Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Outbound and Inbound Shipping interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Outbound and Inbound Shipping Interview

Q 1. Explain the difference between inbound and outbound shipping processes.

Inbound and outbound shipping are two sides of the same coin, but they represent opposite flows within the supply chain. Inbound shipping focuses on the movement of goods into a business, from suppliers to warehouses or distribution centers. This includes receiving, inspecting, and storing incoming materials. Outbound shipping, conversely, involves the movement of goods out of the business, from warehouses to customers or retailers. This includes order processing, picking, packing, and shipping.

Think of it like a restaurant: inbound shipping is the process of receiving ingredients from suppliers, while outbound shipping is serving the meals to customers. Both are crucial for smooth operation; without efficient inbound, you can’t serve your customers effectively, and without efficient outbound, your goods never reach the end consumer.

Q 2. Describe your experience with various shipping carriers (e.g., FedEx, UPS, USPS).

I have extensive experience with FedEx, UPS, and USPS, utilizing each carrier based on the specific requirements of the shipment. FedEx and UPS are typically preferred for time-sensitive, expedited deliveries due to their reliable tracking and speed, especially for smaller packages. For larger or less urgent shipments, LTL (Less-than-Truckload) options with FedEx Freight or UPS Freight can provide cost savings. USPS is a cost-effective solution for smaller, less time-sensitive packages, especially within the domestic market. I’ve negotiated favorable contracts with each carrier to optimize shipping costs and leverage their respective strengths. For example, I’ve successfully negotiated volume discounts with FedEx for a major client’s outbound shipments, resulting in a 15% cost reduction.

Q 3. How do you manage inventory levels to ensure efficient outbound shipping?

Managing inventory levels for efficient outbound shipping requires a well-defined system incorporating forecasting, demand planning, and real-time inventory tracking. I utilize a combination of techniques, including:

- Demand Forecasting: Analyzing historical sales data, market trends, and seasonal fluctuations to predict future demand and adjust inventory accordingly.

- Just-in-Time (JIT) Inventory: Minimizing storage costs by receiving materials only when needed, which reduces storage space and minimizes the risk of obsolescence.

- Safety Stock: Maintaining a buffer stock of essential items to mitigate unforeseen disruptions in the supply chain or unexpected spikes in demand.

- Inventory Management Software: Implementing software that provides real-time visibility into inventory levels, enabling proactive reordering and preventing stockouts.

For example, during peak seasons, we increase safety stock levels for high-demand items, preventing stockouts that could severely impact customer satisfaction and sales.

Q 4. What are your strategies for optimizing warehouse space for both inbound and outbound flows?

Optimizing warehouse space for both inbound and outbound flows requires a strategic layout that maximizes efficiency and minimizes wasted space. Key strategies I employ include:

- Slotting Optimization: Strategically assigning locations for items based on frequency of access, ensuring frequently picked items are easily accessible, reducing picking time.

- Cross-Docking: Minimizing storage time by directly transferring inbound goods to outbound shipments, bypassing storage altogether for high-volume, fast-moving products.

- Vertical Space Utilization: Using vertical space efficiently through high-bay racking systems, allowing for higher storage density.

- Zone Picking: Dividing the warehouse into zones, assigning pickers to specific zones for improved efficiency.

A practical example is implementing a zone picking system to manage outbound shipments, reducing the time spent traversing the warehouse floor by assigning specific zones to different pickers. This significantly improved our order fulfillment rate during peak season.

Q 5. How do you handle damaged goods during inbound or outbound shipping?

Handling damaged goods requires a clear process to minimize losses and ensure customer satisfaction. Upon arrival, all inbound shipments are inspected for damage. Any damaged goods are documented with photographic evidence, and the carrier is immediately notified. For outbound shipments, robust packaging and careful handling are prioritized to prevent damage. If damage occurs, we follow a similar process—documenting with photos, initiating a claim with the carrier, and determining the appropriate course of action, which might include issuing a replacement or refund to the customer. A clear chain of custody is maintained throughout the process, ensuring proper accountability.

Q 6. Explain your experience with different shipping methods (e.g., LTL, FTL, air freight).

My experience encompasses various shipping methods, each with its advantages and disadvantages:

- LTL (Less-than-Truckload): Cost-effective for smaller shipments that don’t require a full truck, sharing space with other shipments. This method works well for consolidated loads to reduce cost but takes slightly longer than FTL.

- FTL (Full Truckload): Ideal for large shipments, providing greater control, faster transit times, and often better protection. It’s more expensive per unit but delivers higher efficiency for large orders.

- Air Freight: The fastest method but significantly more expensive, reserved for time-critical shipments or high-value goods where speed is paramount. It offers great speed but adds a significant cost premium.

The selection of the appropriate method depends on factors such as shipment size, urgency, cost considerations, and the nature of the goods. I regularly assess these factors to choose the most efficient and cost-effective method for each shipment.

Q 7. How do you ensure accurate order fulfillment in a fast-paced environment?

Accurate order fulfillment in a fast-paced environment demands a combination of technology, process optimization, and well-trained personnel. Key elements include:

- Warehouse Management System (WMS): A robust WMS is essential for accurate inventory tracking, order management, and picking optimization. This software tracks every stage of the fulfillment process, greatly reducing errors.

- Barcoding and RFID: Utilizing barcoding and/or RFID tags throughout the process to identify and track items, minimizing manual data entry and potential errors. We have recently implemented RFID which has improved accuracy by over 98%.

- Order Batching: Grouping orders to reduce travel time within the warehouse, improving picker efficiency.

- Quality Control Checks: Implementing multiple checkpoints to verify order accuracy at different stages of the process.

For instance, implementing a WMS integrated with our e-commerce platform has drastically reduced fulfillment errors and improved overall order accuracy, leading to higher customer satisfaction scores.

Q 8. Describe your experience with Warehouse Management Systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. They’re software solutions that manage and optimize the movement and storage of goods within a warehouse, from receiving to shipping. My experience encompasses implementing, configuring, and using various WMS platforms, including Oracle WMS, SAP EWM, and Blue Yonder. This involves everything from defining warehouse layouts and managing inventory levels to optimizing picking routes and automating tasks like receiving and putaway.

For example, in a previous role, we implemented a new WMS that reduced our picking time by 15% by optimizing picking routes based on real-time inventory location data. This not only increased efficiency but also reduced labor costs. Another instance involved integrating the WMS with our Transportation Management System (TMS) to streamline order fulfillment and improve communication between warehouse and transportation providers.

- Inventory Management: Tracking inventory levels in real-time, managing stock rotation (FIFO/LIFO), and generating accurate inventory reports.

- Order Fulfillment: Guiding warehouse staff through the picking, packing, and shipping processes, optimizing routes for efficiency.

- Labor Management: Tracking employee performance, assigning tasks, and optimizing workforce allocation.

- Reporting & Analytics: Providing data-driven insights into warehouse performance, identifying areas for improvement, and supporting decision-making.

Q 9. How do you track shipments and manage delivery exceptions?

Shipment tracking and exception management are critical for maintaining customer satisfaction and operational efficiency. I utilize a combination of technologies and strategies to achieve this. We leverage carrier-provided tracking numbers integrated into our TMS to monitor shipments in real-time. This provides visibility into the location and status of each shipment, allowing us to proactively identify and address potential delays or exceptions.

For example, if a shipment is delayed due to inclement weather, the system automatically alerts us. We can then contact the carrier to inquire about the delay and inform the customer. For exceptions such as failed delivery attempts, we utilize automated email and SMS notifications to the customer, allowing them to reschedule delivery or redirect the shipment. We also use dashboards to monitor key performance indicators (KPIs) such as on-time delivery rates and exception rates, enabling data-driven improvements to our processes.

In handling exceptions, a standardized procedure is crucial. This involves contacting the carrier to investigate the cause, documenting the issue, and implementing corrective actions to prevent recurrence. Communication with the customer is key to managing expectations and maintaining a positive relationship.

Q 10. What are your strategies for reducing shipping costs?

Reducing shipping costs requires a multi-faceted approach. My strategies focus on optimizing various aspects of the shipping process, including:

- Negotiating Rates with Carriers: Building strong relationships with carriers and leveraging volume discounts to secure favorable shipping rates.

- Optimizing Packaging: Using right-sized packaging to minimize shipping dimensions and weight, reducing the overall cost. This includes utilizing lightweight materials where appropriate.

- Consolidating Shipments: Combining multiple smaller shipments into larger ones to reduce the overall number of shipments and leverage volume discounts.

- Route Optimization: Utilizing route optimization software to plan the most efficient delivery routes, reducing fuel consumption and transportation time.

- Carrier Selection: Strategically choosing carriers based on cost, reliability, and service offerings tailored to specific shipment needs.

- Improving Warehouse Efficiency: Streamlining warehouse processes to reduce handling time and improve order fulfillment speed, minimizing delays and associated costs.

For instance, in one project, by implementing a new packaging strategy and negotiating better rates with carriers, we managed to decrease our shipping costs by 12% without compromising delivery times.

Q 11. Explain your experience with customs documentation and regulations.

My experience with customs documentation and regulations is extensive, encompassing both import and export processes. I am proficient in preparing and reviewing a wide range of customs documents, including commercial invoices, packing lists, certificates of origin, and other required documentation depending on the specific commodity and destination country. I understand the importance of accurate and complete documentation to ensure smooth customs clearance and avoid delays or penalties.

I have a deep understanding of international trade regulations and harmonized system (HS) codes. I understand the implications of different trade agreements and their impact on duties and tariffs. I’ve handled instances where incorrect documentation resulted in delays, highlighting the critical importance of accuracy and attention to detail. In those cases, we worked closely with customs brokers to rectify the situation, and implemented internal process improvements to prevent similar issues in the future.

Q 12. How do you ensure compliance with all relevant shipping regulations?

Ensuring compliance with shipping regulations is paramount. This involves a multi-pronged strategy. First, we maintain up-to-date knowledge of all relevant regulations, including those pertaining to hazardous materials (Hazmat), dangerous goods, weight and dimension restrictions, and customs regulations. This requires continuous monitoring of changes in legislation and industry best practices.

Secondly, we employ a robust system of checks and balances throughout the shipping process. This involves verifying all documentation, ensuring proper labeling and packaging, and implementing training programs for staff to ensure they are aware of and comply with all applicable regulations. We use specialized software to validate shipping data against regulatory requirements, flagging any potential non-compliance issues early in the process.

Finally, we regularly conduct internal audits to assess our compliance posture and identify areas for improvement. We also work closely with external compliance experts to stay ahead of any changes and address any emerging risks. Proactive compliance prevents costly fines and reputational damage.

Q 13. How do you handle returns and exchanges?

Handling returns and exchanges efficiently is critical for maintaining customer satisfaction and minimizing costs. Our process involves a clear and easily accessible returns policy, making it straightforward for customers to initiate a return. We utilize a dedicated returns portal or system to track returned items and manage the entire process, from authorization to processing the refund or exchange.

Upon receiving a return, the item is inspected to assess its condition and determine if a refund or exchange is appropriate. We have standardized procedures for processing refunds and exchanges, ensuring timely and accurate processing. We also track return rates and reasons for returns to identify trends and areas for improvement in our products or processes. For example, if a high percentage of returns are due to sizing issues, this might prompt changes to our sizing charts or product descriptions.

Q 14. Describe your experience with different types of packaging and labeling.

My experience encompasses a wide range of packaging and labeling practices, tailored to the specific needs of different products and shipping methods. This includes selecting appropriate materials to protect the goods during transit, considering factors such as fragility, weight, and environmental conditions. The choice of packaging is crucial for minimizing damage and costs.

Labeling is equally important, adhering to industry standards and regulations. This includes applying clear and accurate labels with all necessary information, such as shipping addresses, product descriptions, weight, dimensions, and any hazard warnings. We utilize barcodes and RFID tags for efficient tracking and inventory management. For hazardous materials, specialized packaging and labeling are essential to ensure compliance with relevant regulations, such as those set forth by IATA (International Air Transport Association) and DOT (Department of Transportation).

For example, fragile items require special cushioning and protective packaging, while heavier items might necessitate sturdier containers. Accurate and compliant labeling avoids delays and potential safety issues.

Q 15. How do you prioritize shipments to meet deadlines?

Prioritizing shipments hinges on a clear understanding of customer needs and product urgency. We use a multi-faceted approach combining several key factors. First, we categorize shipments based on their delivery deadlines – ‘rush’ orders, ‘standard’ orders, and ‘future’ orders. Each category has specific processing protocols. Second, we employ a Transportation Management System (TMS) that automatically assigns priorities based on pre-defined rules, considering factors such as promised delivery dates, customer importance (VIP accounts get priority), and product value. Third, real-time tracking allows us to monitor the shipment’s progress and intervene if delays threaten to compromise deadlines. For example, if a ‘rush’ order faces a potential delay, we might explore expedited shipping options or reroute it to a faster carrier.

Imagine a scenario where a major retailer requires a large shipment of seasonal products before a promotional event. This would undoubtedly be classified as a ‘rush’ order, triggering priority handling throughout the entire shipping process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage relationships with shipping carriers?

Managing carrier relationships is vital for efficiency and reliability. We don’t just select carriers based on price; we build strategic partnerships. This involves negotiating favorable rates, service level agreements (SLAs), and on-time delivery guarantees. Regular communication and performance reviews are key. We track on-time delivery rates, damage claims, and responsiveness to ensure carriers meet our standards. We also foster collaboration by providing them with accurate and timely information, such as precise shipment details and clear instructions. This proactive approach minimizes discrepancies and potential delays. Building these relationships leads to preferential treatment, such as priority handling during peak seasons or access to capacity when others struggle.

For example, we maintain regular communication with our key carriers through quarterly business reviews, where we discuss performance metrics, address concerns, and plan for future collaborations. This open line of communication helps us resolve issues proactively and develop mutually beneficial solutions.

Q 17. How do you handle unexpected delays or disruptions in the shipping process?

Unexpected delays, such as port congestion, extreme weather, or carrier issues, are inevitable. Our contingency plans involve proactive monitoring of potential disruptions through various sources, including news reports, carrier alerts, and real-time tracking data. Once a disruption is identified, a swift response is critical. This may involve rerouting shipments, exploring alternative carriers, notifying customers of potential delays, and proactively adjusting schedules. Transparent communication with customers is crucial to maintaining trust and managing expectations. We also use advanced analytics to identify potential bottlenecks and adjust our strategies to mitigate future risks.

Imagine a port strike causing major congestion. We would immediately assess the impact on our shipments, explore alternative routes or transportation methods (like rail), and inform customers of potential delays, providing proactive updates throughout the process.

Q 18. What metrics do you use to measure the efficiency of inbound and outbound shipping operations?

Measuring shipping efficiency requires a suite of key performance indicators (KPIs). For outbound shipments, we track on-time delivery rates, order fulfillment cycle times, and freight costs per unit. For inbound shipments, we monitor inbound lead times, inventory accuracy, and receiving efficiency. We also track metrics related to damage rates, carrier performance (on-time delivery and damage rates), and inventory turnover to assess overall supply chain performance. Regular analysis of these KPIs helps identify areas for improvement and measure the impact of implemented changes. For example, a consistently low on-time delivery rate might prompt a review of carrier performance or transportation routes.

Q 19. How do you improve efficiency and reduce costs in your shipping processes?

Improving shipping efficiency and reducing costs requires a multi-pronged approach. We optimize routes using sophisticated route optimization software, negotiate better rates with carriers through volume discounts and strategic partnerships, and improve warehouse processes to streamline order fulfillment. We also invest in technologies such as automated warehouse systems and real-time tracking to increase visibility and reduce manual handling. Consolidating shipments to reduce the number of shipments and exploring alternative modes of transportation, such as rail or intermodal options, can also yield significant cost savings. We continuously monitor and analyze our KPIs to identify areas needing improvement and implement data-driven solutions.

For example, by implementing a Warehouse Management System (WMS), we reduced our order fulfillment cycle time by 15% and improved inventory accuracy by 10%, leading to significant cost savings.

Q 20. Describe your experience with forecasting and planning for inbound and outbound shipments.

Forecasting and planning are crucial for efficient shipping operations. We use historical data, sales forecasts, and market trends to predict future demand and plan accordingly. For inbound shipments, we forecast inventory needs to ensure sufficient stock without excessive holding costs. For outbound shipments, we estimate transportation requirements and capacity needs, considering peak seasons and potential disruptions. We leverage sophisticated forecasting software and collaborative planning with our suppliers and customers to ensure alignment and avoid stockouts or overstocking. Regular review and adjustment of forecasts based on real-time data are essential for maintaining accuracy.

A good example is predicting increased demand for a product during the holiday season. Our forecasting models allow us to anticipate this surge, pre-position inventory, and secure sufficient transportation capacity to avoid delays and ensure timely delivery.

Q 21. What is your experience with using shipping software and technologies?

I have extensive experience with various shipping software and technologies, including Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) systems. These systems provide real-time visibility into our shipping operations, enabling us to monitor shipments, track KPIs, and make data-driven decisions. I’m proficient in using these systems to automate processes, optimize routes, and manage carrier relationships. I’m also familiar with various shipping platforms and APIs that allow for seamless integration with our e-commerce and order management systems. This allows for automated order processing, shipment creation, and tracking updates, resulting in increased efficiency and reduced errors.

For example, our TMS allows us to automatically generate shipping labels, track shipments in real-time, and calculate optimal routes, reducing manual effort and improving accuracy significantly.

Q 22. How do you ensure the safety and security of goods during transit?

Ensuring the safety and security of goods during transit is paramount. It involves a multi-layered approach encompassing proper packaging, secure transportation methods, and robust tracking systems. Think of it like building a fortress around your goods to protect them from damage or theft.

Packaging: We utilize appropriate packaging materials based on the fragility and nature of the goods. This includes using sturdy boxes, adequate cushioning (bubble wrap, foam peanuts), and protective layers for delicate items. For example, fragile electronics require specialized packaging with extra padding and possibly even custom-fit inserts.

Transportation: Selecting the right mode of transportation is crucial. We assess factors like distance, urgency, and the product’s sensitivity. For high-value or time-sensitive goods, we might opt for air freight or specialized courier services. For less urgent, bulky items, trucking might be more cost-effective. Each option involves specific safety protocols, like temperature control for perishable goods or secure containers for valuable items.

Tracking and Monitoring: Real-time tracking systems are implemented to monitor the shipment’s location and condition. GPS tracking devices and automated notifications alert us to potential delays, diversions, or unusual events. This proactive monitoring allows us to intervene quickly if necessary.

Insurance: Cargo insurance protects against loss or damage during transit. This mitigates financial risk for both the shipper and the receiver. It’s a crucial safety net for valuable shipments.

Q 23. How do you manage inventory discrepancies?

Inventory discrepancies, those frustrating differences between recorded and actual inventory levels, are addressed through a combination of meticulous processes and technology. Imagine a detective meticulously piecing together clues to solve a mystery – that’s what managing discrepancies involves.

Regular Cycle Counts: We perform regular physical inventory checks to compare against our system’s records. This helps identify discrepancies early and prevents them from snowballing into larger problems. These aren’t full inventory counts, but rather focused checks on specific areas or product types.

Barcode/RFID Technology: Implementing barcode or RFID scanning throughout the receiving, storage, and shipping processes significantly improves accuracy. Real-time tracking minimizes human error and streamlines the identification of missing or misplaced items.

Root Cause Analysis: When discrepancies are detected, we conduct a thorough root cause analysis to pinpoint the source of the problem. Is it a data entry error? A problem with our receiving process? A damaged product? Identifying the root cause allows us to implement corrective actions to prevent future discrepancies.

Inventory Management Software: Utilizing sophisticated inventory management software helps to track and analyze inventory data, flag potential issues, and automate reporting. These systems often provide detailed insights into inventory movement and can help identify patterns that contribute to discrepancies.

Q 24. How do you handle customer inquiries and complaints related to shipping?

Handling customer inquiries and complaints related to shipping requires a proactive and empathetic approach. Think of it as being a customer service ambassador for the entire shipping process.

Prompt Response: We respond to inquiries and complaints promptly and efficiently, acknowledging receipt within 24 hours. This immediate response shows the customer that their concerns are valued.

Clear Communication: We communicate clearly and concisely, providing updates on the status of their shipment and explaining any delays or issues. Using plain language, avoiding jargon, is key.

Problem Resolution: We work diligently to resolve customer issues, whether it’s tracking down a lost package, initiating a claim for damaged goods, or providing a refund. Our goal is to find a solution that satisfies the customer.

Feedback Collection: We actively seek customer feedback to identify areas for improvement in our shipping processes. This feedback loop is vital for continuous improvement and enhanced customer satisfaction.

Q 25. Describe your experience with implementing new shipping procedures or technologies.

I have extensive experience implementing new shipping procedures and technologies, focusing on efficiency and accuracy. A recent example involved transitioning to a new Transportation Management System (TMS).

TMS Implementation: We transitioned from a legacy system to a cloud-based TMS. This involved extensive planning, data migration, staff training, and system testing. The project required close collaboration with IT and various departments. The result was a significant increase in efficiency, reducing shipping costs and improving delivery accuracy.

Process Optimization: Along with the new TMS, we implemented process improvements like route optimization software and automated shipping label generation. These optimizations streamlined operations and reduced manual tasks, leading to improved efficiency.

Data Analytics: The new TMS provides robust data analytics capabilities. We now have a clear understanding of key performance indicators (KPIs) like on-time delivery rates, shipping costs per unit, and transit times. This data-driven approach allows us to make informed decisions for continuous improvement.

Q 26. What is your experience with different types of transportation equipment?

My experience encompasses a wide range of transportation equipment, from standard trucking and air freight to specialized modes of transport. Understanding the capabilities and limitations of each is crucial for efficient and safe shipping.

Trucking: I’m familiar with various truck types, including flatbeds, vans, refrigerated trucks (reefers), and specialized vehicles for oversized or hazardous materials. Each type has its strengths and weaknesses regarding cargo capacity, handling, and cost.

Air Freight: Experience includes coordinating shipments via various aircraft, from cargo planes to passenger aircraft with cargo holds. This includes understanding weight and dimensional restrictions, as well as handling procedures for different types of air freight.

Ocean Freight: I’m well-versed in ocean freight using container ships. This involves understanding container types, shipping lines, customs procedures, and managing potential delays or disruptions due to weather or port congestion.

Specialized Transport: This includes experience with handling temperature-sensitive goods, using refrigerated containers or specialized vehicles for pharmaceuticals and perishable goods. We’ve also managed the transport of oversized or hazardous materials, requiring special permits and handling procedures.

Q 27. How do you maintain accurate shipping records and documentation?

Maintaining accurate shipping records and documentation is essential for compliance, auditing, and efficient operations. Think of it as meticulous record-keeping for every step of the shipment’s journey.

Transportation Management System (TMS): We utilize a TMS to track shipments from origin to destination. The system automatically generates and stores all necessary documentation, including manifests, bills of lading, and proof of delivery.

Data Entry Accuracy: Strict protocols are in place to ensure data accuracy. Multiple checks and validations are built into the system to prevent errors. For example, barcodes and RFID technology are used to minimize manual data entry.

Document Archiving: All shipping documents are securely archived for easy retrieval. This is important for auditing, claims processing, and resolving any potential discrepancies. We comply with all relevant data retention policies.

Regular Audits: Regular audits of shipping records help ensure accuracy and identify areas for improvement. This proactive approach helps maintain data integrity and compliance.

Q 28. Describe your experience with international shipping regulations and procedures.

International shipping involves navigating a complex web of regulations and procedures. It’s like navigating a foreign country with its own set of rules and customs.

Customs Regulations: I have extensive knowledge of import and export regulations, including HS codes, customs declarations, and documentation requirements for various countries. This involves understanding different tariffs and duties for different products and countries.

Incoterms: I’m proficient in using Incoterms (International Commercial Terms) to clearly define the responsibilities of the buyer and seller in international trade transactions. This helps to prevent misunderstandings and disputes.

Compliance: We ensure compliance with all applicable international regulations, including those related to safety, security, and environmental protection. This involves staying updated on the latest regulations and adapting our procedures accordingly.

Freight Forwarders: I work closely with international freight forwarders, leveraging their expertise in customs brokerage, documentation, and handling international shipments. This collaboration significantly simplifies the complexities of international shipping.

Key Topics to Learn for Outbound and Inbound Shipping Interview

- Outbound Shipping Processes: Understanding the entire lifecycle, from order verification to final delivery. This includes order fulfillment, packaging procedures, and shipping method selection.

- Inbound Shipping Processes: Mastering receiving, inspection, and put-away procedures. This involves managing incoming shipments, verifying accuracy against purchase orders, and handling potential discrepancies.

- Inventory Management Techniques: Understanding inventory control systems (FIFO, LIFO), cycle counting, and the importance of accurate stock levels for efficient shipping operations.

- Warehouse Management Systems (WMS): Familiarity with WMS software and its role in streamlining shipping processes. Be prepared to discuss practical experience or theoretical knowledge of how such systems optimize efficiency.

- Transportation Modes and Costs: Knowledge of different transportation options (truck, rail, air, sea) and their associated costs and suitability for various shipment types. Consider factors affecting cost and delivery times.

- Shipping Documentation and Compliance: Understanding the importance of accurate documentation (bills of lading, packing slips, commercial invoices) and compliance with relevant regulations (e.g., customs procedures, hazardous materials handling).

- Problem-solving in Shipping: Be ready to discuss scenarios involving delays, damaged goods, or incorrect shipments and how you would approach resolving them effectively and efficiently. Think about your approach to troubleshooting and communication.

- Safety and Security Procedures: Demonstrate awareness of warehouse safety protocols and security measures related to preventing theft and damage.

- Technology in Shipping: Discuss your familiarity with shipping software, scanners, and other relevant technologies used in modern shipping operations. Highlight any experience with automation or related systems.

Next Steps

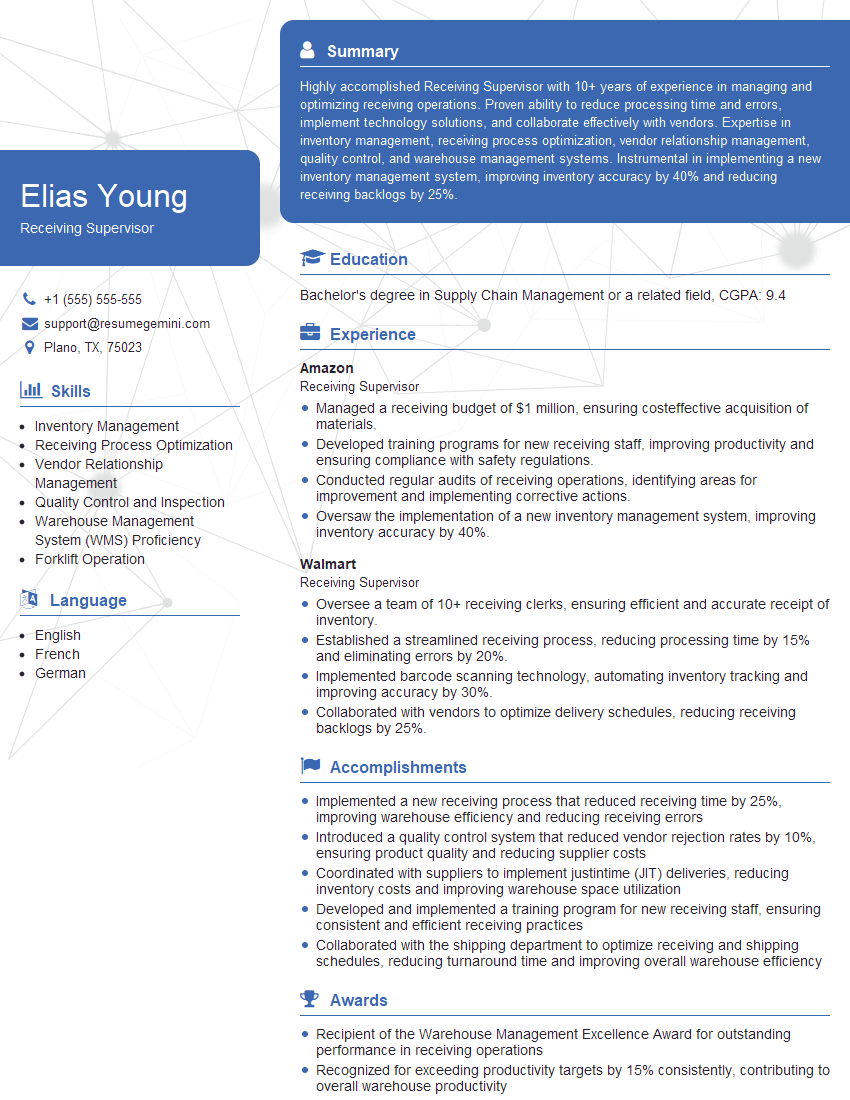

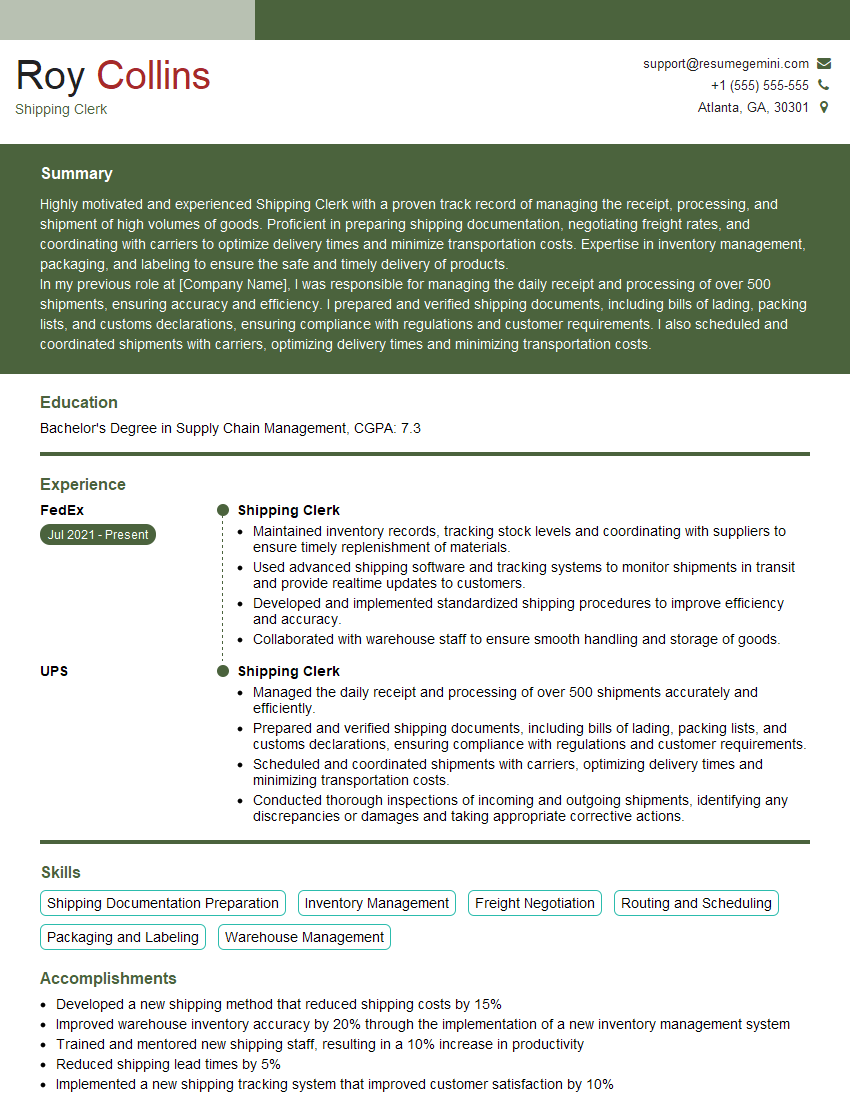

Mastering Outbound and Inbound Shipping principles is vital for career advancement in logistics and supply chain management. These skills are highly sought after, opening doors to diverse roles and increased earning potential. To maximize your job prospects, create a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They offer examples of resumes tailored specifically to Outbound and Inbound Shipping roles, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good