Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Expert in Developing and Implementing Quality Control Programs interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Expert in Developing and Implementing Quality Control Programs Interview

Q 1. Describe your experience developing and implementing quality control programs.

My experience in developing and implementing quality control programs spans over a decade, encompassing various industries including manufacturing, pharmaceuticals, and software development. I’ve led teams in designing and deploying comprehensive QC programs from the ground up, focusing on preventative measures as much as reactive problem-solving. For example, in a manufacturing setting, I spearheaded a project to reduce defect rates in a critical assembly process. This involved implementing a robust inspection protocol at each stage, using statistical process control (SPC) charts to monitor key parameters, and conducting regular operator training to improve their understanding of quality standards. The result was a 30% reduction in defects and a significant improvement in overall product quality and customer satisfaction.

In the pharmaceutical industry, I was instrumental in developing a quality control system that ensured compliance with Good Manufacturing Practices (GMP) and regulatory requirements. This involved creating detailed Standard Operating Procedures (SOPs), implementing a robust documentation system, and establishing a comprehensive audit trail. My approach always prioritizes a risk-based methodology, focusing resources on the areas with the highest potential for defects or non-compliance. This strategic approach ensures efficiency and maximized impact.

Q 2. Explain your understanding of ISO 9001 standards.

ISO 9001 is an internationally recognized standard that outlines requirements for a quality management system (QMS). It’s a framework that helps organizations consistently meet customer and regulatory requirements. My understanding encompasses the entire scope of the standard, including its core principles such as customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management. I’m experienced in leading ISO 9001 certification audits and ensuring ongoing compliance. The standard is not just a checklist, but a philosophy that permeates every aspect of an organization’s operations. For instance, a key aspect is the documented process approach – mapping out the critical steps in each operational area to pinpoint potential quality issues and proactively address them.

I also understand the iterative nature of the standard; continual improvement is paramount. Regular internal audits, management reviews, and corrective actions are essential for demonstrating continuous compliance and striving for better performance. I’ve successfully guided several organizations through ISO 9001 certification and helped them sustain compliance over extended periods.

Q 3. How do you identify and prioritize quality control issues?

Identifying and prioritizing quality control issues is a systematic process. It begins with data collection from various sources: customer feedback, internal inspections, defect reports, and production data. I employ several techniques including Pareto charts (to identify the ‘vital few’ problems contributing to the majority of defects), control charts (to monitor process stability), and root cause analysis (to understand the underlying causes of issues). For example, if customer feedback reveals consistent issues with a particular product feature, we’d use Pareto charts to determine the specific aspect causing the most problems, then conduct a root cause analysis to understand why that issue is recurring.

Prioritization is based on several factors: the severity of the impact on the customer, the frequency of the issue, and the potential financial or reputational risks. We use a risk assessment matrix to weigh these factors and prioritize issues accordingly. High-risk, frequent issues always take precedence, while less critical issues are addressed as resources allow. This risk-based approach ensures we focus on the issues with the biggest impact first.

Q 4. What methods do you use to measure the effectiveness of quality control programs?

Measuring the effectiveness of quality control programs involves a multi-faceted approach. Key performance indicators (KPIs) are crucial, and these can include defect rates, customer complaints, the cost of quality (including prevention, appraisal, internal failure, and external failure costs), and compliance audit results. We use these metrics to track progress and identify areas for improvement. For example, a reduction in the defect rate over time demonstrates the effectiveness of preventative measures, while a decrease in customer complaints indicates improved product quality and customer satisfaction.

Regular audits, both internal and external, are also essential for evaluating the effectiveness of the QC program. These audits assess compliance with standards, procedures, and regulatory requirements. Furthermore, continuous feedback from employees involved in the processes is important to identify blind spots and areas needing improvement. Regular review meetings, involving key stakeholders from across the organization, help assess overall program performance and to identify needed changes and adjustments.

Q 5. How do you handle non-conforming materials or processes?

Handling non-conforming materials or processes requires a structured approach that ensures customer safety and protects the company’s reputation. The first step is to immediately isolate and quarantine the non-conforming items to prevent further processing or use. A thorough investigation then ensues to determine the root cause of the non-conformity. This often involves detailed analysis of process parameters, material properties, and operator actions. Depending on the severity and nature of the non-conformity, several actions may be undertaken.

Options include rework or repair of the non-conforming items, scrap disposal, or concession (allowing the use of non-conforming items with appropriate approval and risk mitigation). A detailed report is documented detailing the non-conformity, root cause analysis, corrective actions taken, and preventative measures implemented to prevent recurrence. This entire process is closely monitored and reviewed to ensure continuous improvement and to prevent similar issues in the future. We maintain a robust system for tracking non-conformances, which informs continuous improvement efforts.

Q 6. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a crucial tool in my quality control arsenal. I have extensive experience in applying SPC methods, including control charts (like X-bar and R charts, p-charts, and c-charts), to monitor process variation and identify potential problems before they escalate. For example, in a manufacturing setting, we use X-bar and R charts to monitor the dimensions of a critical component. If the data points fall outside the control limits, it signals a potential shift in the process that requires investigation and corrective action. This allows for early detection of issues, reducing waste and improving overall product quality.

My experience also includes capability analysis, which helps assess the process’s ability to meet specifications. This data informs decisions about process improvements and helps determine whether the process is capable of consistently producing products that meet customer requirements. I’m proficient in using statistical software packages such as Minitab to analyze data and generate control charts. A thorough understanding of statistical principles is essential to effectively interpret the results and make informed decisions.

Q 7. What are your preferred tools and techniques for root cause analysis?

Root cause analysis is a cornerstone of effective quality control. My preferred tools and techniques include the ‘5 Whys,’ Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis (FTA). The ‘5 Whys’ is a simple yet effective method for iteratively drilling down to the root cause of a problem by repeatedly asking ‘why’ until the fundamental reason is uncovered. For instance, if a product fails, we might ask: ‘Why did it fail? Because a component broke. Why did the component break? Because it was improperly manufactured. Why was it improperly manufactured? Because the machine was misaligned. Why was the machine misaligned? Because it wasn’t properly maintained.’ This process reveals the underlying maintenance issue as the root cause.

Fishbone diagrams help visualize potential causes of a problem by categorizing them (e.g., people, methods, machines, materials, environment, measurement). FTA is useful for complex systems where multiple factors contribute to a failure. By understanding the root cause, we can develop effective corrective and preventative actions to eliminate the problem permanently. Selecting the appropriate tool depends on the complexity of the issue and the available data. Regardless of the tool used, the goal is always to identify the fundamental problem and not just the symptoms.

Q 8. How do you develop and maintain quality control documentation?

Developing and maintaining quality control documentation is crucial for ensuring consistent product or service quality and regulatory compliance. It’s like a recipe book for producing excellence; without it, your process is prone to inconsistencies and errors.

My approach involves creating a comprehensive documentation system that includes:

- Standard Operating Procedures (SOPs): Detailed step-by-step instructions for all key processes, ensuring everyone follows the same procedures consistently. For example, an SOP for conducting a specific laboratory test would outline every step, from sample preparation to data analysis.

- Checklists and Forms: These streamline data collection and verification, ensuring nothing is missed during inspections or audits. A checklist for a machine inspection, for instance, would list all critical components needing verification.

- Quality Records: These document all quality-related activities, including inspection results, corrective actions, and preventative measures. These records serve as evidence of compliance and aid in continuous improvement.

- Control Charts and Statistical Data: These graphically present data trends, allowing for early detection of potential problems. A control chart for a manufacturing process, for example, would visualize the variation in a critical dimension over time.

- Training Materials: Ensuring everyone understands the procedures and the importance of quality. This could include manuals, presentations, or hands-on training sessions.

I utilize a version control system (like SharePoint or a dedicated document management system) to track changes, ensure everyone has access to the latest versions, and maintain a clear audit trail.

Q 9. Explain your experience with quality audits and inspections.

Quality audits and inspections are the cornerstone of any effective quality control program. They’re like a health check for your processes, identifying potential weaknesses before they lead to major problems. My experience spans various industries, including manufacturing and healthcare, where I’ve conducted both internal and external audits.

Internal Audits: I lead teams in conducting regular internal audits, focusing on process adherence, documentation review, and corrective action effectiveness. We use checklists and sampling techniques to ensure comprehensive coverage. For example, in a manufacturing setting, we’d audit the calibration of equipment, the accuracy of measurements, and adherence to safety protocols.

External Audits: I’ve collaborated with external auditors, providing evidence of compliance and addressing their findings. This experience has honed my ability to anticipate auditor expectations and proactively identify and address potential non-conformances.

Inspections: I’m experienced in various inspection techniques, including visual inspections, dimensional measurements, and material testing. For example, in a pharmaceutical setting, I’ve performed visual inspections of finished products for defects and conducted sterility testing.

My audits and inspections always aim to be objective, factual, and constructive, focusing on improving processes and preventing future defects, not just finding fault.

Q 10. How do you ensure compliance with regulatory requirements?

Ensuring compliance with regulatory requirements is paramount. It’s about playing by the rules and ensuring the safety and quality of products and services. Non-compliance can have significant legal and financial ramifications.

My approach to regulatory compliance involves:

- Thorough Knowledge of Regulations: Staying updated on all relevant regulations, such as ISO 9001, FDA guidelines, or industry-specific standards. This requires continuous learning and participation in professional development activities.

- Implementation of Compliance Programs: Developing and implementing programs to address specific regulatory requirements. This includes creating documented procedures, training employees, and establishing a robust audit program.

- Document Control: Maintaining a well-organized and easily accessible system for all regulatory documents. This ensures that the latest versions of regulations and procedures are readily available to all employees.

- Regular Audits and Inspections: Conducting regular internal audits to assess compliance with regulations and identify areas for improvement. This involves using checklists and templates specific to regulatory requirements.

- Proactive Risk Assessment: Identifying potential compliance risks and implementing appropriate preventive measures. This is a proactive approach that aims to prevent non-compliance before it occurs.

I consider regulatory compliance not merely a checklist but an integral part of our quality management system, woven into every aspect of our operations.

Q 11. Describe your experience with continuous improvement methodologies (e.g., Kaizen, Lean).

Continuous improvement methodologies, like Kaizen and Lean, are essential for staying competitive and exceeding customer expectations. They’re about consistently looking for ways to enhance efficiency and quality. It’s like constantly refining a machine to make it run faster and smoother.

My experience with Kaizen involves facilitating workshops, identifying waste in processes (muda), and implementing small, incremental improvements. For instance, in one project, we streamlined a manufacturing process by reorganizing workstations, reducing movement and improving workflow. This resulted in a significant reduction in production time and defect rate.

With Lean principles, I’ve focused on eliminating waste throughout the entire value stream, from design to delivery. This often involves mapping out processes, identifying bottlenecks, and implementing solutions such as just-in-time inventory management. For example, we once reduced lead times by optimizing the supply chain and improving communication between departments.

Both methodologies emphasize data-driven decision-making and employee involvement. I encourage team participation in identifying problems and suggesting solutions, creating a culture of continuous improvement.

Q 12. How do you manage and motivate a quality control team?

Managing and motivating a quality control team requires strong leadership, clear communication, and a focus on development. It’s about building a team that’s not only skilled but also engaged and empowered.

My approach centers on:

- Clear Goals and Expectations: Setting clear performance goals, ensuring everyone understands their role and responsibilities. Regular performance reviews help monitor progress and provide feedback.

- Empowerment and Ownership: Giving team members autonomy and ownership over their work, encouraging initiative and problem-solving. This builds confidence and increases job satisfaction.

- Training and Development: Providing opportunities for professional development, ensuring the team stays current with best practices and new technologies. This could include attending conferences, workshops, or online courses.

- Open Communication: Fostering open and honest communication within the team. Regular team meetings, feedback sessions, and open-door policies help address concerns and build trust.

- Recognition and Reward: Recognizing and rewarding excellent performance, both individually and as a team. This could include bonuses, promotions, or simply acknowledging achievements publicly.

Ultimately, my goal is to create a positive and productive work environment where team members feel valued, respected, and motivated to contribute their best.

Q 13. How do you communicate quality control issues to management and other stakeholders?

Communicating quality control issues effectively is critical for preventing problems from escalating. It requires clear, concise communication tailored to the audience.

My approach involves:

- Prompt Reporting: Reporting issues promptly and accurately, using a standardized system for reporting and tracking non-conformances.

- Data-Driven Approach: Presenting data clearly and objectively, avoiding emotional or subjective language. Using graphs, charts, and other visuals can improve understanding.

- Targeted Communication: Tailoring the message to the audience. A brief summary might suffice for upper management, while a more detailed report might be necessary for the team responsible for corrective actions.

- Root Cause Analysis: Presenting a root cause analysis along with the problem, demonstrating an understanding of the underlying causes and proposed solutions.

- Actionable Recommendations: Providing clear and actionable recommendations for corrective and preventative actions. This should include timelines, responsibilities, and measurable outcomes.

I often use various communication channels, including email, presentations, and team meetings, to ensure effective dissemination of information.

Q 14. Describe a time you had to resolve a significant quality control problem.

In a previous role, we experienced a significant increase in customer complaints regarding a specific product. Initially, we thought it was isolated incidents, but the number kept climbing. This was concerning, as customer satisfaction is crucial to our success.

My first step was to assemble a cross-functional team, including representatives from production, quality control, engineering, and customer service. We conducted a thorough investigation, utilizing data analysis to identify patterns and potential root causes. This involved reviewing production records, customer feedback, and conducting additional testing on the product.

We discovered the problem stemmed from a recent change in a key component supplier. The new component didn’t meet our specifications, resulting in a higher failure rate. We immediately implemented corrective actions: we stopped using the faulty component, switched back to the previous supplier, and implemented a more rigorous incoming inspection process for all components.

We also implemented a communication plan to update customers, assuring them of our commitment to quality and providing updates on our corrective actions. This involved proactively contacting customers and providing updates. The result? Customer satisfaction recovered, and we strengthened our quality control procedures, preventing similar issues in the future.

Q 15. What are your experience with different quality control methodologies (e.g., Six Sigma, TQM)?

My experience encompasses a wide range of quality control methodologies, with significant expertise in Six Sigma and Total Quality Management (TQM). Six Sigma, with its DMAIC (Define, Measure, Analyze, Improve, Control) methodology, is a data-driven approach focusing on minimizing process variation and defects. I’ve successfully led projects using Six Sigma to reduce production errors by over 70% in a previous role. TQM, on the other hand, is a more holistic approach, aiming for continuous improvement across all aspects of an organization. I’ve implemented TQM principles in several organizations, fostering a culture of quality awareness and employee empowerment. Beyond these, I’m also familiar with Lean manufacturing, Kaizen events, and Statistical Process Control (SPC), adapting my approach based on the specific needs of each project.

For example, in one project using Six Sigma, we identified a bottleneck in the assembly line. Using data analysis, we pinpointed the root cause – a faulty component – and implemented a solution which improved cycle time by 15% and reduced defects by 20%.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure customer satisfaction related to product quality?

Measuring customer satisfaction related to product quality requires a multifaceted approach. We use a combination of methods, including surveys (both online and offline), focus groups, feedback forms, and analyzing warranty claims and customer service interactions. Customer satisfaction surveys can be specifically designed to target key quality attributes, allowing us to understand customer perception of specific features and performance levels. Analyzing warranty claims provides a powerful insight into the actual failure rates of products and often reveals underlying quality issues. We use statistical methods to analyze this data, identifying trends and patterns that inform improvements in our processes and products.

For instance, we may ask customers to rate the product’s ease of use, durability, and overall performance on a scale of 1 to 5. This structured data enables quantitative analysis. Focus groups offer richer qualitative data, providing valuable insight into the customer experience and their reasons for satisfaction or dissatisfaction. The combination of quantitative and qualitative data provides a comprehensive picture of customer perception of product quality.

Q 17. Explain your understanding of different types of quality control charts (e.g., control charts, Pareto charts).

Control charts are graphical tools used to monitor process performance over time and detect any deviations from acceptable limits. Different types of control charts exist, such as X-bar and R charts (for continuous data) and p-charts (for proportions). They visually display data points, central tendency (mean), and control limits (upper and lower control limits). Points outside these limits suggest potential problems needing investigation. Pareto charts, on the other hand, are bar charts that rank the causes of defects or problems based on their frequency. They’re particularly useful in identifying the ‘vital few’ causes that contribute to the majority of problems, allowing us to focus our improvement efforts strategically.

Imagine using an X-bar and R chart to track the weight of a product. Consistent points within the control limits indicate stability. A point outside the limits signals a potential issue, prompting investigation into factors like machine malfunction or raw material variations. A Pareto chart might reveal that 80% of product returns are due to just two defects, leading to prioritized corrective actions for these specific causes.

Q 18. How do you balance the cost of quality control with the risk of defects?

Balancing the cost of quality control with the risk of defects requires a careful cost-benefit analysis. The cost of quality includes prevention costs (training, planning, quality improvement projects), appraisal costs (inspection, testing), and failure costs (internal and external failures). The risk of defects, on the other hand, encompasses potential financial losses, reputational damage, and safety hazards. A key approach is to shift the focus towards preventative measures rather than solely reactive failure remediation. Investing in robust processes and training often pays off by significantly reducing long-term costs due to failures.

For example, investing in automated testing might seem expensive upfront but prevents costly recalls and lost revenue due to undetected defects. A proactive approach to risk management uses risk assessment matrices to prioritize preventative actions based on the likelihood and impact of potential failures. We use this approach to determine optimal investment levels for various quality control activities.

Q 19. What is your experience with implementing quality management systems (QMS)?

I have extensive experience in implementing Quality Management Systems (QMS), primarily based on ISO 9001 standards. This involves a structured approach encompassing documentation of processes, establishing quality objectives, conducting regular internal audits, and managing corrective actions. My experience includes all stages, from gap analysis and initial implementation to ongoing maintenance and improvement of the QMS. This includes training personnel, adapting the QMS to specific organizational needs, and ensuring its ongoing effectiveness. A successful QMS implementation requires strong leadership commitment, employee engagement, and continuous improvement mindset.

In a previous role, we successfully implemented ISO 9001, leading to improved efficiency, enhanced customer satisfaction, and enhanced compliance. The implementation involved thorough documentation, employee training, and regular audits to ensure compliance with the standard’s requirements. The results speak for themselves, including reduced production errors and increased customer satisfaction.

Q 20. How do you use data to drive quality control decisions?

Data is the cornerstone of effective quality control decision-making. I utilize data analysis techniques across various stages, from identifying root causes of defects to tracking the effectiveness of implemented improvements. This includes collecting data from various sources such as production records, inspection reports, customer feedback, and warranty claims. Statistical tools like control charts, histograms, and regression analysis are crucial for interpreting this data. Data-driven decision-making ensures objective assessment and facilitates data-backed quality improvements.

For instance, by analyzing production data, we can pinpoint specific times when defect rates increase, allowing us to investigate the underlying causes such as operator fatigue or machine malfunction. We might use regression analysis to determine the relationship between process parameters and defect rates, helping us to optimize processes for improved quality.

Q 21. Describe your experience with quality control in a specific industry.

My experience in the pharmaceutical industry provided invaluable experience in quality control, given the stringent regulatory requirements and high stakes associated with patient safety. This involved implementing and maintaining stringent quality control procedures for raw materials, manufacturing processes, and finished products. This included comprehensive testing protocols, rigorous documentation, and adherence to Good Manufacturing Practices (GMP). I was involved in the validation of manufacturing equipment and processes, ensuring compliance with regulatory standards. A key aspect of this role was risk assessment and mitigation, particularly concerning potential contamination and product defects.

A specific project involved optimizing a sterilization process to reduce the risk of bacterial contamination. By implementing a modified sterilization cycle and rigorous testing, we achieved a significant reduction in contamination rates without affecting product efficacy or increasing manufacturing costs. This reinforced the importance of data-driven decision-making in improving quality in highly regulated environments.

Q 22. How do you ensure the accuracy and reliability of quality control data?

Ensuring accurate and reliable quality control data is paramount. It’s like building a house – you can’t have a strong foundation with shaky measurements. We achieve this through a multi-pronged approach:

- Calibration and Validation: All measuring equipment undergoes regular calibration against traceable standards. We also validate our testing methods to ensure they accurately reflect the desired quality characteristics. For instance, if we’re measuring the tensile strength of a material, we’d validate our testing machine against a known standard to ensure its readings are accurate.

- Data Integrity Procedures: This includes clear documentation protocols, chain-of-custody tracking for samples, and rigorous data entry procedures. We use systems that minimize manual data entry and incorporate automated checks to flag inconsistencies. Think of it like a secure audit trail, ensuring transparency and traceability.

- Statistical Process Control (SPC): SPC uses statistical methods to monitor processes and identify variations. Control charts, for example, visually represent data patterns, helping us detect deviations from the norm early on. This allows us to take corrective action before problems escalate, preventing defects from reaching the customer.

- Internal Audits and Checks: Regular internal audits verify the effectiveness of our quality control systems and identify areas for improvement. This process mimics an external audit, challenging assumptions and reinforcing consistent practices.

- Training and Competence: We invest heavily in training personnel on proper data collection, analysis, and reporting techniques. Competent personnel are crucial to ensuring the reliability of the data.

By implementing these strategies, we establish a robust system that guarantees high confidence in the accuracy and reliability of our quality control data.

Q 23. What are your skills in using quality control software?

My experience encompasses a range of quality control software, including Minitab (for statistical analysis and SPC), JMP (for more advanced statistical modeling and visualization), and enterprise resource planning (ERP) systems with integrated QC modules. I’m proficient in using these tools to:

- Analyze data: Conducting statistical analysis like hypothesis testing, ANOVA, and regression analysis to identify trends and root causes of quality issues.

- Create control charts: Developing and interpreting control charts (X-bar and R charts, p-charts, c-charts etc.) to monitor process stability.

- Generate reports: Creating clear and concise reports summarizing quality data and presenting findings to stakeholders.

- Manage data: Effectively organizing and managing large datasets using database functions in the various software.

Beyond specific software, I possess a strong understanding of data analysis principles and can adapt quickly to new tools and technologies. My approach prioritizes using the right tool for the job, leveraging the capabilities of each software to maximize efficiency and accuracy.

Q 24. How do you stay current with best practices in quality control?

Staying current with best practices is vital in the ever-evolving field of quality control. I actively pursue this through several avenues:

- Professional Organizations: I’m a member of [mention relevant professional organizations, e.g., ASQ], attending conferences and workshops to learn about the latest advancements and industry trends. These events provide networking opportunities and exposure to innovative solutions.

- Industry Publications and Journals: I regularly read publications such as Quality Progress and other peer-reviewed journals to stay abreast of research and best practices. These resources provide valuable insights into new methodologies and technologies.

- Online Courses and Webinars: I leverage online platforms like Coursera, edX, and others to take courses on advanced quality control techniques and software applications. This allows for flexible learning that fits my schedule.

- Networking: Engaging with colleagues and professionals in the field through industry events and online forums fosters the exchange of knowledge and ideas. Learning from others’ experiences is invaluable.

This proactive approach ensures I’m equipped with the most up-to-date knowledge and techniques to deliver the highest quality work.

Q 25. Explain your understanding of risk assessment and mitigation in quality control.

Risk assessment and mitigation are integral to effective quality control. It’s like anticipating potential hazards before they happen, not just reacting after the damage is done. My approach involves:

- Identifying Potential Risks: This involves systematically analyzing the entire process, from raw materials to finished product, pinpointing potential points of failure. Techniques like Failure Mode and Effects Analysis (FMEA) are invaluable in identifying potential risks and their likelihood of occurrence.

- Assessing Risk Severity: Once identified, risks are assessed based on their potential impact and probability. A risk matrix helps categorize risks based on severity and likelihood.

- Developing Mitigation Strategies: Based on the risk assessment, we develop strategies to reduce or eliminate the risk. These strategies might include implementing new controls, improving existing processes, or implementing preventative measures.

- Monitoring and Review: The effectiveness of the mitigation strategies is monitored regularly, and the risk assessment is reviewed periodically to accommodate changes in the process or environment.

For example, in a food manufacturing plant, a risk might be bacterial contamination. Mitigation strategies could include implementing stringent hygiene protocols, regular sanitation checks, and temperature monitoring systems. Regular reviews ensure that these controls remain effective.

Q 26. How do you handle conflict between quality control and production goals?

Conflicts between quality control and production goals are common, but avoidable with proactive communication and collaboration. It’s crucial to remember that quality control isn’t an impediment to production; it’s an enabler of long-term success. My strategy focuses on:

- Defining Clear Expectations: Collaboration starts with setting clear, shared expectations and goals. Open communication channels ensure that both teams understand the overall objectives and their respective roles.

- Data-Driven Decision Making: When conflicts arise, data should guide the discussion. Presenting quality data clearly and objectively can help resolve discrepancies and support necessary changes.

- Finding Common Ground: The focus is on finding solutions that satisfy both quality and production goals. For example, investing in automation or process improvements can enhance efficiency and reduce defects simultaneously.

- Proactive Communication: Regular meetings and open communication channels keep both teams informed and aligned. Early identification of potential conflicts prevents escalation.

- Negotiation and Compromise: Sometimes, compromise is necessary. A collaborative approach ensures that both teams feel heard and respected.

Ultimately, viewing quality control and production as partners rather than adversaries facilitates a mutually beneficial relationship.

Q 27. What is your experience with supplier quality management?

My experience in supplier quality management involves establishing and maintaining relationships with suppliers to ensure consistent quality of materials and services. This is about building trust and collaboration, not just auditing. My approach includes:

- Supplier Selection and Qualification: Rigorous qualification processes are employed to assess suppliers’ capabilities and their commitment to quality. This includes auditing their facilities and reviewing their quality systems.

- Ongoing Monitoring and Audits: Regular audits and performance monitoring ensure continued compliance with quality standards. Corrective actions are put in place to address any deficiencies found.

- Performance Measurement: Key Performance Indicators (KPIs) such as defect rates, on-time delivery, and compliance with specifications are used to track supplier performance. This data is used to manage and improve supplier relationships.

- Collaborative Problem Solving: A collaborative approach focuses on working with suppliers to identify and resolve quality issues rather than simply blaming them. This approach fosters mutually beneficial improvement.

- Continuous Improvement: Promoting a culture of continuous improvement among suppliers helps them enhance their processes and deliver higher quality products or services.

In one instance, working with a key supplier facing persistent delivery delays, we implemented a collaborative process improvement project. By analyzing their supply chain and suggesting operational efficiencies, we not only improved their on-time delivery but also reduced their overall costs, resulting in a win-win situation.

Q 28. How do you measure the return on investment (ROI) of quality control initiatives?

Measuring the ROI of quality control initiatives requires a multifaceted approach, going beyond simple cost savings. We look at both tangible and intangible benefits. Here’s how we do it:

- Cost Reduction: Quantifying the reduction in costs due to fewer defects, less rework, reduced waste, and lower warranty claims. We compare the cost of quality control initiatives with the cost savings achieved.

- Improved Efficiency: Measuring improvements in productivity and cycle times resulting from streamlined processes and enhanced efficiency. This involves measuring things like production output per unit of time, resource utilization, and process cycle times.

- Increased Customer Satisfaction: Tracking increases in customer satisfaction ratings and loyalty due to improved product quality. This can be measured through customer surveys, feedback forms, and return rate analysis.

- Reduced Risk: Quantifying the reduction in risks associated with product liability, safety recalls, and reputational damage. We might assess this by comparing historical recall rates with current rates, or by developing scenarios.

- Improved Employee Morale: Measuring improvements in employee morale and engagement, recognizing that a culture of quality fosters job satisfaction. This is done through engagement surveys and anecdotal evidence.

By carefully tracking and analyzing these factors, we can build a compelling case for the ROI of quality control initiatives, demonstrating their value to the organization beyond just financial metrics.

Key Topics to Learn for Expert in Developing and Implementing Quality Control Programs Interview

- Defining Quality Standards: Understanding various quality management frameworks (ISO 9001, Six Sigma, etc.) and their application to different industries. Learn to articulate how to define measurable quality standards specific to a given context.

- Developing and Implementing QC Programs: Mastering the process of designing, documenting, and deploying effective QC programs. This includes understanding risk assessment, process mapping, and the development of robust control charts and metrics.

- Statistical Process Control (SPC): Gain a strong grasp of statistical methods for monitoring and controlling processes. Practice interpreting control charts, understanding capability analysis, and applying appropriate statistical tests.

- Root Cause Analysis (RCA): Become proficient in identifying the root causes of quality issues using techniques like the 5 Whys, Fishbone diagrams, and Pareto analysis. Be prepared to discuss your experience in implementing corrective and preventative actions.

- Quality Auditing and Reporting: Understand the process of conducting internal and external audits, interpreting audit findings, and preparing comprehensive quality reports for stakeholders. Showcase your ability to communicate complex technical information clearly and concisely.

- Continuous Improvement Methodologies: Demonstrate familiarity with Lean principles, Kaizen events, and other continuous improvement methodologies. Highlight your experience in implementing improvements and measuring their effectiveness.

- Quality Management Systems (QMS): Understand the principles of a robust QMS and your role in maintaining and improving it. Be prepared to discuss your experience in documentation control, change management, and internal communication within a QMS.

- Problem-Solving and Decision-Making: Showcase your analytical and problem-solving skills. Prepare examples of how you have identified, analyzed, and resolved quality-related issues in past roles.

Next Steps

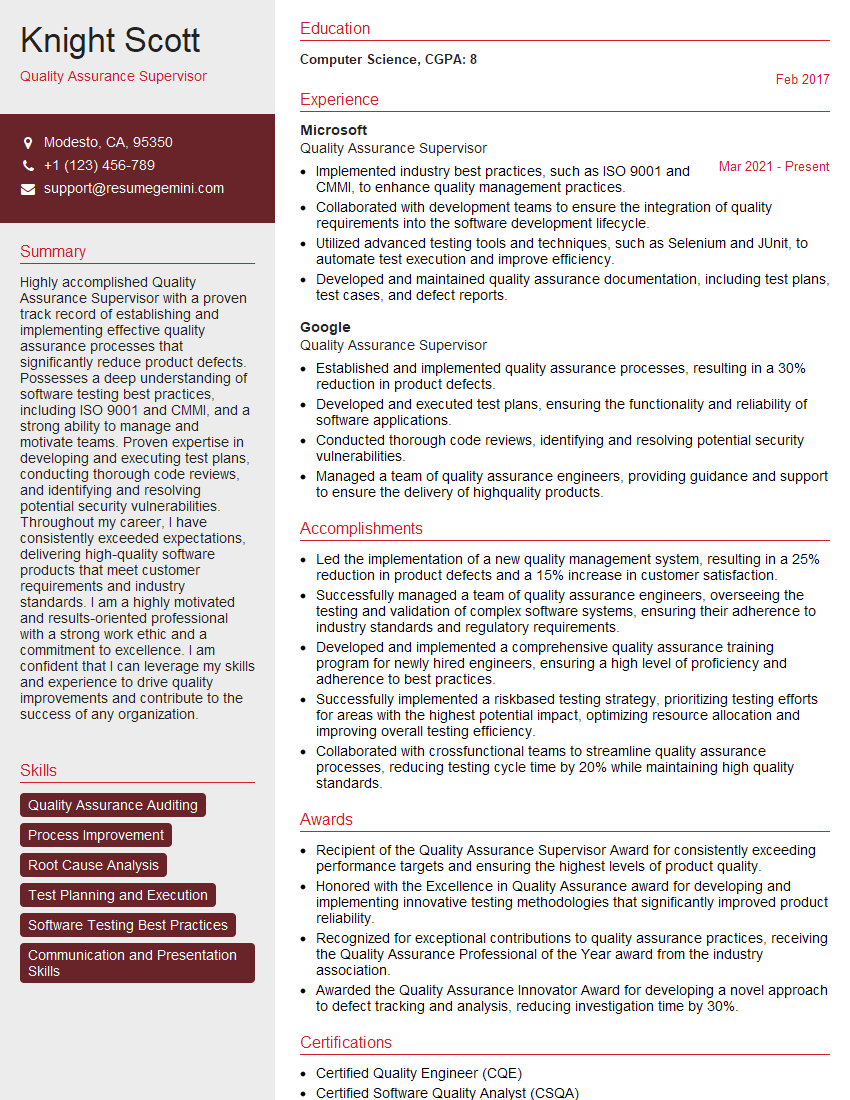

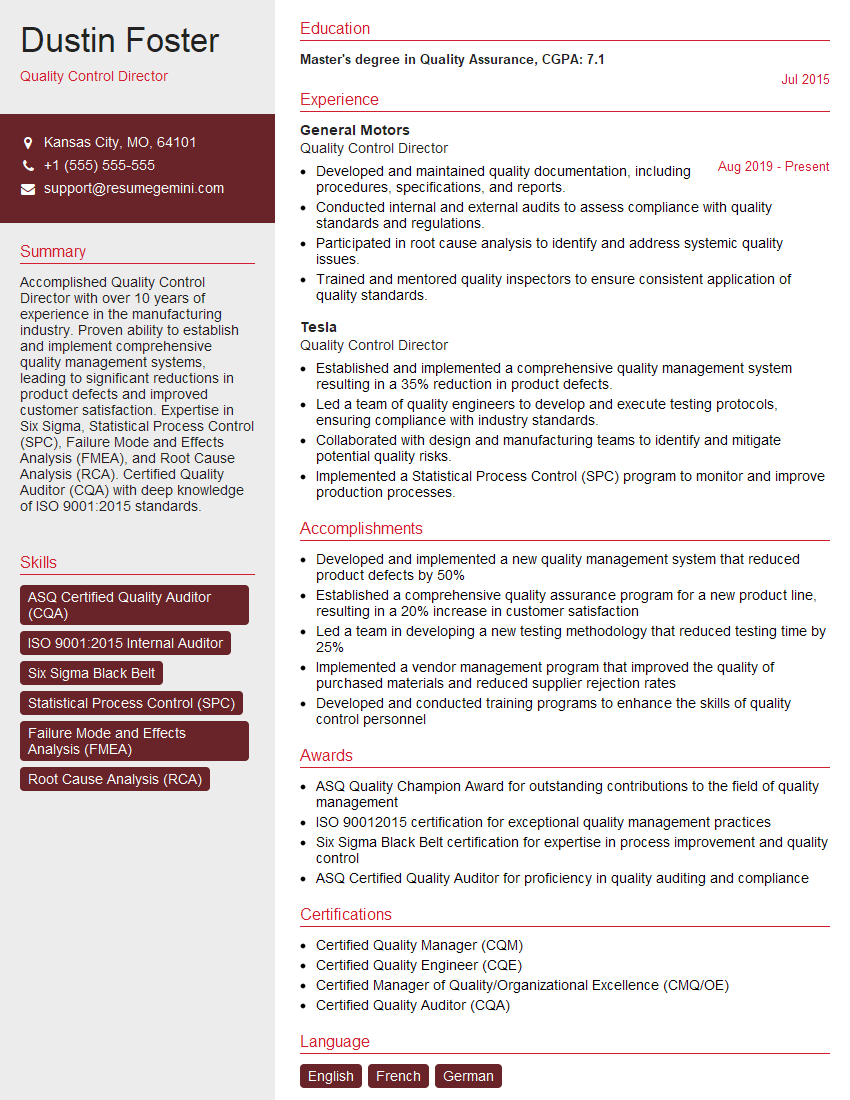

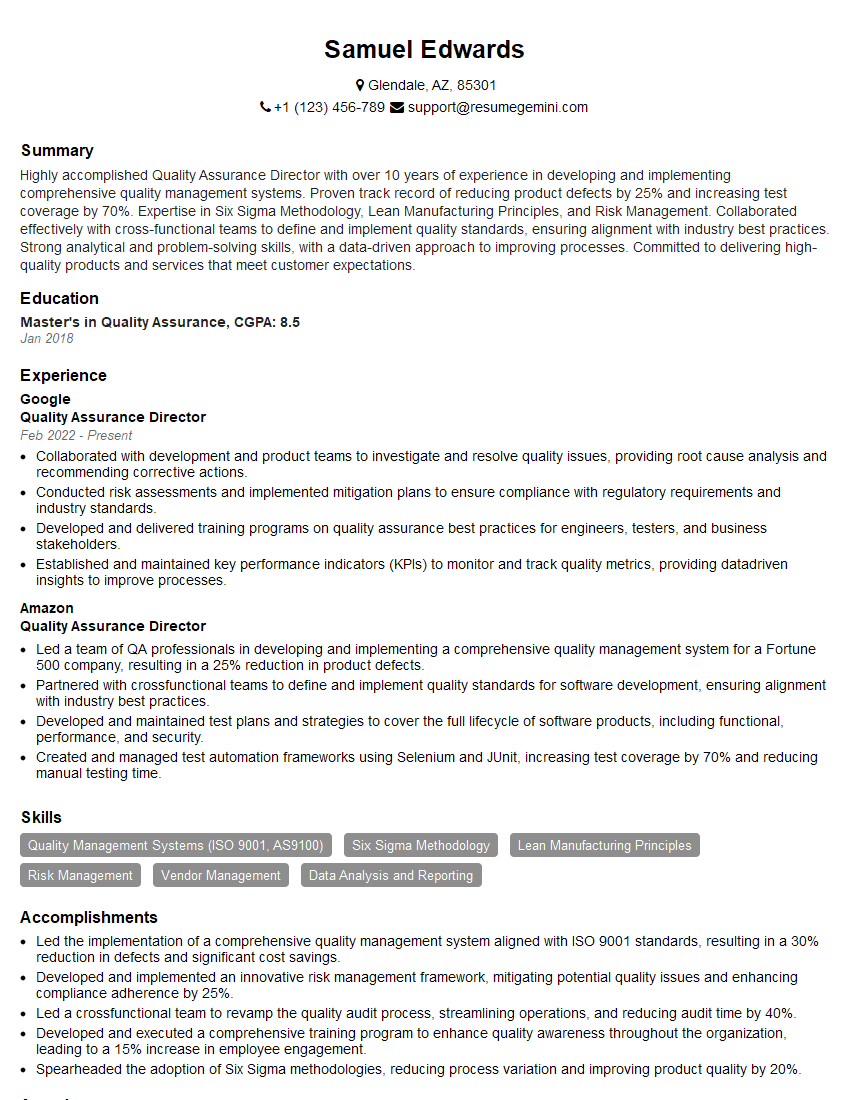

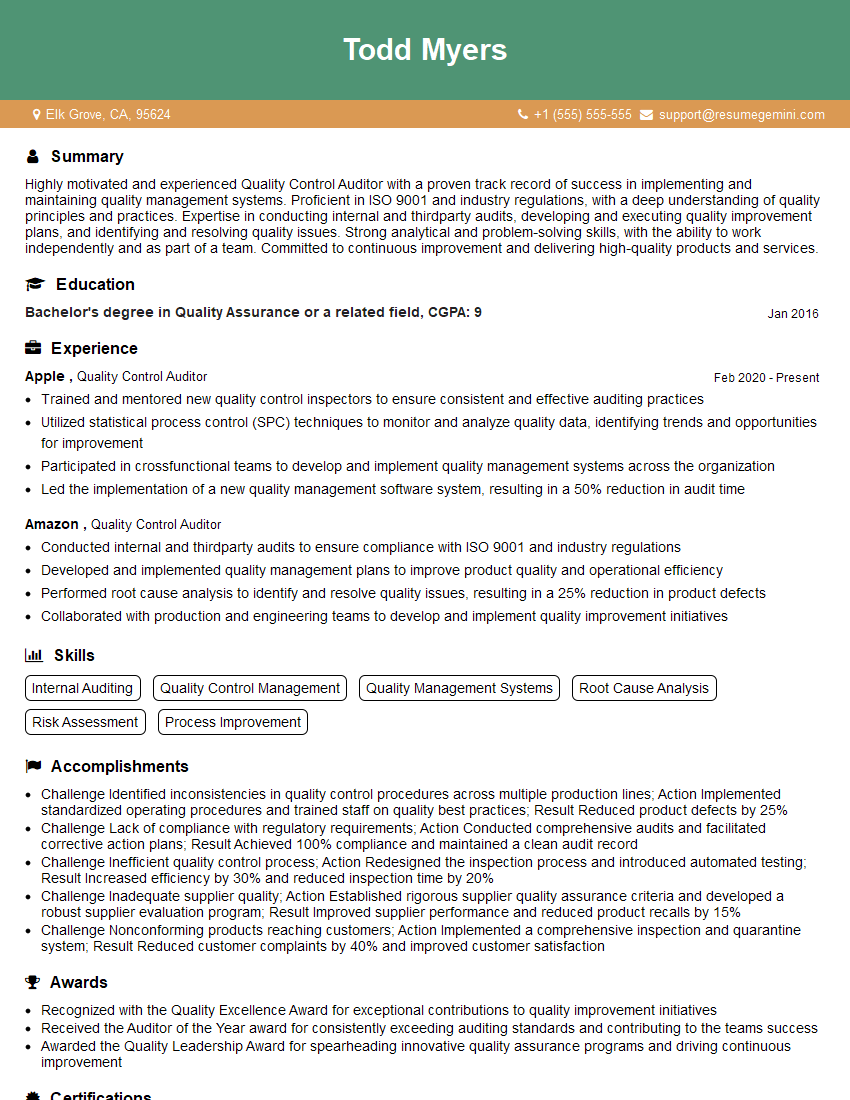

Mastering the development and implementation of quality control programs is crucial for career advancement in many fields. It demonstrates a commitment to excellence and a proactive approach to problem-solving, significantly increasing your value to any organization. To maximize your job prospects, building an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Expert in Developing and Implementing Quality Control Programs are available to help you create a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good