The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Knowledge of MSDS and Safety Regulations interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Knowledge of MSDS and Safety Regulations Interview

Q 1. Explain the purpose and importance of an MSDS (Material Safety Data Sheet).

An MSDS, or Material Safety Data Sheet, is a document that provides comprehensive information on the potential hazards associated with a chemical product and how to work safely with it. Think of it as the chemical’s resume, detailing everything you need to know to handle it responsibly. Its importance lies in protecting worker health and safety, preventing accidents, and ensuring compliance with regulations. Without an MSDS, workers are essentially operating blindly, increasing the risk of serious injury or environmental damage.

Q 2. Describe the key sections of an MSDS and what information each section contains.

A typical MSDS is organized into several key sections. While the exact format may vary slightly depending on the country and governing body, the core information remains consistent. Here are some key sections:

- Identification: Product name, manufacturer’s information, emergency contact details.

- Hazard Identification: Details the potential health, physical, and environmental hazards. This section might include signal words like ‘Danger’ or ‘Warning,’ hazard statements, and precautionary statements.

- Composition/Information on Ingredients: Lists the chemical components of the product and their concentrations.

- First-Aid Measures: Provides guidance on immediate treatment in case of exposure.

- Fire-Fighting Measures: Explains appropriate firefighting techniques and extinguishing agents.

- Accidental Release Measures: Outlines procedures for containing and cleaning up spills.

- Handling and Storage: Provides recommendations for safe handling and storage practices.

- Exposure Controls/Personal Protection: Specifies necessary personal protective equipment (PPE) and engineering controls.

- Physical and Chemical Properties: Lists physical properties like boiling point, melting point, and flammability.

- Stability and Reactivity: Describes the product’s stability, potential hazards from reactions, and incompatible substances.

- Toxicological Information: Provides information on health effects from exposure.

- Ecological Information: Details the environmental impact of the product.

- Disposal Considerations: Explains proper waste disposal methods.

- Transport Information: Specifies transportation regulations.

- Regulatory Information: Lists relevant regulations and labeling requirements.

- Other Information: Includes additional information, such as revision dates and references.

For example, the Hazard Identification section might state that a chemical is flammable and can cause skin irritation, providing specific hazard statements to clarify the risks. The Exposure Controls/Personal Protection section would then recommend specific PPE, such as gloves, eye protection, and respirators, to mitigate these hazards.

Q 3. What are the potential hazards associated with handling chemicals listed on an MSDS?

The potential hazards associated with handling chemicals are diverse and depend entirely on the specific chemical. MSDSs clearly list these hazards. Some common hazards include:

- Acute toxicity: Immediate health effects like irritation, burns, or organ damage.

- Chronic toxicity: Long-term health effects like cancer, reproductive issues, or organ damage from repeated exposure.

- Flammability: The potential for the chemical to easily ignite.

- Reactivity: Potential for dangerous reactions with other substances or under certain conditions.

- Corrosiveness: The ability to damage or destroy living tissue or other materials.

- Carcinogenicity: The potential to cause cancer.

- Respiratory sensitization: The potential to cause allergic reactions in the respiratory system.

- Skin sensitization: The potential to cause allergic reactions on the skin.

- Environmental hazards: Harmful effects on the environment, including water contamination or harm to wildlife.

For example, handling strong acids without proper PPE could lead to severe burns. Working with a known carcinogen without appropriate ventilation could increase the risk of developing cancer. The MSDS provides the information necessary to understand and mitigate these hazards.

Q 4. How would you identify and assess workplace hazards related to chemical handling?

Identifying and assessing workplace hazards related to chemical handling involves a systematic approach. It begins with a thorough walkthrough of the workplace, focusing on areas where chemicals are handled, stored, and used. This involves:

- Identifying chemical hazards: Review the MSDS for each chemical present to determine its potential hazards.

- Identifying tasks and processes: Analyze the tasks and processes involving chemical handling, noting potential points of exposure.

- Identifying exposed workers: Determine which workers are exposed to these chemicals and the frequency and duration of their exposure.

- Assessing the risk: Evaluate the likelihood and severity of potential incidents. A risk matrix is a useful tool to aid this evaluation; it considers both the likelihood and the severity of potential harm, helping to prioritize which hazards need immediate action.

- Implementing control measures: Based on the risk assessment, implement control measures (more on this in the hierarchy of controls below).

- Monitoring and review: Regularly monitor the effectiveness of implemented control measures and review the risk assessment periodically to ensure it remains relevant.

For example, if a risk assessment reveals a high likelihood of spills for a corrosive chemical, additional control measures may include secondary containment, improved spill response procedures, and enhanced worker training.

Q 5. What are the different types of Personal Protective Equipment (PPE) and when should each be used?

Personal Protective Equipment (PPE) is crucial for protecting workers from chemical hazards. The choice of PPE depends entirely on the identified hazards. Some common types include:

- Eye protection: Safety glasses, goggles, or face shields protect against splashes and fumes.

- Respiratory protection: Respirators filter out airborne particles or gases, and the type of respirator needed depends on the specific hazard. Examples include dust masks, half-face respirators, and full-face respirators.

- Hand protection: Gloves protect hands from chemical contact. The type of glove needed depends on the chemical’s properties; some chemicals require specialized gloves (e.g., nitrile, neoprene, or butyl rubber).

- Skin protection: Protective clothing like aprons, coveralls, or full-body suits protects skin from splashes and spills.

- Foot protection: Safety shoes or boots protect feet from falling objects and spills.

- Hearing protection: Earplugs or earmuffs protect hearing from loud noises associated with some chemical handling processes.

It’s crucial that the correct PPE is used for the identified hazard. For example, using only safety glasses when handling a chemical that splashes readily is inadequate; goggles would be necessary. Training on proper PPE selection and use is essential.

Q 6. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls prioritizes control measures to minimize risks. It’s a structured approach that focuses on eliminating hazards whenever possible, rather than relying solely on PPE. The hierarchy, from most to least preferred, is generally:

- Elimination: Removing the hazard altogether. For example, replacing a hazardous chemical with a less hazardous alternative.

- Substitution: Replacing a hazardous chemical or process with a less hazardous one.

- Engineering controls: Implementing physical changes to the workplace to minimize exposure. This includes ventilation systems, enclosed processes, and local exhaust ventilation.

- Administrative controls: Changes to work practices, such as job rotation, reduced exposure times, and enhanced training.

- Personal Protective Equipment (PPE): The least preferred option, as it’s the last line of defense and only protects the individual, not the source of the hazard.

Following this hierarchy ensures that the most effective controls are implemented first. Relying solely on PPE is often insufficient and can create a false sense of security.

Q 7. Describe your experience with conducting risk assessments.

I have extensive experience in conducting risk assessments, both qualitative and quantitative. In my previous role at [Previous Company Name], I was responsible for conducting regular risk assessments for all chemical handling processes. This included identifying hazards using MSDSs, assessing the risks involved using risk matrices, and recommending appropriate control measures based on the hierarchy of controls. I collaborated with safety officers and management to implement these control measures and ensure compliance with relevant regulations. I documented all risk assessments thoroughly and conducted regular reviews to ensure the controls remained effective and up to date. A specific example includes a risk assessment for a process involving highly reactive chemicals, where I recommended replacing the chemicals with less hazardous alternatives, followed by the implementation of an enclosed process and enhanced ventilation as secondary controls. The thoroughness and documentation of these assessments are critical to ensure worker safety and compliance.

Q 8. How would you investigate a workplace accident or incident involving hazardous materials?

Investigating a workplace accident involving hazardous materials requires a systematic and thorough approach, prioritizing safety and preventing further incidents. My process begins with immediate emergency response – ensuring the safety of all personnel and containing the hazard. This often involves evacuation of the immediate area and calling emergency services if necessary.

Next, I would secure the scene to prevent further contamination or exposure. This includes establishing a perimeter and controlling access. A detailed photographic record is essential, documenting the accident scene, the injured party’s location (if applicable), and any spilled or damaged materials. We then interview witnesses to gather information about the events leading to the accident.

Following the initial response, a thorough investigation begins using a structured methodology. This includes:

- Gathering evidence: Collecting samples of the hazardous material, reviewing safety data sheets (SDSs), and examining equipment involved.

- Analyzing data: Reviewing incident reports, maintenance logs, and training records to identify contributing factors.

- Identifying root cause: Using root cause analysis techniques (e.g., 5 Whys) to understand the underlying reasons for the accident.

- Recommending corrective actions: Developing and implementing measures to prevent similar incidents in the future. This may involve changes to work procedures, equipment upgrades, or additional safety training.

- Documenting findings: Creating a comprehensive report detailing the investigation process, findings, and recommendations. This report is crucial for accountability and continuous improvement.

For example, in an incident involving a chemical spill, my investigation would involve analyzing the SDS of the chemical to understand its hazards and handling requirements. I’d then examine the spill response procedures followed and determine if they were adequate and appropriately implemented. The investigation would also uncover if there were any training deficiencies or breaches in established safety protocols.

Q 9. What are your familiarity with OSHA (or equivalent national regulations)?

I am extensively familiar with OSHA regulations (Occupational Safety and Health Administration) in the United States, and their equivalents in other countries. My knowledge covers a wide range of standards, including those concerning hazardous materials handling, personal protective equipment (PPE) usage, emergency response planning, worker training, and record keeping. I understand the requirements for Hazard Communication (HazCom), Process Safety Management (PSM), and the general duty clause which emphasizes an employer’s responsibility to provide a safe and healthful workplace.

I’m also versed in the specific regulations related to different industries and hazardous materials, such as those governing the handling of flammable liquids, compressed gases, and toxic substances. I regularly review updates and revisions to these regulations to maintain my knowledge base and ensure that my safety practices remain current and compliant. Staying current is crucial, as regulations evolve to address new hazards and improved safety practices.

For instance, my experience includes working with OSHA’s Process Safety Management standard (29 CFR 1910.119), which addresses the prevention of catastrophic releases of hazardous materials. I’ve worked with employers to develop and implement comprehensive PSM programs, covering aspects such as hazard identification, risk assessment, operating procedures, training, and emergency planning.

Q 10. How do you ensure compliance with relevant safety regulations and standards?

Ensuring compliance with safety regulations and standards requires a multi-faceted approach that incorporates proactive measures and reactive adjustments. It begins with a thorough understanding of the applicable regulations and standards relevant to the specific workplace and its operations.

My approach involves:

- Regular Safety Audits: Conducting regular safety audits to identify potential hazards and compliance gaps. This includes both planned audits and unannounced spot checks.

- SDS Management: Maintaining up-to-date Safety Data Sheets (SDS) for all hazardous materials used in the workplace and making them readily accessible to all employees.

- Training Programs: Developing and implementing comprehensive safety training programs for all employees, tailored to their specific roles and responsibilities.

- PPE Compliance: Ensuring that all employees are provided with and use appropriate Personal Protective Equipment (PPE).

- Incident Reporting & Investigation: Establishing and maintaining a robust system for reporting and investigating workplace incidents and accidents, which forms the basis for continuous improvement.

- Record Keeping: Maintaining accurate and complete records of safety training, inspections, incidents, and any corrective actions taken.

For example, in a manufacturing environment, we would regularly inspect machinery for safety guards and ensure proper lockout/tagout procedures are followed. Regular training on the proper use of equipment and handling of hazardous materials would be crucial, and records of this training would be maintained for compliance purposes.

Q 11. Explain the process for handling chemical spills.

Handling chemical spills requires a rapid and coordinated response, prioritizing safety above all else. The process depends heavily on the nature of the spilled chemical, as detailed in its Safety Data Sheet (SDS).

The steps typically include:

- Evacuation and Isolation: Immediately evacuate the area and restrict access to prevent further exposure. If possible, isolate the spill to contain its spread.

- Emergency Response: If the spill is large or involves dangerous materials, call emergency services immediately. Follow local emergency response protocols.

- Personal Protective Equipment (PPE): Don appropriate PPE based on the SDS of the spilled chemical. This may include respirators, gloves, eye protection, and protective clothing.

- Spill Containment: Use absorbent materials like spill pads, sand, or vermiculite to absorb the liquid. If possible, create a dike around the spill to prevent it from spreading further.

- Neutralization (if applicable): Some chemicals may require neutralization. Refer to the SDS for specific instructions; attempting neutralization without proper knowledge can be dangerous.

- Cleanup: Carefully collect the absorbed material and place it in appropriate containers for disposal. Follow all local regulations for hazardous waste disposal.

- Decontamination: Thoroughly decontaminate the affected area. This might involve washing with water and detergent, depending on the chemical.

- Documentation: Document the entire process, including the time of the spill, the chemical involved, the actions taken, and any injuries or damages.

For example, a small spill of acetone would require using absorbent materials, proper ventilation, and wearing gloves. A large spill of a corrosive acid would require much more extensive measures, including calling emergency responders and using specialized equipment and neutralization techniques.

Q 12. Describe your experience with developing and implementing safety training programs.

My experience in developing and implementing safety training programs encompasses a wide range of approaches, always prioritizing a practical, engaging, and easily understandable format. I begin by conducting a thorough needs assessment, identifying the specific hazards and risks faced by employees in their different roles.

My training programs generally include:

- Needs Assessment: A detailed analysis of the workplace to identify specific hazards and training needs.

- Curriculum Development: Developing a comprehensive curriculum that addresses these needs, using various methods like lectures, demonstrations, hands-on training, and case studies.

- Delivery Methods: Utilizing diverse training methodologies to cater to different learning styles. This includes classroom training, online modules, videos, and on-the-job training.

- Assessment and Evaluation: Regularly assessing the effectiveness of the training using tests, practical demonstrations, and observations.

- Documentation: Maintaining detailed records of employee training participation and performance.

For example, I developed a comprehensive safety training program for a construction site that involved hands-on training with equipment, simulations of emergency situations, and regular refresher courses. This program included training on hazard recognition, PPE use, fall protection, and emergency response procedures. The success of the program was measured by a significant reduction in workplace accidents and injuries.

Q 13. How do you communicate safety information effectively to workers with varying levels of understanding?

Effective communication is paramount in safety. I tailor my approach to the audience’s understanding. For workers with limited literacy or language skills, I use visual aids, demonstrations, and simple language. I utilize pictures, symbols, and videos to convey complex information effectively.

My strategies include:

- Multi-Modal Communication: Combining verbal instructions, visual aids, and hands-on demonstrations.

- Plain Language: Using simple, clear, and concise language, avoiding technical jargon.

- Visual Aids: Employing posters, diagrams, videos, and other visual aids to enhance understanding.

- Interactive Training: Encouraging active participation through quizzes, discussions, and role-playing exercises.

- Language Support: Providing translated materials and interpreters when necessary.

- Feedback Mechanisms: Establishing open channels for feedback to ensure understanding and address any concerns.

For example, when training workers on the use of a new piece of machinery, I wouldn’t just rely on a written manual. I would demonstrate its proper use, highlight safety features, and answer questions. For those with limited English proficiency, I would use visual cues and simplified instructions translated into their native language.

Q 14. How do you handle non-compliance with safety regulations?

Handling non-compliance with safety regulations requires a systematic and progressive approach, prioritizing corrective action and preventing future violations. This involves identifying the cause of non-compliance, addressing it effectively, and ensuring the issue is resolved permanently.

My process includes:

- Identification: Identifying the specific non-compliance through audits, observations, or incident reports.

- Investigation: Investigating the root cause of the non-compliance. This may involve interviewing employees, reviewing records, and analyzing the circumstances.

- Corrective Action: Implementing appropriate corrective actions to address the non-compliance. This may include retraining employees, improving safety procedures, modifying equipment, or imposing disciplinary actions in accordance with company policy.

- Monitoring: Monitoring the effectiveness of the corrective actions to ensure they resolve the non-compliance and prevent future occurrences.

- Documentation: Maintaining detailed records of the non-compliance, investigation, corrective actions, and monitoring results.

For instance, if I discovered workers weren’t using proper PPE, I would investigate why. Was the PPE inadequate, uncomfortable, or inconvenient? Were workers not properly trained on its use or the dangers of not using it? Once identified, corrective action might involve providing better-fitting PPE, retraining on its use and importance, or enforcing the use of PPE through managerial oversight.

Q 15. What is your experience with emergency response procedures?

My experience with emergency response procedures is extensive. I’ve participated in numerous emergency drills and real-world incidents, ranging from minor chemical spills to more serious equipment malfunctions. My training includes hazard recognition, initial response actions (such as containment and evacuation), and the critical importance of contacting emergency services promptly and accurately. I understand the importance of following established site-specific emergency response plans and communicating effectively with first responders. For instance, during a recent incident involving a small chemical spill in our lab, I immediately implemented our established protocol: secured the area, notified emergency response, and assisted in the cleanup using appropriate Personal Protective Equipment (PPE). My role often involves coordinating evacuation procedures and ensuring the safety of personnel.

I’m proficient in using various emergency response equipment, including spill kits, emergency showers, and eyewash stations. I also understand the importance of post-incident reporting and investigation to prevent future occurrences. This includes documenting the incident, identifying contributing factors, and suggesting corrective actions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energy release during maintenance or repair activities. My experience encompasses all aspects of LOTO, from planning and preparation to verification and release. I’m intimately familiar with the requirements of OSHA’s LOTO standard, and have a proven track record of ensuring compliance.

Before starting any work involving potentially hazardous energy sources, I meticulously follow a five-step process: 1. Planning and preparation – identifying energy sources and the appropriate lockout devices; 2. Notification – informing all relevant personnel; 3. Lockout/Tagout – applying the lockout/tagout devices and verifying the absence of energy; 4. Verification – ensuring that energy cannot be restored inadvertently; and 5. Release – removing the lockout/tagout devices following a thorough inspection and confirmation of safety.

I’ve trained numerous employees in LOTO procedures, emphasizing the importance of meticulousness and adherence to established protocols. A specific example involved a recent maintenance task on a high-pressure system. I personally oversaw the LOTO process, ensuring every step was carefully followed to prevent a potentially dangerous situation. Consistent documentation of all LOTO procedures is essential, and I maintain detailed records of every event, in compliance with company and regulatory requirements.

Q 17. How familiar are you with Globally Harmonized System of Classification and Labelling of Chemicals (GHS)?

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is a globally accepted system for standardizing the classification and communication of chemical hazards. I am very familiar with its key elements, including hazard classification (e.g., health, flammability, environmental hazards), signal words (danger and warning), hazard statements, precautionary statements, and the standardized Safety Data Sheets (SDS).

My understanding extends to the practical application of GHS in various workplace contexts. I can interpret SDSs accurately, identify hazards associated with specific chemicals, and implement appropriate control measures. This includes selecting appropriate PPE, developing safe work procedures, and ensuring proper chemical storage and handling. For instance, if a new chemical is introduced into our workplace, I use the SDS provided by the supplier to assess the hazards and implement the necessary safety protocols, ensuring compliance with GHS standards.

Q 18. What are your experience with different types of fire extinguishers and their appropriate uses?

I have extensive experience with various types of fire extinguishers and their appropriate applications. This includes Class A (ordinary combustibles), Class B (flammable liquids), Class C (electrical fires), and Class D (combustible metals) extinguishers. I understand the PASS method (Pull, Aim, Squeeze, Sweep) and the limitations of each extinguisher type.

It is critical to understand that using the wrong extinguisher on a particular fire type can worsen the situation. Using water on an electrical fire, for example, could be extremely dangerous. I’ve conducted numerous fire extinguisher training sessions, emphasizing the importance of selecting the correct extinguisher based on the type of fire and knowing how to use it effectively and safely. Beyond practical use, I understand the regular inspection and maintenance requirements for ensuring the extinguishers remain fully functional.

Q 19. Explain the process for managing hazardous waste.

Managing hazardous waste involves a multi-step process designed to protect human health and the environment. It starts with identifying and classifying the waste materials according to their hazardous properties (e.g., flammability, toxicity, reactivity). Then, appropriate containment and handling procedures are implemented to prevent spills and exposure. Proper labeling is crucial to clearly identify the hazardous nature of the waste.

Next, the waste is segregated according to its type and regulatory requirements. This often involves using specialized containers and following strict protocols to prevent cross-contamination. Finally, the hazardous waste is transferred to a licensed disposal facility. Throughout the entire process, thorough documentation is essential. This includes maintaining waste manifests, tracking waste disposal activities, and ensuring compliance with all relevant local, state, and federal regulations. Failure to follow these procedures can lead to severe penalties and environmental damage.

Q 20. How do you stay updated on changes to safety regulations and best practices?

Staying updated on changes to safety regulations and best practices is an ongoing process. I regularly review publications from OSHA, EPA, and other relevant regulatory agencies. I also actively participate in professional development activities such as workshops, seminars, and conferences to stay abreast of new technologies and evolving safety standards.

Subscription to industry-specific journals and online resources provides me with the latest information on best practices and emerging safety concerns. Networking with other safety professionals also plays a vital role in knowledge sharing and staying informed about relevant changes in the field. Staying informed is a commitment to workplace safety and ensures I’m always employing the most effective safety practices.

Q 21. How would you respond to an employee who refuses to follow safety protocols?

Addressing an employee’s refusal to follow safety protocols requires a multi-pronged approach. The first step is to understand the reason for their non-compliance. It could be a lack of training, a misunderstanding of the protocols, or even a safety concern that the employee hasn’t voiced. Open and respectful communication is crucial.

If the reason is a lack of training, providing additional instruction and reinforcing the importance of the safety protocols is essential. If the employee is genuinely concerned about the safety of a procedure, addressing their concerns and possibly modifying the procedure or providing additional safety measures might be necessary. However, if the refusal is deliberate and disregards safety regulations, disciplinary action in accordance with company policy will be necessary. Documentation of all interactions and corrective actions is essential.

Q 22. Describe a time you had to resolve a safety conflict or disagreement.

During a project involving the use of a new solvent, a disagreement arose between the lab manager and the research team regarding the adequacy of the existing ventilation system. The manager believed the current system was sufficient, while the research team expressed concerns about potential exposure to hazardous vapors. I facilitated a meeting to address the conflict. We reviewed the solvent’s Safety Data Sheet (SDS) focusing on its vapor pressure and permissible exposure limits (PELs). I then organized air quality monitoring tests to objectively assess the existing ventilation. The results showed vapor levels exceeding the PEL, validating the research team’s concerns. This led to the immediate implementation of a more robust ventilation system and a revised safety protocol for handling the solvent, ultimately resolving the disagreement and ensuring worker safety. This situation underscored the importance of data-driven decision-making in resolving safety conflicts.

Q 23. How would you handle a situation where safety equipment is malfunctioning or inadequate?

If safety equipment malfunctions or is inadequate, my first response is to immediately remove personnel from the hazardous area. I would then follow a multi-step process: 1. Assessment: Identify the specific malfunction or inadequacy. Is the respirator damaged? Are the safety showers not working? Is the PPE insufficient for the task? 2. Immediate Action: If the equipment is critical for ongoing work, I would implement appropriate controls – perhaps using alternative, safer methods, adjusting the work process to eliminate the hazard, or providing alternative PPE. 3. Reporting & Repair: I would report the malfunction or inadequacy through the appropriate channels (e.g., maintenance logs, supervisor notifications), and initiate repairs or replacement. 4. Investigation: Once the immediate issue is resolved, I would investigate the root cause of the malfunction or inadequacy to prevent recurrence. This might involve reviewing maintenance records, conducting training for proper equipment use, or suggesting improvements to safety procedures. For example, if a fire extinguisher is found to be empty, I would not only replace it but also investigate why it wasn’t inspected and refilled according to schedule.

Q 24. Describe your experience with conducting safety inspections and audits.

I have extensive experience conducting both routine and comprehensive safety inspections and audits. My approach involves a systematic evaluation of the workplace, focusing on hazard identification and control. For example, a routine inspection might cover aspects like housekeeping (e.g., clean aisles, proper storage of materials), the condition of safety equipment (e.g., functional fire extinguishers, emergency exits unobstructed), and adherence to safety procedures. Comprehensive audits are more in-depth, often involving a formal checklist and documentation of findings, root-cause analysis, and a plan of action to address identified deficiencies. These audits might include reviewing safety training records, emergency response plans, and regulatory compliance documents. My reports are always objective, providing clear descriptions of any safety hazards and recommending corrective actions. For instance, during an audit of a chemical storage area, I discovered improper labeling of some containers which could lead to accidental misuse. My report clearly outlined this issue, the associated risk, and recommended retraining on chemical handling and proper labeling procedures.

Q 25. Explain the importance of proper ventilation and air quality monitoring in a workplace.

Proper ventilation and air quality monitoring are crucial for worker health and safety, particularly in environments with airborne hazards like dust, fumes, vapors, or gases. Inadequate ventilation can lead to accumulation of harmful substances, causing acute or chronic health problems ranging from respiratory irritation to severe illnesses. For example, insufficient ventilation in a welding shop could result in high concentrations of welding fumes, causing metal fume fever or long-term respiratory damage. Air quality monitoring is essential to ensure the effectiveness of ventilation systems and to identify potential hazards before they impact worker health. This involves measuring concentrations of specific airborne contaminants to compare them against established occupational exposure limits (OELs) such as PELs or Threshold Limit Values (TLVs). Monitoring data guides decisions on ventilation improvements, PPE requirements, and other risk control measures. For example, if air quality monitoring reveals elevated levels of a particular solvent, engineering controls like improved ventilation or local exhaust systems can be implemented.

Q 26. How do you ensure the proper storage and handling of hazardous materials?

Proper storage and handling of hazardous materials are vital to preventing accidents and protecting worker health. My approach involves strict adherence to both internal procedures and relevant regulations. This includes: 1. SDS Review: Always beginning with reviewing the SDS for each hazardous material to understand its specific hazards, storage requirements (e.g., temperature, flammability), and safe handling procedures. 2. Segregation: Storing incompatible materials separately, preventing potential reactions or fires (e.g., oxidizers away from flammables). 3. Labeling and Identification: Clearly labeling containers with hazard warnings and appropriate identification. 4. Containment: Using appropriate secondary containment (e.g., spill pallets, berms) to prevent spills from spreading. 5. Training: Ensuring that all personnel involved in handling these materials are adequately trained in safe practices, including emergency procedures. For instance, storing strong acids and bases in separate cabinets with spill containment would prevent a dangerous neutralization reaction.

Q 27. What are your experience with using and interpreting safety data sheets for various chemical substances?

I have extensive experience using and interpreting Safety Data Sheets (SDSs), formerly known as Material Safety Data Sheets (MSDSs). The SDS provides comprehensive information on the hazards of a chemical substance and how to handle it safely. My experience covers various chemical substances across different industries. I’m proficient in understanding sections such as: 1. Hazard Identification: Identifying the physical, health, and environmental hazards. 2. Composition/Information on Ingredients: Understanding the chemical composition and potential hazards of components. 3. First-aid Measures: Knowing the proper response in case of exposure. 4. Fire-fighting Measures: Understanding appropriate extinguishing agents and safety precautions during fires. 5. Accidental Release Measures: Knowing the correct spill response and cleanup procedures. I can use this information to implement appropriate safety measures such as engineering controls, administrative controls, and PPE. For example, when handling a substance identified as a carcinogen, I would implement stringent controls including engineering controls like local exhaust ventilation and PPE like respirators with appropriate filters.

Q 28. How do you contribute to a strong safety culture within a workplace?

Contributing to a strong safety culture involves a multifaceted approach: 1. Leadership and Commitment: Safety needs to be a top priority communicated consistently by leadership, demonstrating a genuine commitment to employee well-being. 2. Training and Education: Providing comprehensive, regular safety training and education programs, tailoring the training to specific job roles and hazards. 3. Communication and Feedback: Encouraging open communication about safety concerns, actively soliciting feedback from employees, and promptly addressing safety issues. 4. Accountability and Enforcement: Establishing clear expectations for safety compliance, enforcing safety rules consistently and fairly, and recognizing and rewarding safe work practices. 5. Hazard Identification and Control: Implementing systems for proactively identifying and controlling potential hazards. For example, using Job Safety Analysis (JSA) to analyze tasks and develop appropriate safety controls. A strong safety culture is not simply about rules and regulations; it’s about fostering a shared understanding and responsibility for safety among all employees.

Key Topics to Learn for Knowledge of MSDS and Safety Regulations Interview

- Understanding MSDS Sheets: Learn to interpret Material Safety Data Sheets (MSDS), including identifying hazardous components, understanding safety precautions, and recognizing emergency procedures. Practical application includes knowing how to locate and utilize MSDS information for various chemicals in a workplace setting.

- Workplace Hazard Identification and Risk Assessment: Master the process of identifying potential hazards in a workplace environment, evaluating associated risks, and implementing control measures to mitigate those risks. This includes practical application in conducting risk assessments and developing safety plans.

- Safety Regulations and Compliance: Familiarize yourself with relevant safety regulations (OSHA, WHMIS, etc., depending on your region) and understand how to ensure compliance within a workplace. Practical application includes knowing how to implement and maintain safety protocols, and understanding reporting requirements for incidents.

- Personal Protective Equipment (PPE): Understand the different types of PPE, their appropriate use, limitations, and selection criteria based on identified hazards. Practical application involves knowing when and how to use specific PPE, like respirators, gloves, eye protection, etc.

- Emergency Procedures and Response: Become familiar with emergency response procedures, including evacuation plans, first aid protocols, and reporting procedures for accidents and injuries. Practical application involves understanding your role in emergency situations and knowing how to react appropriately.

- Chemical Handling and Storage: Understand safe practices for handling, storing, and disposing of hazardous chemicals. This includes practical application in following proper procedures for chemical usage and waste disposal.

- Communication and Training: Learn how to effectively communicate safety information to colleagues and how to conduct or participate in safety training programs. This includes understanding effective training methods and how to ensure everyone understands safety procedures.

Next Steps

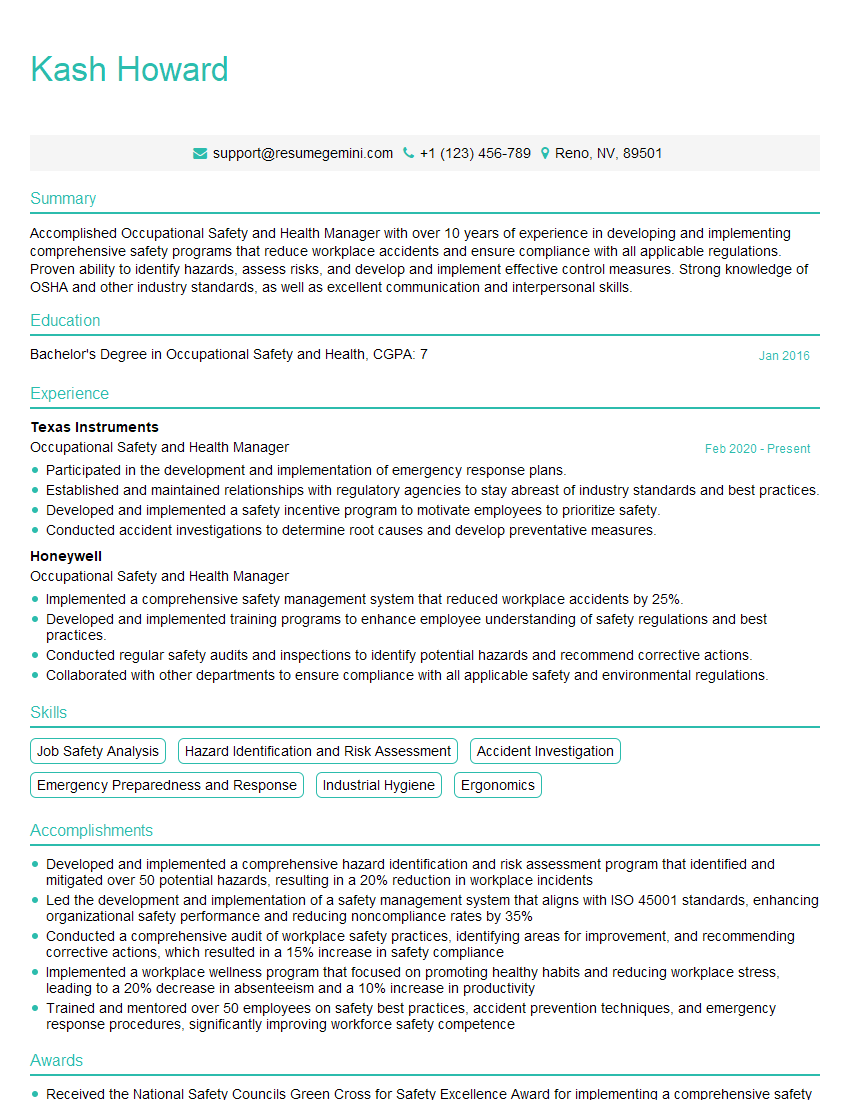

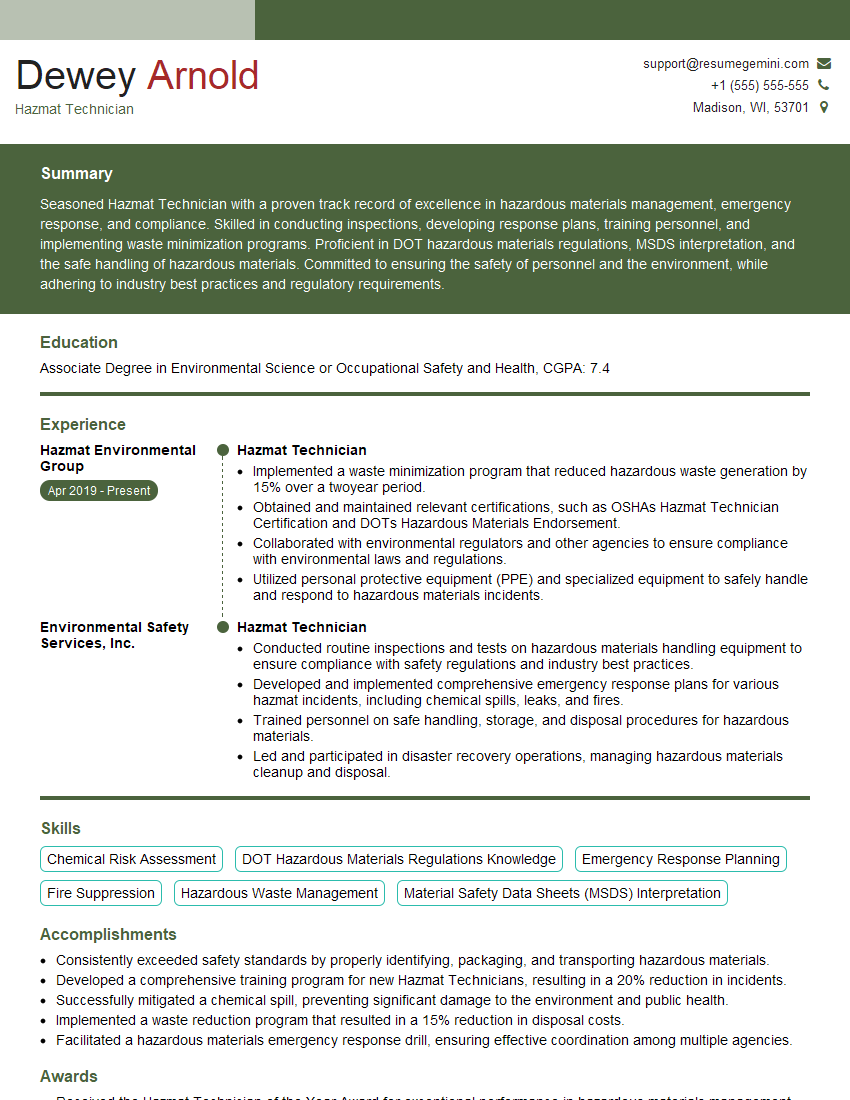

Mastering Knowledge of MSDS and Safety Regulations is crucial for career advancement in many industries, demonstrating your commitment to a safe and compliant workplace. A well-crafted resume is key to showcasing this expertise. Building an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. We highly recommend using ResumeGemini to create a professional and impactful resume tailored to your skills and experience. ResumeGemini provides examples of resumes specifically designed for candidates with expertise in Knowledge of MSDS and Safety Regulations, helping you present your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good