Cracking a skill-specific interview, like one for Bentley WaterCAD, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Bentley WaterCAD Interview

Q 1. Explain the difference between a steady-state and a transient analysis in WaterCAD.

In WaterCAD, steady-state analysis simulates the water distribution system under a constant set of conditions. Think of it like taking a snapshot of the system at a specific moment in time. It calculates pressures and flows assuming demands and supply remain unchanged. This is useful for initial design assessments and understanding the system under typical operating conditions. A transient analysis, on the other hand, simulates the system’s response to dynamic changes, such as pump starts/stops, valve operations, or pipe bursts. It considers the effects of water inertia and compressibility, providing a more detailed picture of pressure surges and flow variations over time. Imagine it as a movie instead of a photograph, showing how the system reacts to changes.

For example, a steady-state analysis might tell you the pressure at a node under average daily demand, whereas a transient analysis would show you how pressure fluctuates when a nearby fire hydrant is opened suddenly.

Q 2. Describe the process of calibrating a WaterCAD model.

Calibrating a WaterCAD model involves adjusting model parameters to match observed field data. It’s crucial for ensuring the model accurately represents reality. The process typically involves these steps:

- Gather Field Data: Collect pressure and flow measurements from various points in the actual water distribution system. This might involve field visits with pressure gauges and flow meters.

- Initial Model Development: Create a WaterCAD model based on design drawings and known system components (pipes, pumps, valves, etc.).

- Parameter Adjustment: Adjust model parameters, such as pipe roughness (Hazen-Williams coefficient or Darcy-Weisbach friction factor), pump curves, and demand patterns, to minimize the difference between simulated and observed data. This often involves iterative adjustments and sensitivity analysis.

- Comparison and Analysis: Compare simulated results (pressures and flows) to the field data. Tools like WaterCAD’s calibration wizard can help automate this process and generate error metrics.

- Refinement: Repeat steps 3 and 4 until satisfactory agreement is achieved between the model and field data. This may involve revisiting assumptions or even re-examining field data for inaccuracies.

For example, if your model consistently underestimates pressure at a specific node, you might need to adjust the pipe roughness coefficient for pipes leading to that node, reflecting a potentially higher level of pipe corrosion than initially assumed.

Q 3. How do you handle negative pressures in a WaterCAD model?

Negative pressures (also called vacuum pressures) in a WaterCAD model indicate a problem, signifying that the pressure is below atmospheric pressure. This can lead to cavitation (formation of vapor bubbles) in pipes, which can damage pumps and pipes in the long run. Here’s how to address them:

- Identify the Cause: Examine the model to find the location and cause of negative pressures. Common causes include inadequate pump capacity, high demands, leaks, or incorrect pipe data.

- Increase System Capacity: If the cause is insufficient capacity, increase pump capacity or add storage tanks to meet peak demands.

- Adjust Demand Patterns: Review and revise demand patterns if high demands are contributing to negative pressures. Ensure peak demands reflect real-world usage.

- Check Pipe Data: Verify the accuracy of pipe properties and roughness coefficients. Incorrect data can lead to inaccurate pressure calculations.

- Leak Detection and Repair: If leaks are suspected, investigate the system for leaks and repair them. This might involve reviewing historical data or conducting field inspections.

- Model Adjustments: Use WaterCAD’s features to adjust the model parameters. For example, refine pipe roughness or recalibrate pump curves.

A real-world example might involve a newly developed area with insufficient supply from a water tower; negative pressures in the new area would indicate the need for increased pumping capacity or the addition of a booster pump station.

Q 4. What are the different types of pipes used in WaterCAD and their properties?

WaterCAD offers several pipe types, each with specific properties influencing flow calculations. These include:

- Pipes: The most common type, representing standard water distribution pipes. Properties include diameter, length, roughness (Hazen-Williams coefficient or Darcy-Weisbach friction factor), and material.

- Conduits: Similar to pipes but often used for larger conveyance channels or structures. They might have a different roughness coefficient reflecting their construction materials.

- Fittings: Represent various pipe fittings, such as bends, elbows, valves, and tees. These introduce head loss, modeled using equivalent length or minor loss coefficients. These coefficients account for the additional resistance to flow caused by the fittings.

- Valves: Used to control flow. Properties include valve type (gate, globe, check, etc.) and setting (open, closed, partially open). Different valve types present different resistances to flow.

For instance, a cast iron pipe might have a different Hazen-Williams coefficient than a ductile iron pipe, reflecting differences in their inner surface roughness.

Q 5. Explain the significance of Hazen-Williams and Darcy-Weisbach equations in WaterCAD.

The Hazen-Williams and Darcy-Weisbach equations are fundamental in WaterCAD for calculating head loss in pipes. Head loss is the energy lost due to friction as water flows through a pipe.

Hazen-Williams is an empirical equation simpler to use but less accurate for wider ranges of flow and pipe diameter. It relies on a roughness coefficient (C-factor) to characterize pipe roughness. A higher C-factor implies smoother pipes and less head loss.

Darcy-Weisbach is a more fundamental and accurate equation, especially for high velocities or large diameter pipes. It uses a friction factor (f), often determined using the Moody diagram or Colebrook-White equation, which accounts for pipe roughness, flow velocity, and pipe diameter. A lower friction factor implies less head loss.

WaterCAD allows you to choose between these equations; the best choice depends on project requirements and data availability. Darcy-Weisbach is generally preferred for its accuracy, especially when dealing with large variations in flow and pipe size.

Q 6. How do you incorporate fire flow demands into a WaterCAD model?

Incorporating fire flow demands into a WaterCAD model is crucial for assessing the system’s ability to handle emergencies. This is done by defining fire flow demands at specific locations (typically fire hydrants) using either:

- Fixed Demand: Specify a fixed flow rate (e.g., 1000 GPM) at a particular node, representing the required fire flow at that location.

- Demand Pattern: Create a demand pattern defining the fire flow rate over time, potentially increasing gradually and then gradually decreasing as firefighters use water. This simulates a more realistic scenario.

Furthermore, you would also use fire flow scenarios to simulate different fire events occurring simultaneously at different locations within the system. This would give you an overall view of the pressure and flow changes when dealing with more than just one fire hydrant being used.

WaterCAD also allows for the definition of fire flow sources that can be used to simulate fire trucks effectively adding water to the system.

After defining fire flow demands, a transient analysis is often used to evaluate the system’s response during fire-fighting operations, checking for pressure drops below acceptable limits.

Q 7. Describe the process of creating a demand pattern in WaterCAD.

Creating a demand pattern in WaterCAD involves defining how the water demand at a node or zone varies over time. This is important because water usage isn’t constant; it fluctuates throughout the day and across different seasons. The process involves:

- Data Acquisition: Gather historical water usage data (if available) for each node or zone to create a realistic pattern. This might come from existing smart meters or utility records.

- Pattern Definition: In WaterCAD, you can manually enter demand values for specific time intervals (e.g., hourly or daily) to build a custom pattern. Alternatively, you could use built-in pattern types.

- Data Input: Assign the pattern to nodes or zones in the model. You can define different patterns for different zones, reflecting varying usage patterns across different parts of the system.

- Validation: Once created, check if the patterns and their values are realistic by comparing them against historical data (if available), or by utilizing professional judgment and estimations.

For example, a residential area might have a higher demand during morning and evening peak hours compared to midday, while a commercial area might have a more uniform demand throughout the day. The pattern would be created reflecting such characteristics.

Q 8. Explain how you would use WaterCAD to analyze the impact of a proposed pipeline.

Analyzing the impact of a proposed pipeline in WaterCAD involves a systematic approach. First, you’d create a hydraulic model of the existing water distribution system, accurately representing pipes, pumps, reservoirs, and demands. Then, you’d add the proposed pipeline to the model, specifying its diameter, length, material, and roughness. After this, you run a hydraulic simulation under various demand scenarios (peak hour, average day, etc.). By comparing the results (pressure, flow, and velocity) of the simulation with and without the new pipeline, you can quantify the impact. For example, you might discover improved pressure in previously low-pressure zones or increased system capacity to accommodate future growth. A crucial part of this analysis is sensitivity analysis, exploring the effect of varying the characteristics of the proposed pipeline (e.g., diameter) on the overall system performance. This allows for optimized design choices.

Imagine a scenario where a town needs to extend water service to a new housing development. Modeling the new pipeline in WaterCAD allows engineers to assess if the existing system has the capacity to supply the additional demand without compromising pressure in other areas. They can explore different pipeline diameters to find the most cost-effective solution while meeting pressure requirements. This avoids costly over-design or under-performance.

Q 9. How do you account for water quality parameters in WaterCAD?

WaterCAD doesn’t directly model water quality parameters in the same way it simulates hydraulics. It primarily focuses on the physical flow of water. However, you can indirectly consider water quality by incorporating factors that influence it into your model. For instance, you can account for the age of pipes (introducing increased roughness to simulate biofilm buildup), the effect of pressure on the potential for leakage and infiltration (affecting bacterial contamination risk), and even represent water treatment plants using sources with specific flow characteristics. You could also use the results of the hydraulic simulation, particularly the flow velocities in different sections of the pipeline, to infer the potential for water quality degradation or to inform a separate water quality model. Remember, WaterCAD’s strength is in hydraulic simulation; other specialized software is often used for detailed water quality modeling.

Q 10. What are the different types of pumps used in WaterCAD and their modeling considerations?

WaterCAD offers several pump types, each with unique modeling considerations:

- Constant Speed Pumps: These are modeled using a characteristic curve that relates flow and head. You need to provide data points or an equation defining this curve. It’s straightforward but doesn’t account for pump efficiency variations.

- Variable Speed Pumps: These are more sophisticated and allow for dynamic control of pump speed based on system demands. You need to supply additional parameters like minimum and maximum speeds and how speed changes with changing demand. This provides a more realistic simulation of modern pump systems.

- Parallel Pumps: These model multiple pumps working in parallel, where you can define the number of pumps and their individual characteristics. You may encounter issues with parallel pump synchronization that require additional analysis.

For accurate modeling, choosing the correct pump type is crucial, and providing reliable pump characteristic curves is essential. Incorrect data will lead to inaccurate predictions.

Example: Imagine a booster pump station needed to maintain adequate pressure during peak demand. Using the variable speed pump type in WaterCAD allows simulating how the pump speed will adjust to match the demands, giving a more accurate picture of system performance. Neglecting the variable speed option might lead to an overestimation of energy consumption if a constant speed pump is used.

Q 11. How do you manage multiple scenarios or design alternatives within WaterCAD?

WaterCAD efficiently manages multiple scenarios and design alternatives using its scenario manager. This feature allows you to create different scenarios representing various operational conditions, design options, or future demands. Each scenario can be defined by modifying the parameters within the model such as pipe diameters, pump curves, demand patterns, or adding new components. You can compare the results of these scenarios side-by-side, using graphs and tables. This facilitates informed decision-making by quickly assessing which design option best suits the needs of the system. WaterCAD also allows for creating reports comparing the results across various scenarios which are easily exportable.

Example: Let’s say you’re designing a new water treatment plant with different capacity options. You could create three scenarios: low capacity, medium capacity, and high capacity. Each would have different supply rates to the network. After running simulations for each, you can easily compare pressure and flow throughout the network under each capacity, making selecting the correct size of the treatment plant simple.

Q 12. Explain the use of control valves and their impact on system performance.

Control valves are crucial components for managing flow and pressure in a water distribution network. In WaterCAD, you can model different types of control valves, including pressure reducing valves (PRVs), pressure sustaining valves (PSVs), and flow control valves (FCVs). Each valve type has its specific function and modeling parameters, influencing pressure and flow in different ways.

PRVs maintain downstream pressure below a set limit. PSVs maintain a specific upstream pressure. FCVs control the flow rate through a pipe. Incorrectly modeling these valves can lead to inaccurate simulation results. The settings for the control valve (set point, characteristics of the valve etc.) significantly affect system performance. For example, a poorly placed or incorrectly sized PRV can cause low pressure in some areas while creating excessive pressure in others.

Example: A PRV can be used to regulate pressure in a high-pressure zone to protect older pipes from excessive stress, and simultaneously maintaining appropriate pressure in the areas downstream of the valve. Improper sizing or placement can lead to insufficient pressure or potential bursts in other parts of the network, highlighting the importance of accurate modeling in WaterCAD.

Q 13. How do you interpret and analyze the results generated by a WaterCAD simulation?

Interpreting WaterCAD results involves a thorough examination of various outputs. Key elements include:

- Pressure Profiles: Examining pressure at different nodes helps identify areas with low pressure (potentially leading to customer complaints) or excessive pressure (increasing the risk of pipe bursts).

- Flow Rates: Analyzing flow in pipes helps check for over- or under-sized pipes, identifies potential bottlenecks, and checks that flows meet the expected demands.

- Velocities: High velocities can cause pipe erosion, while low velocities can contribute to sedimentation. WaterCAD provides this vital information for evaluating flow patterns within your design.

- Energy Consumption: WaterCAD can estimate energy consumption of pumps, facilitating cost-effective design choices. This is a critical metric for operational cost analysis.

WaterCAD provides a suite of tools, including graphs, tables, and reports, to visualize and analyze these results effectively. It is also crucial to compare the results to the system’s design criteria and identify potential issues. This may involve further refinement of the model or adjustment of the design.

It’s important to consider both steady-state and extended period simulations, allowing a comprehensive understanding of the system’s behavior under different conditions.

Q 14. What are the limitations of WaterCAD, and how do you address them?

WaterCAD, like any modeling software, has limitations. It’s a simplified representation of reality, and several factors can affect accuracy:

- Data Accuracy: The quality of the model is heavily dependent on the accuracy of input data (pipe characteristics, demand patterns, pump curves, etc.). Inaccurate data results in inaccurate outputs.

- Model Simplifications: WaterCAD makes assumptions and simplifications, such as the assumption of steady-state flow in certain analyses, which may not always reflect real-world complexities. The software’s ability to accurately model complex system dynamics is limited.

- Transient Conditions: Modeling highly transient events such as water hammer is more complex and may require specialized add-ons or other software.

To address these limitations:

- Data Validation: Always ensure accurate and reliable input data through field measurements and verification.

- Model Calibration: Calibrate the model using observed field data to ensure it reflects real-world behavior.

- Sensitivity Analysis: Perform sensitivity analysis to understand how uncertainties in input data affect the simulation results.

- Multiple Software Use: Consider using specialized software to model the aspects of water distribution networks that WaterCAD doesn’t handle well (e.g. water quality, transient modeling).

By acknowledging and addressing these limitations through careful planning and verification, you can still harness the power of WaterCAD to make informed decisions.

Q 15. Describe your experience with WaterCAD’s reporting and visualization tools.

WaterCAD offers a robust suite of reporting and visualization tools crucial for analyzing model results. These tools allow engineers to effectively communicate findings to clients and stakeholders. I’m proficient in utilizing its various reporting options, from simple tables summarizing pressures and flows to sophisticated charts and graphs illustrating pressure variations over time or throughout the network.

For instance, I frequently use the report generator to create customized reports detailing node pressures, pipe flows, tank levels, and pump performance. These reports are essential for identifying potential problems like low pressure zones or overloaded pipes. The graphical capabilities are equally valuable; I can easily generate contour maps showcasing pressure zones, enabling quick visual identification of critical areas. I also leverage the animation features to visualize flow changes in a dynamic way, particularly helpful in demonstrating the impact of different scenarios, such as pipe bursts or fire flows.

Furthermore, WaterCAD’s ability to export data to various formats (CSV, Excel, etc.) is invaluable for further analysis using other software, like GIS systems for spatial analysis or spreadsheets for detailed calculations. This seamless integration strengthens the overall analysis process and report generation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you validate the accuracy of a WaterCAD model?

Validating a WaterCAD model is a critical step, ensuring its reliability and accuracy before making any significant decisions based on its outputs. My validation approach involves a multi-step process incorporating both model calibration and verification.

- Calibration: I compare the model’s simulated results against real-world field data, adjusting model parameters like pipe roughness coefficients or demand patterns to minimize discrepancies. This often involves iterative adjustments, carefully documenting each change and its impact on the model’s performance. For example, if the model consistently underestimates pressures in a specific area, I might adjust the pipe roughness coefficient for that area’s pipes to better reflect their actual condition.

- Verification: This step focuses on assessing the model’s internal consistency and logic. It involves checking the model’s input data for errors, ensuring correct unit conversions, and verifying that the model’s hydraulic calculations are performed accurately. This includes checking for any inconsistencies or unexpected results that might indicate modeling errors.

- Sensitivity Analysis: A sensitivity analysis is often employed to understand how changes in input parameters affect model outputs. This helps to determine the most critical parameters needing accurate representation and which ones are less sensitive to changes.

Ultimately, a successful validation process results in a model that closely replicates the system’s behavior under various conditions, providing confidence in its ability to accurately predict future performance.

Q 17. Explain your approach to troubleshooting errors or unexpected results in WaterCAD.

Troubleshooting errors or unexpected results in WaterCAD requires a systematic approach. My process typically follows these steps:

- Review Input Data: The first step is meticulously reviewing all input data, checking for any errors or inconsistencies in pipe diameters, elevations, demands, or pump curves. Incorrect data entry is a frequent source of errors.

- Check Model Settings: Verify that all model settings, such as the analysis type (extended period, steady state), hydraulic solver options, and convergence criteria, are appropriate for the specific problem being solved. Incorrect settings can significantly affect results.

- Examine Warning Messages: WaterCAD often provides warning messages during model execution. These messages should be carefully examined, as they often provide clues about potential problems.

- Simplify the Model: If the problem is difficult to isolate in a complex model, I’ll often simplify the model by progressively removing components to pinpoint the source of the error. This is like detective work – isolating variables to see their impact.

- Utilize WaterCAD’s Diagnostic Tools: WaterCAD offers various diagnostic tools, like pressure profiles and energy grade lines, which can help to visually identify areas with unusual behavior.

- Seek Support: If all else fails, seeking support from the Bentley communities or consulting relevant documentation might be necessary.

For example, if the model fails to converge, it could indicate a problem with input data (e.g., unrealistic demands) or model settings (e.g., too tight convergence criteria).

Q 18. Describe your experience working with large-scale WaterCAD models.

My experience with large-scale WaterCAD models involves tackling projects involving thousands of pipes and nodes. Working with such models necessitates a well-structured approach.

- Model Subdivision: For extremely large models, I often break down the model into smaller, more manageable sub-models, focusing on key areas of interest. This allows for efficient processing and easier identification of potential errors or issues.

- Data Management: Rigorous data management is critical, often involving the use of scripting or external databases to manage and update the large amount of input data. This organized approach minimizes the risk of errors.

- Efficient Solver Settings: Choosing appropriate solver settings is essential to ensure efficient solution times. This includes understanding the trade-off between accuracy and solution time. Often, I’ll begin with faster, less accurate solvers, gradually refining the solution if needed.

- Hardware Resources: Large models often demand significant computer resources (RAM, processor power). I am aware of the requirements and know how to effectively utilize available hardware or allocate resources accordingly.

- Parallel Processing: WaterCAD allows parallel processing to speed up the calculations. Utilizing this feature significantly shortens the computation time, especially for computationally intensive simulations.

Working with large models requires not only technical skills but also project management capabilities to ensure smooth model development and analysis.

Q 19. How do you manage data input and output in WaterCAD?

Efficient data input and output in WaterCAD is crucial for productivity and accuracy. My approach involves:

- Using Import/Export Features: WaterCAD supports importing and exporting data in various formats (e.g., shapefiles, text files, spreadsheets). I leverage these features to import GIS data, elevation data, or demand data from external sources. Exporting results to spreadsheets or other software allows for further analysis and report generation.

- Database Connectivity: For large projects, connecting WaterCAD to a database (like an SQL database) enables seamless data management and updates. This approach ensures data consistency and allows for efficient updates as the project evolves.

- Data Validation: Before importing any data, I conduct thorough validation to ensure data integrity and consistency. This step minimizes the risk of errors entering the model.

- Data Organization: Organizing data in a logical and consistent manner is crucial, especially in large projects. This might involve using standardized naming conventions, creating spreadsheets for better data management, and documenting data sources and updates.

- Scripting (Optional): For highly repetitive tasks or complex data manipulation, using scripting (e.g., Python) offers enhanced efficiency. I’m comfortable automating data import, processing, and export through scripting for improved workflows.

By using a consistent and well-defined strategy, data input and output become straightforward, even in complex scenarios.

Q 20. What is the importance of using appropriate units in WaterCAD?

Using appropriate units in WaterCAD is paramount for obtaining accurate and meaningful results. Inconsistencies in units can lead to significant errors in model calculations and outputs.

For example, if pipe diameters are entered in inches while other parameters use feet, the calculated flows and pressures will be severely inaccurate. Similarly, using inconsistent units for demands (e.g., gallons per minute vs. liters per second) will lead to wrong results.

I always ensure that all data, including pipe diameters, lengths, elevations, demands, and roughness coefficients, use a consistent set of units throughout the model. WaterCAD allows the definition of a standard unit system, facilitating this consistency. I typically select a standard system like SI units (meters, seconds, etc.) or US customary units (feet, seconds, etc.) at the start of the project, and I strictly adhere to that choice. Any conversions from different units are performed externally before data entry into the model, ensuring no confusion. This careful attention to units minimizes the chance of significant calculation errors and ensures a reliable and trustworthy model.

Q 21. How do you incorporate GIS data into a WaterCAD model?

Integrating GIS data into a WaterCAD model significantly enhances its accuracy and provides a visual context for the hydraulic network. I use the following steps:

- Import GIS Data: WaterCAD supports importing various GIS data formats, including shapefiles and geodatabases. I import the relevant data like pipe centerlines, node locations, and other geographical features. This process typically involves projecting the GIS data into a compatible coordinate system with WaterCAD.

- Data Alignment: Once imported, I ensure accurate alignment between the GIS data and the WaterCAD model elements. This might involve manual adjustments or using automated tools, depending on the data’s accuracy.

- Attribute Data Transfer: I use the GIS data’s attribute tables to populate parameters in the WaterCAD model. For example, pipe diameters, roughness coefficients, and elevations can be directly populated from attributes in the shapefile. This streamlines the data entry process and reduces the potential for human errors.

- Visualizing Results: After the hydraulic simulation, I overlay the results (e.g., pressure contours, flow velocities) on the GIS map. This enables a visual interpretation of the model’s results within the geographical context, identifying areas with low pressure or high flow velocities which are easily communicated to stakeholders through maps.

- Updating the Model: Finally, the integration allows straightforward updating of the model based on changes to the physical network captured in the GIS. Any changes in the network’s configuration or attribute data in the GIS can readily update the WaterCAD model.

GIS integration streamlines the modeling process, providing a more accurate, visually compelling, and easily updatable model.

Q 22. Explain your experience with WaterCAD’s extended period simulation capabilities.

WaterCAD’s extended period simulation (EPS) is a powerful feature allowing us to model water distribution systems over extended durations, often weeks or months, to capture seasonal variations in demand and other time-dependent factors. Unlike a simple steady-state or short-duration simulation, EPS considers changes in demand throughout the day and across different days of the week and year. This is crucial for evaluating system performance under various operating conditions and long-term planning.

In my experience, I’ve used EPS extensively for projects involving reservoir management, evaluating the impact of planned maintenance, and assessing the effectiveness of different pressure management strategies. For example, in a recent project, EPS helped us demonstrate that a proposed new reservoir would significantly improve the system’s reliability during peak summer demand, preventing low-pressure events affecting several critical areas of the city. We were able to model different reservoir operating strategies, compare their effectiveness, and confidently recommend the best approach based on the EPS results.

Setting up an EPS simulation involves defining time patterns for demands at various junctions, pump schedules, and possibly even source variations (e.g., fluctuating river flow for a surface water source). WaterCAD provides user-friendly interfaces to manage this data, using various temporal profiles for input. Post-processing of the results helps understand the long-term system performance including minimum and maximum pressures, flow rates, tank levels, and pump operations over the entire simulation period. This allows for effective optimization and informed decision-making.

Q 23. How do you handle different types of junctions in WaterCAD?

WaterCAD handles various junction types effectively, each representing a specific point in the water distribution network. Understanding the characteristics of each type is vital for accurate modeling. Common junction types include:

- Regular Junctions: These are the most basic type, representing a simple connection point within the network. They have a defined demand pattern, and pressure is calculated based on the network’s hydraulics.

- Reservoirs: These junctions represent storage points within the system, such as water towers or tanks. They have a defined elevation and storage capacity, influencing pressure and flow within the surrounding network.

- Sources: These simulate water supply sources, like wells or treatment plants. They have a specified supply capacity and pressure, determining the initial pressure and flow in the system.

- Fire Flow Junctions: These junctions model fire hydrants or other high-demand points, with larger than average demands used to simulate fire-fighting scenarios.

Properly defining each junction type in WaterCAD is critical to model accuracy. Misclassifying a junction can lead to inaccurate pressure and flow calculations. For example, failing to specify a junction as a reservoir will lead to an underestimation of its pressure regulating capacity and thus impact calculations of pressure at other network points.

Q 24. Describe your experience with WaterCAD’s pressure management tools.

WaterCAD offers a suite of pressure management tools that are integral to optimizing a water distribution system’s efficiency and reliability. These tools allow for the analysis and control of pressure fluctuations throughout the network. My experience includes using these tools to analyze pressure zones and implement various pressure management strategies. For instance:

- Pressure Reducing Valves (PRVs): WaterCAD accurately models PRVs, allowing us to simulate their impact on pressure profiles. We can specify their set points and evaluate their effectiveness in minimizing pressure surges and preventing over-pressurization in certain parts of the network. This is important for preventing pipe damage and ensuring the longevity of the infrastructure.

- Pressure Sustaining Valves (PSVs): These valves are used to maintain minimum pressure in specific areas, critical for ensuring adequate service during peak demand. WaterCAD’s simulation allows for analyzing the placement and set-point optimization of these valves.

- Pressure-Dependent Demand: This feature allows demands at junctions to vary based on pressure levels, reflecting the reality that leakage rates often increase with pressure. Incorporating this feature ensures more accurate water loss estimations and enhances the system’s overall modeling.

In a recent project, by carefully modeling PRVs and PSVs and considering pressure-dependent demand, we were able to reduce water loss by 15% and improve pressure consistency across the entire distribution network. This resulted in significant cost savings for the utility and improved service reliability for customers.

Q 25. Explain how you would use WaterCAD to optimize a water distribution system.

Optimizing a water distribution system using WaterCAD involves a systematic approach combining hydraulic modeling, analysis, and iterative design modifications. The process usually involves:

- Building a detailed model: This includes accurately representing the network’s topology, pipes, pumps, valves, and demands.

- Hydraulic analysis: Running simulations to assess current system performance, identifying pressure and flow deficiencies.

- Identifying areas for improvement: Pinpointing locations with low pressures, high water losses, or excessive pump energy consumption.

- Implementing design modifications: This could involve adding new pipes, installing PRVs/PSVs, modifying pump schedules, or changing reservoir operating strategies. These modifications are tested in the model iteratively.

- Evaluating the impact of changes: Running new simulations to measure the effect of each modification on pressure profiles, energy consumption, and water loss.

- Iterative refinement: Repeating steps 4 and 5 until the optimal solution is found, balancing cost and performance improvements.

Optimization often involves using WaterCAD’s optimization tools or employing sensitivity analyses to efficiently explore design options. For example, we can use the optimization tool to automatically find the optimal pipe diameters or pump settings that minimize cost while meeting the performance goals. The results of this iterative process provide a clear understanding of the trade-offs between system performance and capital costs, facilitating informed decision-making for the utility.

Q 26. How do you incorporate different water sources into a WaterCAD model?

Incorporating different water sources into a WaterCAD model is a critical aspect of accurately representing a real-world water distribution system. This is done by defining each source as a ‘Source’ junction, specifying key parameters. These parameters often include:

- Source Elevation: The elevation of the water source, crucial for determining the pressure head available.

- Source Capacity: The maximum flow rate the source can supply, which will influence the system’s overall capacity.

- Source Pressure: The initial head or pressure of water at the source.

WaterCAD allows modeling multiple sources, each with different capacities, pressures, and even variable supply depending on temporal patterns. For example, a system might draw water from a reservoir, a well, and a treated water source. Each source can be modeled separately in WaterCAD with its own defined characteristics and temporal variability. The interactions between these sources, how they supplement each other, and their relative importance to system pressure are readily evaluated through simulations. This enables analyses of source reliability, redundancy, and optimal allocation strategies in case of source failure.

For example, in a model I developed, the system drew from both a river source and a groundwater well. Water levels in the river fluctuated seasonally, and the model effectively accounted for the resulting variability in the total available supply by using time-series data for the river source. This provided insights into system vulnerability during low river flow periods.

Q 27. What are your preferred methods for documenting and sharing WaterCAD model results?

Effective documentation and sharing of WaterCAD model results are crucial for project success. My preferred methods combine clear visual representations with well-organized reports. This process often includes:

- Generating reports: WaterCAD generates comprehensive reports that detail model parameters, simulation results, and various performance indicators, including minimum and maximum pressures, flow rates, and water losses.

- Creating maps and visualizations: Using WaterCAD’s mapping capabilities, I create visual representations of pressure zones, flow velocities, and other key metrics. These maps enhance understanding and assist with quick identification of system vulnerabilities.

- Using GIS integration: WaterCAD’s seamless integration with GIS software allows us to overlay model results onto geographic information system maps, facilitating communication with stakeholders who may not be hydraulic modeling experts. It enables clear visualization of the water distribution network within its geographic context.

- Data sharing: We use cloud-based solutions and standardized file formats to facilitate the sharing of model data and results among team members and clients. This ensures accessibility, version control, and ease of collaboration.

In my experience, a well-documented model with clear visual aids greatly reduces ambiguity and promotes better understanding among all stakeholders, leading to more efficient decision-making and project implementation. Therefore I create a project-specific template to streamline reporting and ensure consistency throughout my projects.

Key Topics to Learn for Bentley WaterCAD Interview

- Hydraulic Modeling Fundamentals: Understand the underlying principles of water flow, pressure, and head loss in pipe networks. This includes mastering concepts like Darcy-Weisbach and Hazen-Williams equations.

- WaterCAD Interface and Functionality: Become proficient in navigating the software, creating and editing network models, defining pipe properties, and setting up simulations. Practice importing and exporting data.

- Scenario Management and Analysis: Learn how to create and analyze different scenarios (e.g., fire flow, pipe bursts, demand variations) within WaterCAD to assess system performance and identify vulnerabilities.

- Data Input and Validation: Understand the importance of accurate data input and the techniques for validating model results against real-world observations. Mastering data quality is crucial.

- Report Generation and Interpretation: Learn to effectively generate and interpret reports from WaterCAD simulations, extracting key insights for decision-making. This includes understanding pressure profiles, flow rates, and other critical parameters.

- Calibration and Validation: Understand the process of calibrating your model to match observed field data and validating the model’s accuracy. This is a critical aspect of practical water distribution system analysis.

- Advanced Hydraulic Analysis: Explore more advanced features such as extended period simulations (EPS), water quality modeling, and pump curve analysis. These can demonstrate a deeper understanding of WaterCAD’s capabilities.

- Problem-Solving and Troubleshooting: Practice identifying and resolving common issues encountered during model development and simulation. Being able to diagnose and fix errors is highly valued.

Next Steps

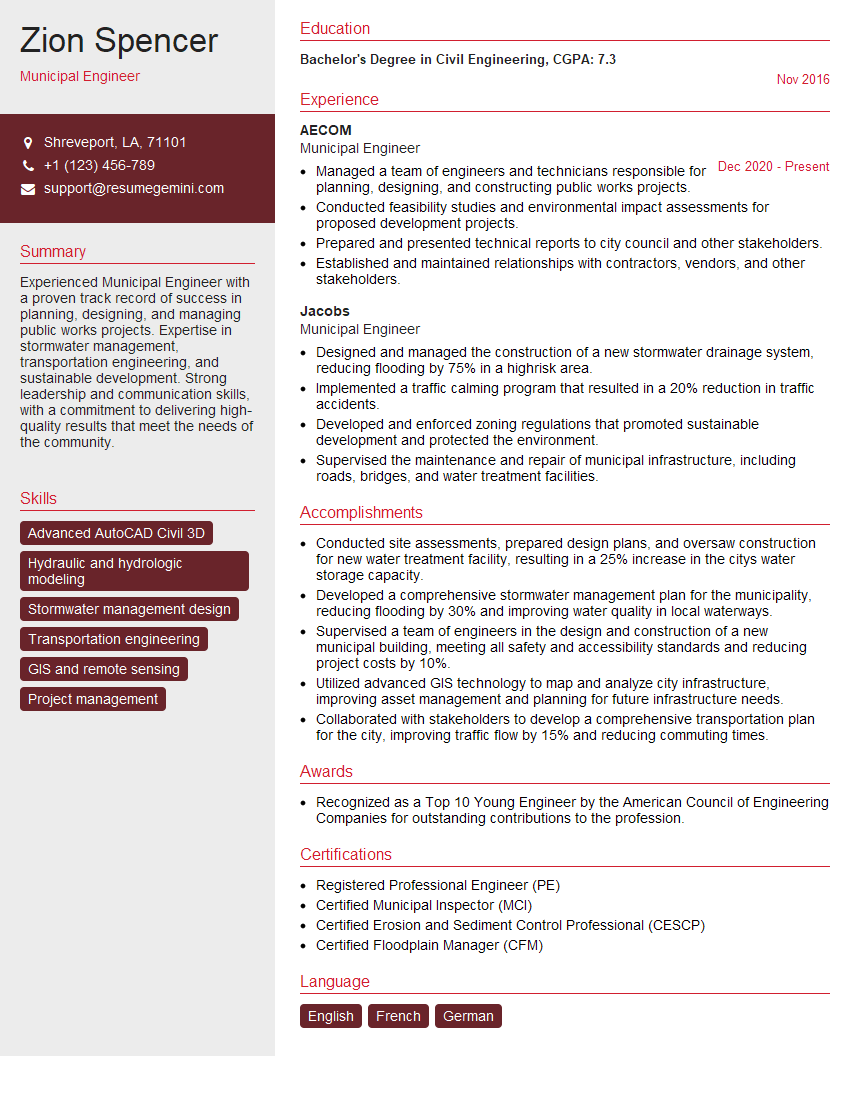

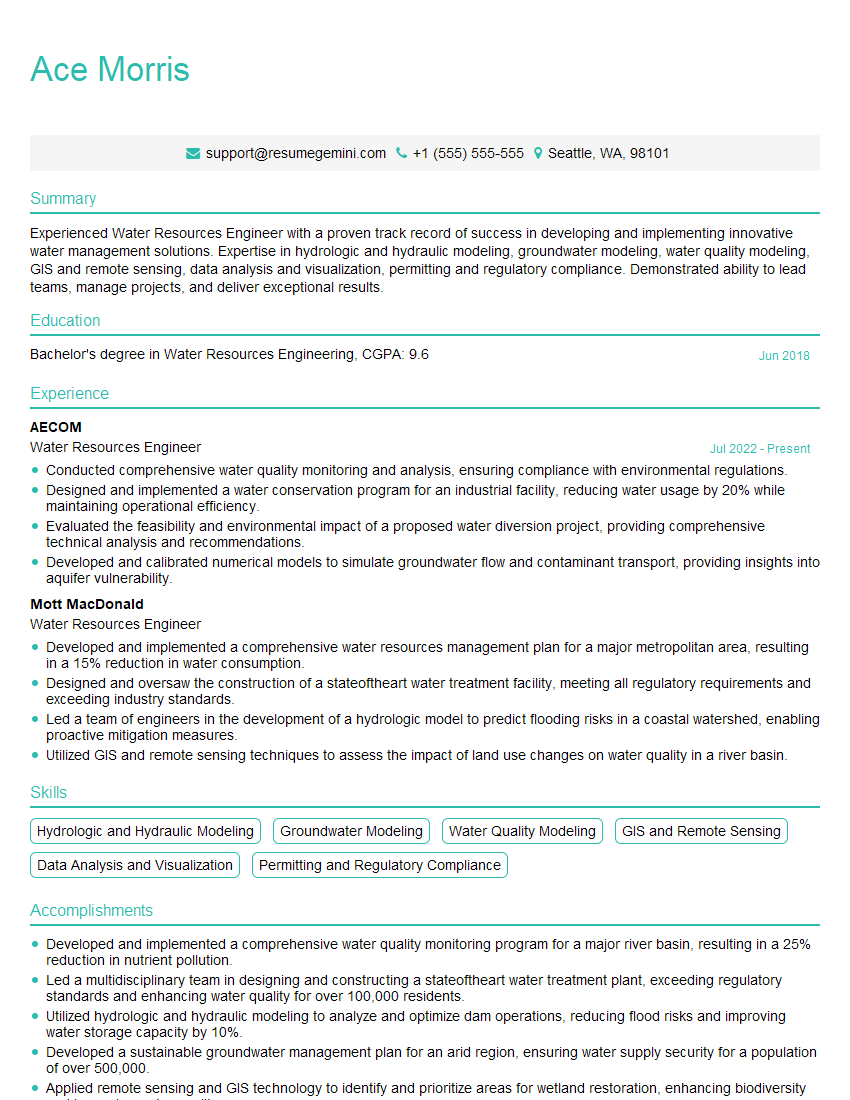

Mastering Bentley WaterCAD significantly enhances your career prospects in water resources management and engineering. It demonstrates a valuable skillset highly sought after by employers. To increase your chances of landing your dream job, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your WaterCAD expertise. Examples of resumes tailored to Bentley WaterCAD roles are provided to help you get started. Take the time to present your skills and experience effectively – it’s an investment in your future!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good