Cracking a skill-specific interview, like one for Maintain Clean and Hygienic Work Area, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Maintain Clean and Hygienic Work Area Interview

Q 1. Describe your experience maintaining a clean and hygienic work area.

Maintaining a clean and hygienic work area is paramount to my professional practice. Throughout my career, I’ve consistently implemented a proactive approach, ensuring cleanliness isn’t just an afterthought but an integral part of my daily workflow. This involves regular cleaning, disinfection, and organization of my workspace, resulting in a safer, more efficient, and productive environment. For example, in my previous role at a medical laboratory, meticulous cleanliness was crucial. I developed and implemented a detailed cleaning schedule that addressed all surfaces, equipment, and common areas, adhering strictly to established protocols to minimize the risk of contamination.

In a food preparation setting, my focus extended to preventing cross-contamination. I adopted a color-coded system for cutting boards, utensils and cleaning cloths to avoid mixing raw and cooked foods. I’m adept at identifying and addressing potential hazards swiftly, preventing any buildup of dirt or debris. My commitment to cleanliness extends beyond my immediate work area; I actively contribute to maintaining a clean and organized shared environment, fostering a sense of collective responsibility.

Q 2. What cleaning methods and products are you familiar with?

My familiarity with cleaning methods and products is extensive and spans various contexts. I’m proficient in using both traditional and advanced cleaning techniques. This includes wet cleaning (using detergents, disinfectants, and water), dry cleaning (using brushes, vacuums, and microfiber cloths), and specialized cleaning methods (such as steam cleaning for delicate surfaces or ultrasonic cleaning for precision instruments).

I have experience with a wide range of cleaning products, including EPA-registered disinfectants, enzymatic cleaners for organic matter, and specialized cleaning agents for different materials (e.g., glass cleaners, stainless steel polish). I always carefully read and follow product labels, ensuring proper dilution and application to avoid damage to surfaces or environmental hazards. I prioritize using environmentally friendly and sustainable products whenever possible. The specific cleaning agents and techniques employed are always tailored to the specific nature of the work environment and the materials involved.

Q 3. How do you prioritize tasks in a cleaning schedule?

Prioritizing cleaning tasks requires a systematic approach. I typically employ a combination of methods to create efficient cleaning schedules. Firstly, I assess the area, identifying high-touch surfaces (like doorknobs, light switches, and keyboards) and areas prone to more significant contamination. These are prioritized for more frequent cleaning. Secondly, I consider the risk associated with different areas. For example, in a food preparation area, thorough cleaning and disinfection are paramount to prevent foodborne illness. In a medical setting, maintaining a sterile environment is essential to prevent infections.

I use a combination of daily, weekly, and monthly cleaning schedules. Daily tasks typically focus on cleaning high-touch surfaces and clearing clutter. Weekly tasks might involve more thorough cleaning of equipment and floors. Monthly tasks might include deep cleaning, such as scrubbing and disinfecting hard-to-reach areas. This tiered approach ensures a balance between regular maintenance and more intensive cleaning.

Q 4. Explain your understanding of proper hand hygiene techniques.

Proper hand hygiene is fundamental to preventing the spread of pathogens and maintaining a clean and healthy work environment. The process typically involves the following steps:

- Wetting hands with water: Ensuring hands are thoroughly wetted.

- Applying soap: Using enough soap to cover all hand surfaces.

- Lathering: Rubbing hands together vigorously, ensuring all surfaces are covered.

- Scrubbing: Paying particular attention to areas such as between fingers, under nails, and around wrists.

- Rinsing: Thoroughly rinsing all soap residue under running water.

- Drying: Drying hands using clean paper towels or an air dryer.

I emphasize the importance of handwashing after handling potentially contaminated materials, before and after eating, and after using the restroom. In settings where handwashing facilities are unavailable, hand sanitizer containing at least 60% alcohol is an acceptable alternative, but handwashing remains the preferred method.

Q 5. How do you handle hazardous waste disposal in a safe manner?

Safe handling and disposal of hazardous waste are critical for environmental protection and worker safety. My approach follows strict protocols and regulations. First, I ensure all hazardous materials are clearly labeled and stored in designated containers according to their type (e.g., sharps containers for needles and syringes, separate containers for chemical waste). Secondly, I strictly adhere to established procedures for the collection, transportation, and disposal of hazardous waste. This usually includes working with a licensed waste disposal company.

Thirdly, I utilize personal protective equipment (PPE), such as gloves, safety glasses, and lab coats, as appropriate, during the handling of hazardous materials. I always follow the guidelines provided by safety data sheets (SDS) and other relevant documents, and promptly report any spills or accidents. Training and continuous learning are essential in staying updated on best practices and regulations regarding hazardous waste management. In my experience, proper training and rigorous adherence to safety protocols significantly reduce risks.

Q 6. Describe your experience with different types of cleaning equipment.

My experience encompasses a range of cleaning equipment, from basic tools to specialized machinery. I am proficient in using various types of vacuum cleaners (upright, canister, and backpack), floor scrubbers, carpet cleaners, and pressure washers. I also have experience with more specialized equipment like autoclaves (for sterilization), ultrasonic cleaners (for delicate instruments), and specialized cleaning solutions for various surfaces.

For example, in a laboratory setting, I’ve used autoclaves to sterilize equipment and work surfaces. In a hospital, I’ve utilized specialized cleaning solutions and equipment designed to combat specific pathogens. My knowledge extends to the proper operation, maintenance, and safety protocols associated with each piece of equipment, emphasizing safety and efficiency in my cleaning practices. I understand the importance of regularly inspecting and maintaining this equipment to ensure its optimal performance and longevity.

Q 7. What are your strategies for preventing cross-contamination?

Preventing cross-contamination is crucial in many environments, particularly in healthcare, food service, and laboratories. My strategies involve multiple layers of protection. First, I use color-coded cleaning cloths and utensils to separate cleaning tasks in different areas. For instance, I use green cloths for general cleaning and red cloths for disinfecting contaminated areas. Secondly, I always clean from cleanest to dirtiest areas to minimize the spread of contaminants.

Thirdly, I thoroughly disinfect all surfaces and equipment after each use, paying special attention to high-touch areas. I follow the manufacturer’s instructions for the use of disinfectants and ensure sufficient contact time for effective disinfection. Proper hand hygiene is paramount; I consistently wash or sanitize my hands between tasks. Finally, I routinely inspect equipment for any signs of damage or contamination, replacing or repairing as needed. Regularly cleaning and disinfecting the equipment is also a crucial step in preventing cross-contamination. This multi-faceted approach ensures a clean and safe work environment.

Q 8. How do you ensure compliance with health and safety regulations?

Ensuring compliance with health and safety regulations regarding workplace cleanliness is paramount. It starts with a thorough understanding of all applicable laws, industry best practices, and company-specific policies. This involves regular review of these documents and attending relevant training sessions.

For example, understanding regulations around handwashing facilities, the proper disposal of waste (especially biohazardous materials if applicable), and the use of personal protective equipment (PPE) like gloves and masks are crucial. We must also ensure that all cleaning products are used and stored according to manufacturer’s instructions and relevant safety data sheets (SDS).

Regular audits and inspections, both self-conducted and potentially by external agencies, are essential to identify any gaps in compliance. Corrective actions are immediately implemented to address any shortcomings found. This proactive approach prevents potential hazards and ensures a safe and healthy work environment for everyone.

Q 9. How do you deal with spills or accidents that create a hygiene risk?

Dealing with spills or accidents that pose a hygiene risk requires a swift and methodical response. The first step is always safety – securing the area to prevent further accidents and ensuring no one is injured. Then, we assess the nature of the spill. Is it a chemical, biological, or simply a messy food spill? This dictates the appropriate cleaning method and PPE required.

For example, a chemical spill necessitates the use of specialized cleaning agents and possibly respiratory protection. A biological spill (like blood) requires different cleaning protocols, often involving disinfectant solutions and adherence to strict infection control guidelines. For simpler spills, absorbent materials are used to soak up the mess followed by thorough cleaning and disinfection of the affected area. All spills must be documented, including the nature of the spill, the cleaning process used, and the time it was addressed.

Following a spill, proper disposal of contaminated materials is vital. This might involve specialized waste disposal containers for biohazards or appropriate recycling methods for other materials.

Q 10. How do you assess the cleanliness of a work area?

Assessing cleanliness goes beyond simply a visual inspection. While a quick glance helps, a thorough assessment uses a multi-faceted approach. We use checklists to ensure all areas are covered consistently. This includes checking for visible dirt, debris, and spills; assessing the hygiene of surfaces; and verifying the proper sanitation of high-touch areas like door handles and light switches.

We also utilize tools and techniques like ATP (Adenosine Triphosphate) bioluminescence testing for a more objective measure of cleanliness. ATP testing quantifies the amount of organic residue present, giving a numerical value of cleanliness. We might also employ visual aids like blacklights to detect otherwise unseen spills or residues. The frequency of these detailed assessments depends on the area’s usage and risk level – high-traffic areas will naturally require more frequent checks.

Documentation of these assessments is critical, allowing for tracking of cleaning effectiveness and identification of recurring issues.

Q 11. What are your methods for organizing and storing cleaning supplies?

Organizing and storing cleaning supplies is crucial for safety, efficiency, and compliance. We use clearly labeled storage containers, dedicated for specific cleaning agents to avoid cross-contamination. Dangerous chemicals are stored separately and in accordance with safety data sheet (SDS) recommendations, often in locked cabinets. Cleaning supplies are organized logically, with frequently used items easily accessible.

For example, we might have a designated caddy for daily cleaning tasks containing all the necessary materials like all-purpose cleaner, disinfectant wipes, and microfiber cloths. Heavier equipment like vacuum cleaners and floor scrubbers would have their own designated storage space. The storage area itself should be well-ventilated and away from any food preparation or storage areas. Regular stock checks ensure we are never short on necessary supplies, preventing disruptions to cleaning schedules.

A color-coded system can help in identifying the purpose of various cleaning solutions, minimizing the chance of accidental misuse.

Q 12. How do you communicate cleaning schedules and requirements?

Effective communication of cleaning schedules and requirements is vital. We use a combination of methods for clarity and accountability. A clearly defined cleaning schedule, perhaps displayed on a whiteboard or shared digitally, is a cornerstone. This schedule outlines tasks, responsible individuals, and specific times or frequencies.

Regular team meetings provide an opportunity to discuss the schedule, address any challenges, and provide feedback. We might use digital tools like task management software to assign tasks, track progress, and facilitate communication. For example, a task management app can send reminders to team members and provide a record of completed tasks.

Training ensures everyone understands their responsibilities and the proper procedures. This includes proper use of equipment and chemicals, as well as the importance of adherence to the schedule.

Q 13. How do you maintain the hygiene of equipment and machinery?

Maintaining the hygiene of equipment and machinery is integral to overall workplace cleanliness and preventing cross-contamination. Cleaning protocols should be tailored to the specific equipment; for instance, food processing equipment requires different cleaning procedures compared to office equipment. We follow manufacturer’s instructions for cleaning and sanitizing each piece of equipment.

Regular maintenance and scheduled deep cleaning are essential to remove accumulated debris and prevent the growth of microorganisms. For instance, ovens may require regular descaling, and food processing equipment may need disassembly for thorough cleaning. Cleaning logs or checklists ensure all areas of the equipment are consistently addressed and help in tracking maintenance activities.

Appropriate PPE must always be worn when cleaning equipment. For example, gloves should be worn during cleaning and sanitization processes, and protective eyewear is needed when handling certain chemicals.

Q 14. How do you prevent the spread of infections?

Preventing the spread of infections is a top priority. This involves a multi-pronged approach starting with robust hand hygiene practices. We provide readily available handwashing facilities with soap and hand sanitizer and encourage frequent handwashing, especially after handling potentially contaminated materials.

Regular and thorough disinfection of frequently touched surfaces like door handles, keyboards, and shared workspaces is crucial. We utilize appropriate disinfectants, following manufacturer’s instructions for contact time and safety precautions. Proper waste disposal is also vital to prevent the spread of pathogens. This includes using appropriate bins for different types of waste, particularly for biohazardous materials.

Finally, promoting good hygiene practices among staff through training and awareness programs helps to create a culture of safety. This could involve educating staff on proper coughing and sneezing etiquette, the importance of staying home when ill, and reporting any potential health concerns.

Q 15. What is your experience with disinfection and sterilization procedures?

Disinfection and sterilization are crucial for maintaining a hygienic work area. Disinfection reduces the number of microorganisms to a safe level, while sterilization eliminates all forms of microbial life. My experience encompasses a wide range of procedures, from using EPA-registered disinfectants on frequently touched surfaces like doorknobs and keyboards, to following strict protocols for cleaning and sterilizing medical equipment in a previous role. This involved understanding the differences between high-level disinfection (inactivating vegetative bacteria, mycobacteria, fungi, and most viruses) and sterilization (eliminating all microorganisms, including spores). I’m proficient in using various methods, including autoclaving, chemical sterilization, and ultraviolet (UV) light disinfection, always selecting the appropriate method based on the surface or equipment and the level of contamination.

For example, in a previous role, I was responsible for sterilizing surgical instruments. This required meticulous attention to detail, ensuring each instrument was properly cleaned, packaged, and then processed in an autoclave to meet strict regulatory standards. Failure to do so could have serious consequences for patient safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to adapt your cleaning methods to a specific situation.

During a large-scale event, we unexpectedly encountered a significant spill of a sticky, unfamiliar substance. My initial cleaning plan, which focused on standard floor cleaning procedures, proved ineffective. I quickly assessed the situation and realized a specialized cleaning solution was needed. After researching the substance’s composition (it turned out to be a type of resin), I found a suitable solvent and adapted my cleaning method accordingly. I carefully diluted the solvent, followed safety precautions (gloves, eye protection), and applied it methodically to the spill, using absorbent materials to lift the residue. This quick adaptation prevented the spill from becoming a larger problem and ensured the area was safe and clean for the event attendees.

Q 17. How do you manage your time efficiently during a busy cleaning schedule?

Efficient time management during a busy cleaning schedule is paramount. My approach involves several key strategies. First, I prioritize tasks based on urgency and importance. For instance, restrooms and high-traffic areas always receive top priority. Second, I use checklists to ensure all tasks are completed. These checklists are broken down into smaller, manageable tasks and are time-stamped to track progress. Third, I utilize appropriate cleaning equipment and tools. Employing efficient tools, such as backpack vacuums and motorized scrubbers, significantly reduces the time needed for certain cleaning tasks. Finally, I constantly strive to streamline my cleaning process by looking for ways to improve efficiency and minimize wasted movements. Thinking ahead and pre-planning, for instance, saves unnecessary trips and time.

Q 18. How do you handle difficult or challenging cleaning tasks?

Challenging cleaning tasks require a systematic and methodical approach. I begin by carefully assessing the nature of the task, identifying the type of soil or stain, and understanding any potential safety hazards. For example, if dealing with a stubborn grease stain on a kitchen floor, I’d first try a degreasing solution, and if that fails, I’d proceed to stronger solutions, always following safety guidelines and test on an inconspicuous area first. For heavily soiled areas, I may need to use specialized equipment or techniques. I always prioritize safety – using the right personal protective equipment (PPE), such as gloves, eye protection and appropriate respiratory gear if needed. If the task is beyond my capabilities or expertise, I will not hesitate to seek assistance or advice from a supervisor or specialized cleaning service.

Q 19. How do you ensure that all cleaning tasks are completed to a high standard?

Ensuring high cleaning standards involves a multi-faceted approach. First, I use checklists to ensure comprehensive cleaning of all areas, based on predetermined standards and frequencies. These checklists are regularly reviewed and updated to reflect any changes or improvements. Secondly, I meticulously follow established cleaning procedures, ensuring that the correct cleaning agents and methods are employed for different surfaces and materials. Regular quality checks and inspections are critical to ensure standards are met, I often use visual inspection methods to check for cleanliness. Finally, I maintain open communication with my supervisor or manager to address any challenges or concerns promptly, providing feedback on improvement areas and necessary adjustments to the cleaning schedule or procedures.

Q 20. What are some common mistakes in maintaining workplace hygiene, and how to avoid them?

Common mistakes in maintaining workplace hygiene include neglecting high-touch surfaces (door handles, light switches, keyboards), infrequent cleaning of restrooms, improper waste disposal, and failing to follow correct disinfection protocols. To avoid these, regular cleaning schedules should be implemented, covering all areas frequently. Appropriate disinfectants should be used according to manufacturer instructions, ensuring adequate contact time for effective disinfection. Proper waste disposal procedures should be strictly followed, and staff should be trained on proper hygiene practices, including handwashing.

- Neglecting high-touch surfaces: Implement a schedule for regular cleaning and disinfection.

- Infrequent restroom cleaning: Establish a more frequent cleaning schedule, focusing on high-traffic areas.

- Improper waste disposal: Provide clear instructions and appropriate bins for different waste types.

- Failing to follow disinfection protocols: Conduct regular training on proper disinfection techniques and provide clear guidelines.

Q 21. Explain your knowledge of different types of disinfectants and their uses.

Different disinfectants target different microorganisms. For example, alcohol-based disinfectants (like isopropyl alcohol) are effective against a wide range of bacteria and viruses but may not be effective against spores. Quaternary ammonium compounds (quats) are also broad-spectrum disinfectants, commonly used in surface cleaners. Bleach solutions (sodium hypochlorite) are potent disinfectants, particularly effective against viruses and bacteria, but require careful handling due to their corrosive nature. Hydrogen peroxide is a versatile disinfectant available in various concentrations, suitable for various surfaces and effective against a wide range of microorganisms. The choice of disinfectant depends on the specific application, considering factors such as the type of surface, the level of contamination, and the type of microorganisms to be eliminated. Always follow manufacturer’s instructions for dilution and application to ensure safety and efficacy.

Q 22. Describe your experience with pest control measures related to hygiene.

Pest control is paramount to maintaining a hygienic work area. My experience encompasses a multi-pronged approach, starting with preventative measures. This includes regularly inspecting the premises for signs of pests, sealing cracks and crevices to prevent entry, and storing food properly in airtight containers. Beyond prevention, I’m proficient in implementing integrated pest management (IPM) strategies. This involves using pest control methods that minimize environmental impact while effectively managing pest populations. For example, I’ve successfully utilized sticky traps for monitoring insect activity in a food processing facility, allowing us to identify infestation sources early and avoid the need for broad-spectrum pesticides. In other situations, I’ve collaborated with licensed pest control professionals to address more significant infestations, ensuring compliance with all relevant safety and regulatory guidelines. Proper documentation of pest control activities, including treatment dates and types, is crucial for maintaining a record of our proactive pest management strategy.

Q 23. How do you respond to customer or client complaints regarding cleanliness?

Responding to customer complaints about cleanliness requires a calm, professional, and empathetic approach. I always begin by actively listening to the customer’s concerns, acknowledging their frustration, and thanking them for bringing the issue to my attention. Then, I conduct a thorough investigation to determine the source of the problem. This might involve revisiting the area, examining cleaning records, and interviewing staff. Once the cause is identified, I immediately take corrective action. This could range from re-cleaning the area to implementing new cleaning protocols. I follow up with the customer to update them on the steps taken and to ensure their satisfaction. Transparency is key; I don’t make excuses but instead focus on resolving the problem and preventing recurrence. For example, a complaint about a sticky floor in a high-traffic area led me to adjust the cleaning schedule to include more frequent mopping and introduce a stronger cleaning solution for those specific areas. In this way, I build customer trust and loyalty through prompt and effective responses.

Q 24. What are your strategies for minimizing the use of chemicals?

Minimizing chemical use is a core principle of my approach to cleaning. My strategies focus on a combination of techniques. Firstly, I prioritize thorough cleaning methods, leveraging the power of good old-fashioned elbow grease and effective tools. This includes using appropriate microfiber cloths for different surfaces, which are more effective at trapping dirt and require less cleaning solution. Secondly, I utilize eco-friendly cleaning products whenever possible, opting for biodegradable and plant-based solutions that are less harmful to the environment and human health. For example, using baking soda and vinegar as effective cleaning agents for various surfaces, instead of harsh chemical-based cleaners. Thirdly, I focus on proper dilution of cleaning products. Using less concentrated solutions can often achieve the same level of cleanliness with significantly reduced chemical consumption. Regular equipment maintenance ensures optimal cleaning effectiveness, further reducing the need for additional chemical applications. Careful planning and training are essential, as they limit the need for excessive cleaning due to avoidable spills or messes. Finally, meticulous record-keeping of chemical use allows for ongoing monitoring and refinement of our cleaning protocols.

Q 25. How do you train or supervise others in maintaining a hygienic work area?

Training and supervision are crucial for maintaining a consistently hygienic work area. My training program begins with a comprehensive orientation covering all relevant hygiene protocols, including proper handwashing techniques, the safe handling and usage of cleaning chemicals, and the appropriate cleaning methods for different surfaces. I use a combination of demonstrations, hands-on practice, and written materials to ensure everyone understands the standards. Regular follow-up sessions reinforce training and address any questions or concerns. Ongoing supervision involves regular inspections, providing constructive feedback, and addressing any deviations from established protocols. I utilize checklists and observation sheets to monitor cleaning performance, provide specific feedback, and identify areas requiring additional training or refinement. Incorporating feedback and ongoing improvement into the training keeps the team engaged and committed to maintaining the highest hygiene standards. For instance, I might introduce a ‘buddy system’ where experienced cleaners mentor newer team members, ensuring a continuous cycle of knowledge sharing and best practice adoption.

Q 26. What are your methods for tracking and evaluating cleaning performance?

Tracking and evaluating cleaning performance is essential for continuous improvement. I utilize a multi-faceted approach. Firstly, I implement detailed checklists for each cleaning task, allowing for a consistent and objective assessment of completion. Secondly, I conduct regular inspections, both announced and unannounced, to observe cleaning practices firsthand. These inspections are documented and used to identify areas for improvement. Thirdly, I utilize feedback from customers and staff to gain a comprehensive perspective on cleaning effectiveness. Finally, I analyze cleaning data to identify trends and patterns, such as areas requiring more frequent cleaning or specific cleaning agents that may be more effective. For instance, I might track the frequency of cleaning for high-traffic areas, or note which cleaning agents are most effective at removing specific types of stains. This data-driven approach allows for ongoing optimization of our cleaning protocols and ensures the highest levels of hygiene are consistently maintained. I often utilize spreadsheets or dedicated cleaning management software to track this data efficiently and generate reports for review.

Q 27. How do you deal with discrepancies in cleaning standards?

Discrepancies in cleaning standards are addressed promptly and systematically. First, I investigate the root cause of the discrepancy. This might involve reviewing cleaning checklists, observing cleaning practices, or discussing the situation with the cleaning staff. Once the underlying issue is identified, I take corrective actions. This could involve additional training, a change in cleaning schedules or products, or improved supervision. I’m always careful to focus on problem-solving rather than placing blame. The goal is to improve cleaning processes and prevent similar issues from arising. For example, a consistent lack of cleanliness in a specific area might indicate the need for additional cleaning time allocated to that area, or the use of a more effective cleaning agent. Clear communication with staff is critical to addressing the discrepancy fairly, offering support and ensuring they understand the expected standards. By maintaining open communication and a focus on process improvement, I ensure that discrepancies are resolved effectively and cleaning standards are consistently met.

Q 28. Describe your experience with implementing and maintaining a cleaning and hygiene program.

My experience with implementing and maintaining a cleaning and hygiene program encompasses all aspects from initial planning and implementation to ongoing monitoring and improvement. I start by conducting a thorough needs assessment, identifying the specific requirements of the work area, considering factors such as size, traffic volume, and types of surfaces. This assessment informs the development of a comprehensive cleaning plan, which outlines cleaning schedules, procedures, and the necessary resources. The plan includes clear expectations for staff, training materials, and methods for monitoring performance. Implementation involves training staff on the established protocols, providing them with the necessary equipment and supplies, and ensuring compliance with all relevant regulations. Ongoing maintenance involves regular monitoring, evaluation, and adjustments as needed. This might include updating cleaning schedules based on changing needs, introducing new cleaning methods or technologies, or refining training programs based on staff performance. For example, in a hospital setting, I implemented a rigorous cleaning program emphasizing infection control, utilizing color-coded cleaning equipment and implementing a robust training program for all staff on infection prevention protocols. Regular audits and feedback loops ensured that the program remained effective and adapted to evolving needs.

Key Topics to Learn for Maintain Clean and Hygienic Work Area Interview

- Understanding Hygiene Standards: Learn about different hygiene protocols and their application in various work environments. This includes understanding relevant regulations and best practices.

- Cleaning and Sanitization Techniques: Explore various cleaning methods, appropriate cleaning agents for different surfaces, and effective sanitization procedures to eliminate germs and bacteria. Be prepared to discuss practical experience with different cleaning equipment.

- Waste Management and Disposal: Understand proper waste segregation, disposal procedures, and the importance of minimizing environmental impact. Consider the safe handling of hazardous waste, if applicable to the role.

- Infection Control: Familiarize yourself with infection prevention and control measures, including hand hygiene, personal protective equipment (PPE) usage, and the prevention of cross-contamination.

- Maintaining Order and Organization: Discuss strategies for maintaining a tidy and organized workspace, including efficient storage solutions and inventory management. Be ready to explain how organization improves efficiency and safety.

- Safety Procedures: Understand relevant safety regulations and protocols related to cleaning and hygiene practices, including the proper use of cleaning chemicals and equipment to prevent accidents.

- Problem-Solving and Adaptability: Be ready to discuss how you would handle unexpected situations, such as spills, equipment malfunctions, or unexpected contamination. Highlight your ability to adapt to changing demands and maintain hygiene standards under pressure.

Next Steps

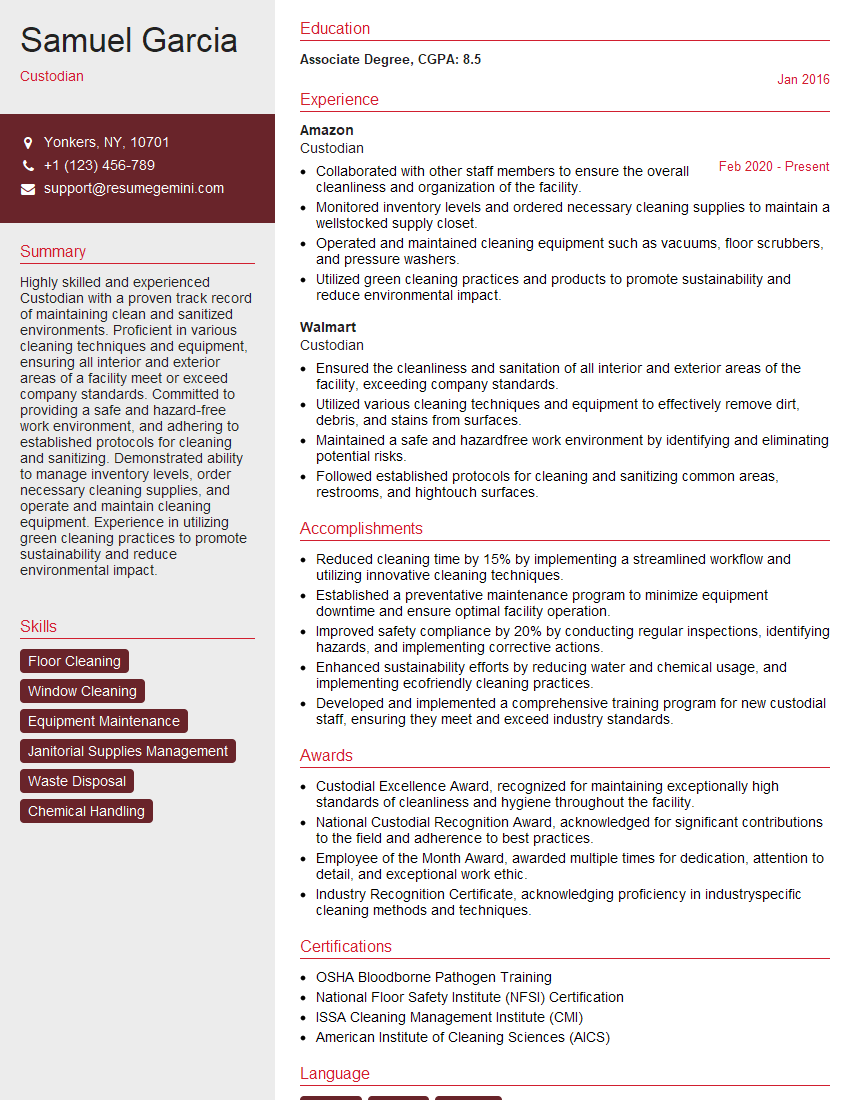

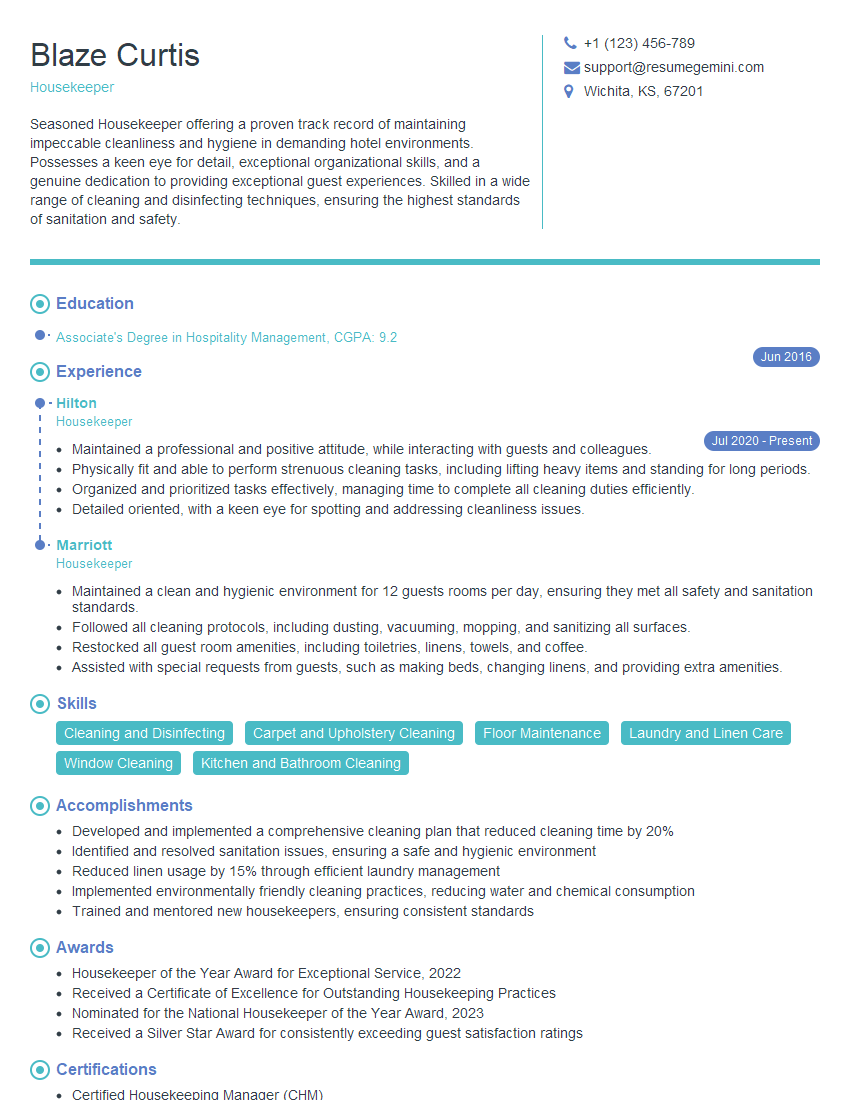

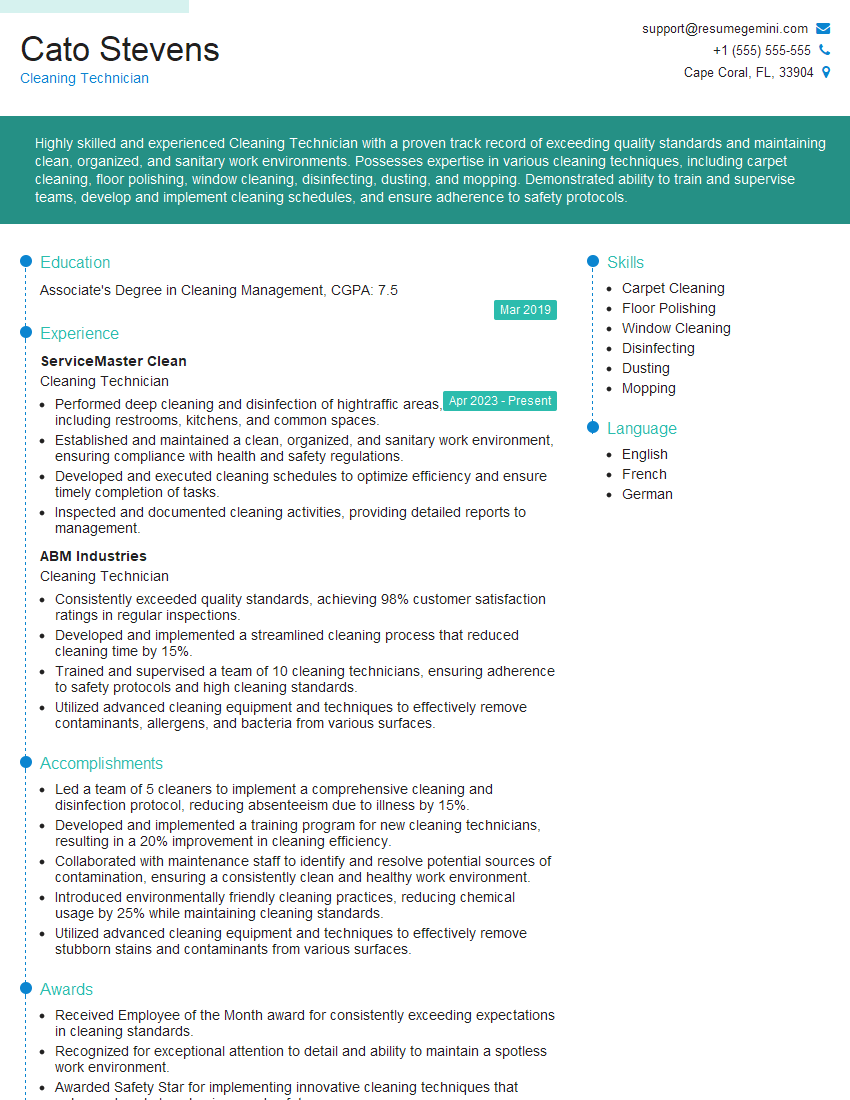

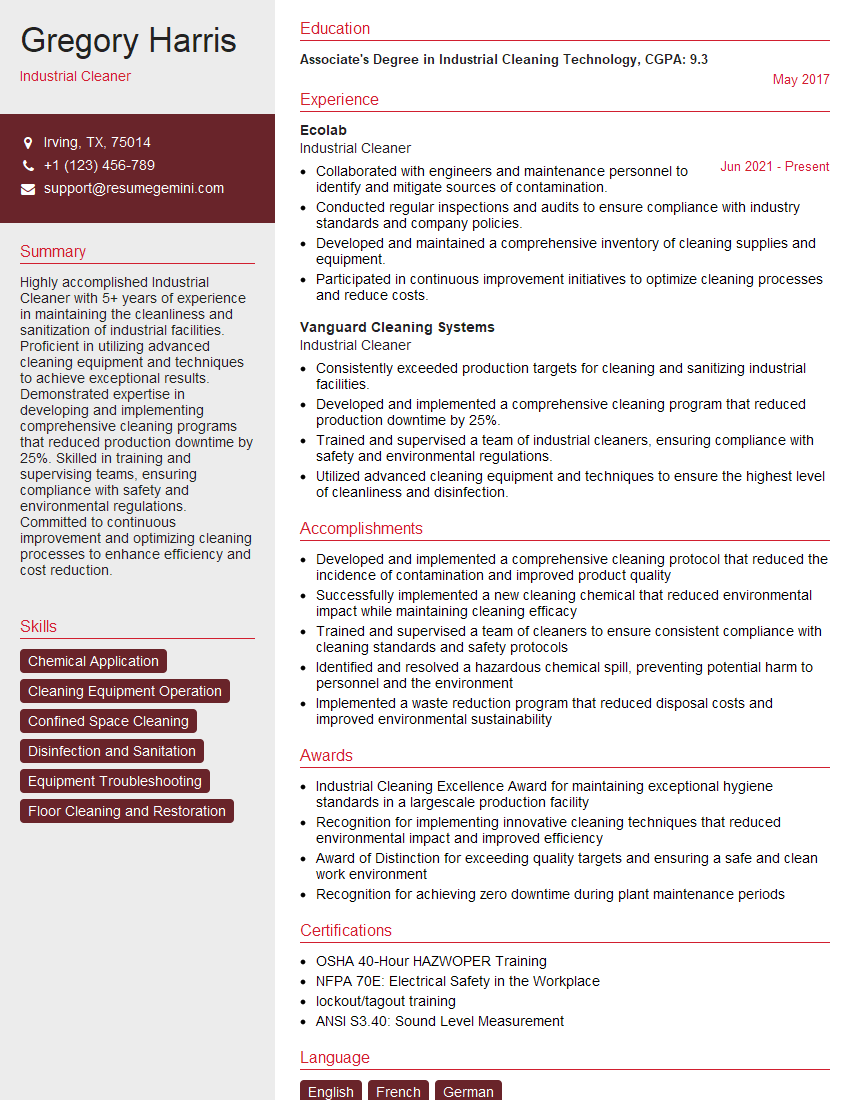

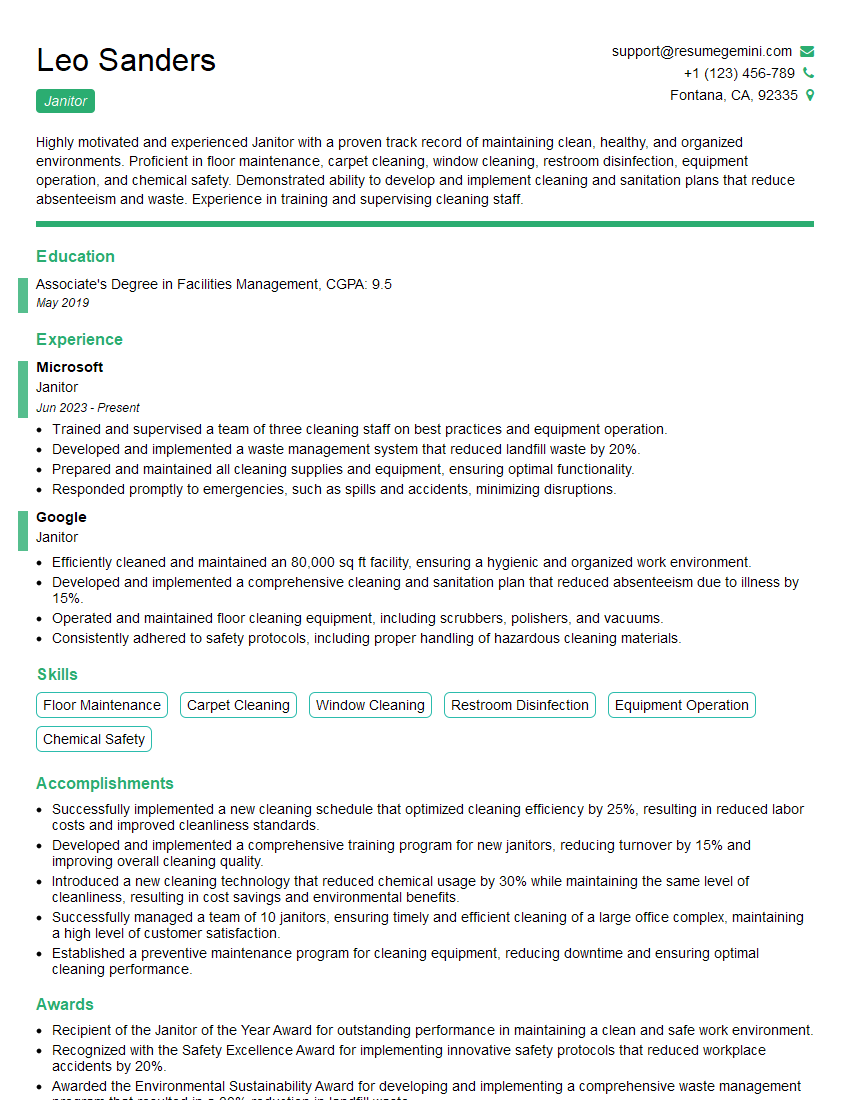

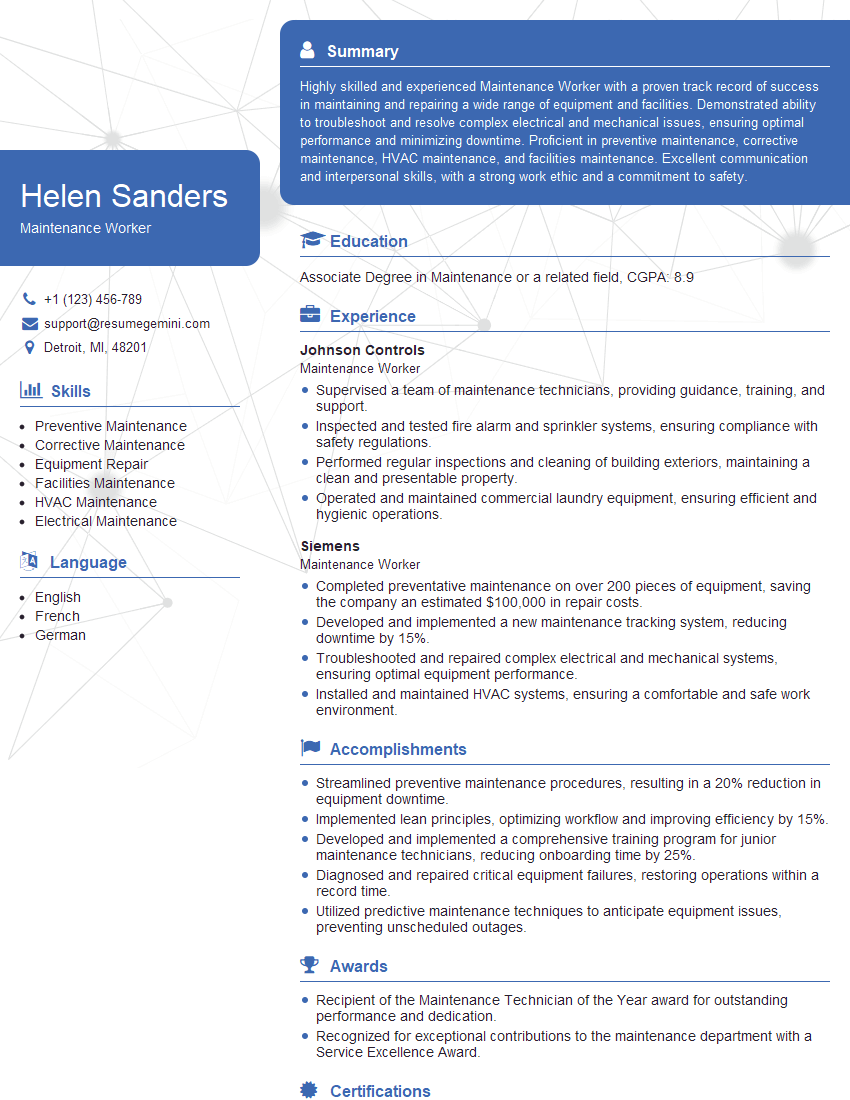

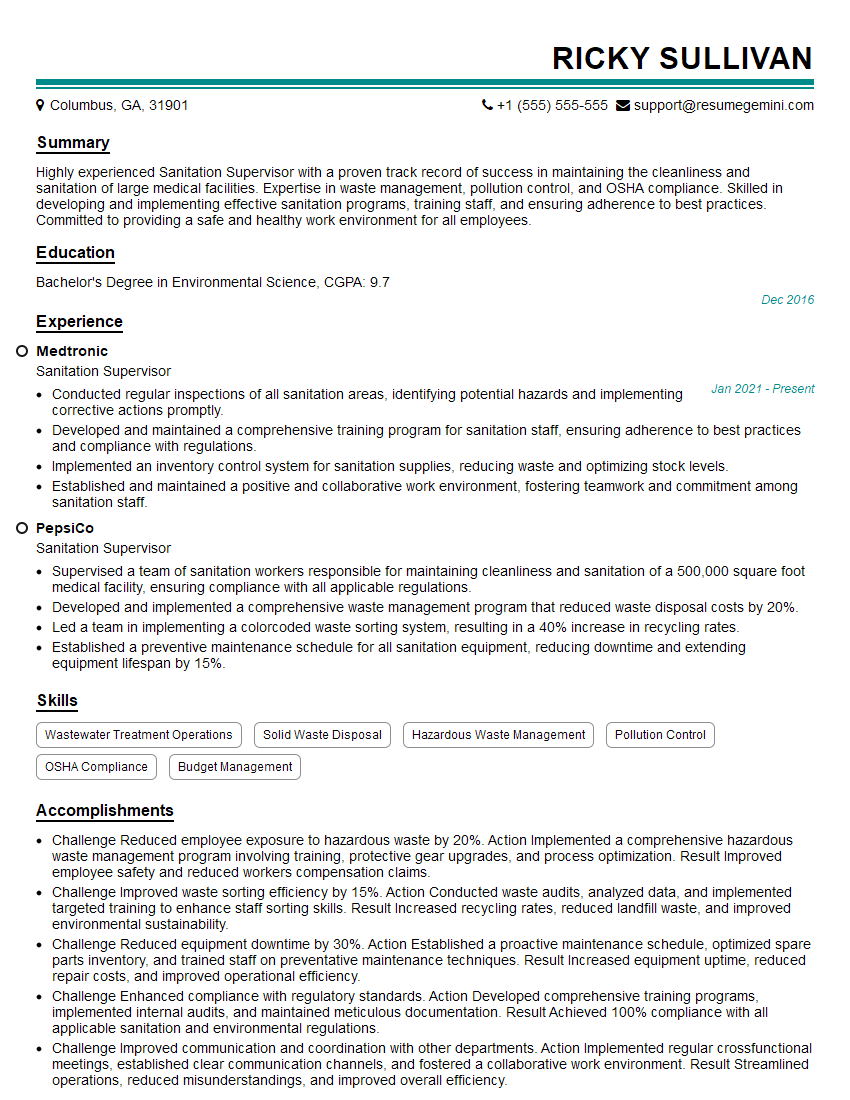

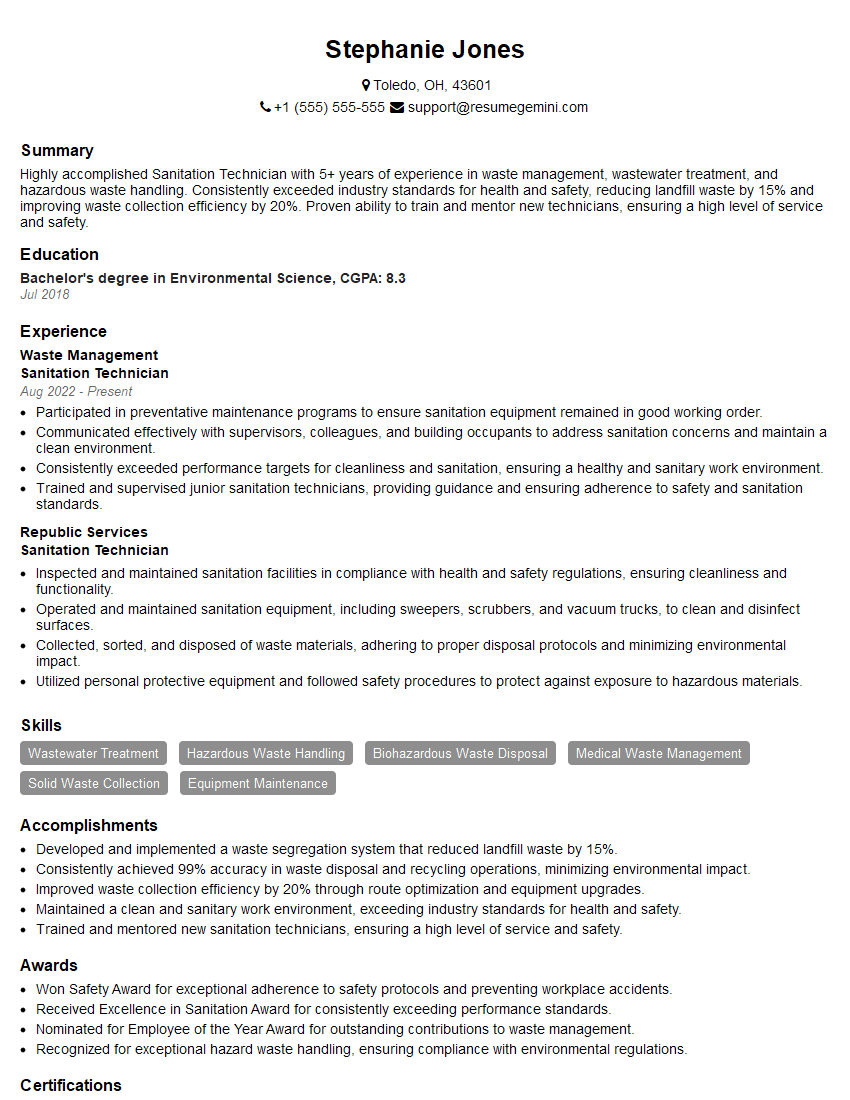

Mastering the art of maintaining a clean and hygienic work area is crucial for success in numerous professions, demonstrating responsibility, professionalism, and attention to detail – qualities highly valued by employers. A strong resume is your first impression; make it count! Building an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you craft a professional and impactful resume. We offer examples of resumes tailored to the “Maintain Clean and Hygienic Work Area” field to guide you. Take advantage of these resources to showcase your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good