The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Conveyor System Operations interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Conveyor System Operations Interview

Q 1. Describe your experience with different types of conveyor systems (roller, belt, chain, etc.).

My experience encompasses a wide range of conveyor systems, each suited for different materials and operational needs. I’ve worked extensively with roller conveyors, ideal for lighter items needing gravity or gentle propulsion; belt conveyors, the workhorses for high-volume, continuous flow of various materials; and chain conveyors, particularly useful for heavier, bulkier items or those requiring precise positioning. For example, I oversaw the installation and commissioning of a roller conveyor system in a small parts distribution center, optimizing it for efficient order picking. In a larger manufacturing plant, I was responsible for maintaining a high-speed belt conveyor system moving raw materials, which required meticulous attention to alignment and tensioning. Finally, I’ve worked with specialized chain conveyors in a bottling plant, carefully managing the delicate handling of filled bottles.

Beyond these common types, I also have experience with other specialized systems like screw conveyors (for powdery or granular materials) and vibratory conveyors (for precise feeding and distribution).

Q 2. Explain the process of troubleshooting a jammed conveyor belt.

Troubleshooting a jammed conveyor belt follows a systematic approach prioritizing safety. First, I’d ensure the system is completely powered down, applying lockout/tagout procedures. Then, I’d visually inspect the belt for any obvious obstructions – a large piece of debris, a buildup of material, or a damaged belt section. I’d carefully remove the obstruction, paying close attention to sharp objects or potential hazards. If the jam is caused by a material buildup, understanding the material’s properties is key to efficient removal; sometimes a gentle loosening is enough, other times specialized tools might be needed. Once the obstruction is removed, I’d check the belt tracking and tension. Incorrect tracking can cause friction and further jamming, so I would carefully realign the belt according to the manufacturer’s recommendations, potentially adjusting the tracking rollers. Finally, I’d check the drive motor and pulleys for any damage or binding, which may indicate the need for more extensive repairs. After resolving the issue, I’d restart the system, closely monitoring its operation before resuming normal production.

Q 3. How do you perform preventative maintenance on a conveyor system?

Preventative maintenance is crucial for conveyor system reliability and longevity. My approach involves a structured program encompassing regular inspections, lubrication, and component replacements. Inspections include checking belt tension, tracking alignment, roller condition, motor performance, and the structural integrity of the entire system. Lubrication involves applying appropriate lubricants to bearings, rollers, and chains according to the manufacturer’s guidelines, preventing wear and tear. Component replacements are planned based on the manufacturers recommendations, but also on actual wear and tear observed during regular inspections. For example, I’ve implemented a preventative maintenance schedule using a computerized maintenance management system (CMMS), enabling tracking and scheduling of all maintenance tasks. This proactive approach reduces downtime and minimizes the risk of catastrophic failures.

I also advocate for a ‘clean-as-you-go’ approach where operators routinely remove spills or material build up, preventing them from escalating into more serious problems.

Q 4. What safety precautions do you take when working with conveyor systems?

Safety is paramount when working with conveyor systems. Before any work is performed, lockout/tagout procedures must be strictly adhered to, ensuring the system is completely de-energized. Personal protective equipment (PPE) is mandatory, including safety glasses, gloves, and steel-toed boots. When working near moving parts, appropriate barriers must be in place to prevent accidental contact. Training is essential; all personnel must receive comprehensive training on safe operating procedures, emergency shutdowns, and the identification of potential hazards. Regular safety audits and inspections are crucial to identify and mitigate potential risks. In my experience, a proactive and rigorous safety culture has always resulted in fewer accidents and a safer working environment.

Q 5. What are the common causes of conveyor belt slippage?

Conveyor belt slippage can stem from several factors. One of the most common causes is insufficient belt tension. If the belt is too loose, it won’t grip the drive pulley effectively, leading to slippage. Another frequent cause is wear and tear on the belt itself. Damaged or worn belts lack the necessary friction to prevent slippage. Excessive dust or debris accumulation on the belt or pulleys can also reduce friction, causing slippage. Furthermore, incorrect pulley alignment or worn pulleys contribute significantly to this issue. Finally, environmental factors such as high temperatures or the presence of certain chemicals can affect belt material and reduce its ability to grip. For example, I once encountered a significant slippage issue caused by a buildup of oil on the pulleys in a food processing plant.

Q 6. How do you identify and resolve issues with conveyor system tracking?

Conveyor system tracking refers to the belt’s alignment with the center of the conveyor system. Issues with tracking lead to uneven wear and tear on the belt, increased friction, and even jamming. Identifying tracking problems usually involves visual inspection, looking for any deviations from the center line. Measuring the distance from the belt edge to the side rollers can provide quantitative data. Causes include misaligned rollers, worn rollers, or damaged conveyor frame components. Resolution involves adjusting the tracking rollers, replacing worn or damaged components, and ensuring the entire structure is properly aligned. In some cases, more extensive adjustments may be necessary involving the re-alignment of the entire conveyor system. Proper tensioning of the belt is crucial to maintain consistent tracking. Precise adjustment ensures smooth operation and prolonged equipment lifespan.

Q 7. Describe your experience with conveyor system control systems (PLCs, HMIs).

I have extensive experience with PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) based control systems for conveyor systems. PLCs are the brains of the operation, controlling motor speeds, sensors, and emergency stops. HMIs provide a user-friendly interface for monitoring and controlling the system, displaying real-time data and allowing for adjustments. I’m proficient in programming PLCs to implement various control strategies, including speed control, sequencing, and safety interlocks. For example, I’ve used PLCs to implement a system that automatically adjusts conveyor speed based on the amount of material entering the system, improving efficiency and preventing jams. My HMI experience allows for clear and concise presentation of system status, alarms, and diagnostic data to operators, improving troubleshooting and maintenance efficiency. I’m familiar with various PLC programming languages (such as ladder logic) and HMI software packages.

Q 8. How do you ensure the proper alignment and tension of a conveyor belt?

Ensuring proper alignment and tension in a conveyor belt is crucial for efficient operation and preventing damage. Think of it like a perfectly tuned guitar string – too loose and it’s slack, too tight and it breaks. We achieve this through a combination of techniques.

- Alignment: We use alignment tools like laser levels to ensure the belt tracking is straight and centered on the rollers. Misalignment can cause uneven wear and belt slippage. Regular checks and adjustments using tracking devices are key. For example, in a large warehouse operation, we’d regularly check for deviations using a laser alignment system and adjust the take-up rollers as needed.

- Tension: The correct belt tension is critical. Too little tension leads to slippage and material spillage; too much causes premature wear and tear on the belt and drive components. We use tension meters to measure the tension, ensuring it falls within the manufacturer’s specified range. This usually involves adjusting the take-up roller mechanism, which acts like a spring, controlling the belt’s tightness. For instance, I once had to adjust the tension on a heavily loaded conveyor transporting aggregates – small adjustments made a significant difference in preventing slippage.

Regular inspections are paramount. We look for signs of wear, damage, and misalignment, addressing any issues promptly to prevent major problems down the line.

Q 9. What are the different types of conveyor belt materials and their applications?

Conveyor belt materials vary widely depending on the application and the material being conveyed. Choosing the right material is critical for longevity and safety.

- Rubber Belts: These are the most common, offering good durability and flexibility. Different rubber compounds are available to withstand abrasion, chemicals, heat, and oils – each suited to a specific application like food processing (food-grade rubber) or mining (abrasion-resistant rubber).

- PVC Belts: Polyvinyl chloride belts are often preferred for lighter-duty applications and offer good resistance to oils and chemicals. They’re a cost-effective option in environments that don’t require extreme durability.

- Fabric Belts: These are made of woven materials like cotton, nylon, or polyester, often coated with rubber or PVC. They offer good flexibility and are suitable for applications requiring high tensile strength, such as moving heavy loads. I’ve seen these used extensively in textile manufacturing and packaging.

- Metal Belts: For high-temperature applications or those involving very abrasive materials, metal belts are used. They can be made of steel, stainless steel, or other specialized alloys. A classic example is in a heat treatment plant where the belts have to withstand high temperatures.

Selecting the wrong material can lead to costly downtime and repairs. Thorough assessment of the application, including the transported materials, environment, and operating conditions, is crucial to choose the optimal belt material.

Q 10. Explain your experience with conveyor system lubrication and maintenance schedules.

Conveyor system lubrication is essential for reducing friction, wear, and tear, extending the lifespan of the system. A well-maintained lubrication schedule is vital.

My experience involves developing and implementing lubrication schedules tailored to specific conveyor systems. This includes:

- Identifying lubrication points: Bearings, chains, gears, and other moving parts require regular lubrication. We use manufacturer’s recommendations and our own assessments to identify all lubrication points.

- Selecting the right lubricant: The choice of lubricant depends on the operating conditions. We consider factors like temperature, speed, and the type of material being transported. For example, food-grade grease is necessary for food processing applications.

- Establishing a maintenance schedule: This schedule outlines the frequency and type of lubrication needed for each component. This often involves a combination of daily, weekly, and monthly lubrication tasks. Using a computerized maintenance management system (CMMS) helps track and schedule these tasks effectively.

Failure to follow a proper lubrication schedule can result in premature bearing failure, increased friction, and ultimately, system breakdowns, leading to costly downtime and potential safety risks. I’ve seen firsthand how a neglected lubrication schedule can drastically shorten the lifespan of a conveyor system, leading to significant repair costs.

Q 11. How do you diagnose and repair a faulty conveyor motor?

Diagnosing a faulty conveyor motor often involves systematic troubleshooting. We start by checking the obvious:

- Power Supply: Is there power to the motor? Check the circuit breakers, fuses, and the power supply itself. A simple voltage check with a multimeter is usually the first step.

- Motor Overload: Is the motor overloaded? This can happen if the conveyor is trying to move too much material or if there is a blockage. Check for jams, and inspect the conveyor belt for obstructions.

- Motor itself: If the power supply is fine and there’s no overload, the problem might be within the motor. We’d listen for unusual noises (grinding or humming), check the motor windings for continuity and insulation resistance using a multimeter, and look for any visible damage.

Repairing a faulty conveyor motor might involve replacing worn bearings, brushes (in DC motors), or even the motor itself. Depending on the motor type and the complexity of the repair, it might involve specialized tools and expertise. In complex situations, we would consult with motor repair specialists. For example, a burned-out motor winding would necessitate replacement or rewinding, while a simple bearing replacement is a more straightforward repair. I’ve had to handle both types of repairs in my career.

Q 12. What are the common causes of conveyor system breakdowns and how to prevent them?

Conveyor system breakdowns are often caused by preventable issues. Understanding these causes and implementing preventive measures is essential for smooth operation.

- Belt Wear and Tear: Improper alignment, tension, or material handling can cause premature belt wear. Regular inspections, proper tensioning, and alignment checks are key to prevent this.

- Component Failure: Bearings, rollers, motors, and other components have a limited lifespan. Preventive maintenance, including regular lubrication and inspections, can significantly extend their life and prevent unexpected failures.

- Blockages and Jams: Material buildup can cause blockages, leading to motor overload and belt damage. Careful material handling, regular cleaning, and the use of appropriate chute designs are essential.

- Electrical Issues: Short circuits, faulty wiring, and power surges can cause motor failure and other electrical problems. Regular electrical inspections and the use of surge protectors are vital.

Preventing breakdowns involves a proactive approach focusing on regular maintenance, proper operation, and operator training. A well-defined preventative maintenance schedule, combined with staff training on safe operational procedures, can drastically reduce the frequency of breakdowns. I’ve seen firsthand how a comprehensive maintenance program can dramatically improve reliability and reduce downtime.

Q 13. Describe your experience with conveyor system upgrades and modifications.

I have extensive experience with conveyor system upgrades and modifications, focusing on improving efficiency, safety, and throughput. These projects often involve:

- Capacity Increases: Upgrading to higher-capacity belts, motors, and drive systems to handle increased throughput. This might involve replacing the entire conveyor system or upgrading individual components.

- Improved Safety Features: Adding emergency stops, safety guards, and other safety mechanisms to reduce the risk of accidents. This includes implementing sensor-based systems to detect potential hazards.

- Automation and Control Upgrades: Integrating modern control systems, including PLC (Programmable Logic Controller) systems, to automate conveyor operation, monitor performance, and improve efficiency. For instance, replacing an older mechanical control system with a modern PLC-based system can significantly improve responsiveness and diagnostics.

- Material Handling Improvements: Modifying chutes, transfer points, and other components to improve material flow and reduce spillage. This often requires careful analysis of the material flow and redesign of the material handling aspects of the conveyor system.

A recent project involved upgrading an outdated conveyor system in a manufacturing plant. We replaced the aging motors, added sensors for improved safety, and integrated a new PLC-based control system. This resulted in a significant increase in throughput, improved safety, and reduced maintenance costs.

Q 14. How do you handle emergency situations involving conveyor system malfunctions?

Handling emergency situations involving conveyor system malfunctions requires a calm and methodical approach. My approach involves:

- Immediate Shutdown: The first step is to safely shut down the affected section of the conveyor system to prevent further damage or injury. This usually involves activating emergency stop buttons or circuit breakers.

- Assessment and Hazard Mitigation: Once the system is shut down, we assess the situation to identify the cause of the malfunction and any potential hazards. This might involve isolating power supplies, securing the area to prevent access, and warning personnel about potential hazards.

- Repair or Replacement: Depending on the nature of the malfunction, we either repair the damaged component or replace it with a spare. We prioritize repairs that can quickly restore operation.

- Root Cause Analysis: After the immediate problem is resolved, we conduct a root cause analysis to determine why the malfunction occurred and implement preventative measures to avoid similar incidents in the future.

For instance, a recent incident involved a belt tear. After the immediate shutdown, we repaired the tear using a vulcanizing repair kit, conducted a root cause analysis (finding a misaligned roller), and realigned the rollers to prevent recurrence. Effective emergency response requires a combination of training, well-defined emergency procedures, and readily available spare parts.

Q 15. What is your experience with conveyor system capacity and throughput calculations?

Conveyor system capacity and throughput calculations are crucial for optimizing material handling. Capacity refers to the maximum amount of material a conveyor can handle in a given time, while throughput represents the actual amount processed. Calculating these requires understanding several factors.

- Conveyor Speed: Measured in feet per minute (fpm) or meters per minute (mpm), this directly impacts throughput. A faster speed generally means higher throughput, but this must be balanced with the system’s limitations and safety considerations.

- Belt Width: A wider belt allows for more material to be carried simultaneously, increasing capacity. The width is selected based on the size and shape of the items being conveyed.

- Material Density and Characteristics: The density of the material significantly affects capacity. Lighter materials allow for higher throughput at a given speed compared to heavier materials. Material characteristics, such as size, shape, and fragility, also influence the design and capacity of the system.

- Loading and Unloading Rates: The efficiency of the loading and unloading points significantly influences throughput. Bottlenecks at these points can reduce overall system efficiency.

- System Efficiency and Downtime: Unplanned downtime due to maintenance or breakdowns dramatically impacts throughput. A well-maintained system with minimal downtime maximizes throughput.

Example: Consider a conveyor system with a belt speed of 100 fpm, a belt width capable of carrying 2 cubic feet of material per foot of length, and a material density of 50 lbs/cubic foot. Its theoretical capacity would be 100 fpm * 2 cubic feet/foot * 50 lbs/cubic foot = 10,000 lbs/minute. However, accounting for loading and unloading efficiency (e.g., 90%), the actual throughput would be approximately 9,000 lbs/minute. This calculation illustrates the importance of considering all factors for realistic throughput estimations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of conveyor system safety regulations and standards.

Conveyor system safety is paramount. Regulations and standards like OSHA (in the US) and equivalent bodies worldwide mandate strict adherence to safety protocols. My understanding encompasses several key areas:

- Lockout/Tagout Procedures: Before any maintenance or repair, proper lockout/tagout procedures must be followed to prevent accidental starts and injuries. This ensures the system is completely de-energized before any work begins.

- Emergency Stops: Multiple easily accessible emergency stop buttons must be strategically located throughout the system for quick response to emergencies. Regular testing of these buttons is critical.

- Guardrails and Safety Enclosures: Moving parts should be adequately guarded to prevent accidental contact. Properly designed guardrails and safety enclosures minimize the risk of injuries to personnel.

- Personal Protective Equipment (PPE): Appropriate PPE, such as safety glasses, gloves, and steel-toed boots, should always be worn when working near or on conveyor systems. Hearing protection might also be necessary depending on noise levels.

- Training and Awareness: All personnel operating or maintaining conveyor systems should receive thorough training on safe operating procedures, emergency response protocols, and hazard recognition.

- Regular Inspections: Regular inspections of the conveyor system are crucial to identify potential hazards and prevent accidents. These inspections should check for worn components, loose parts, and other safety concerns.

Failure to comply with these regulations can lead to serious consequences, including fines, shutdowns, and even severe injuries or fatalities. Safety should always be the top priority in any conveyor system operation.

Q 17. How do you document and report maintenance activities on a conveyor system?

Accurate documentation and reporting of maintenance activities are crucial for system reliability and regulatory compliance. We utilize a computerized maintenance management system (CMMS) to track all maintenance activities. This system allows for:

- Preventive Maintenance Scheduling: The CMMS helps schedule routine inspections, lubrication, and component replacements, preventing breakdowns and extending the lifespan of the equipment. This follows a pre-defined schedule based on manufacturer recommendations and past experience.

- Work Order Management: When maintenance is required, work orders are generated, assigned to technicians, and tracked until completion. This ensures that all necessary repairs are performed promptly and efficiently.

- Parts Inventory Tracking: The CMMS integrates with inventory management, enabling accurate tracking of spare parts and components. This helps ensure that necessary parts are available when needed, minimizing downtime.

- Detailed Records: All maintenance activities are meticulously documented, including dates, times, performed tasks, parts used, and technician signatures. This creates a comprehensive history of the system’s maintenance.

- Reporting and Analysis: The CMMS provides various reports on maintenance costs, downtime, and overall system performance. This data is invaluable for improving maintenance strategies and reducing future maintenance costs.

Example: A work order might detail the replacement of a worn conveyor belt, including the date, time, belt type and size, and the technician who completed the work. This detailed record enables easy traceability and helps predict when future belt replacements might be needed.

Q 18. Describe your experience with different types of conveyor system sensors and their functions.

Conveyor systems utilize various sensors to monitor their performance, detect problems, and ensure safety. Here are some examples:

- Proximity Sensors: Detect the presence or absence of objects without physical contact. Used in applications like detecting material jams or ensuring proper loading.

- Photoelectric Sensors: Detect objects by interrupting a light beam. Commonly used to detect material flow, count items, or detect broken belts.

- Ultrasonic Sensors: Detect objects using ultrasonic waves. Used in applications like level sensing in bulk material handling.

- Temperature Sensors: Monitor the temperature of critical components like motors and bearings. This helps prevent overheating and potential damage.

- Vibration Sensors: Detect unusual vibrations that might indicate bearing wear or other mechanical problems. Early detection prevents catastrophic failures.

- Belt Tracking Sensors: Ensure the belt is properly aligned and prevent it from running off track.

Example: A photoelectric sensor might be placed at the end of a conveyor to detect when a box has reached the unloading point, triggering a signal to activate a robotic arm for unloading. This prevents material buildup and improves efficiency.

Q 19. How do you maintain accurate inventory of conveyor system parts and components?

Maintaining an accurate inventory of conveyor system parts and components is critical for minimizing downtime and optimizing maintenance costs. We employ a combination of methods:

- CMMS Integration: As mentioned before, our CMMS system integrates with inventory management, allowing us to track parts usage, order new parts, and manage stock levels.

- Barcoding and RFID: We use barcodes or RFID tags to track parts throughout their lifecycle, from storage to installation. This ensures accurate tracking and helps prevent errors.

- Regular Stock Audits: Periodic physical audits of the inventory are conducted to verify the accuracy of the CMMS data and identify any discrepancies.

- Vendor Relationships: Strong relationships with reliable vendors are essential for timely delivery of parts and negotiating favorable pricing agreements.

- Strategic Stockpiling: Critical parts prone to failure are strategically stockpiled to minimize downtime in case of unexpected breakdowns.

Example: Our CMMS shows that we have 50 belt tensioners in stock. After a recent repair, the system automatically updates the count to 49, triggering a notification to reorder if the stock level falls below a predefined threshold (e.g., 20).

Q 20. What is your experience with conveyor system cleaning and sanitation procedures?

Conveyor system cleaning and sanitation procedures are especially important in industries handling food, pharmaceuticals, or other sensitive materials. These procedures aim to prevent contamination and ensure product safety. Key aspects include:

- Scheduled Cleaning: A regular cleaning schedule is established, specifying the frequency and methods for cleaning different parts of the conveyor system. This schedule varies depending on the application and the type of materials being handled.

- Cleaning Agents: Appropriate cleaning agents are selected to effectively remove debris and contaminants without damaging the conveyor system components. Food-grade cleaning agents are used in food processing applications.

- Cleaning Methods: Different cleaning methods are employed depending on the type of material and the level of contamination. This might include manual cleaning, pressure washing, or specialized cleaning equipment.

- Drying Procedures: Thorough drying after cleaning is crucial to prevent mold and bacterial growth. This might involve air drying or using absorbent materials.

- Documentation: Cleaning activities are documented, including dates, times, cleaning agents used, and personnel involved. This ensures traceability and facilitates regulatory compliance.

Example: In a food processing plant, a conveyor belt used for transporting raw meat would require frequent cleaning and sanitizing using food-grade cleaning agents and high-pressure water jets. This rigorous cleaning procedure minimizes the risk of contamination and ensures product safety.

Q 21. Explain your understanding of conveyor system energy efficiency and optimization.

Energy efficiency is a critical factor in modern conveyor system operation. Optimization strategies aim to reduce energy consumption without compromising performance. Key aspects include:

- Motor Selection: Using energy-efficient motors with high efficiency ratings (e.g., premium efficiency motors) significantly reduces energy consumption. Variable frequency drives (VFDs) allow for precise speed control, optimizing energy usage based on demand.

- Belt Tension: Proper belt tension is crucial. Excessive tension increases energy consumption, while insufficient tension can lead to slippage and increased wear.

- Idler Alignment and Maintenance: Regular maintenance and proper alignment of idlers reduce friction and minimize energy loss. Worn or misaligned idlers significantly increase energy consumption.

- System Optimization: Analyzing the conveyor system’s layout and operation to identify potential areas for improvement, such as reducing unnecessary uphill sections or eliminating unnecessary conveyors.

- Energy Monitoring and Analysis: Regular monitoring of energy consumption helps identify areas for improvement and track the effectiveness of optimization efforts.

Example: Implementing VFDs on conveyor motors allows for precise speed control, reducing energy consumption during periods of low demand. For instance, the conveyor speed could be reduced during idle periods or adjusted based on the actual material flow rate, significantly reducing energy consumption without compromising efficiency.

Q 22. How do you interpret conveyor system schematics and drawings?

Conveyor system schematics and drawings are the blueprints for these complex systems. Understanding them is crucial for efficient operation and maintenance. I approach them systematically, starting with the overall layout to grasp the flow of material. Then, I delve into the details: individual components like conveyors (belt, roller, screw), transfer points, controls, and safety features. I look for things like conveyor belt specifications (width, length, material), motor details (horsepower, RPM), and sensor locations. Symbols are key – understanding their meaning (e.g., a circle might indicate a motor, a triangle a sensor) is essential. I also pay close attention to the control system diagrams, understanding how the different components interact and are controlled by PLC (Programmable Logic Controller) or other systems. For example, I might trace the path of a signal from a proximity sensor, through a PLC, and finally to a motor starter, to understand how the system stops when an object is detected. Finally, I verify dimensions and clearances to ensure proper space allocation and potential interference between components. This ensures I have a complete picture before any work commences, whether it is troubleshooting, maintenance or system modification.

Q 23. What is your experience with conveyor system noise reduction techniques?

Noise reduction in conveyor systems is critical for worker safety and a positive work environment. My experience includes implementing several strategies. One effective approach is to identify the source of the noise. Common sources include belt slap (belt hitting the rollers), component vibration, and motor noise. Once identified, targeted solutions can be implemented. For instance, belt slap can be reduced by adjusting belt tension, using different belt materials (e.g., a quieter, more flexible belt), or installing idlers and rollers strategically. Vibration can be mitigated by using vibration dampeners on components, ensuring proper alignment, and improving structural support. Motor noise can be lessened through the use of quieter motors (e.g., AC motors over DC motors), sound-dampening enclosures, or even replacing the motor entirely. In one project, we reduced noise levels significantly by using a combination of these approaches, resulting in a much more comfortable work environment for the operators.

Q 24. Describe your experience working with different conveyor system manufacturers.

Throughout my career, I’ve worked extensively with various conveyor manufacturers such as Siemens, Rockwell Automation, and Interroll. Each manufacturer has its own unique design philosophies, control systems, and component specifications. This requires adaptability and a deep understanding of the underlying principles of conveyor operation, regardless of the brand. For example, while Siemens might favor a particular type of motor control, understanding the fundamental principles of motor operation ensures I can troubleshoot and maintain the system effectively. Learning to navigate their manuals, software interfaces, and support systems is also essential. Collaborating with different manufacturers’ representatives on projects has broadened my understanding of industry best practices and different design approaches. This broad experience makes me comfortable troubleshooting and maintaining a wide variety of conveyor systems.

Q 25. How do you handle conflicts or disagreements with other team members during conveyor maintenance?

Disagreements during conveyor maintenance are inevitable, given the complexity of the systems and the diverse expertise within a team. My approach prioritizes clear and respectful communication. I believe in active listening to understand each team member’s perspective and concerns. If a conflict arises, I try to find common ground by focusing on the shared goal: safe and efficient conveyor operation. I often facilitate discussions, encouraging everyone to contribute solutions and data. If a technical disagreement arises, I favor referencing relevant standards, manufacturer documentation, or performing tests to validate our hypotheses. For instance, if there’s a disagreement about the cause of a belt misalignment, measuring belt tension and roller alignment using precision instruments would provide objective data to inform the decision. Documentation and transparent decision-making are vital, ensuring everyone understands the rationale behind the selected course of action.

Q 26. What is your experience with conveyor system integration with other automated systems?

My experience includes integrating conveyor systems with various automated systems, such as warehouse management systems (WMS), order fulfillment systems, and robotic arms. This usually involves understanding the communication protocols (e.g., Modbus, Ethernet/IP, Profinet) used by these systems. I have experience configuring PLCs to interface with these different systems, ensuring smooth data exchange. For example, I worked on a project where we integrated a conveyor system with a robotic palletizer. The conveyor system signaled the robotic arm to pick up a package based on the package’s location on the conveyor, and the robot arm sent a signal back to the conveyor once it had successfully placed the package onto the pallet. Careful programming and precise timing were crucial to the success of this integration. Successful integration relies on detailed planning, thorough testing, and a strong understanding of the individual systems and their communication capabilities. The goal is seamless and efficient material flow throughout the entire automated process.

Q 27. Describe your experience with root cause analysis for conveyor system problems.

Root cause analysis (RCA) is paramount in conveyor system troubleshooting. I utilize a structured approach, often employing the 5 Whys method or a Fishbone diagram. This systematic approach helps avoid addressing symptoms rather than the underlying problem. For example, if a conveyor stops frequently, I wouldn’t just replace a faulty motor (the symptom). Instead, I would ask ‘Why did the motor fail?’ (possibly due to overload), ‘Why was the motor overloaded?’ (possibly due to material jams), ‘Why were there material jams?’ (possibly due to a malfunctioning sensor), and so on. Using data logging and examining the system’s history, I pinpoint the fundamental cause. This approach reduces future occurrences and prevents costly reactive maintenance. In one instance, repetitive belt slippage led us to discover a poorly aligned pulley, not just a worn belt – a far more sustainable and cost-effective solution.

Q 28. How do you stay current with the latest advancements in conveyor system technology?

Staying current in conveyor technology is crucial. I actively participate in industry conferences and workshops, attending webinars, and reading industry publications like trade magazines and technical journals. I also actively follow industry leaders and technology providers online. My professional networks, including memberships in relevant organizations, provide access to the latest advancements, best practices, and insights from experts in the field. I regularly explore new automation software and hardware, and participate in training courses offered by equipment manufacturers. I maintain a keen interest in Industry 4.0 technologies like predictive maintenance, using sensors and data analytics to anticipate issues and schedule maintenance proactively. This proactive approach optimizes efficiency and reduces downtime.

Key Topics to Learn for Conveyor System Operations Interview

- Conveyor System Components & Functionality: Understanding the various types of conveyors (belt, roller, chain, etc.), their components (motors, drives, sensors, controls), and how they work together to transport materials efficiently.

- Safety Procedures & Regulations: Familiarity with OSHA regulations and industry best practices for safe operation, maintenance, and troubleshooting of conveyor systems, including lockout/tagout procedures and personal protective equipment (PPE) requirements.

- Troubleshooting & Maintenance: Practical experience in identifying and resolving common conveyor system malfunctions, performing preventative maintenance tasks, and understanding the importance of regular inspections.

- Material Handling Principles: Knowledge of different material characteristics and how they impact conveyor system design and operation, including considerations for weight, size, fragility, and flow rate.

- Control Systems & Automation: Understanding basic PLC (Programmable Logic Controller) operation, sensor integration, and how automated systems optimize conveyor performance and efficiency. This includes familiarity with basic troubleshooting of control systems.

- Performance Monitoring & Optimization: Analyzing conveyor system data to identify areas for improvement in throughput, efficiency, and safety. This includes understanding key performance indicators (KPIs) relevant to conveyor systems.

- Emergency Procedures: Knowledge of proper response procedures in case of system malfunctions, jams, or safety incidents. This includes understanding emergency shutdown procedures and communication protocols.

Next Steps

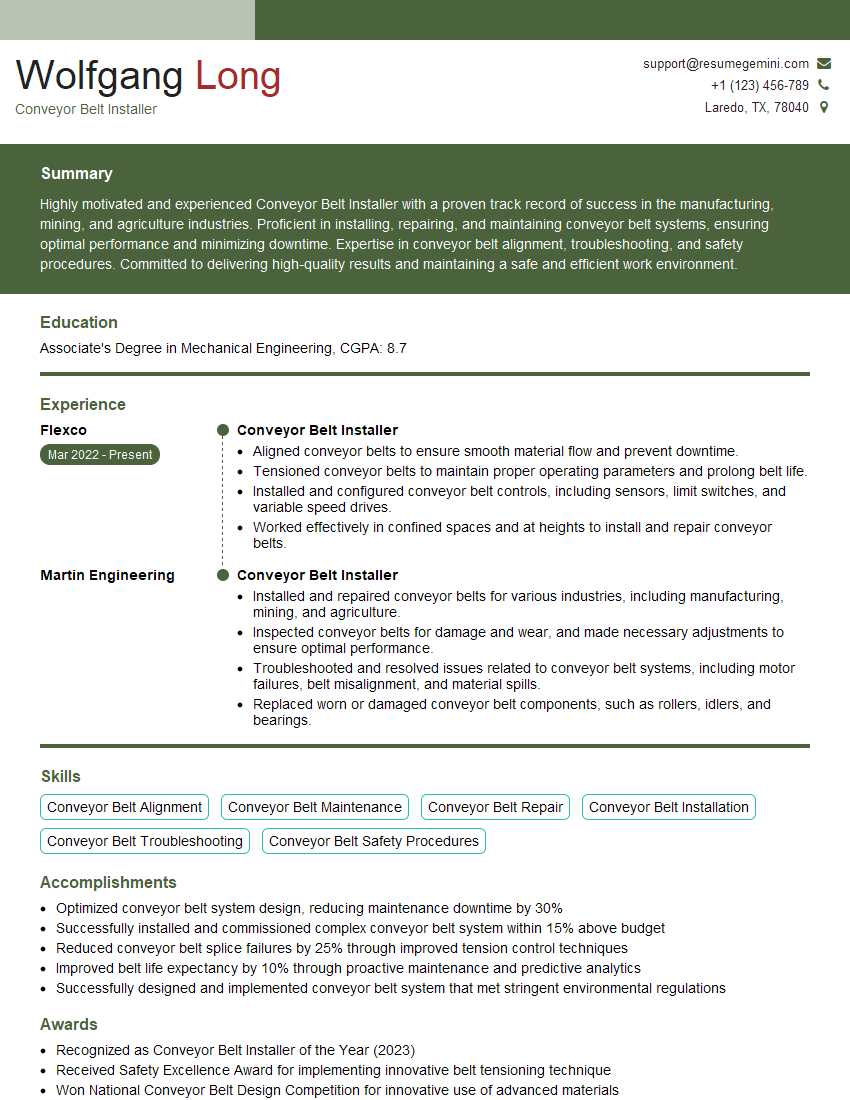

Mastering Conveyor System Operations opens doors to rewarding careers in logistics, manufacturing, and warehousing, offering opportunities for advancement and specialization. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes specifically designed for Conveyor System Operations roles are available to guide you. Take the next step towards your ideal career – build a strong resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good