Preparation is the key to success in any interview. In this post, we’ll explore crucial Experience in Lifting Heavy Objects Correctly interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Experience in Lifting Heavy Objects Correctly Interview

Q 1. Describe the proper lifting techniques you utilize to avoid injury.

Proper lifting techniques are crucial for preventing injuries. My approach centers around minimizing strain on the back and utilizing leg strength. This involves a few key steps:

- Assess the weight and stability of the object: Before even touching it, I gauge its weight and ensure it’s not precariously balanced.

- Get close to the object: Position myself as close as possible to the load, keeping my feet shoulder-width apart for a stable base.

- Bend at the knees and hips: I squat down, keeping my back straight and my spine in a neutral position. Avoid bending only at the waist—this puts immense stress on the lower back.

- Lift with my legs: I use my leg muscles to lift the object, keeping the object close to my body. This prevents twisting and strain.

- Maintain a straight back and neutral spine: Throughout the lift, I consciously maintain a straight back. The object should move smoothly, not in jerky movements.

- Turn with my feet: If I need to change direction, I pivot my feet, not my back, to avoid twisting.

- Set the object down carefully: I use the same technique in reverse to lower the object, controlling its descent with my leg muscles, not my back.

For example, when lifting a heavy box from the floor, I’d first check its weight by attempting a slight lift to see if I can handle it alone. If so, I’d follow the above steps, keeping the box close and lifting smoothly.

Q 2. Explain the importance of maintaining a neutral spine while lifting.

Maintaining a neutral spine is paramount because it distributes the weight evenly across your spinal column. A neutral spine means your spine is aligned naturally—not excessively curved forward (lordosis) or rounded (kyphosis). When lifting with a curved back, the stress concentrates on the discs and vertebrae, increasing the risk of injury such as herniated discs or muscle strains. Think of your spine as a stack of building blocks: a neutral spine keeps them all neatly aligned; a curved spine disrupts this alignment, increasing the risk of one or more blocks shifting or breaking.

For instance, if you attempt to lift a heavy object with your back rounded, the pressure is concentrated on the lower back which can be extremely damaging. Keeping the spine neutral helps prevent such injuries.

Q 3. How do you assess the weight of an object before lifting?

Assessing weight before lifting is a critical safety measure. I use a combination of methods:

- Visual Inspection: I look at the size and apparent density of the object. A small, dense object can be deceivingly heavy.

- Test Lift (if safe): I attempt a very slight lift to get a feel for the object’s weight. This allows me to quickly determine if it’s manageable alone or if assistance is needed.

- Knowing the material: Understanding what the object is made of gives me a general idea of its weight. For example, a metal container will be heavier than a plastic container of the same size.

- Using available scales or weight indicators: Whenever possible I will use tools that quantify the object’s weight.

For example, if I’m unsure about the weight of a large box, I’ll attempt a small lift to get a sense of its mass. If I’m unable to lift it with minimal effort, I’ll either seek help or use lifting equipment.

Q 4. What are the common causes of back injuries related to lifting?

Back injuries from lifting are often caused by a combination of factors:

- Improper Lifting Technique: Bending at the waist, twisting while lifting, and lifting with a rounded back are major culprits.

- Overexertion: Attempting to lift an object that’s too heavy for one person to handle.

- Poor Physical Condition: Weak core muscles, lack of flexibility, and poor posture increase the risk of injury.

- Sudden Movements: Jerky movements or abrupt changes in direction put stress on the back.

- Pre-existing conditions: Individuals with previous back injuries are more susceptible to re-injury.

For example, a worker who constantly bends at the waist to lift boxes will likely develop back problems over time. Similarly, someone lifting an unexpectedly heavy object without proper technique is at significant risk of injury.

Q 5. What steps do you take to ensure a stable base before lifting heavy objects?

A stable base is essential for safe lifting. I ensure stability by:

- Positioning my feet: I place my feet shoulder-width apart, providing a broad base of support.

- Maintaining balance: I ensure I have a solid footing, avoiding uneven or slippery surfaces.

- Using appropriate footwear: I wear shoes with good traction to prevent slipping.

- Keeping the object close: I hold the object close to my body, minimizing leverage and reducing strain.

For instance, before lifting a heavy appliance, I would ensure I’m standing on a flat, stable surface and not on a tilted floor or uneven terrain. I’d also place my feet firmly on the ground to ensure stability.

Q 6. Describe your experience using lifting aids such as dollies or pallet jacks.

I have extensive experience using lifting aids like dollies and pallet jacks. These tools are invaluable for minimizing risk when handling heavy or awkward loads.

- Dollies: Dollies are great for smaller, manageable loads. I ensure the object is properly secured before moving it to prevent tipping or shifting during transportation.

- Pallet Jacks: Pallet jacks are essential for moving heavy pallets. I ensure the forks are properly positioned under the pallet before lifting, and I maintain control during movement. I’m mindful of the weight limits of the equipment itself and never overload the jack.

For example, when moving a heavy refrigerator, I’d use a dolly, making sure to strap it securely to avoid it falling off. With heavy palettes of goods, a pallet jack makes lifting much more efficient and safer.

Q 7. How do you handle an object that is too heavy to lift safely?

If an object is too heavy to lift safely, my first action is to not attempt the lift. Safety always comes first! Instead, I take the following steps:

- Assess the situation: Determine if the object’s size and weight can be safely reduced through disassembly or partial movement.

- Seek assistance: Find colleagues or use a mechanical lifting aid for assistance. Two or more people can often lift loads more safely than one.

- Use proper lifting equipment: Employ mechanical aids like forklifts, cranes, or hoists. Make sure to follow the safety procedures for operating any such device.

- Report the problem: If the object is consistently too heavy or the task repeatedly presents safety challenges, I’ll report it to my supervisor to ensure proper equipment and procedures are implemented.

For example, if I encountered a very large, heavy piece of machinery that needed moving, I would immediately seek assistance from a team or request a forklift to avoid any risk of injury.

Q 8. What are the different types of lifting techniques you are familiar with?

There are several lifting techniques, each tailored to the weight and nature of the object. The most common and safest are variations on the ‘power lift’. This involves maintaining a straight back, bending at the knees and hips, and keeping the load close to the body. Other techniques include:

- Stooping lift: Used for objects close to the ground, involving a slight bend at the knees and hips, keeping the back straight.

- Squat lift: Best for heavier objects, requiring a deeper squat to keep the back straight and lift the weight with leg power.

- Golfer’s lift: Suitable for lightweight objects, involving a twisting motion – generally discouraged for heavier items due to the increased risk of back injury.

- Two-person lift: Essential for excessively heavy loads; involves clear communication and coordinated movement to lift safely.

The choice of technique depends entirely on the object’s weight, size, and shape, along with the lifter’s physical capabilities and the surrounding environment.

Q 9. Explain the concept of center of gravity and its importance in lifting.

The center of gravity (CG) is the point where an object’s weight is balanced. In lifting, understanding the CG is crucial. If the CG is far from your body, it increases the strain on your back. Imagine carrying a heavy box: if it’s off-center, you’ll instinctively lean to counterbalance, stressing your muscles and potentially leading to injury. Keeping the load’s CG as close to your body as possible minimizes strain on your back, shoulders, and legs. This is why proper posture and lifting techniques (keeping the load close) are vital.

For example, when lifting a large sheet of plywood, you’d want to grasp it in a way that keeps its CG centered and close to you. If the plywood’s weight is unevenly distributed, you need to adjust your grip and posture to maintain balance and stability.

Q 10. How do you communicate with others when lifting heavy objects as a team?

Effective communication is paramount in team lifting. Before lifting, we establish clear roles (who lifts which side, who guides, who signals), verbally confirming everyone understands their responsibility. We use clear, concise signals, such as ‘ready,’ ‘lift,’ and ‘down’. Non-verbal cues like eye contact and a steady, synchronized approach also aid in coordination.

During the lift, maintaining consistent communication is vital. If someone encounters difficulty, clear verbal warnings are essential. If a problem occurs, the lift is stopped immediately for reassessment. Post-lift, we always confirm everyone is alright and address any issues. For instance, in a warehouse setting, before moving a heavy pallet, we’d make sure all team members understand the route, any obstacles, and the designated drop-off point. We’d use hand signals and clear verbal commands during the lift and ensure we’re aware of everyone’s position to avoid collisions or mishaps.

Q 11. What are your strategies for preventing workplace accidents related to lifting?

Preventing workplace lifting accidents involves a multi-pronged approach:

- Proper Training: Comprehensive training on safe lifting techniques, including demonstrations, practice, and regular refresher courses.

- Risk Assessment: Identifying potential hazards in the workplace and implementing appropriate control measures (e.g., using mechanical lifting aids for extremely heavy objects).

- Mechanical Aids: Utilizing equipment like forklifts, pallet jacks, and hoists to reduce manual handling whenever possible.

- Ergonomic Design: Ensuring the workplace is designed ergonomically to minimize strain on the body during lifting tasks (proper workstation setups, appropriate tools).

- Pre-lift Check: Checking the load for stability, the path for obstructions, and communication with team members before every lift.

- Regular Inspections: Maintaining lifting equipment regularly to ensure proper functionality and safety.

For example, if we notice that employees consistently struggle with a particular task due to awkward lifting positions, we’d review the job design and potentially introduce new equipment or adjust the layout to improve ergonomics and safety.

Q 12. Describe your experience working with various types of lifting equipment.

My experience encompasses working with a range of lifting equipment, including:

- Forklifts: Operating various types, including counterbalance, reach, and order pickers. Experienced with pre-operational checks, safe operation, and load securement.

- Pallet Jacks: Proficient in maneuvering and operating pallet jacks on various surfaces and navigating tight spaces.

- Overhead Cranes: Familiar with the procedures for operating overhead cranes, including load rating, signaling procedures, and load securing.

- Hoists: Experienced in using different types of hoists, including manual and electric, for lifting and moving heavy objects in various work environments.

For example, I’ve used a forklift to load and unload heavy machinery onto transport trucks, while I’ve used manual hoists for precise placement of large equipment components during construction projects. I always prioritize safety training and adhere to strict operational guidelines before and during the operation of each piece of equipment.

Q 13. How do you adapt your lifting techniques to different environments and conditions?

Adapting lifting techniques to different environments demands careful observation and adjustment. Factors include:

- Surface Conditions: Uneven ground necessitates extra caution and a stable footing. I might need to adjust my stance or use additional support.

- Weather Conditions: Rain or snow can affect footing. I adapt by wearing appropriate footwear and taking extra precautions.

- Space Constraints: Tight spaces require more careful maneuvering and potential adjustments to lifting techniques to avoid collisions.

- Environmental Hazards: Presence of obstacles, electrical wires, or hazardous materials necessitates adapting the route, lifting method, or using protective equipment.

For instance, while lifting a heavy object in a confined space, I would ensure my footing is secure, use smaller steps to prevent swaying, and make sure there’s no risk of the load hitting any obstructions. In icy conditions, I’d reduce the load weight and use anti-slip footwear to ensure a secure footing before attempting any lift.

Q 14. How do you identify potential hazards before lifting?

Identifying hazards before lifting involves a systematic approach:

- Visual Inspection: Thoroughly examine the object, ensuring it is stable and evenly distributed, checking for any damage or weak points.

- Path Assessment: Check the path from origin to destination for any obstructions, uneven surfaces, slippery areas, or environmental hazards.

- Load Assessment: Assess the weight and size of the object, determining whether it’s within my capabilities or requires assistance or mechanical aids.

- Environmental Factors: Consider weather conditions, space constraints, and the presence of any hazards (electrical wiring, overhead obstacles).

- Team Communication: Communicate with any team members involved, clearly defining roles and responsibilities.

For example, before attempting to lift a heavy box in a cluttered warehouse, I’d clear the path of obstacles, ensure the floor is even and safe to walk on, and if the box is too heavy, I’d call for assistance or a forklift. A thorough pre-lift check minimizes accidents and enhances overall safety.

Q 15. What are the signs and symptoms of a musculoskeletal injury related to lifting?

Musculoskeletal injuries from lifting often manifest gradually, starting with aches and stiffness. However, acute injuries can also occur. Signs and symptoms can include:

- Pain: This can range from mild soreness to sharp, debilitating pain in the back, neck, shoulders, arms, or legs. The location depends on the specific injury.

- Stiffness: Difficulty moving or a feeling of tightness in the affected area is common.

- Swelling: Inflammation may cause noticeable swelling around the joint or muscle.

- Weakness: Reduced strength or ability to lift or move the injured area.

- Numbness or Tingling: This can be a sign of nerve involvement.

- Limited Range of Motion: Inability to fully bend, stretch, or rotate the affected joint.

- Muscle Spasms: Involuntary muscle contractions can cause significant pain and discomfort.

- Inflammation: Redness and warmth around the affected area are also possible indicators of inflammation.

It’s crucial to note that these symptoms can vary widely depending on the severity and type of injury. If you experience any of these, seeking medical attention is vital to prevent long-term complications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the employer’s responsibilities regarding lifting safety?

Employers have a legal and ethical responsibility to provide a safe working environment, including implementing measures to prevent musculoskeletal injuries related to lifting. This includes:

- Providing training: Employers must offer comprehensive training on proper lifting techniques, risk assessment, and the use of assistive devices.

- Risk assessment: Regularly assessing workplaces to identify and mitigate lifting hazards is essential. This includes evaluating the weight of objects, distances to be carried, and the physical demands of the job.

- Providing appropriate equipment: Employers should supply lifting aids such as hoists, dollies, and ergonomic equipment to reduce the strain on employees.

- Implementing mechanical lifting devices: Wherever feasible, employers should utilize mechanical lifting devices to eliminate manual handling altogether.

- Promoting ergonomic design: Workspaces should be designed ergonomically to minimize awkward postures and repetitive movements.

- Establishing clear procedures: Safe lifting procedures must be documented and communicated clearly to all employees.

- Monitoring and evaluating: Regular monitoring of employee health and safety is crucial, including tracking injury rates and identifying areas for improvement.

Failure to comply with these responsibilities can result in significant legal and financial consequences.

Q 17. What are the employee’s responsibilities regarding lifting safety?

Employees also play a vital role in preventing lifting-related injuries. Their responsibilities include:

- Following training and procedures: Adhering to the employer’s provided training on safe lifting techniques is paramount.

- Reporting hazards: Promptly reporting any unsafe conditions or equipment to their supervisor is critical.

- Using lifting aids: Employees must utilize provided equipment such as hoists or dollies when lifting heavy objects.

- Communicating limitations: If an employee feels a lift is beyond their physical capabilities, they should immediately report it and request assistance.

- Maintaining good physical condition: Regular exercise and maintaining a healthy weight can improve strength and reduce the risk of injury.

- Using proper body mechanics: Always employing correct posture and lifting techniques is essential.

- Seeking medical attention: Employees should seek medical help promptly if they experience any pain or discomfort after a lifting incident.

A proactive approach to safety is a shared responsibility between employer and employee, contributing to a safer and more productive work environment.

Q 18. How do you perform a pre-lift assessment?

A pre-lift assessment is crucial for preventing injuries. It involves systematically evaluating the lifting task before attempting it. Here’s a step-by-step approach:

- Assess the load: Determine the weight, size, shape, and stability of the object. Is it awkward to handle?

- Analyze the path: Examine the route you’ll take, checking for obstacles, uneven surfaces, or slippery conditions.

- Evaluate your capabilities: Consider your own physical strength and limitations. Are there any health conditions that might affect your ability to lift safely?

- Check for assistance: If the object is too heavy or awkward, request assistance from a colleague or utilize available equipment.

- Assess the environment: Is the environment well-lit and free of obstructions? Is there adequate space to maneuver?

- Plan your lift: Visualize the lift and plan your movements to minimize strain. Think about your stance, grip, and the path you’ll take.

For example, if you’re moving a heavy box across a room, assess its weight, check the floor for obstructions, and ensure you have a clear path before lifting. If the box is too heavy, find a hand truck or ask for assistance.

Q 19. How do you handle unexpected situations or obstacles during lifting?

Unexpected situations during a lift demand immediate and safe responses. Here are some strategies:

- Lower the load slowly and carefully: If you encounter an unexpected obstacle or feel unstable, carefully lower the load to the ground rather than risking a drop or injury.

- Adjust your grip and posture: If the object shifts unexpectedly, make slight adjustments to your grip and posture to maintain control.

- Seek assistance: Don’t hesitate to ask for help if you encounter a problem beyond your ability to manage safely.

- Re-assess and replan: Once the immediate situation is resolved, reassess the lift and re-plan your approach, taking into account the unexpected obstacle or issue.

- Report the incident: Report any near misses or incidents to your supervisor to improve safety procedures and prevent future occurrences.

Imagine you’re lifting a box and suddenly the floor becomes unexpectedly slippery. You should immediately lower the box, adjust your footing, and potentially ask for assistance before attempting the lift again. Reporting the slippery floor to your supervisor would also prevent similar accidents in the future.

Q 20. What is your experience with using personal protective equipment (PPE) while lifting?

Personal Protective Equipment (PPE) plays a vital role in minimizing the risk of injury while lifting. My experience includes using:

- Gloves: To improve grip and protect hands from abrasions or cuts. Different gloves are suitable for varying tasks and materials.

- Safety shoes: Steel-toe safety boots are crucial for protecting feet from dropped objects or crushing hazards.

- Back supports: Lumbar support belts can provide additional stability and reduce strain on the lower back, but they are not a replacement for proper lifting techniques.

- Lifting belts: Specialized lifting belts can assist with some heavy lifts, but should only be used with proper training and supervision.

It’s critical to remember that PPE is a supplement, not a replacement, for proper lifting techniques. Even with PPE, adhering to correct lifting methods is essential to prevent injuries.

Q 21. What is your understanding of workplace safety regulations related to lifting?

My understanding of workplace safety regulations related to lifting is comprehensive. These regulations often cover aspects such as:

- Manual Handling Regulations: These regulations require employers to assess and control risks associated with manual handling, including lifting. They emphasize risk reduction through training, equipment, and the implementation of safe working practices.

- Occupational Safety and Health Administration (OSHA) standards (if applicable): These standards, or their equivalents in different jurisdictions, provide detailed guidelines for workplace safety, including requirements related to lifting, ergonomics, and the use of PPE.

- Specific industry regulations: Certain industries, like construction or warehousing, might have additional regulations that address specific lifting hazards within those sectors.

- Reporting requirements: Regulations usually mandate reporting procedures for lifting-related injuries or near misses. This data is crucial for identifying trends and implementing preventative measures.

Staying updated on the latest regulations and best practices is crucial for ensuring a safe and compliant work environment. Regular training and adherence to these regulations are vital in minimizing lifting-related injuries.

Q 22. Describe a time you had to lift a particularly heavy or awkward object.

During my time as a warehouse manager, we received a shipment of industrial machinery. One component, a large cast iron gear, weighed well over 300 pounds and was exceptionally awkward to maneuver due to its irregular shape. It had no easy lifting points, making it a significant challenge. I coordinated a team lift, ensuring everyone understood their roles and the weight distribution. We used a heavy-duty pallet jack to initially move it, then employed straps and teamwork to carefully tilt and lift it onto a stand. The whole operation required meticulous planning and flawless execution to avoid injury.

Q 23. What measures do you take to prevent repetitive strain injuries?

Preventing repetitive strain injuries (RSIs) is paramount in my line of work. My approach is multi-faceted. First, I prioritize proper lifting techniques in every task, as described in my answer to question 3. Second, I ensure adequate rest and recovery periods during work shifts, avoiding prolonged periods of strenuous lifting. I also incorporate regular stretching and strengthening exercises to improve muscle endurance and flexibility. This includes targeted exercises for the back, shoulders, and legs. Finally, I utilize ergonomic tools and equipment whenever possible—such as appropriately sized carts, dollies, and lifting aids—to reduce strain on the body. Proper posture and taking breaks are equally crucial.

Q 24. Describe your understanding of proper body mechanics during lifting.

Proper body mechanics in lifting involve a coordinated approach that minimizes strain on the spine and other joints. Imagine lifting a heavy box. The key principles are:

- Assess the Load: Check the weight and ensure you can safely lift it. If unsure, get assistance.

- Get Close: Position yourself as close to the object as possible.

- Bend Your Knees: Keep your back straight and bend at your knees and hips, lowering your center of gravity.

- Lift with Your Legs: Use your leg muscles to lift the object, straightening your legs while keeping your back straight.

- Keep it Close: Hold the object close to your body throughout the lift.

- Maintain a Stable Base: Keep your feet shoulder-width apart for a wide, stable base of support.

- Avoid Twisting: Turn your whole body instead of twisting at the waist.

- Set it Down Carefully: Use your legs to lower the object smoothly, avoiding sudden movements.

Think of it like this: your legs are the powerful engines, your core is the stabilizing chassis, and your back is the delicate cargo. Don’t overburden your cargo!

Q 25. What types of training have you received on safe lifting techniques?

I’ve received extensive training on safe lifting techniques through various channels. Initially, I completed a comprehensive OSHA (Occupational Safety and Health Administration) course specifically on material handling and lifting. This covered various lifting methodologies, risk assessment, and emergency response procedures. I’ve also undergone company-specific training, which focused on our particular equipment and operating procedures. Regular refresher courses and on-the-job coaching from senior supervisors have reinforced and updated my knowledge over the years. Furthermore, I’ve attended workshops on ergonomics and injury prevention.

Q 26. How do you handle objects that are difficult to grasp?

Handling objects with poor grasp points requires careful planning and the use of appropriate tools. I would first assess the object’s shape, weight, and material to determine the safest handling method. This could involve using gloves with improved grip, lifting straps, or specialized gripping equipment. For example, if dealing with a cylindrical object that’s difficult to hold, I might wrap it securely with a lifting strap to provide better control and distribute the weight more evenly. Using additional personnel and teamwork is vital in such situations.

Q 27. How would you handle an emergency situation if someone is injured during lifting?

In an emergency situation where someone is injured during lifting, the priority is immediate action to minimize further harm. I would first assess the scene for any immediate dangers. Then:

- Call for Emergency Services: Contact emergency medical services (EMS) immediately.

- Secure the Scene: Ensure the area is safe to prevent further accidents.

- Provide First Aid: Administer first aid as appropriate, if I’m qualified.

- Preserve Evidence: Note details of the incident, including witness accounts and details about the object being lifted.

- Follow Company Protocol: Comply with the established injury reporting procedures of the company.

Remember, your first priority is the injured person’s safety and well-being.

Q 28. Explain the importance of reporting any lifting-related injuries or near misses.

Reporting all lifting-related injuries and near misses is crucial for several reasons. First, it allows for prompt medical attention for injured workers. Second, it helps identify potential hazards and weaknesses in safety procedures. By analyzing reported incidents, we can proactively implement corrective actions to prevent future occurrences. Third, thorough reporting contributes to the creation of a safer work environment for everyone. Failing to report incidents prevents the opportunity to learn from mistakes and improve safety practices. It’s a vital component of a proactive safety culture.

Key Topics to Learn for Experience in Lifting Heavy Objects Correctly Interview

- Understanding Body Mechanics: Learn the principles of proper posture, leverage, and weight distribution to minimize strain and risk of injury when lifting.

- Lifting Techniques: Master various lifting techniques, including the squat lift, power lift, and deadlift, adapting them to different object shapes, weights, and environments.

- Assessing the Load: Discuss methods for evaluating the weight and stability of an object before attempting to lift it, including identifying potential hazards.

- Using Lifting Aids: Explain the safe and effective use of various lifting aids, such as hand trucks, dollies, hoists, and lifting straps, and when to utilize them.

- Safety Procedures and Regulations: Familiarize yourself with relevant workplace safety regulations and procedures concerning heavy object lifting, including reporting procedures for incidents.

- Preventing Injuries: Discuss common causes of lifting injuries (back pain, strains, sprains) and preventative measures, such as stretching and warm-up routines.

- Team Lifting Techniques: Describe safe and efficient collaborative lifting strategies for extremely heavy or awkwardly shaped objects.

- Situational Awareness and Adaptability: Explain how to adjust lifting techniques based on the specific environment (e.g., uneven surfaces, confined spaces).

Next Steps

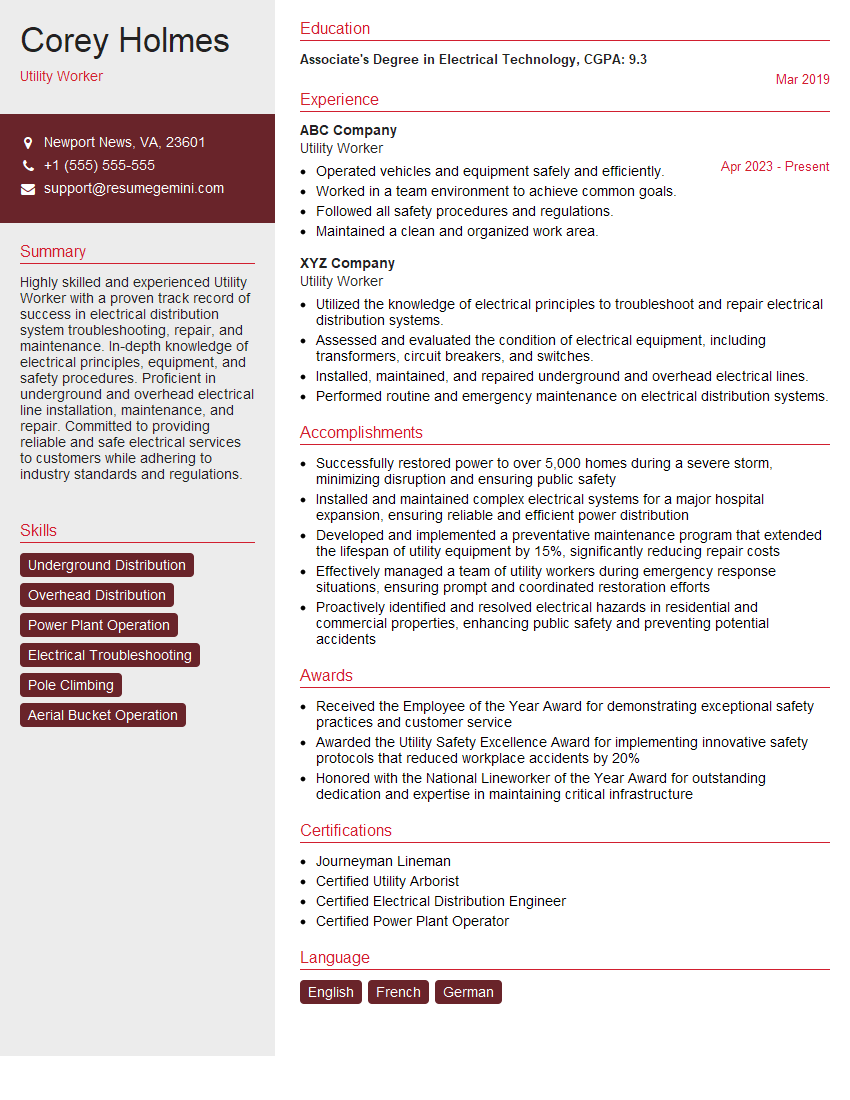

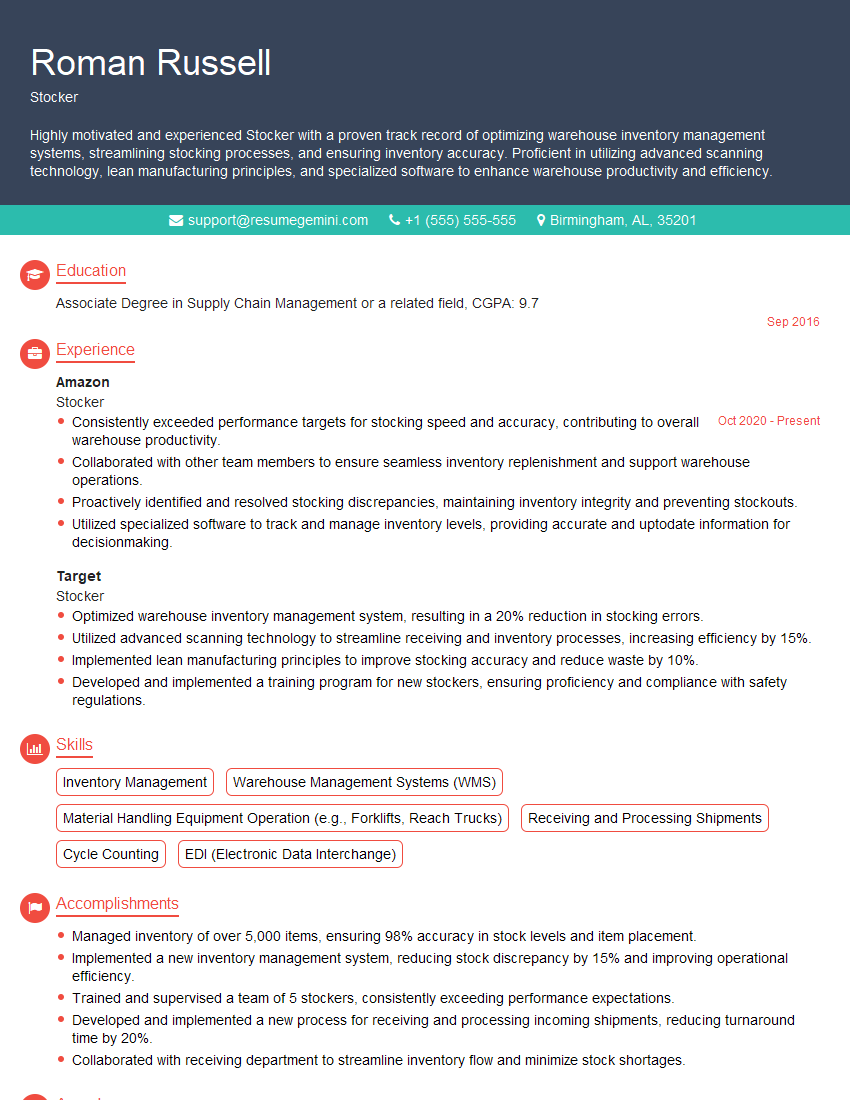

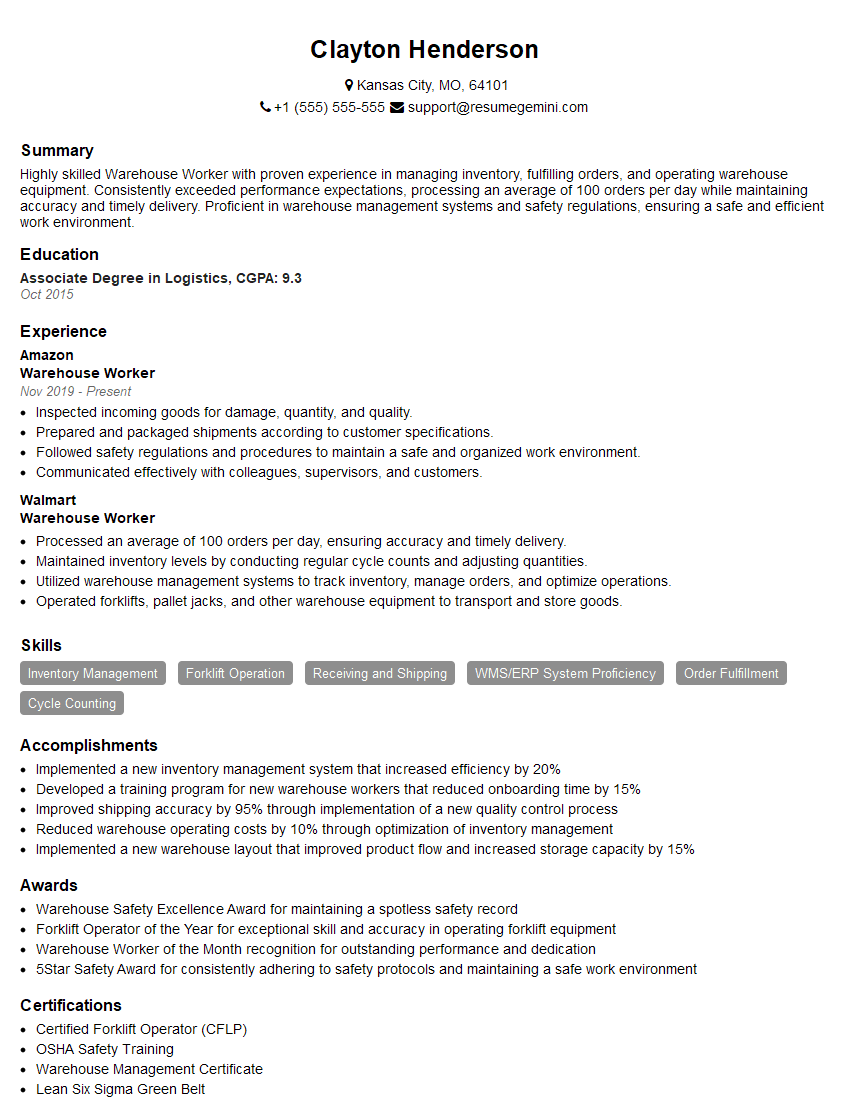

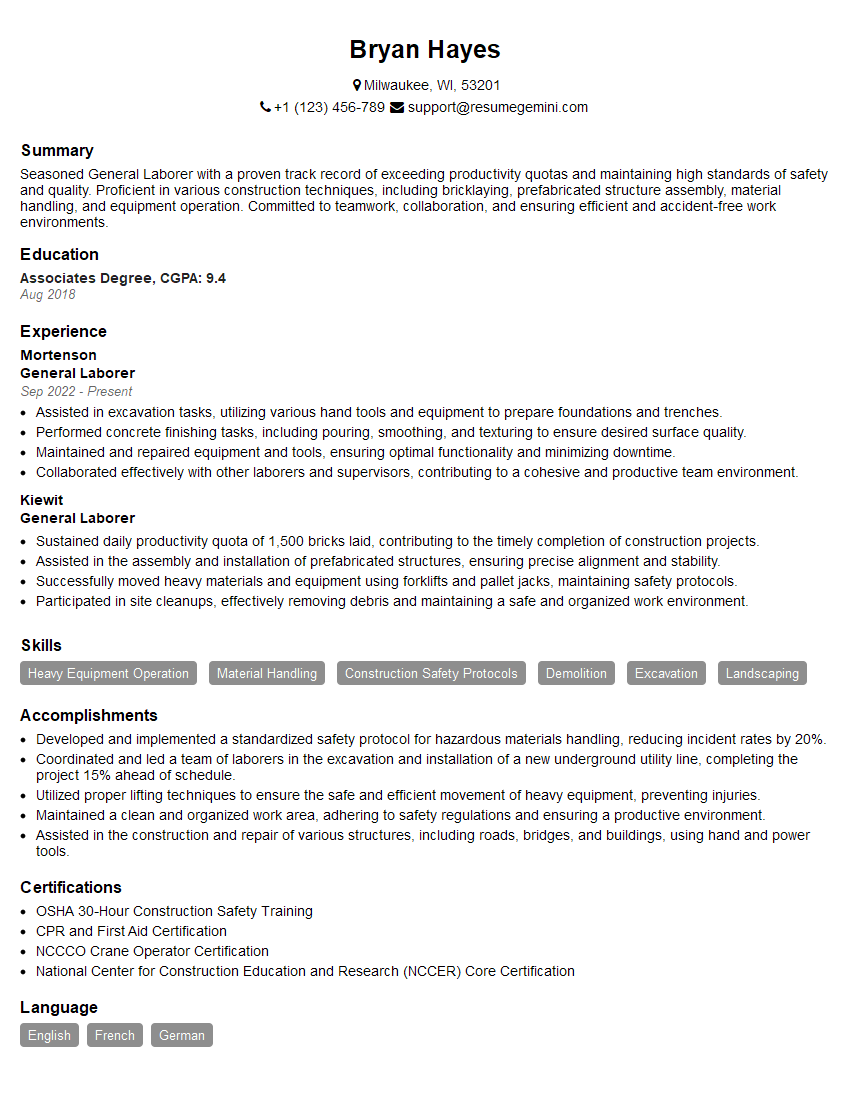

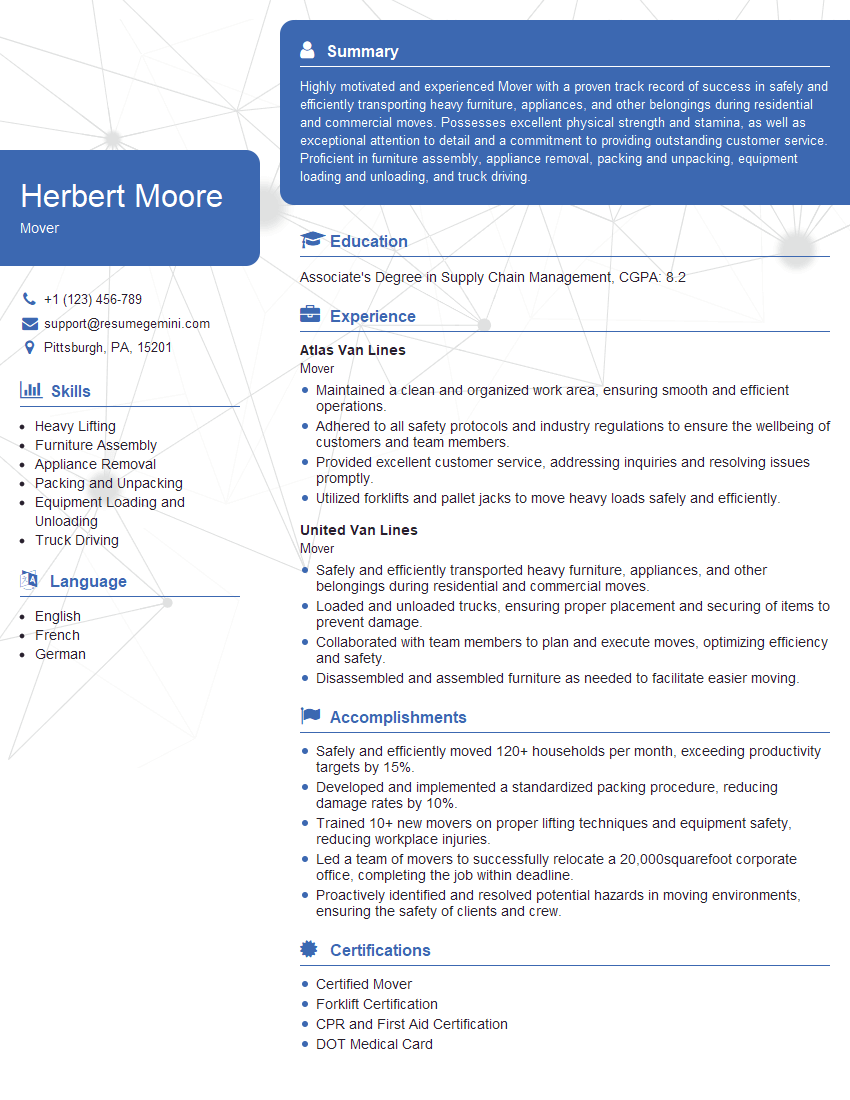

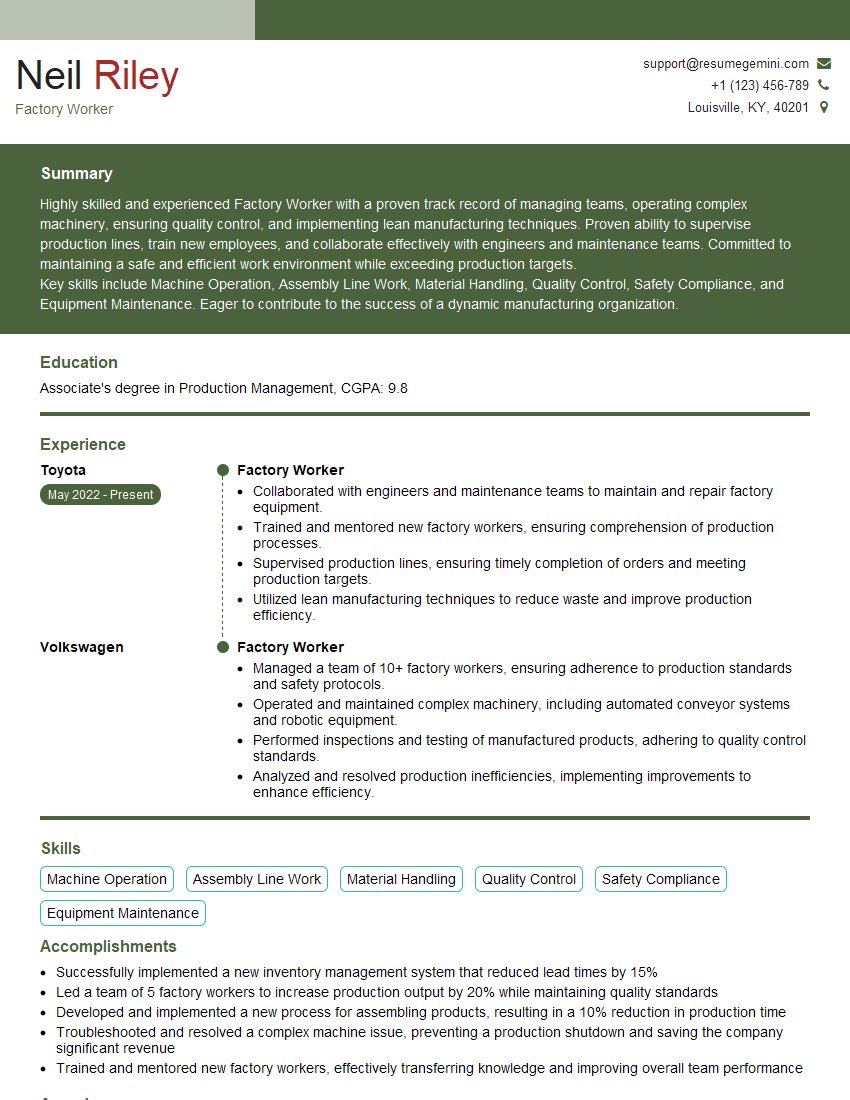

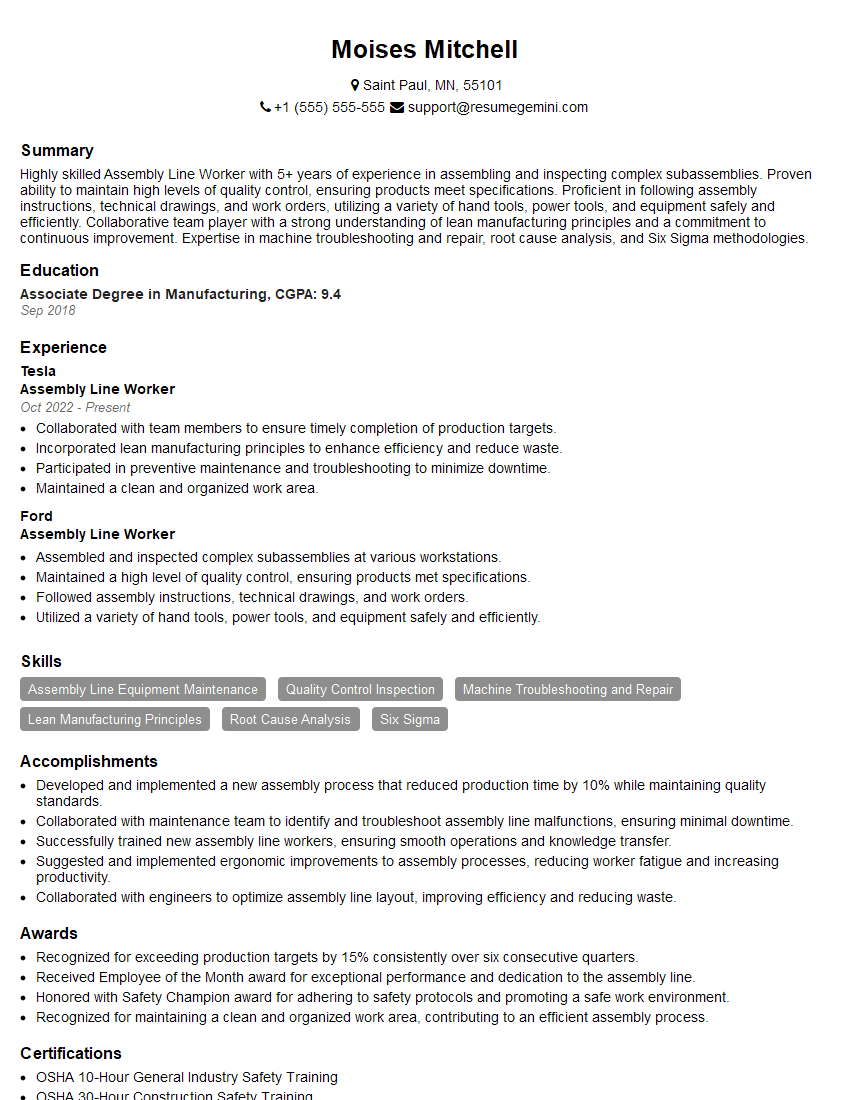

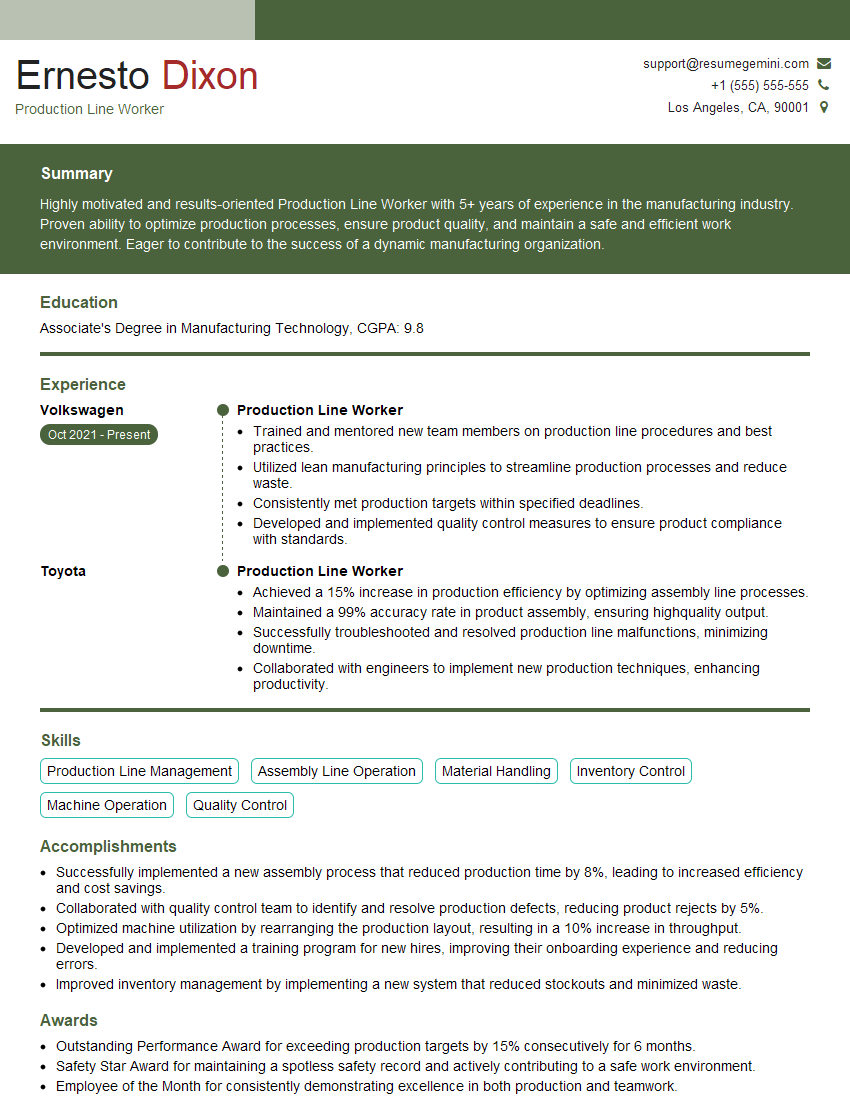

Mastering safe and efficient heavy object lifting techniques is crucial for career advancement in many physically demanding roles. It demonstrates your commitment to safety, efficiency, and a proactive approach to workplace well-being. To increase your job prospects, create an ATS-friendly resume that highlights your experience and skills effectively. ResumeGemini is a trusted resource for building professional resumes that stand out. We provide examples of resumes tailored to showcasing experience in lifting heavy objects correctly to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good