed fish, utensils, and waste is crucial to prevent cross-contamination. Color-coded cutting boards or equipment can help maintain this separation.

Think of it like preparing for surgery – cleanliness is not just important, it’s essential. A clean workspace directly translates to higher-quality product and a healthier work environment.

Q 23. What is your understanding of fish grading and sorting?

Fish grading and sorting is a critical step in fish processing that involves categorizing fish based on several factors to ensure consistent product quality and market value. These factors include:

- Size: Fish are often sorted by weight and length to meet specific market demands. For example, fillets destined for restaurants might require a uniform size.

- Species: Different fish species are processed differently and have varying market values. Sorting by species ensures efficient processing.

- Quality: This involves assessing the freshness, appearance, and overall condition of the fish. Fish showing signs of spoilage are rejected. Factors like flesh firmness, absence of damage, and color are all evaluated.

- Fat content: The fat content influences the taste and texture of the fish and its suitability for different processing methods. Higher-fat fish might be suitable for canning, while leaner fish are ideal for filleting.

For instance, a salmon processing plant might sort salmon based on size (e.g., small, medium, large), then further grade them based on quality (A, B, C) based on appearance and flesh integrity. This ensures customers receive consistently high-quality products while maximizing the value of the catch.

Q 24. What experience do you have with working in a team environment?

I have extensive experience working in team environments within fish processing. Effective teamwork is crucial for efficient and safe operations. In my previous role, I was part of a team responsible for processing up to 10 tons of cod daily.

- Collaboration: We collaborated closely on tasks, such as filleting, scaling, and packing, ensuring each step was done efficiently and accurately.

- Communication: Open and clear communication was essential. We used hand signals and verbal communication to coordinate our actions and ensure a smooth workflow. Regular team meetings ensured we stayed informed about daily goals and any changes in the processing line.

- Mutual support: We supported each other when facing challenges, like dealing with difficult cuts or handling large volumes of fish. This mutual support fosters efficiency and creates a positive work atmosphere.

- Problem-solving: As a team, we proactively identified and resolved problems that arose during processing to minimize downtime and maintain quality.

My experience shows that I thrive in collaborative environments. I am comfortable sharing knowledge, assisting colleagues, and contributing to a positive and productive team dynamic. Teamwork, in a fish processing plant, isn’t just about efficiency; it’s about safety and quality control.

Q 25. How do you prioritize tasks in a fish processing facility?

Prioritizing tasks in a fish processing facility requires a structured approach that balances speed, quality, and food safety. I use a combination of techniques:

- Urgency and Importance: I employ the Eisenhower Matrix (urgent/important) to categorize tasks. Urgent and important tasks, such as processing highly perishable fish, take precedence.

- Production Schedule: Following the daily production schedule is paramount. Tasks are prioritized based on the processing line’s requirements and order fulfillment.

- Fish Type and Condition: Perishable fish are always given priority to prevent spoilage. The processing method (e.g., filleting, canning) and required processing time also influence prioritization.

- Order Fulfillment: Meeting customer orders on time is crucial. Tasks related to timely order fulfillment are highly prioritized.

- Cleaning and Sanitation: Maintaining a clean and sanitary workspace is an ongoing priority, interspersed with processing tasks. This prevents cross-contamination and ensures food safety.

Essentially, it’s a dynamic process requiring flexibility and quick adaptation to unexpected changes or delays. A systematic approach ensures that efficiency is maintained while adhering to food safety protocols.

Q 26. Describe your experience with inventory management in a seafood setting.

Inventory management in a seafood setting is critical for minimizing waste, ensuring product freshness, and meeting customer demands. My experience involves:

- First-In, First-Out (FIFO): I strictly adhere to the FIFO method to ensure that the oldest stock is used first, minimizing spoilage. This is particularly crucial with perishable goods like fish.

- Accurate Record Keeping: Maintaining accurate records of incoming and outgoing inventory is vital. This includes detailed tracking of fish species, quantities, catch dates, and storage locations.

- Stock Rotation: Regular stock rotation helps prevent spoilage and maximizes shelf life. This involves strategically placing newer stock behind older stock.

- Temperature Monitoring: Constant monitoring of storage temperatures is essential for maintaining product quality and safety. Deviation from optimal temperatures can lead to spoilage.

- Waste Management: Careful inventory management minimizes waste by accurately forecasting demand and optimizing stock levels. Proper disposal of waste according to regulations is also vital.

In my previous role, implementing a more efficient inventory system using barcodes and a digital tracking system reduced waste by 15% within six months. Efficient inventory management directly translates to reduced costs and increased profitability.

Q 27. How familiar are you with various types of fish processing byproducts and their uses?

Fish processing generates several byproducts, many of which have valuable uses. My familiarity includes:

- Fish heads, bones, and trimmings: These can be used to produce fishmeal and fish oil, valuable ingredients in animal feed and supplements. They can also be used to create fish stock or broth.

- Fish skin: Fish skin can be used in leather production or processed into gelatin.

- Fish viscera (internal organs): Although often discarded, these can be processed to produce fish oil rich in omega-3 fatty acids. They also contain enzymes with potential industrial applications.

- Roe and milt: These are highly valuable products used in caviar production or other culinary applications.

Understanding the various byproducts and their potential uses is important for maximizing the economic value of the entire fish and minimizing waste. Responsible byproduct management contributes to sustainability and responsible resource utilization.

Q 28. What is your experience with sustainable fish processing practices?

Sustainable fish processing practices are vital for the long-term health of our oceans and the fishing industry. My experience and knowledge encompass several key aspects:

- Minimizing Waste: Employing efficient processing techniques and utilizing byproducts to their fullest potential significantly reduces waste. This is crucial for environmental sustainability.

- Responsible Sourcing: I ensure that the fish being processed comes from sustainable and responsibly managed fisheries, certified by organizations like the Marine Stewardship Council (MSC).

- Energy Efficiency: Reducing energy consumption during processing is vital. This includes optimizing equipment usage and exploring renewable energy sources.

- Water Conservation: Minimizing water usage during processing is crucial. This includes using efficient cleaning methods and recycling water whenever possible.

- Wastewater Treatment: Proper treatment of wastewater generated during processing to minimize environmental impact is crucial. This ensures compliance with environmental regulations.

Sustainability isn’t just an ethical consideration; it’s also good business. Consumers are increasingly demanding sustainably sourced seafood, and adopting these practices helps ensure the long-term viability of the industry.

Key Topics to Learn for Fish Cutting and Processing Interview

- Fish Anatomy and Physiology: Understanding fish muscle structure, bone placement, and organ systems is crucial for efficient and safe processing.

- Hygiene and Safety Protocols: Mastering sanitation procedures, including proper knife handling, personal hygiene, and food safety regulations, is paramount in this industry.

- Different Cutting Techniques: Learn various filleting, skinning, and portioning methods for different fish species, emphasizing speed and precision.

- Equipment Operation and Maintenance: Familiarity with processing equipment like automated filleting machines, scales, and packaging systems is essential. Understanding basic maintenance is a plus.

- Quality Control and Grading: Learn about assessing fish quality, identifying defects, and applying industry grading standards for consistent product quality.

- Yield Optimization: Understanding techniques to maximize usable portions from each fish, minimizing waste and maximizing profitability.

- Value-Added Processing: Explore techniques like smoking, curing, or marinating to enhance product value and marketability.

- Waste Management and Sustainability: Understanding environmentally responsible practices for waste disposal and resource management within the processing facility.

- Troubleshooting and Problem-Solving: Develop your ability to identify and resolve common issues related to equipment malfunction, product quality, and workflow efficiency.

- Teamwork and Communication: Highlight your ability to collaborate effectively within a team environment, following instructions and communicating clearly.

Next Steps

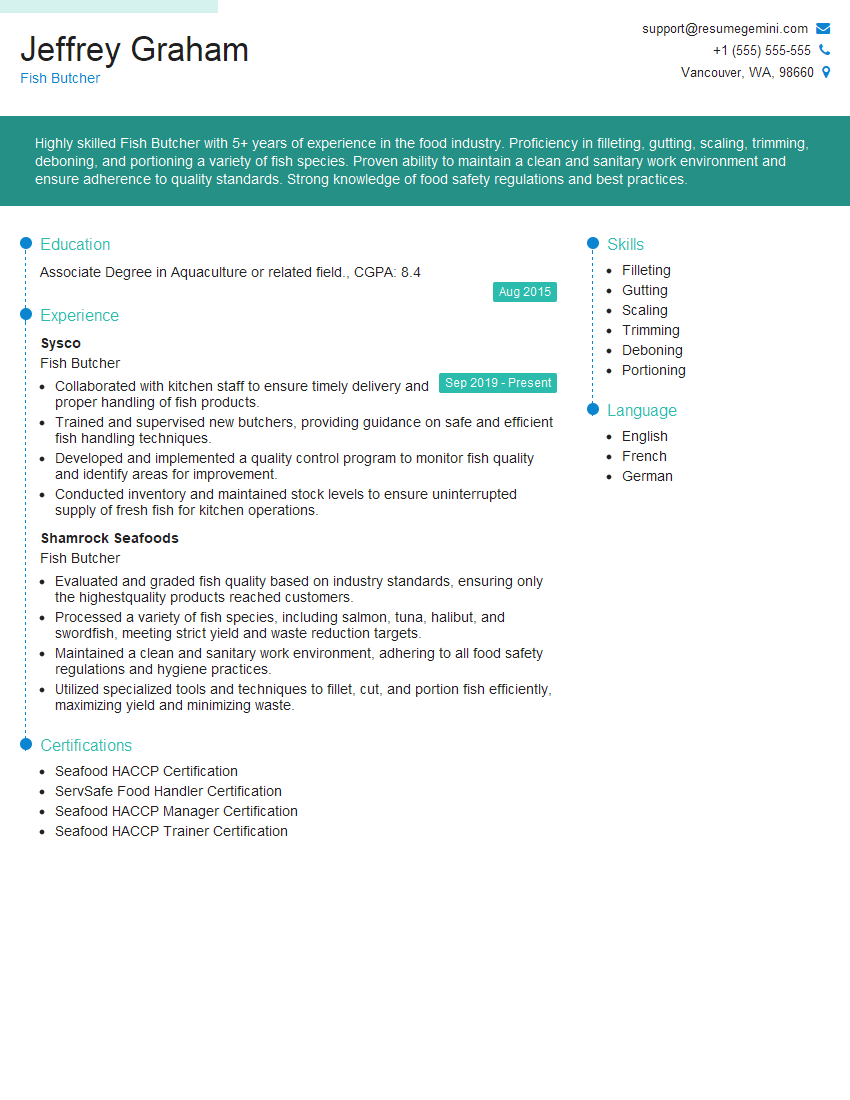

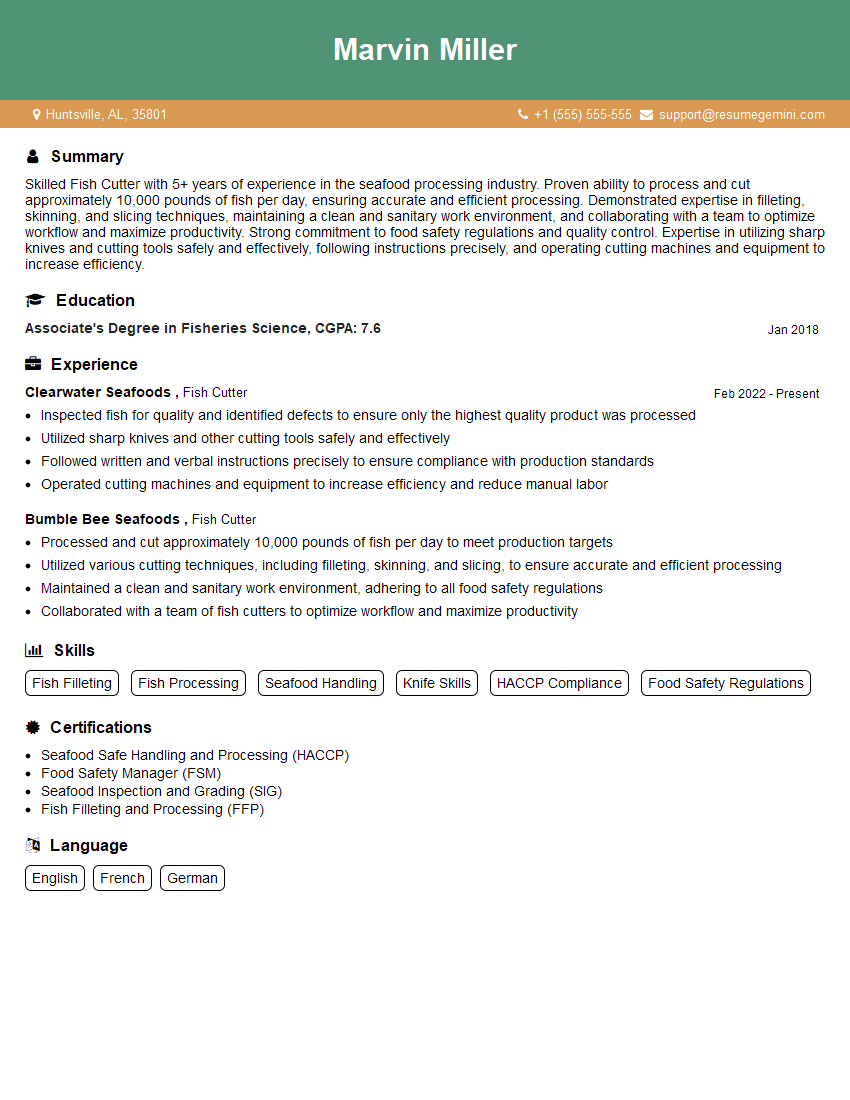

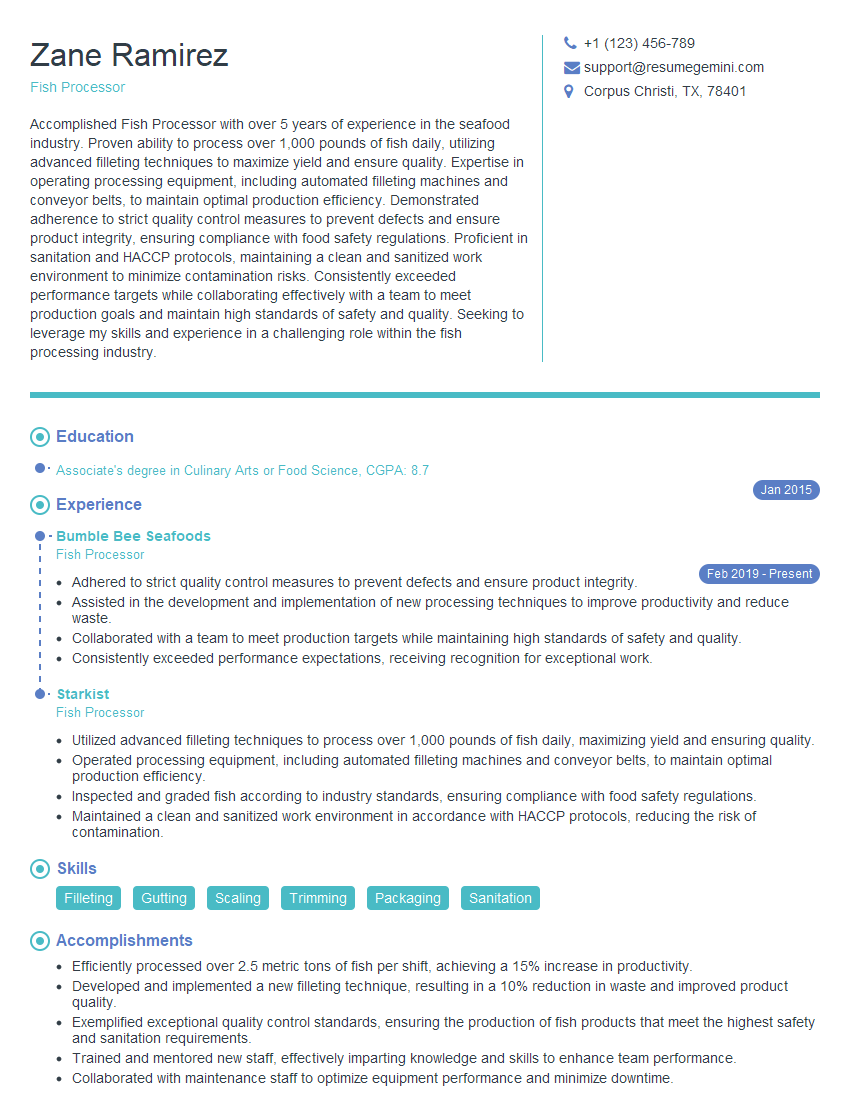

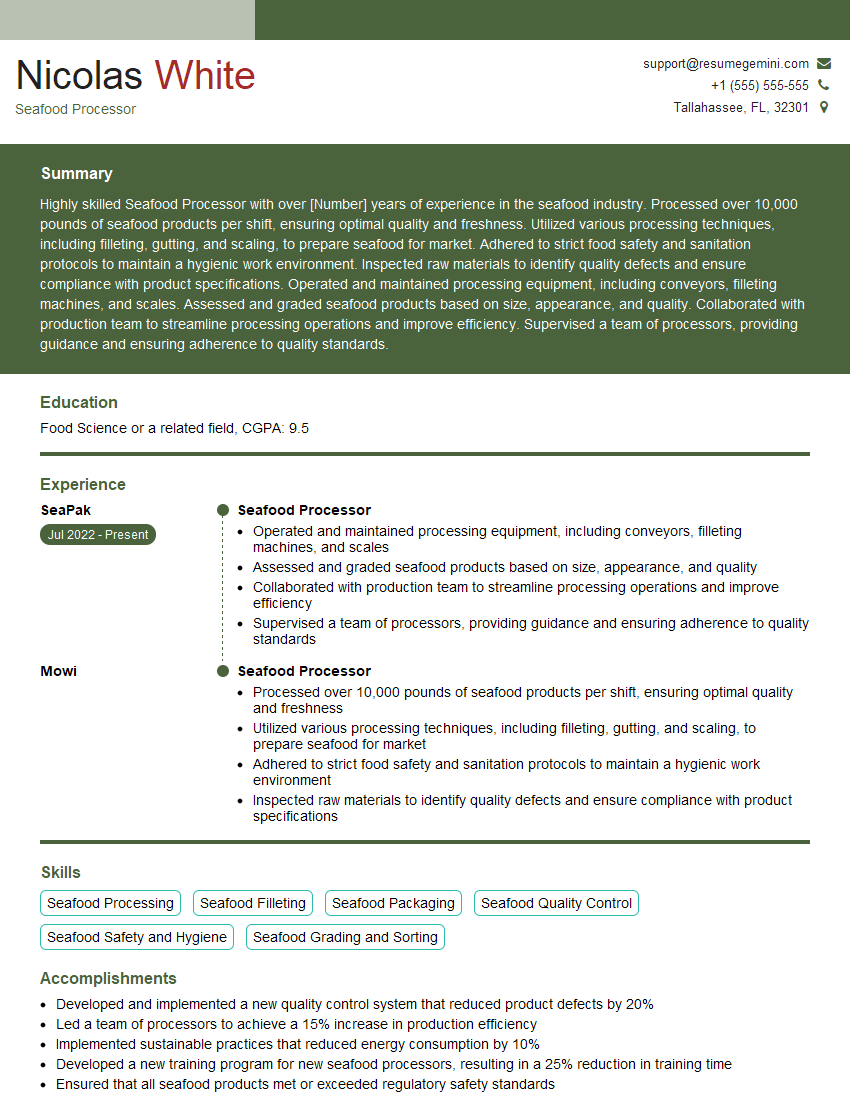

Mastering fish cutting and processing opens doors to a rewarding career with opportunities for advancement into supervisory roles, specialized processing techniques, or even entrepreneurship. To stand out, create an ATS-friendly resume that clearly showcases your skills and experience. We highly recommend using ResumeGemini to build a professional and impactful resume that gets noticed by recruiters. ResumeGemini provides examples of resumes tailored to the Fish Cutting and Processing industry, helping you craft a document that effectively highlights your qualifications. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good