The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Sand Compaction and Stabilization interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Sand Compaction and Stabilization Interview

Q 1. Explain the principles of sand compaction.

Sand compaction is the process of increasing the density of a sand mass by reducing the void space between sand particles. Imagine a jar of marbles: if you shake it vigorously, the marbles settle closer together, occupying less space. Similarly, compacting sand reduces the air pockets, making it stronger and more stable.

This process primarily relies on the rearrangement of sand grains. Applying external forces, like pressure or vibration, pushes the grains closer together, ultimately leading to an increase in dry density. The denser the sand, the stronger and more resistant it is to deformation or settlement.

Q 2. Describe different methods of sand compaction.

Several methods exist for compacting sand, each with its own application and efficiency:

- Mechanical Compaction: This is the most common method, employing heavy machinery like vibratory rollers, smooth-wheeled rollers, and sheepsfoot rollers. Vibratory rollers are particularly effective for achieving high densities, particularly in granular soils.

- Impact Compaction: This technique uses heavy weights dropped from a height to compact the sand. While effective for deep compaction, it’s less precise than other methods.

- Dynamic Compaction: This involves dropping a heavy weight repeatedly from a significant height. This method is useful for deep compaction of loose, saturated granular soils.

- Vibro-flotation: A specialized method that uses a vibrating probe to compact saturated loose sands. It’s particularly useful for improving the bearing capacity of saturated, loose sandy soils.

- Manual Compaction: For small-scale projects, hand tampers can be used for compaction, although this is labor-intensive and less effective for large volumes.

Q 3. What are the factors affecting the compaction of sand?

Several factors influence sand compaction effectiveness:

- Moisture Content: The presence of water acts as a lubricant between sand grains, facilitating compaction up to a certain point. Too much or too little water hinders effective compaction.

- Grain Size Distribution: A well-graded sand (with a mix of fine and coarse grains) typically compacts better than uniformly graded sand. The finer grains fill the voids between coarser grains.

- Compaction Energy: Higher energy input from the compaction equipment leads to higher density. This includes factors like the weight of the roller, number of passes, and vibration frequency.

- Soil Type: The type of sand itself matters. Clean, well-graded silica sands typically compact better than other types of sands.

- Layering and Lifting: Compaction is best achieved by layering the sand in lifts (thin layers) and compacting each lift thoroughly before adding the next. This ensures uniform compaction throughout the depth.

Q 4. How do you determine the optimum moisture content for sand compaction?

Determining the optimum moisture content (OMC) for sand compaction is crucial for achieving maximum dry density. The OMC is the moisture content at which the sand achieves its maximum density for a given compaction energy. This is typically determined through laboratory testing using a Proctor compaction test (explained in the next answer).

In essence, it’s a trial and error approach where different moisture contents are tested, and the moisture content producing the highest dry density is selected as the optimum moisture content.

Q 5. Explain the use of Proctor compaction tests in sand compaction.

The Proctor compaction test is a standard laboratory procedure used to determine the relationship between the moisture content of a soil and its dry density. For sand, a modified Proctor test is often used due to the higher compaction energy usually applied in the field. A sample of sand is prepared at various moisture contents and compacted using a standardized method. The dry density is then calculated for each sample.

A graph is plotted with dry density on the y-axis and moisture content on the x-axis. The peak of this curve represents the maximum dry density and the corresponding moisture content is the optimum moisture content. This data is crucial for guiding field compaction operations to ensure the desired density is achieved.

Q 6. Describe the role of compaction energy in achieving desired density.

Compaction energy is the work done per unit volume of soil during compaction. It directly influences the achievable density. Higher compaction energy leads to a higher maximum dry density and reduces the void ratio. Think of it like kneading dough – the more you knead (more energy), the denser and more compact the dough becomes.

The compaction energy is dependent on factors like the weight and type of compaction equipment, the number of passes, the lift thickness, and the amplitude and frequency of vibration (if applicable). Selecting appropriate compaction equipment and parameters is crucial for achieving the specified density requirements in the project specifications.

Q 7. What are the implications of under-compaction and over-compaction of sand?

Both under-compaction and over-compaction have significant negative consequences:

- Under-compaction: Results in a lower than required density, leading to increased settlement under load, reduced bearing capacity, and potential for instability. This could cause structural damage, uneven pavement surfaces, and even failure of the structure built on that compacted sand.

- Over-compaction: While seemingly desirable, over-compaction can also be detrimental. Excessive compaction can lead to reduced permeability (making drainage difficult), increased risk of erosion and water damage, and potentially damage to the compaction equipment itself. Furthermore, it can create weak zones if not done uniformly.

Therefore, achieving the optimum moisture content and applying the correct amount of compaction energy is critical for ensuring long-term stability and functionality of any sand-based structure.

Q 8. How do you ensure uniform compaction across a large area?

Achieving uniform compaction across a large area requires a meticulous approach combining proper planning, appropriate equipment, and rigorous quality control. Think of it like baking a cake – you need even heat distribution to avoid burnt edges and a raw center. Similarly, inconsistent compaction leads to weak points in the sand layer.

Firstly, we divide the area into smaller, manageable sections. Each section is then compacted using overlapping passes to ensure complete coverage. This overlapping is crucial; it prevents gaps and ensures uniform density. We monitor the equipment’s performance and adjust the parameters like speed, vibration frequency, and roller weight to match the soil conditions within each section. GPS-guided equipment and compaction monitoring systems help us track progress and identify areas that may require additional passes. Finally, regular testing at multiple points within each section confirms the achieved uniformity.

Q 9. Explain the different types of compaction equipment used for sand.

Several types of compaction equipment are used for sand, each suited for different conditions and project scales. The choice depends on factors like the required density, the moisture content of the sand, and the accessibility of the site. Common types include:

- Vibratory Rollers: These are widely used for large-scale projects and offer excellent compaction efficiency. The vibrations effectively densify the sand. Think of a washing machine—the spinning motion compacts the clothes.

- Static Rollers (Smooth-wheeled): These are used for achieving high density, particularly with well-graded sands. The weight of the roller compacts the sand through sheer pressure.

- Pneumatic Rollers: These use inflatable tires, providing excellent compaction, especially on uneven terrain or for cohesive soils. The air pressure helps conform to the surface and achieve even distribution.

- Plate Compactors: These are handheld or small, ride-on machines suitable for smaller areas or confined spaces. They are ideal for finishing work around obstacles.

In many projects, we might utilize a combination of these machines—for example, vibratory rollers for the bulk compaction and plate compactors for areas difficult to access with larger equipment. The selection is a critical decision affecting project cost and quality.

Q 10. Describe the quality control measures for sand compaction.

Quality control in sand compaction is paramount; it guarantees the structural integrity and longevity of the project. Our measures include:

- Regular Density Testing: We use methods like the nuclear density gauge or sand cone method to measure the in-situ dry density of the compacted sand. These tests are performed at regular intervals and at different points across the site.

- Moisture Content Determination: Optimum moisture content is crucial for achieving maximum density. We regularly monitor moisture content using a moisture meter and adjust the water content if needed. Too much or too little water impacts the effectiveness of compaction.

- Visual Inspection: Regular visual checks are done to identify any areas with insufficient compaction, such as potholes or loose sand.

- Documentation: Meticulous records are kept on the type of equipment used, the number of passes, the moisture content, and the density test results. This documentation allows for traceability and problem-solving.

By implementing this robust system, we ensure that the compacted sand meets specified requirements and specifications.

Q 11. How do you interpret compaction test results?

Compaction test results, primarily the dry density and the moisture content, are compared with the project specifications and the optimum moisture content (OMC) for that particular sand.

The dry density value should be within an acceptable range of the maximum dry density (MDD) determined from laboratory tests. If the dry density is significantly below the MDD, it suggests inadequate compaction; further compaction is needed. A dry density close to or exceeding the MDD indicates sufficient compaction. The moisture content should ideally be close to the OMC; deviation from OMC results in lower density. We use graphical representations like compaction curves to visualize these results and make informed decisions.

For instance, if the achieved dry density is 95% of the MDD, we may require additional compaction. If it falls below 90%, we need to investigate potential issues like incorrect equipment operation, unsuitable soil conditions, or excessive moisture content.

Q 12. What are the common problems encountered during sand compaction and their solutions?

Several common problems can arise during sand compaction.

- Insufficient Compaction: This is often caused by inadequate equipment, incorrect moisture content, or too few compaction passes. The solution involves adjustments to these factors – using heavier equipment, adjusting the water content, and increasing the number of passes.

- Uneven Compaction: Uneven terrain, improper equipment operation, or insufficient overlapping of passes can lead to uneven density. Addressing this requires careful planning, correct equipment operation, and utilizing GPS-guided equipment.

- Excessive Moisture Content: High moisture content hinders compaction, reducing the achievable density. Allowing sufficient time for the sand to dry or using appropriate dewatering techniques can resolve this.

- Presence of Large Debris: Large rocks or debris obstruct proper compaction. Careful removal of any substantial debris before compaction is essential.

Problem-solving involves systematic investigation: we identify the potential cause, review our compaction procedures, and take corrective actions, often including retesting after the corrective measures are implemented.

Q 13. Explain the concept of soil stabilization and its applications.

Soil stabilization is the process of improving the engineering properties of soil to enhance its strength, stiffness, and durability. Imagine trying to build a house on loose sand; it’s unstable. Stabilization makes that sand strong enough to support a foundation. This is achieved by adding various stabilizers to modify the soil’s behavior.

Applications of soil stabilization are extensive, including:

- Road Construction: Improving the subgrade strength for pavements and roadways.

- Foundation Engineering: Strengthening the foundation soil to support structures.

- Earth Dams and Embankments: Increasing the shear strength and reducing permeability.

- Erosion Control: Enhancing soil stability to prevent erosion.

Stabilization significantly reduces the risk of settlement, increases bearing capacity, and improves the overall performance of the soil in various engineering applications.

Q 14. Describe different methods of soil stabilization for sand.

Several methods can stabilize sand, each with its advantages and disadvantages:

- Cement Stabilization: Portland cement is mixed with sand to improve its strength and stiffness. This is effective but can be more expensive.

- Lime Stabilization: Lime reacts with the soil particles, improving strength and reducing permeability. It’s often a more cost-effective option than cement.

- Bituminous Stabilization: Bitumen, a petroleum-derived material, is mixed with sand to improve its strength and water resistance. This is effective in areas requiring high water resistance.

- Chemical Stabilization: Various chemicals, such as polymers or silicates, are used to improve the sand’s engineering properties. This offers options for specialized properties but may require more careful control.

- Mechanical Stabilization: This involves compaction techniques or the addition of granular materials to improve the sand’s density and strength. This often is a pre-requisite to chemical stabilization.

The choice of method depends on factors such as project requirements, cost considerations, environmental concerns, and the specific properties of the sand.

Q 15. How does cement stabilization improve the properties of sand?

Cement stabilization significantly improves the engineering properties of sand by binding the loose sand particles together, transforming it from a granular material into a stronger, more cohesive mass. The cement acts as a binder, filling the voids between sand grains and creating a cementitious matrix. This process increases the sand’s shear strength, compressive strength, and reduces its permeability.

Think of it like making a sandcastle: dry sand crumbles easily, but adding water (in this case, cement) acts as a binder, allowing you to create a much more stable structure. The cement hydration process creates a strong interlocking network of crystals that binds the sand grains firmly together. This results in increased bearing capacity, making the stabilized sand suitable for various applications like road bases, embankments, and foundations.

Career Expert Tips:

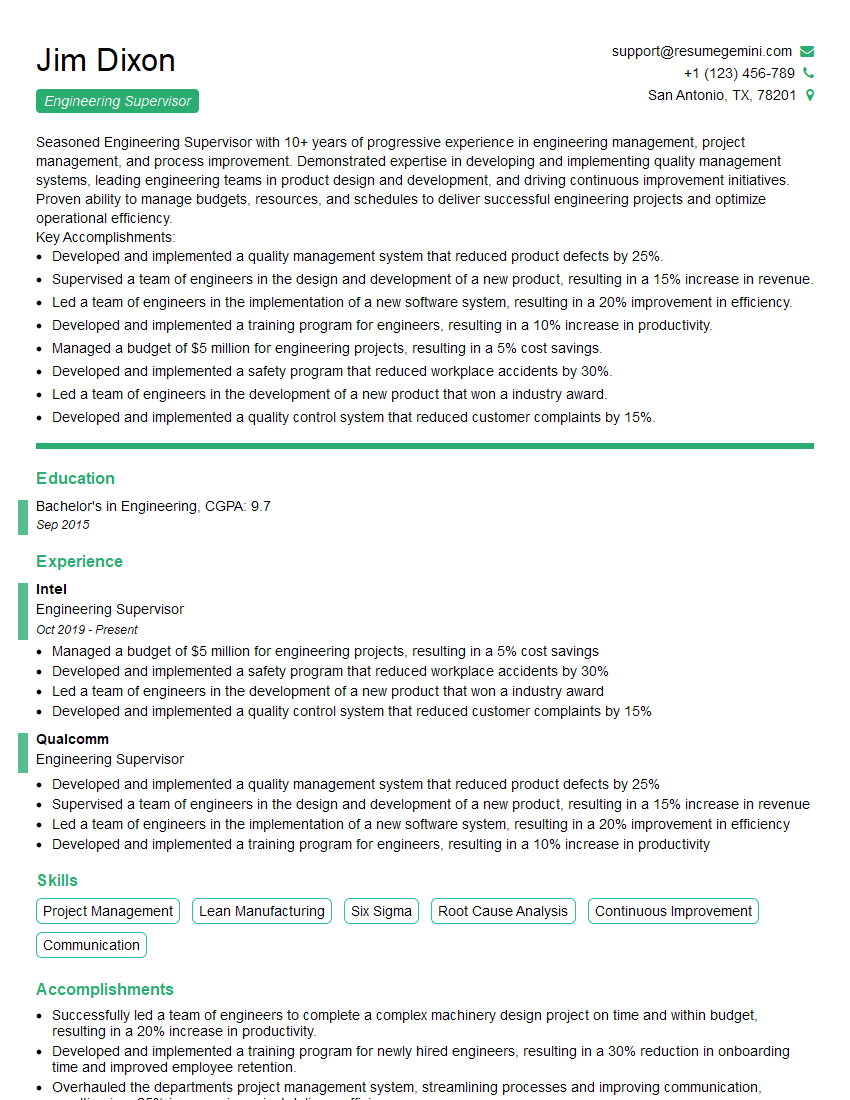

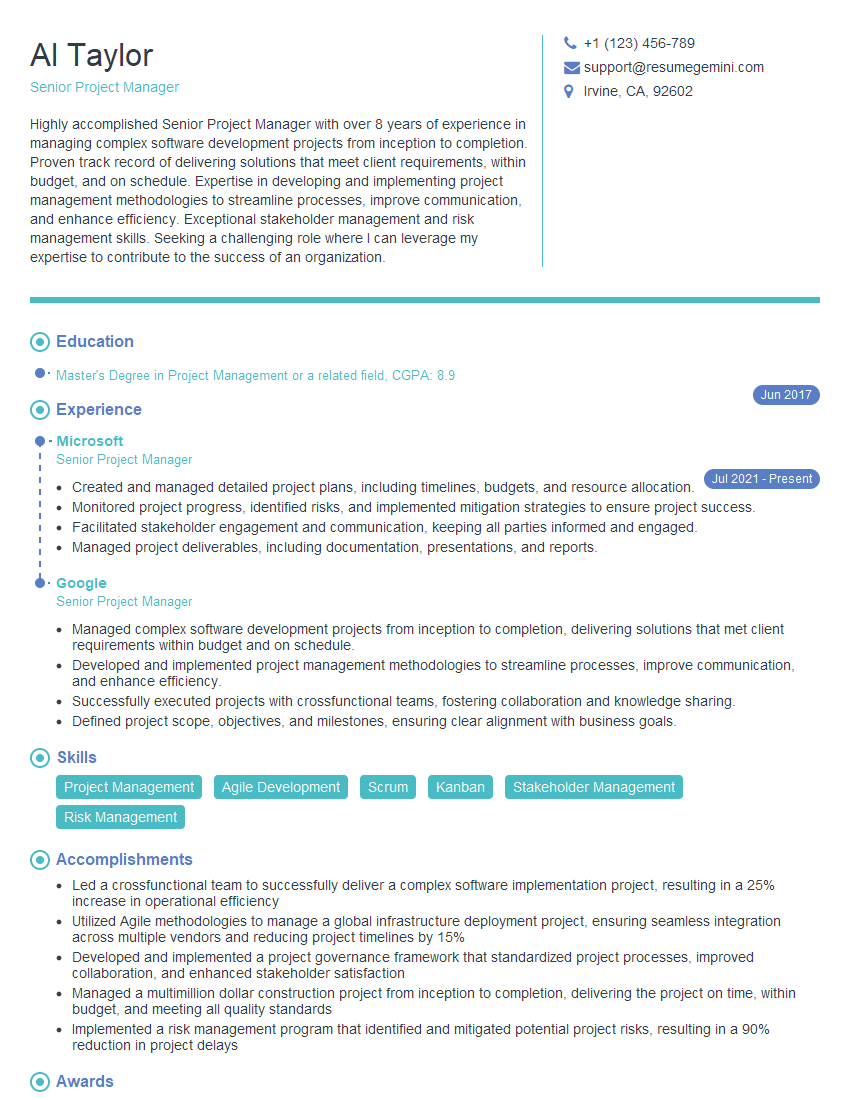

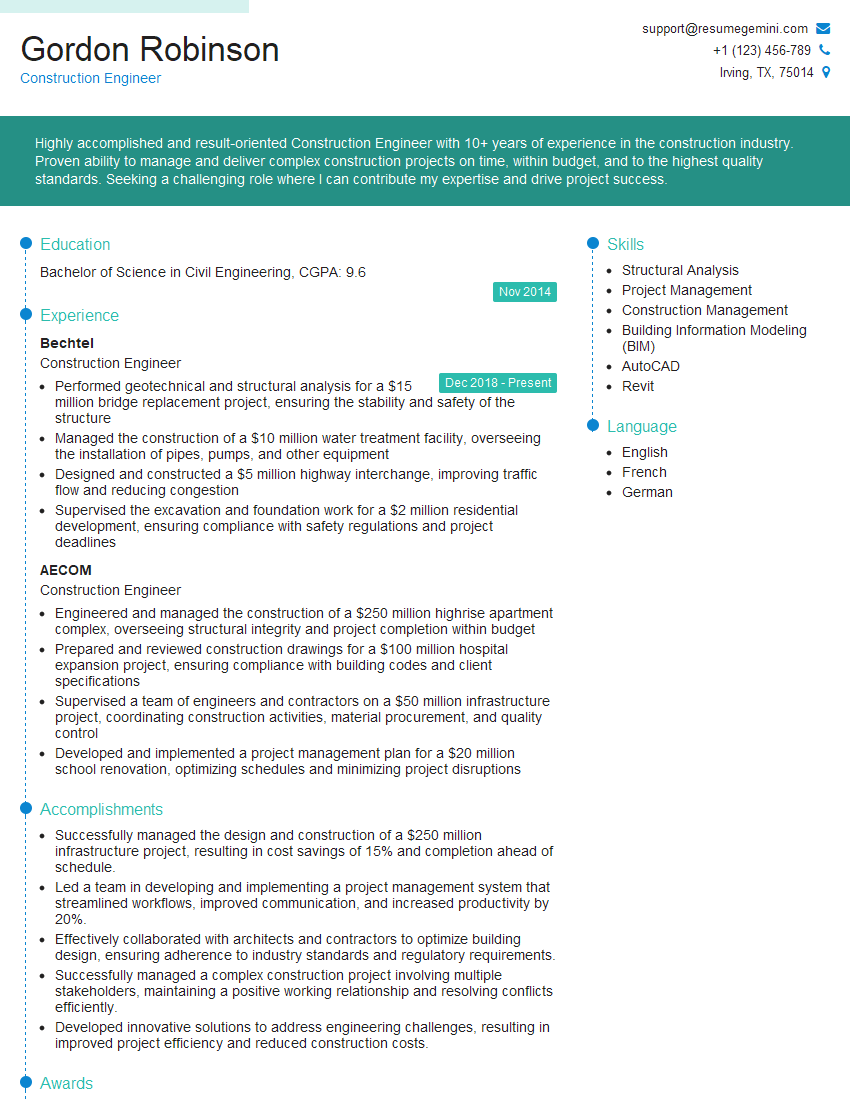

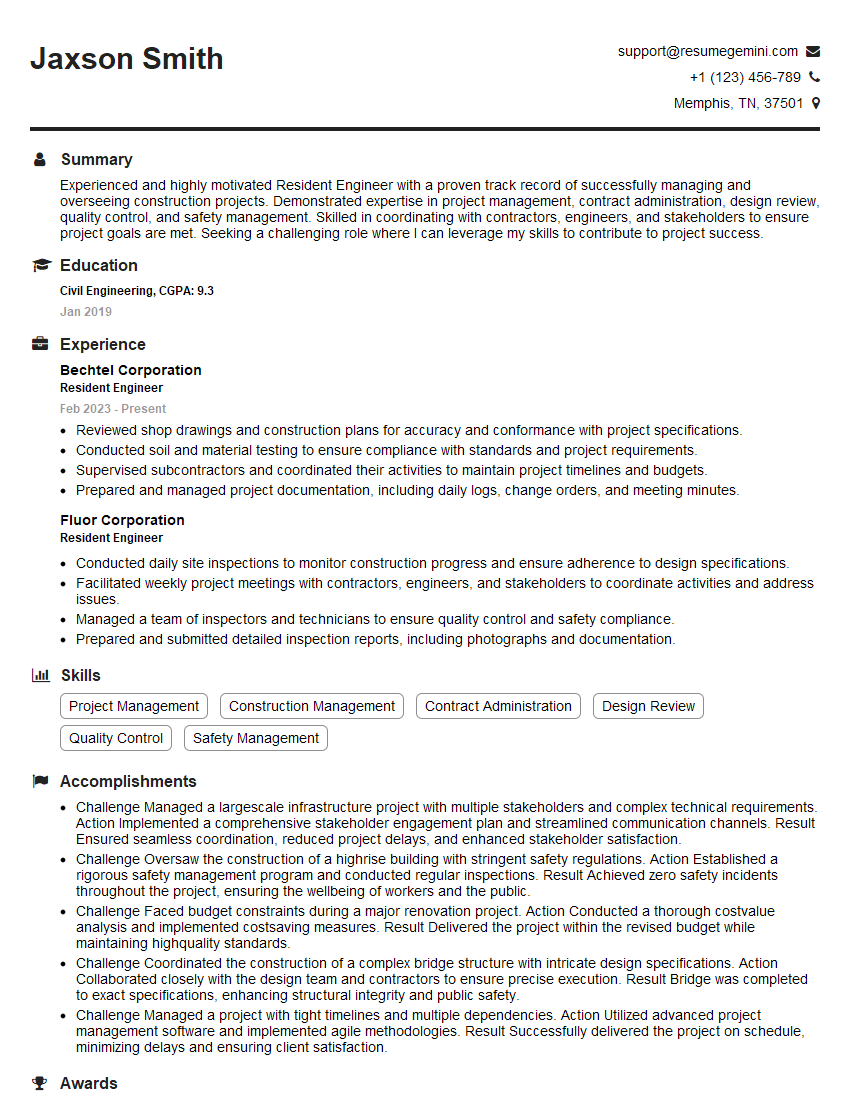

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the advantages and disadvantages of chemical stabilization for sand?

Chemical stabilization offers several advantages, including:

- Increased strength and stiffness: Chemical additives significantly enhance the shear strength and bearing capacity of sand.

- Reduced permeability: This minimizes water infiltration, crucial for applications like road bases and retaining walls.

- Improved durability: The treated sand is more resistant to erosion and weathering.

- Faster construction: Compared to some mechanical methods, chemical stabilization can be quicker and more efficient.

However, disadvantages include:

- Environmental concerns: Some chemicals can be harmful to the environment if not handled properly. Careful selection of eco-friendly additives is crucial.

- Cost: The cost of chemical additives can be substantial, especially for large-scale projects.

- Potential for long-term degradation: The effectiveness of some chemical treatments can degrade over time, requiring potential maintenance.

- Uniformity challenges: Achieving uniform mixing and distribution of the chemical additive throughout the sand mass can be difficult.

For example, using lime stabilization for a sandy soil foundation requires careful consideration of the lime content, mixing methods, and curing time to ensure proper stabilization and avoid environmental issues.

Q 17. How do you select the appropriate stabilization method for a given project?

Selecting the appropriate stabilization method depends on several factors, including:

- Project requirements: What strength, permeability, and durability are needed? A high-speed roadway requires a different level of stabilization than a simple access road.

- Soil properties: The type of sand, its gradation, and its initial properties significantly influence the choice of method.

- Environmental conditions: Climate, moisture content, and potential environmental impact must be carefully considered.

- Cost-effectiveness: The overall cost, including materials, labor, and equipment, needs to be evaluated.

- Accessibility: The location of the project and accessibility for equipment can influence the practicality of different methods.

A systematic approach involving laboratory testing, geotechnical analysis, and cost estimation is essential. For instance, if we’re working on a coastal area with high water table and erosion concerns, we might prioritize a method that improves permeability and resistance to erosion over simply increasing compressive strength.

Q 18. Explain the design considerations for sand compaction and stabilization.

Design considerations for sand compaction and stabilization involve a holistic approach encompassing:

- Compaction effort: Determining the appropriate number of passes, lift thickness, and compaction energy needed to achieve the desired density.

- Moisture content optimization: Achieving optimum moisture content (OMC) is critical for maximum compaction. Too much or too little water will lead to suboptimal density.

- Layer thickness: The thickness of the compacted layers should be chosen based on the equipment used and the desired density.

- Quality control: Regular field density tests (e.g., nuclear density gauge) are necessary to verify the compaction achieved.

- Material characterization: Thorough laboratory testing of the sand is necessary to determine its gradation, plasticity, and other relevant properties.

- Stability analysis: Geotechnical analyses are essential to ensure long-term stability under anticipated loads and environmental conditions.

For instance, constructing a highway embankment requires precise control of compaction parameters to ensure that the embankment remains stable under heavy traffic loads and environmental changes.

Q 19. How do environmental factors influence sand compaction and stabilization?

Environmental factors significantly impact sand compaction and stabilization. These include:

- Rainfall and water content: Excess water can hinder compaction and weaken the stabilized sand. Conversely, excessively dry conditions can also affect compaction efficiency.

- Temperature fluctuations: Temperature changes can affect the curing process of cementitious materials and the effectiveness of certain chemical additives.

- Freeze-thaw cycles: Repeated freezing and thawing cycles can damage the stabilized sand, particularly if improper materials or inadequate compaction have been used.

- Vegetation: Vegetation growth can destabilize the compacted sand, requiring careful site preparation and potential erosion control measures.

- Wind erosion: In arid and semi-arid regions, wind erosion can significantly affect the surface stability of the compacted sand, needing protective measures.

For example, in a desert environment, wind erosion can be a significant design constraint. Protective measures, such as geotextiles, may be necessary to prevent wind erosion and maintain the integrity of the stabilized sand layers. We need to factor these environmental influences into our design and selection of stabilization methods.

Q 20. What are the safety precautions to be taken during sand compaction?

Safety precautions during sand compaction are crucial. These include:

- Proper training: Operators of compaction equipment must be properly trained and certified to operate the machinery safely.

- Protective equipment: Workers should wear appropriate personal protective equipment (PPE), including safety glasses, hard hats, and hearing protection.

- Traffic control: If compaction is performed near roads or other areas with traffic, appropriate traffic control measures must be implemented.

- Machine maintenance: Regular maintenance of compaction equipment is vital to prevent accidents and ensure optimal performance.

- Environmental considerations: Dust control measures should be implemented to minimize dust pollution during the compaction process.

- Emergency procedures: Emergency response plans should be in place to handle any unforeseen accidents or emergencies.

For example, operating a large vibratory roller requires specific training and adherence to safety protocols to prevent accidents involving the machine or personnel. Regular inspections and maintenance are also vital to ensure the equipment remains in safe working order.

Q 21. Describe your experience with different types of compaction equipment.

My experience encompasses a variety of compaction equipment, including:

- Vibratory rollers: These are commonly used for compacting granular materials like sand, offering excellent compaction efficiency. I’ve worked extensively with both smooth-drum and padfoot rollers, choosing between them based on the specific soil type and compaction requirements.

- Static rollers: These are used for preliminary compaction or for materials that are less responsive to vibrations. They are generally less efficient than vibratory rollers but are effective in certain situations.

- Pneumatic rollers: These use inflatable tires to provide a kneading action, making them effective for cohesive soils, but also suitable for some sand applications, particularly where surface irregularities need to be smoothed out.

- Plate compactors: These are smaller, hand-guided machines suitable for compacting smaller areas or confined spaces where larger equipment cannot access.

The choice of equipment depends on factors like project scale, soil type, and desired density. For instance, for large-scale highway projects, large vibratory rollers are typically preferred for their efficiency, while for smaller projects or confined spaces, plate compactors might be more suitable. Each type has its strengths and limitations, and the selection process requires careful consideration of various parameters.

Q 22. How do you handle unexpected problems during a sand compaction project?

Unexpected problems in sand compaction are inevitable. My approach involves a proactive, multi-step strategy. First, I emphasize thorough pre-project planning, including detailed site investigations to identify potential challenges like unexpected subsurface conditions (e.g., buried debris, high water table). Second, I establish clear communication protocols among the project team. This ensures that any anomalies are reported immediately and addressed efficiently. Third, I maintain a flexible approach, ready to adjust the compaction plan as needed. For instance, if we encounter unexpectedly loose sand, we might need to adjust the number of passes with the compactor, change the type of compactor, or employ additional stabilization techniques. Finally, I meticulously document all deviations from the original plan and the corrective actions taken. This ensures accountability and provides valuable lessons learned for future projects.

For example, on a recent project, we unexpectedly encountered a layer of soft clay beneath the sand. This significantly hampered compaction efforts. Our immediate response involved adjusting the compaction strategy using vibratory rollers instead of smooth drum rollers, and we also implemented pre-wetting and pre-compaction techniques to increase the bearing capacity of the clay layer. Regular monitoring using nuclear density gauges ensured we achieved the required compaction levels.

Q 23. Explain your experience with quality control and testing procedures for sand compaction.

Quality control and testing are paramount in sand compaction. My experience includes extensive use of various methods to ensure the project meets specifications. This begins with representative sampling of the sand to determine its gradation and moisture content. We then conduct in-situ density tests, using methods like nuclear density gauges or sand cone methods, to assess the achieved compaction levels. These tests are performed at various locations throughout the project area to ensure uniformity. We also monitor the moisture content throughout the compaction process using moisture meters to ensure that it remains within the optimal range for maximum compaction. Beyond in-situ testing, laboratory tests are often conducted on representative samples to validate the field density measurements and to determine the maximum dry density and optimum moisture content of the sand. This data allows us to fine-tune the compaction process and ensures we achieve consistent results.

Non-conformance to these specifications triggers immediate corrective actions, ranging from re-compaction of deficient areas to adjustments in the compaction equipment or methods. Detailed records of all tests and results are maintained throughout the project lifecycle, demonstrating our commitment to quality.

Q 24. How do you ensure compliance with relevant standards and regulations?

Compliance is fundamental. My approach involves a detailed review of all applicable standards and regulations at the project’s outset. This often includes local building codes, environmental regulations, and industry best practices such as those specified by ASTM (American Society for Testing and Materials) or other relevant organizations. We incorporate these requirements into the project specifications and ensure that all project personnel are fully aware of them. We use standardized procedures for testing and documentation, and regular audits are conducted to monitor compliance. Any potential deviations are promptly identified and addressed through corrective actions. For example, if dealing with a site near a water body, we adhere strictly to erosion and sediment control regulations, utilizing appropriate measures to prevent environmental damage. Thorough documentation of compliance is crucial, ensuring that we have a verifiable audit trail for inspection purposes.

Q 25. Describe your experience working with different types of soil stabilization methods.

My experience encompasses a range of soil stabilization methods, often used in conjunction with sand compaction. These methods improve the engineering properties of the sand, enhancing its strength, bearing capacity, and durability. These include:

- Cement Stabilization: Adding cement to the sand to bind the particles, increasing its strength and reducing permeability.

- Lime Stabilization: Similar to cement stabilization, but using lime instead of cement. Lime is particularly effective in improving the properties of clayey sands.

- Fly Ash Stabilization: Utilizing fly ash, a byproduct of coal combustion, as a pozzolanic material to improve the strength and durability of the sand.

- Geosynthetics: Incorporating geotextiles or geogrids to reinforce the sand and improve its stability, particularly on slopes or areas with poor subsoil conditions.

The choice of method depends on factors such as soil type, project requirements, and budget constraints. I select the most appropriate method based on detailed geotechnical investigations and laboratory testing.

Q 26. How do you manage and coordinate work with different contractors and subcontractors?

Effective coordination among contractors and subcontractors is crucial. I employ a collaborative approach, establishing clear roles, responsibilities, and communication channels from the outset. This involves regular meetings with all involved parties, ensuring transparency and fostering a shared understanding of project goals and timelines. I utilize project management software to track progress, manage resources, and address potential conflicts. Contracts are meticulously drafted, outlining specific deliverables, timelines, and payment schedules. Regular progress monitoring and performance evaluations help to maintain project momentum and address any issues proactively. Open communication and conflict resolution mechanisms are established to ensure prompt resolution of any disputes that might arise.

For example, on a large-scale project, we had separate contractors for earthworks, compaction, and geotechnical testing. Regular coordination meetings ensured seamless transitions between phases, preventing delays and optimizing resource allocation.

Q 27. Explain your understanding of project management principles in relation to sand compaction projects.

Project management principles are integral to successful sand compaction projects. I apply a structured approach, starting with clear definition of project scope, objectives, and deliverables. Detailed planning includes scheduling, resource allocation, and risk assessment. Regular monitoring and evaluation of progress against the plan are critical, allowing for timely adjustments and corrective actions. Effective communication, both internal and external, is maintained throughout the project lifecycle. This includes regular reporting to stakeholders and proactive problem-solving. Cost control is also paramount, ensuring that the project remains within budget. Finally, I adhere to best practices for quality management, ensuring that the final product meets the required specifications.

Q 28. Describe a challenging situation you faced during a sand compaction project and how you resolved it.

One challenging situation involved an unexpected increase in groundwater levels during a large-scale project. This led to significant softening of the sand, making compaction extremely difficult. Our initial compaction strategy proved ineffective. My approach involved a multi-pronged solution: First, we implemented measures to lower the groundwater level, including temporary dewatering wells. Secondly, we adjusted our compaction strategy, employing specialized equipment designed for wet soil conditions. We also incorporated pre-wetting and pre-compaction techniques to enhance the compaction efficiency. Third, we implemented additional quality control measures, including more frequent density tests to ensure we were achieving the required compaction levels despite the challenging conditions. Through proactive communication and collaboration, we successfully overcame the challenge, completing the project on time and within budget while maintaining high quality standards. This experience reinforced the importance of thorough site investigation, contingency planning, and a flexible, adaptive approach to project management in challenging environments.

Key Topics to Learn for Sand Compaction and Stabilization Interview

- Soil Mechanics Principles: Understanding soil behavior, shear strength, and consolidation theories as they relate to sandy soils.

- Compaction Techniques: Familiarize yourself with various methods like vibratory compaction, dynamic compaction, and roller compaction. Understand their applications and limitations.

- Stabilization Methods: Explore different stabilization techniques including cement stabilization, lime stabilization, and the use of geosynthetics. Know the chemical reactions and mechanical improvements involved.

- Material Properties: Understand the importance of grain size distribution, plasticity index, and other relevant parameters in influencing compaction and stabilization effectiveness.

- Field Testing and Quality Control: Be prepared to discuss standard Proctor tests, in-situ density tests, and other quality control measures used to ensure proper compaction and stabilization.

- Practical Applications: Review case studies of sand compaction and stabilization in various projects, such as road construction, embankment construction, and foundation engineering.

- Problem-Solving Approaches: Practice analyzing scenarios involving poor compaction, inadequate stabilization, and potential remedies. Consider how to troubleshoot issues in the field.

- Environmental Considerations: Understand the environmental impact of different compaction and stabilization methods and best practices for minimizing negative effects.

- Design Considerations: Learn how to incorporate compaction and stabilization requirements into the design of earthworks and geotechnical structures.

- Safety Procedures: Be familiar with relevant safety regulations and procedures associated with heavy machinery and field operations in sand compaction and stabilization.

Next Steps

Mastering Sand Compaction and Stabilization significantly enhances your career prospects in geotechnical engineering and related fields, opening doors to challenging and rewarding roles. A well-crafted resume is crucial in showcasing your expertise to potential employers. Focus on creating an ATS-friendly resume that highlights your skills and experience effectively. To help you achieve this, consider using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Sand Compaction and Stabilization, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good