Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Knowledge of Moving Equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Knowledge of Moving Equipment Interview

Q 1. Describe your experience operating a forklift.

I have over eight years of experience operating various forklift models, including counterbalance, reach trucks, and order pickers. My experience spans diverse warehousing and manufacturing environments, encompassing tasks such as loading and unloading trucks, moving pallets within a warehouse, stacking inventory to considerable heights, and transporting materials between production lines. I’ve consistently exceeded performance expectations in terms of efficiency and safety, achieving a flawless record in terms of accidents or near misses. For instance, in my previous role at Acme Manufacturing, I was responsible for handling the daily movement of over 500 pallets, consistently meeting tight deadlines without compromising safety protocols.

Q 2. What safety procedures do you follow when operating heavy machinery?

Safety is paramount in my approach to operating heavy machinery. My adherence to safety procedures is unwavering. This includes, but is not limited to: always conducting pre-operational checks; wearing appropriate Personal Protective Equipment (PPE), such as safety glasses, gloves, and steel-toed boots; ensuring the area is clear of obstructions and personnel before commencing operation; maintaining a safe speed appropriate for the load and environment; never exceeding the forklift’s rated load capacity; using the horn to signal my presence; and completing post-operational checks. Additionally, I actively participate in workplace safety training and am familiar with all relevant regulations and company-specific safety guidelines. A specific example: Before moving a load near a pedestrian area, I always make sure to visually confirm the space is clear and I use my horn to alert anyone nearby before proceeding.

Q 3. Explain the pre-operational checks you perform on a forklift.

My pre-operational checks are meticulous and follow a standardized checklist. I begin by inspecting the forklift’s tires for proper inflation and damage. Then, I check the mast for any signs of bending or damage. I visually inspect the forks for any wear or damage, ensuring they’re securely attached. I also check the hydraulic fluid levels, brakes, lights, horn, and seatbelt. I test the steering, lift, and tilt mechanisms to confirm they function correctly. I also verify that the load backrest is in place if needed. Finally, I check my fuel levels and confirm the parking brake is engaged. This thorough inspection ensures the safe and efficient operation of the forklift, minimizing the risk of accidents and malfunctions. If any discrepancies are found, I immediately report them to my supervisor and avoid operating the machine until repairs are completed.

Q 4. How do you handle a mechanical malfunction during operation?

In case of a mechanical malfunction, my immediate priority is safety. I immediately stop the forklift, secure the load, engage the parking brake, and turn off the engine. I then assess the situation to determine the nature of the problem. If it’s a minor issue that I can safely address (e.g., a minor hydraulic leak that isn’t affecting operation), I might attempt a temporary fix after seeking approval from my supervisor. However, for significant issues that require professional attention (e.g., engine trouble or a significant hydraulic leak), I immediately report the problem to my supervisor or the maintenance department, clearly explaining the circumstances and preventing anyone from using the malfunctioning equipment. I then wait for professional assistance and document the incident fully.

Q 5. What are the different types of forklift attachments and their uses?

Forklifts can be equipped with a variety of attachments to enhance their versatility. Some common types include:

- Side Shifters: Allow for precise lateral movement of the forks, useful for placing pallets in tight spaces or aligning them accurately.

- Paper Roll Clamps: Specifically designed for handling large paper rolls.

- Rotating Clamps: These allow the operator to rotate the load 90 degrees, streamlining placement in certain configurations.

- Fork Extensions: Increase the length of the forks, facilitating the handling of longer or oddly shaped loads.

- Carriage Movers: Allow for movement of the load carriage without raising or lowering the forks.

- Bucket Attachments: Used for handling bulk materials or loose items.

The choice of attachment depends entirely on the nature of the material being handled and the task at hand. For example, when handling oversized steel beams, fork extensions increase reach and stability, while paper roll clamps are essential for efficiently moving those large paper rolls without damaging them.

Q 6. Describe your experience with load securing techniques.

I have extensive experience in load securing techniques, understanding the crucial role it plays in preventing accidents and damage during transportation. My approach always prioritizes the type of load and the transportation method. For pallets, I ensure that they’re stable and properly stacked, using stretch wrap or strapping as needed to secure the load. For loose materials, I use appropriate containers and ensure they are properly secured to prevent spillage. When transporting long or awkwardly shaped materials, I use additional securing mechanisms like chains or straps, ensuring that these are appropriately fastened and tensioned to prevent shifting during transport. My understanding of weight distribution and center of gravity is crucial in this process, as is my knowledge of relevant safety regulations. For example, I might use a different type of strapping for heavier or more fragile loads than lighter ones to ensure optimal security.

Q 7. How do you ensure the stability of a load during transportation?

Ensuring load stability is critical for safe transportation. My approach involves several key steps: First, I accurately assess the weight and dimensions of the load, never exceeding the forklift’s rated capacity. Second, I evenly distribute the weight across the forks. For uneven loads, I might use load stabilizers or adjust the forks to ensure balance. Third, I utilize appropriate load securing techniques, as previously mentioned, such as stretch wrap, straps, or chains to prevent shifting. Fourth, I maintain a slow and controlled speed during transportation, especially when negotiating turns or inclines. Fifth, I avoid sudden braking or acceleration that could cause the load to shift. For particularly challenging loads, I may even work alongside a spotter to further enhance safety and visibility. If I have any concerns about the stability of a load, I will always stop and seek assistance before proceeding. A poorly secured or unstable load can have disastrous consequences, so safety is my absolute priority.

Q 8. What are the load capacity limits of a forklift you’re familiar with?

Load capacity limits on forklifts vary greatly depending on the model, manufacturer, and mast configuration. I’m familiar with several models, including the Hyster H160FT, which has a rated capacity of approximately 16,000 pounds (7257 kg) at a specific load center. Another common model I’ve worked with is the Toyota 8-Series, with capacities ranging from 3,000 to 10,000 pounds (1360 to 4535 kg), again dependent on the load center and mast height. It’s crucial to always consult the manufacturer’s data plate on the forklift itself for the exact load capacity under various conditions. Never exceed the stated capacity; doing so compromises safety and could result in serious damage or injury.

Think of it like this: just as a car has a maximum weight limit for passengers and cargo, a forklift has a maximum weight limit for the goods it carries. Exceeding this limit is dangerous and can lead to tipping.

Q 9. Explain your understanding of load center and its importance.

The load center is the distance from the face of the forks to the center of gravity of the load. It’s absolutely critical for safe forklift operation. The closer the load’s center of gravity is to the mast, the more weight the forklift can safely lift. Conversely, the further away the load’s center of gravity, the less weight the forklift can handle without risking a tip-over. The manufacturer provides load capacity charts that specify the maximum allowable weight for different load centers.

Imagine trying to balance a book on the end of a ruler. If you hold the ruler close to the book (small load center), it’s easy. But if you move your hand far from the book (large load center), it becomes much harder to balance, and the ruler is more likely to tip.

Q 10. How do you identify and avoid potential hazards in a warehouse environment?

Identifying and avoiding hazards in a warehouse involves a proactive and multi-faceted approach. It starts with regular inspections of the facility, looking for things like obstructed walkways, damaged equipment, spills, uneven flooring, and poorly stacked pallets. Proper lighting is also essential, and I always check to ensure adequate visibility.

Beyond the physical environment, I carefully observe the actions of other workers to ensure adherence to safety protocols and look out for any unsafe behaviors, like speeding on forklifts or improper load handling. I actively participate in safety training and maintain my certifications, including refresher courses that keep my skills sharp. Communication is also key, reporting any unsafe conditions immediately to my supervisor.

- Regular Inspections: Check for spills, obstructions, and damaged equipment.

- Proper Lighting: Ensure adequate visibility.

- Safe Practices Observation: Monitor colleagues for safe operation of equipment.

- Communication: Report unsafe conditions immediately.

Q 11. What is your experience with different types of cranes?

My experience encompasses various crane types, including:

- Overhead Cranes: These are commonly found in factories and warehouses for lifting heavy materials. I’m proficient in operating various types, from simple single-girder cranes to more complex double-girder models with variable-speed hoists. I’m familiar with their different braking systems and load-limiting devices.

- Mobile Cranes: I have experience with both crawler cranes (used for heavy lifting in tough terrain) and truck-mounted cranes (for more mobile applications). I understand the importance of proper outrigger setup and weight distribution for stability.

- Tower Cranes: I’ve worked around tower cranes on construction sites, understanding their unique safety considerations regarding wind speed limitations and load-carrying capacity at various jib radii.

Each crane type requires a different level of expertise and understanding of its operational limitations and safety features. I’m always careful to prioritize safety when operating any type of crane, carefully checking the equipment’s condition before operation and adhering to all safety guidelines.

Q 12. Describe your experience with rigging and load slings.

My experience with rigging and load slings is extensive. I’m well-versed in selecting appropriate slings for different loads and lifting angles, understanding the limitations of different materials like nylon, polyester, and wire rope. I’m adept at inspecting slings for wear and tear, damage, or any signs of weakness, rejecting those with visible defects. I always inspect the load to ensure it’s properly secured and balanced before initiating the lift.

For instance, when lifting a heavy steel beam, I would choose a wire rope sling with a sufficient capacity and multiple legs for increased stability and load distribution. Conversely, for a delicate object, a soft sling such as nylon would be more suitable to prevent damage. It’s crucial to understand the different types of hitches and how they affect load distribution and sling capacity. Improper rigging can lead to catastrophic equipment failure.

Q 13. What are the different types of lifting equipment and their applications?

Lifting equipment encompasses a wide range of tools and machinery:

- Cranes (Overhead, Mobile, Tower): Used for lifting heavy loads in various settings.

- Forklifts: Essential for material handling in warehouses and factories.

- Hoists (Chain, Electric, Lever): For lifting lighter loads vertically.

- Jacks (Hydraulic, Mechanical): For lifting and supporting heavy objects temporarily.

- Winches: Used for pulling and hoisting loads, often in construction and marine applications.

- Lifting Beams and Spreader Beams: Used to distribute the load across multiple points for better stability.

The application of each type depends heavily on the specific load, environment, and required lifting method. Selection requires careful consideration of load weight, dimensions, and the overall lifting environment. It’s crucial to match the equipment to the task, ensuring it has sufficient capacity and suitability for the load and conditions.

Q 14. How do you calculate the safe working load of a crane?

Calculating the safe working load (SWL) of a crane is crucial for preventing accidents. The SWL is the maximum load a crane can safely lift under specific conditions. It’s not simply a single number; it changes depending on several factors.

The calculation often involves referring to the crane’s load chart which provides the SWL at various jib radii (for tower and mobile cranes) or across the crane’s span (for overhead cranes). You’ll need to consider:

- Crane Type and Model: Different cranes have different capacities.

- Jib Radius (for tower and mobile cranes): The further the load is from the crane, the lower the SWL.

- Boom Angle (for mobile cranes): The boom angle affects the load capacity.

- Wind Speed: High wind speeds significantly reduce the safe working load.

- Load configuration: The distribution of the load and its center of gravity.

It is extremely important to always consult the crane’s load chart and the manufacturer’s instructions, taking all the above factors into consideration. It’s never advisable to make assumptions; safety always comes first.

Q 15. Explain the importance of regular maintenance for moving equipment.

Regular maintenance for moving equipment is paramount for ensuring safety, maximizing equipment lifespan, and maintaining operational efficiency. Neglecting maintenance can lead to costly repairs, downtime, and, most importantly, serious accidents. Think of it like regular check-ups for your car – preventative care is far cheaper and safer than waiting for a catastrophic breakdown.

- Safety: Regular inspections identify potential hazards like worn brakes, leaking hydraulics, or faulty electrical systems before they cause accidents.

- Efficiency: Properly maintained equipment operates more smoothly, reducing fuel consumption, wear and tear, and downtime.

- Lifespan: Preventative maintenance extends the operational life of equipment, reducing the need for frequent and expensive replacements.

- Cost Savings: While maintenance requires upfront investment, it’s far less expensive than emergency repairs or complete equipment failure.

For example, a forklift with worn tires is significantly more prone to tipping, posing a serious safety risk. Regular tire inspections and replacements prevent this.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventive maintenance procedures.

My experience with preventive maintenance procedures encompasses a wide range of equipment, from forklifts and pallet jacks to reach trucks and aerial lifts. I’m proficient in creating and following scheduled maintenance plans, including daily, weekly, and monthly checks. This includes visually inspecting components, lubricating moving parts, checking fluid levels (hydraulic fluid, engine oil), and performing functional tests to ensure everything operates correctly.

For instance, during weekly forklift maintenance, I’d check the battery levels, inspect the mast for damage or wear, ensure the brakes are functioning correctly, and test the horn and lights. A comprehensive log is maintained for each piece of equipment, documenting all maintenance activities, repairs, and any anomalies observed. This creates a detailed history, allowing us to identify potential issues before they escalate.

Q 17. How do you troubleshoot common problems with forklifts or other equipment?

Troubleshooting moving equipment involves a systematic approach combining knowledge of the equipment’s mechanics, electrical systems, and hydraulics. I start by identifying the specific problem, listening for unusual sounds, noting any error codes, and visually inspecting the equipment for obvious damage.

For example, if a forklift won’t start, I would first check the battery connections, then the battery voltage. If that’s fine, I would move to check the starter motor, fuel system, and finally, the engine control unit. Similarly, a hydraulic leak would require identifying the source of the leak (hose, cylinder, pump), and determining the appropriate repair strategy – from replacing a hose to a more extensive repair of a hydraulic component.

My process generally follows these steps:

- Identify the problem: What exactly is malfunctioning?

- Gather information: Look for clues like error codes, unusual noises, or leaks.

- Visual inspection: Examine the relevant components for damage or wear.

- Systematic testing: Check individual components to isolate the issue.

- Repair or replacement: Once the problem is identified, fix or replace the faulty component.

- Testing and verification: Ensure the equipment functions correctly before returning it to service.

Q 18. What are the legal requirements for operating moving equipment in your area?

Legal requirements for operating moving equipment vary by location, but generally include licensing, training, and adherence to safety regulations. In my area, operators must possess a valid operator’s license specific to the type of equipment they operate (e.g., forklift license). This license is typically obtained after completing a certified training course that covers safe operating procedures, pre-operational checks, and emergency procedures.

Beyond licensing, regular inspections are mandated to ensure equipment is in safe operating condition. Operators are required to follow specific safety protocols, such as wearing appropriate personal protective equipment (PPE) including safety glasses, gloves, and steel-toe boots. Furthermore, there are strict regulations concerning load capacity, speed limits, and operating the equipment in designated areas.

Failure to comply with these regulations can result in fines, suspension of licenses, and even criminal charges in cases involving accidents or injuries.

Q 19. How do you handle a near-miss incident involving moving equipment?

A near-miss incident, even without resulting in an accident, is a serious event that requires immediate attention. My approach involves a thorough investigation to understand what happened and prevent future incidents. The goal isn’t to assign blame but to identify underlying causes and implement corrective actions.

My process involves:

- Immediate Action: Secure the area and ensure no one is injured.

- Investigation: Gather information from witnesses, review any relevant footage, and inspect the equipment.

- Root Cause Analysis: Determine the factors contributing to the near miss (e.g., operator error, equipment malfunction, environmental factors).

- Corrective Actions: Implement changes to prevent recurrence, which might include retraining operators, repairing equipment, improving signage, or adjusting work processes.

- Documentation: Thoroughly document the incident, investigation, and corrective actions taken.

For instance, a near miss might involve a forklift almost colliding with a pedestrian. The investigation might reveal a blind spot in the warehouse layout or a failure by the operator to properly sound the horn. Corrective actions could include installing mirrors to eliminate the blind spot and retraining the operator on safe operating procedures.

Q 20. Explain your understanding of OSHA regulations for material handling.

My understanding of OSHA regulations for material handling is extensive. OSHA (Occupational Safety and Health Administration) sets standards to minimize workplace hazards associated with moving materials. These regulations cover a broad range of aspects, including equipment maintenance, operator training, safe operating procedures, and the proper use of personal protective equipment (PPE).

Key OSHA regulations pertaining to material handling include:

- Training Requirements: Operators must receive adequate training before operating powered industrial trucks (forklifts, etc.).

- Equipment Inspection: Regular inspections are crucial to ensure equipment is in safe working order.

- Load Capacity: Operators must adhere to the equipment’s load capacity limits to prevent accidents.

- Safe Operating Procedures: Specific procedures need to be followed, such as proper load handling, travel paths, and communication protocols.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, such as safety glasses, gloves, and steel-toe boots.

- Workplace Conditions: The work environment must be safe and free from hazards like obstructions and uneven surfaces.

Non-compliance with OSHA regulations can result in significant penalties for employers. Understanding and implementing these regulations is critical for maintaining a safe and productive work environment.

Q 21. Describe your experience with inventory management and material flow.

My experience with inventory management and material flow involves optimizing the movement of goods within a facility to ensure efficient operations and minimal waste. This includes coordinating with warehouse staff, tracking inventory levels, and analyzing data to identify areas for improvement.

For example, I’ve worked on projects to improve warehouse layout, implement barcode scanning systems for efficient inventory tracking, and optimize picking routes to reduce travel time. Analyzing material flow data helps identify bottlenecks and inefficiencies, allowing us to implement changes like reorganizing storage locations or adjusting transportation methods. Accurate inventory tracking ensures that we have the right materials available when and where needed, preventing delays and minimizing production downtime.

This involves a combination of practical skills such as using warehouse management systems (WMS) and analytical skills to interpret data and identify areas needing attention. Effective inventory management also helps minimize storage costs and prevents stockouts or overstocking.

Q 22. How do you optimize warehouse layout for efficient material handling?

Optimizing warehouse layout for efficient material handling is crucial for minimizing costs and maximizing throughput. It involves strategically placing storage areas, workstations, and equipment to minimize travel distances and material movement. Think of it like designing a well-organized kitchen – everything is within easy reach.

Flow Optimization: Design a smooth, unidirectional flow of goods, from receiving to shipping, minimizing backtracking. This could involve using a U-shaped layout or a straight line configuration depending on the warehouse size and throughput requirements.

Zone-Based Organization: Divide the warehouse into distinct zones for different tasks (receiving, storage, picking, packing, shipping). This reduces congestion and allows for specialized equipment placement.

Strategic Equipment Placement: Place equipment like forklifts, conveyor belts, and automated guided vehicles (AGVs) close to high-traffic areas to minimize idle time. Consider the weight and size of the goods being handled when positioning ramps, lifts, and conveyors.

Storage System Selection: Select appropriate storage systems (shelving, racking, pallet racking) based on the size, weight, and type of goods stored. High-density storage solutions can significantly increase storage capacity in limited space.

AISLE Design: Ensure aisles are wide enough for efficient movement of equipment, allowing for safe maneuvering and reducing the risk of accidents. Consider using narrow-aisle forklifts to optimize space if necessary.

For example, in a distribution center for fast-moving consumer goods (FMCG), frequently accessed items should be placed in easily accessible locations closer to the shipping dock, while less frequently accessed items can be placed further back. This minimizes travel time and improves picking efficiency.

Q 23. Explain your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) spans over [Number] years, involving implementations and management of several systems, including [mention specific WMS software names, e.g., SAP EWM, Oracle WMS, Blue Yonder]. I’m proficient in all aspects of WMS, from system configuration and integration with other enterprise systems (like ERP and TMS) to user training and data analysis.

I’ve successfully implemented WMS solutions to improve inventory accuracy, optimize picking and packing processes, and track shipments in real-time. One notable project involved implementing a new WMS in a high-volume distribution center, resulting in a [quantifiable result, e.g., 15%] increase in order fulfillment efficiency and a [quantifiable result, e.g., 5%] reduction in inventory discrepancies. This involved detailed data migration, extensive user training, and ongoing system optimization.

My skills include:

- System Configuration and Customization

- Integration with ERP and TMS

- Reporting and Data Analysis

- User Training and Support

- Process Improvement and Optimization

Q 24. How do you manage multiple priorities and deadlines in a fast-paced environment?

Managing multiple priorities and deadlines in a fast-paced environment requires a structured approach and excellent time management skills. I utilize several techniques:

Prioritization Matrix: I use a prioritization matrix (e.g., Eisenhower Matrix) to categorize tasks based on urgency and importance, ensuring that critical tasks are addressed first.

Project Management Tools: I leverage project management tools like [mention specific tools, e.g., Asana, Trello, Microsoft Project] to track progress, set milestones, and manage dependencies.

Effective Communication: Open and transparent communication with my team and stakeholders is vital for ensuring everyone is aligned and understands priorities. Regular updates and status meetings help keep everyone informed.

Delegation and Teamwork: I effectively delegate tasks based on team members’ skills and capabilities, fostering a collaborative environment and maximizing efficiency.

Flexibility and Adaptability: The ability to adapt to changing circumstances and re-prioritize tasks as needed is crucial in a dynamic environment. Unexpected issues require quick thinking and efficient problem-solving.

For example, during a peak season rush, we faced a sudden surge in order volume. By effectively prioritizing urgent orders, leveraging overtime judiciously, and optimizing picking routes, we were able to meet all deadlines without compromising quality.

Q 25. Describe your experience with different types of transportation vehicles.

My experience encompasses a wide range of transportation vehicles used in material handling, including:

Forklifts: I’m experienced with various types, including counterbalance, reach trucks, order pickers, and narrow-aisle forklifts, understanding their capabilities and limitations. Safety procedures and regular maintenance are paramount.

Conveyors: I’ve worked with various conveyor systems, from simple roller conveyors to complex automated systems, understanding the importance of proper alignment and maintenance to ensure efficient material flow.

Automated Guided Vehicles (AGVs): I have experience with AGV systems, including their programming, operation, and integration with WMS for automated material handling. They require specific safety considerations and maintenance routines.

Trucks and Trailers: I understand the logistics of loading and unloading trucks and trailers efficiently, ensuring proper securing of goods and compliance with safety regulations. Knowledge of loading docks and equipment is crucial.

Other Equipment: This includes pallet jacks, hand trucks, and other material handling equipment.

My experience allows me to select the most appropriate equipment for specific tasks, ensuring safety and efficiency.

Q 26. How do you ensure on-time delivery and efficient route planning?

Ensuring on-time delivery and efficient route planning involves a multifaceted approach that combines technology and strategic planning:

Transportation Management Systems (TMS): Utilizing TMS software to optimize routes, considering factors like traffic, distance, and delivery windows. Real-time tracking helps monitor progress and address any potential delays.

Route Optimization Algorithms: Employing route optimization algorithms to create the most efficient routes for delivery vehicles, minimizing travel time and fuel consumption. This often includes dynamic route adjustments based on real-time traffic conditions.

Order Prioritization: Prioritizing orders based on delivery deadlines and urgency, ensuring that time-sensitive deliveries are handled with utmost care.

Communication and Collaboration: Maintaining clear communication with drivers and customers, providing updates on delivery status and addressing any potential issues promptly. This often involves real-time tracking.

Predictive Modeling: Utilizing predictive modeling to anticipate potential delivery delays and proactively adjust schedules to mitigate risks.

For instance, during a severe weather event, I used the TMS to reroute deliveries to avoid affected areas, minimizing delays and ensuring on-time delivery for the majority of our clients.

Q 27. What are your strategies for reducing costs and improving efficiency in material handling?

Reducing costs and improving efficiency in material handling requires a holistic approach focusing on various aspects:

Process Optimization: Streamlining material handling processes through lean principles, eliminating waste and improving workflow. This could involve implementing techniques such as 5S methodology, value stream mapping, or Kaizen events.

Equipment Selection and Maintenance: Choosing energy-efficient equipment and implementing a robust maintenance program to minimize downtime and extend equipment lifespan. Regular inspections and preventive maintenance are key.

Inventory Management: Implementing strategies to optimize inventory levels, reducing storage costs and minimizing waste from obsolescence or spoilage. This often involves utilizing ABC analysis to prioritize inventory management efforts.

Technology Adoption: Utilizing technologies like WMS, TMS, and RFID to enhance visibility, track materials, and automate processes. Automation reduces manual labor costs and increases accuracy.

Employee Training: Providing comprehensive training to employees on safe and efficient material handling techniques. This leads to fewer accidents, damage, and improved productivity.

For example, by implementing a new picking system and optimizing warehouse layout, we reduced order fulfillment time by 10% and lowered labor costs by 5%.

Q 28. Describe a time you had to solve a complex problem related to moving equipment.

In a previous role, we experienced a major breakdown in our automated conveyor system during peak season. This resulted in a significant backlog of orders and threatened to cause significant delays. The problem was initially diagnosed as a simple motor failure, but after several hours of troubleshooting, it became apparent that the issue was more complex, involving a malfunctioning control system.

To solve this, I implemented a structured problem-solving approach:

Gather Information: We systematically collected data on the system’s performance, error messages, and maintenance logs.

Identify Root Cause: We worked with the maintenance team and the vendor to identify the root cause, which turned out to be a software glitch in the control system that was causing unexpected shutdowns.

Develop Solutions: We explored several solutions, including a temporary workaround to bypass the faulty section of the conveyor and a longer-term solution involving a software update from the vendor.

Implement Solution: We implemented the temporary workaround immediately to minimize downtime and began working with the vendor on the software update.

Monitor and Evaluate: Once the software update was implemented, we closely monitored the system’s performance to ensure the problem was fully resolved.

Through this systematic approach, we managed to restore the conveyor system functionality within a short timeframe, minimizing the impact on operations and meeting customer deadlines. This experience highlighted the importance of proactive maintenance, effective troubleshooting, and the ability to think critically under pressure.

Key Topics to Learn for Knowledge of Moving Equipment Interview

- Types of Moving Equipment: Familiarize yourself with various types of moving equipment, including their functionalities, limitations, and appropriate applications (e.g., forklifts, cranes, conveyors, automated guided vehicles). Understand the differences between various models and their capabilities.

- Safety Procedures and Regulations: Master the safety protocols and regulations surrounding the operation and maintenance of moving equipment. This includes pre-operation checks, safe operating procedures, emergency protocols, and relevant industry standards (e.g., OSHA regulations).

- Maintenance and Troubleshooting: Develop a strong understanding of preventative maintenance, routine inspections, and troubleshooting common issues. Be prepared to discuss practical scenarios involving equipment malfunction and your approach to resolving them.

- Load Capacity and Stability: Demonstrate your knowledge of load capacity calculations, weight distribution, and maintaining equipment stability during operation. Understand how to assess risks associated with overloading or improper weight distribution.

- Operational Efficiency and Optimization: Discuss strategies for maximizing efficiency and minimizing downtime. This includes optimizing routes, minimizing energy consumption, and implementing best practices for equipment usage.

- Technological Advancements: Stay updated on the latest technological advancements in moving equipment, including automation, remote control systems, and data-driven operational improvements. Be ready to discuss the implications of these advancements on safety and efficiency.

Next Steps

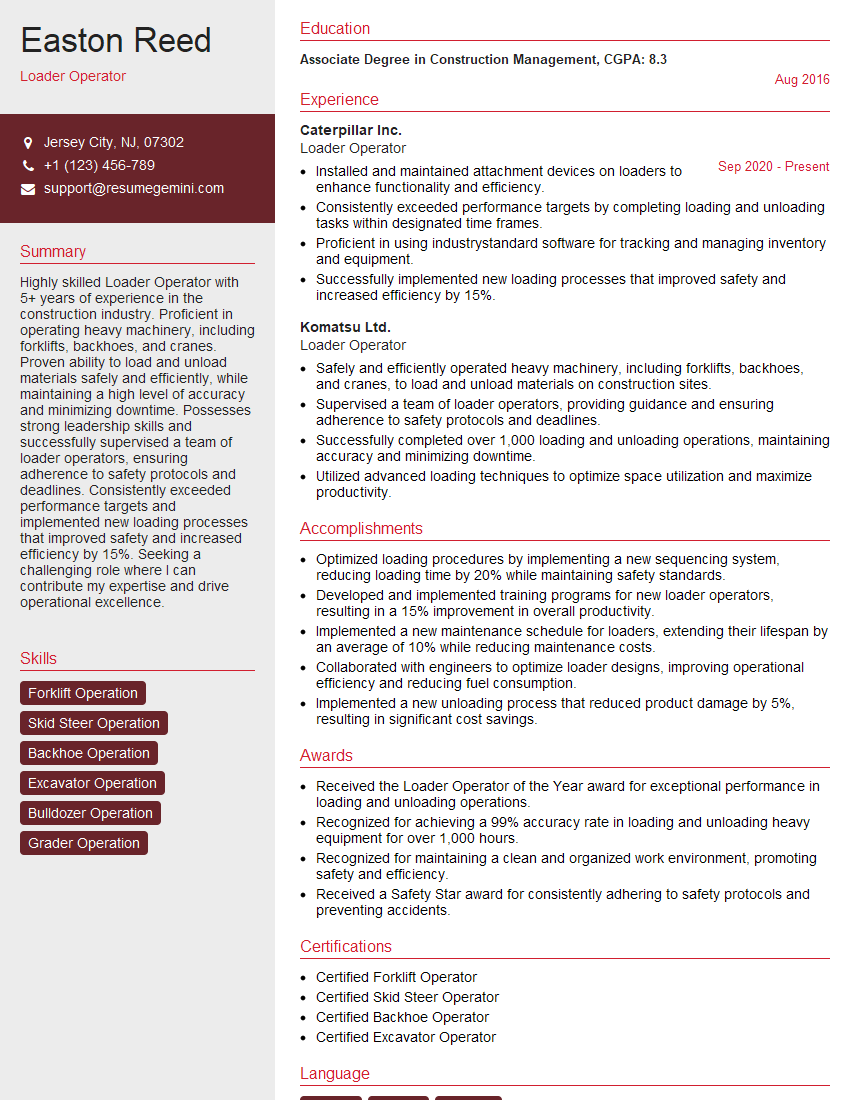

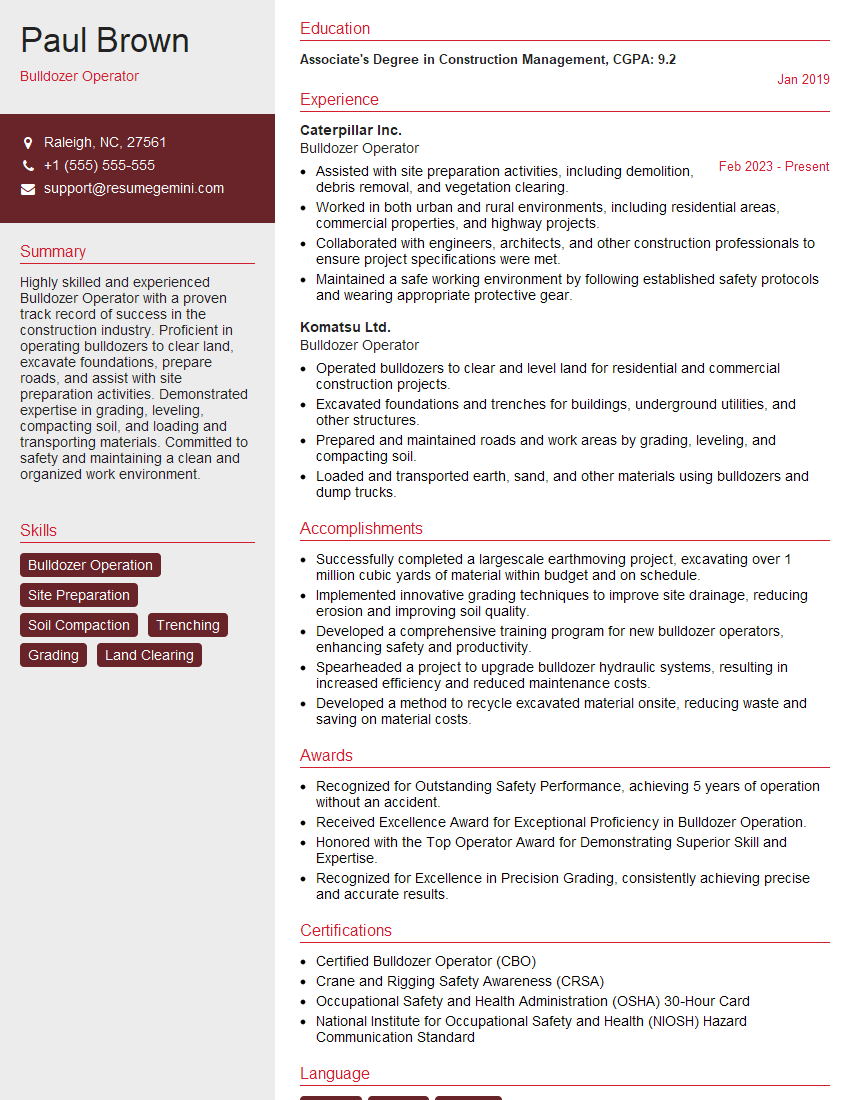

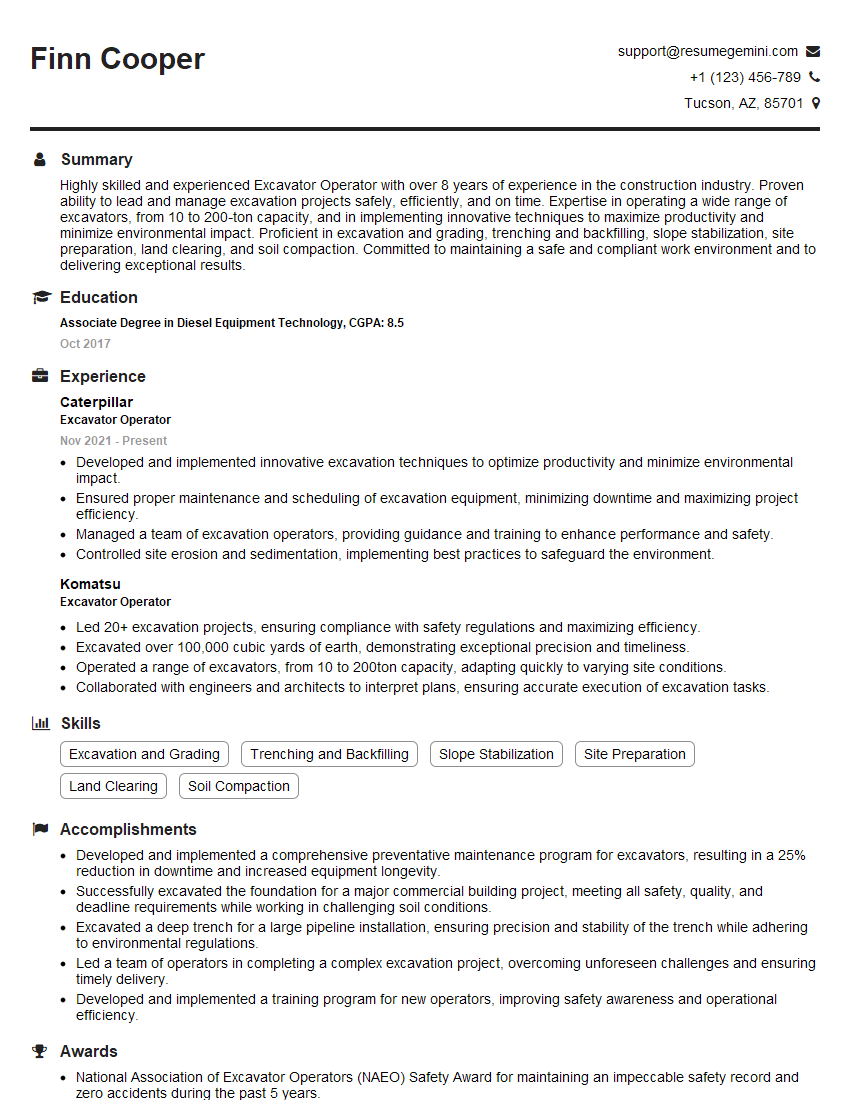

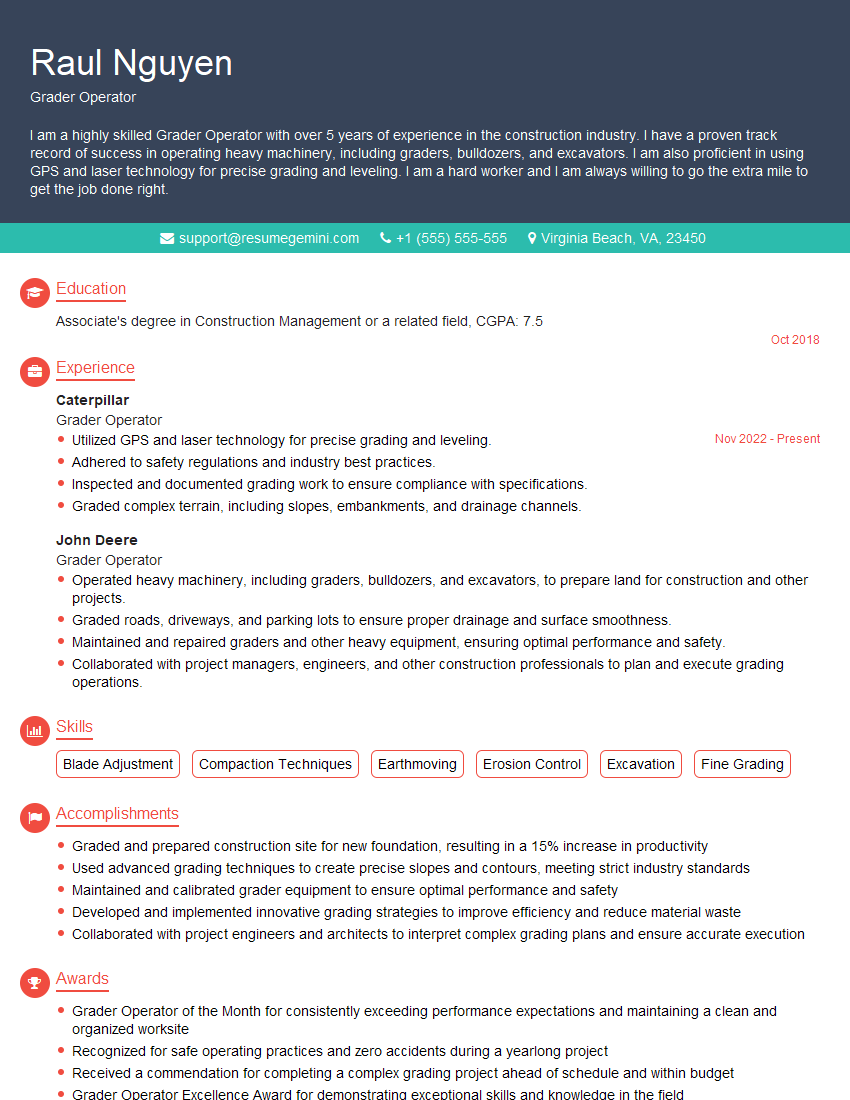

Mastering knowledge of moving equipment is crucial for career advancement in logistics, manufacturing, and warehousing. A strong understanding of these concepts demonstrates your commitment to safety, efficiency, and technological proficiency, making you a highly valuable asset to any organization. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Knowledge of Moving Equipment to guide you through the process, ensuring your qualifications shine.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good