Unlock your full potential by mastering the most common Timbering interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Timbering Interview

Q 1. Explain the different methods of timber harvesting.

Timber harvesting methods are broadly categorized by how trees are selected and removed. The key distinction lies between clearcutting and selective logging, with variations within each.

- Clearcutting: This involves removing all trees from a designated area. While efficient and cost-effective for establishing even-aged stands, it can have significant environmental impacts, such as soil erosion and habitat loss. There are variations like strip clearcutting (removing trees in strips, leaving buffer strips of trees) and shelterwood cutting (leaving some mature trees for seed production and shade).

- Selective Logging: This method focuses on removing specific trees, leaving the majority of the forest intact. This approach is better for biodiversity and minimizes environmental disruption but is more labor-intensive and potentially less cost-effective. Types include single-tree selection (removing individual trees), group selection (removing small groups of trees), and seed-tree selection (leaving a few seed trees to regenerate the stand).

- Seed-Tree Cutting: A variation of clearcutting where a small number of seed trees are left to regenerate the stand naturally.

The choice of method depends on factors like forest type, environmental regulations, economic considerations, and desired future forest structure.

Q 2. Describe your experience with selective logging.

My experience with selective logging spans over 15 years, working across various forest types in both public and private lands. I’ve been involved in projects ranging from small-scale operations targeting specific high-value timber to large-scale selective harvests aimed at improving forest health and promoting biodiversity. In one particular project, we selectively harvested mature Douglas firs in a mixed conifer stand. By carefully choosing trees to remove, we were able to create openings in the canopy, promoting the growth of understory species while retaining the overall forest structure. This method allowed for a sustainable harvest that also benefitted wildlife habitat. Precision and careful planning are paramount to ensure only targeted trees are removed and minimal damage is caused to the remaining forest.

Q 3. What are the safety regulations you adhere to during timber harvesting?

Safety is my absolute top priority. We adhere strictly to all relevant OSHA (Occupational Safety and Health Administration) regulations and industry best practices. This includes:

- Pre-harvest planning: Detailed assessments of terrain, tree conditions, and potential hazards.

- Proper Personal Protective Equipment (PPE): Hard hats, safety glasses, hearing protection, high-visibility clothing, and appropriate footwear are mandatory for all personnel.

- Safe operating procedures for machinery: Regular maintenance checks, training for operators, and adherence to safe working distances.

- Designated escape routes and communication systems: Ensuring clear communication and escape plans in case of emergencies.

- Emergency response plan: Including first aid training and access to emergency medical services.

- Regular safety meetings and training: To keep everyone updated on safe practices and address any safety concerns.

We also conduct daily safety briefings before any work commences to ensure everyone is aware of specific hazards and safety procedures for the day’s activities.

Q 4. How do you assess the risk of tree failure during felling operations?

Assessing tree failure risk is a crucial aspect of safe felling operations. We use a combination of visual inspection and knowledge of tree biology and mechanics. Factors we consider include:

- Tree species and age: Some species are inherently more prone to failure.

- Tree defects: Signs of decay, rot, cracks, broken branches, leaning, and unusual growth patterns are all indicators of potential weakness.

- Crown condition: A heavy or unbalanced crown puts extra stress on the tree.

- Soil conditions: Poor drainage, unstable soil, and root damage can increase the risk of uprooting.

- Weather conditions: Strong winds, heavy snow, and rain can weaken trees.

We employ experienced arborists who can expertly assess these factors, determining the best felling strategy to minimize the risk of failure. In cases of high risk, specialized techniques and equipment may be used.

Q 5. What are the common types of timber diseases and how do they affect harvesting?

Several timber diseases can significantly affect harvesting operations. These diseases can weaken trees, making them more susceptible to breakage during felling or reducing the quality and value of the timber. Some common examples include:

- Heart rot: Causes decay in the heartwood, weakening the tree and reducing its structural integrity. It’s often difficult to detect from the outside.

- Root diseases: These diseases attack the root system, leading to instability and making trees more susceptible to windthrow.

- Rust diseases: These fungal infections can affect needles and branches, reducing growth and making the timber less valuable.

The presence of disease can necessitate adjustments to harvesting plans, potentially requiring the removal of affected trees to prevent spread or using different harvesting methods to minimize damage to healthy trees. Careful tree selection and potentially pre-harvest disease assessments are critical in such situations.

Q 6. Explain the process of creating a timber harvesting plan.

Creating a timber harvesting plan is a multifaceted process requiring meticulous planning and collaboration with various stakeholders. The process typically involves the following steps:

- Site assessment and inventory: Detailed mapping of the area, tree species identification, volume estimation, and assessment of environmental factors.

- Defining objectives: Establishing the goals of the harvest, such as timber volume, forest health improvement, or habitat restoration.

- Developing a harvesting method: Choosing the most appropriate harvesting method based on the objectives, site conditions, and environmental regulations.

- Road planning and layout: Designing a road network that minimizes environmental impact and allows for efficient timber extraction.

- Environmental impact assessment: Identifying and mitigating potential environmental impacts of the harvest, such as soil erosion, water quality, and wildlife habitat disruption.

- Safety plan development: Incorporating safety measures for personnel and equipment.

- Permitting and regulatory compliance: Obtaining all necessary permits and adhering to all applicable laws and regulations.

- Implementation and monitoring: Overseeing the harvesting operations and monitoring compliance with the plan.

The final plan is a detailed document outlining all aspects of the operation and serves as a guide throughout the entire process.

Q 7. How do you ensure sustainable forestry practices in your work?

Sustainable forestry practices are at the core of my work. We actively incorporate several strategies to ensure the long-term health and productivity of the forests we manage. These include:

- Selective logging techniques: Prioritizing methods that minimize damage to the remaining forest and promote natural regeneration.

- Reforestation and afforestation: Planting trees to replace those harvested, ensuring forest cover is maintained.

- Forest health monitoring: Regularly assessing forest health to detect and address potential problems early.

- Protection of sensitive habitats: Identifying and protecting areas of high ecological value.

- Minimizing soil erosion and compaction: Utilizing appropriate harvesting techniques and road design to minimize environmental damage.

- Protecting water resources: Implementing measures to prevent water pollution and maintain water quality.

- Working with local communities: Engaging with local stakeholders to build consensus and ensure sustainable management practices are socially responsible.

Ultimately, sustainable forestry ensures that we can meet present needs without compromising the ability of future generations to meet their own needs. It’s about balance – responsible timber harvesting that contributes to economic prosperity while protecting the environment and its resources.

Q 8. Describe your experience with different types of logging equipment.

My experience with logging equipment spans a wide range, from traditional to highly mechanized systems. I’m proficient in operating and maintaining various harvesters, forwarders, skidders, and feller bunchers. For example, I’ve extensively used Ponsse harvesters, known for their precision and efficiency in selective logging, and John Deere skidders, reliable workhorses for challenging terrains. I understand the nuances of each machine, including their capabilities, limitations, and appropriate applications. My experience also includes working with smaller equipment like chainsaws, which require a different skill set focused on precision and safety. I’m familiar with the maintenance schedules and safety protocols for all equipment types, ensuring optimal performance and minimizing downtime.

- Harvesters: These machines combine felling, limbing, and delimbing in one process, significantly increasing efficiency. I’ve worked with both wheeled and tracked harvesters, adapting to various terrain conditions.

- Forwarders: These are used to transport felled timber from the harvesting site to a designated landing area. I’m familiar with different forwarding methods, optimizing for both efficiency and minimizing ground disturbance.

- Skidders: These are primarily used in steep or challenging terrain, dragging logs to the landing. Understanding their limitations in terms of ground pressure is crucial for minimizing environmental impact.

- Feller Bunchers: These are effective for large-scale clear-cutting operations, felling and bunching trees for easier extraction.

Q 9. How do you manage a team during a timber harvesting operation?

Managing a team during timber harvesting requires strong leadership, communication, and safety awareness. I prioritize clear communication, ensuring everyone understands their roles and responsibilities. This involves daily briefings, outlining tasks, safety procedures, and potential hazards. I foster a collaborative environment where team members feel comfortable raising concerns. Safety is paramount; I regularly conduct safety inspections, enforce safety protocols, and provide ongoing training to mitigate risks. A crucial aspect is recognizing individual strengths and delegating tasks effectively. For instance, I might assign experienced operators to complex tasks while providing mentorship to less experienced members. I also monitor performance, provide constructive feedback, and address conflicts promptly and fairly. Open communication and mutual respect contribute to a high-performing and safe team. Building trust is key – team members need to know they can rely on each other and their leader.

Q 10. What are the environmental considerations involved in timber harvesting?

Environmental considerations are deeply ingrained in every stage of timber harvesting. Minimizing soil erosion is critical, which often involves planning harvesting routes carefully, using directional felling techniques, and potentially implementing erosion control measures like silt fences or water bars. Protecting water quality requires careful consideration of riparian zones (areas alongside water bodies), avoiding harvesting within these sensitive areas to prevent sedimentation and pollution. Wildlife habitat preservation is crucial; understanding species present and their requirements allows for strategic harvesting to minimize disruption. We employ selective logging techniques, avoiding clear-cutting unless absolutely necessary, leaving behind sufficient residual trees to support biodiversity. Additionally, reducing fragmentation of forest habitats is a key goal. Sustainable harvesting ensures that future generations can benefit from our forests. Post-harvest activities, such as reforestation or afforestation, are crucial for ecological recovery. We must always balance the economic benefits of timber harvesting with the long-term ecological well-being of the forest.

Q 11. Explain your understanding of forest certification schemes (e.g., FSC).

Forest Stewardship Council (FSC) certification is a globally recognized standard for responsible forest management. It ensures that timber comes from forests managed according to strict environmental, social, and economic criteria. Understanding FSC principles is vital for ensuring sustainable practices. The certification process involves rigorous audits, evaluating aspects like tree planting rates, biodiversity conservation, and worker’s rights. Adherence to FSC guidelines contributes to legally sourced timber, protecting endangered species and ensuring that local communities benefit economically from the forests. It provides traceability of the timber from forest to the end-product, offering assurance to consumers seeking environmentally responsible choices. I have experience working in FSC-certified forests, understanding the requirements and ensuring compliance at every step of the process. This includes maintaining accurate records, following specific harvesting plans, and collaborating with certification bodies.

Q 12. How do you handle unexpected challenges or delays during a project?

Handling unexpected challenges is a key aspect of project management in timber harvesting. Unforeseen weather events like storms can cause delays and damage. In such cases, I immediately assess the damage, prioritize safety, and adjust the project timeline accordingly. Equipment malfunctions can also cause disruptions; a well-maintained fleet minimizes this, but contingency plans for repairs or replacements are essential. For instance, I’ve had to organize emergency repairs and source replacement parts quickly during a project. Efficient communication is crucial when addressing such issues. Keeping stakeholders informed prevents misunderstandings and allows for collaborative solutions. Problem-solving involves a systematic approach – identifying the root cause, assessing the impact, and developing solutions that minimize disruptions while ensuring quality and safety. Thorough planning and risk assessment, identifying potential challenges in advance, significantly improves our ability to handle unforeseen circumstances effectively.

Q 13. Describe your experience with timber volume estimation.

Timber volume estimation is crucial for efficient planning and resource management. I’m proficient in various techniques, including using diameter tape measurements to estimate tree volume and applying appropriate volume equations specific to the tree species. More advanced techniques like using LiDAR (Light Detection and Ranging) data and GIS (Geographic Information Systems) software enable precise volume estimations over large areas. I’m comfortable working with different measurement units and converting between them. Accuracy is paramount, as miscalculations can lead to financial losses or overestimation that damages the forest ecosystem. I always strive for accurate volume estimation to ensure sustainable harvesting and fair compensation. Regular calibration of equipment, using established formulas and software, and cross-checking measurements increase precision. For example, using a combination of ground measurements and aerial LiDAR data provided a more accurate estimation of the timber volume in a particularly challenging terrain.

Q 14. How do you ensure the quality and safety of harvested timber?

Ensuring the quality and safety of harvested timber requires attention to detail throughout the process. This starts with careful felling techniques, minimizing damage to the logs. Proper limbing and delimbing are essential for producing high-quality timber, reducing defects, and making it easier to process. Safe handling and transportation are critical to prevent damage during movement. I ensure that logs are properly stacked and secured during transport to reduce the risk of damage or accidents. Regular maintenance of equipment, ensuring sharp chains and blades, helps to reduce defects and maintain the quality of the product. Adhering to safety regulations and protocols, providing proper training to staff on safe handling practices, using Personal Protective Equipment (PPE), and regular safety inspections contribute to a safe working environment. Maintaining detailed records throughout the process ensures traceability and accountability.

Q 15. What are the different methods of transporting harvested timber?

Timber transportation methods vary significantly depending on factors like terrain, distance to mills, timber volume, and environmental concerns. Common methods include:

- Truck Transport: This is the most prevalent method, particularly for shorter distances. Different truck types exist, from single-axle trucks for smaller loads to large logging trucks with specialized trailers capable of carrying massive quantities of logs. Careful consideration must be given to load distribution to prevent damage and ensure safety.

- Rail Transport: For long distances and high volumes, rail transport becomes economically advantageous. Logs are typically loaded onto flatcars and transported to processing facilities. This method is environmentally friendly in terms of fuel efficiency per unit of timber transported.

- Barge Transport: Common in areas with navigable rivers and waterways, barge transport is suitable for large volumes of timber and offers a cost-effective solution. Environmental considerations, such as potential waterway impacts, must be carefully managed.

- Aerial Transport: In remote areas with difficult terrain, helicopters or cable logging systems are employed to transport timber. While effective, this method is significantly more expensive and often employed for selective harvesting of high-value species.

The choice of method is a crucial logistical decision, balancing cost, efficiency, and environmental impact. A thorough assessment of all factors is critical for successful and sustainable timber operations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the profitability of a timber harvesting operation?

Calculating the profitability of a timber harvesting operation involves a comprehensive analysis of costs and revenues. Here’s a simplified framework:

- Revenues: This is determined by the volume of timber harvested, the species’ market price, and any additional revenue streams (e.g., sale of byproducts).

- Costs: This includes a wide range of expenses, such as:

- Harvesting Costs: Felling, bucking, skidding, loading.

- Transportation Costs: Fuel, labor, maintenance, tolls.

- Permitting and Regulatory Costs: Fees, inspections.

- Labor Costs: Wages, benefits, insurance.

- Equipment Costs: Purchase, maintenance, repairs.

- Land Management Costs: Reforestation, site preparation.

Profitability Calculation: Total Revenue – Total Costs = Profit

To enhance accuracy, sophisticated financial models that incorporate factors like inflation, risk, and discounting are often used. Detailed cost accounting and meticulous record-keeping are crucial for a reliable assessment of profitability.

Example: A company harvests 1000 cubic meters of timber at $50/cubic meter, generating $50,000 in revenue. Total costs amount to $35,000. The profit is $15,000. However, this simplified example ignores numerous important costs and potential revenue variations.

Q 17. What software or tools do you use for timber management and planning?

Several software and tools are instrumental in effective timber management and planning. These often integrate various functionalities:

- GIS (Geographic Information Systems) Software: ArcGIS, QGIS. These are used for spatial data management, mapping forest resources, planning harvesting activities, and creating road networks.

- Forest Management Software: ForestryPro, TimberMatic. These are specialized software packages for planning, inventory management, growth modeling, and yield prediction.

- Inventory and Measurement Tools: Laser scanners, dendrometers, GPS devices. These provide accurate data on tree size, volume, and location, which is crucial for planning harvests and resource assessments.

- Data Analysis Software: R, Python, Excel. These are used for analyzing data gathered from inventory, modeling, and other sources to make informed decisions.

The specific tools used depend on the scale and complexity of the operation, the type of forest, and the available resources. Many operations integrate multiple tools to create a comprehensive system for forest management.

Q 18. How do you ensure compliance with relevant regulations and permits?

Compliance with regulations and permits is paramount in timber operations. The process typically involves:

- Identifying Applicable Regulations: This involves understanding federal, state, and local laws related to forestry, environmental protection, and worker safety.

- Obtaining Necessary Permits: This often includes harvesting permits, road construction permits, and environmental impact assessments. The specific permits vary by jurisdiction and the type of operation.

- Developing and Implementing a Compliance Plan: This should detail procedures for adhering to regulations, including safety protocols, environmental protection measures, and responsible harvesting practices.

- Regular Audits and Inspections: Regular internal audits and external inspections ensure ongoing compliance. Corrective actions are promptly implemented if any non-compliance is detected.

- Record Keeping: Meticulous documentation of all activities, permits, and inspections is crucial for demonstrating compliance.

Failure to comply with regulations can result in significant penalties, including fines, legal action, and reputational damage. A strong commitment to compliance is essential for a sustainable and responsible timber business.

Q 19. Describe your experience with forest road construction and maintenance.

Forest road construction and maintenance are vital aspects of timber harvesting. My experience includes:

- Road Design and Planning: Designing road networks that minimize environmental impact, optimize transportation efficiency, and ensure access to all harvesting areas. Factors such as terrain, soil type, and water resources are carefully considered.

- Construction Supervision: Overseeing the construction of forest roads, ensuring adherence to engineering specifications, and implementing best practices for erosion and sediment control.

- Maintenance and Repair: Developing and executing maintenance programs for existing roads, addressing issues such as drainage, erosion, and surface damage. Regular inspection and timely repairs are crucial for extending road life and minimizing disruption to operations.

- Environmental Mitigation: Implementing measures to minimize the environmental impact of road construction and maintenance, such as using environmentally friendly materials and employing techniques to reduce erosion and sedimentation.

I’ve worked on projects ranging from small-scale road repairs to the construction of extensive road networks in challenging terrain. Experience includes using various construction equipment and working with specialized contractors.

Q 20. Explain the different types of wood and their properties.

Wood is a complex natural material with a wide range of properties varying considerably across species. Classifications are often made based on properties like density, strength, and durability.

- Hardwoods: Generally, hardwoods are deciduous trees (lose their leaves annually) and tend to be denser, harder, and more durable than softwoods. Examples include oak, maple, cherry, and mahogany, each with its unique grain pattern and characteristics affecting its use in furniture, flooring, and construction.

- Softwoods: These are typically coniferous trees (cone-bearing) and tend to be lighter, softer, and less durable than hardwoods. Examples include pine, fir, spruce, and cedar. Softwoods are often used in construction, paper production, and general carpentry due to their availability and cost-effectiveness.

Key Properties:

- Density: Affects strength, durability, and workability.

- Strength: Resistance to bending, compression, and tension.

- Durability: Resistance to decay, insects, and weathering.

- Grain Pattern: Influences appearance and workability.

- Moisture Content: Affects dimensional stability and strength.

Understanding these properties is crucial for selecting the appropriate wood for specific applications. For instance, durable hardwoods like oak are ideal for flooring, while lighter softwoods like pine are often preferred for framing in construction.

Q 21. How do you handle conflicts with landowners or other stakeholders?

Conflicts with landowners or other stakeholders are sometimes unavoidable in timber operations. My approach emphasizes proactive communication and collaboration:

- Open Communication: Maintaining open and transparent communication with landowners throughout the process, addressing their concerns, and providing regular updates.

- Early Engagement: Engaging stakeholders early in the planning stages to identify potential conflicts and collaboratively develop solutions.

- Respectful Negotiation: Approaching disagreements with respect, actively listening to opposing viewpoints, and seeking mutually acceptable solutions through negotiation.

- Mediation and Arbitration: If negotiation fails, engaging a neutral third party mediator or arbitrator to facilitate resolution.

- Legal Counsel: Seeking legal advice when necessary to ensure compliance with all agreements and regulations.

Building strong relationships with landowners and other stakeholders is crucial for minimizing conflicts and ensuring the long-term success of timber operations. My aim is always to find solutions that benefit all parties involved.

Q 22. Describe your experience with different types of sawmills and their operations.

My experience encompasses a range of sawmills, from small, family-owned operations utilizing band saws for local markets to large-scale, industrial facilities employing sophisticated circular saws and optimizing technologies for mass production. I’ve worked with both stationary and portable sawmills. Stationary mills offer greater efficiency and capacity due to their fixed infrastructure and integration with drying kilns and other processing equipment. They’re ideal for consistent, high-volume production. Portable sawmills, conversely, are more flexible, easily moved to different logging sites, making them valuable for smaller operations or accessing remote timber resources. The operations differ significantly in scale and technology. For instance, a small band sawmill might focus on producing dimensional lumber with minimal waste, while a large-scale operation might incorporate residue utilization for creating biomass pellets or engineered wood products. My understanding of sawmill operations includes log handling, sawing techniques (e.g., optimizing cut patterns to maximize yield), lumber grading, and quality control. I’m familiar with the regulatory aspects and safety protocols associated with each type of sawmill.

- Band Sawmills: These use a continuous, thin blade resulting in less kerf loss (the width of wood removed by the saw blade), leading to higher lumber yield. They are often preferred for higher-value species.

- Circular Sawmills: Employ circular blades and are generally more suited for high-volume production of lower-grade lumber. They are faster but result in slightly higher kerf loss.

- Gang Sawmills: Simultaneously saw multiple logs using multiple blades. These are highly efficient for large-scale production of standardized lumber dimensions.

Q 23. How do you manage waste and by-products from timber harvesting?

Waste management in timber harvesting is crucial for environmental and economic reasons. We employ a multi-pronged approach. Firstly, careful pre-harvest planning minimizes waste by optimizing the felling and extraction routes. Secondly, we prioritize the utilization of all parts of the tree. This includes using branches and tops for biomass energy, chipped wood for pulp and paper production, or even smaller pieces for mulch. Thirdly, we employ responsible disposal techniques for unusable residue. This might involve chipping and burying the material, creating designated burn piles (under controlled conditions and in compliance with regulations), or transporting waste to licensed disposal facilities. We meticulously record the volumes of harvested wood and residual waste to track our environmental impact. For example, we might use a combination of biomass boilers and wood-to-energy plants to utilize the non-timber components of trees. We always aim to minimize landfill disposal and strive for a ‘zero-waste’ approach wherever feasible.

Q 24. Explain the importance of pre-harvest planning and site preparation.

Pre-harvest planning and site preparation are foundational to efficient and sustainable timber harvesting. Pre-harvest planning involves detailed assessment of the forest stand, identifying tree species, size, and quality, and establishing harvesting goals. We use Geographic Information Systems (GIS) mapping to precisely locate high-value trees and plan felling and extraction paths to minimize soil disturbance. Site preparation includes creating access roads and skid trails, ensuring they are correctly graded to prevent erosion. We also identify and delineate environmentally sensitive areas, such as streams and wetlands, to protect them from damage during operations. Appropriate buffer zones are established to safeguard these areas. Careful planning drastically reduces environmental impact and improves operational efficiency, reducing costs and improving safety by avoiding unplanned obstacles. For instance, we might use GIS to identify areas with sensitive topsoil and plan our routes accordingly to minimize compaction.

Q 25. How do you ensure the safety of your crew and equipment?

Crew and equipment safety is paramount. Our safety program is multifaceted. It begins with comprehensive training for all personnel, covering safe operating procedures for equipment, hazard identification, first aid, and emergency response. We conduct regular safety meetings and toolbox talks to reinforce best practices and address specific safety concerns. We implement strict adherence to safety protocols, including the use of Personal Protective Equipment (PPE) such as hard hats, safety glasses, hearing protection, and high-visibility clothing. Equipment undergoes regular maintenance and inspections to prevent malfunctions. We implement traffic management systems in the harvesting area, clearly marking access roads and hazardous areas. Moreover, we utilize technology like GPS tracking on machinery to monitor their location and operation, enhancing safety during the harvesting process. We maintain detailed accident records to identify trends and implement preventative measures.

Q 26. What are the key factors to consider when selecting harvesting equipment?

Selecting harvesting equipment involves careful consideration of various factors. The primary factor is the type of terrain and timber being harvested. Steep slopes require specialized machines with enhanced stability, such as feller bunchers with increased maneuverability and skidders with superior traction. The volume and species of timber dictate the choice of harvesting system. High-volume harvesting benefits from efficient machinery like harvesters and forwarders. The size and density of the trees influence the type of feller buncher or harvester needed. Economic factors such as purchase or lease costs, operational costs (fuel, maintenance), and productivity are equally vital. Finally, maintenance accessibility and the availability of skilled operators are also key considerations. For example, in a dense forest with smaller trees, a smaller harvester might be more efficient than a large one, whereas in a plantation with large uniform trees, a larger machine might be more cost-effective.

Q 27. Describe your experience with erosion control and reforestation.

Erosion control and reforestation are integral parts of responsible timber harvesting. Erosion control measures begin during site preparation, employing techniques such as water bars and ditch checks to manage water runoff and prevent soil erosion. After harvesting, we use techniques like mulching or leaving residual slash on the forest floor to reduce erosion. Reforestation efforts involve planting seedlings of native species, carefully selecting appropriate species that thrive in the local environment. We monitor the growth and survival rate of planted seedlings and implement measures to protect them from damage. My experience involves employing various reforestation techniques, including aerial seeding in areas with challenging terrain. We also work with local communities and organizations to enhance the long-term success of reforestation efforts. The ultimate goal is to restore the forest to a healthy state, promoting biodiversity and ecological balance.

Q 28. How do you stay updated on the latest advancements in timber harvesting technology?

Staying updated on advancements in timber harvesting technology is crucial. I regularly attend industry conferences and workshops, participate in online forums, and read trade publications to stay abreast of the latest developments. I also maintain professional memberships in relevant organizations and networks, enabling me to connect with experts and share knowledge. I closely follow the research and development efforts of leading equipment manufacturers. This includes exploring improvements in harvesting machinery, such as advancements in automated systems, GPS-guided felling, and remote sensing technologies for improved forest inventory and planning. Moreover, I explore and evaluate new techniques for sustainable forest management, such as precision forestry and innovative erosion control methods. Continuous learning is crucial to optimizing efficiency, improving safety, and minimizing environmental impact in timber harvesting operations.

Key Topics to Learn for Timbering Interview

- Ground Control: Understanding soil mechanics, slope stability analysis, and ground investigation techniques relevant to timbering design.

- Support Systems: Familiarity with various timbering methods (e.g., soldier piles and lagging, sheet piling, cross-bracing) and their applications in different geological conditions.

- Design Principles: Grasping the fundamental principles of structural design as applied to timbering, including load calculations, stress analysis, and safety factors.

- Practical Application: Understanding how to select appropriate timbering systems based on project requirements (e.g., depth, soil type, construction sequence). Experience with design software is a plus.

- Construction Sequencing and Methodology: Knowledge of the practical steps involved in the installation and removal of timbering systems, ensuring safety and efficiency.

- Risk Assessment and Mitigation: Understanding potential hazards associated with timbering and implementing strategies for risk mitigation (e.g., shoring inspections, safety protocols).

- Regulations and Codes: Familiarity with relevant building codes and regulations related to excavation and timbering practices.

- Cost Optimization: Understanding the cost implications of various timbering methods and strategies for optimizing cost-effectiveness.

- Troubleshooting and Problem Solving: Ability to identify and solve potential problems during the design and construction phases of timbering projects.

- Sustainability and Environmental Considerations: Understanding the environmental impact of timbering materials and exploring sustainable alternatives.

Next Steps

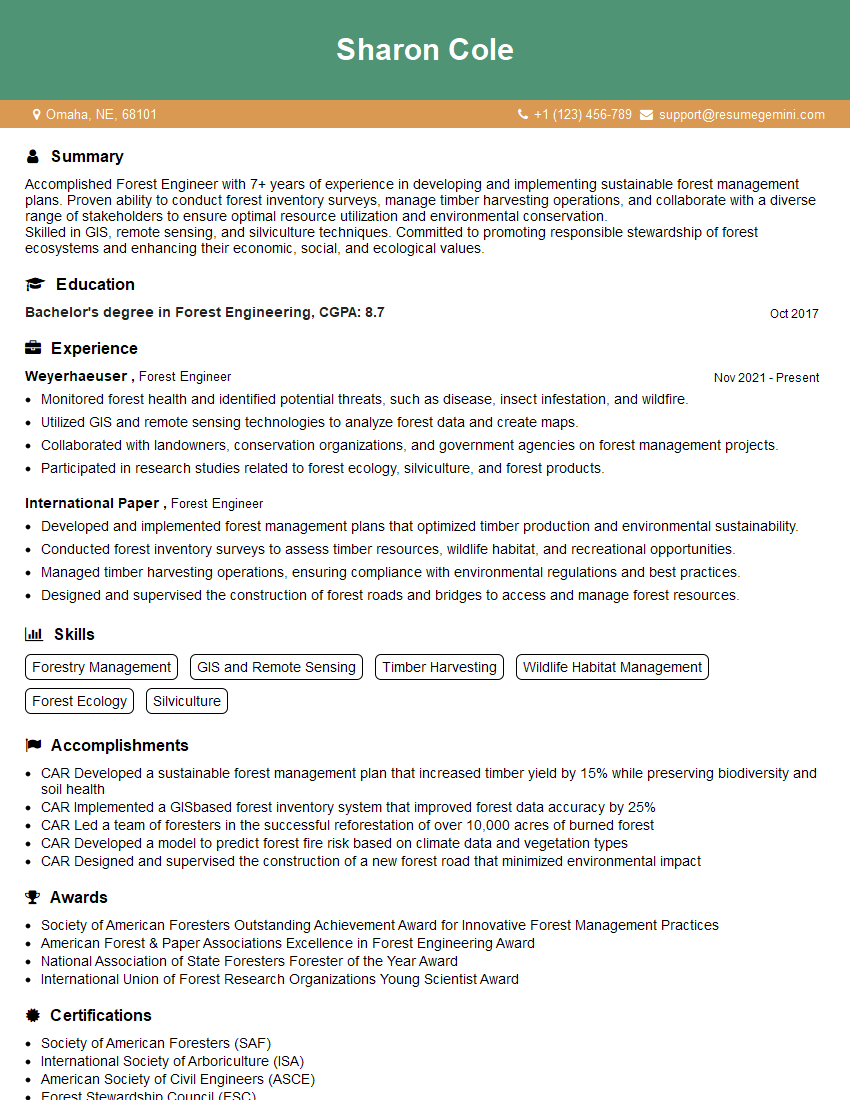

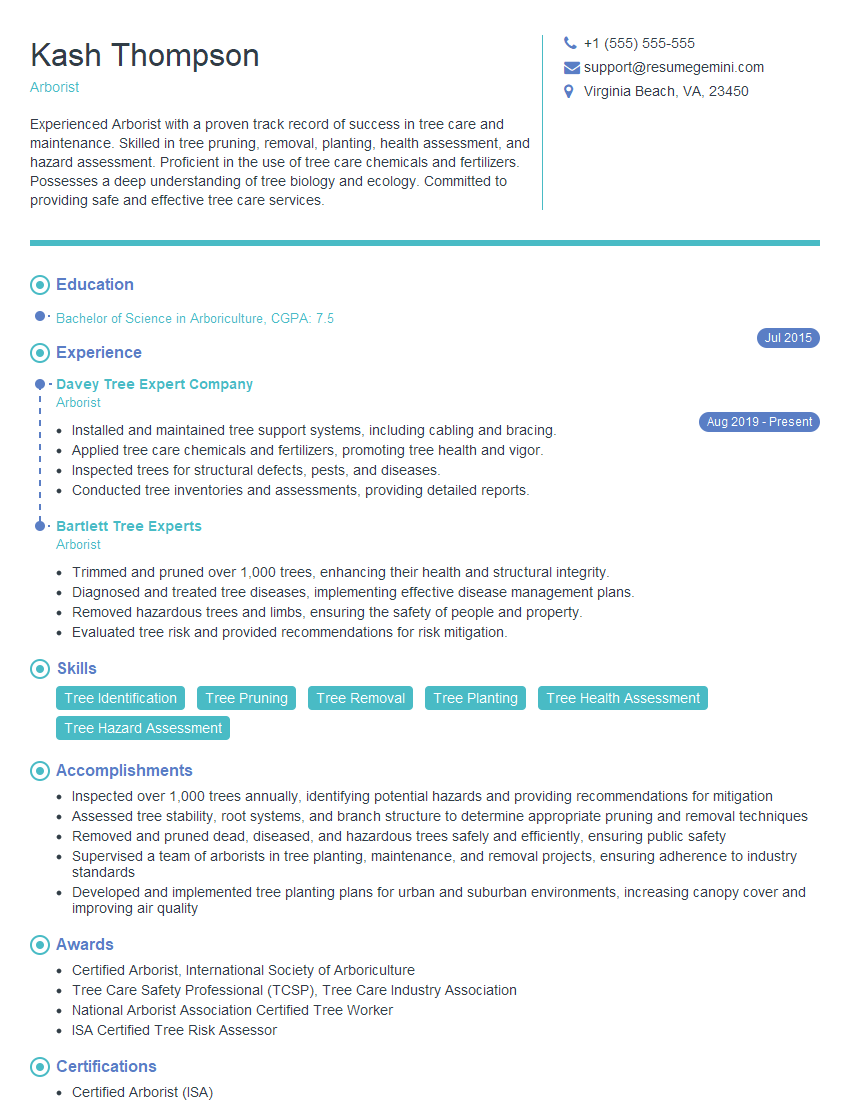

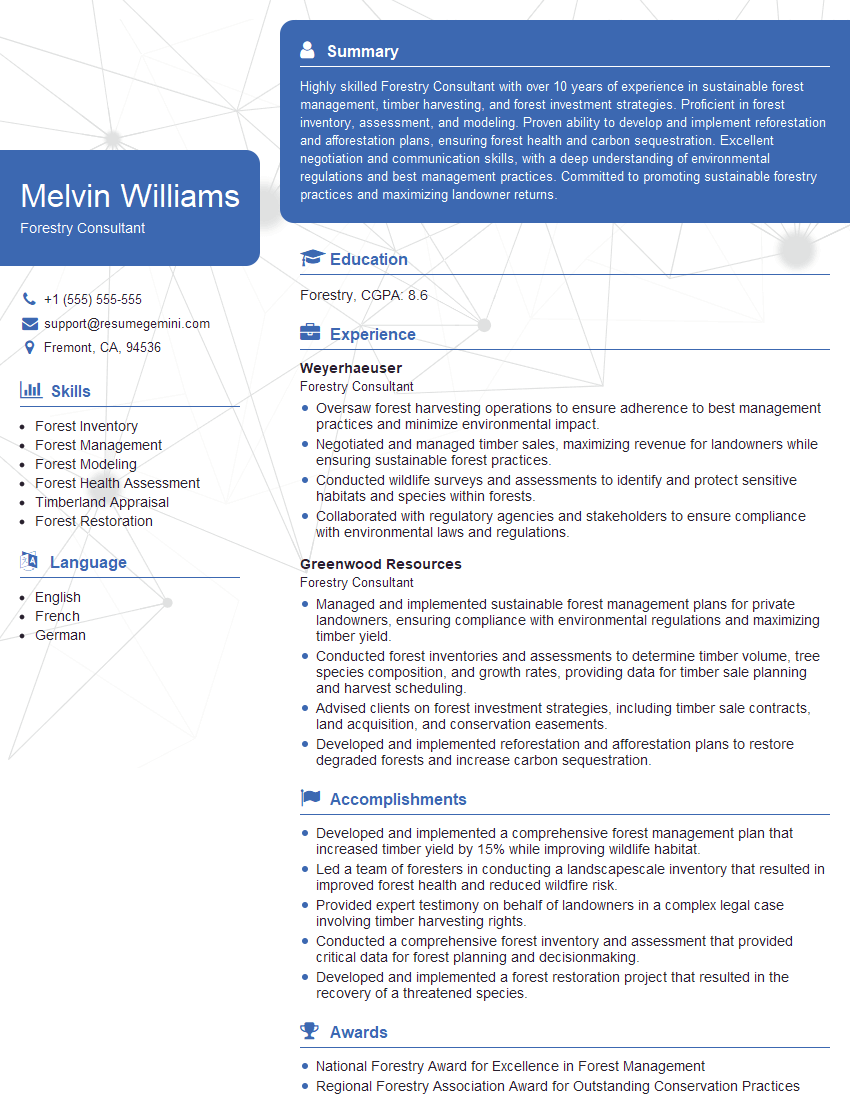

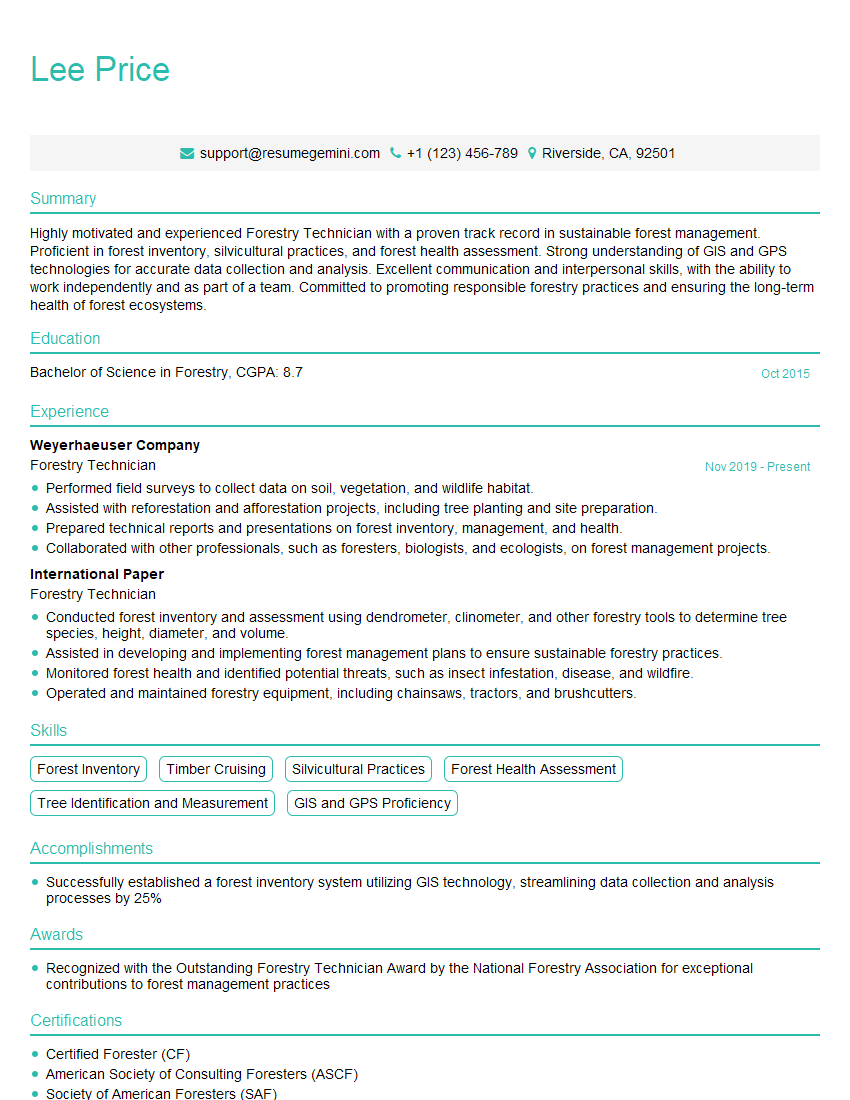

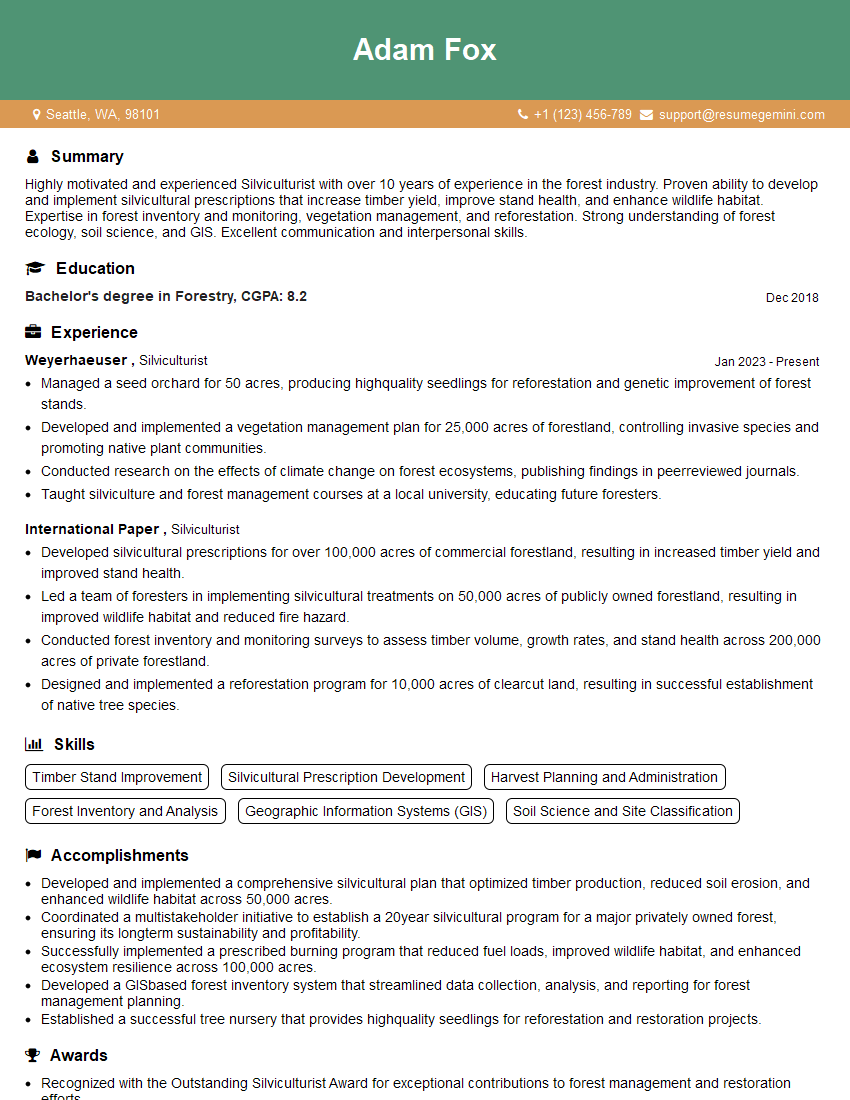

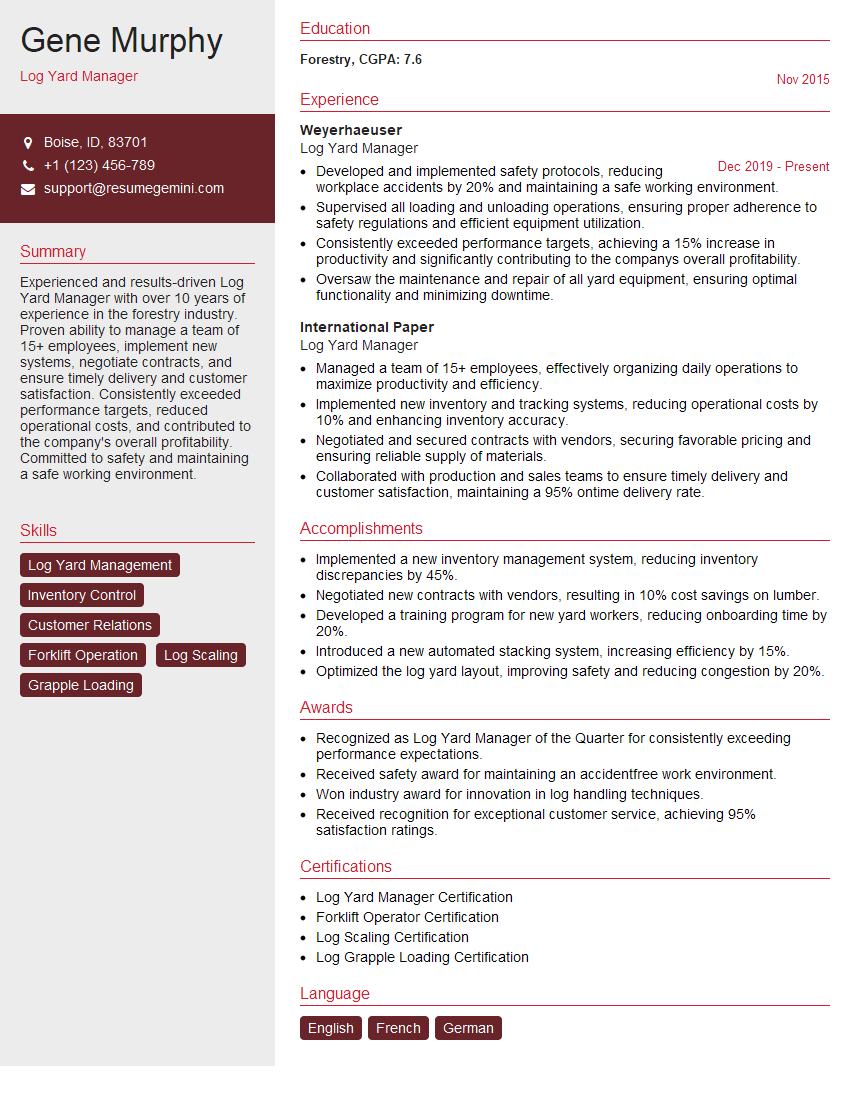

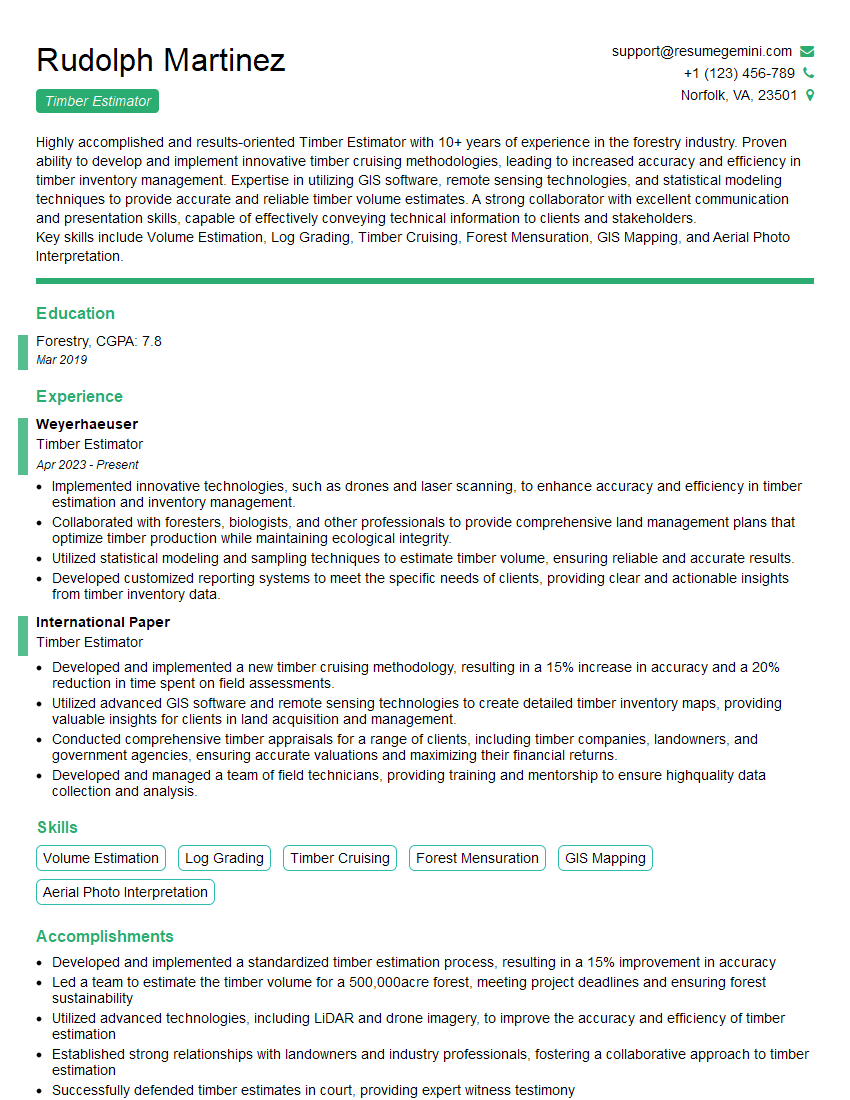

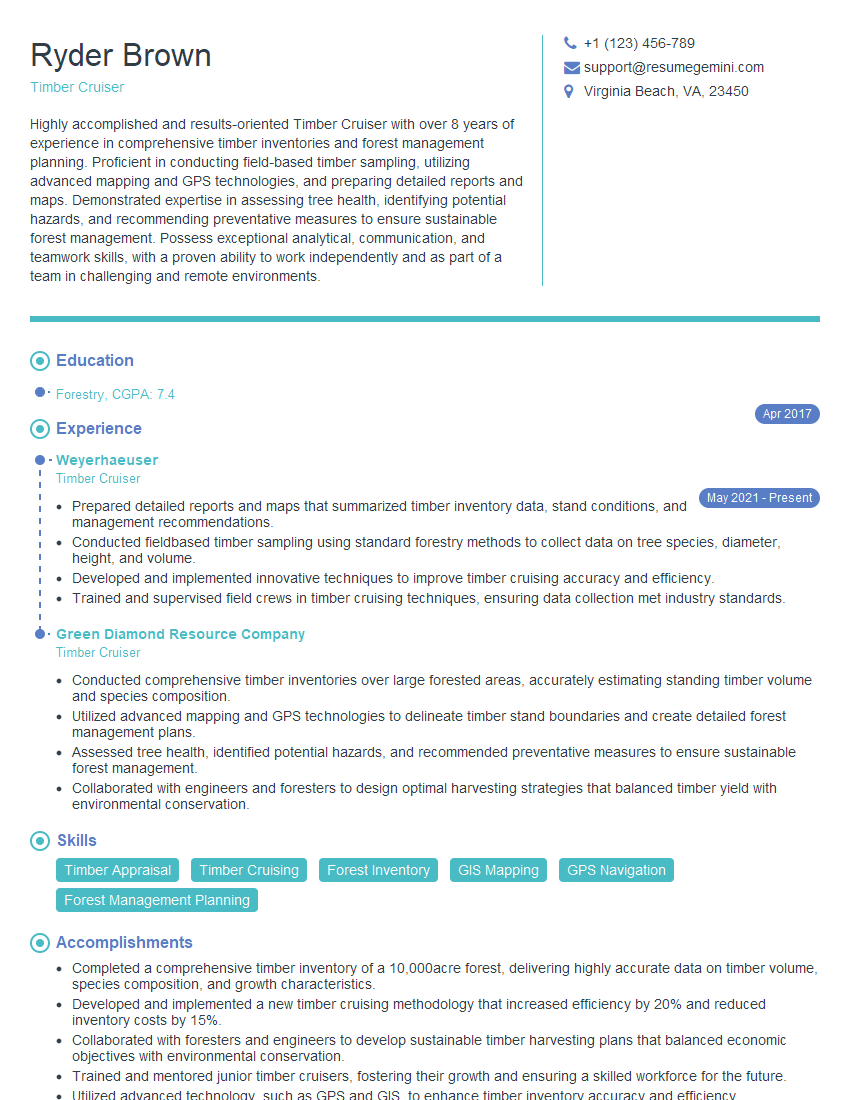

Mastering timbering principles significantly enhances your career prospects in civil engineering and construction, opening doors to specialized roles and higher earning potential. To increase your chances of landing your dream job, focus on crafting a resume that is easily parsed by Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to highlight your timbering expertise. Examples of resumes specifically tailored for timbering positions are available to guide you. Invest time in creating a strong resume—it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good