Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Adhering to quality control standards interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Adhering to quality control standards Interview

Q 1. Describe your experience implementing quality control procedures.

Throughout my career, I’ve been deeply involved in implementing and improving quality control procedures across various manufacturing and service environments. My approach is always multifaceted, focusing on preventative measures as much as reactive problem-solving. This involves a strong emphasis on establishing clear quality standards, implementing robust inspection processes, and fostering a culture of continuous improvement.

For example, in my previous role at Acme Manufacturing, I spearheaded the implementation of a new Statistical Process Control (SPC) system. This involved training the production team on data collection methods, charting techniques, and the interpretation of control charts. We saw a significant reduction in defects and improved overall process efficiency as a direct result. In another instance, I developed and implemented a comprehensive quality manual outlining specific procedures and checklists for each stage of our product development cycle, from raw material inspection to final product testing. This standardized approach significantly improved consistency and traceability across all production batches.

Q 2. Explain your understanding of ISO 9001 standards.

ISO 9001 is an internationally recognized standard that outlines the requirements for a quality management system (QMS). It provides a framework for organizations to consistently meet customer and regulatory requirements, enhance customer satisfaction, and achieve sustainable business success. The standard emphasizes a structured approach to managing processes, ensuring the necessary resources are available, and continuously improving the effectiveness of the QMS.

My understanding encompasses all aspects of ISO 9001, including its core principles such as customer focus, leadership engagement, process approach, improvement, and data-driven decision-making. I’m familiar with the requirements for documentation, internal audits, management review, and corrective and preventive actions (CAPA). I have personally overseen the implementation and maintenance of ISO 9001-certified QMS in several organizations, leading to successful certifications and ongoing compliance. The key is not just ticking boxes, but embedding the principles into the company culture.

Q 3. How do you identify and address quality issues in a manufacturing process?

Identifying and addressing quality issues in a manufacturing process requires a systematic approach. It begins with proactive measures like regular inspections and monitoring of key process parameters. We use statistical methods, like control charts, to detect deviations from expected performance. For example, if a control chart shows a consistent trend exceeding the upper control limit, it indicates a potential problem.

Once an issue is identified, root cause analysis is critical. This might involve tools like Fishbone diagrams (Ishikawa diagrams) or the 5 Whys to pinpoint the underlying cause. Addressing the issue might involve adjustments to the manufacturing process, improved operator training, replacement of faulty equipment, or even a redesign of the product itself. Crucially, we also implement corrective and preventive actions (CAPA) to ensure that the issue doesn’t recur. This could involve updating standard operating procedures, implementing new quality checks, or improving training programs. Documenting the entire process is crucial for traceability and continuous improvement.

Q 4. What are your preferred quality control tools and techniques?

My preferred quality control tools and techniques are diverse and tailored to the specific context. Statistical Process Control (SPC) is fundamental, utilizing tools like control charts (X-bar and R charts, p-charts, c-charts) to monitor process stability and identify variations. This helps to prevent defects before they occur. In addition, I frequently use:

- Pareto charts: To identify the ‘vital few’ causes contributing to the majority of problems.

- Checklists: For standardized inspections and to ensure consistency.

- Flowcharts: To visualize processes and identify bottlenecks or potential failure points.

- Root cause analysis techniques: Such as the 5 Whys and Fishbone diagrams, to get to the bottom of quality issues.

- Data analysis software: To analyze large datasets and identify trends.

The selection of specific tools is driven by the nature of the product, the manufacturing process, and the specific quality challenges being addressed.

Q 5. Describe a time you had to deal with a significant quality problem. What was your approach?

In a previous role, we experienced a significant increase in customer complaints about a specific product feature – a faulty weld on a crucial component. My approach was systematic and data-driven.

- Data Collection: We thoroughly analyzed the customer complaints, documenting the nature of the defect and the affected batches.

- Root Cause Analysis: We employed the 5 Whys technique and a Fishbone diagram to identify the root cause, which turned out to be a poorly maintained welding machine causing inconsistent weld strength.

- Corrective Actions: We immediately took the faulty machine offline for thorough maintenance and recalibration. We also implemented a stricter inspection protocol for welds.

- Preventive Actions: We established a preventative maintenance schedule for all welding equipment and implemented additional training for the welding operators to emphasize quality control procedures.

- Follow-up: We closely monitored the production process and conducted regular audits to ensure the problem had been resolved and wasn’t recurring.

This situation underscored the importance of proactive maintenance, thorough operator training, and robust quality checks to prevent such issues from happening in the future.

Q 6. How do you ensure consistent quality across multiple production batches?

Ensuring consistent quality across multiple production batches demands a combination of robust processes and meticulous attention to detail. This starts with standardized operating procedures (SOPs) that clearly outline every step of the manufacturing process, leaving no room for ambiguity. Regular calibration of equipment and tooling is essential to maintain consistent performance. In-process inspections at key stages help catch potential deviations early on.

Furthermore, the use of statistical process control (SPC) charts allows us to track key parameters over time and spot trends or anomalies that might indicate a drift in quality. Regular review of control charts and other quality data ensures timely identification and correction of any emerging issues. Finally, training and continuous improvement initiatives aimed at empowering employees to identify and report quality issues play a vital role in achieving and sustaining consistency across multiple batches. A well-defined system for tracking and managing materials from procurement to production is also essential.

Q 7. What metrics do you use to measure quality control effectiveness?

Measuring the effectiveness of quality control relies on a combination of key metrics. These metrics provide insights into the performance of the QMS and allow for continuous improvement. Some of the most important metrics I utilize include:

- Defect rate: The percentage of defective units produced.

- Yield rate: The percentage of good units produced relative to total units produced.

- Customer complaints: The number of complaints received regarding product quality.

- Cost of quality: The total cost associated with preventing, appraising, and failing to meet quality requirements.

- Process capability indices (Cp, Cpk): Measures of process performance relative to specification limits.

- Cycle time: Measures the time it takes to produce a unit.

Regularly tracking and analyzing these metrics allows me to identify areas for improvement and demonstrate the overall effectiveness of our quality control efforts. The specific metrics utilized will vary depending on the industry, product, and specific quality objectives. Regular reporting to stakeholders is crucial.

Q 8. How do you prioritize quality control tasks when facing time constraints?

Prioritizing quality control tasks under time pressure requires a strategic approach. I use a risk-based prioritization method. This involves identifying tasks with the highest potential impact on product quality or customer satisfaction, and addressing those first. For instance, if a particular component is critical to the functionality of the final product and its quality is questionable, it will take precedence over a less critical aspect. I leverage tools like risk matrices to visually represent the likelihood and impact of potential defects, enabling data-driven decision-making.

Next, I employ timeboxing techniques. I allocate specific time blocks to specific tasks, ensuring I stay focused and efficient. Finally, I regularly reassess priorities, as unexpected issues may arise. This ensures that resources are dynamically allocated to address the most pressing concerns, ultimately balancing speed and quality.

Q 9. What is your experience with statistical process control (SPC)?

My experience with Statistical Process Control (SPC) is extensive. I’ve utilized SPC methods extensively to monitor and improve processes, particularly in manufacturing environments. I’m proficient in using control charts – such as X-bar and R charts, p-charts, and c-charts – to identify trends, variations, and potential sources of defects. For example, in a previous role, we used control charts to monitor the weight of a particular product. By analyzing the data, we were able to detect a gradual shift in the average weight, indicating a potential problem with the filling machine. This allowed us to address the issue before a large number of non-conforming products were produced. I also have experience interpreting control chart results and taking appropriate corrective actions, including root cause analysis and process adjustments.

Q 10. Explain the difference between preventive and corrective quality control.

Preventive and corrective quality control are two complementary approaches. Preventive QC focuses on preventing defects from occurring in the first place. This might involve thorough process design, rigorous material inspection, employee training, and regular equipment maintenance. Think of it as proactive healthcare – regular check-ups to prevent illnesses.

Corrective QC, on the other hand, addresses defects that have already occurred. This involves identifying defects, analyzing root causes, and implementing solutions to prevent recurrence. It’s like reactive healthcare – treating an illness once it’s developed. A good example of preventive QC would be implementing a robust quality management system before starting a project. A corrective action example would be conducting a failure analysis after a batch of products fails inspection and then implementing corrective measures.

Q 11. How do you ensure the accuracy and reliability of your quality control data?

Ensuring accuracy and reliability of quality control data is paramount. I utilize several methods to achieve this. First, I ensure that all measurement equipment is properly calibrated and regularly maintained according to a schedule. Second, I implement rigorous data collection procedures with clear instructions and checklists to minimize human error. Third, I employ statistical methods to analyze the data and identify potential outliers or inconsistencies. For example, if a particular data point seems significantly different from others, I will investigate to determine whether there was an error in measurement or if it indicates a genuine issue.

Finally, I maintain meticulous records and documentation to ensure traceability and allow for auditing. Data integrity is crucial, so I use version control and secure storage to protect against loss or corruption.

Q 12. Describe your experience with root cause analysis.

I have extensive experience with root cause analysis (RCA), using various techniques such as the 5 Whys, fishbone diagrams (Ishikawa diagrams), and fault tree analysis. For example, in a situation where a production line experienced frequent stoppages due to machine malfunctions, I used the 5 Whys to progressively drill down into the underlying cause. The process involved repeatedly asking “Why?” until we reached the root cause, which ultimately involved a worn-out component that wasn’t included in the regular maintenance schedule. This allowed us to implement preventative measures and eliminate the recurring issue. This systematic approach is essential for identifying the true reason for a defect or problem, rather than just addressing the symptoms.

Q 13. How do you collaborate with different departments to maintain quality standards?

Collaboration is key to maintaining quality standards. I work closely with various departments – engineering, manufacturing, procurement, and sales – to ensure that quality is integrated throughout the entire product lifecycle. Regular meetings and cross-functional teams are essential for effective communication and problem-solving. For example, if a defect is discovered in a finished product, I will work with engineering to identify the root cause, with manufacturing to implement corrective actions, and with procurement to ensure the quality of materials used.

Open communication, shared goals, and a collaborative spirit are essential for success. I utilize project management software and shared platforms to facilitate seamless information sharing.

Q 14. How do you stay updated on the latest quality control best practices?

Staying updated on quality control best practices is a continuous process. I actively participate in professional organizations like ASQ (American Society for Quality), attend conferences and workshops, and subscribe to relevant industry publications and journals. I also regularly review industry standards and regulations to ensure that our practices remain compliant. Online courses and webinars are also valuable resources for continuous learning and skill enhancement. Staying informed allows me to introduce innovative techniques and best practices into our processes, ensuring our quality control programs remain effective and efficient.

Q 15. What are your strengths and weaknesses in relation to quality control?

My greatest strength in quality control is my proactive approach. I don’t just react to problems; I anticipate them. I’m meticulous in identifying potential risks throughout the entire process, from design to delivery. For instance, in my previous role at XYZ Company, I noticed a trend in minor defects during assembly. By analyzing the process, I identified a slight variation in the supplier’s component tolerances. Proactively addressing this with the supplier prevented a significant batch of faulty products and saved the company considerable costs. A weakness I’m actively working on is delegating tasks effectively while maintaining the high quality standards I expect. Sometimes, my desire for perfection can lead to micromanagement. To overcome this, I’m focusing on training junior team members and implementing robust quality control checks that allow me to trust their work.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with quality control documentation and reporting.

My experience with quality control documentation and reporting is extensive. I’m proficient in creating and maintaining various documentation such as quality manuals, standard operating procedures (SOPs), inspection reports, and non-conformance reports (NCRs). I’m also adept at utilizing various software platforms like spreadsheets (Excel) and dedicated Quality Management Systems (QMS) software (like ISO 9001 compliant systems) to track and analyze quality data. In my previous role, I developed a new system for tracking NCRs, which improved our efficiency in identifying and resolving recurring issues. This new system involved using a color-coded system within our spreadsheets to easily identify the severity and trend of different types of defects. We presented this improved system to the board, showcasing the substantial reduction in defect-related costs. My reporting includes clear, concise summaries with actionable insights, presented visually through charts and graphs, for improved communication and decision-making.

Q 17. How do you handle conflicting priorities between quality and production speed?

Balancing quality and production speed requires a strategic approach. It’s not a zero-sum game; both are crucial for success. My strategy involves prioritizing tasks based on risk assessment. High-risk areas, where even minor defects can have major consequences, demand stricter quality control, even if it slows down production slightly. Lower-risk areas might allow for some speed optimization. For example, if we’re launching a new product, we would prioritize rigorous testing on its critical functionalities, even if it delays the overall timeline. However, for established products with stable processes, we can focus on streamlining production to increase efficiency without sacrificing quality. I find effective communication with the production team crucial. Open dialogue helps them understand the reasoning behind the prioritization and collaborate effectively to manage timelines while meeting quality standards.

Q 18. What is your experience with quality audits?

I have extensive experience participating in and leading quality audits, both internal and external. I’m familiar with various audit methodologies, including ISO 9001, and understand the importance of objective assessment and unbiased reporting. During audits, I follow a systematic approach: reviewing documentation, conducting on-site observations, interviewing personnel, and analyzing data. I’m adept at identifying non-conformances and generating clear, concise reports that highlight areas for improvement. In a previous audit, I identified a critical gap in our calibration procedure for a key measuring instrument, which if left unchecked could have significantly impacted the accuracy of our products. This finding led to immediate corrective actions and a revision of our procedures to ensure compliance and product accuracy.

Q 19. How do you ensure the quality of outsourced components or services?

Ensuring the quality of outsourced components or services is vital. My approach involves a multi-step process: first, selecting reputable suppliers through thorough due diligence, including verification of certifications and audits of their facilities. Second, establishing clear and comprehensive specifications and quality control parameters in contracts. This includes defining acceptable quality levels (AQLs) and defining clear acceptance criteria. Third, implementing robust monitoring mechanisms, such as regular inspections, testing of samples, and performance reviews. Fourth, building strong relationships with suppliers to facilitate open communication and address issues promptly. Finally, regular performance reviews and scorecards to monitor performance and identify areas for improvement. For example, at ABC company, we developed a detailed supplier rating system based on various criteria, helping us choose high quality partners and continuously monitor their performance.

Q 20. How do you use data to drive quality improvements?

Data is the cornerstone of effective quality improvement. I use data analysis to identify trends, pinpoint root causes of defects, and track the effectiveness of corrective actions. I’m proficient in utilizing statistical process control (SPC) tools such as control charts to monitor process variation and identify out-of-control situations. For instance, using control charts, we noticed a gradual increase in the defect rate of a specific component. By analyzing the data further, we were able to pinpoint the root cause to a faulty batch of raw materials from a supplier, allowing us to address the issue and prevent further defects. This data-driven approach helps us make informed decisions, prioritize resources, and continuously improve our processes.

Q 21. Describe your experience with continuous improvement methodologies (e.g., Kaizen, Lean).

I have experience implementing continuous improvement methodologies such as Kaizen (continuous improvement) and Lean manufacturing principles. I’m familiar with tools such as value stream mapping, 5S methodology, and root cause analysis (e.g., 5 Whys). In my previous role, we used Kaizen events to improve our assembly line efficiency. Through a collaborative team effort, we identified and eliminated several bottlenecks, resulting in a significant reduction in production time and improved overall quality. We documented the improvements and created standard operating procedures to maintain these gains. Lean principles helped us identify and eliminate waste throughout the process, optimizing our resource allocation and improving overall productivity. I believe that continuous improvement is a journey, not a destination; it’s a mindset of constant learning and adaptation.

Q 22. How do you communicate quality control findings to different stakeholders?

Communicating quality control findings effectively requires tailoring the message to the audience. For executive stakeholders, I focus on high-level summaries, key performance indicators (KPIs), and the overall impact on business objectives. For example, I might present a dashboard showing the defect rate and its cost implications. For technical teams, I provide detailed reports with root cause analyses, corrective actions, and supporting data, perhaps including statistical process control (SPC) charts. With line managers, the focus is on actionable steps, resource allocation needs, and the impact on their specific teams. I always ensure clear, concise language, avoiding jargon, and using visuals to enhance understanding. I encourage two-way communication, welcoming questions and actively listening to concerns to foster collaboration and ownership.

For instance, when identifying a consistent defect in a manufacturing process, I’d present a concise executive summary highlighting the cost impact and recommended solutions. Then, for the engineering team, I’d detail the root cause analysis, the statistical evidence, and the proposed corrective actions. This ensures everyone has the information they need in a format they can easily understand.

Q 23. What is your experience with calibration and verification procedures?

Calibration and verification are crucial for ensuring the accuracy and reliability of our measurement systems. My experience includes managing the entire calibration process, from selecting accredited calibration labs to tracking calibration certificates and managing equipment maintenance schedules. I’m proficient in using various calibration techniques and instruments, depending on the type of equipment. For example, I’ve managed the calibration of precision balances, thermometers, and pressure gauges using traceable standards. Verification involves confirming that equipment is functioning within acceptable limits between calibrations and ensuring that the methods and processes used meet specifications. This often involves periodic checks and the creation of verification procedures that can be easily followed by operators. I’ve developed and implemented verification procedures using control charts and other statistical methods to monitor the stability and performance of our measurement equipment.

In one project, we implemented a new automated testing system. Before full rollout, we rigorously verified its accuracy and precision by comparing its results to those from our existing, calibrated equipment. This systematic approach ensured the new system’s outputs were reliable, saving us from potential costly errors later on.

Q 24. How do you handle pressure and deadlines while maintaining high quality standards?

Handling pressure and deadlines while maintaining quality is a key skill. My approach involves prioritizing tasks effectively, utilizing project management tools to track progress, and proactively communicating potential roadblocks. I believe in building strong relationships with team members and clearly defining roles and responsibilities. When under pressure, I focus on the critical elements first, ensuring that core quality standards are not compromised. I also advocate for realistic deadlines and communicate openly about any challenges that may impact quality. This includes escalating concerns when necessary to avoid cutting corners.

For example, during a product launch with a tight deadline, I prioritized critical testing phases, ensuring compliance with regulatory requirements. By clearly communicating potential delays stemming from unforeseen issues, I secured additional resources and adjusted the schedule, avoiding a compromised launch.

Q 25. Describe your experience with different quality control methodologies (e.g., Six Sigma, TQM).

I have extensive experience with various quality control methodologies. Six Sigma, with its focus on reducing variation and defects, has been instrumental in streamlining processes and improving efficiency. I’ve led projects using DMAIC (Define, Measure, Analyze, Improve, Control) to identify and eliminate root causes of defects. Total Quality Management (TQM) has shaped my understanding of a holistic approach to quality, emphasizing continuous improvement and employee involvement. I’ve implemented TQM principles through employee training programs, promoting a culture of quality across the organization. Other methodologies I’ve utilized include Statistical Process Control (SPC), Failure Mode and Effects Analysis (FMEA) – which I’ll elaborate on further – and Lean manufacturing principles, focusing on waste reduction and process optimization. Each methodology provides a different lens through which to examine and improve quality.

In one project using Six Sigma, we reduced the defect rate in a particular assembly process by 80% by identifying and eliminating the primary sources of variability through data analysis and process adjustments.

Q 26. How do you balance the cost of quality control with the potential costs of defects?

Balancing the cost of quality control with the potential costs of defects requires a risk-based approach. A thorough cost-benefit analysis is essential. While implementing extensive quality control measures can increase upfront costs, failing to do so can result in far greater expenses from product recalls, warranty claims, customer dissatisfaction, and reputational damage. Therefore, a proactive approach focused on preventing defects is generally more cost-effective in the long run. This includes investing in robust testing procedures, employee training, and preventative maintenance of equipment. The key is finding the optimal balance – investing enough to mitigate risks without incurring unnecessary expenses.

For example, implementing a new automated inspection system may seem costly initially. However, if it prevents even a small number of defects that would otherwise lead to costly customer returns, the investment pays for itself quickly.

Q 27. How do you adapt your quality control approach to different products or services?

Adapting my quality control approach depends entirely on the specific product or service. The methodologies and techniques employed differ significantly between manufacturing a complex electronic device and providing a customer service hotline. For physical products, I focus on robust testing procedures, including inspection, functional testing, and environmental testing. For services, the focus shifts to customer satisfaction surveys, feedback analysis, and monitoring key performance indicators such as response times and resolution rates. The critical elements remain consistent: defining clear quality standards, implementing appropriate monitoring mechanisms, and employing data-driven decision-making to continuously improve processes.

For example, while developing a rigorous inspection protocol for a new medical device requires a very different approach than designing a customer feedback program for a software application, both involve clear quality standards, ongoing monitoring, and continuous improvement based on data analysis.

Q 28. Explain your understanding of failure mode and effects analysis (FMEA).

Failure Mode and Effects Analysis (FMEA) is a systematic approach to identifying potential failures in a system or process and assessing their potential impact. It’s a proactive risk assessment tool. The process involves identifying potential failure modes, assessing their severity, occurrence, and detection, and calculating a risk priority number (RPN). A high RPN indicates a failure mode that requires immediate attention. The FMEA process then helps to develop and implement corrective actions to mitigate the risks. The resulting documentation serves as a living document, updated as the system or process evolves.

For instance, in designing a new software application, a FMEA might identify a potential failure mode as a database crash. Assessing severity, occurrence, and detection, one can determine if this failure requires immediate action. The corrective action might involve implementing database redundancy or robust error handling.

Key Topics to Learn for Adhering to Quality Control Standards Interview

- Understanding Quality Control Methodologies: Explore different approaches like Six Sigma, Lean Manufacturing, ISO 9001, and their practical applications in various industries.

- Statistical Process Control (SPC): Learn about control charts, process capability analysis, and how to interpret data to identify trends and potential quality issues.

- Root Cause Analysis Techniques: Master methods like the 5 Whys, Fishbone diagrams, and Pareto analysis to effectively identify and address the root causes of quality problems.

- Quality Assurance vs. Quality Control: Understand the distinction between these two crucial concepts and their respective roles in maintaining high quality standards.

- Implementing Quality Control Procedures: Discuss practical examples of creating and implementing quality control plans, including inspection protocols, testing methods, and corrective actions.

- Documentation and Record Keeping: Understand the importance of meticulous documentation in maintaining a verifiable quality control system and complying with industry regulations.

- Continuous Improvement: Discuss the importance of continuous improvement methodologies like Kaizen and their role in driving quality enhancements.

- Problem-Solving and Decision-Making in Quality Control: Develop your ability to analyze complex quality issues, propose effective solutions, and make data-driven decisions.

- Communication and Collaboration: Highlight the importance of effective communication and collaboration with cross-functional teams to maintain quality across different departments.

Next Steps

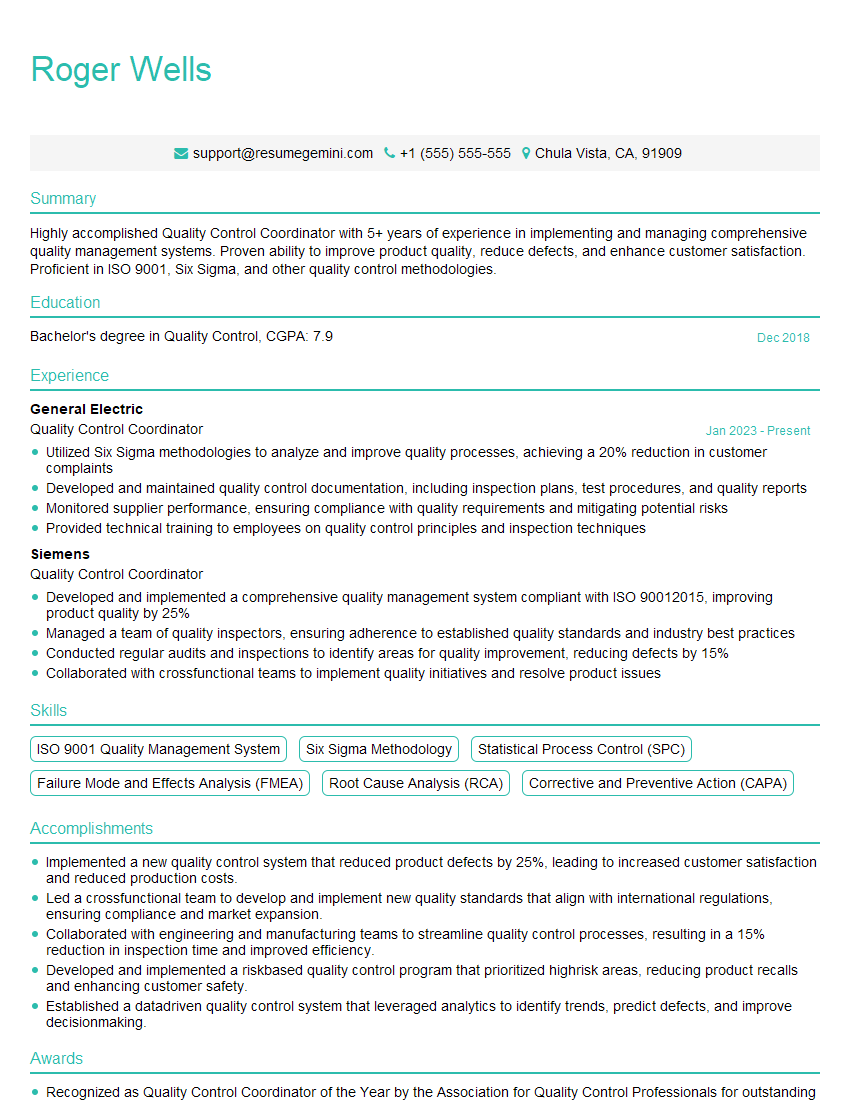

Mastering adherence to quality control standards is crucial for career advancement in many fields. Demonstrating a strong understanding of these principles significantly enhances your value to any organization. To improve your job prospects, invest time in crafting an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to quality control standards are available on ResumeGemini to guide you in showcasing your capabilities effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good