Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Light Carpentry interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Light Carpentry Interview

Q 1. What types of wood are best suited for interior trim work?

Choosing the right wood for interior trim is crucial for both aesthetics and durability. Hardwoods are generally preferred for their strength, beauty, and resistance to wear and tear. However, the best choice depends on factors like budget and desired look.

- Hard Maple: Exceptionally hard and durable, offering a smooth, light-colored finish. Ideal for high-traffic areas.

- Red Oak: A classic choice with a rich reddish-brown tone. Relatively hard and easy to work with.

- Cherry: A beautiful hardwood with a warm, reddish-brown hue that darkens with age. It’s more expensive than oak but adds elegance.

- Poplar: A softer wood, easier to work with, and more affordable. It accepts paint exceptionally well, making it a popular choice for painted trim.

- Pine: A softwood, offering a more rustic look. It’s less durable than hardwoods but is affordable and readily available. Suitable for projects where durability isn’t paramount.

For example, I recently completed a project where the client wanted a modern, minimalist look. We opted for painted poplar trim because of its smooth finish and ability to accept paint flawlessly. In another project where the client desired a more traditional aesthetic, we used red oak for its rich grain and durability.

Q 2. Explain the process of installing crown molding.

Installing crown molding is a rewarding but detail-oriented process. Accuracy is key for a professional finish. Here’s a step-by-step approach:

- Measure and Cut: Precise measurements are crucial. Use a measuring tape and a miter saw for accurate 45-degree cuts, ensuring a seamless fit at the corners.

- Prepare the Walls: Ensure your walls are clean, smooth, and free of any imperfections. Caulk any gaps for a cleaner look.

- Apply Adhesive: Use a construction adhesive designed for crown molding. Apply a generous bead to the back of the molding.

- Install the Molding: Starting at a corner, carefully press the molding against the wall, ensuring it’s level and aligned. Use nails or finishing pins to secure it in place. Spacing should be consistent.

- Fill Nail Holes and Caulk Gaps: Once the molding is secured, fill any nail holes with wood filler and caulk any gaps between the molding and the wall.

- Sand and Paint/Stain: After the filler and caulk dry, sand the surface smooth. Finally, apply your chosen finish, whether paint or stain.

Think of installing crown molding like building a puzzle. Each piece needs to fit precisely, and attention to detail is vital for a successful outcome. I always recommend using a level to ensure everything is perfectly aligned, creating a professional and elegant look.

Q 3. Describe your experience with different types of wood fasteners.

My experience encompasses a wide range of wood fasteners, each with its specific advantages and applications. Selecting the right fastener is crucial for both strength and aesthetics.

- Finishing Nails: Small, thin nails designed to be countersunk and hidden, providing a clean, seamless look. Ideal for trim work and delicate applications.

- Brad Nails: Similar to finishing nails but even smaller, often used with a nail gun for faster installation.

- Construction Screws: Stronger and more versatile than nails, they offer better holding power, especially in hardwoods. They can be countersunk for a cleaner finish.

- Wood Glue: Often used in conjunction with other fasteners, glue provides additional strength and prevents wood movement. It’s essential for stronger joints.

For example, when installing crown molding, I prefer using finishing nails for a clean, invisible fastener. However, when assembling cabinets or building frames, I utilize construction screws for their superior holding power. The choice always depends on the application and the desired aesthetic.

Q 4. How do you ensure accurate measurements for cabinetry installation?

Accurate measurements are paramount in cabinetry installation. Inaccurate measurements can lead to significant problems and rework. My process involves a multi-step approach:

- Detailed Drawings and Plans: Start with accurate drawings or plans that specify dimensions and locations of cabinets.

- Precise On-Site Measurements: Measure the space multiple times, double-checking for any inconsistencies or deviations. Account for wall irregularities and existing features.

- Template Creation: For complex installations, creating templates (cardboard or plastic) from the actual space ensures a perfect fit. This is particularly useful for countertops and custom cabinetry.

- Double-Check Measurements: Before cutting any materials, always double-check all measurements to minimize errors. A small mistake can have large consequences.

- Pilot Holes: Drill pilot holes before driving screws or nails to prevent wood splitting, especially in hardwoods.

I remember one project where a seemingly minor measurement error could have cost a lot of time and money had we not created templates. This saved us from having to redo significant portions of the work.

Q 5. What safety precautions do you take when using power tools?

Safety is my top priority when using power tools. I consistently follow a strict set of safety procedures:

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and a dust mask when operating power tools. Appropriate clothing, like closed-toe shoes, is also crucial.

- Tool Maintenance: Regularly inspect and maintain my tools. Sharp blades and properly functioning equipment reduce the risk of accidents.

- Proper Technique: Maintain a firm grip on the tool and follow the manufacturer’s instructions carefully. Never rush the job.

- Work Area Safety: Ensure my work area is clean, well-lit, and free of clutter. Keep bystanders away from the work area.

- Disconnecting Power: Always disconnect power tools before making adjustments or cleaning them.

Safety isn’t just a matter of rules; it’s a mindset. By developing safe work habits, I’ve been able to avoid injuries throughout my career, and I encourage everyone in the trade to do the same.

Q 6. How do you handle damaged or warped wood during a project?

Dealing with damaged or warped wood requires careful assessment and appropriate techniques. The approach depends on the severity and type of damage.

- Minor Warping: Sometimes, gentle clamping or the use of a moisture meter can help correct minor warping. This is often caused by changes in humidity.

- Significant Warping or Damage: Severely warped wood may need to be replaced. For minor damage like knots, I might cut around them or use wood filler to repair the imperfection.

- Moisture Control: Understanding and controlling the moisture content of the wood is crucial. Wood that is too dry or too wet is more prone to warping and damage.

One time, I encountered a batch of lumber with some significant warping. After assessing the situation, I determined that replacing the affected pieces was the most efficient and reliable solution. It prevented potential issues later in the project.

Q 7. What experience do you have with installing doors and windows?

I have extensive experience installing doors and windows, ranging from standard installations to more complex projects. My experience includes:

- Precise Measurements and Preparation: Accurate measurements are critical for proper fit and function. Preparing the rough opening is also a vital step.

- Framing and Shimming: Ensuring the door or window frame is properly plumb and level, using shims as needed, is vital for a professional finish.

- Installation Techniques: I’m proficient in various installation methods, including using different types of fasteners and sealants to ensure a secure and weathertight installation.

- Finishing Touches: This includes caulking, painting, and installing hardware (hinges, handles, locks) to complete the installation.

I once worked on a historic building restoration where installing the replacement windows required meticulous attention to detail and understanding of traditional methods. Successfully completing this project showcased my skills in handling unique challenges.

Q 8. Explain your experience with using different types of wood glue.

Wood glue is the backbone of many light carpentry projects, and my experience spans several types, each with its strengths and weaknesses. I’m proficient with PVA (polyvinyl acetate) glues, which are the workhorses for most interior projects. They’re readily available, relatively inexpensive, and offer good strength once cured. I often use yellow PVA for general assembly and white PVA for projects where a cleaner, less visible glue line is desired. For exterior work or projects requiring superior water resistance, I frequently use exterior-grade PVA or polyurethane glues. Polyurethane glues are significantly stronger and water-resistant, ideal for situations like outdoor furniture or projects exposed to moisture. Finally, I’ve worked with aliphatic resin glues, known for their very strong bond and clarity, making them perfect for fine woodworking where the glue joint needs to be virtually invisible. The choice of glue always depends on the specific project requirements, the types of wood being joined, and the anticipated environmental conditions.

For example, when building a cabinet, I’d use yellow PVA for its cost-effectiveness and strong bond in interior conditions. But for constructing a garden bench, I’d definitely opt for a polyurethane glue for its superior weather resistance to ensure longevity.

Q 9. How do you prepare a surface for painting or staining?

Surface preparation is critical for a professional-looking and long-lasting paint or stain job. It’s not just about aesthetics; proper preparation prevents peeling and chipping. My process begins with a thorough cleaning of the surface. This often involves removing dust, dirt, grease, or any old finish using appropriate cleaners or a light sanding. For painted surfaces, I might use a deglosser to ensure the new paint adheres properly. After cleaning, any imperfections, such as cracks or nail holes, need to be filled with wood filler, then sanded smooth once dry. The next step is sanding the entire surface to create a uniform texture and to remove any raised grain. I typically start with a coarser grit sandpaper (around 100-grit) and gradually move to finer grits (up to 220-grit or higher) for a smoother finish, paying close attention to achieve a uniform surface. Finally, I’ll wipe the surface down with a tack cloth to remove all sanding dust, ensuring a clean surface ready for painting or staining.

Q 10. What methods do you use to ensure square cuts?

Achieving square cuts is fundamental in carpentry, and I employ several methods to ensure accuracy. My primary tool is a combination square, which I use to check the squareness of my cuts before and after making them. For marking square cuts on larger pieces of wood, I rely on a speed square, which allows for quick and precise marking of angles. For the actual cutting, I prefer a miter saw for the precision it offers. However, for smaller pieces or more intricate cuts, I may use a hand saw, always double-checking my work with the combination square. If extreme accuracy is essential, I might use a marking gauge to create a precise line to follow with the saw. The key is to always double-check measurements and use sharp tools, this leads to more accurate cuts and saves time later on in the project.

Q 11. Describe your experience with installing baseboards and casings.

I have extensive experience installing baseboards and casings, having completed countless installations in various settings. The process typically involves measuring and cutting the pieces to the exact length needed, accounting for any angles or obstacles like doors or windows. I carefully miter the ends for a clean, seamless look at the corners. Before installation, I prepare the wall by cleaning it and filling any gaps or holes with wood filler, ensuring a smooth surface. I then apply construction adhesive to the back of the baseboards and casings to secure them to the wall, using finishing nails to hold them in place while the adhesive cures. Finally, I use wood filler to conceal the nail holes and then sand the filler smooth before priming and painting to match the wall’s color. I always strive for a tight, gap-free fit, ensuring a professional and refined finish.

Q 12. How do you troubleshoot common problems encountered during trim installation?

Troubleshooting trim installation often involves addressing issues like gaps, uneven surfaces, or poorly mitered corners. Gaps can be caused by improper measurements, uneven walls, or insufficient adhesive. To address gaps, I use wood filler to carefully fill the spaces, ensuring a smooth, seamless finish. Uneven walls can sometimes be addressed by using shims to level the trim. Poorly mitered corners are usually a result of inaccurate cuts or using dull tools. In such cases, I may need to recut the pieces to ensure a precise 45-degree angle, ensuring a clean joint. Sometimes, a slight gap in a mitered corner is acceptable and can be filled with paintable wood caulking. Systematic problem-solving, involving careful inspection and the application of relevant solutions, is key to successful trim installations.

Q 13. What types of finishing techniques are you familiar with?

My finishing techniques include staining, painting, and clear-coating. Staining enhances the natural beauty of the wood grain while allowing it to show through. Painting provides a uniform color and protects the wood. Clear-coating protects the wood from scratches, moisture, and UV damage, while maintaining the natural look. I’m familiar with various types of finishes, including water-based and oil-based stains, latex and oil-based paints, and polyurethane and shellac clear coats. I’m adept at applying multiple coats, sanding between coats to achieve a smooth, even finish. I always select the appropriate finish based on the project’s requirements, the type of wood, and the desired aesthetic. For instance, a rich stain enhances the grain of oak, while a glossy paint offers a smooth, durable finish for kitchen cabinets.

Q 14. Describe your experience with working from blueprints or plans.

Working from blueprints and plans is an integral part of my carpentry work. I’m proficient in reading and interpreting various types of construction documents, including detailed drawings, specifications, and material lists. I carefully review plans to understand the scope of work, the dimensions of components, and the desired aesthetic. I meticulously measure and cut materials according to the provided plans, ensuring accuracy and minimizing waste. I also make use of digital measuring tools and design software to aid in the accurate planning and execution of my work, ensuring that everything fits perfectly together and according to specifications. When discrepancies arise, I always consult the client or supervisor for clarification. This ensures accurate and efficient project completion.

Q 15. How do you maintain your tools and equipment?

Maintaining my tools and equipment is paramount to ensuring safety, efficiency, and longevity. It’s not just about cleaning; it’s about proactive care. My routine involves several key steps:

- Cleaning after each use: I wipe down all tools, removing sawdust, resin, or any other debris. This prevents build-up and corrosion. For power tools, I blow out any dust accumulation using compressed air.

- Lubrication: Moving parts, such as saw blades, hinges on clamps, and drill chucks, require regular lubrication with appropriate lubricants. This reduces friction and extends their lifespan. I always refer to the manufacturer’s instructions for specific lubrication recommendations.

- Sharpening blades and bits: Dull blades are dangerous and inefficient. I regularly sharpen my hand tools (chisels, planes) using sharpening stones and maintain my power tool blades by either sharpening them myself or taking them to a professional sharpening service.

- Storage: Proper storage is crucial. Tools are kept in a dry, organized location, away from excessive moisture and temperature fluctuations. I use tool organizers and cases to prevent damage and keep things easily accessible.

- Regular Inspection: Before each project, I visually inspect my tools for any damage, cracks, or loose parts. Any compromised tools are immediately repaired or replaced.

Think of it like this: your tools are your partners. Treating them well ensures they’ll perform their best when you need them most.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of saws (e.g., circular saw, miter saw)?

I’m proficient with various saws, each suited for different tasks. My experience includes:

- Circular Saw: A workhorse for crosscuts and rip cuts in sheet goods. I’m experienced in using various blades (e.g., fine-tooth for plywood, coarser tooth for framing lumber), adjusting the blade depth, and employing safety practices like using a push stick and hearing protection. I can accurately cut large sheets and manage complex cuts with precision.

- Miter Saw: Essential for accurate angled cuts, ideal for trim work, crown molding, and picture frames. I’m familiar with different miter saw types (sliding compound miter saws offer versatility) and consistently achieve precise angles. I understand the importance of using a miter saw stand for stability and safety.

- Hand Saws: I appreciate the precision and control offered by hand saws, particularly in tight spaces where power tools are less practical. I’m proficient with rip saws, crosscut saws, and backsaws.

- Jigsaw: Excellent for intricate curves and cutting out shapes in wood and other materials. I’m adept at using jigsaws to create decorative elements and follow complex patterns.

Choosing the right saw for the job is key – a circular saw wouldn’t be ideal for delicate trim work, just as a hand saw isn’t suited for cutting large sheets of plywood.

Q 17. How do you calculate the amount of material needed for a project?

Calculating material needs requires careful planning and accurate measurements. The process typically involves these steps:

- Detailed Drawings/Plans: Start with accurate drawings or plans that clearly indicate the dimensions of each component.

- Measurements: Carefully measure all required dimensions, adding extra material for waste and potential errors. This is especially crucial for projects involving multiple cuts or complex shapes.

- Waste Factor: Account for waste generated during cutting. This varies depending on the material, the type of cut, and the skill of the craftsman. For example, cutting lumber requires adding extra length to account for kerf (the width of the saw blade’s cut).

- Material Selection: Consider the type of material needed based on the project’s requirements. Different materials may have different sizes and strengths.

- Calculations: Calculate the total amount of each material needed based on the measurements, accounting for waste and any additional material needed for mistakes.

Example: Building a simple shelf requires calculating the length and width of the shelves, the sides, and supports. Remember to add extra length to accommodate for cuts and any potential miscalculations. I’d typically add 10-15% extra material to account for waste.

Q 18. Describe your experience with using a level and plumb bob.

A level and a plumb bob are essential tools for ensuring accuracy and structural integrity in carpentry. My experience encompasses:

- Level: I use levels (both torpedo and standard levels) frequently to ensure surfaces are perfectly horizontal or vertical. I understand the importance of checking the level’s accuracy before starting a project and knowing how to read and interpret the level’s bubble to achieve precise alignment. I’ve used levels for everything from installing cabinets and countertops to ensuring the proper alignment of wall studs.

- Plumb Bob: A plumb bob is indispensable for establishing a truly vertical reference point. I use it to ensure walls and posts are perfectly plumb, a crucial step in building structures that will stand the test of time. This is particularly important when working on framing, ensuring walls are perfectly vertical to avoid structural issues.

Imagine building a house without these – the walls would lean, shelves wouldn’t be level, and the entire structure would be compromised. Precision is critical, and these tools guarantee it.

Q 19. What is your experience with working at heights?

Working at heights requires rigorous adherence to safety protocols. My experience includes working from ladders, scaffolding, and elevated platforms. I always prioritize safety:

- Proper Equipment: Using appropriately sized and rated ladders, scaffolds, and harnesses. I inspect equipment before use, ensuring its stability and safety.

- Fall Protection: When working at significant heights, I use fall protection systems, including harnesses and safety lines, in accordance with safety regulations.

- Spotter: For particularly challenging tasks, I’ll have a spotter to assist and provide extra security.

- Awareness: I’m constantly aware of my surroundings, potential hazards, and weather conditions. I avoid working at heights in adverse weather conditions.

Safety isn’t optional; it’s a non-negotiable aspect of working at heights. A single lapse in judgment can have devastating consequences.

Q 20. How do you handle unexpected issues that arise during a project?

Unexpected issues are inevitable in any construction project. My approach involves:

- Assessment: Calmly assessing the situation, identifying the root cause of the problem, and determining its potential impact on the project.

- Problem Solving: Drawing on my experience and knowledge to develop a solution. This might involve making adjustments to the plans, sourcing new materials, or employing different techniques.

- Communication: If the problem is significant, I communicate openly and honestly with clients, explaining the issue, the proposed solution, and any potential implications on the timeline or budget.

- Documentation: Documenting the issue, the solution, and any lessons learned to avoid similar issues in the future.

For example, discovering a hidden pipe during demolition requires adjusting the layout to accommodate it. Adaptability and problem-solving skills are crucial for navigating these unexpected challenges.

Q 21. What is your experience with installing laminate flooring?

I have extensive experience installing laminate flooring, understanding both the process and its nuances. My experience covers:

- Subfloor Preparation: Ensuring the subfloor is clean, level, and dry is essential for a successful installation. This might involve repairing damaged areas or using underlayment to address unevenness.

- Acclimation: Allowing the laminate flooring to acclimate to the room’s temperature and humidity is crucial to avoid expansion and contraction issues.

- Installation Techniques: I’m proficient in different installation methods, including click-lock and glue-down systems. I can accurately cut and install planks, paying attention to proper expansion gaps around the perimeter of the room.

- Finishing Touches: Installing transition strips at doorways and baseboards to create a professional and finished look.

- Troubleshooting: I can troubleshoot common problems such as uneven planks, gaps, or squeaking floors. Understanding the causes of these problems is crucial to resolving them effectively.

Laminate flooring installation requires precision and attention to detail. A well-installed floor looks great and lasts for years. I approach each installation with the same care and precision.

Q 22. Describe your experience with repairing minor drywall damage.

Repairing minor drywall damage is a fundamental skill in light carpentry. It involves patching small holes, cracks, or dents to restore the wall’s surface to a smooth, seamless finish. The process typically involves several steps, depending on the severity of the damage.

- Assessment: First, I carefully assess the extent of the damage. Small nail holes might only require spackle, while larger holes need more extensive patching with drywall compound.

- Preparation: For larger holes, I often need to cut a clean, square patch, ensuring that the edges are flush with the surrounding drywall. This creates a stable base for the repair.

- Patching: I apply drywall compound (also called joint compound) in thin layers, feathering the edges to blend seamlessly with the existing wall. Multiple thin coats are better than one thick coat to prevent cracking.

- Sanding: Once the compound is dry, I carefully sand the patched area with progressively finer grit sandpaper, until it’s smooth and flush with the surrounding wall. This is crucial for a professional finish.

- Priming and Painting: Finally, I prime the repaired area to improve paint adhesion and then paint to match the existing wall color.

For example, I once repaired a large hole in a client’s hallway wall caused by a moving mishap. By carefully following these steps, I was able to restore the wall to its original condition, leaving no visible signs of the repair.

Q 23. How do you ensure a clean and professional finish to your work?

Achieving a clean and professional finish is paramount in light carpentry. It’s about attention to detail at every stage of the process. This includes proper preparation, precise execution, and meticulous cleanup.

- Cleanliness: Maintaining a clean workspace is crucial. I always clean up sawdust and debris regularly to prevent them from interfering with the work and to ensure a smooth finish.

- Precision: Accurate measurements and cuts are key to avoiding gaps and imperfections. I use high-quality tools to ensure precise work, and I double-check my measurements before making any cuts.

- Finishing Touches: This is where the ‘magic’ happens. Careful sanding, proper application of finishes (paint, stain, varnish), and attention to details like caulking and filling any gaps ensure a smooth, flawless surface.

- Protective Measures: Protecting surfaces and floors with drop cloths and masking tape prevents damage and ensures a professional clean-up.

Think of it like baking a cake: You need precise measurements, careful mixing, and attention to the oven temperature to achieve a perfect result. Light carpentry is similar; precision and attention to detail are vital for a professional outcome.

Q 24. What is your experience with different types of wood stains and finishes?

My experience with wood stains and finishes is extensive. I’m familiar with a wide range of products, each with its own properties and applications.

- Stains: I regularly use oil-based stains, water-based stains, and gel stains. Oil-based stains penetrate deeply into the wood, enhancing its natural grain. Water-based stains are easier to clean up, and gel stains are ideal for vertical surfaces as they don’t drip as much.

- Finishes: I’m proficient in applying various finishes, including varnish, polyurethane, shellac, and lacquer. Varnish offers good protection and durability, while polyurethane is known for its toughness and water resistance. Shellac is a traditional finish known for its clarity, and lacquer dries quickly, ideal for fast-paced projects.

- Matching Finishes: One of the most challenging aspects is matching existing finishes. I carefully analyze the existing finish to determine its type and then select a compatible product to ensure a seamless blend.

For instance, I recently refinished an antique table, carefully selecting a stain to match the original color and applying multiple coats of polyurethane to restore its luster and protect it from damage. The key is understanding the properties of each product and choosing the right one for the specific project and wood type.

Q 25. How do you manage your time effectively on a project?

Effective time management is crucial for completing projects on schedule and within budget. My approach involves meticulous planning and efficient execution.

- Detailed Planning: I begin each project with a thorough plan, breaking down the tasks into smaller, manageable steps. This allows for better tracking of progress and identification of potential bottlenecks.

- Prioritization: I prioritize tasks based on their urgency and dependency on other tasks. This ensures that critical steps are completed first, keeping the project on track.

- Realistic Scheduling: I create a realistic schedule, accounting for potential delays and unexpected issues. This helps me stay organized and avoid rushing through the work.

- Regular Monitoring: I regularly monitor my progress against the schedule, making adjustments as needed. This allows for early detection of problems and proactive solutions.

For example, on a recent deck building project, I meticulously planned each phase, from foundation work to finishing touches. By adhering to the schedule, I completed the project ahead of schedule, exceeding client expectations.

Q 26. Explain your understanding of building codes related to light carpentry.

Understanding building codes is essential for safe and compliant light carpentry work. My knowledge covers key areas relevant to my work, such as:

- Structural Integrity: I understand the requirements for proper fastening techniques, ensuring that any additions or modifications I make are structurally sound and won’t compromise the building’s integrity. This includes using appropriate fasteners for the type of wood and application.

- Fire Safety: I am aware of the regulations related to fire-resistant materials, especially when working near electrical wiring or in areas with potential fire hazards.

- Accessibility: I’m familiar with accessibility guidelines, ensuring that any modifications I make don’t create barriers for people with disabilities.

- Electrical Codes: While not directly a carpentry task, I’m careful to never work near exposed electrical wiring and know when to involve qualified electricians.

Ignoring building codes can lead to safety hazards and legal issues. My commitment to adherence to these regulations ensures that my work is safe, durable, and meets all legal requirements.

Q 27. Describe a challenging carpentry project and how you overcame it.

One challenging project involved building custom bookshelves for a client with extremely high ceilings and oddly shaped walls in their library. The challenge was not only in the construction itself, but in safely accessing and working at such heights.

To overcome this, I developed a three-pronged approach:

- Detailed Planning & Measurements: I took incredibly precise measurements, accounting for every irregularity in the walls and ceiling. I created detailed drawings to plan the bookshelf structure and ensure all components would fit perfectly.

- Safe Working Practices: Safety was paramount. I used appropriate scaffolding and harnesses for working at heights, strictly adhering to all safety protocols.

- Creative Solutions: Due to the unusual wall shapes, I had to create custom-sized shelves and adapt the design to fit the space efficiently. I utilized various joinery techniques to ensure the strength and stability of the structure.

The final result was stunning; the custom bookshelves seamlessly integrated into the library, showcasing both my craftsmanship and problem-solving abilities. This project reinforced the importance of thorough planning, safe practices, and adapting creative solutions when facing unusual challenges.

Q 28. What are your salary expectations for this role?

My salary expectations are in line with the industry standards for a light carpenter with my experience and skillset. Considering my years of experience, proven ability to manage projects efficiently, and commitment to delivering high-quality work, I am seeking a compensation package of [Insert Salary Range or Hourly Rate]. I am open to discussing this further and am confident that my contributions will significantly benefit your company.

Key Topics to Learn for Your Light Carpentry Interview

- Measuring and Marking: Understanding accurate measurement techniques using various tools (tape measures, squares, etc.) and transferring those measurements to materials precisely. This includes understanding fractions and decimals in the context of construction.

- Basic Hand Tools: Demonstrate familiarity with common hand tools like saws (hand saws, coping saws), hammers, chisels, screwdrivers, and their safe and effective use in different scenarios. Practical application includes explaining the differences between various types of saws and their appropriate uses.

- Woodworking Joints: Understanding and explaining different types of basic woodworking joints (butt joints, lap joints, miter joints) and their applications in various projects. Be prepared to discuss the strengths and weaknesses of each joint type.

- Safety Procedures: Discuss standard safety practices in a carpentry setting, including proper use of personal protective equipment (PPE), safe tool handling, and awareness of potential hazards. This includes understanding and explaining relevant safety regulations.

- Material Selection: Knowledge of different types of wood and their properties (hardwoods vs. softwoods, grain direction, etc.) and how to select the appropriate material for a specific project. Consider explaining how different woods might be used for different applications.

- Basic Carpentry Projects: Be ready to discuss your experience with common light carpentry projects such as building simple shelving units, repairing furniture, or framing small structures. Highlight your problem-solving skills during the construction process.

- Reading and Interpreting Plans: Demonstrate the ability to understand and interpret simple blueprints or sketches. This includes understanding scale, dimensions, and symbols commonly used in construction drawings.

- Finishing Techniques: Familiarity with basic finishing techniques, such as sanding, staining, and painting, and how to achieve a professional finish. Understanding the purpose and application of different finishes is also crucial.

Next Steps

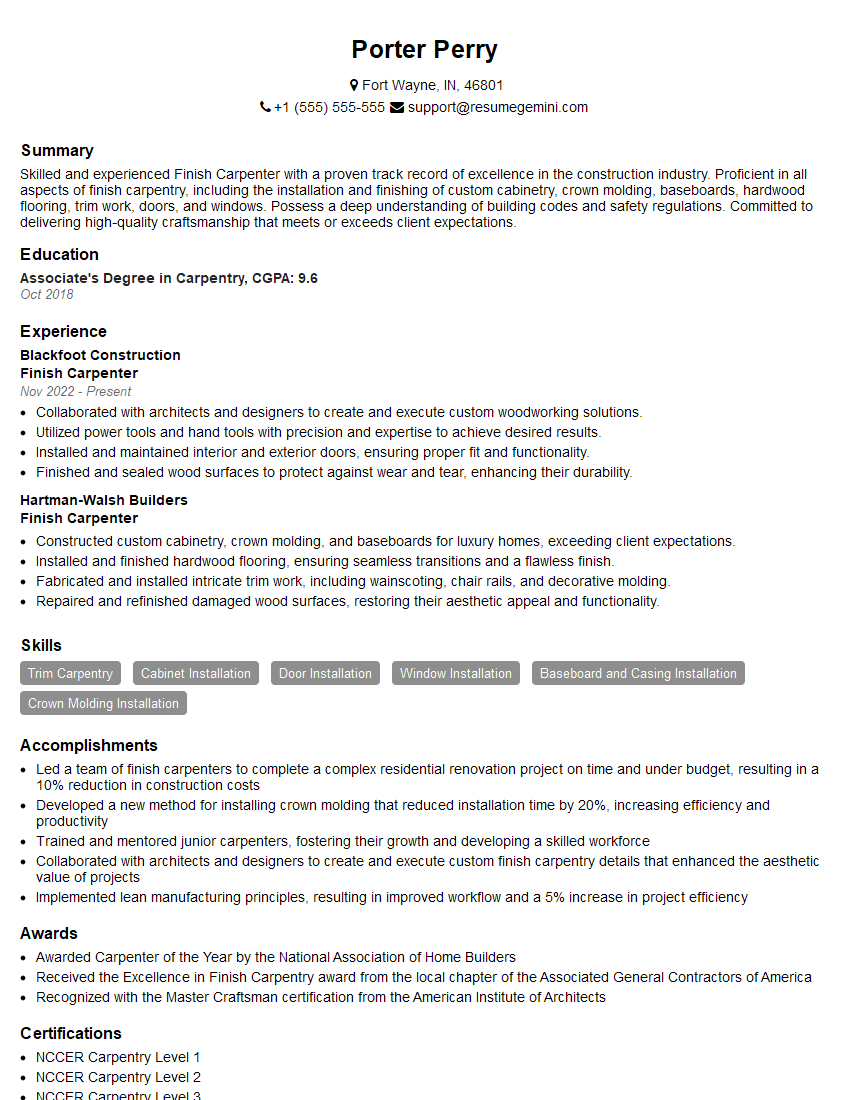

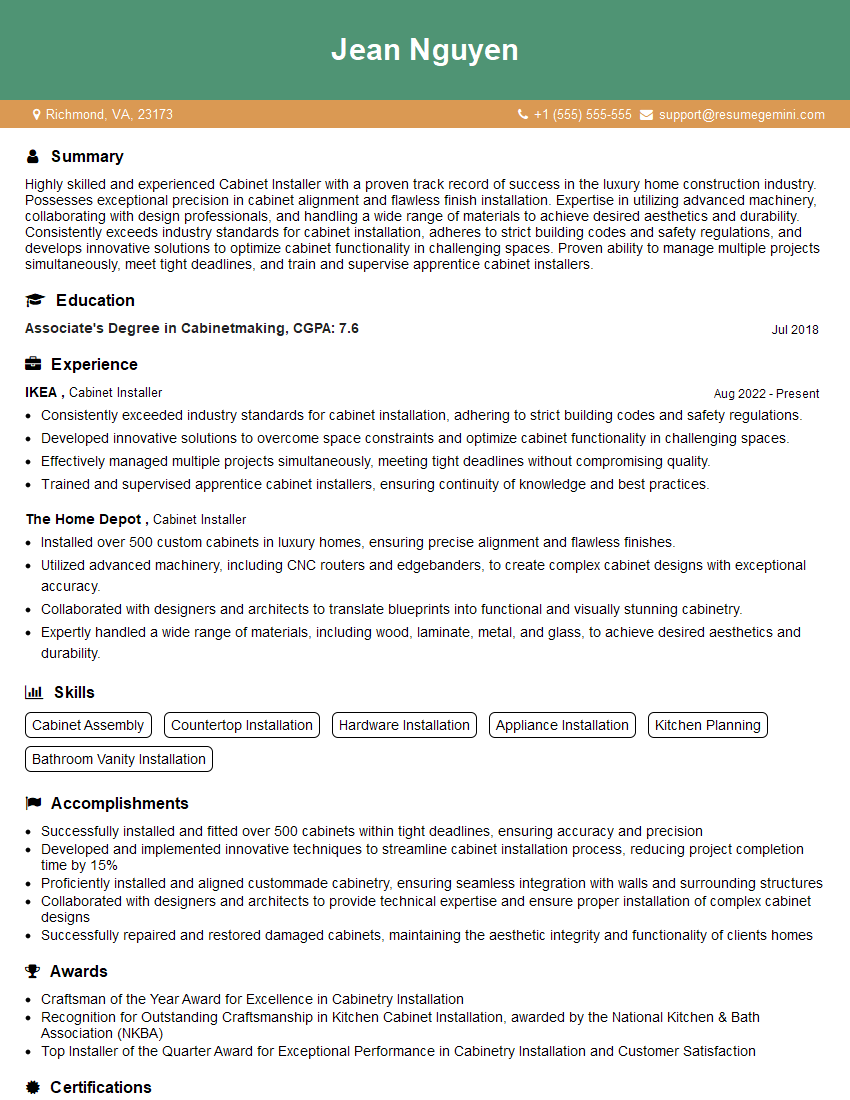

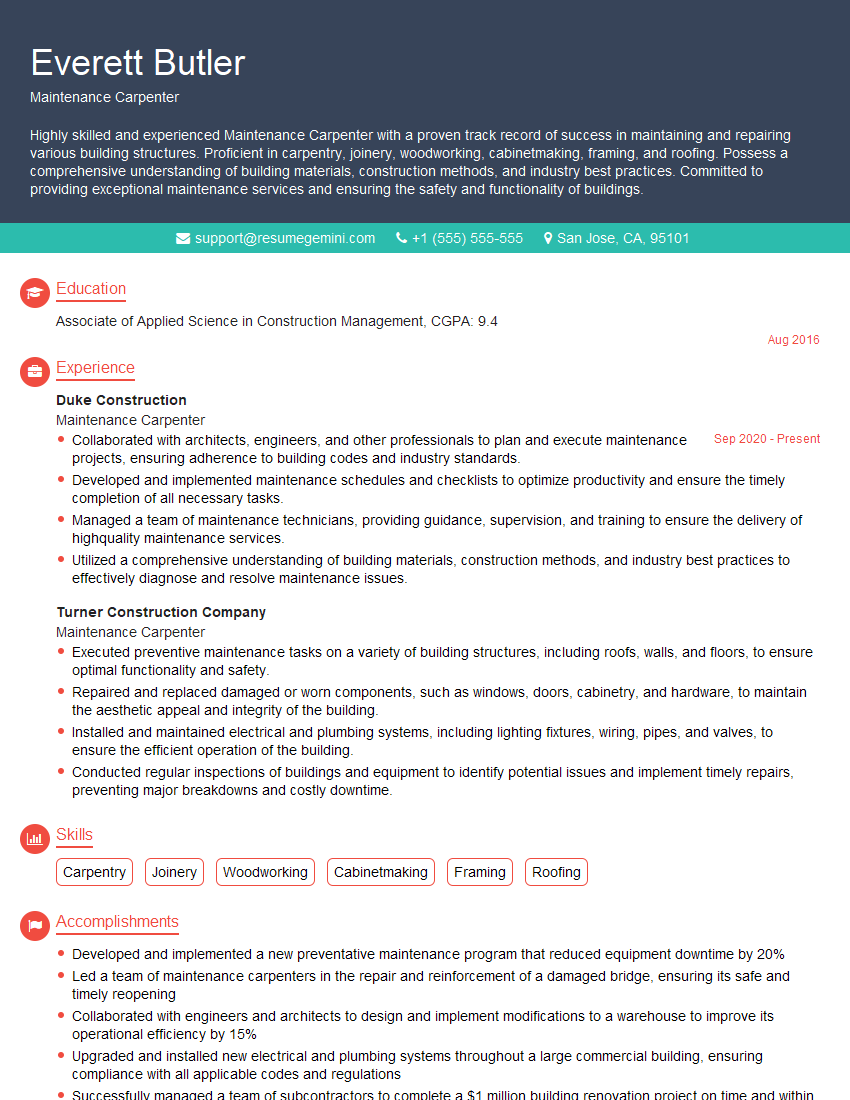

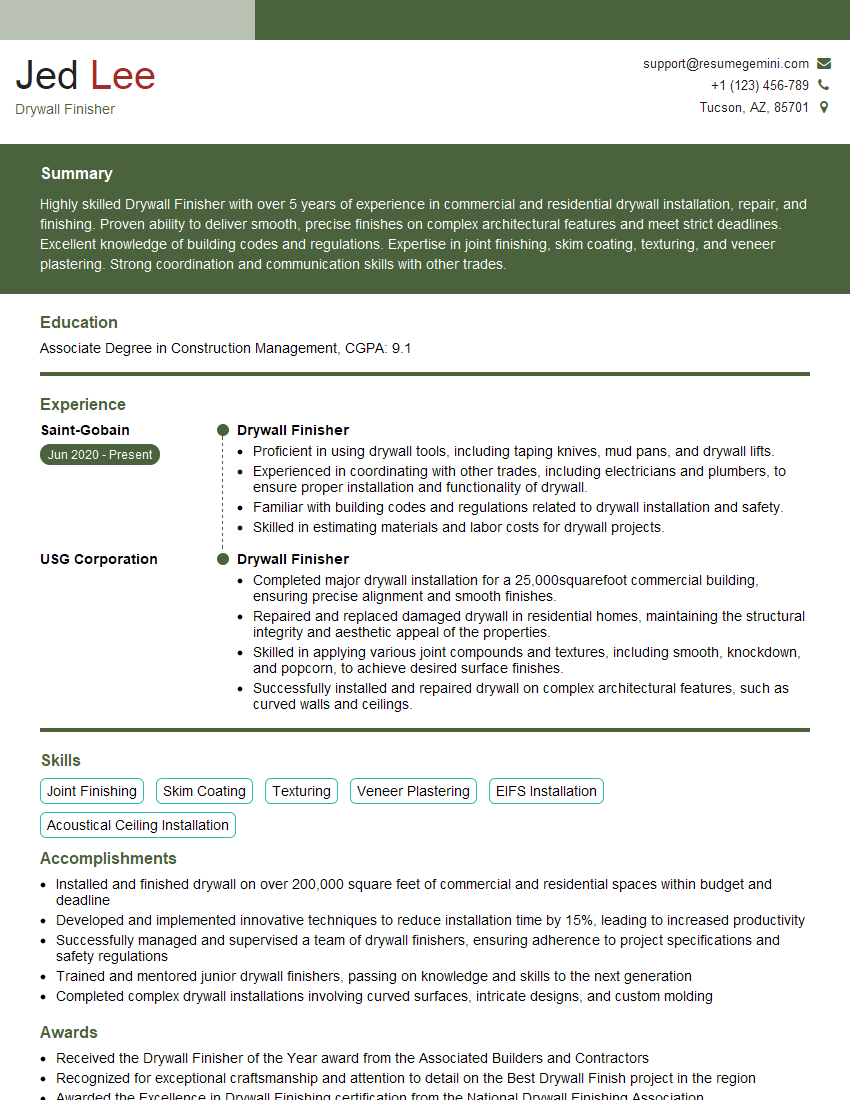

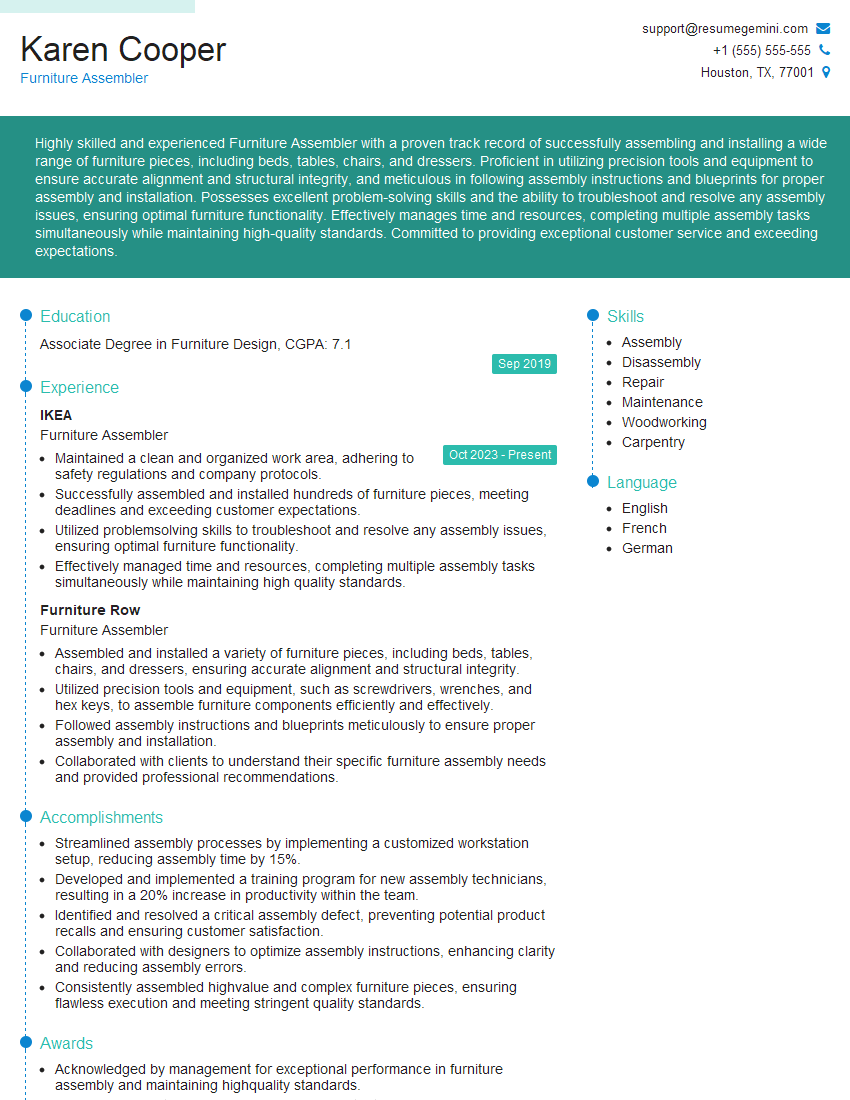

Mastering light carpentry skills opens doors to a rewarding career with diverse opportunities for growth and specialization. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. ResumeGemini can help you create a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini offers examples of resumes tailored specifically to the light carpentry field, providing you with a strong foundation to build upon. Take advantage of these resources to present yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good