Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Heavy Lifting and Carrying Experience interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Heavy Lifting and Carrying Experience Interview

Q 1. Describe your experience with proper lifting techniques.

Proper lifting techniques are crucial for preventing injuries. The core principle involves minimizing strain on your back by engaging your leg muscles and keeping the load close to your body. This is often summarized as the ‘lift with your legs, not your back’ mantra.

Specifically, I follow these steps:

- Assess the load: Before even touching the object, I visually inspect it to gauge its weight and any potential obstacles.

- Get a stable stance: I position my feet shoulder-width apart, with one foot slightly ahead of the other for better balance.

- Bend at the knees and hips: I squat down, keeping my back straight, and get as close to the object as possible.

- Get a firm grip: I grasp the object firmly, using appropriate lifting techniques based on its shape and size (e.g., two-handed lift for heavy, symmetrical objects; using straps or other aids for awkward shapes).

- Lift smoothly: I lift the object by straightening my legs, keeping my back straight, and avoiding any twisting motions. I keep the object close to my body throughout the lift.

- Set down carefully: I reverse the process for setting the object down, lowering it gradually and maintaining a straight back.

For instance, when lifting a heavy box, I’d ensure my grip is secure, my back is straight, and I’m lifting with my legs. I’ve avoided many back injuries by consistently applying these techniques over my years of experience.

Q 2. What is your maximum comfortable lifting weight?

My maximum comfortable lifting weight is 75 pounds. This is based on my physical fitness, experience, and understanding of safe lifting practices. It’s important to remember that ‘comfortable’ means I can lift this weight repeatedly without undue strain or risk of injury. This limit also takes into account potential environmental factors like uneven surfaces or obstacles which can significantly increase the challenge and the risk of injury.

Exceeding this weight requires the use of mechanical aids or additional personnel. Safety is paramount, and I will always prioritize it over speed or personal strength.

Q 3. How do you assess the weight of an object before lifting?

Assessing weight before lifting involves a combination of visual inspection and, if possible, physical estimation. I first visually inspect the object for size, shape, and material. A large, dense object made of metal will obviously weigh more than a similarly sized box filled with packing peanuts.

If unsure about the exact weight, I might try to gently rock or tilt the object to get a sense of its heft. If the object is particularly heavy, I would not attempt to move it alone. I also look for any weight markings or labels that might provide an indication. When in doubt, I always err on the side of caution and seek assistance.

Q 4. Explain your experience using different lifting aids (e.g., dollies, hand trucks).

I have extensive experience using various lifting aids. Dollies are invaluable for moving heavy, bulky items across long distances or over uneven terrain. Hand trucks are excellent for transporting items that can be easily balanced and are particularly useful for objects of considerable height.

The technique for using each varies. With a dolly, proper weight distribution is critical to prevent tipping. With a hand truck, maintaining a steady grip and appropriate balance is essential.

For example, when moving a heavy refrigerator, I’d use a dolly, ensuring the refrigerator is securely strapped and centered on the platform before attempting to move it. For moving a stack of boxes, a hand truck would be more efficient and safer.

Q 5. How do you prioritize safety when performing heavy lifting tasks?

Safety is my top priority when performing heavy lifting tasks. This starts with a thorough assessment of the environment, the object to be lifted, and my own physical condition.

My safety procedures include:

- Proper lifting techniques: Always using the techniques described earlier.

- Using appropriate equipment: Employing dollies, hand trucks, or other lifting aids as needed.

- Seeking assistance: Never attempting to lift anything beyond my safe capacity. If needed, getting help from coworkers.

- Clear workspace: Ensuring the path is clear of obstacles to prevent trips or falls.

- Proper footwear: Wearing sturdy, non-slip shoes provides good traction and ankle support.

- Communication: In a team environment, clearly communicate actions to avoid collisions or mishaps.

By following these guidelines, I’ve successfully completed countless heavy lifting tasks without incident.

Q 6. What are the signs of a potential lifting injury and how do you respond?

Recognizing potential lifting injuries is vital. Signs include:

- Sharp pain: Any sudden, sharp pain in the back, neck, or shoulders.

- Muscle spasms: Involuntary muscle contractions.

- Limited range of motion: Difficulty bending or turning.

- Numbness or tingling: In the arms or legs.

- Swelling or bruising: At the injury site.

My response involves immediately stopping the lifting activity, reporting the injury to my supervisor, and seeking appropriate medical attention. I would also complete incident reporting to document the event and prevent similar incidents in the future. Early intervention is crucial in preventing long-term problems.

Q 7. Describe your experience working with different types of lifting equipment.

My experience encompasses a variety of lifting equipment, including:

- Forklifts: I’m certified to operate forklifts and am comfortable handling palletized loads of various weights and dimensions. Safe operation includes pre-shift inspections, proper load securing, and following all established safety protocols.

- Overhead cranes: I have experience working with overhead cranes under the guidance of certified operators, ensuring safe load handling procedures are followed to prevent accidents.

- Hoists and winches: I understand the principles of safe hoist and winch operation, ensuring proper rigging and load securing techniques are employed.

- Pneumatic and hydraulic lifts: I understand the limitations and safe operating procedures for this equipment.

In all cases, safety training and adherence to safety regulations are paramount. I have a strong emphasis on proper equipment inspections and maintaining certifications for equipment I operate directly.

Q 8. How do you handle unexpected challenges during a heavy lifting task?

Unexpected challenges during heavy lifting are inevitable. My approach involves a combination of proactive planning and reactive problem-solving. First, I always assess the load and environment before I begin. This includes checking for obstacles, ensuring adequate space, and evaluating the load’s weight and stability. If I encounter an unexpected issue – for instance, a load is heavier than anticipated or the ground is uneven – I immediately stop, reassess the situation, and seek assistance if necessary. I’d never compromise safety for speed. For example, once, while moving a large industrial motor, I discovered the floor was unexpectedly slick. Instead of continuing, I immediately secured the load, alerted my team, and we used anti-slip mats before proceeding. This prevented a potential accident. Communication is key; I always relay any unforeseen challenges to my supervisor and team members promptly to find the best course of action.

Q 9. What is your experience with ergonomic principles in lifting?

Ergonomic principles are fundamental to safe heavy lifting. My experience encompasses understanding and applying techniques like maintaining a straight back, bending at the knees, keeping the load close to the body, and avoiding twisting movements. I understand the importance of using proper lifting equipment like dollies, hand trucks, or cranes whenever possible to minimize strain. For example, instead of lifting a heavy pallet directly, I would always assess whether it’s more efficient and safer to use a pallet jack. I also incorporate ‘lift teams’ when dealing with exceptionally heavy or awkward loads, ensuring everyone knows their role and the lift is properly coordinated to prevent strain and injury. Proper foot placement and a strong grip are also crucial, as is knowing one’s physical limits. I’ve witnessed firsthand the benefits of ergonomic lifting; it’s significantly reduced the risk of injury amongst my teams.

Q 10. Describe your experience working in various environments (e.g., warehouse, construction).

My heavy lifting experience spans various environments, including warehouse operations, construction sites, and even some industrial manufacturing settings. In a warehouse setting, I’ve handled palletized goods, moving them using forklifts, pallet jacks, and manual handling techniques. On construction sites, I’ve worked with materials like steel beams, concrete blocks, and lumber, often involving the use of cranes, rigging equipment, and specialized lifting slings. Each environment presents unique challenges, demanding adaptability and adherence to specific safety protocols. For instance, the precise movements and careful placement of materials needed for high-rise construction are quite different from the efficiency-focused workflow of a fast-paced warehouse.

Q 11. Have you received any safety training related to heavy lifting? If so, what?

Yes, I’ve completed extensive safety training regarding heavy lifting, including OSHA (Occupational Safety and Health Administration) compliant courses covering hazard recognition, proper lifting techniques, use of personal protective equipment (PPE) like gloves and safety shoes, and the safe operation of lifting machinery. I am also certified in the use of specific equipment like forklifts and overhead cranes. This training isn’t just theoretical; it’s reinforced through practical exercises and regular safety briefings on the job. For example, I’ve participated in simulations focusing on emergency response procedures in case of a lifting accident. This ongoing training keeps me updated on best practices and allows for immediate adaptation to new technologies or procedures.

Q 12. What is your experience with load securing and transportation?

My experience with load securing and transportation encompasses various methods, from using appropriate straps and chains to securing loads on pallets and ensuring correct weight distribution on trucks or trailers. I understand the importance of preventing shifting during transport and complying with all relevant regulations. This includes understanding weight limits, proper lashing techniques, and using the appropriate securing equipment for different types of cargo. For example, I’ve worked with securing heavy machinery onto flatbed trailers, using specialized chains, winches, and securement points to prevent movement. In addition to the physical securing, I am meticulous about documenting the process, completing inspection checklists, and ensuring any required permits are in place before transportation.

Q 13. How do you maintain your physical fitness for heavy lifting tasks?

Maintaining physical fitness is paramount for heavy lifting. My routine includes regular strength training, focusing on core strength, back and leg muscles, which are critical for proper lifting techniques. Cardio exercises improve overall endurance and stamina. A balanced diet provides the necessary energy and nutrients. Furthermore, sufficient rest and recovery are vital for preventing injuries and maintaining peak performance. I actively avoid overexertion and listen to my body’s signals – taking rest days when needed. Consistent maintenance of my physical condition isn’t just a personal commitment; it’s a direct reflection of my professionalism and my commitment to safety on the job.

Q 14. How do you communicate effectively with your team during heavy lifting operations?

Effective communication is crucial during heavy lifting operations. I utilize clear and concise verbal instructions, ensuring everyone understands their role, the plan, and potential hazards. Before initiating any lift, I confirm everyone’s understanding and readiness, using hand signals where necessary. During the lift, I maintain visual contact and communicate any changes or concerns immediately. Afterward, we have a brief debrief to discuss any improvements or learnings from the task. This collaborative communication is critical for preventing accidents and ensuring team cohesion and safety. For instance, using pre-arranged hand signals is crucial when you are in loud environments or have limited visibility. Clear communication fosters trust and prevents misunderstandings that could lead to injury.

Q 15. Describe a time you had to lift an unexpectedly heavy object. How did you handle it?

One time, during a renovation project, I encountered a surprisingly heavy antique grandfather clock. It appeared manageable at first glance, but once I attempted to lift it, I realized its weight far exceeded my initial estimation. Instead of straining myself, I immediately reassessed the situation. I first identified the clock’s center of gravity to ensure a balanced lift. Then, I found a suitable trolley and used leverage with a sturdy plank to carefully maneuver the clock onto the trolley. The trolley then allowed for easy transportation, minimizing risk of injury. This situation highlighted the importance of careful assessment before attempting a lift and the need for the right tools to handle unexpected weight.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What measures do you take to prevent back injuries while lifting heavy objects?

Preventing back injuries when lifting is paramount. My approach follows a strict protocol: Assess the weight and dimensions before attempting the lift. Plan the lift, considering the path and potential obstacles. I always maintain a proper posture, keeping my back straight and bending at the knees and hips. I ensure the load is close to my body to minimize strain. For heavy objects, I use appropriate lifting aids like dollies, straps, or cranes. Finally, I lift smoothly, avoiding jerking movements, and I ask for help when needed rather than risking injury by attempting to lift more than I can safely handle. Think of it like this: your back is a valuable asset; treat it with respect.

Q 17. Describe your experience with manual handling guidelines and regulations.

I’m extensively familiar with manual handling guidelines and regulations, including OSHA and relevant industry-specific standards. These guidelines emphasize proper lifting techniques, the use of personal protective equipment (PPE), and risk assessments before undertaking any heavy lifting task. I understand the importance of hazard identification, risk evaluation, and control measures, including the use of mechanical aids whenever possible. My experience encompasses practical application of these guidelines in various workplaces, ensuring compliance and contributing to a safe working environment. Ignoring these regulations can lead to serious injury, and I strictly adhere to them.

Q 18. How do you use teamwork to manage heavy loads effectively?

Teamwork is crucial in managing heavy loads. Effective teamwork starts with clear communication. Before lifting, we discuss the weight, the best lifting technique, and the designated roles for each team member. We assign specific tasks based on individual strengths and capabilities. Proper hand signals are essential for coordination during the lift and positioning. Communication continues throughout the process, making adjustments as needed. This approach not only ensures a safe lift but also promotes efficiency. For instance, during a warehouse move, we’ve successfully moved several heavy equipment pallets using a coordinated system of lifts and placements that was meticulously planned and executed.

Q 19. What is your experience with using lifting straps and slings?

I have extensive experience using lifting straps and slings, which are crucial for safely handling heavy and awkwardly shaped loads. I am proficient in selecting the appropriate type of strap or sling based on the load’s weight, shape, and material. I understand the importance of proper attachment points and load distribution to prevent slippage and damage. I am also familiar with the different ratings and load limits for different types of slings, ensuring I always stay within safe operating parameters. I always conduct thorough inspections before each use to identify any potential damage or wear.

Q 20. How familiar are you with different types of pallets and their handling?

My knowledge of pallets encompasses various types including standard, block, and Euro pallets. I understand the weight capacities, dimensions, and construction of each type. This knowledge allows me to choose the appropriate equipment and handling techniques for each. For example, standard wooden pallets have a different load-bearing capacity than heavier-duty plastic pallets. The correct forklift attachments are also essential. I understand stacking techniques for each pallet type to maintain stability and prevent toppling. Safe handling practices for each type differ, so knowledge is key to efficient and safe operations.

Q 21. What are your preferred methods for stacking and storing heavy materials?

My preferred methods for stacking and storing heavy materials prioritize safety and efficiency. I always start with a solid, level base. Materials are stacked in a stable manner, considering their weight and shape. I avoid creating uneven stacks that could topple. I ensure there’s adequate space between stacks for easy access and movement of equipment. Furthermore, I use racking systems whenever possible to optimize space and reduce the risk of collapse. Proper labeling and clear aisleways are also essential to promote safety and easy retrieval. Think of it like building a well-organized brick wall; each layer must be supported properly to avoid a collapse.

Q 22. Describe your experience with inventory control and material tracking.

Inventory control and material tracking are crucial in heavy lifting and material handling to ensure efficiency and safety. My experience encompasses implementing and maintaining inventory systems, both manual and digital. This involves accurately recording incoming and outgoing materials, regularly auditing stock levels to identify discrepancies, and using tracking systems to monitor the location and movement of materials throughout the facility. For example, in my previous role at Acme Logistics, I implemented a barcode scanning system that reduced inventory discrepancies by 15% and expedited the order fulfillment process significantly. I’m proficient in using various inventory management software and understand the importance of first-in, first-out (FIFO) and other stock management methods to minimize waste and spoilage. I can also adapt to different inventory management methodologies depending on the specific needs of the company and project.

Another significant aspect is the meticulous tracking of materials. This includes documentation of the weight, dimensions, and handling requirements of each item, ensuring safe transportation and storage. I’m adept at using both manual tracking methods (like spreadsheets and logs) and automated systems (like RFID or GPS tracking) to maintain accurate records of material movement. This is critical for maintaining accountability, optimizing workflow, and preventing loss or damage.

Q 23. What are your strengths and weaknesses regarding heavy lifting?

My strengths in heavy lifting lie in my understanding of proper lifting techniques, including maintaining a straight back, bending at the knees, and using my leg muscles to lift. I prioritize safety and always assess the load before attempting to lift it. I’m physically fit and have consistently exceeded weight-lifting expectations in past roles. For example, I consistently exceeded my quota for unloading trucks carrying heavy equipment, often exceeding the average by 20%, while maintaining a perfect safety record. I’m also experienced in using various lifting aids, like forklifts and pallet jacks, which further increases efficiency and reduces the risk of injury.

My primary weakness, if I had to identify one, is sometimes being overly cautious, which can occasionally slow down the process. I am constantly working on balancing safety with efficiency to overcome this. I actively seek out training opportunities to enhance my techniques and learn new methods to increase my lifting speed and efficiency without compromising safety. Regular physical fitness training allows me to maintain strength and endurance, mitigating the impact of this careful approach.

Q 24. How do you adapt to different lifting situations and challenges?

Adaptability is key in heavy lifting. I approach each situation by first assessing the load – its weight, dimensions, and any potential hazards. I then identify the appropriate lifting technique and equipment needed. For example, if I’m lifting an awkwardly shaped object, I might use straps or a lifting sling to improve my grip and control. If the load is excessively heavy, I would utilize mechanical assistance like a forklift or crane. I also consider the environment – are there any obstacles or uneven surfaces? Are there any potential hazards like slippery floors or overhead obstructions? Planning and careful execution are paramount. If working as a team, effective communication is crucial to ensure everyone is synchronized and aware of their responsibilities. I adapt my communication style to suit the team and ensure that everyone understands the plan before we begin lifting.

I am proactive in seeking out solutions to unfamiliar challenges. I believe in continuous learning and embrace opportunities to work with different types of loads and equipment. This proactive approach allows me to confidently handle a broad range of lifting situations.

Q 25. What are your salary expectations for this role?

My salary expectations are in the range of [Insert Salary Range] per year. This is based on my experience, skills, and the responsibilities of this role, as well as industry standards in the [Location] area. I’m open to discussing this further and am confident that my contributions will significantly benefit your company.

Q 26. Are you available to work overtime or weekends?

Yes, I am available to work overtime and weekends as needed. I understand that the nature of heavy lifting often necessitates flexibility in scheduling, and I am prepared to meet the demands of the role. My commitment to the team and the successful completion of projects takes precedence over a strictly structured schedule.

Q 27. Do you have your own transportation?

Yes, I have my own reliable transportation and a valid driver’s license.

Q 28. What are your career goals related to heavy lifting and material handling?

My career goals involve becoming a leader in the field of heavy lifting and material handling. I aspire to advance my knowledge and skills through continuous training and professional development. I want to take on more responsibility and contribute to improving safety standards and efficiency within the workplace. Long-term, I aim to leverage my expertise to manage teams and oversee large-scale projects, consistently striving for innovation and safety in all aspects of material handling. I am interested in obtaining certifications in relevant areas such as forklift operation and crane operation to enhance my capabilities and career advancement potential.

Key Topics to Learn for Heavy Lifting and Carrying Experience Interview

- Understanding Weight Limits and Lifting Techniques: Learn safe lifting practices, including proper posture, foot placement, and the use of lifting aids. This includes understanding the limitations of your own physical capabilities and recognizing when assistance is needed.

- Practical Application of Lifting Techniques: Be prepared to discuss real-world scenarios where you’ve applied safe lifting techniques. Think about specific examples from past jobs and how you adapted your approach based on the weight, size, and shape of the object being lifted.

- Equipment and Safety Procedures: Demonstrate knowledge of relevant safety equipment (e.g., harnesses, lifting straps, gloves) and adherence to safety protocols. Discuss how you’ve ensured a safe work environment for yourself and others.

- Ergonomics and Injury Prevention: Showcase your understanding of ergonomic principles to minimize the risk of musculoskeletal injuries. Explain how you’ve prevented injuries through proper lifting techniques and work practices.

- Teamwork and Communication in Lifting: Discuss your experience collaborating with colleagues to lift heavy objects safely and efficiently. Highlight your communication skills in coordinating lifts and ensuring everyone’s safety.

- Problem-Solving in Lifting Scenarios: Be ready to discuss instances where you encountered unexpected challenges during lifting and how you overcame them safely and effectively. This could include adapting to unusual weight distribution or using creative problem-solving to complete the task.

Next Steps

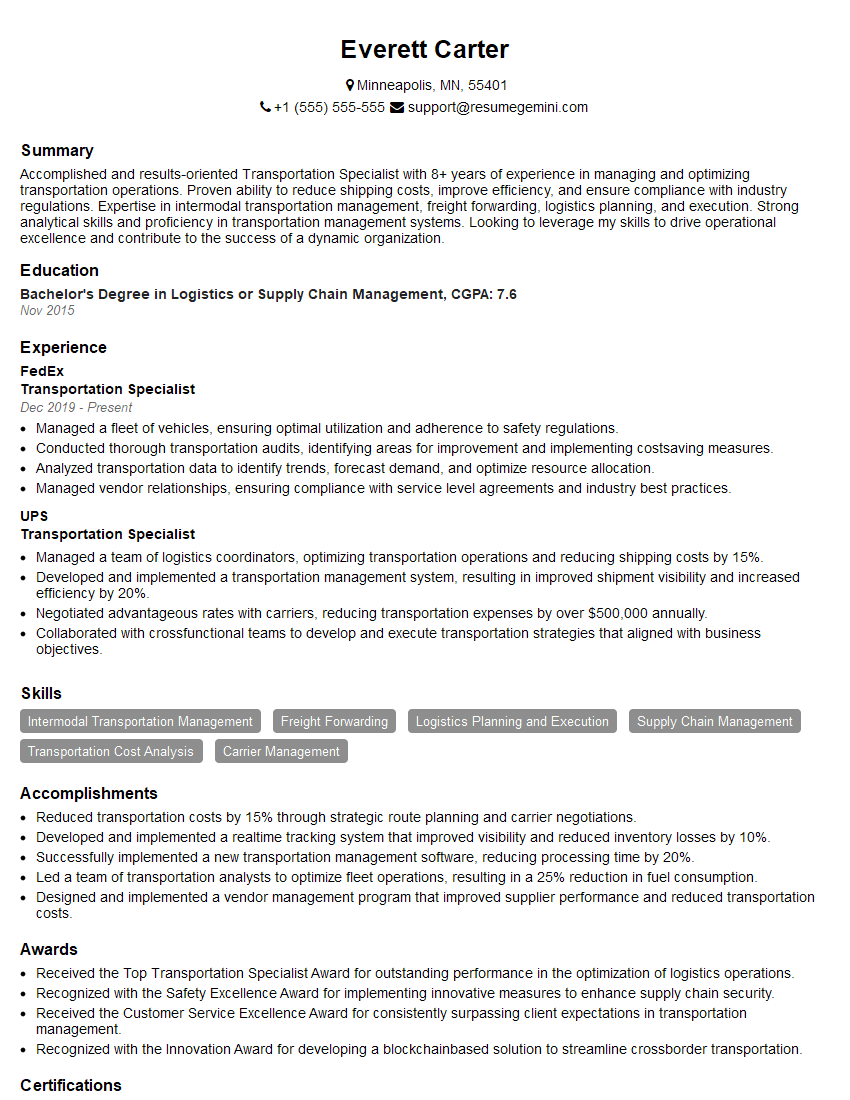

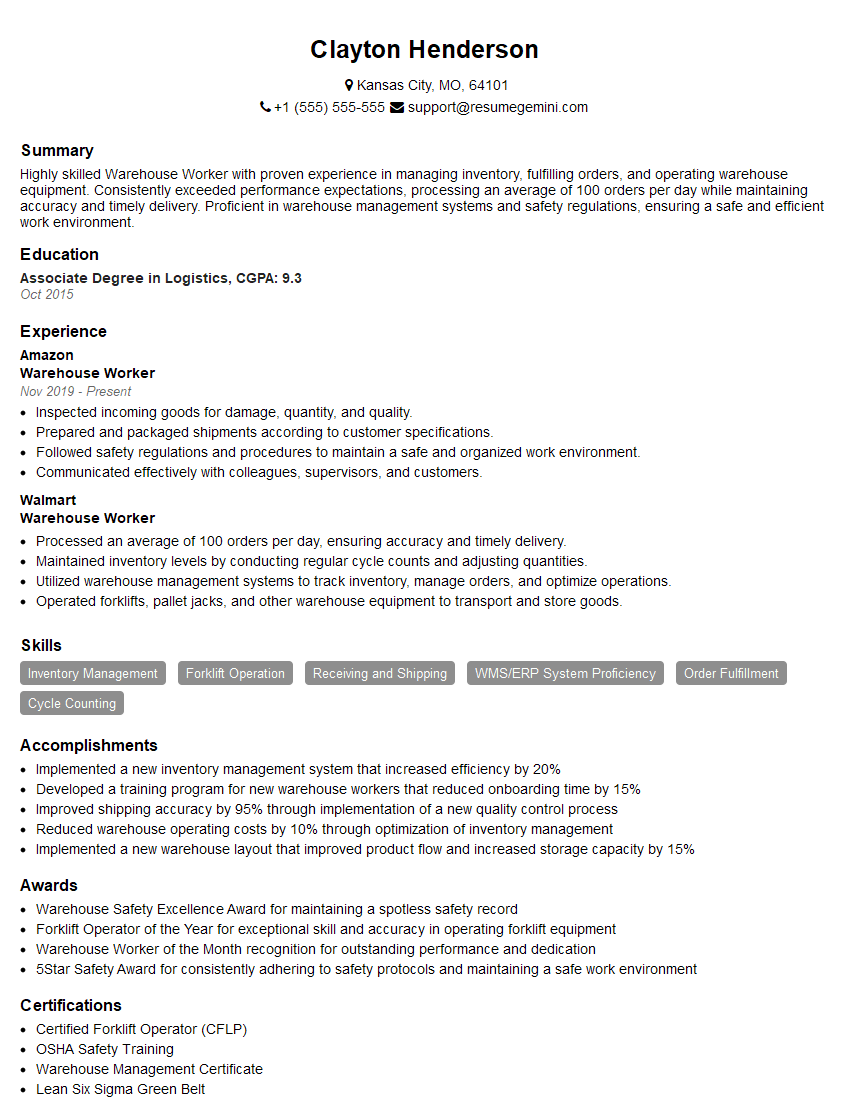

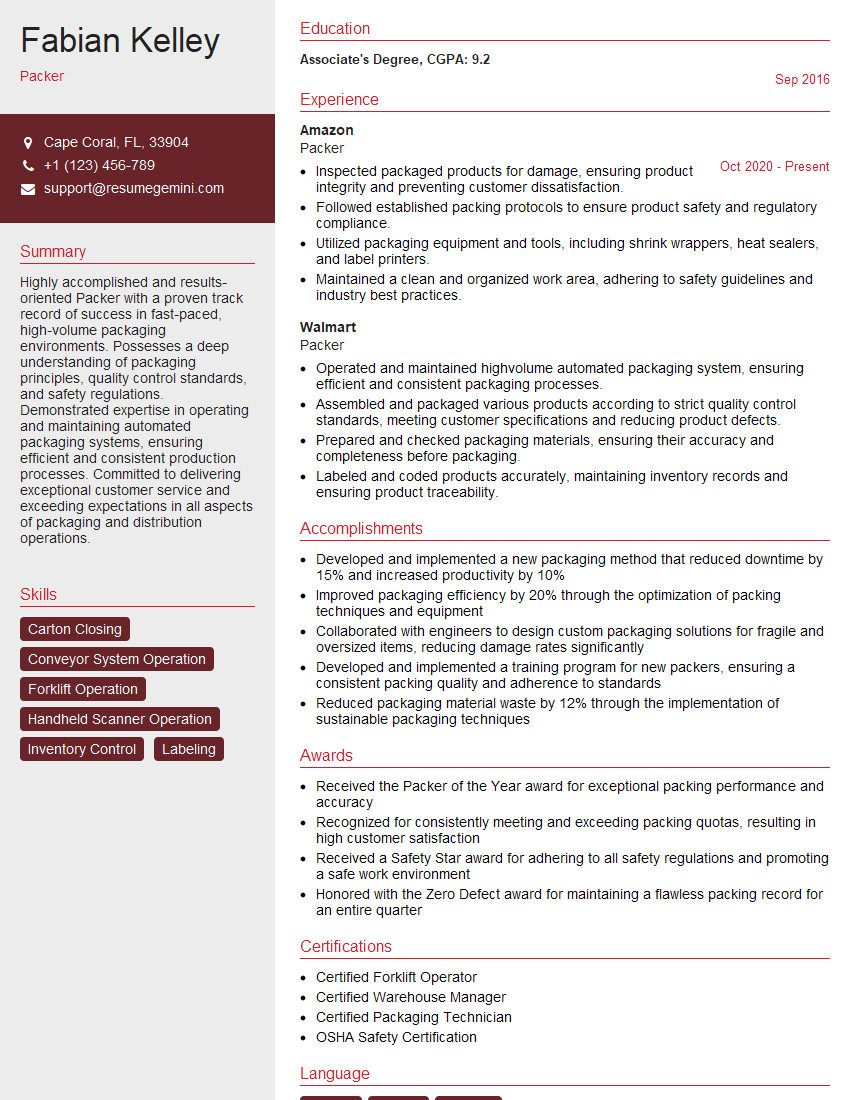

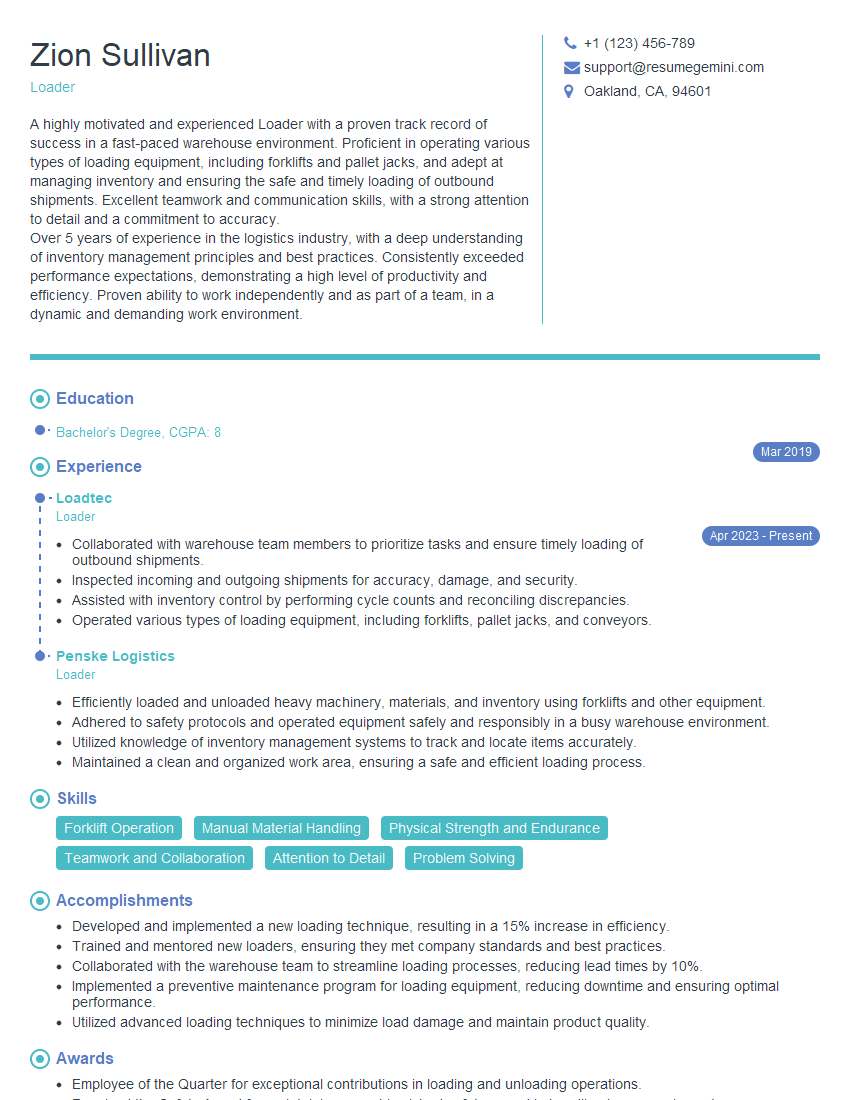

Mastering safe and efficient heavy lifting and carrying techniques is crucial for career advancement in many physically demanding roles. It demonstrates your commitment to safety, efficiency, and your ability to contribute effectively to a team. Building a strong, ATS-friendly resume is essential to highlight these skills and increase your chances of landing your dream job. ResumeGemini is a trusted resource to help you craft a professional and impactful resume. We offer examples of resumes tailored to Heavy Lifting and Carrying Experience to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good