Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Casing Troubleshooting Protocols interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Casing Troubleshooting Protocols Interview

Q 1. Explain the common causes of casing failures.

Casing failures, unfortunately, are a common occurrence in the oil and gas industry. They can stem from a variety of sources, broadly categorized as mechanical, chemical, or environmental factors.

- Mechanical Failures: These often involve issues during installation, such as poor cementing leading to annular leaks, or excessive stress on the casing from pressure changes or differential settling of the formation. Imagine a building – if the foundation isn’t properly set, the entire structure can be compromised. Similarly, weak points in casing installation can lead to cracking or collapse under pressure.

- Chemical Failures: Corrosion is a major culprit. Hydrogen sulfide (H2S) and carbon dioxide (CO2) in the formation can react with the casing material, causing it to weaken and eventually fail. Think of rust on a car – it eats away at the metal, leaving it vulnerable. This is analogous to how corrosive fluids weaken casing over time.

- Environmental Failures: These can include issues like ground movement (subsidence) or temperature variations causing thermal stress on the casing. Just as extreme temperatures can crack asphalt roads, similar effects can happen to casing, especially in areas with significant temperature fluctuations.

Understanding the specific cause is crucial for effective preventative measures and remedial action. A thorough investigation, including well logs and pressure tests, is usually necessary to pinpoint the exact failure mechanism.

Q 2. Describe different types of casing and their applications.

Casing comes in various types, each suited for specific applications based on depth, pressure, and formation conditions. The selection process is critical for well integrity and safety.

- Conductor Casing: This is the first string of casing run, often relatively small diameter, designed to protect the wellbore during surface operations and provide a stable platform for subsequent casing strings. It’s like a pilot hole for the larger casing strings to follow.

- Surface Casing: This protects the upper portions of the wellbore from shallow, unstable formations and surface water. Think of this as a protective sleeve, shielding the sensitive well layers from the unpredictable conditions near the surface.

- Intermediate Casing: Placed between the surface and production casing, its purpose is to isolate various formations to prevent unwanted fluid influx or migration. It’s like strategically placed barriers to isolate different water/oil/gas reservoirs.

- Production Casing: This is the main casing string that isolates the reservoir to control the production of hydrocarbons. It’s usually the largest diameter and must withstand significant pressure. This is the powerhouse – the casing that controls and channels the extracted oil and gas.

- Liner Casing: This is a smaller diameter casing placed inside an existing casing string to provide additional zonal isolation or to support a specific section of the wellbore where strength is needed. Think of it as a patch, reinforcing a specific area.

The choice of casing material (usually steel) depends on factors like strength requirements, corrosion resistance, and cost. Different grades of steel are used to ensure suitability for the anticipated pressures and temperatures.

Q 3. How do you diagnose a casing leak?

Diagnosing a casing leak requires a systematic approach combining various techniques. It’s like detective work – we need to gather clues to identify the culprit.

- Pressure Surveys: Monitoring casing pressure over time can reveal leaks. A gradual pressure drop may indicate a slow leak, while a sudden drop suggests a more serious event. Consistent monitoring is key.

- Temperature Surveys: Leaks can cause temperature anomalies in the wellbore, especially where fluids mix. A temperature log can reveal where heat is escaping.

- Fluid Sampling and Analysis: Analyzing the fluid retrieved from the wellbore helps identify the source and nature of the leak. This is like analyzing a blood sample to diagnose an illness.

- Acoustic Logging: This uses sound waves to detect leaks and identify the location of the leak within the casing. It’s a powerful non-invasive method that allows for pinpoint detection.

- Inspection Tools: Tools like specialized cameras or magnetic flux leakage detectors can identify casing damage, such as cracks or corrosion, providing visual evidence of a leak path.

Often, a combination of these techniques is necessary for a conclusive diagnosis. The complexity of the investigation depends on the type and location of the suspected leak.

Q 4. What are the different methods for casing repair?

Casing repair methods vary depending on the severity and location of the damage. The goal is to restore well integrity and prevent further damage.

- Cement Squeeze: For small leaks, injecting cement into the annular space can seal the leak. This is like applying a sealant to patch a hole in a wall.

- Bridge Plugs: These are used to isolate a damaged section of the casing, effectively sealing off the leak zone. This is like a dam, stopping the flow of water.

- Snubbing Unit Repairs: This involves using a specialized unit to run tools downhole to perform repairs, such as installing packers or sealing leaks directly on the casing. This is a more sophisticated procedure that requires specialized equipment.

- Casing Patching: This involves placing a patch over the damaged section of the casing to restore its integrity. Similar to patching a puncture in a tire.

- Selective Milling: In extreme cases, the damaged section of casing might be milled out and replaced with a new liner or casing string. This is like surgically removing and replacing a damaged part.

The selection of repair methods requires careful evaluation of factors such as the extent of damage, the well’s operating conditions, and the cost-effectiveness of each approach.

Q 5. Explain the process of running casing during well completion.

Running casing is a critical part of well completion, requiring precise execution and coordination. It involves carefully lowering the casing string into the wellbore and cementing it in place.

- Preparation: Before running casing, the wellbore is thoroughly cleaned and prepared to ensure a smooth running and proper cement placement.

- Casing String Makeup: The casing strings (individual joints of pipe) are assembled on the surface, inspected, and equipped with necessary accessories such as centralizers and float equipment. This is a carefully orchestrated process – each joint must be meticulously checked to prevent mishaps.

- Running the Casing: Using a top drive or draw works, the casing string is carefully lowered into the wellbore. This needs to be done slowly and steadily to prevent damage to the casing or wellbore.

- Cementing: Once the casing is in place, cement slurry is pumped into the annulus (the space between the casing and the wellbore) to isolate formations, provide support, and prevent leaks. The cementing operation is paramount for well integrity.

- Displacing the Cement: After cementing, the cement slurry is displaced from the casing by pumping drilling mud or other displacement fluids. This process removes excess cement and ensures a clean, functioning well.

- Testing: After cementing, pressure tests are conducted to verify the integrity of the cement job and the casing string. This is a critical verification step to guarantee successful casing installation.

The entire process needs to be meticulously planned and executed to ensure the success of the well completion process. This is a significant undertaking requiring careful management and expert oversight.

Q 6. How do you interpret a casing pressure test?

Interpreting a casing pressure test involves analyzing the pressure response of the casing string to determine its integrity. A successful test indicates a leak-free casing, while deviations show potential issues.

- Pressure Build-up: The rate at which pressure increases during the test indicates the volume and tightness of the annular space. A slow increase could suggest a leak.

- Pressure Drop: A decrease in pressure over time indicates a leak in the casing or cement. The rate of decline helps pinpoint the severity of the leak.

- Pressure Stabilization: A stable pressure after a period of time usually indicates a successful cement job and an intact casing string.

- Comparison to Previous Tests: Analyzing pressure data from previous tests provides a baseline for comparison, aiding in detection of potential changes. This allows us to see if there’s a degradation or leak that wasn’t present before.

The interpretation of a casing pressure test requires expertise in wellbore hydraulics and experience in interpreting pressure data. Deviations from expected behavior warrant further investigation and potential remedial action. It’s like a health checkup – the results guide us to take appropriate action.

Q 7. What are the safety precautions during casing operations?

Safety is paramount during all casing operations. Stringent safety protocols are essential to protect personnel and equipment. Failure to adhere to these protocols can lead to catastrophic accidents.

- Rig-site Safety: Adherence to all rig-site safety rules, including proper use of personal protective equipment (PPE) such as hard hats, safety glasses, and safety boots, is essential. This is a foundation for every operation – safety first.

- Lifting and Handling Procedures: Proper lifting techniques must be employed when handling casing strings, preventing injuries from dropped loads or mishandling. This is especially crucial given the weight of the casing.

- Well Control Procedures: Stringent well control procedures must be followed to prevent uncontrolled flow of fluids, ensuring the safety of personnel and the environment. This is absolutely non-negotiable – well control is the most important aspect.

- Emergency Preparedness: A thorough emergency response plan must be in place to respond to any potential accidents or emergencies. This includes regular drills and the appropriate equipment.

- Hydrogen Sulfide (H2S) Precautions: If H2S is present, strict safety protocols must be implemented to protect personnel from exposure to this toxic gas. This requires specialized equipment and training.

Regular safety inspections, training programs, and adherence to best practices are crucial for minimizing risks during casing operations. The safety of everyone involved should always be the top priority.

Q 8. Describe the role of cement in casing integrity.

Cement is the backbone of casing integrity, acting as a robust barrier between different geological formations and the wellbore. Its primary role is to prevent fluid migration between these zones. Think of it like a strong, waterproof seal around a pipe running through different layers of soil – each with its own unique pressure and fluid content. Without proper cementing, you risk uncontrolled fluid flow, leading to environmental contamination, formation damage, and potential wellbore instability.

Specifically, cement:

- Prevents fluid migration: It seals the annulus (the space between the casing and the borehole wall), preventing the mixing of fluids from different formations and prohibiting the escape of valuable hydrocarbons or the ingress of unwanted fluids like water or gas.

- Provides support to the casing: The cement sheath provides mechanical support, preventing casing collapse under high external pressure conditions. This is particularly important in unstable formations.

- Enhances wellbore stability: By strengthening the wellbore, cement contributes to the overall stability of the well, reducing the risk of boreholes caving in.

Imagine a scenario where cementing is poorly done. You could experience a blowout – a sudden, uncontrolled release of well fluids – or a casing collapse, leading to costly repairs and potential environmental damage. Therefore, meticulous cementing is crucial for well integrity and safety.

Q 9. How do you handle a stuck pipe incident during casing operations?

A stuck pipe incident during casing operations is a serious issue demanding immediate action to prevent well damage and potential loss of equipment. The first step is to establish communication – assess the situation, understand the depth of the stuck pipe, and gather data like the torque and drag readings. This assessment will guide the next steps.

Our response typically follows these steps:

- Weight-on-bit Reduction: The first attempt is usually to gradually reduce the weight on the pipe to see if friction can be overcome. This is like gently trying to unstick something stuck in mud.

- Rotation: Carefully rotating the pipe can sometimes help break the friction. Think of it like twisting a jar lid to unscrew it.

- Washover: If the pipe is stuck due to differential pressure, injecting a drilling fluid with lower density can sometimes free the pipe.

- Circulation: Circulating the drilling fluid helps clear any debris that might be causing the blockage. This is similar to flushing a clogged drain.

- Mechanical freeing operations: This could involve using specialized tools such as jars, or employing more aggressive methods like using pressure to break the stuck pipe. This is a more forceful approach, so it’s employed as a last resort.

- Cutting the Pipe: If all else fails, the stuck pipe might need to be cut and abandoned, with a new casing string run. This is the most expensive option, so it’s only used if the other methods fail.

Throughout this process, careful monitoring of well pressure and other parameters is critical. Prevention is key. Proper drilling practices, accurate well planning, and the use of appropriate drilling fluids significantly reduce the likelihood of stuck pipe incidents.

Q 10. Explain the importance of casing design in preventing failures.

Casing design is paramount in preventing failures. It’s about selecting the right materials, dimensions, and grades for the specific geological conditions and operational parameters of the well. A poorly designed casing is like building a house on unstable ground – it’s destined to fail.

Key aspects of casing design include:

- Grade of steel: Different grades of steel offer varying levels of strength and yield point. The selection depends on the pressure and stress the casing will endure.

- Wall thickness: Thicker walls provide greater resistance to collapse and burst. The choice depends on the expected pressures and the formation strength.

- Casing length: The required length depends on the depth of the well and the geological formations encountered.

- Connections: The strength and integrity of the casing connections are crucial to preventing leaks and failures. Proper threading and sealing are vital.

Consider a scenario where a well is drilled in a high-pressure formation. A casing with insufficient wall thickness could collapse under the external pressure. Similarly, using a low-grade steel could result in the casing yielding or failing to withstand the tensile stress during operation. Therefore, a thorough understanding of the subsurface environment and the subsequent informed selection of casing parameters are vital for a successful well.

Q 11. What are the environmental considerations related to casing failures?

Environmental considerations are paramount in relation to casing failures. A failure can lead to severe environmental consequences, impacting both land and marine ecosystems. The main concern is the uncontrolled release of hydrocarbons or other drilling fluids into the environment. This can contaminate soil and groundwater, harming wildlife and potentially impacting human health.

For example:

- Hydrocarbon leaks: If a casing fails, it can allow oil or gas to leak into the surrounding environment, resulting in soil and water contamination.

- Drilling fluid contamination: Drilling fluids, often containing chemicals, can also be released causing soil and water pollution.

- Greenhouse gas emissions: Leaks of methane, a potent greenhouse gas, are a significant concern.

Strict regulations and well-designed prevention strategies are in place to minimize the risk of casing failures and their environmental impacts. This includes thorough pre-drilling geological assessments, robust casing design, and regular well integrity monitoring.

Q 12. How do you assess the risk of casing collapse?

Assessing the risk of casing collapse involves a multifaceted approach that combines engineering analysis with real-time monitoring. We use a combination of techniques, including:

- Geomechanical modeling: This involves creating a computer model of the subsurface, incorporating data on rock strength, pore pressure, and stress conditions. The model simulates the stresses on the casing to determine the risk of collapse.

- Annular pressure monitoring: Continuous monitoring of pressure in the annulus between the casing and the formation reveals potential issues, such as pressure build-up that could lead to casing collapse.

- Cement bond logs: These logs assess the quality of the cement bond between the casing and the formation. A poor cement bond increases the risk of casing collapse.

- Acoustic logs: These logs can detect micro-annuli or fractures in the cement sheath, suggesting potential weakness.

- Stress analysis: This involves calculating the stress exerted on the casing due to formation pressure, overburden, and other forces.

By combining these methods, we develop a comprehensive understanding of the risks involved and implement mitigation strategies to prevent casing collapse.

Q 13. What are the different types of casing cementing techniques?

Various casing cementing techniques exist, each tailored to specific well conditions. The choice depends on factors such as well depth, formation characteristics, and the required quality of the cement sheath. Here are some common methods:

- Conventional cementing: This is the most common method, involving pumping cement slurry into the annulus through a centralizer system that ensures even distribution. It’s like filling a pipe with cement to ensure a tight seal.

- Casing-while-drilling (CWD) cementing: This technique involves cementing the casing while simultaneously drilling the well. It’s a faster method but requires specialized equipment.

- Underbalanced cementing: This technique is used in high-pressure formations and involves pumping cement slurry at a pressure lower than the formation pressure. This minimizes the risk of fracturing the formation.

- Expanded cement slurry: This approach uses a cement slurry that expands after placement, ensuring complete filling of the annulus even in irregular formations.

- Foamed cementing: This method involves mixing the cement with a foaming agent, resulting in a lighter and more easily pumpable cement slurry. It’s useful in formations prone to fracturing.

The choice of cementing technique involves careful consideration of the specific circumstances to ensure effective and safe operation.

Q 14. Explain the significance of annular pressure monitoring.

Annular pressure monitoring is critical for ensuring well integrity and preventing casing failures. It provides real-time insights into the pressure conditions in the annulus between the casing and the formation. These pressures can indicate potential problems before they escalate into major incidents.

Its significance stems from its ability to:

- Detect leaks: A sudden pressure change in the annulus can signal a leak in the casing or cement sheath.

- Monitor cement integrity: Pressure fluctuations can reveal a poor cement bond or other issues with the cement sheath.

- Prevent casing collapse: By monitoring pressure, we can detect increasing external pressure that could lead to casing collapse.

- Improve operational efficiency: Real-time monitoring reduces the risk of costly failures and allows for timely intervention.

- Enhance safety: Early detection of potential problems increases the overall safety of the well.

Think of it as a vital sign for the wellbore. Just as we monitor blood pressure in a patient, continuous annular pressure monitoring provides essential data for maintaining the health and integrity of the well.

Q 15. How do you manage casing wear and corrosion?

Managing casing wear and corrosion is crucial for well integrity and safety. It involves a multi-pronged approach focusing on prevention and mitigation.

Prevention starts with selecting the right casing material based on the anticipated environment (e.g., high H2S, high CO2, corrosive fluids). This often includes using corrosion-resistant alloys like stainless steel or specialized coatings. Careful cementing practices are also paramount to prevent fluid ingress and subsequent corrosion. Regular monitoring of downhole conditions via pressure and temperature gauges, and regular fluid analysis help in early detection of potential issues.

Mitigation techniques are implemented when wear and corrosion are detected. These may involve internal or external casing repairs. Internal repairs might involve deploying casing packers or specialized tools to isolate the damaged section. External repairs could involve applying corrosion inhibitors directly to the casing, or even using specialized sleeves to encapsulate damaged sections. In severe cases, replacement of the damaged casing section may be necessary.

Example: In a well producing highly acidic fluids, using a corrosion-resistant alloy casing like duplex stainless steel and regularly injecting corrosion inhibitors can significantly extend the casing’s lifespan. Conversely, neglecting corrosion monitoring in a high-CO2 environment can lead to premature casing failure and costly repairs or even well abandonment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe various casing inspection methods.

Various methods exist for inspecting casing, each offering different levels of detail and invasiveness.

- Conventional Logging: Techniques like caliper logging measure casing diameter to detect wear and corrosion. Cement bond logs assess the quality of cement behind the casing, identifying potential pathways for fluid migration.

- Magnetic Flux Leakage (MFL): This non-destructive method detects flaws such as cracks and corrosion pits on the casing’s external surface. It’s especially useful for detecting external corrosion that might not be evident through other methods.

- Ultrasonic Inspection: This technique uses sound waves to detect internal and external flaws, offering high-resolution imaging of the casing wall. It’s particularly effective for detecting wall thinning caused by corrosion.

- Optical Inspection: In cases where accessibility allows, a camera or fiber optic probe can be used to visually inspect the casing condition. This is mainly suitable for shorter well sections or surface casing.

- Downhole Video Inspection: A video camera is lowered down the wellbore to visually inspect the condition of the casing. This allows for direct observation of the casing and the surrounding environment, identifying potential problems such as corrosion, cracks, or other damage.

The choice of method depends on factors such as well depth, casing material, accessibility, and the specific concerns regarding casing integrity.

Q 17. Explain the importance of wellbore stability in casing design.

Wellbore stability is paramount in casing design, as instability can lead to casing collapse, leaks, and ultimately well failure.

Casing design must account for the formation’s mechanical properties (strength, stress, and pore pressure), the in-situ stresses, and the potential for induced stresses during drilling and production. Accurate geomechanical modeling is crucial to predict wellbore stability. Proper casing design involves selecting the appropriate casing grade, weight, and size to withstand the expected stresses. This may include using larger diameter casing, heavier weight casing, or specialized casing strings to manage formations prone to instability.

Example: In a shale formation with high differential pressure, the casing needs to withstand significant pressure loads. If the casing is not appropriately selected to provide sufficient strength and resistance, the shale formation may collapse into the wellbore, potentially crushing the casing and causing well failure.

Q 18. How do you prevent gas migration through the casing?

Preventing gas migration through the casing is crucial for safety and environmental protection. This involves several strategies, primarily focused on ensuring a robust cement sheath and identifying and addressing any potential pathways for gas movement.

Proper Cementing: A high-quality cement job is the primary defense against gas migration. This means using the correct cement slurry design, ensuring complete displacement of drilling mud, and obtaining a good cement bond with the casing and the formation. Post-cementing evaluation tools, such as cement bond logs, are used to verify the quality of the cement job.

Leak Detection and Repair: Regular pressure testing and monitoring can detect leaks in the casing or cement sheath. Leak detection logs can help identify the location of leaks, and repair techniques, such as squeeze cementing, can be used to seal these pathways.

Casing design: Choosing the appropriate casing materials and design can improve resistance to corrosion and other forms of damage that can increase the likelihood of gas migration.

Packers and seals: The use of packers and other seals can isolate sections of the wellbore and prevent gas flow along the casing.

Example: In a high-pressure gas well, thorough quality control of the cementing process, coupled with regular pressure testing and leak detection logs, is vital in preventing gas migration and ensuring safe operation.

Q 19. What are the key parameters to consider for casing selection?

Casing selection is a critical aspect of well design, demanding careful consideration of various parameters.

- Wellbore conditions: Pressure, temperature, and the chemical composition of the formation fluids greatly influence casing selection. High temperatures might necessitate the use of high-temperature alloys, while corrosive fluids would demand corrosion-resistant materials.

- Formation properties: The mechanical properties of the formation, including strength, stress, and the potential for instability, dictate the required casing strength and grade.

- Well depth: The depth of the well determines the required burst and collapse resistance of the casing.

- Production requirements: The planned production methods and expected production rates influence casing design. High-production rates may require larger-diameter casings.

- Cost-effectiveness: Balancing the cost of casing materials with the long-term well integrity and safety is vital.

Example: In a deep, high-pressure well with corrosive fluids, a high-grade steel casing with a specialized corrosion-resistant coating would be chosen to ensure long-term well integrity and safety.

Q 20. Describe different types of casing accessories and their functions.

Casing accessories play a vital role in enhancing well integrity and operational efficiency.

- Casing Centralizers: These devices maintain a consistent annular space between the casing and the wellbore, ensuring even cement distribution and maximizing the effectiveness of the cement sheath.

- Casing Shoes: These are placed at the bottom of the casing string to protect the casing from damage during running and to provide a stable base for the cement sheath.

- Casing Packers: These are used to seal off sections of the wellbore, isolating zones or preventing fluid migration between different formations.

- Casing Hangers: These suspend the casing string in the wellbore, allowing for the proper installation of the casing.

- Casing Couplings: These connect individual lengths of casing, forming a continuous string.

The selection of appropriate casing accessories depends on the specific well design and operational requirements.

Q 21. How do you troubleshoot a problem with a casing packer?

Troubleshooting a casing packer problem begins with careful analysis of available data and a systematic approach.

- Gather Information: Collect data on packer type, set depth, pressure readings, and any operational anomalies experienced.

- Pressure Testing: Conduct pressure tests to determine the integrity of the packer seal and identify any leaks.

- Logging: Use appropriate logging tools to evaluate the condition of the packer and the surrounding formations. This could involve pressure tests, temperature logging, or specialized packer integrity tools.

- Visual Inspection (if possible): If the packer is accessible, visual inspection can provide valuable insight into its condition.

- Specialized Tools: Depending on the severity and nature of the problem, specialized tools may be required to repair or replace the packer.

The specific troubleshooting steps will vary depending on the type of packer and the nature of the problem. In many cases, expertise in downhole tooling and well intervention techniques is required for effective resolution.

Example: If pressure tests indicate a leak around a set packer, the cause may be improper setting, damage to the packer elements, or a poorly cemented interval. A thorough investigation using logs and potentially specialized tools is essential to identify and remedy the issue.

Q 22. Explain how geomechanical modeling is used in casing design.

Geomechanical modeling is crucial in casing design because it helps predict how the wellbore and casing will behave under various stress conditions. Think of it as a virtual stress test for your well. It uses sophisticated software to integrate data from geological surveys, such as formation pressure, stress, and pore pressure, to create a 3D model of the subsurface. This model simulates the stresses acting on the casing during drilling, completion, and production. The model helps engineers determine the optimal casing design—the weight, grade, and setting depth—to prevent collapse, buckling, or tensile failure.

For example, in a high-pressure, high-temperature (HPHT) well, geomechanical modeling helps engineers select casing with sufficient strength to withstand the extreme pressures and temperatures. Without this modeling, the risk of casing failure and potential blowouts would be significantly higher. The model will also identify potential zones of weakness within the formation, allowing for preventative measures, such as using heavier weight casing or implementing specialized cementing techniques.

Q 23. How do you interpret caliper logs in relation to casing integrity?

Caliper logs measure the diameter of the wellbore. When interpreting these logs in relation to casing integrity, we are looking for inconsistencies that indicate potential problems. A consistent diameter shows that the casing is seated correctly and the wellbore is stable. However, variations in diameter might suggest issues.

For instance, an enlargement of the wellbore diameter compared to the nominal casing size suggests casing deformation, perhaps due to crushing or buckling from excessive formation pressure. Conversely, a reduced diameter might indicate a collapsed casing or cement sheath problems. The severity of the irregularity, such as the length and magnitude of the diameter variation, will help determine the extent of casing damage.

Combining caliper logs with other logs, such as cement bond logs, helps provide a comprehensive picture of the well’s condition. For example, a significant diameter change correlated with a poor cement bond might indicate a weak point where the casing is vulnerable to further damage.

Q 24. What is the significance of the mud weight in preventing casing problems?

Mud weight is vital in preventing casing problems because it provides the necessary pressure to balance the formation pressure. Imagine a balloon – if the pressure inside (formation pressure) exceeds the pressure outside (mud pressure), the balloon (casing) might burst. Conversely, if the outside pressure is too high, the balloon might crush.

Maintaining the correct mud weight prevents formation fluids from entering the wellbore (kicks), which can cause pressure surges that damage the casing. Insufficient mud weight can lead to casing collapse due to the formation pressure exceeding the hydrostatic pressure exerted by the mud column. Conversely, excessive mud weight could cause casing fracturing, as the outward force from the mud column overcomes the strength of the casing and formation.

Determining the appropriate mud weight is a complex calculation considering formation pressure, pore pressure, fracture pressure, and casing strength. It requires careful monitoring and adjustment throughout the drilling process.

Q 25. Describe the procedure for conducting a casing pressure integrity test.

A casing pressure integrity test is performed to verify the leak-tightness of the casing string. The general procedure is as follows:

- Isolate the section: The casing section to be tested is isolated using packers or other sealing devices, creating a closed system.

- Pressurize the casing: The isolated casing section is pressurized using a pump to a pressure slightly above the expected maximum operating pressure.

- Monitor pressure: The pressure is continuously monitored for any pressure drop. A steady pressure indicates that the casing is leak-tight. Any pressure drop indicates a leak.

- Locate the leak: If a leak is detected, pressure testing techniques and downhole tools are used to locate the exact location of the leak along the casing.

- Document results: All pressure readings, test parameters, and any identified leaks are carefully documented in the well’s official records.

Different types of pressure tests exist, such as the hydrostatic test or a pressure pulse test, chosen based on the specific requirements of the well and casing. Failure to maintain casing integrity can lead to serious safety and environmental risks and significant financial losses.

Q 26. How do you evaluate the effectiveness of casing repair techniques?

Evaluating the effectiveness of casing repair techniques depends on the type of repair and the nature of the damage. After a repair is conducted, several steps are taken to assess its success:

- Pressure testing: A pressure integrity test is again performed on the repaired casing section to ensure it can withstand the intended pressure.

- Logging: Tools such as caliper logs, cement bond logs, and acoustic logs might be re-run to assess the condition of the wellbore and casing after the repair. These logs help to determine if the repair successfully addressed the previous integrity issues.

- Production monitoring: After the well returns to production, continuous monitoring of production parameters, such as pressure and flow rates, will help to detect any signs of further casing damage. Any deviations from normal operations could signal a problem with the repair.

For example, if a squeeze cementing job is performed to repair a leak, the cement bond log can indicate whether the cement has successfully sealed the leak. Successful repair will be indicated by a lack of pressure loss during the pressure test and stable production parameters during operation.

Q 27. Explain the differences between primary and secondary cementing.

Primary cementing is the initial cementing operation performed after casing is set. Its purpose is to provide a strong, continuous seal between the casing and the formation. It’s like building a strong foundation for a house – vital for long-term stability.

Secondary cementing, on the other hand, is a subsequent cementing operation performed to repair defects in the primary cement job, such as channeling or poor bond. This is like repairing a crack in the foundation – needed when the initial construction wasn’t perfect. Secondary cementing might involve squeezing cement through the existing channels or filling voids behind the casing. Successful primary cementing is key, reducing the need for costly and time-consuming secondary cementing operations. A well-executed primary cementing job saves time, money, and potential environmental damage.

Q 28. How would you address a situation where casing is damaged during drilling?

Casing damage during drilling is a serious issue that requires immediate attention. The first step is to fully assess the extent of the damage using logging tools and possibly visual inspection with a downhole camera. The specific response then depends on the severity and location of the damage. Options include:

- Minor Damage: If the damage is minimal (e.g., small dents), it may be acceptable to proceed with drilling after carefully assessing the remaining casing strength. However, this decision needs to carefully weigh the risks.

- Major Damage: For significant damage such as cracks or buckling, the damaged casing section might need to be repaired using techniques like squeeze cementing or the insertion of a liner (a smaller diameter pipe placed inside the damaged casing).

- Severe Damage: In cases of catastrophic failure, the damaged casing might need to be replaced entirely, involving costly remedial operations.

Throughout this process, safety is paramount. A rigorous risk assessment is crucial to ensure the safety of personnel and the environment. Proper planning and execution of the repair strategy are essential to minimize downtime and prevent further complications.

Key Topics to Learn for Casing Troubleshooting Protocols Interview

- Casing Design and Integrity: Understanding casing materials, specifications, and their impact on wellbore stability and pressure containment. Practical application: Analyzing casing failure scenarios based on design limitations.

- Pressure Testing and Leak Detection: Mastering various pressure testing methods (e.g., hydrostatic tests, leak-off tests) and interpreting results to identify potential leaks or weaknesses. Practical application: Diagnosing casing leaks based on pressure data and well logs.

- Cementing Operations and Evaluation: Understanding cementing techniques, properties of cement slurries, and evaluating cement bond quality through various logging tools. Practical application: Troubleshooting poor cement bonds leading to casing failures.

- Casing Running and Completion Procedures: Familiarity with standard operating procedures for running and completing casing strings, including safety protocols and best practices. Practical application: Identifying potential issues during casing installation and proposing solutions.

- Troubleshooting Common Casing Problems: Developing systematic approaches for diagnosing and addressing common issues such as casing collapse, corrosion, and perforation problems. Practical application: Formulating effective repair strategies for various casing defects.

- Advanced Wellbore Diagnostics: Utilizing advanced logging techniques (e.g., acoustic logging, cement bond logs) to assess casing condition and identify potential problems. Practical application: Interpreting advanced log data to determine the root cause of casing failures.

- Regulatory Compliance and Safety Procedures: Understanding and adhering to relevant industry regulations and safety protocols for casing operations. Practical application: Ensuring compliance during all phases of casing design, installation, and maintenance.

Next Steps

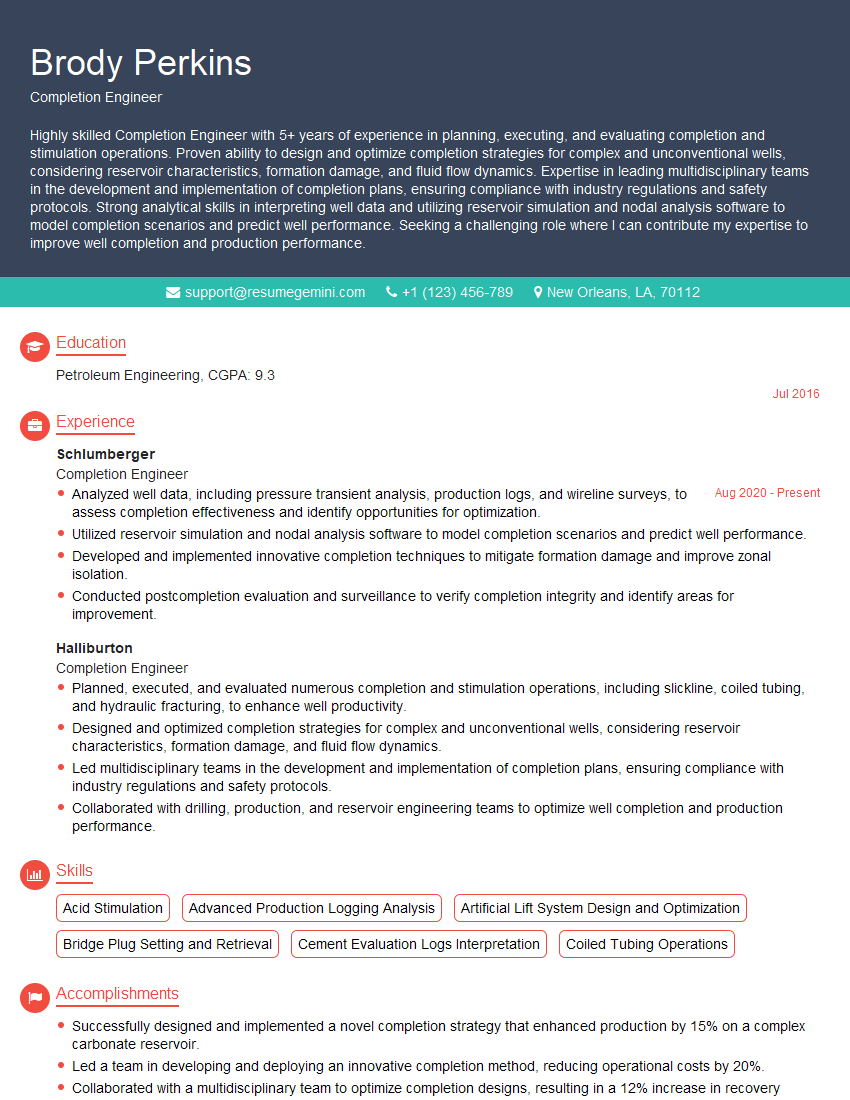

Mastering Casing Troubleshooting Protocols is crucial for career advancement in the oil and gas industry, opening doors to specialized roles and increased earning potential. A well-crafted resume is your key to unlocking these opportunities. To make sure your skills and experience shine, focus on building an ATS-friendly resume that highlights your expertise in this critical area. ResumeGemini is a trusted resource that can help you create a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Casing Troubleshooting Protocols are available for your review to guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good