Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Equipment Transportation and Handling interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Equipment Transportation and Handling Interview

Q 1. Explain the different types of equipment used in transportation and handling.

Equipment transportation and handling involves a diverse range of vehicles and tools. The specific equipment used depends heavily on the size, weight, and type of the equipment being moved.

- Heavy-duty trucks and trailers: These are the workhorses for most large equipment moves, ranging from flatbed trailers for carrying construction equipment to specialized trailers for oversized loads. For example, a lowboy trailer is essential for moving heavy machinery with a low center of gravity.

- Forklifts and cranes: These are crucial for loading and unloading equipment onto transport vehicles. Forklifts are efficient for palletized goods or smaller equipment, while cranes are needed for heavier or awkwardly shaped items. Think of the massive cranes used in moving wind turbine components.

- Specialized carriers: For exceptionally large or delicate equipment, specialized carriers like heavy-haul trucks, modular trailers, and even barges may be necessary. Moving a transformer or a prefabricated building house often requires these.

- Lifting and securing equipment: This includes chains, straps, winches, and other devices for safely securing the load during transit. Using appropriate straps and chains to prevent movement is crucial for both safety and cargo protection.

- Loading ramps and docks: These facilitate the smooth transfer of equipment between trucks and storage areas or worksites. A well-designed loading dock can significantly enhance efficiency and safety.

Q 2. Describe your experience with load securing techniques.

Load securing is paramount to safe and efficient transportation. My experience includes working with a variety of techniques tailored to different equipment types and transport modes. This involves a thorough risk assessment before any securing is undertaken.

I’m proficient in using:

- Chain and binder systems: For heavier and more robust equipment, these provide excellent strength and securement. Proper tensioning and the use of appropriate rated equipment is critical.

- Webbing straps and ratchet systems: Ideal for securing items of varying shapes and sizes, these offer a flexible and effective solution. I am familiar with calculating the appropriate number of straps based on weight and load distribution.

- Cribbing and blocking: This is essential for preventing shifting and damage to loads, particularly during transport of delicate or unevenly shaped equipment. I have experience in calculating the appropriate amount of cribbing materials.

- Specialized equipment: For oversized and heavy loads, I’ve used specialized securing devices including air bags, and load distribution beams.

In all cases, adherence to relevant standards (such as those set by the International Standards Organization) are followed, and documentation is meticulously maintained.

Q 3. What safety regulations must be followed during equipment transportation?

Safety is non-negotiable in equipment transportation. Regulations vary by location, but key aspects universally include:

- Vehicle inspections: Regular checks of brakes, lights, tires, and securing mechanisms are mandated to ensure the vehicle is roadworthy. Pre-trip inspections are mandatory and detailed logs are kept.

- Load securement: Equipment must be secured properly to prevent shifting or falling during transit. Failure to properly secure a load can lead to serious accidents and hefty fines.

- Driver qualifications: Drivers must possess appropriate licenses and undergo training on safe driving practices, especially for heavy equipment transportation. Driver logs and adherence to driving hours regulations are paramount.

- Route planning: Routes must consider weight limits, bridge clearances, and other potential hazards, often requiring permits for exceptional loads.

- Hazardous materials regulations: If transporting hazardous materials, strict protocols concerning labeling, storage, and emergency procedures must be followed.

- Personal Protective Equipment (PPE): Appropriate PPE such as high-visibility clothing, safety boots, and helmets must be worn by all personnel involved in loading, unloading, and transporting equipment.

Q 4. How do you ensure efficient route planning for equipment transport?

Efficient route planning is crucial for minimizing transport time, fuel costs, and risks. My approach involves:

- Mapping and route selection software: I utilize specialized software to identify optimal routes considering factors like weight restrictions, bridge clearances, and road conditions. Google Maps is useful for basic navigation but specialized software offers more detailed information.

- Permitting and approvals: For oversized or overweight loads, obtaining necessary permits and approvals from relevant authorities is essential and often requires advance planning.

- Weather monitoring: Real-time weather information is considered to avoid potential delays or safety issues due to adverse weather conditions. A severe storm might delay transportation for safety reasons.

- Traffic and congestion analysis: I analyze traffic patterns and potential congestion points to optimize the timing of the transport. Avoiding peak hour traffic is often crucial.

- Communication and coordination: Maintaining clear communication with drivers, dispatchers, and relevant parties is vital for smooth execution. I often use radio communications or mobile apps to keep track of the transport.

Q 5. What are the common challenges in transporting oversized or heavy equipment?

Transporting oversized or heavy equipment presents unique challenges:

- Route restrictions: Oversized loads may require special permits and specific routes, avoiding low bridges and narrow roads.

- Escort vehicles: These are often required to guide oversized loads, ensuring safe passage and alerting other road users.

- Specialized trailers and equipment: Heavy-haul trailers, modular transporters, and other specialized equipment are necessary for handling oversized loads.

- Increased risk of accidents: The size and weight of oversized equipment increase the risk of accidents, demanding extra caution and safety measures.

- Cost considerations: Transporting oversized loads is significantly more expensive than standard transportation due to the specialized equipment, permits, and escort vehicles required.

Successfully navigating these challenges requires meticulous planning, close collaboration with various stakeholders, and strict adherence to safety regulations.

Q 6. Explain your experience with different types of trailers and their applications.

My experience encompasses various trailer types, each suited to different applications:

- Flatbed trailers: These are versatile and commonly used for transporting construction equipment, steel, and other relatively flat and stable items. Their simplicity makes them cost-effective for many applications.

- Lowboy trailers: Designed for heavy and low-slung equipment, they offer a low deck height for easy loading and unloading of items with a low center of gravity. Think of moving excavators.

- Step-deck trailers: These offer a two-level deck, enabling the transport of taller equipment while still maintaining a manageable overall height.

- Gooseneck trailers: These feature a gooseneck connection to the towing vehicle, providing increased maneuverability and stability. They are commonly used for hauling heavy-duty equipment.

- Extendable trailers: These offer adjustability in length, making them suitable for transporting oversized loads. The ability to extend and retract them is crucial for efficiency.

- Specialized trailers: For exceptional loads, specialized trailers like those with heavy-duty suspension, or even those equipped with specialized securing systems are necessary.

The selection of the appropriate trailer type is crucial for safe and efficient transport and depends on the specific requirements of the load.

Q 7. How do you handle equipment damage during transportation?

Handling equipment damage requires a methodical approach:

- Documentation: Thorough documentation of the damage, including photos and descriptions, is essential. This is vital for insurance claims.

- Investigation: Determining the cause of the damage is crucial, whether it was due to improper loading, unforeseen circumstances during transit, or pre-existing conditions.

- Reporting: Damage must be reported to relevant parties, including insurers and clients. A timely and clear report facilitates a smoother resolution process.

- Repair or replacement: Depending on the extent of the damage and its nature, repair or replacement of the damaged equipment may be necessary. Depending on the value of the damage, a professional assessment may be necessary.

- Insurance claims: In many cases, insurance claims are necessary to cover the cost of repairs or replacements. Proper documentation is key for a successful claim.

Preventing damage is always the priority, but a robust process for handling damage is essential to mitigate losses and ensure accountability.

Q 8. Describe your experience with inventory management related to equipment.

Effective inventory management for equipment is crucial for optimizing resource allocation and minimizing downtime. My experience encompasses a range of strategies, from implementing robust database systems to utilizing barcode scanning and RFID technology for real-time tracking. I’ve worked with both manual and automated inventory systems, adapting my approach to the specific needs of each project. For instance, in one project involving the transportation of large construction equipment, we used a custom-built database that integrated with our GPS tracking system, allowing us to pinpoint the location and status of each piece of equipment at any given time. This level of detail significantly improved our ability to predict maintenance needs, allocate resources effectively, and reduce instances of equipment loss or theft. Another example involves a smaller project where a spreadsheet system worked perfectly well for tracking a smaller volume of handheld equipment.

My approach always prioritizes accuracy and accessibility. Data is regularly audited for discrepancies, and reports are generated to highlight trends, potential shortages, and areas for improvement. This proactive approach ensures that the right equipment is available at the right time, preventing delays and minimizing operational disruptions.

Q 9. How familiar are you with GPS tracking and its application in transportation?

GPS tracking is indispensable in modern equipment transportation. I’m highly familiar with its various applications, from real-time location monitoring and route optimization to geofencing (setting virtual boundaries to trigger alerts if equipment leaves a designated area) and driver behavior analysis. I’ve used GPS tracking systems to manage fleets of vehicles transporting various types of equipment, including heavy machinery, sensitive electronics, and hazardous materials. The data provided allows for proactive problem-solving – for example, we can identify potential delays due to traffic congestion and reroute vehicles to maintain schedules. It also provides valuable data for optimizing routes, leading to fuel savings and reduced emissions.

Furthermore, GPS tracking systems can be integrated with other technologies, such as telematics, to provide even more detailed information about equipment performance and condition. This integrated approach allows for predictive maintenance, which minimizes unplanned downtime and maintenance costs. The data collected can also be used to analyze driver behavior, helping to improve safety and efficiency.

Q 10. Explain your process for selecting appropriate transportation modes.

Selecting the appropriate transportation mode is a critical decision that impacts cost, speed, and safety. My process involves a careful consideration of several factors, starting with an assessment of the equipment’s size, weight, fragility, and value. For instance, shipping oversized or heavy equipment often requires specialized permits and transportation.

- Size and Weight: Heavy or oversized equipment typically necessitates the use of lowboy trailers or specialized heavy-haul trucks.

- Fragility: Sensitive equipment may require climate-controlled transport or specialized packaging.

- Value: High-value equipment might necessitate increased security measures, possibly including armed escorts.

- Distance and Time Sensitivity: Longer distances often favour rail or sea freight, while time-sensitive deliveries may necessitate air freight or expedited trucking.

- Cost: Each mode of transport carries a different price tag; optimizing cost is always a factor.

Once these factors are assessed, I compare various options, weighing the pros and cons of each to choose the most efficient and cost-effective solution. This often involves collaborating with logistics providers to obtain quotes and assess the suitability of their services. I also factor in potential risks, such as weather conditions or security concerns, and select accordingly.

Q 11. What is your experience with risk assessment in equipment handling?

Risk assessment is paramount in equipment handling. My process follows a structured approach, beginning with identifying potential hazards associated with the specific equipment and its handling environment. This often involves checklists that consider several dimensions.

- Equipment-Specific Hazards: Sharp edges, moving parts, unstable loads, hazardous materials.

- Environmental Hazards: Uneven terrain, inclement weather, limited visibility.

- Human Factors: Lack of training, fatigue, improper lifting techniques.

Once hazards are identified, I assess the likelihood and severity of each potential incident, quantifying the risks. This quantitative risk assessment informs the development of control measures to mitigate those risks. This could include things like implementing safety protocols, providing specialized training, procuring suitable safety equipment (like harnesses or specialized lifting gear), and selecting appropriate handling equipment. Finally, I document the entire process, including the risk assessment, control measures, and responsibilities. Regular audits and reviews ensure the effectiveness of these controls are maintained.

Q 12. Describe your experience with using different types of lifting equipment.

My experience with lifting equipment encompasses a wide range of types and capacities. I’m proficient in the safe and efficient operation of cranes (both mobile and tower cranes), forklifts, overhead hoists, and specialized lifting devices, such as vacuum lifters for delicate equipment. I also understand the importance of selecting the appropriate lifting equipment for the task, ensuring it’s within its safe working load limit (SWL). For instance, attempting to lift a load exceeding the SWL can result in catastrophic equipment failure.

Beyond operation, I am equally experienced in pre-use inspection and maintenance of lifting equipment, ensuring that it’s in good working order and meets all relevant safety standards. This includes checking for any signs of damage or wear, verifying that safety mechanisms are functioning correctly, and ensuring that all operators are properly trained and certified. Regular maintenance and inspections are vital for accident prevention, something I have always prioritized in my career. In one instance, a routine pre-lift inspection revealed a faulty cable on a crane, preventing a potential accident.

Q 13. How do you manage scheduling conflicts in equipment transportation?

Managing scheduling conflicts in equipment transportation requires proactive planning and communication. My approach utilizes scheduling software to track all planned movements, considering factors like equipment availability, crew assignments, and potential delays. When conflicts arise, I employ several strategies:

- Prioritization: Identifying the most time-sensitive deliveries and adjusting the schedule accordingly.

- Rescheduling: Negotiating with clients to adjust delivery windows, when possible.

- Resource Allocation: Optimizing the allocation of resources, like drivers and equipment, to minimize conflicts.

- Contingency Planning: Developing backup plans to address unexpected delays or equipment breakdowns.

- Communication: Maintaining clear communication with all stakeholders – clients, drivers, and logistics providers – to keep everyone informed of any changes.

Effective communication is key to resolving conflicts quickly and minimizing disruptions. For example, a sudden weather event might cause significant delays. In this situation, clear and timely communication with clients helps to manage their expectations, and the use of alternative routes or transport modes (when possible) may still allow for timely delivery, or at least a minimized impact.

Q 14. How do you ensure the timely delivery of equipment?

Ensuring timely delivery relies on a combination of meticulous planning, proactive monitoring, and efficient problem-solving. My strategies include:

- Detailed Route Planning: Optimizing routes to avoid congestion and potential delays. This often involves using route planning software that considers real-time traffic data.

- Real-time Tracking: Utilizing GPS tracking to monitor the progress of shipments and identify potential problems early on.

- Proactive Communication: Regularly updating clients on shipment status and addressing any concerns promptly.

- Contingency Planning: Developing backup plans to address unexpected events, such as traffic accidents or equipment malfunctions.

- Efficient Documentation: Maintaining detailed records of all shipments, including pickup times, delivery times, and any associated documentation.

By consistently applying these strategies and adapting to unexpected situations, I ensure that equipment is delivered on time and in excellent condition. This proactive approach also helps minimize potential costs associated with late deliveries, maintaining a high level of client satisfaction.

Q 15. What are your strategies for optimizing transportation costs?

Optimizing transportation costs is crucial in equipment handling. My strategies focus on a multi-pronged approach encompassing route optimization, carrier negotiation, and efficient load planning. First, I leverage route planning software to identify the most cost-effective routes, considering factors like fuel prices, toll costs, and potential delays. This might involve comparing multiple routes and considering alternative modes of transport. For instance, for a short-distance, high-value shipment, a specialized truck might be more cost-effective than rail, despite a higher per-mile cost. Second, I actively negotiate with carriers, seeking competitive rates and exploring contract options for volume discounts or guaranteed service levels. This requires building strong relationships and demonstrating the value of consistent business. Third, optimizing load planning is essential, maximizing the space and weight capacity of each shipment to reduce the number of trips required. This might involve careful consideration of equipment dimensions and securement techniques to safely maximize space utilization. For example, using specialized racking systems can significantly increase the number of smaller components that can be transported at once.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected delays or disruptions during transportation?

Unexpected delays and disruptions are inherent risks in equipment transportation. My response strategy involves proactive risk mitigation, robust communication, and flexible contingency planning. Firstly, I incorporate buffer time into the schedule, anticipating potential delays due to weather, traffic, or unforeseen circumstances. This buffer allows for some flexibility without significantly impacting the overall timeline. Secondly, transparent and frequent communication is key. I maintain regular contact with carriers, clients, and relevant stakeholders, providing timely updates and proactively addressing potential issues. This ensures everyone is informed and can adapt to changing circumstances. Thirdly, I develop contingency plans for various scenarios. This might involve identifying backup carriers, alternative routes, or securing temporary storage solutions. For instance, if a port experiences unexpected congestion, having an alternate delivery point or carrier ready can prevent significant delays.

Q 17. Explain your experience with documentation and paperwork in equipment transportation.

Documentation and paperwork are the backbone of efficient and compliant equipment transportation. My experience spans the entire lifecycle, from initial booking confirmation to final delivery documentation. This includes creating accurate bills of lading, ensuring proper insurance coverage, preparing customs documentation (where applicable), and maintaining detailed records of all transactions and communications. I am proficient in using electronic documentation systems and tracking software, which ensures traceability and minimizes the risk of errors or loss of paperwork. For example, I’ve utilized systems that electronically integrate with carriers’ platforms, streamlining the exchange of information and significantly reducing processing time and the risk of manual errors. I also have extensive experience in handling hazardous material documentation, ensuring strict adherence to all relevant regulations.

Q 18. How do you maintain equipment records and ensure traceability?

Maintaining accurate and readily accessible equipment records is critical for traceability and asset management. I utilize a combination of physical and digital records. Physical records such as maintenance logs and inspection reports are maintained in a secure, organized manner. Digitally, I utilize database systems that allow for comprehensive tracking of equipment location, condition, maintenance history, and movement. This system generates audit trails and enables quick retrieval of information, crucial for tracking assets and resolving potential discrepancies. Barcoding or RFID tagging of equipment further enhances traceability, facilitating quick identification and real-time location tracking. For instance, in one project involving the transportation of numerous sensitive instruments, a real-time tracking system with GPS and temperature monitoring ensured complete visibility and immediate alerts for any deviation from specified conditions.

Q 19. What are the different types of permits required for transporting specific equipment?

The permits required for equipment transportation vary significantly depending on the type of equipment, its dimensions, weight, and the route it will travel. For oversized or overweight loads, special permits are usually needed from state and local authorities. These permits might stipulate specific routes, travel times, and escort requirements. Hazardous materials require additional permits and documentation, adhering to strict regulations set by agencies like the Department of Transportation (DOT). For example, transporting a large transformer would necessitate permits for oversize loads, possibly including pilot cars and route restrictions to ensure public safety. Similarly, transporting chemicals would require a hazardous materials permit detailing the substance, its classification, and safety protocols. International shipments require customs documentation and may necessitate permits from multiple jurisdictions.

Q 20. Describe your experience with working with different transportation providers.

My experience working with various transportation providers is extensive. I’ve collaborated with a wide range of carriers, from large multinational logistics companies to specialized local trucking firms. My approach emphasizes building strong, collaborative relationships based on clear communication, mutual respect, and a shared commitment to safety and efficiency. I select carriers based on their reputation, expertise in handling specific equipment types, insurance coverage, and adherence to safety regulations. I meticulously evaluate their performance based on metrics like on-time delivery rates, damage claims, and customer service responsiveness. This allows me to build a network of reliable carriers, tailored to different transportation needs. For instance, for time-sensitive shipments of high-value equipment, I prefer carriers with proven experience and a strong track record of on-time delivery.

Q 21. How do you ensure compliance with relevant environmental regulations?

Ensuring compliance with environmental regulations is paramount in equipment transportation. This includes adherence to emission standards, waste disposal regulations, and spill prevention protocols. I am well-versed in relevant regulations and ensure that chosen carriers have the necessary permits and certifications. I actively monitor fuel consumption and explore opportunities to reduce carbon footprint, such as optimizing routes, utilizing fuel-efficient vehicles, and exploring alternative fuels. For example, when transporting equipment requiring specialized cleaning, I ensure the waste is managed in accordance with all local and federal regulations, employing licensed disposal companies. Proper handling of hazardous materials is strictly adhered to, including using approved packaging, securement methods, and emergency response plans. This proactive approach minimizes environmental impact while ensuring regulatory compliance.

Q 22. Describe your experience with using specialized equipment for specific materials.

My experience with specialized equipment is extensive, encompassing various material types and transportation modes. For instance, I’ve overseen the transport of oversized wind turbine components using specialized trailers and heavy-lift cranes. The process involves meticulous planning, considering factors like weight distribution, route feasibility, and necessary permits. We also utilized air-ride suspension trailers to minimize vibration damage during transit. Another example involves the handling of delicate electronic components. Here, we employed temperature-controlled containers and anti-vibration packaging to prevent damage during shipping. Each material necessitates a unique approach, dictated by its fragility, weight, dimensions, and environmental sensitivity. I’ve also worked with vacuum trucks for the transport of hazardous materials, ensuring complete containment and safety throughout the process. Choosing the right equipment is crucial for efficient and damage-free transportation.

Q 23. How do you deal with communication breakdowns during a transport operation?

Communication breakdowns during transport operations are a serious concern, often leading to delays and increased costs. My approach to mitigating this risk involves establishing clear communication protocols at the outset of each project. This includes regular check-ins with all stakeholders – drivers, loading crews, dispatchers, and clients – using a combination of methods such as dedicated communication channels (e.g., a project-specific group chat), email updates, and scheduled conference calls. If a breakdown occurs, I immediately identify the root cause. Is it a technological issue, a misunderstanding of instructions, or a lack of timely information? Once identified, I implement corrective actions. For example, if the issue is a lack of real-time updates from drivers, I’ll implement GPS tracking and regular location reporting. Documentation is key; every communication, decision, and modification to the plan is documented thoroughly. Proactive communication prevents issues; reactive communication addresses them promptly and efficiently.

Q 24. What is your experience with managing transportation budgets?

Managing transportation budgets demands careful planning and cost-control measures. My experience involves developing detailed budgets that encompass all aspects of the operation – fuel costs, driver salaries, equipment rental, insurance, permits, and unforeseen expenses (a contingency buffer of 10-15% is crucial). I use various software tools to track expenses, monitor progress against the budget, and identify potential areas for cost savings. For example, I optimize routes using route planning software to minimize fuel consumption and mileage. Negotiating favorable rates with carriers and equipment suppliers is also critical. I actively seek competitive bids and leverage volume discounts whenever possible. Regular budget reviews ensure we remain on track and allow for timely adjustments if needed. This approach, combined with meticulous record-keeping, ensures cost-effectiveness without compromising safety or efficiency.

Q 25. Explain your knowledge of different types of cargo insurance.

Cargo insurance is vital to mitigating risks associated with equipment transport. Several types exist, each tailored to specific needs.

- Cargo insurance: This covers loss or damage to goods during transit, irrespective of the cause (excluding intentional acts). Different coverage levels exist, impacting the premium.

- All-risks insurance: This offers broader coverage, including losses due to unforeseen events like fire, theft, and accidental damage.

- Specific perils insurance: This only covers losses resulting from explicitly stated perils, like fire or collision.

- Liability insurance: This protects against claims of third-party damage or injury caused by the transported goods.

Q 26. How do you prioritize tasks during peak periods of equipment transportation?

Peak periods require a strategic approach to task prioritization. My method involves using a combination of techniques, including a prioritized task list based on urgency and impact. Tasks with imminent deadlines and potential for significant disruption get top priority. I utilize project management software to track progress, assign tasks to team members, and monitor overall workflow. I also leverage real-time data from GPS tracking and other monitoring systems to adjust schedules dynamically. Clear communication with all stakeholders is crucial during peak periods; transparent updates on progress and potential delays help manage expectations. If necessary, I will utilize additional resources, such as temporary staffing, to ensure timely completion of critical tasks. In short, a proactive, data-driven approach to task management and effective communication helps navigate the challenges of peak periods effectively.

Q 27. How do you adapt to changes in regulations or transportation procedures?

Adapting to regulatory changes and procedural updates is an ongoing requirement in equipment transportation. I stay abreast of changes through industry publications, professional networks, and regulatory websites. When a change occurs, I carefully analyze its impact on our operations. This includes reviewing existing procedures, identifying areas requiring modification, and updating documentation accordingly. I ensure all personnel receive adequate training on the new regulations and procedures, frequently utilizing training videos and practical demonstrations. The process of updating our systems can be complex, so I prioritize and implement changes systematically, focusing on aspects with the most significant impact first. Continuous monitoring and improvement are crucial to ensuring compliance and maintaining efficient operations.

Q 28. Describe your experience resolving conflicts between different departments involved in equipment transportation.

Resolving conflicts between departments is a key aspect of effective management. My approach centers on open communication and collaborative problem-solving. I initiate a meeting involving all relevant parties to clearly articulate the conflict, encourage each department to express their perspectives, and identify the root cause of the disagreement. I facilitate a neutral environment to encourage constructive dialogue and actively seek common ground. We collectively explore potential solutions, evaluating each for its feasibility and impact on each department. Once a mutually acceptable solution is reached, we document the agreement and establish clear responsibilities for implementation. Post-resolution, I monitor progress and address any emerging issues proactively. This collaborative approach fosters stronger inter-departmental relations and improves overall operational efficiency.

Key Topics to Learn for Equipment Transportation and Handling Interview

- Logistics and Planning: Understanding route optimization, load planning, and scheduling for efficient and safe transportation.

- Equipment Selection and Operation: Knowing the capabilities and limitations of various equipment (cranes, forklifts, trailers, etc.) and selecting the appropriate tools for specific tasks. Practical application includes assessing weight limits, dimensions, and terrain suitability.

- Safety Regulations and Procedures: Familiarity with relevant safety standards, regulations (OSHA, etc.), and best practices for safe equipment operation and handling, including pre-operation checks and risk assessments.

- Maintenance and Repair: Basic understanding of equipment maintenance schedules, common malfunctions, and troubleshooting techniques. This includes preventative maintenance procedures and recognizing signs of potential problems.

- Transportation Documentation and Compliance: Knowledge of necessary paperwork, including Bills of Lading, shipping manifests, and compliance with relevant transportation regulations.

- Load Securing and Transportation Methods: Understanding appropriate methods for securing loads to prevent shifting or damage during transport, and knowledge of different transportation modes (trucking, rail, sea).

- Problem-Solving and Decision-Making: Demonstrating the ability to effectively assess and resolve problems related to equipment malfunctions, delays, or safety concerns in a timely and efficient manner.

- Technology and Automation in Equipment Handling: Familiarity with modern technologies used in equipment transportation and handling, such as GPS tracking, telematics, and automated guided vehicles (AGVs).

Next Steps

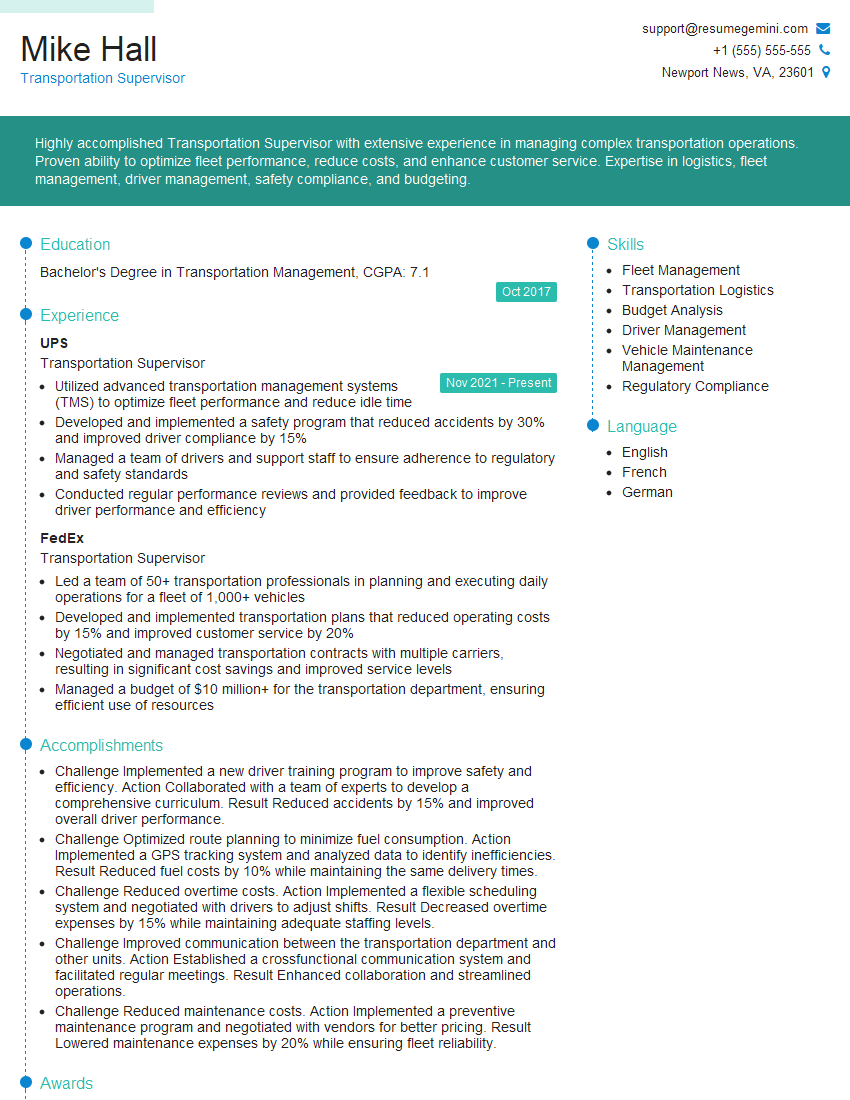

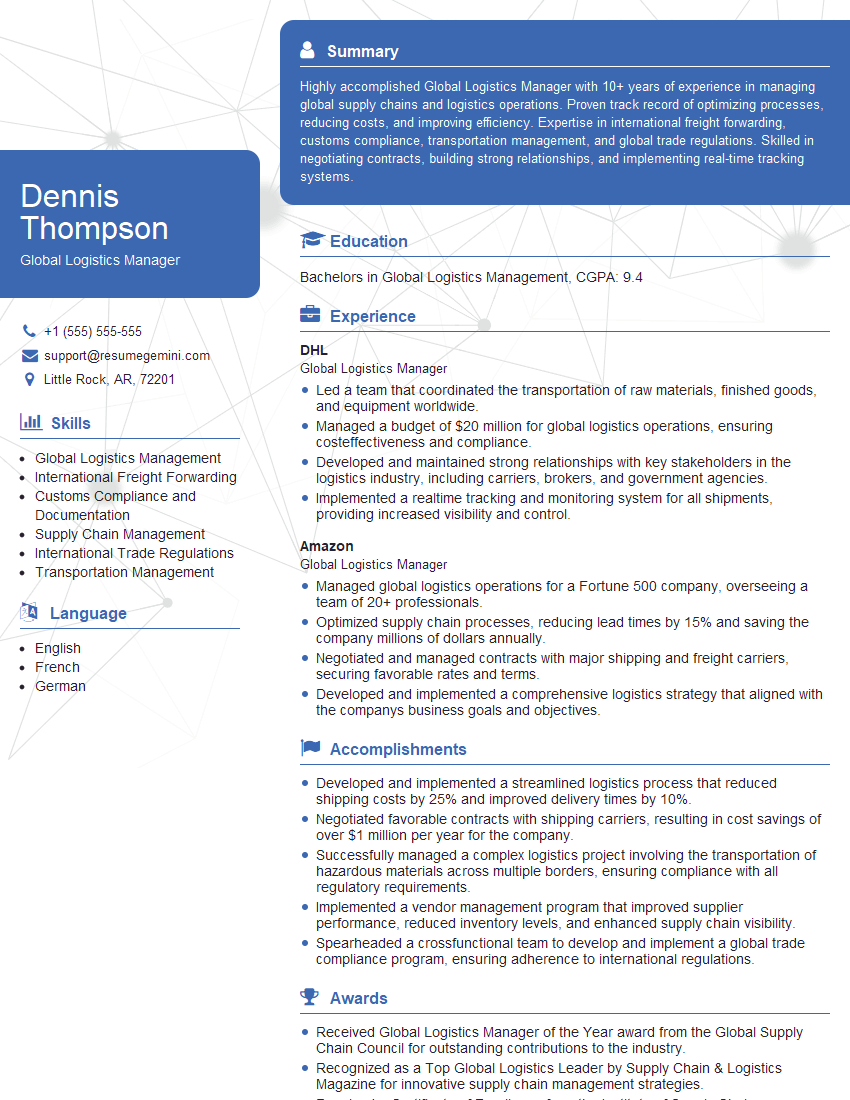

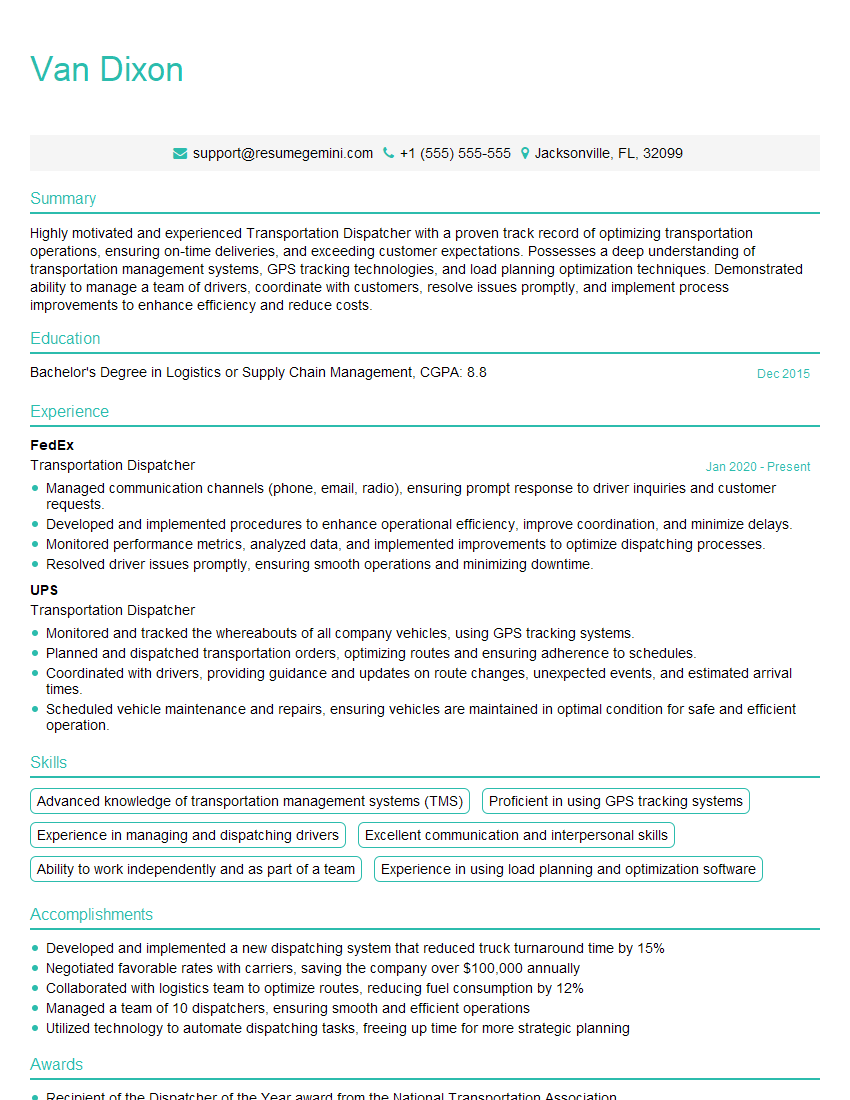

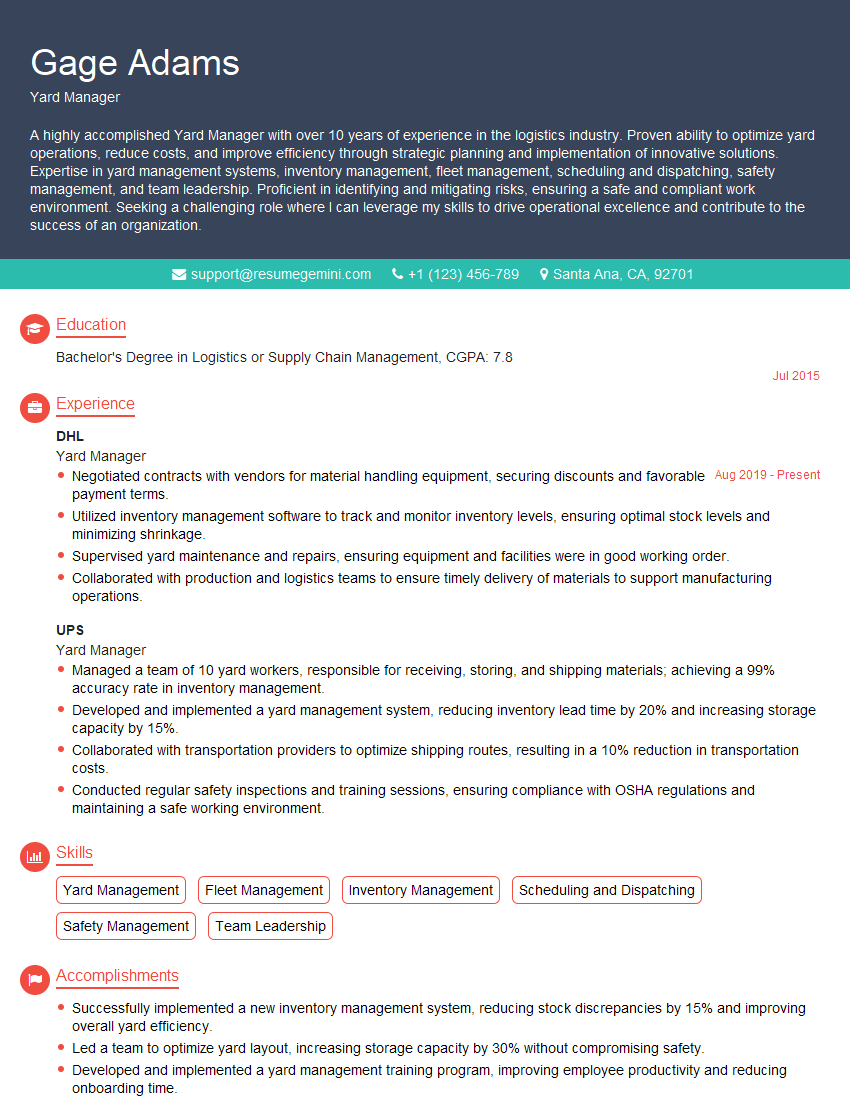

Mastering Equipment Transportation and Handling opens doors to exciting career opportunities with significant growth potential in logistics, manufacturing, and construction. A strong understanding of these concepts will significantly improve your interview performance and overall career prospects. To maximize your chances of landing your dream job, it’s crucial to present your skills and experience effectively. Building an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you craft a professional and compelling resume tailored to the Equipment Transportation and Handling industry. Examples of resumes specifically designed for this field are available to guide you. Take advantage of these resources to showcase your expertise and achieve your career goals.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good