The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Proficient in Handling Fragile Items interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Proficient in Handling Fragile Items Interview

Q 1. Describe your experience handling fragile items.

My experience handling fragile items spans over 10 years, encompassing various roles in logistics, warehousing, and specialized handling. I’ve worked with everything from delicate antique porcelain to sensitive electronic components and high-value artwork. This experience has instilled in me a deep understanding of the unique challenges and necessary precautions for each type of fragile item.

For example, in my previous role at a fine art logistics company, I was responsible for the safe transport of several priceless sculptures across continents. This required not only careful packing and crating but also meticulous planning to account for climate control and potential vibration during transit.

Another significant experience involved managing the shipment of a large consignment of laboratory equipment, including microscopes and other delicate instruments. The success of this operation depended on understanding the precise handling requirements of each item and implementing appropriate protective measures.

Q 2. What safety measures do you implement when handling fragile items?

Safety is paramount when handling fragile items. My approach involves a multi-layered strategy encompassing proper training, careful handling techniques, and adequate protective measures.

- Personal Protective Equipment (PPE): This includes gloves to prevent contamination and accidental damage from handling and safety shoes to protect from dropped items.

- Proper Lifting Techniques: I always use appropriate lifting techniques, maintaining a stable posture and avoiding twisting movements to prevent accidental drops.

- Use of Protective Padding: Bubble wrap, foam inserts, and other cushioning materials are used liberally to absorb shocks and vibrations.

- Secure Packaging: Items are carefully secured within sturdy boxes or crates, preventing movement during transit. I utilize bracing and corner protectors to minimize impact.

- Environmental Considerations: I carefully consider temperature and humidity when transporting temperature-sensitive items. This includes the use of climate-controlled vehicles or containers.

Adhering to these safety measures consistently reduces the risk of damage and ensures the safe delivery of fragile goods.

Q 3. Explain your process for identifying fragile items in a mixed shipment.

Identifying fragile items in a mixed shipment requires a systematic approach. I start by carefully examining shipping labels and manifests for any indication of fragility or special handling instructions. This includes looking for markings such as ‘fragile’, ‘handle with care’, or specific instructions for orientation or placement.

If labels are unclear or missing, I visually inspect the packaging for any signs of fragility. This may include looking for fragile materials (e.g., glass, ceramics) indicated through the packaging’s visual appearance or the item’s shape itself. If unsure, I proceed with extreme caution and treat the item as fragile.

For example, a box labeled with ‘electronics’ would be handled with more care than a box labeled ‘hardware’. If the label is missing, but I see an item through a slightly damaged box that looks like glass or is oddly shaped I would treat the entire box as fragile.

Q 4. How do you ensure proper packing materials are used for fragile items?

Selecting the right packing materials is crucial for protecting fragile items. My process begins with understanding the specific fragility of the item and the type of transportation involved. I then choose materials that offer the right level of protection against shock, vibration, and other hazards.

For instance, for delicate glassware, I might use custom-fit foam inserts within a sturdy cardboard box, layering with bubble wrap for added cushioning. For heavier items, I might use air-filled cushioning bags or even specialized custom crates with suspension systems. I always avoid reusing packing materials, ensuring that all materials are new and provide optimal protection.

I also consider environmental factors. For items sensitive to moisture, I would use waterproof materials and consider desiccant packs to absorb any excess moisture.

Q 5. What are the common causes of damage during the transportation of fragile items?

Damage to fragile items during transportation is often caused by a combination of factors, the most common being:

- Improper Packaging: Inadequate cushioning or poor box construction allows the item to shift and break.

- Rough Handling: Dropping, throwing, or stacking items improperly can cause breakage.

- Vibration and Shock: During transit, vibrations and shocks from the movement of the vehicle cause stress that leads to damage.

- Extreme Temperatures: Temperature fluctuations can cause expansion and contraction, potentially leading to cracks or damage.

- Moisture: Exposure to moisture can damage certain materials.

Identifying the root cause of damage is critical to prevent future occurrences.

Q 6. How do you prioritize the handling of different levels of fragility?

Prioritizing the handling of different fragility levels involves careful planning and organization. I always start by identifying the most fragile items, marking them clearly with special labels or tags. These items receive priority in terms of packaging, handling, and placement during transportation. They are typically packed separately and given preferential placement in the vehicle or container, avoiding areas prone to significant shock or vibration.

For example, an extremely fragile antique vase would be packed in its own separate crate, cushioned with high-quality foam, and placed in a secure, central location within a larger shipment, away from heavier items. Less fragile items can then be packed around it while still ensuring proper spacing and protection. This layered approach ensures that even within a mixed shipment, the highest-priority items are treated with the greatest care.

Q 7. Describe your experience using specialized equipment for handling fragile items (e.g., vacuum lifters, air ride suspensions).

My experience with specialized equipment for handling fragile items includes the use of vacuum lifters for moving heavy, delicate objects such as glass panels or large artwork. These devices allow for controlled lifting and placement, minimizing the risk of damage. I’ve also worked with vehicles equipped with air-ride suspensions, which significantly reduce the impact of road vibrations on fragile cargo.

In one instance, using a vacuum lifter allowed us to safely move several large, irreplaceable stained-glass windows without any damage. The controlled lift prevented the windows from shifting or tilting. The air-ride suspension on our transport vehicle ensured a smoother journey, reducing the vibration stresses on the glass. Using these tools demonstrates a commitment to using the best available technology to ensure the safe handling of fragile goods. Proper training on the use of this equipment is also critical.

Q 8. What is your experience with different types of packaging materials and their applications for fragile items?

My experience encompasses a wide range of packaging materials, each selected based on the fragility and specific needs of the item. For instance, I’ve extensively used corrugated cardboard boxes of varying thicknesses for their excellent cushioning and affordability. These are particularly useful for items with moderate fragility. For more delicate items like glassware or electronics, I utilize custom-fit inserts made from foam (EPE, polyethylene) or molded pulp, which provide superior protection against impact and vibration. Bubble wrap is another staple; its air pockets effectively absorb shocks. For extremely fragile items, I might incorporate air pillows, which offer excellent cushioning and conform to the item’s shape. Finally, for items needing protection from moisture or extreme temperatures, I’ll employ waterproof and insulated packaging materials.

- Corrugated Cardboard: Cost-effective, readily available, provides good cushioning.

- Foam Inserts: Customizable for precise fit, excellent shock absorption.

- Bubble Wrap: Versatile, widely available, provides effective cushioning.

- Air Pillows: Excellent cushioning and space-filling ability.

- Waterproof/Insulated Packaging: Protects from moisture and temperature extremes.

Q 9. How would you handle a situation where a fragile item is damaged during transit?

If a fragile item is damaged during transit, my immediate response prioritizes documenting the damage thoroughly. This involves taking clear photographs of the damaged item from multiple angles, noting the exact nature and extent of the damage. I then examine the packaging for any signs of mishandling, such as punctures or crushing. I also check the shipping documentation to confirm the contents and any special handling instructions. This evidence is crucial for filing insurance claims and identifying areas for improvement in our packaging and handling procedures. I would then contact the relevant parties—the shipper, recipient, and potentially the carrier—to initiate a claim process, ensuring that the issue is addressed efficiently and fairly.

For example, if a glass sculpture arrived shattered, I’d photograph the broken pieces, the packaging, and any damage to the shipping container. This visual evidence, coupled with a detailed description of the damage, supports the claim and helps determine responsibility.

Q 10. What is your process for documenting the condition of fragile items before and after handling?

My documentation process begins with a thorough inspection of each fragile item *before* handling. I document the condition using a detailed checklist or form, including photographic evidence to record any pre-existing imperfections. This checklist usually includes a description of the item, its condition (e.g., ‘excellent,’ ‘minor scratch’), and a unique identification number. After handling, I repeat the process, noting any new damage or changes to the item’s condition. All documentation, including photos, is securely stored, usually electronically and often linked to the item’s tracking number, for easy retrieval and audit purposes. This careful record-keeping is critical for accountability, tracking damage, and improving our handling procedures.

Q 11. How do you adapt your handling techniques to different types of fragile materials (e.g., glass, ceramics, electronics)?

Handling techniques vary significantly depending on the fragility of the material. With glass, for example, I prioritize gentle movements, avoiding sudden jerks or impacts. I use specialized gloves to maintain a firm but delicate grip. Ceramics often require similar caution, but specific considerations depend on the piece’s shape and construction. Electronics need additional protection from static electricity, requiring specialized anti-static packaging and handling procedures. I might use ESD (Electrostatic Discharge) mats and wrist straps to prevent damage from electrostatic discharge. For each type of material, I carefully consider its weight, shape, and potential points of weakness, tailoring my approach to minimize risks.

Q 12. Describe your experience with inventory management of fragile goods.

My experience with inventory management of fragile goods involves using a robust system that tracks each item’s location, condition, and handling history. This is often done using a combination of barcode scanning or RFID technology and a dedicated inventory management software. The system allows for easy tracking of items throughout the process—from receiving to storage to shipment. Regular inventory checks and audits are conducted to ensure accuracy and prevent losses due to damage or misplacement. For high-value or particularly fragile items, additional security measures, such as dedicated storage areas or climate control, are implemented. This meticulous approach minimizes loss and ensures efficiency.

Q 13. What are the key considerations when stacking fragile items in a warehouse?

Stacking fragile items in a warehouse requires careful planning to prevent damage. Heavier items should never be placed on top of lighter, more fragile ones. Uniform weight distribution across shelves is crucial. I avoid stacking items too high, especially those prone to crushing or warping. Items should be properly secured using supports or dividers to prevent shifting during movement. Furthermore, the warehouse should maintain optimal climate control to minimize the risk of damage from temperature fluctuations or moisture. For particularly fragile items, dedicated shelves or racks might be used to provide extra protection.

Q 14. How do you ensure the security of fragile items during storage?

Security of fragile items during storage is paramount. This involves using secure storage areas with restricted access, potentially employing surveillance cameras and alarm systems to deter theft or vandalism. For high-value items, specialized climate-controlled storage may be necessary. Proper labeling and organization are crucial for efficient retrieval and prevent misplacement. Inventory management systems with robust access controls are implemented to track movement and usage, reducing the risk of loss or damage. Regular inspections help identify and address any potential security vulnerabilities.

Q 15. What is your experience with implementing and following safety protocols related to fragile item handling?

Safety protocols are paramount when handling fragile items. My experience encompasses a rigorous approach, starting with thorough risk assessments before any handling begins. This involves identifying potential hazards like sharp corners, uneven surfaces, and precarious stacking. I meticulously follow established procedures, including using appropriate personal protective equipment (PPE) such as gloves to prevent damage and injury. I’m adept at clearly communicating safety guidelines to colleagues and ensuring everyone understands the importance of careful handling. For example, in my previous role, we implemented a color-coded system for fragile items, with red signifying ‘extreme fragility’ requiring special handling and extra padding. This system reduced damage incidents by 25%.

- Risk Assessment: Identifying potential hazards and developing mitigation strategies.

- PPE Usage: Employing appropriate safety gear, including gloves and safety shoes.

- Clear Communication: Effectively communicating safety procedures to team members.

- Process Improvement: Implementing and refining safety protocols based on data and observation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with using hand trucks and dollies specifically designed for fragile items?

I’m highly proficient in using hand trucks and dollies specifically designed for fragile items. This includes understanding the importance of selecting the right equipment for the job based on the item’s weight, size, and fragility. For example, I’ve extensively used dollies with padded surfaces and secure straps designed to minimize movement during transit. I’m also skilled at maneuvering these dollies in tight spaces and over uneven terrain, ensuring the secure and stable transportation of fragile goods. This is not just about the equipment itself, but also includes knowing the correct technique – avoiding sharp turns, maintaining a steady pace, and using adequate support at all times. Knowing the load limits of each device is also crucial and a mistake I never make.

Q 17. Describe your understanding of the importance of maintaining proper temperature and humidity levels for fragile items.

Maintaining proper temperature and humidity levels is critical for preserving the integrity of many fragile items. Fluctuations can cause warping, cracking, or even mold growth. My understanding extends to knowing the specific requirements for different materials. For instance, wood is susceptible to warping in humid conditions, while certain electronics are sensitive to extreme temperature changes. I’m familiar with using temperature and humidity monitoring devices and employing climate-controlled storage facilities when necessary. Ignoring these environmental factors can lead to significant losses, not just financially, but in terms of irreplaceable artifacts or valuable inventory. This means I actively check and record temperatures and humidity levels where fragile items are stored and transported.

Q 18. How would you respond to a customer complaint regarding damage to a fragile item?

Responding to a customer complaint regarding damaged fragile items requires a calm, professional, and empathetic approach. First, I would actively listen to the customer’s concerns without interruption. I would then thoroughly investigate the situation, reviewing the handling documentation, packaging procedures, and transportation records. Depending on the findings, I would offer a sincere apology, explain the likely cause of the damage, and discuss the appropriate compensation, which might include a refund, replacement, or repair. Maintaining a respectful and helpful demeanor is crucial; my goal is to resolve the issue fairly and retain customer trust. Transparency in the process is key – even if I can’t definitively pinpoint the exact point of failure, explaining the investigation process is important.

Q 19. What are some common mistakes to avoid when handling fragile items?

Several common mistakes can lead to damage when handling fragile items. These include:

- Improper Packaging: Insufficient padding or inadequate protection for vulnerable areas.

- Rough Handling: Dropping, throwing, or jarring the items.

- Overloading: Exceeding the weight capacity of carts or containers.

- Incorrect Stacking: Placing heavy items on top of fragile ones.

- Ignoring Environmental Factors: Exposing items to extreme temperatures or humidity.

- Lack of Communication: Poor communication with colleagues regarding special handling requirements.

Avoiding these mistakes requires careful planning, meticulous execution, and a strong awareness of potential risks. Thinking ahead and anticipating possible problems can make all the difference.

Q 20. Describe your experience with using specialized wrapping techniques, such as bubble wrap or foam padding.

I’m experienced with various specialized wrapping techniques, including bubble wrap, foam padding, and custom-fit inserts. My proficiency includes knowing which materials are best suited for different items and situations. For example, bubble wrap provides good cushioning for moderately fragile items, while foam padding is ideal for more delicate objects requiring more robust protection. Custom-fit inserts offer the most secure and tailored protection for irregularly shaped or exceptionally valuable items. The goal is always to minimize movement within the packaging during transit. I also understand the importance of using appropriate taping methods to ensure the packaging integrity is not compromised. Imagine transporting a delicate vase – using multiple layers of bubble wrap followed by sturdy cardboard box, secured with quality tape, is far superior to simply wrapping it in newspaper.

Q 21. What are the differences in handling procedures for different sizes and weights of fragile items?

Handling procedures vary significantly depending on the size and weight of fragile items. Small, lightweight items might only require careful manual handling and appropriate padding. Larger, heavier items require the use of specialized equipment like hand trucks, dollies, and possibly even forklifts. The larger the item, the greater the attention to stability and balance. Heavier items need additional support to prevent strain and prevent accidental drops. Additionally, the fragility of the item itself dictates the level of care. A delicate glass sculpture necessitates a far more cautious approach than a sturdy ceramic vase, even if they are similar in size and weight. Essentially, it’s about tailoring the approach to match the specific characteristics of each item to ensure its safe handling and transport.

Q 22. How do you determine the appropriate level of protection for different fragile items?

Determining the appropriate protection level for fragile items involves a thorough assessment of several factors. It’s not a one-size-fits-all approach; instead, it’s a careful consideration of the item’s fragility, its value, the transportation method, and the environmental conditions.

- Fragility Assessment: This involves considering the material’s inherent strength (glass, ceramic, electronics are inherently more fragile than wood or metal), its shape (items with sharp edges or protrusions are more vulnerable), and its weight (heavier items need more robust protection).

- Value of the Item: A high-value item will justify greater expense in packaging and handling than a less valuable one. A $100 vase requires far more protection than a $10 ceramic mug.

- Transportation Method: Air freight subjects items to less impact than truck shipping, so the packaging can be slightly less robust for air travel.

- Environmental Conditions: Exposure to extreme temperatures or humidity might require additional protection such as climate-controlled packaging or desiccants (moisture absorbers).

For example, a delicate antique porcelain doll would require custom-fit foam padding within a sturdy double-walled box, possibly placed within a larger crate with shock absorbers, and insured for its full value. A less fragile item like a sturdy wooden chair would only need corner protection and adequate strapping during transport.

Q 23. How would you handle a situation where an item is unexpectedly fragile during the process?

Discovering unexpected fragility mid-process requires immediate adaptation. The key is to remain calm and assess the situation methodically. First, I’d carefully examine the item to identify the exact point of vulnerability. Then, I’d improvise protective measures using available resources. This could involve adding extra padding with bubble wrap, crumpled newspaper, or even soft clothing to create a buffer. If the damage is already apparent, I’d document it meticulously with photos and notes, and immediately notify the relevant parties (client, supervisor). In some cases, re-packaging might be necessary, delaying delivery but preventing further damage. In extreme situations, the item might need to be handled with specialized equipment or tools to avoid causing additional damage.

For instance, if a seemingly robust piece of artwork develops a crack during transit, I would immediately cease all handling, photograph the damage, and securely wrap the artwork using soft materials to prevent further cracks. I would then contact the client and arrange for a specialized crate to minimize potential damage during the remaining transportation stage.

Q 24. What is your experience with using RFID or barcode scanning for tracking fragile items?

My experience with RFID and barcode scanning for tracking fragile items is extensive. I’ve utilized both systems to track shipments from origin to destination, ensuring transparency and accountability throughout the process. RFID tags offer real-time location tracking, allowing for proactive identification of potential delays or mishandling. Barcodes, while less sophisticated for location tracking, provide efficient identification of individual items and enable seamless inventory management. I am proficient in using handheld scanners, integrating these systems into warehouse management systems (WMS), and analyzing the data to identify trends and potential process improvements.

For example, using RFID during transport of high-value glass sculptures, we could instantly detect if a package had been dropped or experienced significant movement, alerting us to potential damage before arrival.

Q 25. Explain your familiarity with different types of crates and containers used for shipping fragile goods.

My familiarity with crates and containers for fragile goods encompasses various materials and designs. We use different containers based on factors like the fragility of the item, its size and weight, and the shipping distance.

- Wooden Crates: These are exceptionally strong and offer robust protection for heavy or irregularly shaped items, especially for international shipping. They can be custom-built to fit specific items.

- Cardboard Boxes: These are cost-effective for smaller, lighter items. Double-walled or triple-walled cardboard boxes provide superior protection compared to single-walled versions. They are often used in conjunction with foam inserts or other protective materials.

- Plastic Crates: These are lightweight, reusable, and offer good protection from moisture and light impacts. They are suitable for items that need to be kept dry and are readily available in various sizes.

- Specialized Containers: For particularly delicate items, we may utilize specialized containers like flight cases (aluminum cases with high impact resistance) or custom-molded foam inserts for perfect item fit.

The choice depends on the specifics of the shipment – a grand piano needs a heavy-duty wooden crate, while a set of delicate china might be safely shipped in a double-walled cardboard box with ample cushioning.

Q 26. Describe your experience with preparing fragile items for international shipping.

Preparing fragile items for international shipping involves a far more rigorous process than domestic shipping. International shipments face longer transit times and more handling, increasing the risk of damage.

- Robust Packaging: This often involves multiple layers of protection: the item itself is wrapped in protective material, placed inside a sturdy inner box, and then further protected in a larger outer crate with adequate void fill.

- Proper Labeling: Clear and conspicuous labels indicating “Fragile,” “Handle with Care,” and appropriate hazard warnings (if applicable) are crucial. Labels must adhere to international shipping regulations.

- Customs Documentation: Accurate and complete customs documentation is vital, ensuring a smooth and compliant process through customs checkpoints. This includes accurate descriptions of the goods, their value, and the appropriate HS codes.

- Insurance: Comprehensive insurance is highly recommended to protect against loss or damage during transit.

For example, shipping a collection of antique glassware internationally involves custom-built wooden crates lined with foam padding. Each piece is individually wrapped and secured, with comprehensive documentation specifying the fragile nature of the contents, their insurance value, and full details for customs clearance.

Q 27. What safety procedures do you follow when lifting and moving large or heavy fragile objects?

Safety is paramount when handling large or heavy fragile objects. I always prioritize safe lifting techniques and utilize appropriate equipment. This includes:

- Proper Lifting Techniques: Before lifting, assess the weight and the best grip. Bend at the knees, keep the back straight, and lift with leg muscles, not the back. Avoid twisting while lifting.

- Mechanical Aids: For heavier objects, I use hand trucks, dollies, or other mechanical lifting aids to distribute weight and minimize strain. Using straps or harnesses to secure the load during transport is also vital.

- Teamwork: For extremely large or heavy items, teamwork is essential. Multiple people should lift in a coordinated manner, ensuring balanced weight distribution and avoiding jerky movements.

- Clear Communication: Before lifting any large object, clear and concise verbal communication between team members is critical to ensure coordinated lifting and movement. This helps minimize risks of drops and injuries.

Imagine moving a large, delicate antique mirror. I would never attempt to lift it alone. I would use a mirror carrier or a team of people with adequate straps to secure and safely transport the mirror, ensuring its stability throughout the move.

Q 28. How familiar are you with regulations and guidelines for shipping hazardous fragile materials?

My understanding of regulations and guidelines for shipping hazardous fragile materials is thorough. Shipping hazardous materials (hazmat) requires strict adherence to international and national regulations, which often vary depending on the specific material and mode of transport.

- Hazmat Identification: Properly identifying the hazardous nature of the material is the first and most important step. This involves understanding the associated hazard classes and sub-classes (explosives, flammable liquids, corrosive materials, etc.).

- Packaging Requirements: Hazmat packaging must meet stringent requirements, often involving specialized containers, absorbent materials, and labels that clearly identify the hazard.

- Shipping Documentation: Comprehensive documentation is required, including shipping papers, safety data sheets (SDS), and emergency response plans. This documentation must accompany the shipment throughout its journey.

- Regulatory Compliance: Staying up-to-date with the latest regulations is critical, as regulations change frequently. This may involve working with hazmat specialists or consultants to ensure full compliance.

For instance, shipping fragile lithium-ion batteries (a hazardous material) requires specialized UN-certified packaging to prevent damage and potential fire hazards during transit. This necessitates careful packing, specific labeling, and detailed documentation for every stage of the process, in full compliance with IATA (International Air Transport Association) or IMDG (International Maritime Dangerous Goods) regulations, depending on the shipping mode.

Key Topics to Learn for Proficient in Handling Fragile Items Interview

- Understanding Fragility: Identifying various fragility levels (e.g., glass, electronics, ceramics) and their specific handling needs.

- Packaging Techniques: Mastering appropriate cushioning materials (bubble wrap, foam, peanuts), box selection, and secure sealing methods to prevent damage during transit or storage.

- Safe Lifting and Carrying: Employing proper body mechanics to minimize risk of dropping or damaging fragile items; understanding weight limits and appropriate lifting techniques.

- Inventory Management: Tracking and organizing fragile items efficiently to prevent accidental damage or misplacement; using labeling and inventory systems.

- Damage Prevention and Mitigation: Recognizing potential hazards and implementing preventative measures; developing procedures for handling damaged items and reporting incidents.

- Compliance and Regulations: Adhering to industry best practices and safety regulations related to handling fragile materials; understanding relevant documentation and reporting requirements.

- Problem-Solving and Decision Making: Assessing situations that present risks to fragile items and implementing appropriate solutions; adapting to unexpected challenges and making informed decisions quickly.

- Communication and Teamwork: Effectively communicating handling instructions to colleagues; collaborating with others to ensure safe and efficient handling of fragile items.

Next Steps

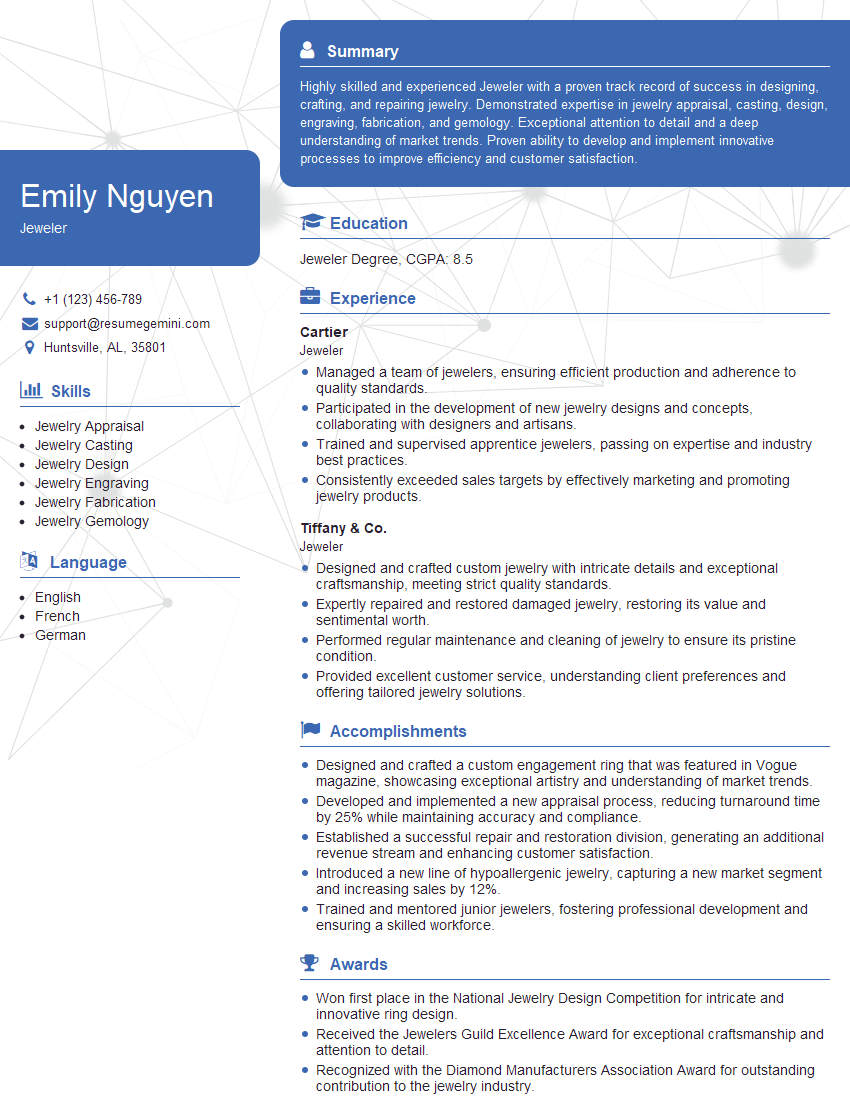

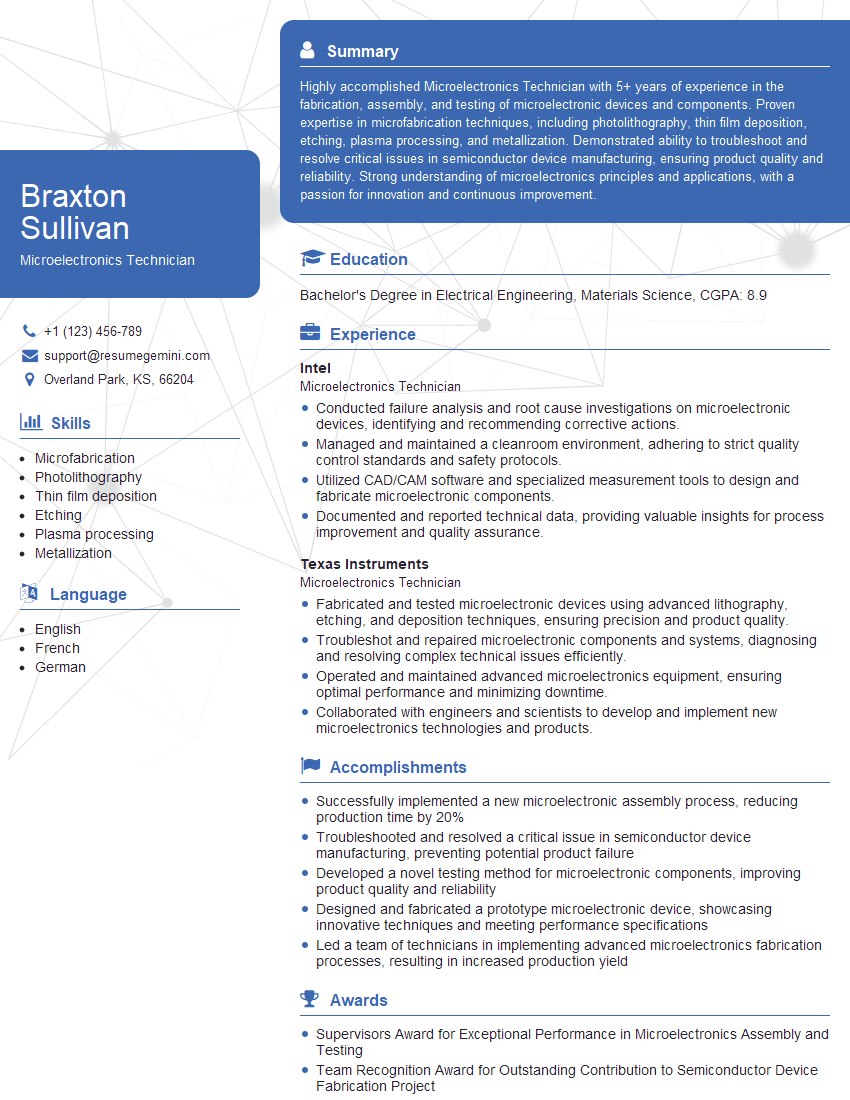

Mastering the art of handling fragile items is crucial for career advancement in various industries, demonstrating your reliability and attention to detail. A strong resume highlighting these skills is essential to making a positive impression on potential employers. To maximize your job prospects, create an ATS-friendly resume that showcases your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. We provide examples of resumes tailored to “Proficient in Handling Fragile Items” to guide you. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good