Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Ability to Identify and Resolve Cotton Defects interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Ability to Identify and Resolve Cotton Defects Interview

Q 1. Describe the different types of cotton defects.

Cotton defects encompass a wide range of imperfections that negatively impact fiber quality and the final textile product. These defects can be broadly categorized into those affecting fiber properties and those related to foreign matter.

- Fiber Defects: These pertain to the inherent characteristics of the cotton fibers themselves. Examples include short fiber length, immature fibers (thin and weak), weak fibers, neps (small entangled masses of fibers), and fiber color variations.

- Foreign Matter Defects: These are contaminants mixed with the cotton fibers during harvesting, processing, or storage. Common examples are leaf trash (pieces of leaves and other plant material), seed coat fragments, motes (small, immature seeds), and trash (general foreign material).

Understanding these different categories is crucial for effective quality control throughout the cotton supply chain, from field to finished fabric.

Q 2. Explain the HVI system and its role in cotton quality assessment.

The High Volume Instrument (HVI) system is a sophisticated, automated instrument used for assessing cotton fiber properties. It’s the industry standard for objective quality evaluation, providing key data used in pricing, blending, and processing decisions. The system analyzes a representative sample of cotton fibers, measuring several crucial parameters.

- Fiber Length: Determines the strength and fineness of the yarn.

- Fiber Strength: Indicates the yarn’s tensile strength and durability.

- Fiber Maturity: Reflects the fiber’s thickness and wall development; immature fibers are weaker.

- Fiber Uniformity: Measures the consistency of fiber length; a higher uniformity index means more consistent fiber length, resulting in stronger yarn.

- Micronaire: Indicates fiber fineness and maturity; it’s related to yarn strength and softness.

- Color: Assesses the color grade of the cotton, impacting the final product’s appearance.

HVI data allows cotton buyers and sellers to objectively assess quality and negotiate fair prices. It also guides spinners in selecting the right cotton blends for optimal yarn production. Think of it as a thorough ‘health check’ for a batch of cotton.

Q 3. How do you identify and classify nep in cotton?

Neps are small, tangled masses of short, immature fibers found within the cotton fiber mass. They appear as small, fuzzy knots or specks and significantly impact the appearance and quality of the final fabric, often showing up as small bumps or imperfections. Identification and classification involve a visual assessment, often aided by magnification.

Identification: Neps are usually visible to the naked eye, particularly on a light-colored background, but magnification (e.g., using a magnifying glass or microscope) is usually needed for precise counting and sizing.

Classification: Nep classification is often based on the number of neps per gram of cotton (nep count) and their size. Higher nep counts generally indicate lower quality cotton. Industry standards exist for acceptable nep levels depending on the intended use of the cotton. For example, finer yarns have stricter tolerance to neps compared to coarser ones.

Imagine a tightly wound ball of yarn – that’s essentially what a nep is, but at the micro-fiber level. Their presence is directly related to plant growth conditions and fiber development processes.

Q 4. What are the common causes of leaf trash in cotton?

Leaf trash, essentially bits of plant leaves and other vegetative matter, contaminates cotton during harvesting. Its presence reduces fiber quality and adds considerable processing difficulty. Several factors contribute to increased leaf trash:

- Inadequate Harvesting Techniques: Inefficient harvesting methods, such as using less refined machinery or delayed harvesting, can lead to higher leaf trash content.

- Adverse Weather Conditions: Heavy rains or storms can damage the cotton plant, increasing the likelihood of leaf contamination during picking.

- Plant Disease or Pest Infestation: Infected or pest-damaged plants may contain more leaf material.

- Lack of Proper Cleaning: Insufficient cleaning during the ginning process (the process of separating fibers from seeds) can result in high leaf trash levels in the final product.

Minimizing leaf trash requires careful attention to detail across all stages, from planting and cultivation to harvesting and processing. Think of it as maintaining a clean workspace—a clean field leads to cleaner cotton.

Q 5. How do you differentiate between immature fibers and mature fibers?

Differentiating between immature and mature cotton fibers is crucial for quality assessment. Mature fibers are longer, thicker, stronger, and more uniform, while immature fibers are shorter, thinner, weaker, and less uniform.

- Visual Inspection: Under magnification, mature fibers exhibit a thicker, more defined wall and a distinct lumen (the central cavity of the fiber). Immature fibers appear thinner, with a less defined wall and a larger lumen. They often appear collapsed or twisted.

- HVI System: The HVI system provides quantitative measures of fiber maturity, such as maturity index (MI) and micronaire. Higher values indicate better maturity.

- Microscopic Examination: Detailed examination under a microscope reveals the distinct structural differences between mature and immature fibers.

The analogy of a fully-developed fruit versus an underdeveloped one is helpful: a mature fiber is like a ripe fruit – strong, full, and ready, while an immature fiber is like an under-ripe fruit – weak and lacking in full development.

Q 6. What are the visual indicators of short fiber content?

Visual indicators of short fiber content aren’t always readily apparent without magnification, but some clues can be detected. Short fibers generally lead to weaker, less consistent yarns. The visual cues are subtle and require experience.

- Lower Strength and Cohesiveness: Short fibers produce yarns that are less strong and less cohesive, potentially leading to more breakage during processing. This is usually apparent during spinning or weaving.

- Poor Appearance: In finished fabrics, a higher proportion of short fibers can result in a fuzzy or uneven surface. It reduces the overall aesthetic quality.

- Increased Waste During Processing: Short fibers are more likely to break and cause waste during spinning and weaving processes.

While you might not directly see the short fibers easily, their impact on yarn strength and fabric quality is noticeable. Think of it like building a house with short, flimsy bricks versus long, strong ones; the overall stability and strength differ significantly.

Q 7. Explain the process of assessing fiber strength.

Fiber strength is a critical factor determining yarn and fabric quality. It’s assessed using instruments that measure the force required to break a single fiber or a bundle of fibers.

- Single Fiber Strength Tester: This instrument measures the tensile strength of individual fibers by clamping them at both ends and applying force until breakage. The force at breakage is recorded as fiber strength.

- Bundle Strength Tester: A bundle of fibers is subjected to tensile force, providing an average strength for the bundle. This gives an indication of the overall strength of the cotton sample.

- HVI System: While not the primary method for strength determination, the HVI system provides a strength value based on the bundle’s behavior during testing.

The results are typically expressed in units like grams per tex (g/tex) or centiNewtons (cN/tex). These figures are vital for determining the suitability of the cotton for specific applications, for example, high-strength cotton is preferred for industrial fabrics.

Q 8. How do you determine the micronaire value of cotton?

Micronaire is a crucial measure of cotton fiber fineness and maturity, impacting yarn quality and fabric properties. It’s determined using a Micronaire instrument, which measures the resistance to airflow through a compressed sample of cotton fibers. Think of it like measuring how easily air can pass through a tightly packed bundle of fibers; finer, more mature fibers offer greater resistance.

The process involves carefully preparing a representative sample of cotton, then placing it in the Micronaire instrument. The instrument precisely controls the airflow and measures the resistance. The result is a micronaire value, usually expressed as a number between 3.0 and 5.0. A higher micronaire value generally indicates thicker, less mature fibers, while a lower value suggests finer, more mature fibers. For example, a micronaire of 3.8 might be suitable for fine fabrics, while 4.5 might be better for more durable materials like denim.

Understanding micronaire is critical for spinners and textile manufacturers because it directly affects yarn quality, spinning performance, and the final fabric’s properties. A carefully chosen micronaire value ensures optimal fiber processing and fabric characteristics for the intended application.

Q 9. What are the implications of high trash content in cotton yarn?

High trash content in cotton yarn, meaning an excessive presence of impurities like leaves, stems, seeds, and other foreign matter, has several significant negative implications. Imagine trying to weave a beautiful tapestry with bits of straw and dirt woven into the threads – it’s not going to be pretty or strong.

- Reduced Yarn Strength: Trash acts as weak points, significantly weakening the overall yarn strength and making it more prone to breakage during processing and in the finished fabric.

- Poor Fabric Appearance: Trash leads to unsightly imperfections in the fabric, such as uneven texture, discoloration, and visible foreign particles. This drastically reduces the fabric’s aesthetic appeal and market value.

- Increased Production Costs: Cleaning and removing trash during yarn processing is time-consuming and expensive, increasing production costs.

- Damage to Machinery: Trash can damage spinning and weaving machinery, leading to downtime and costly repairs.

- Reduced Fabric Quality: The resulting fabric is likely to have a poor drape, reduced durability, and increased susceptibility to damage.

Therefore, controlling trash content is paramount in cotton production and processing, ensuring high-quality yarn and fabrics.

Q 10. How does the presence of seed coat fragments affect fabric quality?

Seed coat fragments, those tiny bits of the cottonseed that sometimes cling to the fibers, are a significant problem in cotton processing. Their presence directly impacts fabric quality in several ways. Picture trying to create a smooth, luxurious fabric with tiny, hard particles embedded within the fibers.

- Rough Texture: Seed coat fragments create a rough and uneven surface on the fabric, reducing its softness and overall hand feel. This is especially noticeable in fine fabrics.

- Weaving Difficulties: They can interfere with the weaving process, leading to broken yarns, uneven fabric structure, and reduced efficiency.

- Poor Dyeing and Finishing: The fragments can hinder the even absorption of dyes, leading to uneven coloration and a less appealing finished product. They also impede the application of other finishes.

- Reduced Fabric Strength: While individually small, concentrated seed coat fragments can weaken the fabric structure, making it more prone to wear and tear.

Removing seed coat fragments is therefore crucial for achieving high-quality fabrics with desired texture, appearance, and durability.

Q 11. Describe the methods for assessing cotton color uniformity.

Assessing cotton color uniformity is crucial for producing high-quality, consistent fabrics. Cotton color can vary due to several factors including growing conditions and harvesting practices. We use a couple of methods to objectively quantify this.

- Visual Assessment: While subjective, a skilled grader can visually assess color uniformity based on experience and standardized color charts. This method is often used for initial screening.

- Instrumental Color Measurement: This is more objective and precise, using instruments like spectrophotometers. These instruments measure the light reflectance of the cotton sample at various wavelengths, generating color coordinates (like L*, a*, b* values in the CIELAB color space). Software then analyzes these data to quantify color uniformity across the sample.

The difference between these values across a sample indicates the degree of color uniformity. Consistent, low variation indicates high color uniformity which is necessary for producing high quality, visually appealing fabrics.

Q 12. Explain the effect of fiber maturity on yarn strength.

Fiber maturity significantly impacts yarn strength. Think of it this way: a fully mature fiber is like a strong, fully developed stem, whereas an immature fiber is like a weak, underdeveloped shoot.

Mature fibers have thicker cell walls and a higher degree of polymerization, which translates to stronger inter-fiber bonds. This results in a stronger yarn. Immature fibers, conversely, have thinner cell walls and fewer strong bonds, making the resulting yarn weaker and more prone to breakage. The level of maturity can be assessed through various methods, such as the maturity index obtained from high volume instrument testing. A higher maturity index correlates directly with stronger yarns. For instance, a yarn spun from highly mature cotton will be significantly stronger and more resistant to breakage compared to one made from immature cotton. This directly affects the overall quality and durability of the final fabric.

Q 13. How do you identify and measure fiber length variations?

Fiber length variation is a critical factor affecting yarn quality and fabric properties. Imagine trying to build a strong rope with strands of varying lengths – the result would be uneven and weak. Measuring and identifying these variations is crucial.

- High Volume Instrument (HVI) System: This automated system is the industry standard, measuring thousands of fibers to determine length parameters like mean length, upper half mean length (UHML), and length uniformity index (UI). A higher UI indicates greater uniformity in fiber length, whereas a lower UI signifies more variation.

- Fiber Length Distribution Analysis: Using the data from the HVI system, a distribution graph can be generated to visually represent the variations in fiber length across the sample. This allows for a detailed understanding of the extent of the variation and its impact on yarn quality.

The HVI system allows for a precise, objective measurement of fiber length variations, guiding the selection of cotton for different yarn types and fabric applications. For example, longer and more uniform fibers are preferred for fine yarns and high-quality fabrics, while shorter fibers might be suitable for coarser yarns.

Q 14. What are the common causes of weak places in cotton fabric?

Weak places in cotton fabric, those areas prone to breakage or tearing, can result from several factors, disrupting the fabric’s structural integrity. Think of these as hidden vulnerabilities in the fabric’s structure.

- Short Fibers: The presence of a high proportion of short fibers in the yarn weakens the overall structure. These short fibers act as weak points, reducing the overall yarn strength.

- Poor Yarn Twist: Insufficient twist in the yarn leads to loose fibers that are easily pulled out, creating weak areas.

- Fiber Damage: Fiber damage during processing, such as excessive beating or harsh chemical treatment, can weaken individual fibers, leading to weak places in the fabric.

- Uneven Yarn Thickness: Variations in yarn thickness create stress points where the fabric is more prone to breaking.

- Improper Weaving: Weaving defects, like missed picks or floats, can create weak areas in the fabric structure.

- Entanglement issues:** Inadequate fiber disentanglement in the initial stages can lead to regions of high stress and weakened yarn.

Identifying and addressing these causes through improved processing techniques and quality control is critical for producing durable, high-quality cotton fabrics.

Q 15. How do you assess the impact of cotton defects on spinning performance?

Assessing the impact of cotton defects on spinning performance requires a holistic approach. Defects like short fibers, neps (small entangled fiber clusters), leaf fragments, and seed coat fragments directly influence yarn quality and spinning efficiency. Short fibers lead to weaker yarns prone to breakage, increasing production downtime and waste. Neps and other trashy matter cause yarn imperfections, affecting the final fabric’s appearance and strength.

We assess this impact by analyzing several key parameters:

- Yarn strength and elongation: Defective cotton results in lower tensile strength and reduced elongation, making the yarn less durable.

- Spinning efficiency: Higher defect levels often translate to more frequent machine stoppages and lower production speeds due to frequent yarn breaks.

- Yarn imperfections: Neps and other trash appear as visible flaws in the yarn, impacting the fabric’s aesthetic quality.

- Waste generation: Defective fibers are often removed during spinning, increasing waste and production costs.

For example, a batch of cotton with a high nep count might result in a 15% reduction in spinning speed and a 10% increase in yarn breakage, directly impacting profitability. We use statistical analysis of spinning data, combined with visual inspection of the raw cotton and the resulting yarn, to quantify the effects of specific defects.

Career Expert Tips:

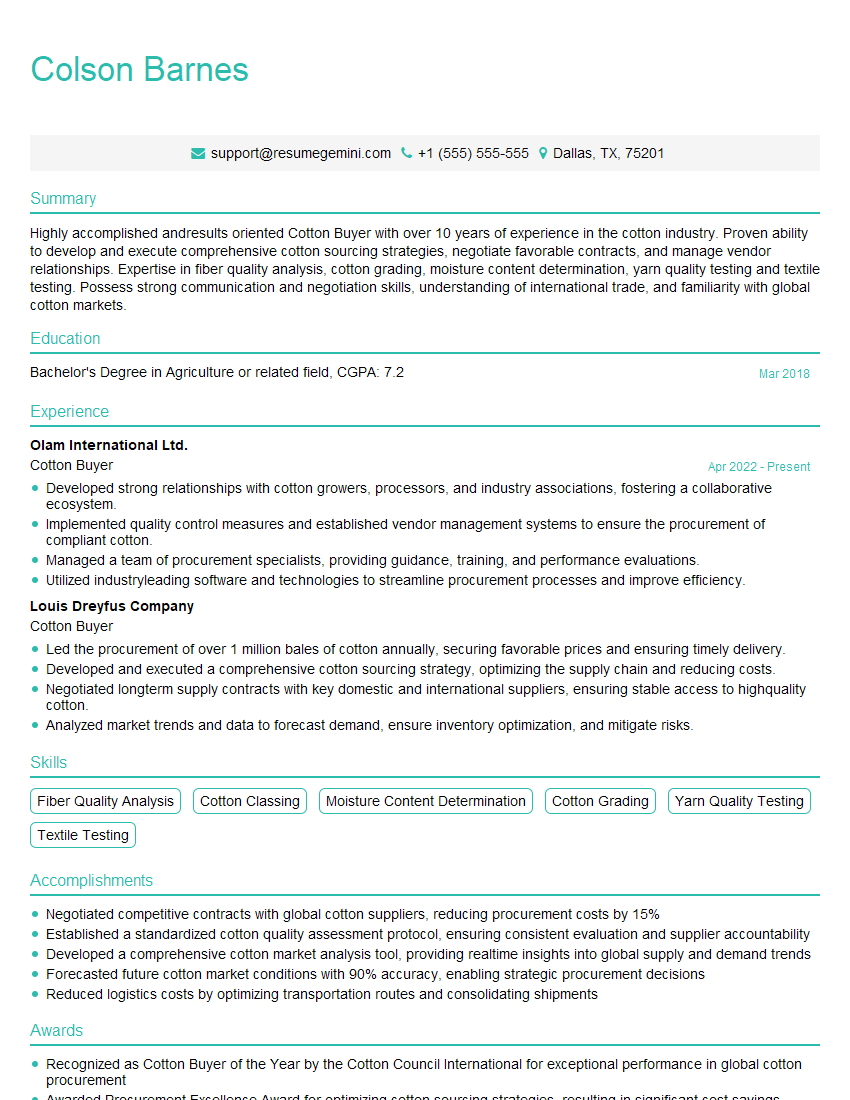

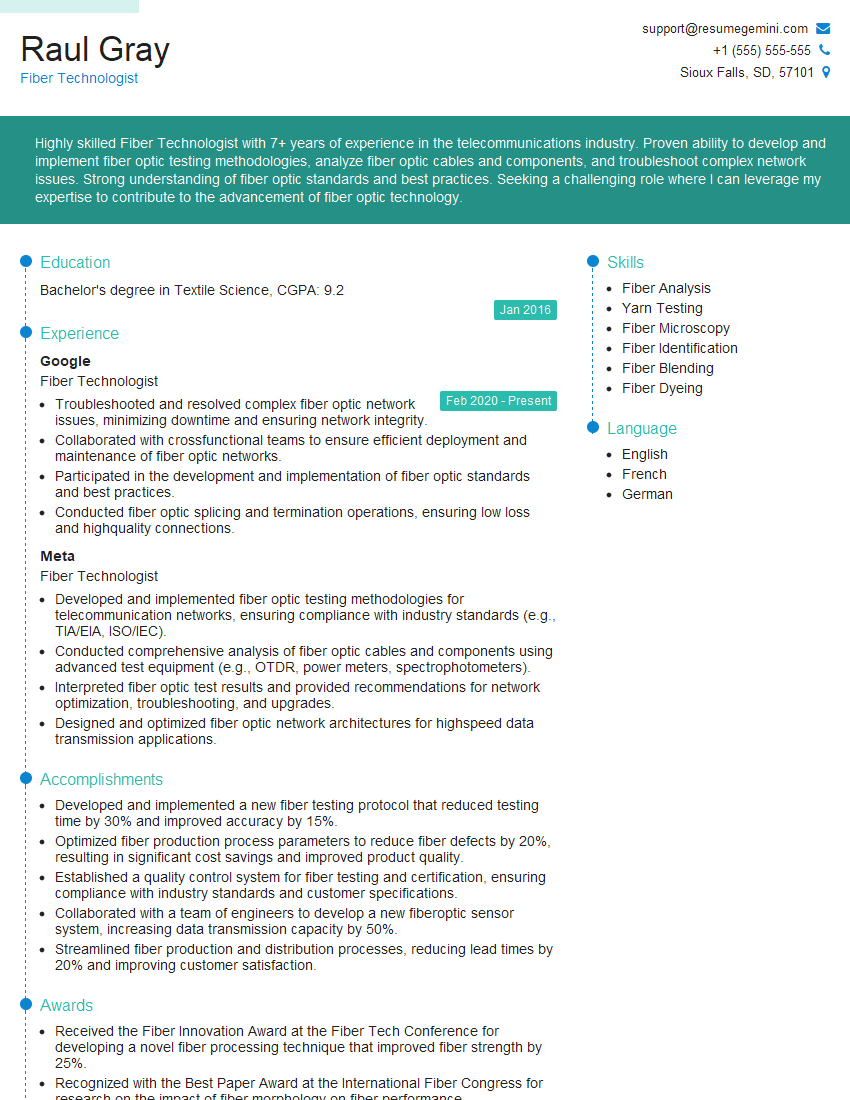

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different methods for removing cotton defects during processing.

Removing cotton defects is crucial for producing high-quality yarn. This is achieved through a series of methods applied at various stages of processing:

- Seed extraction (ginning): This initial stage removes seeds and a significant amount of trash. Modern gins utilize advanced technologies for efficient seed removal.

- Cleaning: This involves processes like lint cleaning, which uses air currents to separate light trash and dust. Other methods involve mechanical cleaning using saws or beaters to remove larger debris like leaves and sticks.

- Carding: This stage uses fine wire-covered cylinders to disentangle fibers and remove remaining impurities. The carding process also aligns fibers, improving yarn quality.

- Optical sorting: Advanced optical sorters use cameras and sensors to identify and remove colored impurities, nep, and other defects based on color, size, and shape. This is a highly effective method for removing defects that are difficult to remove by other means.

- Manual sorting: While less common in large-scale operations, manual sorting is still employed for very high-quality cotton, allowing for careful removal of subtle defects.

The choice of methods depends on the type and level of contamination in the raw cotton and the desired quality of the final product. A high-end product will undergo more rigorous cleaning and sorting than a lower-grade product.

Q 17. Explain the role of instrumentation in cotton quality control.

Instrumentation plays a vital role in ensuring cotton quality control throughout the entire process. High-precision instruments allow for objective measurements, reducing reliance on subjective visual assessments.

- Fiber length and strength testers: These instruments measure the length, strength, and uniformity of cotton fibers, crucial indicators of yarn quality. Examples include AFIS (Advanced Fiber Information System) and HVI (High Volume Instrument).

- Microscopic analysis: Microscopes are used to examine fiber maturity, fineness, and the presence of defects like neps and immature fibers.

- Colorimeters: These instruments measure the color of the cotton, important for assessing fiber uniformity and identifying colored impurities.

- Moisture meters: Precise measurement of moisture content is critical as it affects fiber processing and yarn quality.

- Trash analysis instruments: These tools are used to quantify the amount of different types of trash present in the cotton, allowing for targeted defect removal.

By using these instruments, we collect quantitative data that helps us monitor quality, identify trends, and make data-driven decisions to optimize processes and reduce waste. The data also serves as a crucial part of our quality reports to clients.

Q 18. What are the economic consequences of undetected cotton defects?

Undetected cotton defects can have significant economic consequences throughout the textile supply chain:

- Reduced yarn quality: Leading to lower yarn prices and decreased market value for the final product.

- Increased production costs: Higher rates of yarn breakage, machine stoppages, and reworking increase production time and expenses.

- Waste generation: Rejected yarn and fabric due to defects represent a significant loss of materials and resources.

- Damaged reputation: Delivering substandard products can severely damage a company’s reputation, leading to loss of contracts and customers.

- Legal issues: In extreme cases, severe defects might lead to lawsuits or claims from customers.

Imagine a scenario where a large shipment of cotton contains numerous hidden impurities. The resulting yarn may be weaker and prone to breakage, causing massive production losses and impacting the company’s ability to meet deadlines and fulfill orders. The financial repercussions could be substantial.

Q 19. How do you report your findings on cotton quality assessment?

Reporting findings on cotton quality assessment involves a structured and detailed approach. Our reports typically include:

- Detailed description of the cotton sample: Including origin, bale number, and other identifying information.

- Quantitative data: From various instruments such as AFIS, HVI, and other relevant testing equipment. This includes fiber length distribution, strength, uniformity, micronaire, color, and trash content.

- Visual assessments: Observations on the presence of specific defects (neps, leaf, seed coat fragments, etc.), along with their estimated frequency and severity.

- Statistical analysis: Summary statistics and graphs to illustrate the quality characteristics of the cotton sample.

- Interpretations and recommendations: Our assessment of the overall quality of the cotton, highlighting potential issues and suggesting processing adjustments to mitigate problems.

- Photographs and microscopic images: To visually showcase the defects and fiber characteristics.

We generate customized reports tailored to specific client needs, focusing on the information most relevant to their manufacturing process and quality standards.

Q 20. What are the industry standards for acceptable levels of cotton defects?

Industry standards for acceptable levels of cotton defects vary depending on the cotton grade, intended end-use, and customer requirements. However, there are established benchmarks and guidelines, often based on industry-standard tests like AFIS and HVI.

These standards might specify acceptable ranges for parameters like:

- Fiber length: Minimum average fiber length, uniformity index, and upper and lower limits of fiber length distribution.

- Strength: Minimum tensile strength of the fibers.

- Micronaire: A measure of fiber fineness, with acceptable ranges defined for different cotton types.

- Trash content: Maximum permissible levels of different types of trash.

- Nep count: Maximum acceptable number of neps per gram of cotton.

International organizations such as the International Cotton Advisory Committee (ICAC) and national standards bodies publish guidelines and specifications that guide the cotton industry. These standards continuously evolve with advancements in technology and changing consumer demands.

Q 21. Explain the use of optical sorting in cotton processing.

Optical sorting is a highly efficient and effective method for removing various defects from cotton during processing. It utilizes advanced image processing and machine vision techniques to identify and separate foreign matter, color variations, and other impurities.

The process typically involves:

- Feeding: The cotton is fed onto a conveyor belt or other suitable feeding system.

- Image capture: High-resolution cameras capture images of the cotton fibers as they pass by.

- Image processing: Advanced algorithms analyze the captured images to identify defects based on color, size, shape, and other visual characteristics. This often involves sophisticated pattern recognition techniques.

- Sorting: Based on the image analysis, a precise air jet or mechanical device removes the identified defects.

- Separation: The cleaned cotton is separated from the removed impurities.

Optical sorters are capable of handling large volumes of cotton at high speeds, significantly improving the quality and consistency of the final product. This technology is particularly useful for removing subtle defects that are difficult to detect manually, leading to significant improvements in yarn quality and reducing production costs by decreasing waste.

Q 22. Discuss the importance of traceability in managing cotton quality.

Traceability in cotton quality management is paramount. Think of it like a detective following a trail of clues to solve a mystery. Each step in the cotton’s journey, from planting to the final product, leaves a record. This record allows us to pinpoint the origin of any quality issues. For example, if a batch of yarn shows inconsistencies, traceability allows us to trace back to the specific field where the cotton was grown, the gin where it was processed, and even the specific harvesting equipment used. This granular level of information enables precise corrective actions and prevents future defects. Without traceability, identifying the source of a problem becomes a costly and time-consuming guessing game.

- Improved Quality Control: Quickly identify and isolate problematic batches.

- Enhanced Risk Management: Proactively address potential quality issues before they escalate.

- Better Supplier Relationships: Foster transparency and collaboration throughout the supply chain.

- Increased Efficiency: Streamline problem-solving and reduce waste.

Q 23. How do you handle discrepancies in cotton quality assessments?

Discrepancies in cotton quality assessments are inevitable. My approach involves a methodical investigation to identify the root cause. This often starts with a thorough review of the assessment methodologies used by different parties involved – ensuring standardization and calibration of equipment is key. Then, I cross-reference the results with other data points such as fiber testing reports, historical data for that specific cotton variety, and environmental records from the growing region. For instance, if there’s a significant difference in fiber length between two assessments, I’ll explore possibilities like variations in sampling techniques, errors in testing procedures, or even contamination during processing. If the discrepancies persist after careful analysis, I engage in open communication with all stakeholders to arrive at a consensus, potentially involving independent testing to resolve the conflict.

Sometimes, mediating between parties and explaining technical aspects to non-technical staff requires patience and clear communication. Ultimately, the goal is to reach a mutually agreed-upon assessment, documenting the process and learning from the experience to prevent similar future inconsistencies.

Q 24. What is your experience with different types of cotton fiber (e.g., upland, pima)?

My experience encompasses various cotton types, with a particular focus on upland and pima cotton. Upland cotton, the most widely grown variety, offers a balance of yield and quality, but its characteristics can vary significantly depending on growing conditions and processing. Pima cotton, on the other hand, is known for its exceptionally long, fine fibers, resulting in a luxurious and durable fabric. I’ve worked extensively with both, understanding their unique properties and how these influence quality parameters like fiber length, strength, micronaire (fiber fineness), and color. This knowledge allows me to tailor quality control measures to the specific cotton type being processed, leading to better yield and product quality. For example, I understand the different optimal spinning parameters for each type, considering factors like twist and tension to mitigate the risk of defects during yarn production.

Q 25. How do environmental factors influence cotton quality?

Environmental factors significantly impact cotton quality. Think of it as a plant’s response to its surroundings. Factors such as rainfall, temperature, and sunlight directly influence fiber development. Insufficient rainfall can lead to shorter, weaker fibers, whereas extreme heat can cause fiber damage and discoloration. Pests and diseases are also significantly influenced by the environment; humid conditions, for instance, favor the growth of certain fungal diseases, negatively impacting fiber quality. Soil conditions, including nutrient levels and soil pH, play a vital role in plant health and fiber development. I’ve seen firsthand how unpredictable weather patterns can affect yield and quality. For instance, a sudden hailstorm during a crucial growth stage can severely damage the cotton bolls, resulting in reduced yield and lower quality fibers. Hence, environmental monitoring and data analysis are critical for predicting potential quality issues and adjusting farming practices accordingly.

Q 26. Explain your experience with using statistical process control in cotton quality.

Statistical Process Control (SPC) is a cornerstone of my quality control approach. I use SPC techniques like control charts (e.g., X-bar and R charts) to monitor key quality parameters such as fiber length, strength, and micronaire throughout the cotton processing stages. By plotting these data points over time, I can identify trends and variations that deviate from established standards. For example, if a control chart shows a pattern of increasing fiber breakage, it alerts me to a potential problem in the ginning process. This allows for timely intervention, preventing a large number of defective fibers from reaching the textile mill and impacting downstream processes. SPC also helps to identify the assignable causes of variation, enabling more efficient troubleshooting and improvement efforts.

I use software such as Minitab for data analysis and charting. Example: A control chart showing fiber length exceeding the upper control limit would indicate a need for process adjustment.

Q 27. Describe a time you successfully identified and resolved a significant cotton defect.

During a large-scale cotton processing operation, we noticed an unusually high rate of neps (small entangled fiber clusters) in the final product. This defect significantly reduced the quality of the yarn and could lead to substantial financial losses. My team and I conducted a detailed investigation across all stages of processing. Initially, we suspected issues in the ginning process. However, after analyzing data from different gins, we discovered that the issue originated from the harvesting method. A new harvesting machine, intended to improve efficiency, was found to be causing excessive fiber damage resulting in increased nep formation. We implemented immediate corrective actions, including adjusting the machine settings and retraining the operators. We also introduced a new quality control check at the harvesting stage. This problem resolution resulted in a significant reduction in neps and saved the company considerable financial losses. It also showcased the importance of meticulous data analysis and the value of collaborative teamwork in solving complex quality control challenges.

Q 28. How do you stay updated on the latest advancements in cotton quality control technology?

Staying updated on advancements in cotton quality control technology is a continuous process. I regularly attend industry conferences and workshops, subscribe to relevant industry journals and publications, and actively participate in online forums and communities. I also engage with equipment suppliers and research institutions to learn about the latest technologies in fiber testing, image analysis, and automation. For example, I’ve recently been researching advanced fiber testing technologies, such as high-volume instrument (HVI) systems, and the use of machine learning algorithms for defect detection in high-resolution images of cotton fibers. This ensures that I am aware of new advancements and can adopt them to improve the efficiency and accuracy of our quality control procedures.

Key Topics to Learn for Ability to Identify and Resolve Cotton Defects Interview

- Cotton Fiber Properties: Understanding fiber length, strength, fineness, maturity, and uniformity; their impact on yarn and fabric quality.

- Common Cotton Defects: Identifying and classifying various defects like nep, leaf, trash, short fiber, weak fiber, and discoloration; understanding their causes and consequences.

- Visual Inspection Techniques: Mastering the art of visually assessing cotton samples for defects; utilizing appropriate lighting and magnification tools.

- Instrumental Testing Methods: Familiarizing yourself with common testing instruments like the HVI system (High Volume Instrument) and their role in quantitative defect analysis.

- Defect Grading and Classification Systems: Understanding industry-standard grading systems and their application in assessing cotton quality and pricing.

- Problem-Solving and Root Cause Analysis: Applying analytical skills to identify the root causes of cotton defects within the production process, from farming to processing.

- Quality Control Procedures: Understanding and applying quality control measures to minimize defects and maintain consistent cotton quality throughout the supply chain.

- Communication and Collaboration: Effectively communicating defect findings and recommendations to colleagues, supervisors, and clients.

- Continuous Improvement Strategies: Identifying opportunities for improvement in defect detection and resolution processes.

Next Steps

Mastering the ability to identify and resolve cotton defects is crucial for career advancement in the textile industry. It demonstrates a strong understanding of quality control, problem-solving, and technical expertise, leading to increased responsibilities and higher earning potential. To significantly boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini can help you build a professional and effective resume that highlights your skills and experience in this specialized area. We offer examples of resumes tailored to showcase expertise in identifying and resolving cotton defects, giving you a head start in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good