Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Experience in warehousing and inventory management interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Experience in warehousing and inventory management Interview

Q 1. Explain your experience with different inventory management systems (e.g., FIFO, LIFO, FEFO).

Inventory management systems dictate how we manage stock based on its age or other factors. Three common methods are FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and FEFO (First-Expired, First-Out).

- FIFO: Imagine a bakery. The first loaves of bread baked are the first ones sold. This minimizes waste with perishable goods. In a warehouse setting, this means the oldest inventory is shipped out first. This is great for products with short shelf lives or those susceptible to obsolescence.

- LIFO: Think of a stack of plates. You take the top plate (the last one added) first. This method can be beneficial for tax purposes in some situations, as the cost of goods sold reflects current market prices, potentially lowering tax liability. However, it’s less ideal for perishable goods.

- FEFO: This is crucial for products with expiration dates, like food or pharmaceuticals. The inventory closest to its expiration date is shipped or used first, ensuring minimal waste and preventing the sale of expired products. I’ve used FEFO extensively in managing a pharmaceutical warehouse, preventing significant losses from product expiration.

My experience spans using all three methods; the choice depends entirely on the product type, industry regulations, and business objectives. In one role, we used FIFO for most inventory, but switched to FEFO for specific pharmaceutical products nearing their expiry dates, utilizing a WMS (Warehouse Management System) to track this effectively.

Q 2. Describe your experience with warehouse management systems (WMS).

Warehouse Management Systems (WMS) are the backbone of efficient warehouse operations. They’re software solutions that manage and optimize warehouse processes, from receiving and putaway to order fulfillment and shipping. My experience includes working with several WMS platforms, both cloud-based and on-premise.

I’ve used WMS to track inventory levels in real-time, manage picking and packing processes, optimize storage locations based on product popularity and size, and generate crucial reports on warehouse performance. For instance, one WMS I used generated reports on picking efficiency, allowing us to identify bottlenecks and improve workflows. It also integrated with our ERP system, providing a seamless flow of information between sales, inventory, and warehouse management.

Beyond basic functionality, I’ve leveraged advanced WMS features like slotting optimization (maximizing space utilization), automated guided vehicle (AGV) integration, and labor management tools to improve productivity and reduce operational costs. The most impactful feature was the ability to track key performance indicators (KPIs) such as order accuracy, picking time, and storage density, allowing for data-driven decision-making and continuous improvement.

Q 3. How do you ensure accuracy in inventory counts?

Accuracy in inventory counts is paramount. Inaccuracies lead to stockouts, overstocking, and financial losses. I employ a multi-pronged approach:

- Regular Cycle Counting: Instead of a full inventory count annually, we conduct cycle counts regularly. This is a more efficient and less disruptive method to identify discrepancies early. For example, in my previous role, we counted a specific section of the warehouse daily, rotating through all sections.

- WMS Integration: A robust WMS is crucial for real-time inventory tracking. It automatically updates inventory levels after each transaction, reducing manual entry errors. Regular reconciliation between the physical count and the WMS record is essential.

- Barcode/RFID Scanning: Barcodes and RFID technology ensure accurate and efficient counting of inventory. These minimize manual entry mistakes and significantly speed up the counting process.

- Trained Personnel: Proper training of warehouse personnel on inventory procedures, including accurate scanning and counting techniques, is essential.

- Discrepancy Investigation: Any discrepancies identified during cycle counts or physical inventories are thoroughly investigated to pinpoint the root cause (e.g., damaged goods, theft, data entry error) and prevent future occurrences.

By combining these methods, we can maintain a high level of accuracy, minimizing inventory discrepancies and ensuring accurate financial reporting.

Q 4. What methods do you use to optimize warehouse space utilization?

Optimizing warehouse space utilization is a continuous process. It’s about maximizing storage capacity while maintaining efficient workflows. My strategies include:

- Strategic Slotting: Products are assigned storage locations based on factors like popularity, size, weight, and turnover rate. Fast-moving items are located closer to picking areas, while slower-moving items are placed in less accessible locations. WMS software significantly aids in this process.

- Vertical Space Maximization: Utilizing vertical space with racking systems, mezzanines, and high-bay storage solutions increases storage capacity without expanding the warehouse footprint.

- Efficient Layout Design: Designing a warehouse layout that minimizes travel distances between receiving, storage, picking, and shipping areas improves efficiency and reduces handling time.

- Regular Space Audits: Periodically reviewing space utilization and identifying areas for improvement, such as removing obsolete or slow-moving inventory, and re-allocating space based on changing demand.

- Cross-Docking: For products that don’t require storage, implementing cross-docking can significantly improve space utilization by moving goods directly from receiving to shipping.

For example, in one project, by implementing strategic slotting and optimizing the warehouse layout, we increased storage capacity by 15% without increasing the warehouse’s physical size, leading to significant cost savings.

Q 5. Explain your experience with cycle counting and its benefits.

Cycle counting is the process of regularly counting a small portion of inventory instead of a full physical inventory. It’s a more efficient and less disruptive approach to maintaining accurate inventory records. My experience with cycle counting has been very positive.

Benefits include:

- Improved Accuracy: Regular counts identify discrepancies early, allowing for timely correction.

- Reduced Downtime: Unlike a full physical inventory, cycle counting doesn’t shut down warehouse operations.

- Cost Savings: The reduced downtime translates into cost savings in terms of labor and lost productivity.

- Enhanced Inventory Control: Regular counts provide a more accurate and up-to-date picture of inventory levels.

- Data-Driven Decisions: The data collected through cycle counting can be analyzed to identify trends and areas for improvement in warehouse processes.

In one company, implementing a robust cycle counting program reduced inventory discrepancies by 20% within six months, directly impacting financial reporting accuracy and improving customer service levels.

Q 6. How do you handle discrepancies in inventory records?

Inventory discrepancies are inevitable, but a systematic approach to handling them is essential. My process involves:

- Immediate Investigation: Any discrepancy identified during cycle counting or a physical inventory is investigated immediately to determine the root cause.

- Verification: The discrepancy is verified by recounting the inventory and double-checking the data in the WMS.

- Root Cause Analysis: Once the discrepancy is verified, the root cause is identified. This could be due to data entry errors, picking mistakes, theft, damage, or even system glitches.

- Corrective Action: Appropriate corrective action is taken to prevent similar discrepancies in the future. This might involve retraining staff, improving processes, or upgrading equipment.

- Documentation: The entire process, from identification to resolution, is meticulously documented for tracking and audit purposes.

For example, a recurring discrepancy in a particular aisle led us to discover a problem with the barcode scanner in that area. After replacing the scanner, the discrepancies ceased.

Q 7. Describe your experience with receiving and shipping procedures.

Receiving and shipping procedures are critical for efficient warehouse operations. My experience encompasses all aspects, from the moment goods arrive to their departure.

Receiving:

- Verification: Upon arrival, shipments are verified against purchase orders to ensure quantity and condition accuracy.

- Inspection: Goods are inspected for damage or discrepancies.

- Put-away: Inventory is put away in designated storage locations according to the WMS instructions.

- Documentation: All receiving activities are meticulously documented.

Shipping:

- Order Fulfillment: Orders are picked, packed, and labeled according to customer specifications.

- Shipping Label Generation: Accurate shipping labels are generated and affixed to packages.

- Carrier Selection: Appropriate carriers are selected based on cost and delivery time requirements.

- Shipment Tracking: Shipments are tracked to ensure timely delivery and address any potential issues.

- Documentation: All shipping activities are documented.

In one role, I implemented a new receiving system that reduced processing time by 25%, improving efficiency and minimizing errors. Similarly, optimizing the shipping process by streamlining order fulfillment resulted in faster turnaround times and improved customer satisfaction.

Q 8. How do you manage damaged or obsolete inventory?

Managing damaged or obsolete inventory is crucial for maintaining profitability and warehouse space. It involves a multi-step process focusing on identification, segregation, and disposal or repurposing.

- Identification: Regular stock checks, using both visual inspections and potentially barcode scanning, are key to identifying damaged goods (e.g., broken packaging, expired products). We use a clear system of marking damaged items, often with specific labels indicating the damage type and date of discovery. Obsolete inventory is identified by tracking slow-moving items and analyzing sales data. We set thresholds for slow-moving items; anything below a certain sales rate for a specified period is flagged.

- Segregation: Once identified, damaged and obsolete items are immediately segregated from sellable inventory. This prevents accidental sale or use of damaged products and keeps a clean inventory area. Dedicated areas within the warehouse—perhaps even separate rooms—are designated for these items.

- Disposition: The final step involves deciding how to handle the identified items. Options include:

- Repair/Refurbishment: If economically viable, damaged goods might be repaired or refurbished for resale.

- Salvage/Discount Sale: Salvageable items (e.g., items with minor damage) might be sold at a discounted price or salvaged for parts.

- Donation/Recycling: Non-salvageable items may be donated to charity, or if environmentally responsible, recycled or disposed of according to regulations.

- Write-off: In cases of complete damage or significant obsolescence, a formal write-off process, usually involving accounting department approval, is required to remove the items from inventory records.

For example, in a previous role, we implemented a system using RFID tags to track inventory, allowing for quick identification of slow-moving items and efficient segregation of damaged goods. This improved our accuracy and speed of managing obsolete and damaged stock.

Q 9. What are your strategies for improving warehouse efficiency?

Improving warehouse efficiency involves optimizing processes, technology, and workforce management. My strategies revolve around these three pillars:

- Process Optimization: This includes analyzing the workflow to identify bottlenecks and inefficiencies. Techniques like Value Stream Mapping help visualize the entire process, allowing us to pinpoint areas for improvement. For instance, optimizing picking routes using software can significantly reduce travel time and increase order fulfillment speed. We also implement lean principles to minimize waste and maximize efficiency in every step of the process.

- Technology Integration: Warehouse Management Systems (WMS) are crucial. A robust WMS can automate tasks like inventory tracking, order management, and shipping, significantly reducing manual effort and human error. Implementing barcode scanning or RFID technology further streamlines picking, packing, and receiving processes. Real-time visibility provided by these technologies allows for quicker responses to inventory discrepancies and demand fluctuations.

- Workforce Management: Efficient workforce management involves proper training, clear communication, and motivating the team. Cross-training employees enhances flexibility, allowing for better coverage during peak times or absences. Regular performance reviews and feedback sessions help improve productivity and identify skill gaps. Furthermore, providing the right equipment and ergonomic workspace design minimizes fatigue and workplace injuries.

In a past role, implementing a WMS and optimizing picking routes resulted in a 15% increase in order fulfillment speed and a 10% reduction in labor costs.

Q 10. How do you prioritize tasks in a fast-paced warehouse environment?

Prioritization in a fast-paced warehouse is critical for meeting deadlines and maintaining order. I use a combination of methods:

- Urgency and Importance Matrix (Eisenhower Matrix): This framework categorizes tasks based on urgency and importance. High-urgency, high-importance tasks (e.g., urgent customer orders) are tackled immediately. High-importance, low-urgency tasks (e.g., preventative maintenance) are scheduled proactively. Low-importance tasks are delegated or eliminated.

- FIFO (First-In, First-Out): This applies to inventory management, ensuring that older items are moved first to minimize obsolescence and spoilage. This also applies to tasks, prioritizing those received first or closest to deadlines.

- Prioritization Software/Systems: Many WMS systems include task management modules that assign priorities based on factors like order deadlines, shipping schedules, and product demand.

- Visual Management: Kanban boards or similar visual tools provide real-time visibility of tasks and their status. This allows for clear communication and quick adjustments based on changing priorities.

Imagine a scenario with a large rush order alongside routine tasks. Using the Eisenhower Matrix, the rush order takes priority, while routine tasks are scheduled efficiently to ensure everything gets done.

Q 11. Explain your experience with safety regulations in a warehouse setting.

Safety is paramount in a warehouse environment. My experience encompasses adherence to OSHA (or equivalent) regulations and the implementation of safety protocols. This includes:

- Regular Safety Training: Ensuring all employees receive comprehensive training on topics like forklift operation, hazard communication, proper lifting techniques, and emergency procedures. Regular refresher courses are also crucial.

- Proper Equipment Maintenance: Forklifts, conveyors, and other equipment must be regularly inspected and maintained to prevent malfunctions that could lead to accidents.

- Safe Work Practices: Implementing and enforcing safe work practices, such as the use of personal protective equipment (PPE), proper storage of materials, and clear signage to indicate potential hazards.

- Incident Reporting and Investigation: Establishing a system for reporting and investigating workplace accidents to identify root causes and prevent future incidents. Data from these investigations can be used to improve safety procedures.

- Emergency Preparedness: Having a well-defined emergency plan that includes evacuation procedures, first-aid response, and communication protocols.

For example, in a previous role, we implemented a ‘near-miss’ reporting system where employees could report potential hazards without fear of reprimand. This proactive approach led to significant improvements in safety practices and a reduction in workplace accidents.

Q 12. How do you maintain accurate inventory records in a high-volume environment?

Maintaining accurate inventory records in a high-volume environment requires a combination of technology and robust processes.

- WMS Integration: A well-configured WMS is indispensable, automating the tracking of inventory movements throughout the entire process, from receiving to shipping. Real-time updates eliminate delays in recording changes.

- Barcode/RFID Technology: Utilizing barcode or RFID scanning at every stage of the supply chain (receiving, put-away, picking, shipping) minimizes manual data entry and human error. This ensures that every item is accurately tracked.

- Cycle Counting: Regular cycle counting, where a portion of the inventory is counted and verified periodically, allows for early detection of discrepancies and prevents large-scale recounts. This minimizes disruption compared to a full inventory count.

- Regular Reconciliation: Regular reconciliation of physical inventory against the WMS records helps identify and rectify discrepancies. This ensures the system reflects the true state of the warehouse.

- Inventory Audits: Periodic, more comprehensive inventory audits provide an independent verification of accuracy. This helps identify systematic errors or areas needing improvement.

In a previous warehousing role, the implementation of RFID tracking in conjunction with cycle counting led to a significant reduction (90%) in inventory discrepancies compared to the previous manual system.

Q 13. Describe your experience with forecasting inventory needs.

Forecasting inventory needs involves predicting future demand to optimize stock levels and minimize waste. My experience incorporates various methods:

- Historical Data Analysis: This forms the basis of any forecast. Analyzing past sales data, taking into account seasonality, trends, and promotions, provides a baseline prediction. We often utilize statistical software for detailed analysis.

- Market Trends and External Factors: Considering broader market trends (e.g., economic conditions, competitor activity) and external factors (e.g., weather patterns, supply chain disruptions) helps refine the forecast. For example, anticipating a seasonal surge in demand due to the holiday season requires preemptive adjustments to inventory levels.

- Sales and Marketing Input: Collaboration with the sales and marketing teams provides valuable insights into planned promotions and anticipated demand. This input helps to adjust forecasts based on anticipated marketing campaigns or new product launches.

- Demand Forecasting Software: Specialized software packages can leverage advanced statistical models (e.g., ARIMA, exponential smoothing) to improve forecasting accuracy by taking into account complex factors and large datasets.

- Safety Stock Consideration: Including a safety stock buffer in the forecast accounts for unforeseen demand spikes or supply chain disruptions. The level of safety stock is determined based on lead times and demand variability.

In one instance, by incorporating market trend analysis and collaboration with the marketing team into our forecasting model, we successfully predicted a surge in demand for a product during a promotional campaign, avoiding potential stockouts and maximizing sales.

Q 14. How do you manage stock replenishment to avoid stockouts or overstocking?

Managing stock replenishment requires a delicate balance between avoiding stockouts (loss of sales) and overstocking (increased storage costs and obsolescence). My approach incorporates the following:

- Economic Order Quantity (EOQ): This model calculates the optimal order quantity to minimize the total cost of inventory management. It considers factors such as ordering costs, holding costs, and demand.

- Reorder Point (ROP): The ROP determines the inventory level at which a new order should be placed. This takes into account lead time (the time it takes for an order to be received) and demand during that lead time.

- Just-in-Time (JIT) Inventory: In some cases, a JIT approach minimizes inventory holding costs by receiving materials only when needed. This requires close coordination with suppliers and precise demand forecasting.

- Vendor-Managed Inventory (VMI): This allows suppliers to manage inventory levels in our warehouse, reducing our workload and improving efficiency. This requires trust and strong collaboration with suppliers.

- Inventory Control Software: WMS systems often incorporate modules to automate reorder point calculations, generate purchase orders, and monitor inventory levels.

For example, using EOQ and ROP calculations, we optimized our ordering strategy for a particular product, resulting in a 10% reduction in storage costs without increasing the risk of stockouts.

Q 15. What are your methods for preventing inventory shrinkage?

Inventory shrinkage, the difference between recorded inventory and actual inventory, is a significant concern in warehousing. Preventing it requires a multi-pronged approach focusing on process improvement, technology, and employee accountability.

- Robust Receiving Procedures: Implementing strict checks during receiving, including accurate quantity counts against purchase orders and condition checks, is crucial. Discrepancies should be immediately flagged and investigated.

- Cycle Counting: Regularly counting a small subset of inventory items instead of a full inventory count minimizes disruption and identifies discrepancies early. We use a cycle counting schedule that prioritizes high-value or fast-moving items.

- Secure Storage: Implementing measures to prevent theft and damage, such as secure storage areas, access controls, and surveillance systems, is essential. We use a combination of CCTV cameras, motion sensors, and restricted access areas based on job roles.

- Improved Inventory Management Software: Implementing an inventory management system (IMS) with real-time tracking capabilities allows for immediate identification of discrepancies. This system also helps to optimize storage and reduce the risk of misplacement.

- Employee Training and Accountability: Thorough training on proper inventory handling procedures, emphasizing accuracy and responsibility, is vital. Clear policies on theft and damage should be established and communicated. We implement a system of checks and balances to reduce the risk of internal theft.

For example, in my previous role, implementing a more rigorous cycle counting program reduced our shrinkage rate by 15% within six months.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with using barcode scanners and RFID technology.

Barcode scanners and RFID (Radio-Frequency Identification) technology are invaluable tools for efficient inventory management. Both technologies improve accuracy and speed, but they have different strengths.

- Barcode Scanners: I have extensive experience with barcode scanners, using them for receiving, putaway, picking, and shipping. They are cost-effective and provide accurate data entry for individual items. However, they require line-of-sight and individual scanning.

- RFID: RFID technology offers a significant advantage in its ability to track multiple items simultaneously without line-of-sight. This is particularly useful for tracking pallets or large quantities of items. In my previous role, implementing RFID for pallet tracking improved our receiving efficiency by 20% and reduced stocktaking time significantly. We used an RFID system integrated with our warehouse management system (WMS) to provide real-time visibility into inventory movement.

While RFID offers greater efficiency and real-time tracking, the initial investment is higher than barcode scanners. The choice often depends on the budget, scale of operation, and specific needs.

Q 17. Describe a time you had to resolve a significant inventory discrepancy.

During a large-scale inventory reconciliation, we discovered a significant discrepancy in our high-value electronics inventory. The recorded quantity was considerably higher than the physical count.

To resolve this, we implemented a systematic approach:

- Isolate the Problem: We focused on the specific area where the discrepancy was most pronounced, which was the electronics section of the warehouse.

- Review Processes: We meticulously examined all procedures relating to the electronics inventory, from receiving to shipping, looking for potential points of error. We discovered a lapse in our cycle counting process concerning this specific area.

- Data Reconciliation: We compared our inventory management system data against physical counts, purchase orders, and sales records, cross-referencing to identify any potential errors in data entry or system glitches.

- Root Cause Analysis: The root cause was identified as inconsistent cycle counting practices, leading to inaccurate inventory records. We also discovered a potential case of internal theft. We worked with security to investigate further.

- Corrective Actions: We implemented stricter cycle counting procedures with increased oversight, improved training for staff on accurate data entry, and implemented better inventory management software. We also improved security measures around high-value items.

This experience highlighted the importance of robust processes, thorough investigation, and the need for regular review of inventory management procedures.

Q 18. How do you handle peak seasons or unexpected surges in demand?

Managing peak seasons requires proactive planning and flexible strategies. Unexpected surges demand adaptability and efficient communication.

- Demand Forecasting: Accurately forecasting demand allows for proactive inventory planning and staff scheduling to meet anticipated needs. Historical data analysis and market trend insights are crucial for effective forecasting.

- Temporary Staffing: Hiring temporary staff to support increased workloads during peak seasons can alleviate pressure on existing teams and improve efficiency. Thorough training for temporary workers is critical to maintain quality standards.

- Flexible Warehouse Layout: Adapting the warehouse layout to maximize space and streamline processes is beneficial. This might involve optimizing storage locations for high-demand items or creating temporary staging areas.

- Prioritization: Implementing a system for prioritizing orders based on urgency and importance ensures efficient fulfillment during periods of high demand. We use a first-in, first-out (FIFO) system, and often supplement it with prioritization during peak periods.

- Overtime Management: Offering overtime opportunities to existing staff can be a cost-effective way to handle increased workload, provided it’s managed fairly and within legal guidelines.

For instance, during last year’s holiday season, we used demand forecasting to predict a 30% increase in orders and successfully managed the surge by proactively hiring temporary staff and adjusting our warehouse layout to increase efficiency.

Q 19. How do you train and supervise warehouse staff?

Training and supervising warehouse staff is crucial for safety, efficiency, and maintaining accuracy. My approach involves a combination of formal training, on-the-job coaching, and regular performance feedback.

- Initial Training: New hires receive comprehensive training on safety protocols, warehouse procedures (receiving, putaway, picking, packing, shipping), inventory management systems, and equipment operation. We use a combination of classroom training and hands-on practice.

- On-the-Job Coaching: Experienced staff mentors new hires, providing ongoing support and guidance. Regular check-ins ensure proper technique and adherence to procedures.

- Performance Feedback: Regular performance reviews provide constructive feedback, identifying areas for improvement and recognizing achievements. This promotes continuous learning and improvement.

- Cross-Training: Cross-training staff on various warehouse tasks increases flexibility and efficiency, ensuring coverage across different roles.

- Safety Training: Regular refresher courses and safety meetings emphasize safe work practices to mitigate risks of injury and accidents. This is crucial for maintaining a safe work environment.

I believe in fostering a supportive and collaborative environment where staff feel empowered to contribute their ideas and address concerns.

Q 20. What are your experience with different types of warehouse layouts?

Experience with various warehouse layouts is essential for optimizing space, workflow, and efficiency. Different layouts suit different operational needs.

- U-Shaped Layout: Efficient for smaller warehouses, where processes are arranged in a U-shape to minimize movement.

- L-Shaped Layout: Often used in larger facilities to maximize space utilization, particularly when dealing with multiple product lines.

- I-Shaped Layout: A simple, linear layout suitable for warehouses with a single processing line.

- Flow-Through Layout: Optimizes the flow of goods through the warehouse, minimizing handling and maximizing throughput. This is particularly effective for high-volume operations.

- Block Stacking: Simple and commonly used but can be inefficient for faster picking times.

The optimal layout depends on factors like product types, volume, order fulfillment methods, and available space. In my previous role, we transitioned from a U-shaped layout to a flow-through layout, resulting in a 10% increase in picking efficiency.

Q 21. How do you manage relationships with suppliers and carriers?

Managing relationships with suppliers and carriers is critical for maintaining a reliable supply chain. Effective communication and collaboration are essential.

- Supplier Relationship Management (SRM): Establishing strong relationships with key suppliers through regular communication, performance monitoring, and collaborative problem-solving ensures timely delivery of high-quality goods. We utilize a system of key performance indicators (KPIs) to track supplier performance.

- Carrier Management: Choosing reliable carriers with appropriate service levels and negotiating favorable rates are important. We regularly evaluate carrier performance based on factors such as on-time delivery, damage rates, and cost-effectiveness. We use a combination of different carriers to ensure redundancy and resilience in our supply chain.

- Negotiation and Contracts: Negotiating favorable terms with suppliers and carriers, including pricing, lead times, and service level agreements (SLAs), is crucial for cost control and operational efficiency. We maintain formal contracts specifying key terms and conditions.

- Conflict Resolution: Developing effective strategies for resolving disputes or addressing issues with suppliers or carriers is essential for maintaining smooth operations. We prioritize open communication and collaborative problem-solving to maintain positive relationships.

- Technology Integration: Integrating supplier and carrier information into inventory management systems allows for real-time tracking and improved coordination across the supply chain. We use a system that provides real-time tracking of shipments, allowing us to anticipate delays and proactively adjust our operations as needed.

Building strong, collaborative relationships is key to ensuring a reliable and cost-effective supply chain.

Q 22. What are your strategies for preventing warehouse accidents?

Preventing warehouse accidents requires a multi-faceted approach focusing on proactive measures, employee training, and robust safety protocols. It’s not just about reacting to incidents; it’s about building a culture of safety.

- Proactive Measures: This includes regular inspections of the warehouse to identify and rectify potential hazards like damaged flooring, faulty equipment, or poor lighting. Implementing a robust preventative maintenance program for all machinery is crucial. Properly designed walkways, clearly marked areas, and adequate aisle space are essential for preventing collisions and falls.

- Employee Training: Thorough training on safe operating procedures for equipment, proper lifting techniques, and hazard awareness is paramount. Regular refresher courses keep safety top-of-mind. We can use interactive simulations or practical demonstrations to reinforce learning. For instance, I once implemented a forklift safety training program that included hands-on practice in a controlled environment, resulting in a 30% reduction in forklift-related incidents.

- Safety Protocols: Clear and concise safety protocols, readily accessible to all employees, are essential. This includes procedures for reporting accidents, handling spills, and emergency evacuations. Regular safety meetings and drills help familiarize employees with these procedures. I’ve successfully implemented a ‘Near Miss’ reporting system, encouraging employees to report potential hazards before they lead to accidents. Analyzing these reports helps proactively identify and mitigate risks.

Q 23. Explain your experience with implementing new warehouse technologies or processes.

I have extensive experience implementing new warehouse technologies and processes, focusing on improving efficiency and accuracy. My approach involves careful planning, phased implementation, and thorough employee training.

- Warehouse Management System (WMS) Implementation: In a previous role, I spearheaded the implementation of a new WMS, replacing a largely manual system. This involved selecting the appropriate software, customizing it to our specific needs, migrating existing data, and training staff on its use. The result was a significant improvement in order accuracy, inventory tracking, and overall warehouse efficiency. We saw a 20% reduction in picking errors and a 15% increase in order fulfillment speed.

- Automated Guided Vehicles (AGVs): I also oversaw the integration of AGVs into a high-volume distribution center. This involved mapping the warehouse floor, programming the AGVs’ routes, and training staff on their safe operation. The AGVs significantly reduced travel time for materials handling, leading to increased throughput and reduced labor costs.

- Radio Frequency Identification (RFID) Technology: I’ve successfully implemented RFID tracking for inventory management, allowing for real-time tracking of goods throughout the warehouse. This improved inventory accuracy, reduced stockouts, and simplified cycle counting processes. We saw a 10% decrease in inventory discrepancies.

In each case, a key to success was ensuring a smooth transition, minimizing disruption to operations, and providing comprehensive training to employees. Change management strategies were critical to adoption and success.

Q 24. How do you measure the success of your inventory management strategies?

Measuring the success of inventory management strategies involves several key performance indicators (KPIs). It’s not enough to simply have inventory; you need to manage it efficiently and effectively.

- Inventory Turnover Rate: This indicates how efficiently inventory is sold. A higher turnover rate generally suggests efficient inventory management, but an excessively high rate might point to stockouts.

Inventory Turnover = Cost of Goods Sold / Average Inventory - Inventory Accuracy: This measures the difference between the recorded inventory and the actual physical inventory. High accuracy minimizes discrepancies and prevents stockouts or overstocking. We typically measure this as a percentage:

Accuracy = (Physical Inventory - Recorded Inventory) / Recorded Inventory * 100% - Order Fulfillment Rate: This tracks the percentage of orders fulfilled on time and completely. A high rate indicates efficient order processing and inventory availability.

- Stockout Rate: This metric indicates the frequency of items being unavailable when needed. A low stockout rate is crucial for customer satisfaction and minimizing lost sales.

- Holding Costs: This considers the costs associated with storing inventory, such as warehouse rent, insurance, and taxes. Minimizing holding costs without compromising availability is a key goal.

By tracking these KPIs, we can identify areas for improvement and fine-tune our strategies. Regular reporting and analysis are crucial to maintain optimal performance.

Q 25. Describe your experience with analyzing warehouse data to identify areas for improvement.

Analyzing warehouse data is crucial for identifying areas for improvement. I use a combination of descriptive, diagnostic, predictive, and prescriptive analytics to gain insights and optimize operations.

- Descriptive Analytics: This involves summarizing historical data to understand past performance. For example, analyzing order fulfillment times, picking errors, and inventory levels over time provides a baseline understanding of current performance. Tools like Excel or data visualization software are often used here.

- Diagnostic Analytics: This delves deeper into the ‘why’ behind the data, identifying the root causes of issues. For instance, if order fulfillment times are consistently high, diagnostic analysis might reveal bottlenecks in the picking process or insufficient staff.

- Predictive Analytics: This involves forecasting future performance using statistical models. For example, predicting future demand based on historical sales data can help optimize inventory levels and prevent stockouts or overstocking. Tools like statistical software or machine learning algorithms can be employed.

- Prescriptive Analytics: This uses data-driven insights to recommend actions for improvement. For example, based on predictive analysis, we might recommend adjusting staffing levels or optimizing warehouse layouts.

I’ve used this approach in several situations to improve efficiency, reduce costs, and enhance customer satisfaction. For example, by analyzing data on picking routes, we identified inefficiencies and redesigned the warehouse layout, which led to a 10% reduction in picking times.

Q 26. How do you handle customer inquiries related to order status or delivery?

Handling customer inquiries regarding order status or delivery requires a proactive and customer-centric approach. Clear communication, efficient processes, and readily available information are key.

- Real-time Order Tracking: Providing customers with access to real-time order tracking through a website or mobile app allows them to monitor their shipment progress independently. This minimizes the number of inquiries regarding order status.

- Proactive Communication: Sending automated email updates on order status at key points in the fulfillment process keeps customers informed and reduces anxiety. For example, sending an update when the order is received, when it’s shipped, and when it’s out for delivery.

- Dedicated Customer Service Team: Having a dedicated customer service team trained to handle order inquiries efficiently and effectively is crucial. Empowering this team to resolve issues quickly and efficiently contributes to customer satisfaction. Clear escalation procedures for complex issues are also essential.

- Multiple Communication Channels: Offering various communication channels, such as phone, email, and chat, enables customers to contact us in their preferred way.

I’ve found that a well-trained and empowered customer service team, combined with transparent communication and robust order tracking systems, leads to high customer satisfaction and positive reviews.

Q 27. What is your experience with lean manufacturing principles in a warehouse environment?

Lean manufacturing principles, focused on eliminating waste and maximizing efficiency, are highly applicable to warehouse environments. My experience involves implementing several lean techniques to optimize operations.

- 5S Methodology: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) improves workplace organization, reducing wasted time searching for items. This leads to a safer and more efficient workspace. I successfully implemented this in a previous warehouse, resulting in a 15% reduction in search time for materials.

- Value Stream Mapping: This technique helps visualize the entire material flow in the warehouse, identifying bottlenecks and areas for improvement. By mapping the current state and then the future state, we can identify opportunities for waste reduction and process optimization. I utilized this to streamline our receiving process, reducing processing time by 20%.

- Kaizen Events: These are focused improvement events involving cross-functional teams to identify and implement quick, impactful changes. These events foster a culture of continuous improvement within the warehouse. Through several Kaizen events, we’ve been able to identify and eliminate numerous inefficiencies in our operations.

- Kanban Systems: These systems help control workflow and prevent overproduction. Implementing Kanban for inventory replenishment improved inventory control and reduced storage costs.

By systematically applying lean principles, we can create a more efficient, productive, and cost-effective warehouse operation.

Q 28. Describe your experience with implementing and maintaining quality control procedures in a warehouse.

Implementing and maintaining quality control procedures in a warehouse is crucial for ensuring the integrity of products and meeting customer expectations. My approach involves a combination of proactive measures and reactive processes.

- Incoming Inspection: A rigorous incoming inspection process is essential to ensure that all received goods meet quality standards. This includes verifying quantities, checking for damage, and assessing compliance with specifications. Any discrepancies are documented and communicated to suppliers. I implemented a system using barcode scanners to improve the speed and accuracy of incoming inspections.

- Storage Conditions: Maintaining appropriate storage conditions (temperature, humidity, etc.) is vital for preserving product quality, particularly for perishable or sensitive goods. Regular monitoring and adjustments ensure optimal storage conditions are maintained.

- Regular Audits: Conducting regular audits of inventory and processes helps identify potential quality issues early on. These audits might include physical inventory checks, temperature monitoring, and documentation review. I’ve used these audits to proactively identify and rectify potential quality problems before they impact customers.

- Training and Documentation: Proper training for warehouse staff on quality control procedures is crucial. Clear documentation of procedures and standards ensures consistency and compliance. I developed comprehensive training manuals and checklists to support this.

- Corrective Actions: Implementing a robust system for identifying, analyzing, and addressing quality issues is essential. This includes root cause analysis to prevent recurrence and implementing corrective actions to address the issue immediately.

By incorporating these quality control procedures, we ensure high product quality, reduce waste, and enhance customer satisfaction. A proactive approach is key to minimizing problems before they escalate.

Key Topics to Learn for Your Warehousing and Inventory Management Interview

- Inventory Management Techniques: Understanding FIFO, LIFO, and weighted average costing methods; their practical implications on financial reporting and operational efficiency.

- Warehouse Layout and Design: Optimizing space utilization, workflow design for efficient picking, packing, and shipping processes; discussing the impact of different layout strategies on productivity.

- Inventory Control Systems: Experience with WMS (Warehouse Management Systems) software; proficiency in data entry, reporting, and inventory tracking; troubleshooting system issues and suggesting improvements.

- Supply Chain Management Principles: Understanding the flow of goods from supplier to customer; identifying bottlenecks and inefficiencies; strategies for improving order fulfillment and delivery times.

- Safety and Compliance: Adherence to OSHA regulations and warehouse safety protocols; implementing best practices to prevent accidents and injuries; knowledge of hazardous materials handling.

- Teamwork and Communication: Collaborating effectively with warehouse staff, management, and other departments; clear and concise communication skills; experience leading or mentoring team members.

- Problem-Solving and Decision-Making: Analyzing inventory discrepancies, resolving stock issues, and implementing solutions to improve accuracy and efficiency; demonstrating critical thinking skills in addressing logistical challenges.

- Data Analysis and Reporting: Interpreting key performance indicators (KPIs) related to warehouse operations; generating reports to track performance and identify areas for improvement; using data to support decision-making.

Next Steps

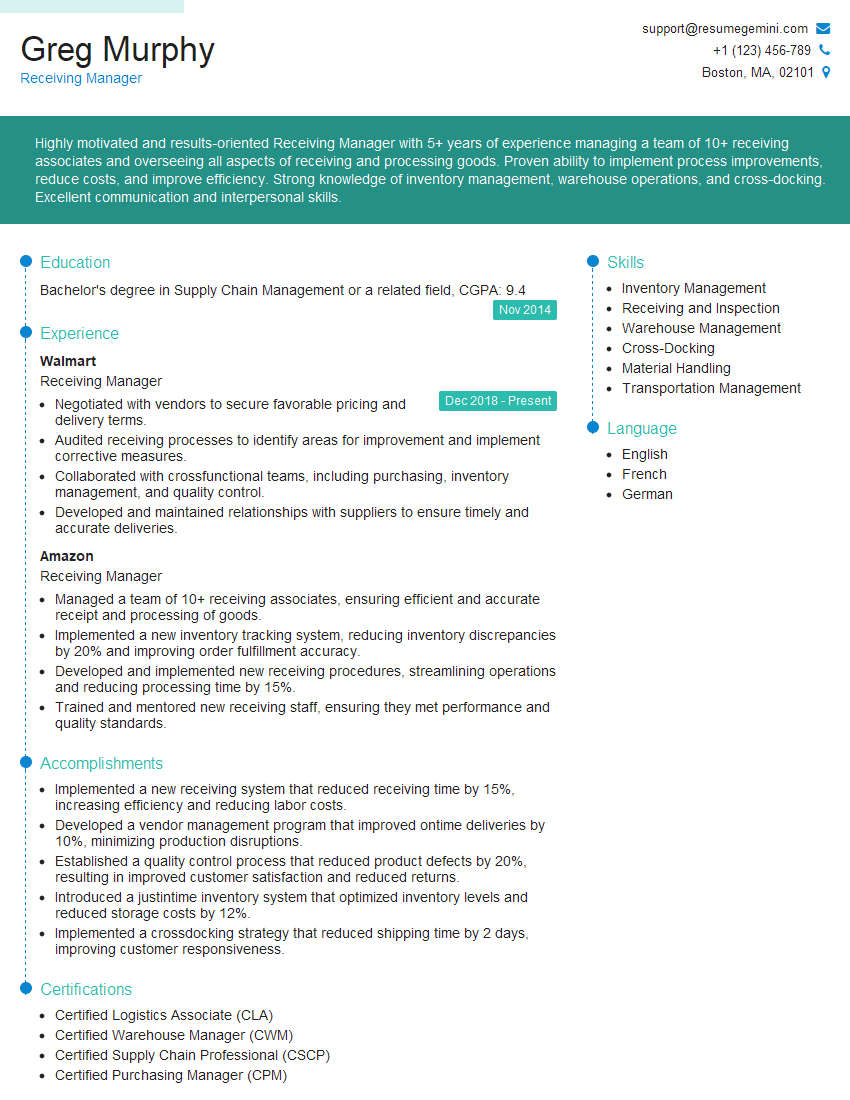

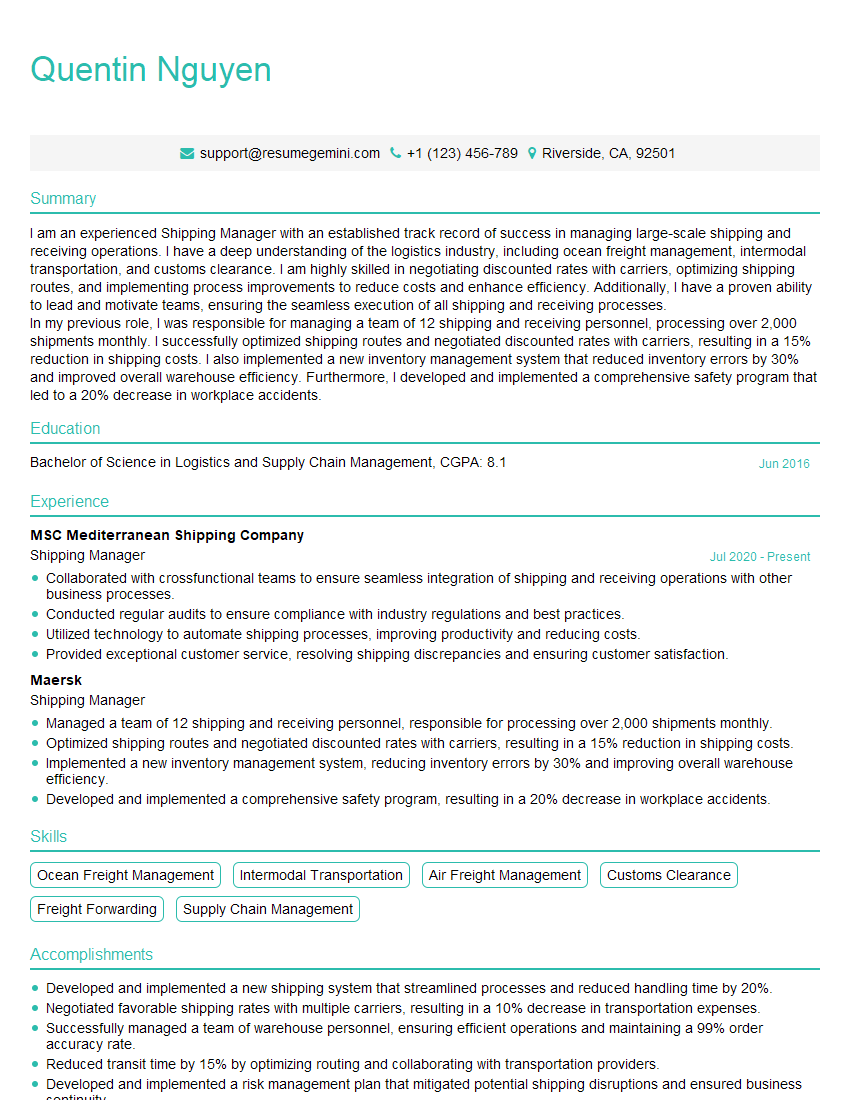

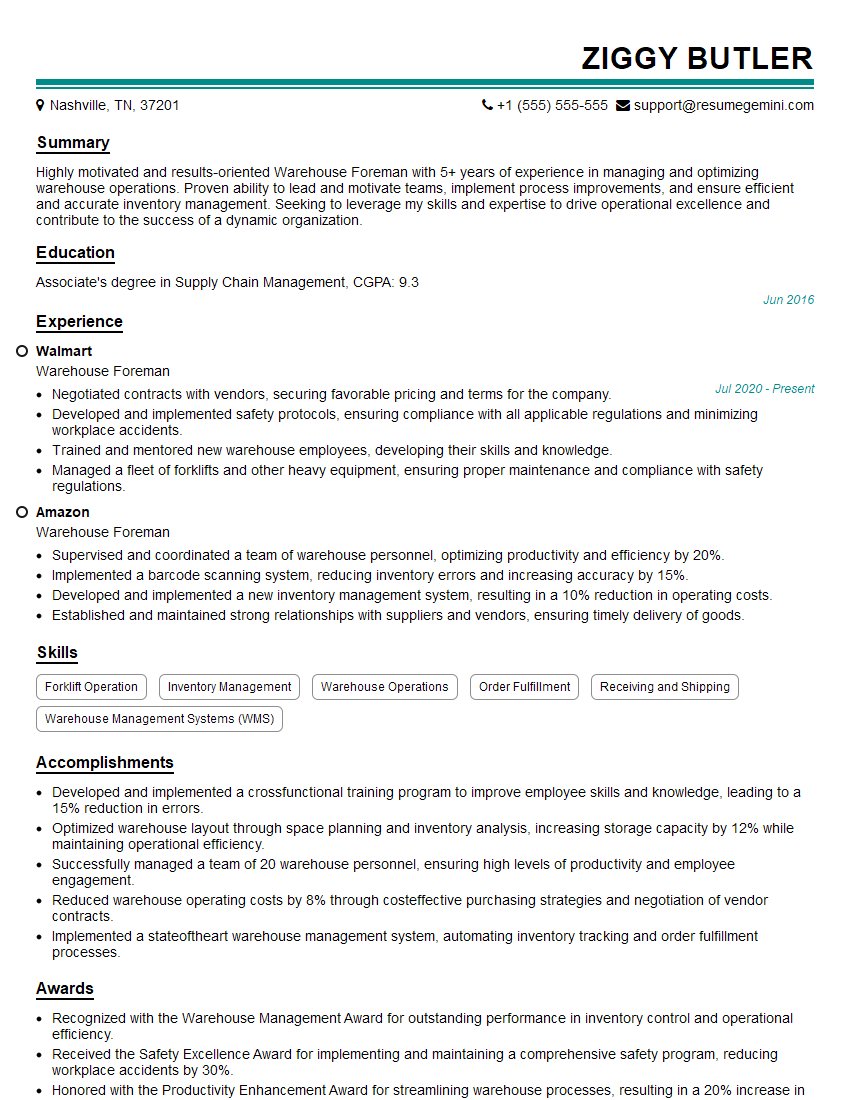

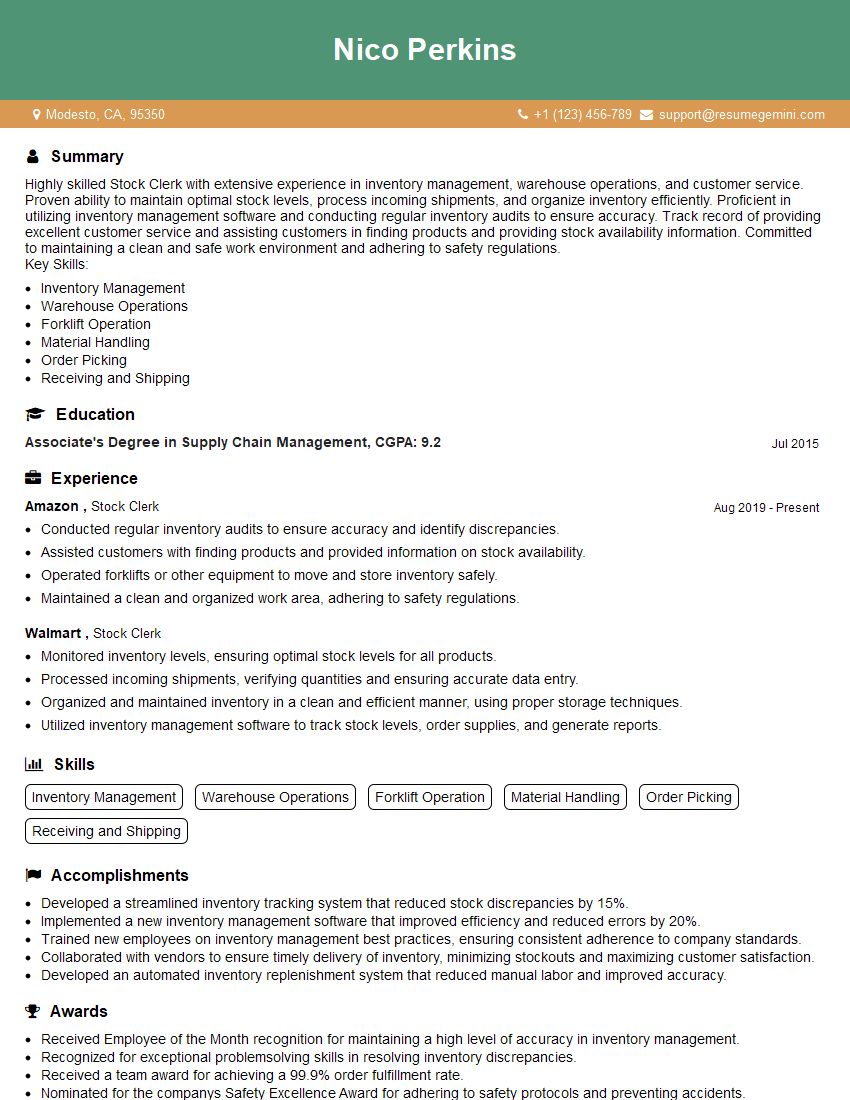

Mastering warehousing and inventory management skills is crucial for career advancement in logistics, supply chain, and operations. A strong understanding of these concepts significantly improves your job prospects and opens doors to leadership roles. To maximize your chances of landing your dream job, create an ATS-friendly resume that highlights your accomplishments and skills effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications are presented in the best possible light. We provide examples of resumes tailored specifically to warehousing and inventory management experience to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good