Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Equipment Operation (e.g., dollies, hand trucks) interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Equipment Operation (e.g., dollies, hand trucks) Interview

Q 1. What are the different types of hand trucks and dollies?

Hand trucks and dollies come in a variety of types, each designed for specific tasks and load capacities. The most common include:

- Two-wheel hand trucks (or sack trucks): These are the most basic, featuring two large wheels and handles for pushing and pulling. They’re great for smaller, manageable loads.

- Four-wheel hand trucks: Offering increased stability, these are suitable for heavier loads and longer distances. They often have a platform for stacking items.

- Appliance dollies: Designed for moving large appliances, these typically have a sturdy platform and straps to secure the load. Some have swiveling casters for easy maneuverability.

- Heavy-duty dollies: Built for extreme weight capacities, these are often found in warehouse and industrial settings. They might have pneumatic tires for rough terrain.

- Specialty dollies: These cater to specific needs, such as furniture dollies (with padded surfaces to protect furniture) or drum dollies (for moving barrels).

The choice depends on the weight, size, and type of load, as well as the terrain.

Q 2. Describe the proper technique for loading and unloading a hand truck.

Proper loading and unloading techniques are crucial for safety and efficiency. Always assess the weight and balance of the load before attempting to move it.

- Loading: Position the load centrally on the hand truck or dolly’s platform. Distribute weight evenly to prevent tipping. For heavy or awkward items, use a lifting technique that avoids straining your back; consider using lifting straps or asking for assistance.

- Securing: Use straps, ropes, or other securing devices to prevent the load from shifting during transport. Always double-check that everything is secure before moving.

- Unloading: Reverse the loading process. Slowly lower the load to the ground, maintaining control and avoiding sudden movements. Again, ask for help if needed, particularly with heavier items.

Imagine moving a heavy box of books – you wouldn’t just shove it on; you’d carefully place it centrally and secure it to prevent it from sliding off during transport.

Q 3. How do you safely maneuver a hand truck around corners and obstacles?

Maneuvering around corners and obstacles requires careful planning and technique. Never rush the process.

- Short, controlled movements: Instead of wide turns, use a series of short pushes and pulls, adjusting your grip as needed. This increases control and reduces the risk of tipping.

- Assess the path: Before starting, check for obstacles like steps, uneven surfaces, or tight spaces. Plan a route that avoids potential hazards.

- Lift and pivot: For sharp corners, consider slightly lifting the front of the hand truck to pivot it more easily. This technique can be especially helpful with heavier loads.

- Use your body weight: Distribute your weight to maintain stability. Lean slightly in the direction of the turn to help guide the hand truck.

Think of it like driving a car – you wouldn’t make a sharp turn at high speed. Smooth, controlled movements are key.

Q 4. What are the weight limits for the hand trucks and dollies you’ve used?

The weight limits vary considerably depending on the type and manufacturer of the hand truck or dolly. I’ve used hand trucks with capacities ranging from 300 lbs to 1500 lbs. Appliance dollies typically have lower weight limits (often 500-800 lbs) while heavy-duty models used in warehouses can exceed 2000 lbs. Always check the manufacturer’s label for the specific weight limit before using any equipment. Exceeding the weight limit is extremely dangerous and can lead to accidents and equipment damage.

Q 5. How do you secure cargo on a hand truck or dolly to prevent shifting?

Securing cargo is vital to prevent shifting and potential accidents. Methods depend on the type of load and hand truck.

- Straps: Ratchet straps are ideal for securing large or irregularly shaped items. Ensure they’re tightly fastened and properly routed to avoid slippage.

- Ropes: Ropes can be used to secure smaller items or to supplement straps. Use appropriate knots and ensure they’re tied securely.

- Blocking: Use blocks of wood or other materials to prevent smaller items from shifting within a larger load. This is particularly useful for loosely packed items.

- Nets: For smaller items, a cargo net can help keep the load contained and prevent it from scattering.

For instance, when moving fragile items on a hand truck, I’d use both straps and padding to prevent damage and shifting.

Q 6. What safety measures do you take when operating hand trucks and dollies?

Safety is paramount when operating hand trucks and dollies. My safety measures include:

- Inspecting equipment before use: Checking for damage, loose parts, and ensuring the wheels are in good working order.

- Wearing appropriate footwear: Sturdy, closed-toe shoes provide good support and protection.

- Using proper lifting techniques: Bending at the knees, keeping the back straight to avoid injury.

- Maintaining awareness of surroundings: Being mindful of other people and potential obstacles.

- Avoiding overloading: Never exceeding the weight limit of the equipment.

- Using appropriate personal protective equipment (PPE) when necessary: Gloves might be used when handling sharp or heavy items.

Following these simple precautions significantly minimizes the risk of accidents and injuries. It’s all about proactive, responsible usage.

Q 7. What do you do if you encounter a damaged hand truck or dolly?

If I encounter a damaged hand truck or dolly, I immediately take it out of service.

- Report the damage: Immediately notify my supervisor or the appropriate personnel about the damage, providing details about the condition and location.

- Tag it as unusable: Place a tag or sign on the damaged equipment to clearly indicate that it’s unsafe to use. This prevents accidental use by others.

- Secure the area: If the damage poses a safety hazard, take steps to secure the area to prevent accidents.

- Do not attempt to repair: Unless I’m specifically trained to repair such equipment, I will not attempt to fix it myself. Repair should be done by qualified personnel.

Ignoring damaged equipment is dangerous and could lead to serious injuries. Reporting it promptly ensures that the problem is addressed and prevents potential accidents.

Q 8. How do you handle different types of loads (e.g., boxes, barrels, pallets)?

Handling diverse loads efficiently requires understanding the load’s characteristics and choosing the appropriate equipment. For instance, lightweight boxes can often be stacked on a two-wheeled hand truck, ensuring the weight is evenly distributed. Heavier, irregularly shaped boxes might necessitate a four-wheeled dolly for better stability. Barrels, due to their cylindrical shape, often require specialized dollies with cradles or straps to secure them properly. Pallets, standardized for forklift use, are best moved with a pallet jack or a heavy-duty platform dolly. In each case, securing the load using straps, rope, or other restraints is critical to prevent shifting or falling during transit.

Example: Imagine moving a stack of heavy books. A two-wheeled hand truck would work well, but I’d carefully distribute the weight to prevent tipping. However, if I were moving a stack of large, unwieldy appliances, I’d opt for a sturdy, four-wheeled dolly, securing the appliances with straps to avoid accidents.

Q 9. Describe your experience using hand trucks/dollies on ramps or inclines.

Maneuvering hand trucks and dollies on ramps or inclines demands extra caution and technique. The steeper the incline, the more challenging it becomes. My approach involves always assessing the incline’s steepness. On gentler slopes, I can usually proceed cautiously, maintaining a firm grip and keeping the load balanced. For steeper inclines, I might need to use a different technique altogether, such as breaking the load into smaller, more manageable portions or possibly requesting assistance. The key is to maintain control and avoid sudden movements that could lead to a loss of balance or an accident.

Example: During a recent move, I encountered a particularly steep ramp. Instead of attempting to transport the entire load at once, I divided it into several smaller trips, ensuring safe movement and preventing the risk of a dangerous fall.

Q 10. How do you prevent accidents or injuries while using hand trucks and dollies?

Preventing accidents when operating hand trucks and dollies involves a multifaceted approach encompassing proper technique, regular inspections, and awareness of surroundings. Always lifting with your legs, keeping your back straight, helps prevent back injuries. Maintaining a firm grip on the handles is paramount, as is ensuring the load is properly secured and balanced. Never overload the equipment beyond its weight capacity, and be mindful of uneven surfaces, obstacles, and sharp turns. Furthermore, wearing appropriate footwear to provide good traction can prevent slips and falls.

- Proper Lifting Techniques: Bend at your knees, keeping your back straight.

- Secure Load: Use straps or other restraints to keep the load stable.

- Regular Inspection: Check wheels, handles, and structure for damage before use.

- Awareness of Surroundings: Pay attention to your path, avoiding obstacles and other people.

Q 11. What is your experience with different types of wheels on hand trucks and dollies?

Hand trucks and dollies come with a variety of wheels, each suited to different surfaces and load capacities. Pneumatic tires, filled with air, offer excellent cushioning and shock absorption on uneven surfaces, but they can be prone to punctures. Hard rubber wheels are more durable and less prone to damage but offer less shock absorption. Polyurethane wheels provide a good balance between cushioning and durability. The choice of wheel often depends on the terrain and the type of load being transported. For example, a hand truck with pneumatic tires would be ideal for moving heavy loads across a bumpy outdoor area, while a dolly with hard rubber wheels might be better suited for smooth indoor surfaces.

Example: I once used a hand truck with pneumatic tires to move heavy equipment across a gravel driveway, where the cushioning was essential to protect both the equipment and my back. On other occasions, hard rubber wheels have been a far better choice when the surface was smooth and even, as they proved far more durable.

Q 12. What is your experience with ergonomic lifting techniques when using hand trucks and dollies?

Ergonomic lifting is critical when using hand trucks and dollies to prevent injuries. It begins with assessing the load’s weight and size before attempting to move it. Always use proper lifting techniques: bend at your knees, keeping your back straight, and lift with your legs. Avoid twisting your body while lifting or moving the load. If the load is too heavy, get assistance. Push rather than pull whenever possible, using your body weight for leverage. Regular breaks can also help prevent fatigue and strain.

Example: If a load is too heavy to lift comfortably by hand, I will utilize a ramp and a dolly to avoid straining my back. I would also break a heavy load into smaller, more manageable portions.

Q 13. Explain the importance of regular inspection of hand trucks and dollies.

Regular inspection is essential for safety and efficiency. A quick pre-use inspection checks for damage to wheels, handles, and the frame. Loose bolts or damaged wheels could lead to accidents. Checking the load capacity and ensuring it matches the load are also critical. Worn-out wheels or a cracked frame could cause malfunctions, posing both safety risks and operational inefficiencies. A regular maintenance schedule ensures these issues are caught early.

Example: Before starting work each day, I always visually inspect the hand truck for any visible damage, such as bent handles, cracked wheels or broken welds. If any problems are found, I immediately report it and don’t use the equipment until it is repaired.

Q 14. How do you choose the right type of hand truck or dolly for a specific job?

Selecting the appropriate hand truck or dolly depends on several factors, including the load’s weight, size, and shape; the distance it needs to be moved; and the terrain. Heavy loads might require a heavy-duty platform dolly, while lighter loads can be handled by a two-wheeled hand truck. Irregularly shaped items necessitate dollies with secure straps or cradles. For long distances or uneven terrain, pneumatic tires are beneficial. Smooth surfaces might be better served by hard rubber wheels. Always check the load capacity of the equipment before use.

Example: For moving heavy boxes across a warehouse with smooth floors, I might select a four-wheeled, heavy-duty dolly with hard rubber wheels. For lighter boxes across a rougher, uneven surface, a two-wheeled hand truck with pneumatic tires might be a better choice.

Q 15. What are the common causes of accidents involving hand trucks and dollies?

Accidents involving hand trucks and dollies stem from a combination of factors, often preventable with proper training and adherence to safety protocols. Common causes include:

- Improper Lifting Techniques: Lifting heavy loads incorrectly strains muscles and increases the risk of back injuries, slips, and falls. This often involves lifting with the back instead of the legs.

- Uneven Loads: Unbalanced loads can cause the hand truck or dolly to tip, leading to injuries or damage to property. Imagine trying to balance a stack of books precariously on a dolly – it’s a recipe for disaster!

- Obstructions and Slippery Surfaces: Uneven floors, wet surfaces, or obstacles in the path create hazardous conditions. A simple spill can become a major hazard if not cleaned up immediately.

- Poor Wheel Condition: Damaged or improperly inflated wheels reduce maneuverability and stability, increasing the chances of accidents. Think of a bicycle with flat tires – much harder to control.

- Lack of Training and Awareness: Operators unfamiliar with safe operating procedures are more prone to errors. Proper training is paramount.

- Overloading: Exceeding the weight capacity of the equipment leads to instability and potential structural failure. Always check the weight limits clearly marked on the equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain proper posture while operating hand trucks and dollies?

Maintaining proper posture is crucial for preventing injuries. Think of it as a three-point system:

- Feet: Keep your feet shoulder-width apart for a stable base.

- Back: Keep your back straight, avoiding bending at the waist. Engage your core muscles for support. Imagine a straight line from your head to your hips.

- Grip: Keep a firm grip on the handles, avoiding sudden jerky movements. Keep your arms close to your body.

Before lifting, position yourself close to the load. Bend your knees and use your leg muscles to lift, keeping the load close to your body. Avoid twisting your torso while lifting. Always push, rather than pull, whenever possible. This minimizes strain and keeps the load under control. Take breaks when needed, and avoid lifting loads beyond your capacity.

Q 17. What are the regulations and safety guidelines for operating hand trucks and dollies?

Regulations and safety guidelines for hand truck and dolly operation vary depending on location and industry, but common themes include:

- Proper Training: Employers are often legally obligated to provide training on safe operation techniques.

- Load Limits: Never exceed the weight capacity of the equipment. This information is typically found on a label attached to the equipment.

- Personal Protective Equipment (PPE): Safety shoes, gloves, and sometimes back supports may be required depending on the job and potential hazards.

- Inspection: Regularly inspect hand trucks and dollies for damage. Wheels, handles, and structural integrity should be checked for any wear or tear that could compromise stability and safety.

- Workplace Safety: Maintaining a clear and unobstructed path is essential to prevent accidents. Proper lighting is also vital.

Compliance with OSHA (Occupational Safety and Health Administration) regulations or equivalent local standards is vital. These regulations often address workplace safety measures relating to equipment operation. It’s always best to check for specific guidelines applicable to your workplace and industry.

Q 18. Describe a time you had to solve a problem related to hand truck/dolly operation.

In a previous role, we were moving heavy equipment during a facility relocation. One of the dollies developed a wobbly wheel, making it extremely difficult and risky to navigate the tight corridors. Instead of attempting to use it as is, which risked damage to the equipment and injuries to my colleagues, I immediately reported the issue to my supervisor. We then secured a replacement dolly. In the meantime, to avoid delays, I assisted in moving the lighter pieces of equipment using the other available dollies and hand trucks while adhering strictly to safety protocols. This ensured the safety of everyone involved and demonstrated a problem-solving approach prioritizing safety above all.

Q 19. What is your experience with using hand trucks/dollies in a fast-paced environment?

I have extensive experience operating hand trucks and dollies in fast-paced warehouse and distribution center environments. Efficiency is key, but it never comes at the cost of safety. In these situations, my strategies focus on organized workflows, pre-planning routes, and teamwork. I’ve learned to anticipate bottlenecks, and to coordinate with colleagues to ensure smooth material flow. Clear communication regarding load distribution and movement is also very important to avoid accidents in a busy setting. The focus is always on quick but safe operation.

Q 20. How do you prioritize safety when working under pressure?

Prioritizing safety under pressure is paramount. My approach involves several key steps:

- Risk Assessment: Quickly assessing the situation and identifying potential hazards is the first step. This means noticing obstacles, considering the weight and balance of loads, and evaluating the condition of the equipment.

- Procedural Adherence: Even under pressure, adhering to established safety procedures is non-negotiable. This may involve taking a few extra seconds to double-check your route or to ensure a balanced load, but that extra time is a worthwhile investment in safety.

- Communication: Clear and open communication with colleagues is vital. If a situation feels unsafe, speak up. This is paramount for teamwork in a fast-paced setting.

Remember, a minor delay caused by prioritizing safety is always better than a major incident resulting from rushing.

Q 21. What are your strategies for efficient hand truck/dolly operation?

Efficient hand truck/dolly operation involves a combination of techniques and planning:

- Route Planning: Before starting, survey the route, checking for obstacles and ensuring a clear path.

- Load Optimization: Distribute the weight evenly to prevent tipping and maintain balance. Consider the center of gravity.

- Proper Technique: Utilize the correct lifting and pushing techniques. Remember to use your leg muscles and keep your back straight. Pushing is always preferred over pulling.

- Equipment Maintenance: Regularly check the equipment for any damage, ensuring wheels are properly inflated, and handles are securely attached.

- Teamwork and Coordination: In team settings, coordinate movements to avoid collisions and maintain smooth workflows.

Efficient operation is about smart planning and execution, resulting in getting the job done safely and quickly. It’s a balance between speed and safety, with safety always taking precedence.

Q 22. How do you adapt your technique when handling unusual or awkwardly shaped loads?

Handling unusual loads requires careful assessment and adaptation. My approach involves first analyzing the load’s shape, weight distribution, and center of gravity. For example, if I’m moving a long, narrow piece of equipment, I’d consider using a longer hand truck or dolly to improve stability and distribute weight evenly. If it’s oddly shaped and prone to tipping, I would secure it with appropriate straps or ropes to prevent shifting during transit. I might also need to recruit a second person for assistance, employing techniques like one person guiding and stabilizing the load while the other maneuvers the hand truck. If the load is particularly heavy or awkward, I’d opt for mechanical equipment like a pallet jack or forklift if available, prioritizing safety over speed.

Imagine moving a large, irregularly shaped piece of furniture. I wouldn’t just shove it onto a standard dolly; I’d first assess its weight distribution and secure it using straps and padding to prevent damage and shifting. Then, I’d choose a dolly that could adequately support its weight and use a slow, controlled movement to prevent accidents.

Q 23. What training have you received on safe hand truck/dolly operation?

My training in safe hand truck and dolly operation includes formal certification courses covering topics such as proper lifting techniques, weight distribution, load securing, pre-trip inspections (checking for loose parts, tire pressure, brake function), and emergency procedures. I’ve also received extensive on-the-job training, guided by experienced colleagues, emphasizing safe practices and the importance of risk assessment before every task. This includes training on recognizing and avoiding hazards like uneven surfaces and cluttered walkways. My training refreshed annually to ensure my knowledge remains current.

Q 24. How would you handle a situation where a hand truck or dolly malfunctions during a task?

If a hand truck or dolly malfunctions during a task – for instance, a wheel breaks or the braking mechanism fails – my immediate response is to stop work immediately and secure the load to prevent any accidents. I would then assess the severity of the malfunction. If it’s a minor issue that can be quickly fixed (e.g., a loose bolt), I might attempt a repair, always prioritizing safety and ensuring the repair is sound. If it’s a significant problem (e.g., a broken wheel), I’d immediately report the incident to my supervisor, obtain a replacement hand truck or dolly, and document the event following company protocol.

For example, if a wheel collapses, I would carefully lower the load to the ground, ensuring it is properly supported, before reporting the issue and getting a replacement. Never attempt to continue using a damaged piece of equipment.

Q 25. What is your experience with different types of hand truck brakes?

I have experience with several types of hand truck brakes, including friction brakes (often found on simple hand trucks), spring-loaded brakes (which automatically engage when the handle is released), and locking brakes (lever-operated mechanisms that firmly lock the wheels). I understand the importance of each brake type in various situations. Friction brakes require more user attention, as they aren’t self-activating, while spring-loaded and locking brakes provide added safety, particularly on inclines or uneven surfaces. The choice of hand truck and its brakes depends on the task and weight being handled. For heavier or more precarious loads, I prefer hand trucks with more robust, reliable brakes.

Q 26. What are your strategies for teamwork when using hand trucks/dollies?

Effective teamwork when using hand trucks or dollies is crucial for safety and efficiency. My strategy emphasizes clear communication, pre-task planning, and the division of labor. Before we start, we discuss the weight, dimensions, and fragility of the load. We decide on the best route and the roles each person will play – one might steer while the other stabilizes the load, especially with awkward shapes or heavy objects. We maintain consistent visual contact and use hand signals to coordinate our movements, ensuring the load moves smoothly and safely. We adjust our technique based on the environment – perhaps one person takes the lead in navigating tight spaces while the other supports the load. Open communication is key; if someone is struggling, we immediately adjust our strategy.

For instance, moving a large appliance requires clear communication on when to turn, where to support, and how to navigate tight corners. One person leads the way while the other makes sure the appliance remains stable.

Q 27. How do you deal with challenging work conditions (e.g., uneven surfaces, tight spaces)?

Challenging work conditions, such as uneven surfaces or tight spaces, require careful planning and adaptation. On uneven surfaces, I take smaller, slower steps, maintaining a firm grip on the hand truck and using extra caution to avoid tipping or sudden movements. In tight spaces, I may need to adjust my grip, take a slightly different route, and work more closely with my team members to maneuver the load effectively. If the conditions are too hazardous, I’d consider using alternative methods or even reporting the issue to prevent accidents. For example, I might consider using a smaller, more maneuverable hand truck for narrow spaces. If the surface is excessively uneven, I might need to use additional support or seek alternative ways to move the load.

Q 28. Describe your understanding of load-bearing capacity and its importance.

Load-bearing capacity is the maximum weight a hand truck or dolly can safely support. Understanding this is paramount, as exceeding the capacity can lead to equipment failure, damage to the load, and serious injury. Before undertaking any task, I always check the load-bearing capacity, usually found on a label on the equipment itself. I carefully weigh the load (or estimate its weight accurately) and ensure that the hand truck or dolly selected has a capacity that is significantly greater to provide a safety margin. For example, I wouldn’t use a hand truck with a 500-pound capacity to move a 450-pound load, especially if the load’s shape makes it top-heavy or unevenly balanced; I’d select a hand truck with a higher capacity to account for these factors. Ignoring load-bearing capacity is a major safety hazard that I always take extremely seriously.

Key Topics to Learn for Equipment Operation (e.g., dollies, hand trucks) Interview

- Safe Operating Procedures: Understanding and adhering to safety regulations for using dollies and hand trucks, including proper lifting techniques and load securing methods.

- Equipment Selection: Choosing the appropriate dolly or hand truck for different loads, considering weight, size, and terrain. Knowing the limitations of each type of equipment.

- Load Balancing and Stability: Distributing weight evenly to prevent tipping or instability. Techniques for maneuvering heavy or awkward loads.

- Maneuvering Techniques: Efficient and safe techniques for navigating tight spaces, corners, and inclines. Understanding how to avoid obstacles and maintain control.

- Maintenance and Inspection: Basic inspection procedures to identify potential mechanical issues (e.g., worn wheels, loose bolts). Knowing when to report equipment problems.

- Problem-Solving Scenarios: Preparing for scenarios involving unexpected challenges (e.g., a jammed wheel, an uneven surface). Demonstrating practical solutions.

- Workplace Safety Regulations: Familiarity with relevant OSHA or company-specific safety protocols regarding material handling.

- Teamwork and Communication: Highlighting experience working collaboratively with colleagues during material handling tasks, including clear communication about load requirements and safety concerns.

Next Steps

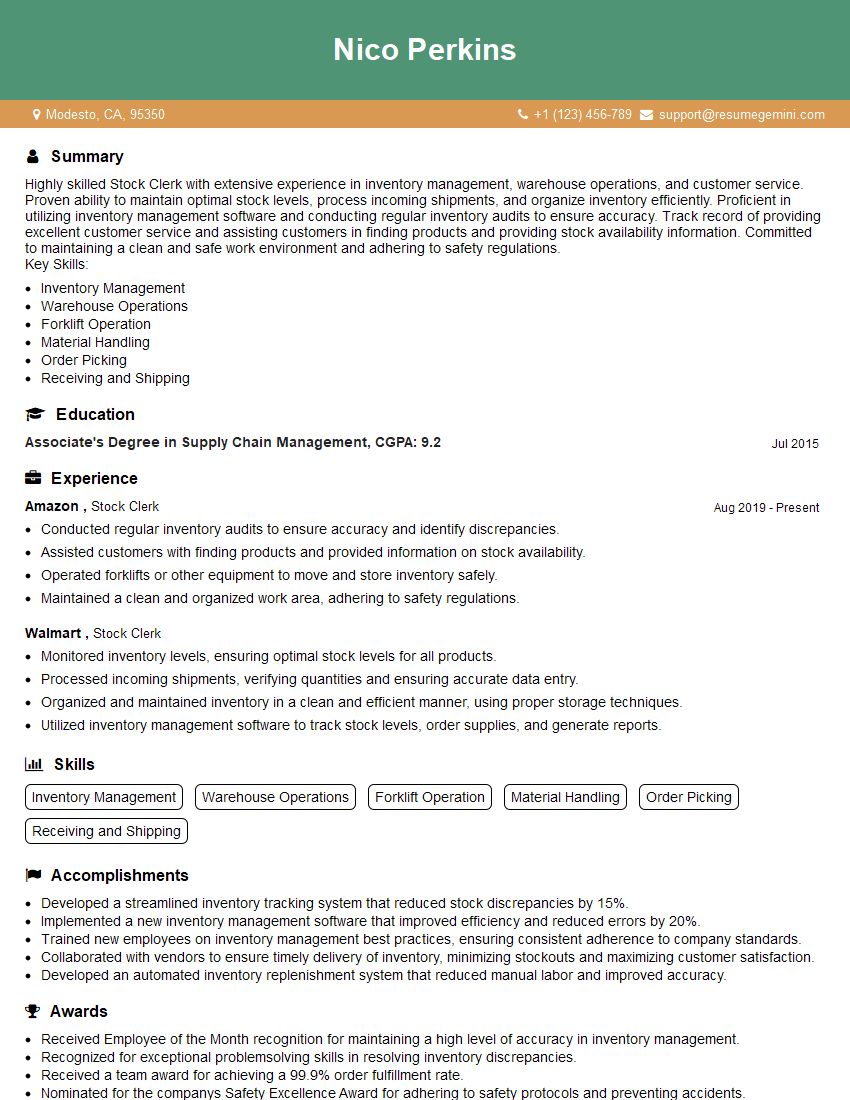

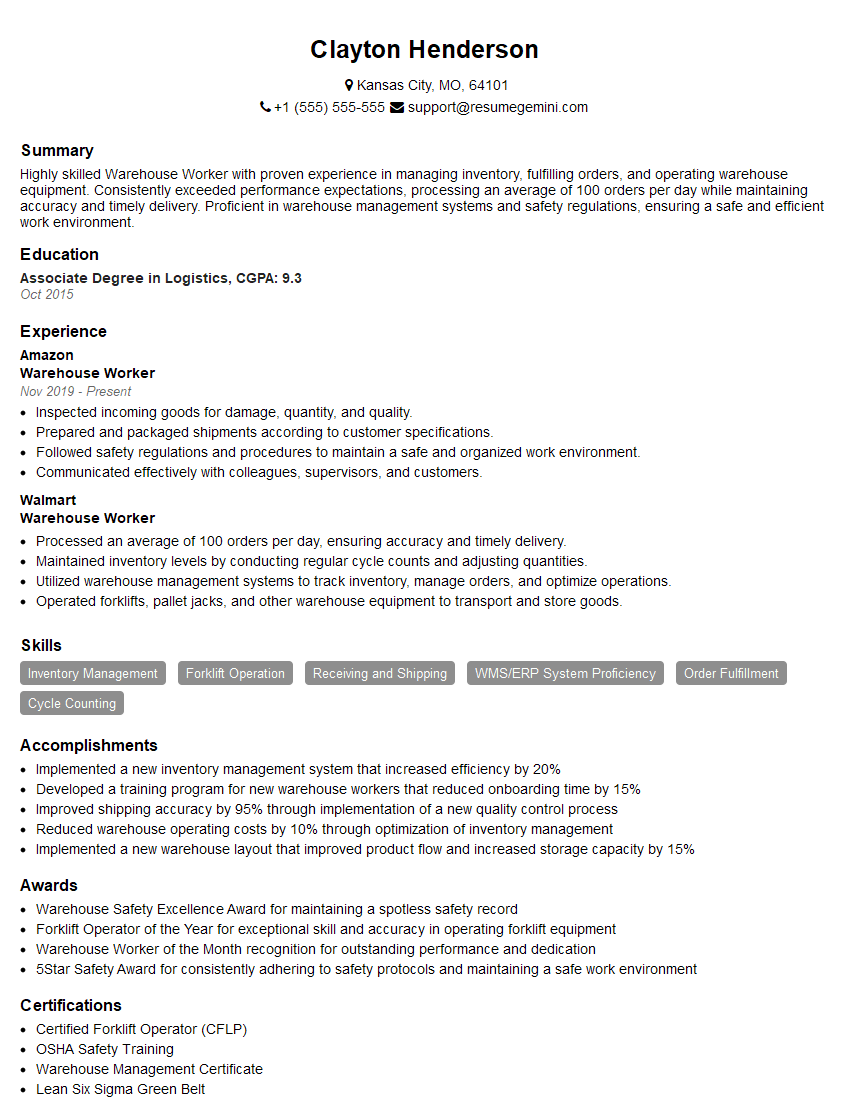

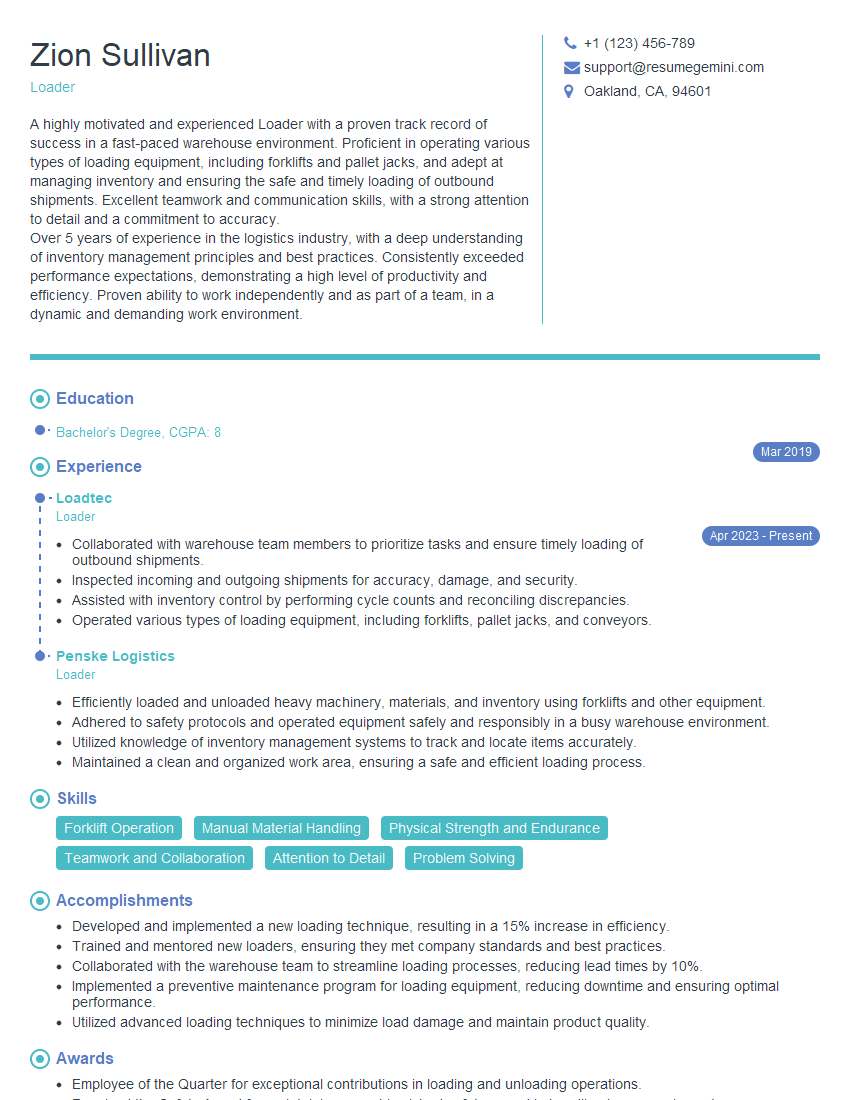

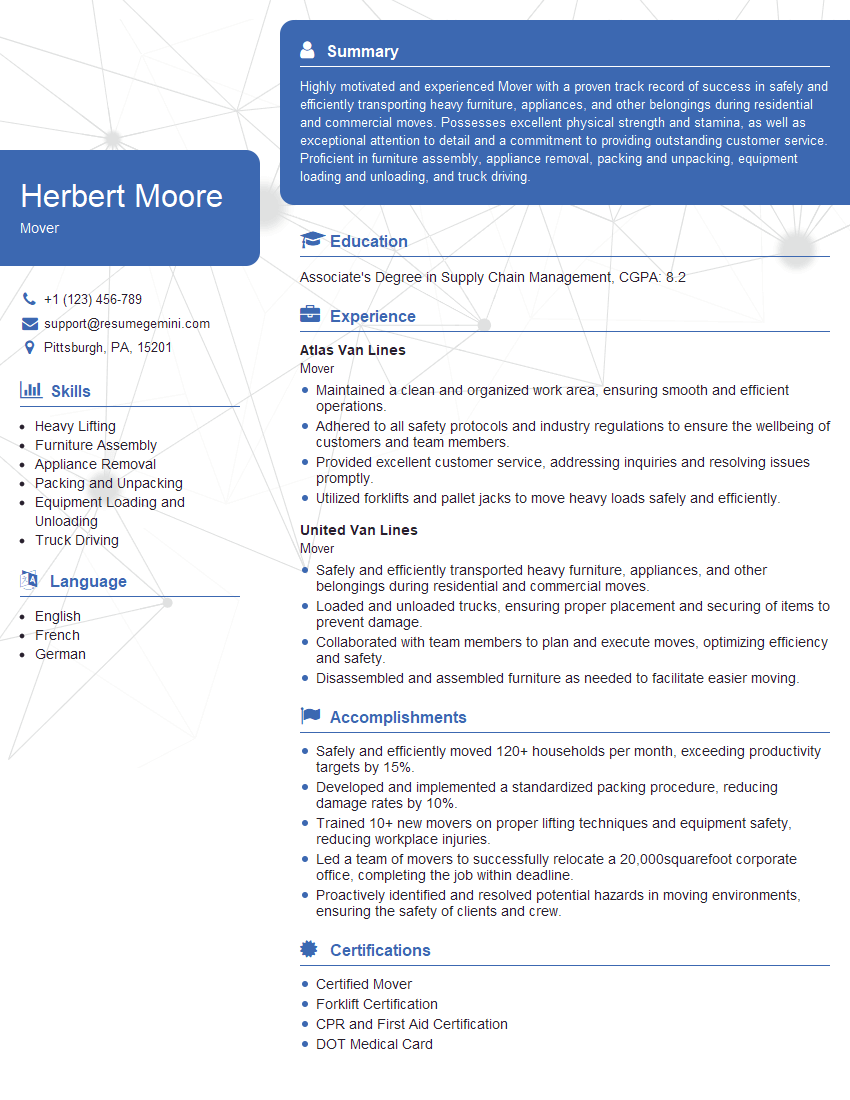

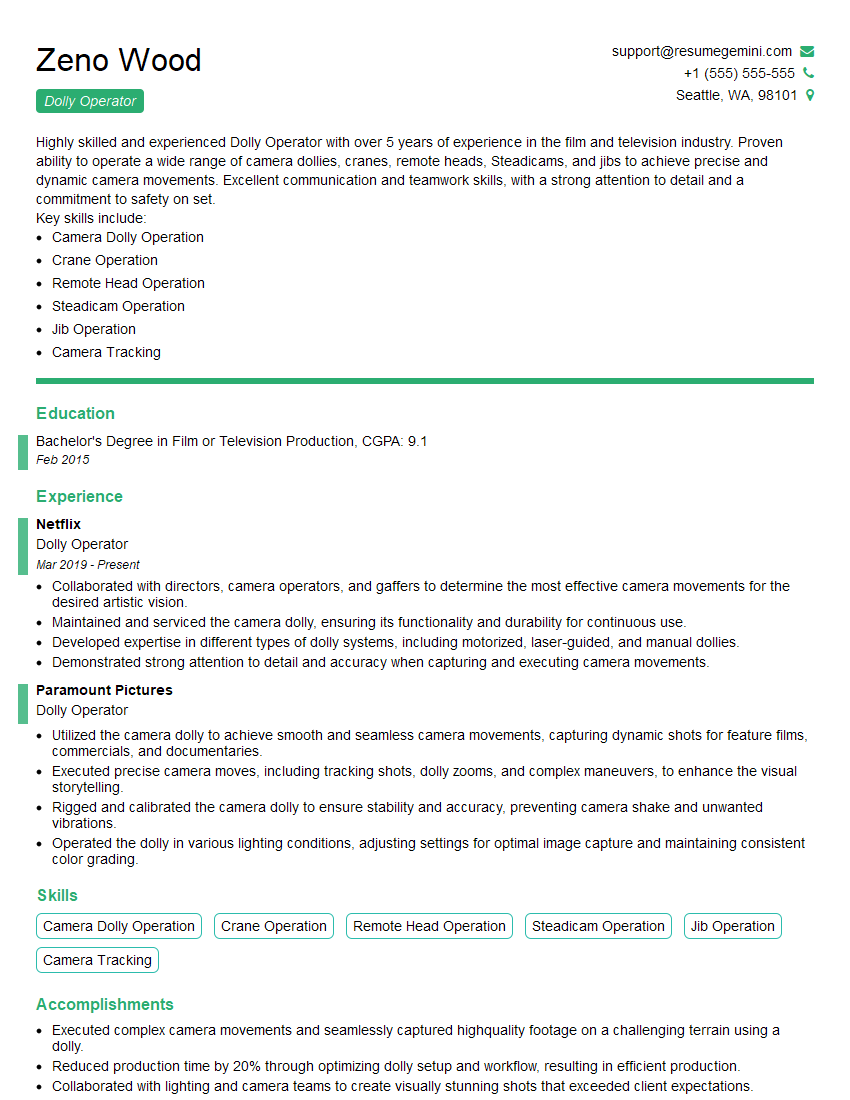

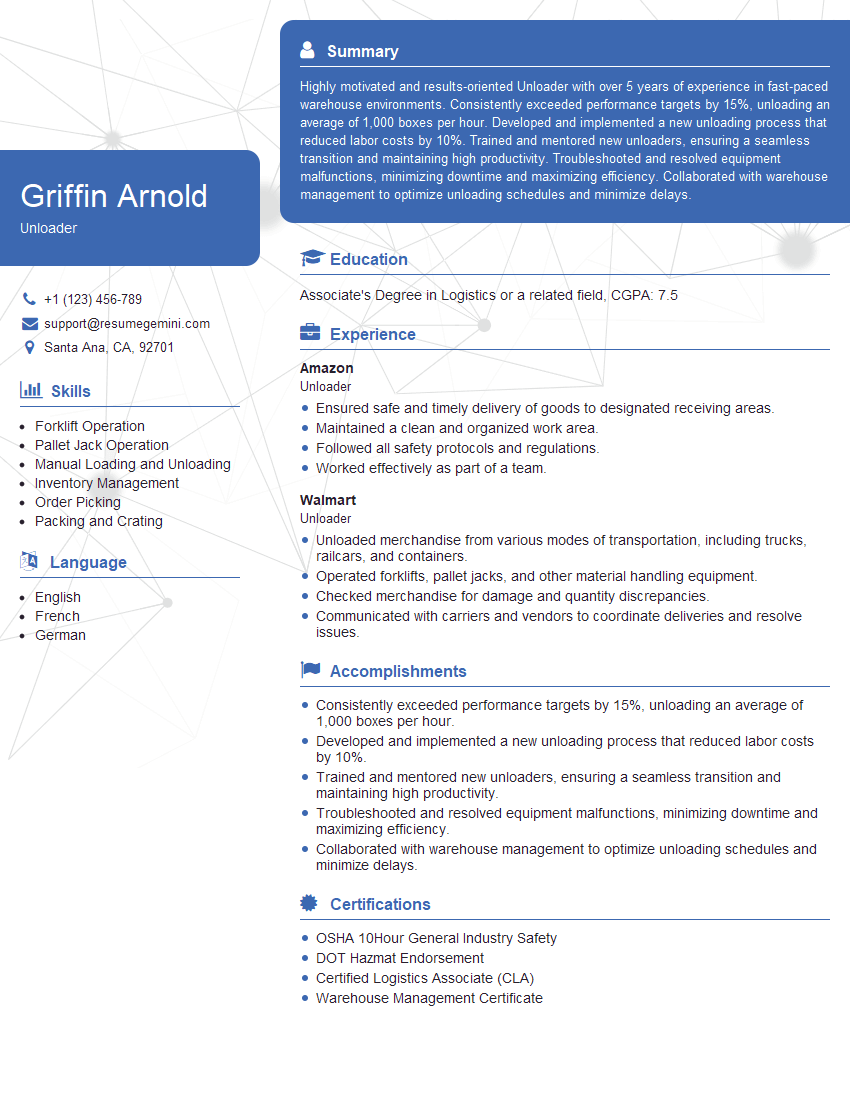

Mastering equipment operation, like using dollies and hand trucks proficiently, is crucial for demonstrating reliability and efficiency in many roles. This skill is highly valued across various industries and can significantly boost your career prospects. To maximize your job search success, it’s essential to create a resume that effectively highlights your abilities to potential employers. Building an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you craft a compelling and effective resume. Examples of resumes tailored specifically to Equipment Operation roles (e.g., using dollies and hand trucks) are available through ResumeGemini to help guide your process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good