Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience with Loading and Unloading Trucks interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience with Loading and Unloading Trucks Interview

Q 1. Describe your experience with different types of loading equipment.

My experience encompasses a wide range of loading equipment, from basic hand trucks and pallet jacks to sophisticated forklifts, reach trucks, and conveyor systems. I’m proficient in operating and maintaining these machines, understanding their limitations and capabilities. For example, I’ve used forklifts to efficiently load pallets of heavy goods onto flatbed trailers, while reach trucks proved invaluable in high-bay warehouses for accessing and retrieving goods from multiple levels. I also have experience with specialized equipment like boom lifts for loading unusually shaped or oversized items onto trucks. The choice of equipment always depends on the specific goods, the truck type, and the warehouse layout. Safety training and regular inspections are crucial aspects of my work with all equipment.

Q 2. How do you ensure the safe loading and unloading of goods?

Safe loading and unloading hinges on meticulous planning and execution. It begins with a thorough pre-load inspection of the truck, ensuring structural integrity and proper functioning of securing mechanisms. Next, I carefully assess the goods, noting weight, dimensions, and fragility. Items are secured using appropriate methods, including straps, shrink wrap, and blocking and bracing, to prevent shifting during transit. Weight distribution is crucial – heavier items go at the bottom, and we always ensure the center of gravity remains low. I strictly adhere to weight limits and regulations, using load charts and securing documentation to maintain records. Clear communication with the driver and warehouse staff is essential to ensure coordinated movements and avoid accidents. Before departure, a final inspection verifies that everything is secure and the load is compliant with all safety protocols.

Q 3. What methods do you use to prevent damage to goods during loading and unloading?

Preventing damage requires a multi-pronged approach. Proper handling is paramount; we avoid dropping or throwing items, using equipment appropriate to the weight and fragility of the goods. Padding and cushioning materials, like bubble wrap or air pillows, protect delicate items. We use appropriate stacking techniques; similar items are grouped together and stacked to optimize weight distribution and prevent crushing. Fragile goods are clearly labeled and placed strategically to minimize impact risks. During transportation, securing the load with suitable straps and bracing minimizes movement and damage during transit. Regular maintenance of loading equipment also helps reduce the risk of accidental damage.

Q 4. Explain your experience with inventory management related to loading and unloading.

My inventory management experience is integrated with the loading and unloading process. I participate in cycle counting to verify stock accuracy. Before loading, I cross-reference the loading manifest with the warehouse inventory system, ensuring that all items listed are available and accounted for. During loading, I record quantities loaded and the condition of goods. Any discrepancies are immediately reported. Post-loading, I update the inventory system to reflect the outflow of goods. This precise record-keeping ensures accurate inventory levels and aids in identifying potential shortages or discrepancies. I have worked with different inventory management systems, from simple spreadsheets to sophisticated software applications, allowing me to track inventory effectively and efficiently.

Q 5. How do you prioritize tasks when multiple trucks need loading/unloading simultaneously?

Prioritizing tasks with multiple trucks requires a systematic approach. I usually begin by reviewing the delivery schedules and prioritizing urgent deliveries. Factors like delivery deadlines, the type of goods (e.g., perishable vs. non-perishable), and the truck’s capacity influence the order of loading. I might allocate specific loading bays or equipment to each truck to optimize workflow. Clear communication with the drivers about estimated loading times is vital. Utilizing a first-in, first-out (FIFO) method for certain goods ensures timely deliveries. Continuous monitoring and adjustments might be necessary to maintain efficiency and meet deadlines, as unexpected delays or issues may arise.

Q 6. Describe your experience with different types of trucks and their loading mechanisms.

I’ve worked with various truck types, including flatbeds, dry vans, refrigerated trailers (reefers), and tankers. Each has unique loading mechanisms. Flatbeds require careful placement and securing of cargo using straps and chains. Dry vans involve loading through the rear doors, often using forklifts or pallet jacks. Reefers require maintaining temperature control throughout loading and unloading. Tankers necessitate specialized procedures and equipment for handling liquids or gases, including careful pumping and venting. Understanding the specific loading capacity and limitations of each truck type is crucial for safe and efficient operations. I’m familiar with different loading mechanisms like loading docks, ramps, and liftgates, and I adapt my technique based on the specific truck and goods involved.

Q 7. How do you handle damaged or defective goods during loading and unloading?

Handling damaged or defective goods requires a structured process. Upon discovery, I carefully document the damage, including the type and extent of damage, and the item’s location and condition before loading. Photographs are often taken to provide clear visual evidence. Depending on the company policy, I may either set aside the damaged goods for inspection and potential return to the supplier or separate them for disposal, following all necessary regulations. Accurate reporting is essential to track damage rates and identify potential causes or areas for improvement within the loading/unloading process. Maintaining clear communication with both the warehouse and the transportation provider is crucial to manage the situation efficiently and prevent further issues.

Q 8. How do you ensure compliance with safety regulations during loading and unloading?

Safety is paramount in loading and unloading operations. My approach begins with a thorough understanding of all applicable regulations, including OSHA guidelines and company-specific safety protocols. This includes proper use of personal protective equipment (PPE) like safety shoes, high-visibility vests, and gloves. Before starting any operation, I perform a pre-shift inspection of the equipment, ensuring everything is in good working order – no loose parts on forklifts, secure straps on pallet jacks, and clear pathways around the loading dock. I also ensure that the load is properly secured to prevent shifting or falling during transit. For instance, I’ll use appropriate dunnage (protective materials) to fill gaps and prevent movement. I always follow load-bearing weight limits specified for the equipment and the receiving area. Finally, I strictly adhere to procedures for reporting any near misses or incidents immediately to the supervisor to prevent recurrence.

- Example: If loading a truck with fragile items, I’d use extra padding and ensure the load is carefully balanced to minimize risk of damage during transit.

- Example: Before operating a forklift, I perform a walk around check to make sure the mast is free of obstructions, tires are adequately inflated, and the hydraulics are functioning correctly.

Q 9. What is your experience with using forklifts or pallet jacks?

I’m highly proficient in operating both forklifts and pallet jacks. I’ve held certifications for both for several years and have extensive hands-on experience in various warehouse settings. My experience includes safely navigating tight spaces, loading and unloading various types of goods with differing weights and sizes. I’m familiar with different types of forklifts – sit-down, stand-up, and reach trucks – and I can adapt my operating technique to suit each one and the specific task at hand. Similarly, with pallet jacks, I’m comfortable with both manual and electric models, understanding their limitations and utilizing best practices to maximize efficiency and safety. For instance, I always perform pre-operational checks and understand the importance of maintaining the correct posture to prevent injuries.

- Example: When using a forklift to stack pallets, I always ensure the forks are fully inserted and the load is properly centered before lifting.

- Example: When using a pallet jack, I make sure the load is evenly distributed and the wheels are aligned correctly before moving it to prevent tipping.

Q 10. How do you maintain accurate records of goods loaded and unloaded?

Maintaining accurate records is crucial for inventory management and traceability. I utilize a combination of methods, including digital and paper-based systems, to track goods. This often includes using handheld scanners to record the number of pallets, individual items (if necessary), and their corresponding SKU numbers. I also use shipping manifests and packing lists provided by clients, checking off items as they are loaded or unloaded. I meticulously cross-check these documents to ensure accuracy. Any discrepancies are immediately reported. Additionally, I may use warehouse management system (WMS) software to update inventory counts in real time. My documentation is detailed and clear, making it easy to audit and verify.

- Example: Using a barcode scanner to scan each individual item loaded onto the truck for higher accuracy and detailed record keeping.

- Example: Manually documenting pallet numbers and checking them off on a printed manifest in scenarios where scanners are unavailable.

Q 11. Explain your process for verifying the quantity and quality of goods before and after loading/unloading.

Verifying the quantity and quality of goods is a critical step in the loading/unloading process. Before loading, I visually inspect the goods and compare them against the packing list or invoice to ensure the correct items and quantities are present. I also check for any visible damage. For example, I’ll look for dents, scratches, or tears on boxes. After unloading, I conduct a similar check, often in collaboration with the receiving team. This involves verifying that the goods match the delivery documentation. This may also include spot-checking weights or dimensions, especially for bulk or high-value items. Any discrepancies or damage are documented immediately with photos or videos as evidence. This evidence is crucial for insurance claims or addressing issues with the supplier or customer.

- Example: When unloading a truckload of electronics, I’d thoroughly check each box for any signs of damage and note any discrepancies in the delivery paperwork.

- Example: For perishable goods, I’d verify the temperature and condition of the shipment before and after loading/unloading to ensure quality is maintained.

Q 12. Describe your experience with working in a fast-paced warehouse environment.

I thrive in fast-paced warehouse environments. My experience includes working in high-volume distribution centers where efficiency is paramount. I’m adept at prioritizing tasks, managing my time effectively, and working under pressure to meet tight deadlines. I’m also a strong team player, comfortable collaborating with colleagues to ensure smooth and efficient operations. My approach is methodical, even under stress; I maintain focus on safety and accuracy despite the demanding nature of the work. I’m also used to adapting to changing priorities and responding quickly to unexpected situations.

- Example: During peak seasons, I’ve successfully managed to maintain accuracy and efficiency despite increased volume and shorter turnaround times.

- Example: I’ve worked effectively within a team to expedite the loading/unloading process to support various shipping schedules.

Q 13. How do you handle unexpected delays or changes in loading/unloading schedules?

Unexpected delays and schedule changes are common in warehouse operations. My response is always proactive and focused on minimizing disruption. First, I identify the cause of the delay. Is it a logistical issue like traffic congestion or a problem with the goods themselves? Once the cause is identified, I communicate transparently with all relevant parties, including supervisors, drivers, and receiving teams. This open communication is key to finding the best solution. This might involve adjusting the loading/unloading sequence, prioritizing urgent shipments, or finding alternative solutions such as utilizing different equipment or personnel. Flexibility and problem-solving skills are essential in these scenarios. My aim is always to minimize any negative impacts on overall operations.

- Example: If a shipment arrives late, I’d prioritize its unloading to minimize delay for other operations and immediately inform the relevant parties.

- Example: If a forklift malfunctions, I’d quickly report it and find a suitable replacement to avoid halting the entire loading/unloading operation.

Q 14. What is your experience with different types of packaging and how it impacts loading/unloading?

Experience with diverse packaging types is crucial for efficient loading and unloading. I’m familiar with various packaging materials, including cardboard boxes, pallets, crates, and specialized containers for fragile or hazardous goods. The type of packaging significantly affects the loading and unloading process. For instance, pallets are ideal for stacking and handling with forklifts, but fragile items may require additional protection within the pallet or specialized packaging. Similarly, irregular shapes may require customized loading strategies to prevent damage or instability during transit. I understand the importance of proper stacking techniques for different packaging types to maximize space utilization and minimize damage. Knowing how to handle different materials and adapt my approach is vital for safety and efficiency.

- Example: Handling oddly shaped goods may necessitate using extra padding and careful placement to prevent damage during transport.

- Example: Understanding the weight and structural integrity of different packaging types (e.g., heavier wooden crates versus lighter cardboard boxes) to load the truck safely and efficiently.

Q 15. How do you identify and address potential hazards during loading and unloading?

Identifying and addressing potential hazards during loading and unloading is paramount for safety and efficiency. My approach is proactive, involving a thorough pre-load assessment and ongoing vigilance.

- Pre-load Inspection: Before any loading begins, I inspect the area for obstacles like uneven ground, debris, or damaged equipment. I also check the truck’s condition, ensuring the ramp is secure and properly positioned. I assess the weight distribution of the planned load to anticipate any potential stability issues.

- Load Securement Assessment: I verify the integrity of the packaging and ensure that appropriate materials – like straps, shrink wrap, or dunnage – are available to securely fasten the load. I identify any items that may be fragile or require special handling.

- Personal Protective Equipment (PPE): I always ensure I, and my team members, are wearing appropriate PPE, including safety shoes, high-visibility vests, and gloves, as needed.

- Communication: Clear communication with the driver and warehouse personnel is crucial. We establish a common understanding of the loading process, including hand signals, designated loading zones, and emergency procedures.

- Ongoing Monitoring: Throughout the loading process, I stay alert for potential hazards, including stacking instability, overloading, or slips and falls. I address any issues immediately and correct them before they escalate.

For example, if I notice uneven ground, I’ll reposition the truck or utilize wooden planks to create a stable surface. If a package is damaged, I’ll work with the warehouse team to replace it before loading it. Safety is always my top priority.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using handheld scanners or other technology for loading/unloading.

I have extensive experience using handheld scanners in loading and unloading operations. This technology significantly improves efficiency and accuracy.

- Inventory Management: Scanners allow for real-time tracking of items as they are loaded and unloaded. This helps prevent errors and ensures inventory accuracy.

- Shipping Documentation: Scanners verify that the correct items are being loaded onto the correct truck based on the shipping manifest. This minimizes the risk of mis-shipments and ensures timely delivery.

- Proof of Delivery: Scanners facilitate the quick and accurate capture of proof of delivery signatures, improving transparency and reducing disputes.

- Data Collection: The data collected through scanners provides valuable information for improving operational efficiency, identifying bottlenecks, and optimizing workflows.

In my previous role, we used RF scanners that communicated with a central warehouse management system (WMS). This system provided real-time updates on the status of each shipment, allowing us to manage the loading and unloading process more effectively. It dramatically reduced paperwork and eliminated the need for manual data entry, minimizing the chance of human error.

Q 17. How do you communicate effectively with drivers and warehouse staff during loading and unloading?

Effective communication is vital for safe and efficient loading and unloading. I use a multi-faceted approach that emphasizes clarity, respect, and teamwork.

- Pre-load Briefing: Before we begin, I have a brief meeting with the driver and warehouse staff to review the manifest, identify any special handling requirements, and discuss the loading plan.

- Clear Hand Signals: We utilize standard hand signals to guide the driver during maneuvering and loading. This prevents miscommunication and ensures safe positioning of the truck.

- Two-Way Radios: We often use two-way radios for continuous communication, especially during busy periods. This allows for immediate feedback and problem-solving.

- Active Listening: I make a point of actively listening to the driver and warehouse staff and addressing any concerns or questions they may have. This builds trust and fosters a positive working relationship.

- Respectful Demeanor: I treat everyone with respect and courtesy. A positive atmosphere improves morale and contributes to better teamwork and overall productivity.

For example, if a driver has a concern about a particular piece of equipment, I take the time to address it and find a solution that satisfies everyone’s safety requirements.

Q 18. Describe a time you had to resolve a problem related to loading or unloading.

Once, we were loading a shipment of fragile glassware. During the process, one pallet shifted, causing several boxes to fall and break.

Problem: Damaged goods and potential for further damage.

Solution:

- Immediate Stoppage: I immediately stopped the loading process to prevent further damage.

- Damage Assessment: I worked with the warehouse team to assess the extent of the damage and separate the broken items from the undamaged ones.

- Communication: I contacted the shipping manager and the customer to inform them of the incident and discuss possible solutions (replacement, insurance claim).

- Root Cause Analysis: We investigated why the pallet shifted. We discovered that the pallet wrap was insufficient, and the weight wasn’t evenly distributed.

- Corrective Action: We implemented stricter protocols for securing fragile goods, including reinforcing pallet wrap and double-checking weight distribution before loading.

This incident emphasized the importance of thorough load planning and proper securement techniques. We learned valuable lessons that improved our procedures and prevented similar occurrences in the future.

Q 19. How do you ensure the proper securing of loads to prevent shifting or damage during transit?

Proper load securing is crucial for preventing damage and ensuring safety during transit. My experience includes utilizing various techniques depending on the type of cargo.

- Strapping: Using high-quality straps to tightly secure the load to the truck bed. Proper tension is crucial to prevent shifting.

- Shrink Wrap: Encasing the entire load with plastic shrink wrap helps to consolidate items and prevent them from moving around.

- Dunnage: Employing fillers, such as cardboard or air bags, to fill gaps and prevent items from shifting or colliding.

- Blocking and Bracing: Using wooden blocks or other materials to create a stable structure that supports the load and prevents it from tipping.

- Load Bars and Anchors: Using specialized bars and anchors securely attached to the truck bed to provide tie-down points for straps.

I always follow established guidelines and regulations for load securing, ensuring compliance with weight limits and proper placement of securing devices. For example, when loading heavy machinery, I would use multiple straps secured at several points, adding blocking and bracing as needed to distribute the weight evenly and maintain stability.

Q 20. What are some common challenges you face when loading and unloading trucks, and how do you overcome them?

Common challenges in loading and unloading include time constraints, improper packaging, and unexpected issues with equipment.

- Time Constraints: Meeting tight deadlines requires efficient planning, teamwork, and clear communication. We often prioritize critical shipments and utilize multiple loading docks to maximize throughput.

- Improper Packaging: Damage caused by inadequate packaging is a frequent problem. I work closely with the shipping team to ensure appropriate packaging is used for each type of goods.

- Equipment Malfunctions: Forklift breakdowns or other equipment issues can disrupt operations. Having backup equipment or a service plan in place mitigates this.

- Weather Conditions: Inclement weather can create hazardous conditions, slowing the process. Safety is paramount, so we may need to adjust our methods or pause work until conditions improve.

- Inaccurate Documentation: Errors in paperwork can cause delays and confusion. We meticulously check manifests and ensure all information is accurate.

Overcoming these challenges relies on proactive planning, adaptable strategies, strong teamwork, and a commitment to problem-solving. Being flexible and prepared for unexpected problems is a vital skill in this field.

Q 21. What is your experience with hazardous materials handling during loading and unloading?

My experience with hazardous materials (HAZMAT) handling is extensive. I am trained and certified in the proper procedures for handling these materials, adhering to all relevant regulations and safety guidelines.

- Proper Identification: Accurate identification of HAZMAT is crucial. We always check the labels and shipping documents to confirm the materials’ classification and handling requirements.

- Specialized Equipment: We use specialized equipment and containers designed for safely transporting and handling HAZMAT, preventing spills or leaks.

- Safety Data Sheets (SDS): I always consult SDS sheets for each HAZMAT to understand the specific hazards and required precautions.

- Emergency Response: I am trained in emergency procedures for handling HAZMAT incidents, including spill containment and reporting protocols.

- PPE: Specialized PPE is used to protect against the specific hazards of the material, including respirators, protective suits, and gloves.

Compliance with all regulations is non-negotiable. Careful planning, thorough training, and diligent adherence to safety protocols are essential when handling hazardous materials.

Q 22. How do you adapt your loading/unloading techniques to accommodate different types of goods?

Adapting loading/unloading techniques depends entirely on the goods’ characteristics. Fragile items like glassware require careful handling, often involving extra padding and slower, more deliberate movements. Conversely, heavier, bulkier items like pallets of bricks can be handled more efficiently using forklifts and pallet jacks, prioritizing speed and safety within weight limits.

- Fragile Goods: Think of loading fine china. We’d use plenty of bubble wrap, strategically place items to avoid shifting, and avoid stacking too high. Each piece would be handled individually with care.

- Heavy Goods: Loading pallets of cement requires a different approach. Forklifts are essential for efficient and safe movement. We’d ensure the pallets are stable, properly secured, and the forklift’s capacity is not exceeded.

- Liquid Goods: Handling drums of chemicals requires additional safety precautions, including proper labeling identification, secure placement to prevent spills, and adherence to all relevant safety regulations.

Essentially, a successful strategy involves understanding the specific needs of each shipment and utilizing the appropriate equipment and techniques to ensure safe and efficient transport.

Q 23. Describe your understanding of weight distribution and its importance in safe loading practices.

Weight distribution is paramount to safe loading. An unevenly loaded truck is prone to rollovers, especially during turns or on uneven roads. The goal is to achieve a balanced load, distributing weight evenly across the axles to maintain stability.

Imagine a seesaw: if all the weight is on one side, it tips over. A truck is similar. Proper weight distribution prevents this, ensuring the truck remains stable and reduces stress on the vehicle’s structure.

- Center of Gravity: Keeping the center of gravity low and central is crucial. Heavier items should be loaded lower and closer to the center of the truck bed.

- Axle Weight Limits: We must always be aware of the axle weight limits for the truck. Exceeding these limits is illegal and incredibly dangerous. We use weight scales to ensure compliance and to avoid fines.

- Load Securing: Properly securing the load using straps, chains, or other methods is essential to prevent shifting during transit. A shifting load can significantly alter weight distribution and cause accidents.

Q 24. What safety measures do you take to protect yourself from injury during loading and unloading?

Safety is my top priority. I consistently use the following measures:

- Personal Protective Equipment (PPE): This includes steel-toed boots, high-visibility vests, gloves (appropriate for the material being handled), and safety glasses. I always ensure my PPE is in good condition before beginning work.

- Proper Lifting Techniques: I always lift with my legs, keeping my back straight to avoid strains and injuries. For heavy items, I utilize appropriate lifting equipment like forklifts, pallet jacks, or hand trucks.

- Awareness of Surroundings: I maintain constant awareness of my surroundings, watching out for potential hazards like uneven ground, other workers, or moving vehicles.

- Communication: Clear communication with fellow workers is crucial, especially when working in a team. We use hand signals and verbal communication to coordinate loading and unloading activities.

- Reporting Hazards: I immediately report any unsafe conditions or hazards to my supervisor.

I’ve personally witnessed the devastating consequences of neglecting safety, so I’m extremely diligent.

Q 25. How familiar are you with different types of shipping documentation?

I’m very familiar with various shipping documents, including:

- Bill of Lading (BOL): This is a crucial document that serves as a contract between the shipper and the carrier. It details the goods being shipped, the origin and destination, and the agreed-upon terms.

- Packing List: This document lists the contents of each package within a shipment, detailing the quantity and description of each item. It’s essential for accurate inventory management.

- Commercial Invoice: This invoice details the transaction between buyer and seller, including pricing, payment terms, and other relevant information. It’s essential for customs purposes.

- Certificate of Origin (COO): This document verifies the origin of goods, often required for international shipments.

- Delivery Receipts: Confirmation documents signed by the recipient acknowledging receipt of the goods.

Understanding these documents is crucial for ensuring the correct goods are loaded, properly documented, and delivered to the intended destination.

Q 26. Explain your experience with working in a team environment during loading and unloading operations.

Teamwork is fundamental in loading and unloading operations. Efficient and safe operations depend on effective communication and coordination amongst team members.

For example, in one instance we were unloading a large shipment of appliances. One team member directed the forklift, another guided the placement of appliances onto the loading dock, while a third ensured everything was properly secured. Clear communication prevented damage and ensured we completed the task quickly and safely.

My experience highlights the importance of clear roles, mutual respect, and effective problem-solving within the team.

Q 27. What are your strengths and weaknesses regarding loading and unloading trucks?

My strengths lie in my efficiency, attention to detail, and my commitment to safety. I’m adept at adapting to various loading scenarios and am proficient in using various loading equipment. I’m also a quick learner and am always eager to improve my skills.

My weakness, if I had to identify one, would be delegating tasks in very large-scale operations. While I can effectively manage my own responsibilities, I’m still refining my skills in leading and coordinating larger teams.

Q 28. Where do you see yourself in five years regarding your career in loading and unloading?

In five years, I envision myself in a supervisory role, overseeing loading and unloading operations, and perhaps training new team members. I’m keen to develop my leadership skills and contribute to a more efficient and safer working environment. I’d also like to expand my knowledge of logistics and supply chain management, aiming for a more comprehensive understanding of the industry. My long-term goal is to become a trusted expert in this field, contributing to operational excellence and safety.

Key Topics to Learn for Experience with Loading and Unloading Trucks Interview

- Safety Procedures: Understanding and adhering to all relevant safety regulations, including proper lifting techniques, equipment operation, and hazard identification.

- Efficient Loading Techniques: Optimizing load placement for balance, stability, and efficient space utilization within the truck. This includes understanding weight distribution and securement methods.

- Unloading Procedures: Safe and efficient unloading methods, considering the type of cargo and destination. This includes using appropriate equipment and minimizing damage risk.

- Equipment Operation: Demonstrating proficiency in operating relevant equipment, such as forklifts, pallet jacks, and loading ramps. This includes both safe operation and maintenance awareness.

- Inventory Management: Accurately tracking and documenting loaded and unloaded items, ensuring accuracy and minimizing discrepancies. This might involve using scanners or manual record-keeping.

- Problem-Solving and Adaptability: Describing how you’ve handled unexpected challenges, such as damaged goods, equipment malfunctions, or time constraints. Highlight your ability to adapt to changing situations.

- Teamwork and Communication: Illustrating your ability to collaborate effectively with colleagues, supervisors, and potentially clients to ensure smooth loading and unloading processes.

- Logistics and Route Optimization (if applicable): Demonstrating understanding of efficient route planning and logistics involved in the transportation process.

Next Steps

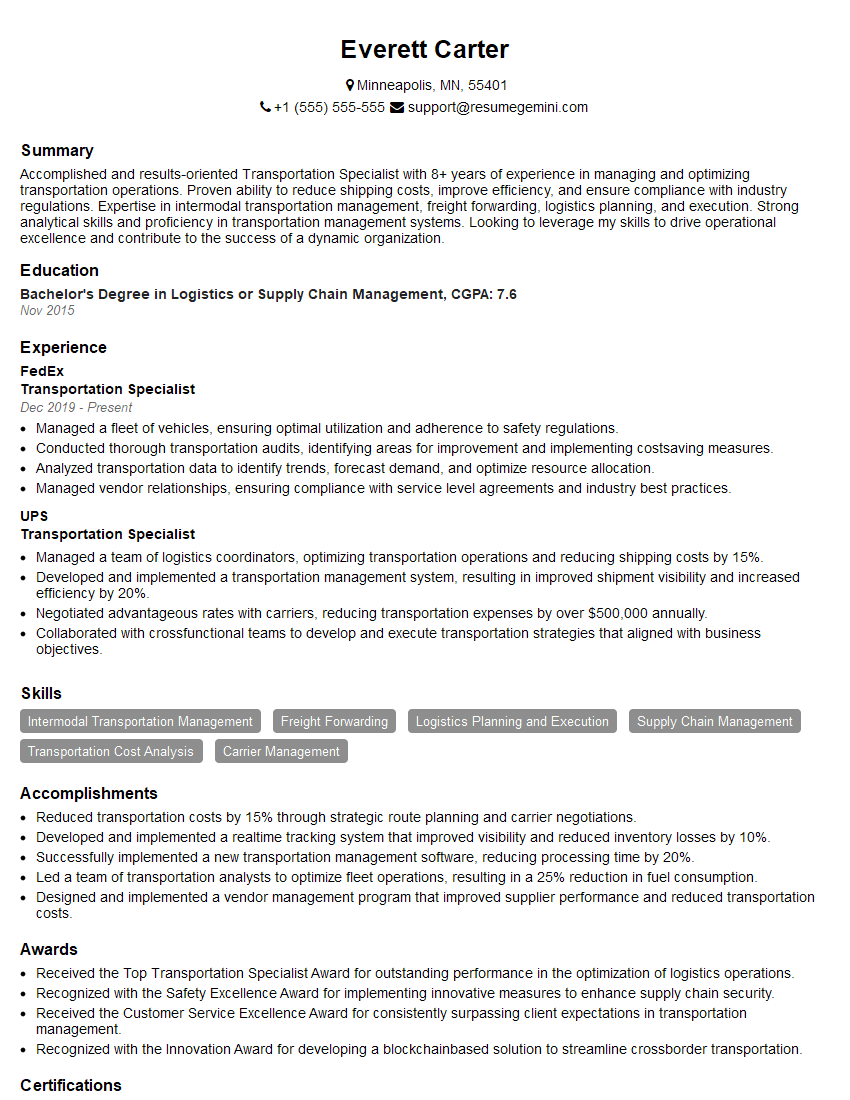

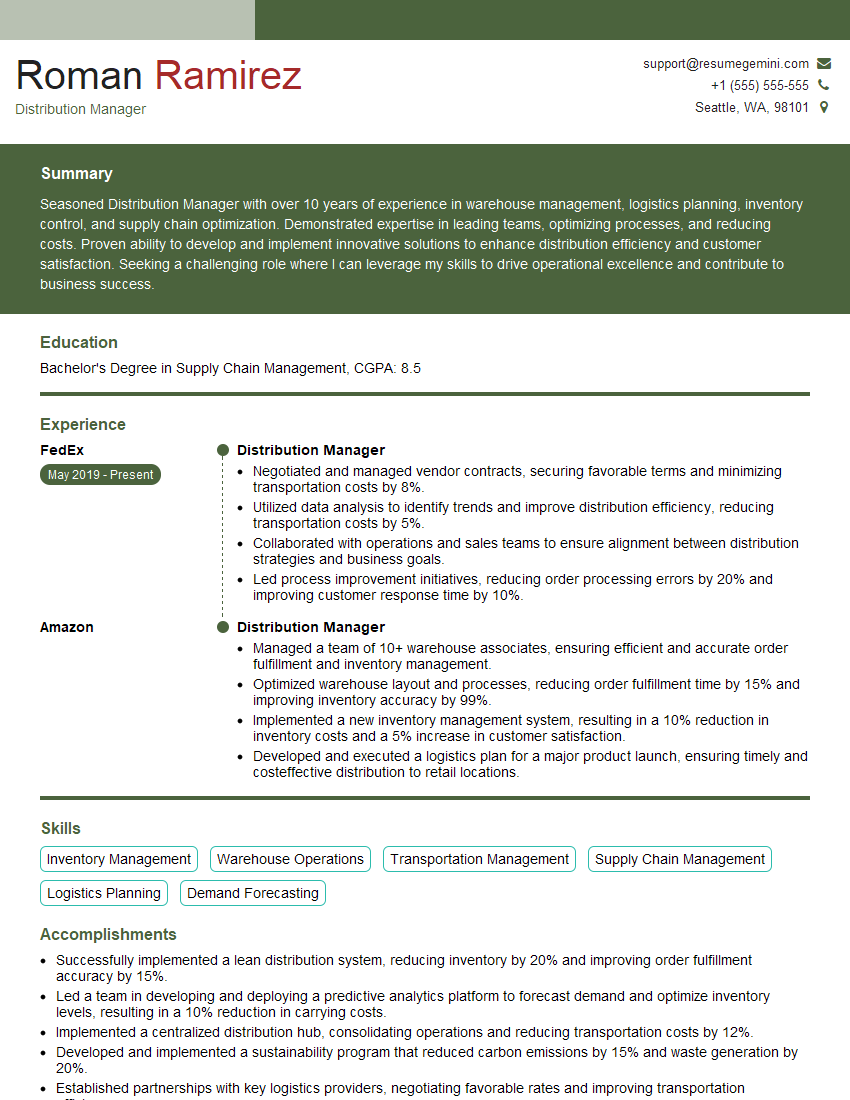

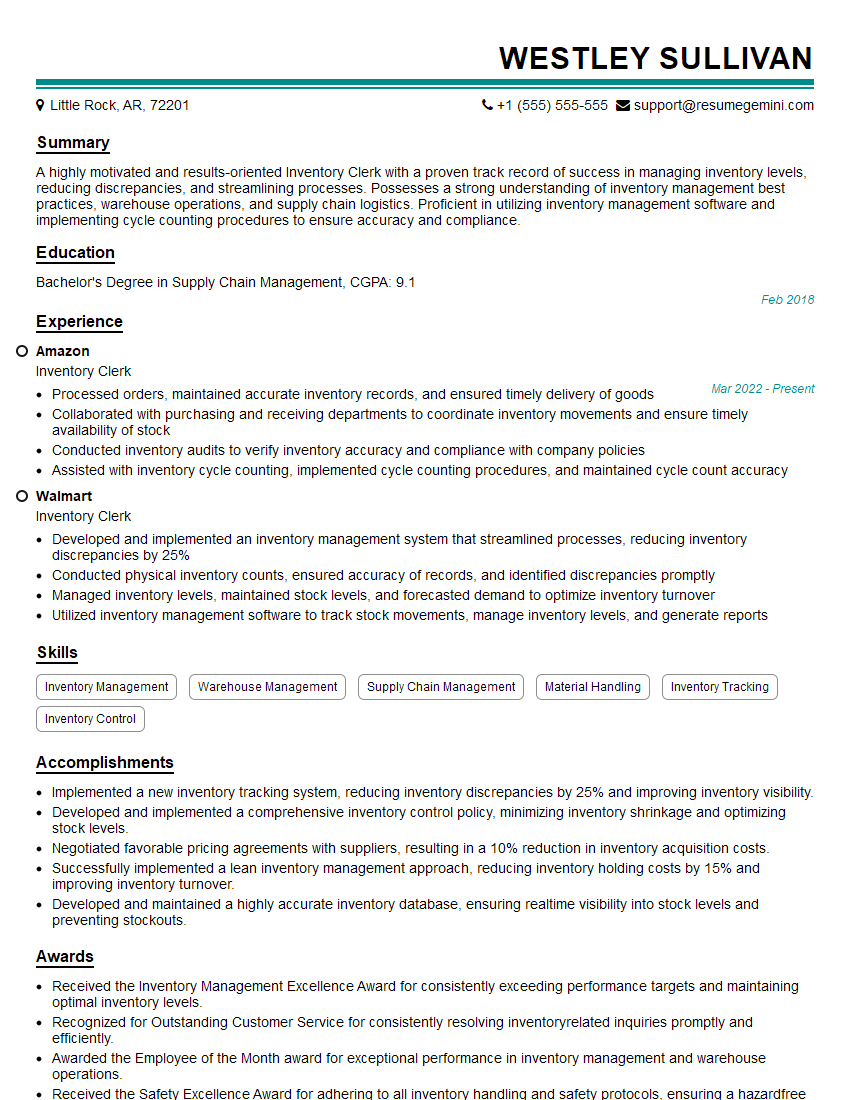

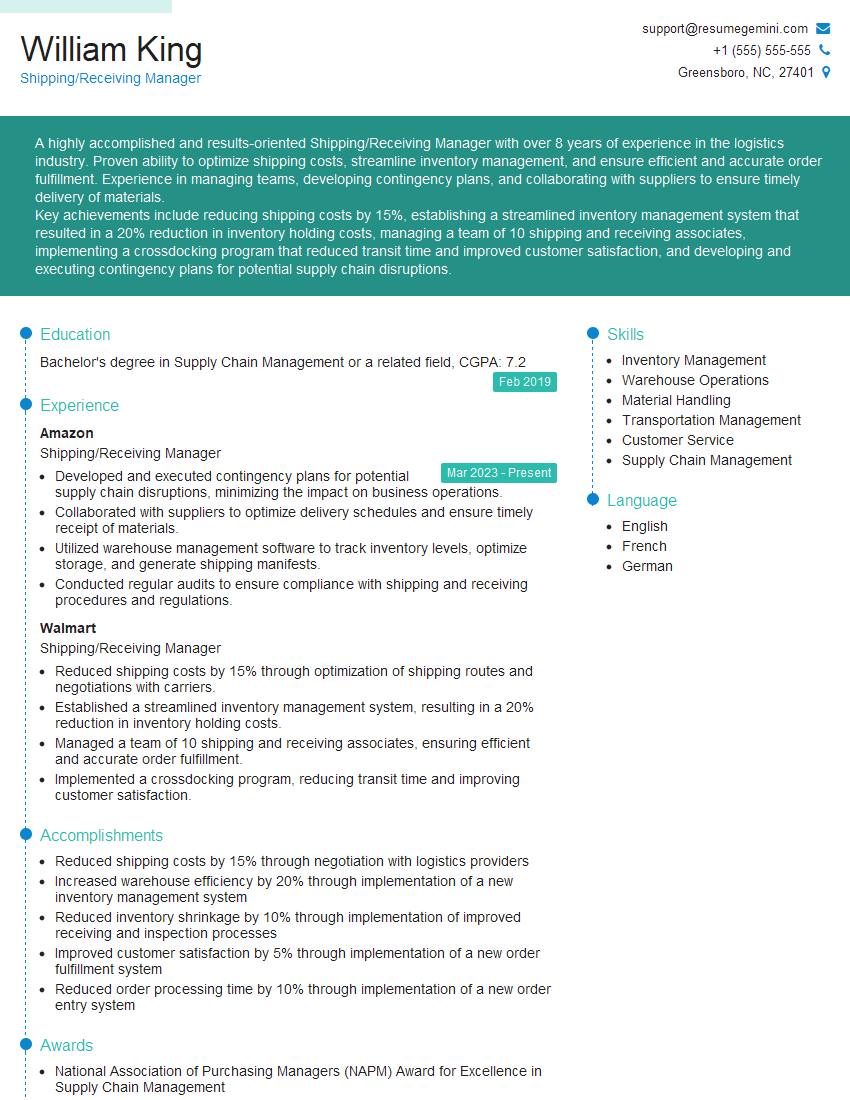

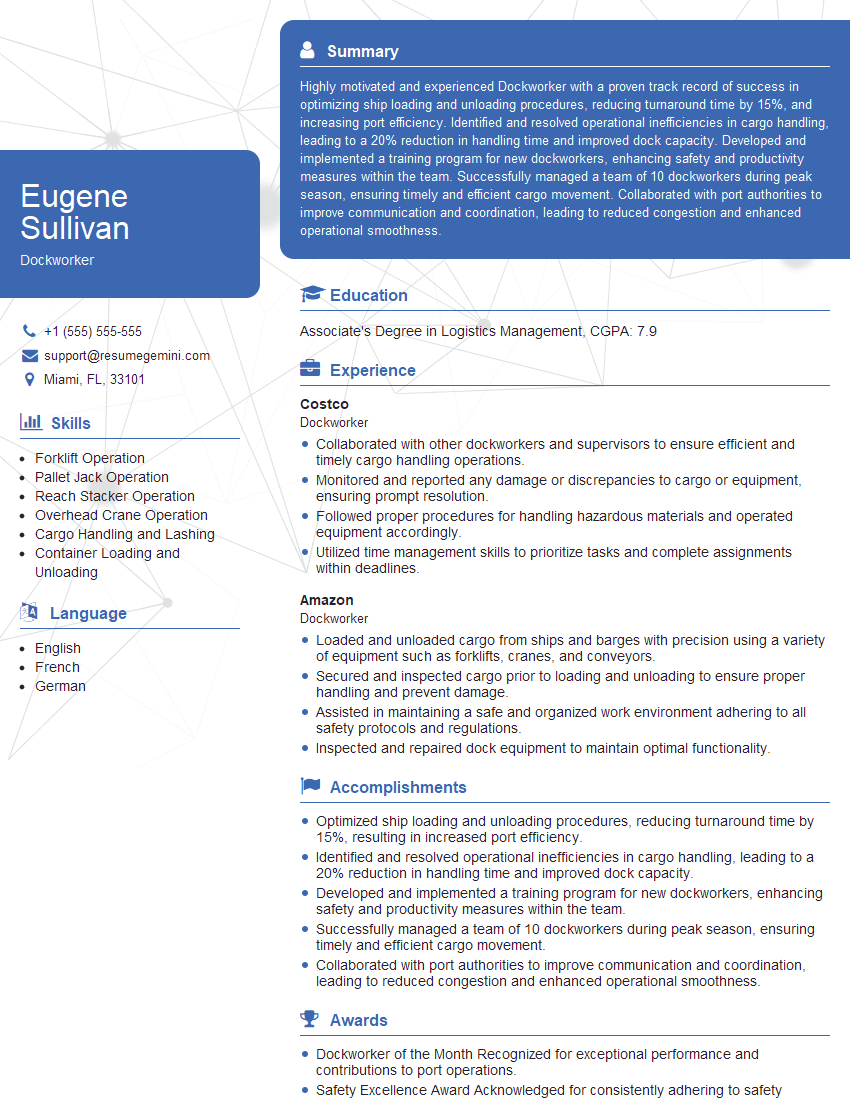

Mastering the skills and knowledge related to loading and unloading trucks is crucial for career advancement in logistics, warehousing, and transportation. A strong understanding of safety, efficiency, and problem-solving will significantly increase your job prospects. To stand out, create an ATS-friendly resume that highlights your relevant experience and skills. ResumeGemini is a trusted resource to help you build a professional resume that captures the attention of recruiters. Examples of resumes tailored to experience with loading and unloading trucks are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good