Are you ready to stand out in your next interview? Understanding and preparing for Operating Cranes and Heavy Machinery interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Operating Cranes and Heavy Machinery Interview

Q 1. Describe your experience operating different types of cranes.

My experience encompasses a wide range of crane operations, including tower cranes, mobile cranes (both crawler and wheeled), and overhead cranes. I’ve worked on construction sites of varying scales, from small residential projects to large-scale industrial developments. For instance, on a recent high-rise construction project, I was responsible for operating a tower crane, lifting pre-fabricated components with precision and efficiency. The experience involved meticulously managing the crane’s load capacity and swing radius to avoid collisions with other structures or personnel. In another project involving a large industrial plant, my experience with mobile cranes was crucial for maneuvering heavy machinery and materials within a confined space. This required careful planning, precise maneuvering and an understanding of the crane’s limitations in diverse terrains.

My proficiency extends to understanding and applying different operating techniques depending on the specific crane and the project’s demands. This includes mastering various lifting methods, such as using multiple hook blocks for heavier loads or employing specialized lifting gear for delicate materials.

Q 2. Explain the different types of crane hooks and their applications.

Crane hooks are designed for various lifting needs and are categorized primarily by their design and function. Common types include:

- Standard Hooks: These are the most basic type, suitable for general lifting operations. They’re relatively simple to use and maintain. They usually have a safety latch to prevent accidental disengagement of the load.

- Clevis Hooks: These have a clevis (a U-shaped piece) instead of a simple eye, providing more versatility for attaching slings and chains with shackles or other rigging hardware.

- Grab Hooks: Designed for lifting materials which are not easily hooked using a standard hook. Think of grabbing large pieces of scrap metal.

- Self-Closing Hooks: These hooks automatically close around the load, offering improved safety and reducing the risk of accidental slippage.

- Speciality Hooks: This category encompasses various designs tailored for specific loads or lifting environments, such as those with load-holding mechanisms or those designed for use in hazardous environments.

The choice of hook depends entirely on the nature of the load, the type of lifting equipment, and safety considerations. For example, a standard hook might be sufficient for lifting steel beams, whereas a grab hook would be necessary for handling bundles of scrap metal.

Q 3. What are the critical safety procedures before operating a crane?

Critical safety procedures before operating a crane are paramount. They include:

- Pre-operational Inspection: A thorough check of the crane’s mechanical components, electrical systems, and safety devices is mandatory.

- Load Capacity Verification: Ensuring that the crane’s load capacity is sufficient for the intended lift, considering factors like weight, center of gravity, and wind conditions.

- Weather Conditions Assessment: High winds, rain, or ice can significantly impact crane stability and operations; postponing operations in unfavorable conditions is essential.

- Area Clearance: Making sure the area around the crane is clear of obstructions and personnel, establishing safe zones and using appropriate signaling procedures.

- Personal Protective Equipment (PPE): Wearing appropriate safety gear including hard hats, safety glasses, and high-visibility clothing.

- Communication Protocols: Establishing clear communication lines with the signal person and ground crew, ensuring all parties understand the lift plan.

Ignoring any of these procedures can lead to serious accidents and injuries. A disciplined and proactive approach to safety is absolutely non-negotiable.

Q 4. How do you conduct a pre-operational inspection of a crane?

A pre-operational inspection follows a structured checklist to ensure the crane’s readiness for operation. This involves a visual examination and functional testing of:

- Structural Integrity: Checking for any signs of damage or wear on the boom, jib, and other structural components.

- Mechanical Components: Inspecting the hoisting mechanism, slew drive, and other moving parts for proper function and lubrication.

- Hydraulic System: Checking for leaks, proper fluid levels, and the correct operation of hydraulic cylinders and valves.

- Electrical Systems: Verifying the functionality of control systems, limit switches, and emergency stops.

- Brakes and Safety Devices: Testing the functionality of brakes, load limiting devices, and emergency shut-off mechanisms.

- Load Indicators and Gauges: Ensuring accurate readings from load indicators and other monitoring instruments.

- Rigging Equipment: Checking the condition of slings, chains, hooks, and other lifting equipment.

I always document the inspection results to maintain a record of the crane’s condition and any necessary repairs.

Q 5. What are the load capacity limits you need to be aware of?

Load capacity limits are crucial for safe crane operation and are determined by several factors. The most important is the crane’s rated capacity, which is the maximum weight the crane can lift under ideal conditions. However, this limit changes depending on several parameters such as:

- Boom Length and Angle: The longer the boom and the greater its angle from vertical, the lower the crane’s capacity.

- Radius: The distance between the crane’s pivot point and the load affects lifting capacity; capacity decreases with increasing radius.

- Wind Speed and Direction: High winds significantly reduce the crane’s safe operating capacity.

- Terrain Conditions: Uneven terrain can affect crane stability and reduce its lifting capacity.

I never exceed the load capacity indicated on the crane’s load charts for the specific configuration at any given time. Operating beyond these limits risks structural failure and catastrophic accidents.

Q 6. Describe your experience with load charts and weight calculations.

I possess extensive experience with load charts and weight calculations, crucial for ensuring safe and efficient lifting operations. Load charts provide a graphical representation of a crane’s capacity at different boom lengths, radii, and angles. To determine the appropriate crane and lifting technique, I carefully consider:

- Weight of the load: Accurate weight determination is critical, often requiring multiple weight estimation techniques.

- Center of gravity: The location of the load’s center of gravity is equally important, as an improperly balanced load can lead to instability.

- Load configuration: The manner in which the load is attached to the crane (slinging method) impacts the load’s stability and the distribution of stress on the crane.

I use load charts in conjunction with mathematical calculations to confirm that the crane is adequately suited for the task and that the lift is within safe parameters. For instance, I recently used a complex lifting plan involving multiple lifts of heavy transformers with intricate rigging, requiring precise calculations and careful monitoring of the load distribution and stability using the load charts. Accurate calculations ensure a smooth, efficient, and above all, safe operation.

Q 7. Explain how you would handle an unexpected equipment malfunction.

My response to unexpected equipment malfunction prioritizes safety above all else. The first step is immediate shutdown of the crane using the emergency stop mechanisms, if applicable. Then:

- Assess the situation: Determine the nature and extent of the malfunction. Is it a minor issue, or does it pose an immediate safety risk? For example, a sudden drop in hydraulic pressure requires a different response than a minor electrical fault.

- Secure the load: If a load is suspended, take steps to secure it safely using available safety mechanisms, or if necessary, plan a controlled lowering procedure. This might involve using alternative equipment.

- Report the incident: Immediately notify supervisors, maintenance personnel, and relevant authorities. Accurate documentation of the incident is essential.

- Evacuate the area: Clear the immediate vicinity of the crane to prevent any injuries to personnel.

- Await expert assessment: Do not attempt to repair the equipment unless you are qualified to do so. Leave the repair to trained technicians.

Throughout this process, maintaining clear communication with all involved parties remains crucial. This methodical approach minimizes the risk of secondary accidents, and ensures the safety of both personnel and equipment.

Q 8. What are the common causes of crane accidents and how to prevent them?

Crane accidents are sadly common, often stemming from a combination of factors. Let’s break down the major causes and prevention strategies.

- Human Error: This is the leading cause, encompassing improper operation, inadequate training, ignoring safety procedures, and poor communication. Prevention requires rigorous training programs, regular competency assessments, clear safety protocols, and enforced adherence to them. Think of it like learning to drive – you wouldn’t get behind the wheel without proper instruction and practice, and the same applies to operating a crane.

- Equipment Failure: Mechanical malfunctions, inadequate maintenance, and lack of regular inspections can lead to catastrophic failures. A comprehensive preventative maintenance schedule, regular inspections by qualified personnel, and prompt repairs are essential. It’s like regularly servicing your car – neglecting it leads to breakdowns.

- Environmental Factors: Adverse weather conditions like strong winds, heavy rain, or ice can significantly impact crane stability and visibility. Implementing stringent weather monitoring systems, delaying operations when conditions are unsafe, and using appropriate safety gear are critical. Think of it as not driving in a blizzard; you need to know your limits and conditions.

- Load Instability: Improper load securing, overloading, and uneven load distribution can cause the load to shift, swing, or even fall. This calls for proper rigging techniques, load weight verification, and careful planning of the lifting operation. Imagine carrying a heavy box – you wouldn’t carry it carelessly; you’d ensure it’s balanced and secure.

In short, preventing crane accidents involves a multi-pronged approach: robust training, meticulous maintenance, vigilant risk assessment, and adherence to strict safety protocols. It’s about a culture of safety, not just a checklist.

Q 9. How familiar are you with different types of rigging equipment?

My familiarity with rigging equipment is extensive. I’m proficient in selecting and using various types, including:

- Wire ropes: Understanding different rope constructions, diameters, and load capacities is crucial for safe lifting. I know how to inspect for wear and tear, and recognize signs of damage.

- Slings: I’m experienced with various types such as chain slings, wire rope slings, and synthetic web slings, and I understand the importance of choosing the right sling for the load and working load limits.

- Shackles and Hooks: I’m familiar with different types and sizes, understanding their load capacities and proper inspection methods to ensure they’re free from defects.

- Beam Clamps: These are often crucial for specialized lifting applications, and I have experience selecting and using them safely.

- Other rigging hardware: This includes things like spreader beams, load balancers, and other specialized equipment that are essential for safe and efficient lifting operations.

I always emphasize proper inspection of all rigging equipment before every lift, documenting the inspection and immediately replacing anything showing signs of wear or damage. Safety is paramount.

Q 10. Explain your understanding of signal communication during crane operations.

Signal communication is paramount during crane operations. It’s the lifeline between the crane operator and the signal person, ensuring the smooth and safe execution of the lift. Miscommunication can lead to serious accidents.

I’m well-versed in both standard hand signals and radio communication protocols. Hand signals should be clear, concise, and unambiguous, following industry-standard practices. Radio communication provides an alternative, particularly useful in noisy environments or long distances. I ensure that all parties involved understand and utilize the chosen communication method effectively. Regular communication drills are important to maintain proficiency.

For example, I have successfully managed numerous lifts using a combination of hand signals for proximity work and radio communication for more complex tasks involving multiple cranes or long-distance communication.

Q 11. How do you ensure the safety of personnel and equipment around the crane?

Ensuring the safety of personnel and equipment is my top priority. I employ a layered approach:

- Pre-lift Planning: This involves a detailed risk assessment, identifying potential hazards, and developing a safe operating procedure. This includes defining exclusion zones around the crane and establishing clear communication pathways.

- Site Safety Management: Implementing physical barriers (like fencing or cones) to create exclusion zones, clear signage warning about crane operations, and constant monitoring of the work area to prevent unauthorized entry.

- Crane Operator Competency: Ensuring the operator is properly trained, certified, and familiar with the specific crane and its limitations.

- Rigging Inspection: A thorough inspection of all rigging equipment before each lift, to ensure its condition and suitability for the load.

- Load Weight Verification: Verifying the load weight to ensure it’s within the crane’s capacity.

- Post-lift Inspection: A final check of the equipment and area after the lift, ensuring everything is safely secured and there’s no damage.

Think of it as building a fortress of safety around the operation – multiple layers protecting against potential incidents.

Q 12. Describe your experience with different types of crane control systems.

My experience encompasses various crane control systems. I’m proficient with both traditional mechanical and modern electronic control systems.

- Mechanical Controls: I’m familiar with lever-operated systems, understanding their mechanical linkages and limitations. These systems require a high level of skill and precision.

- Electronic Controls: I’m experienced with computer-controlled systems, including those with load moment indicators (LMIs), anti-collision systems, and sophisticated monitoring features. These offer increased precision and safety features.

- Radio Remote Controls: I’m adept at using radio remote control systems, understanding the importance of signal strength, interference avoidance, and emergency stop procedures.

Each system has its advantages and disadvantages, and my experience allows me to adapt quickly and safely to different control systems.

Q 13. What are your experience with different types of ground conditions?

Ground conditions significantly impact crane stability and safety. My experience includes working on various surfaces:

- Firm Ground: This provides a stable base, but even here, proper ground bearing pressure needs to be considered to prevent ground settlement.

- Soft Ground: Requires special considerations, such as using mats or cribbing to distribute the load and prevent sinking. Thorough ground surveys are essential.

- Sloped Ground: Requires careful assessment of ground stability and often necessitates additional measures like outriggers or specialized crane setups. I’m experienced in calculating appropriate angles and utilizing appropriate safety measures.

- Uneven Ground: Requires leveling procedures or the use of specialized mats or cribbing to create a stable base for the crane.

My experience ensures that I select the appropriate ground support methods and make any necessary adjustments to the crane setup to maintain stability and prevent accidents.

Q 14. How do you deal with challenging weather conditions during operation?

Challenging weather conditions demand a cautious approach. My response depends on the specific weather condition:

- High Winds: I know when to cease operations; wind speed limits are strictly adhered to based on the crane’s specifications and the load’s size and weight. The safety of everyone on site is prioritized over completing the work.

- Heavy Rain: Reduced visibility and potential for slippery conditions require extra caution. Safety protocols such as additional lighting and improved communication protocols are implemented.

- Ice or Snow: Similar to rain, ice and snow can increase the risk of slips and falls. All personnel must wear appropriate clothing and extra measures are taken to ensure ground stability.

I always consult weather forecasts before beginning operations and have a clear plan for response to unforeseen weather changes. Safety trumps efficiency. I will never compromise safety for the sake of schedule.

Q 15. Explain your experience with maintenance and troubleshooting of cranes.

Crane maintenance and troubleshooting are critical for ensuring safety and operational efficiency. My experience encompasses preventative maintenance, which includes regular inspections of all mechanical, electrical, and hydraulic components, lubrication of moving parts, and the timely replacement of worn-out components. I’m proficient in diagnosing malfunctions, utilizing both diagnostic tools and my understanding of crane mechanics to pinpoint issues. For example, I once identified a hydraulic leak in a boom hoist by carefully observing oil stains and using a pressure gauge to isolate the faulty cylinder. Troubleshooting involved systematically checking each section of the hydraulic system, culminating in the replacement of a damaged seal. This proactive approach minimized downtime and prevented a potential catastrophic failure.

Beyond preventative maintenance, I’m skilled in reactive troubleshooting. This involves systematically analyzing the problem, starting with the symptoms, and working backwards to identify the root cause. I rely on a combination of my experience, manufacturer’s manuals, and relevant diagnostic tools. A specific example includes resolving an intermittent electrical fault on a tower crane’s upper control console. Through careful examination and testing of wiring and electrical components, I traced the problem to a loose connection within a junction box. This was quickly resolved by securing the connection, averting potential delays and safety hazards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with emergency shutdown procedures.

Emergency shutdown procedures are paramount in crane operation. My training emphasizes immediate response and the correct execution of procedures in various scenarios. This involves understanding the various emergency stop mechanisms on the crane, such as the emergency stop button, the main power disconnect, and the lowering system. I’m trained to assess the situation quickly, prioritizing the safety of personnel and the crane itself.

For instance, if I observe a malfunction that could lead to a load swing or structural failure, my first action is to immediately activate the emergency stop button. After ensuring the crane is safely secured, I would communicate the situation to the site supervisor and other relevant personnel. We then follow a structured procedure that includes securing the area, conducting a safety assessment, and identifying the cause of the malfunction. Each crane I operate has a unique emergency shutdown procedure clearly documented. I am familiar with all these procedures and strictly follow them.

Q 17. How do you communicate effectively with other workers on a construction site?

Effective communication is essential on a construction site. I utilize clear, concise language, avoiding jargon, to ensure everyone understands instructions and warnings. I believe in active listening and always confirm understanding. Non-verbal communication, like hand signals, is crucial, especially in noisy environments or when verbal communication is difficult. I always make eye contact to ensure everyone is attentive, and maintain a respectful and professional demeanor.

For example, when guiding a crane lift near power lines, I’d use a combination of hand signals and radio communication to provide the crane operator with precise directions regarding boom angle, hoisting speed, and proximity to the power lines. This ensures everyone understands the risks and the necessary precautions are taken. Regular team briefings and open dialogue are also crucial for fostering a safe and productive work environment.

Q 18. What is your understanding of OSHA or other relevant safety regulations?

My understanding of OSHA (Occupational Safety and Health Administration) regulations and other relevant safety standards is extensive. I’m fully aware of the regulations concerning crane operation, including pre-operational inspections, load capacity limits, operator certification requirements, and emergency procedures. I always adhere to these regulations to ensure a safe work environment for myself and my colleagues. I regularly review and stay updated on any changes to these regulations.

For instance, I’m familiar with the detailed requirements for crane inspections, including both daily and periodic inspections. I meticulously document these inspections and ensure any deficiencies are addressed immediately and documented correctly. This includes regular inspections of the crane’s structural integrity, hoisting mechanisms, braking systems, and all safety devices.

Q 19. Explain your experience with load stability and preventing tipping.

Load stability and preventing tipping are paramount in crane operation. I carefully assess the weight, dimensions, and center of gravity of the load, considering factors like wind speed and ground conditions. This involves understanding the crane’s load charts and utilizing appropriate rigging techniques to ensure the load remains balanced and stable throughout the lift. I am skilled in performing load calculations considering the radius and various other factors that influence stability.

For instance, before lifting a heavy, oddly shaped object, I would carefully plan the lift path, selecting the appropriate crane and utilizing outriggers for additional stability. I would also communicate the plan to the ground crew to ensure everyone is aware of the lift’s constraints and potential risks, such as swing radius. I am also trained in handling off-center loads to minimize risk of tipping.

Q 20. How do you calculate the safe working load for a specific lift?

Calculating the safe working load (SWL) for a specific lift is crucial for preventing accidents. This involves consulting the crane’s load chart, which provides the maximum permissible load for various boom lengths and radii. It’s essential to also consider the weight of the rigging equipment (slings, shackles, etc.) and any additional factors that could affect the load, such as wind speed or the terrain. One should never exceed the SWL specified in the load chart.

For example, if lifting a 10,000 lb load with a 50-foot boom radius, I would consult the crane’s load chart to determine the maximum permissible load at that configuration. I would then add the weight of the rigging to that value and ensure the total doesn’t exceed the safe working load. If the calculated total exceeds the SWL, I would either adjust the boom length or radius, utilize a different crane, or break down the load into smaller, manageable lifts.

Q 21. Describe your experience with different types of lifting techniques.

My experience encompasses various lifting techniques, including the use of different types of slings, shackles, hooks, and other rigging equipment. I’m proficient in techniques like vertical lifts, swing lifts, and tandem lifts, each requiring careful consideration of load stability, balance, and potential hazards. I also have experience with specialized lifting techniques like using spreader beams for handling large, bulky objects or employing specific rigging methods to lift delicate or sensitive equipment.

For example, when lifting a large, precast concrete panel, I would use a spreader beam to evenly distribute the weight and prevent damage to the panel. For a delicate piece of machinery, I’d use soft slings or appropriate padding to protect the equipment during the lift. In tandem lifts, where two cranes are utilized, I am proficient in coordinating and ensuring a safe and synchronized operation. Choosing the appropriate lifting technique is key to a successful and safe operation, tailored to the load and environmental conditions.

Q 22. What is your understanding of crane certifications and licensing?

Crane certifications and licensing are crucial for ensuring operator competency and workplace safety. The specifics vary by location, but generally, they involve a tiered system. Initially, operators might obtain a basic certification after completing a training course covering safety regulations, crane operation techniques, load calculations, and pre-operational checks. This often leads to a written and practical examination. More advanced certifications may require experience and demonstrate proficiency with specific crane types or lifting capacities. Licensing often involves government oversight, including background checks and potential renewal requirements. Think of it like a driver’s license, but for operating heavy machinery with potentially life-threatening consequences if mishandled. A lack of proper certification can lead to severe penalties, including fines and job loss, as well as endangering lives.

For example, in many jurisdictions, operating a tower crane requires a separate, more advanced certification than operating a smaller mobile crane. This reflects the increased complexity and potential risks associated with larger, taller equipment.

Q 23. How do you maintain accurate logs and records of crane operations?

Maintaining accurate logs and records of crane operations is paramount for safety and legal compliance. These logs typically include the date, time, crane ID number, operator’s name and certification number, lift details (weight, type of load, location), pre-operational inspections, any incidents or near misses, and maintenance records. I use a combination of digital and paper-based systems to ensure comprehensive record-keeping. Digital logs allow for easy search and retrieval, while paper backups offer redundancy in case of technological failures. These records are crucial for identifying trends, improving safety procedures, and demonstrating compliance with regulatory requirements during audits or in the event of an accident. It’s a matter of accountability and proactive safety management.

For instance, if an incident occurs, the detailed log allows investigators to quickly determine the circumstances, helping to prevent similar incidents in the future. Keeping meticulous records also helps to track crane maintenance needs, ensuring that equipment is always operating safely and efficiently.

Q 24. Describe your experience with different types of lifting slings.

My experience encompasses a wide range of lifting slings, each suited to specific load types and conditions. I’m proficient with:

- Wire rope slings: Durable and strong, suitable for heavy and bulky loads but require regular inspection for wear and damage.

- Synthetic web slings: Lighter and more flexible than wire rope, ideal for various loads, offering better grip and less chance of load slippage, but they are susceptible to UV degradation and sharp objects.

- Chain slings: Robust and suitable for harsh environments, providing high tensile strength, however, they can be prone to wear and stretching over time, requiring careful inspection of the links.

- Nylon and Polyester slings: Offer good strength-to-weight ratio and are relatively easy to handle but can be prone to damage from abrasion and chemicals.

Selecting the right sling is crucial for load safety. Factors like load weight, shape, and environment dictate the appropriate sling type and its capacity. Improper sling selection can lead to catastrophic equipment failure and injury.

Q 25. Explain the importance of regular crane maintenance.

Regular crane maintenance is not merely preventative; it’s essential for safety, efficiency, and longevity. Neglecting maintenance can lead to catastrophic equipment failure, resulting in serious injury or death. A comprehensive maintenance program includes daily, weekly, monthly, and annual inspections and servicing. Daily inspections focus on visual checks for damage or wear. Weekly checks may involve more detailed inspections of components such as brakes, hooks, and sheaves. Monthly and annual inspections often involve more extensive checks and lubrication by qualified technicians. This includes detailed inspections of the structural components, electrical systems, hydraulics, and other critical systems. Proper maintenance logs and documentation are also crucial. Think of it like regular check-ups for your car; neglecting them can lead to major problems down the line.

A real-world example: A seemingly minor crack in a crane’s boom, undetected during routine inspection, can lead to catastrophic failure under stress, potentially resulting in a serious accident.

Q 26. What is your experience with working at heights and fall protection?

Working at heights is an inherent part of operating cranes, and safety is my top priority. My experience includes extensive training in fall protection protocols, including the proper use of harnesses, lanyards, and fall arrest systems. I’m familiar with various types of fall protection equipment, including safety nets and guardrails. I always ensure that all safety equipment is regularly inspected and in good working order. Moreover, I am trained in emergency rescue procedures and know how to perform a self-rescue if necessary. Safety awareness is more than just following procedures; it is an ingrained habit, consistently assessing risk and adjusting procedures as needed. A proactive approach to safety includes anticipating potential hazards and taking steps to mitigate them.

For instance, before commencing any operation at height, I conduct a thorough risk assessment, identifying potential hazards such as unstable ground or overhead obstructions, and implement appropriate control measures.

Q 27. How do you handle difficult or challenging supervisors?

Handling difficult or challenging supervisors requires a professional and proactive approach. My strategy focuses on open communication, documentation, and professional boundaries. If there is a disagreement, I attempt to address it directly and professionally, outlining my concerns and offering solutions. If the issue persists, I document all interactions, ensuring I have a record of the situation. If the issue impacts safety or workplace standards, I escalate the problem through appropriate channels within the company. The key is to remain professional, focus on factual information, and prioritize safety and compliance.

For instance, if a supervisor demands an unsafe work practice, I would clearly state my safety concerns, referencing company policies and regulations, and refuse the unsafe task, documenting the request and my refusal. I would then report the incident to a higher authority to ensure the safety of myself and my colleagues.

Q 28. Describe a time you had to solve a complex problem while operating a crane.

During a large construction project, we were lifting a massive prefabricated section of a building. Due to unforeseen circumstances, the wind picked up significantly, exceeding the safe operating limits for the crane. The initial plan was no longer feasible due to the increased risk of swaying. I immediately assessed the situation, reevaluated the load capacity relative to the wind speed, and determined that continuing with the original plan was too risky. Instead, I collaborated with the site engineer and the rigging crew to develop an alternative strategy involving repositioning the crane and securing additional support to counter the wind’s force. We used additional counterweights and adjusted the rigging to minimize the load’s sway. This ensured a safe and successful lift, avoiding potential damage to the load or equipment. The key was quick thinking, adaptation to changing circumstances, and collaboration to overcome a challenging situation safely.

Key Topics to Learn for Operating Cranes and Heavy Machinery Interview

- Crane Types and Operations: Understanding the mechanics and operation of various crane types (tower, mobile, overhead) including their limitations and safe operating procedures.

- Load Handling and Stability: Calculating load capacity, understanding center of gravity, and applying safe lifting techniques to prevent accidents. Practical experience with load charts and weight estimations will be invaluable.

- Safety Regulations and Procedures: Demonstrating knowledge of OSHA (or relevant regional) regulations, pre-operational checks, emergency procedures, and hazard identification and risk assessment techniques.

- Maintenance and Troubleshooting: Familiarity with routine maintenance procedures, recognizing common mechanical issues, and basic troubleshooting skills. This shows initiative and a proactive approach to safety.

- Signaling and Communication: Understanding hand signals, radio communication protocols, and effective collaboration with ground crews and other operators.

- Heavy Machinery Operation (Beyond Cranes): Depending on the role, this could include experience with excavators, loaders, forklifts, or other heavy equipment. Highlight relevant experience and transferable skills.

- Advanced Concepts (if applicable): Depending on seniority, be prepared to discuss topics like load moment indicators (LMIs), advanced rigging techniques, or specific software used in crane operation.

Next Steps

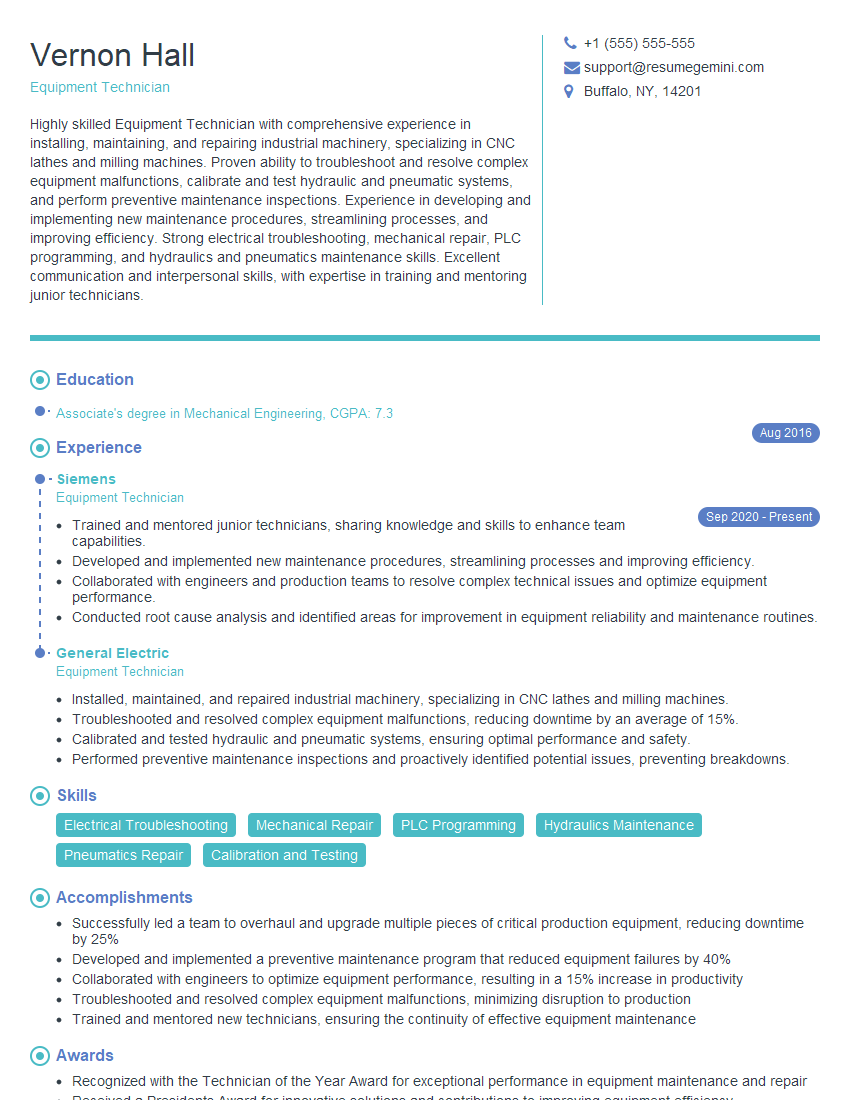

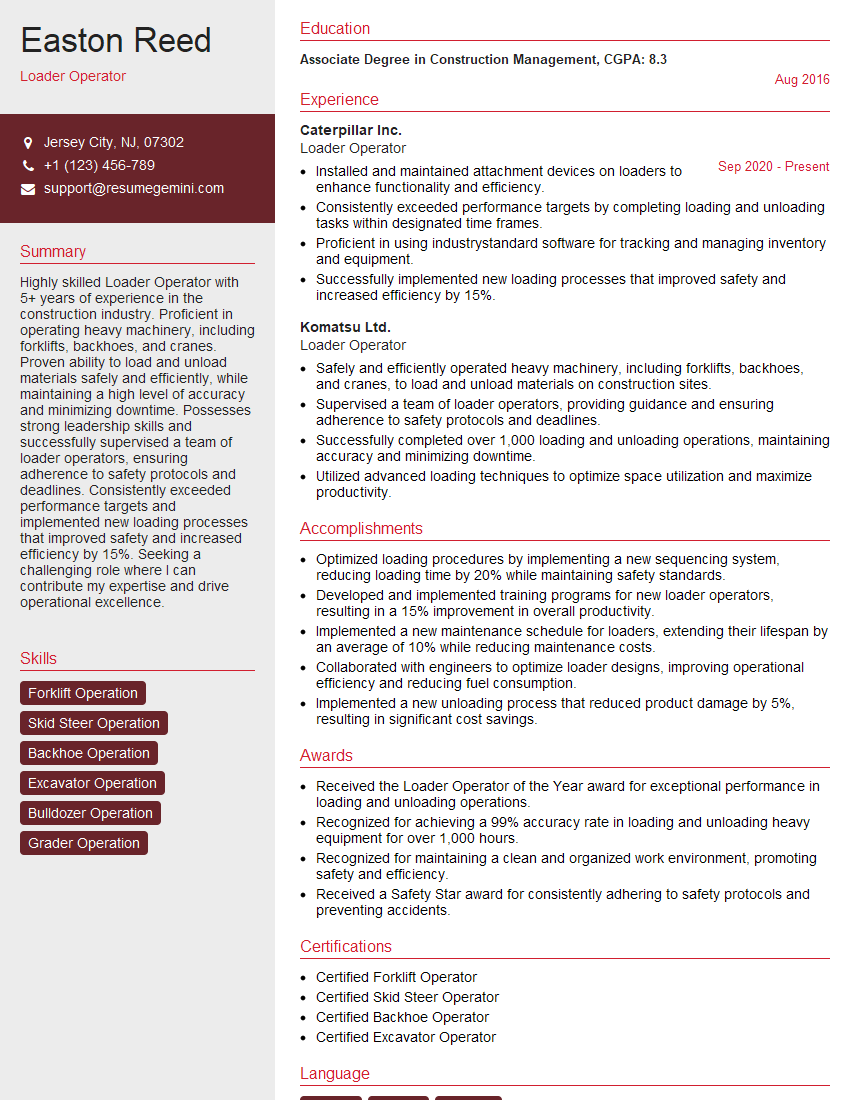

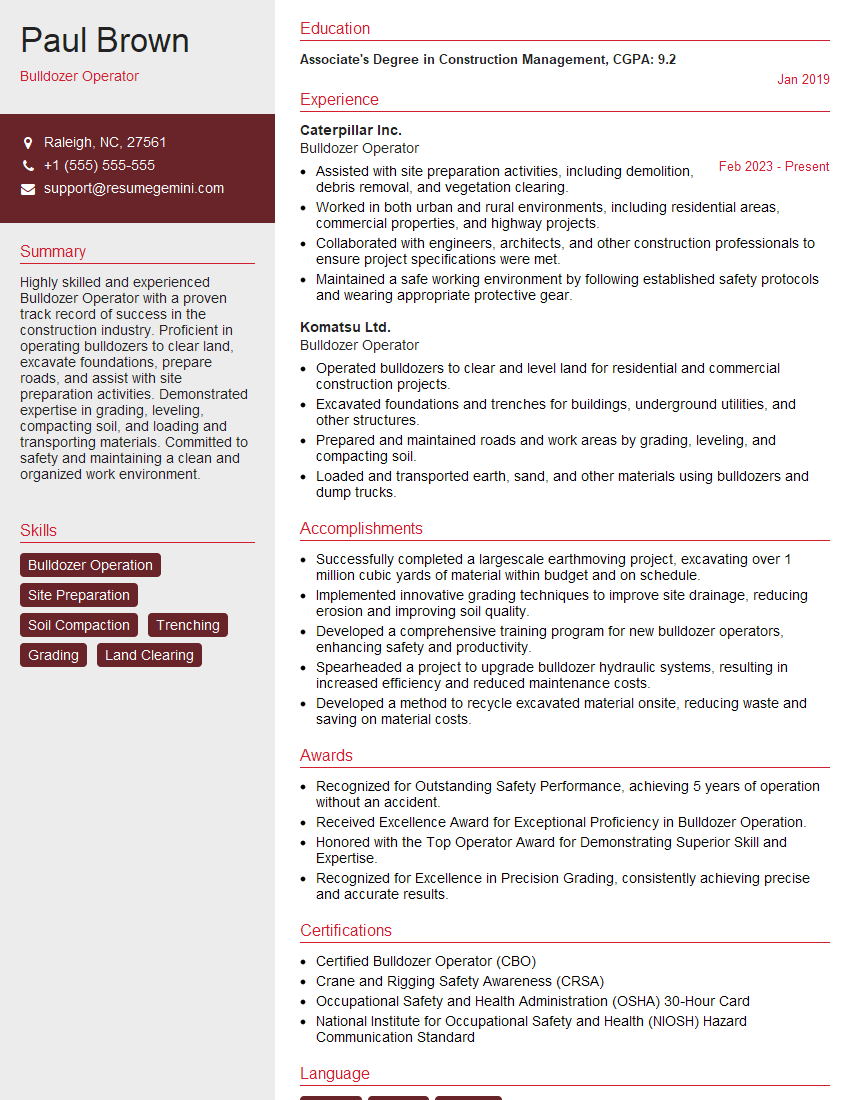

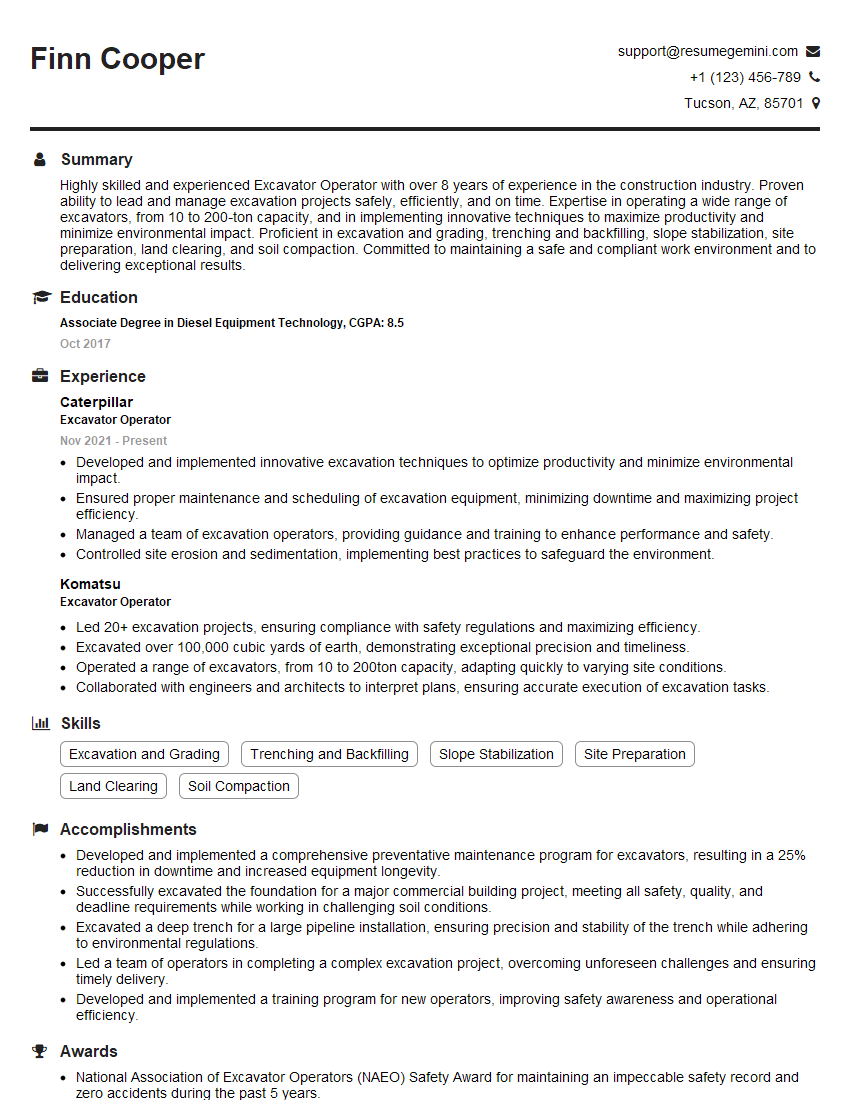

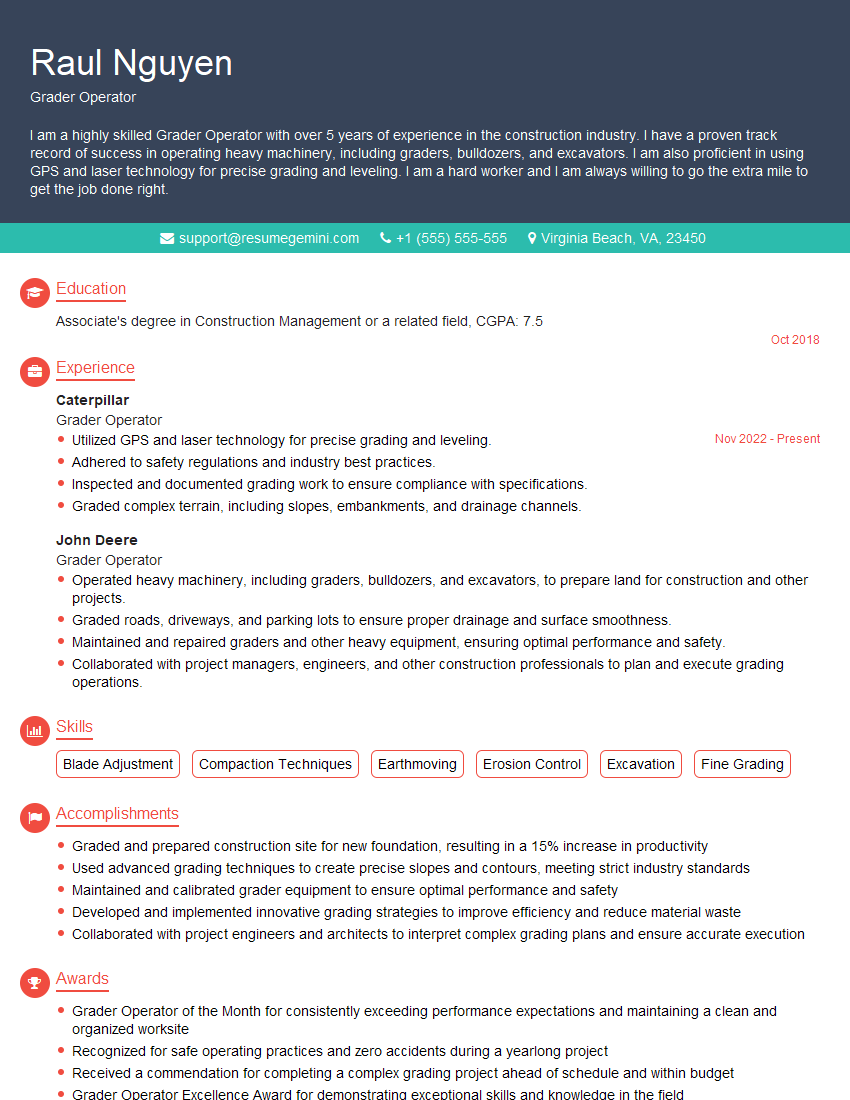

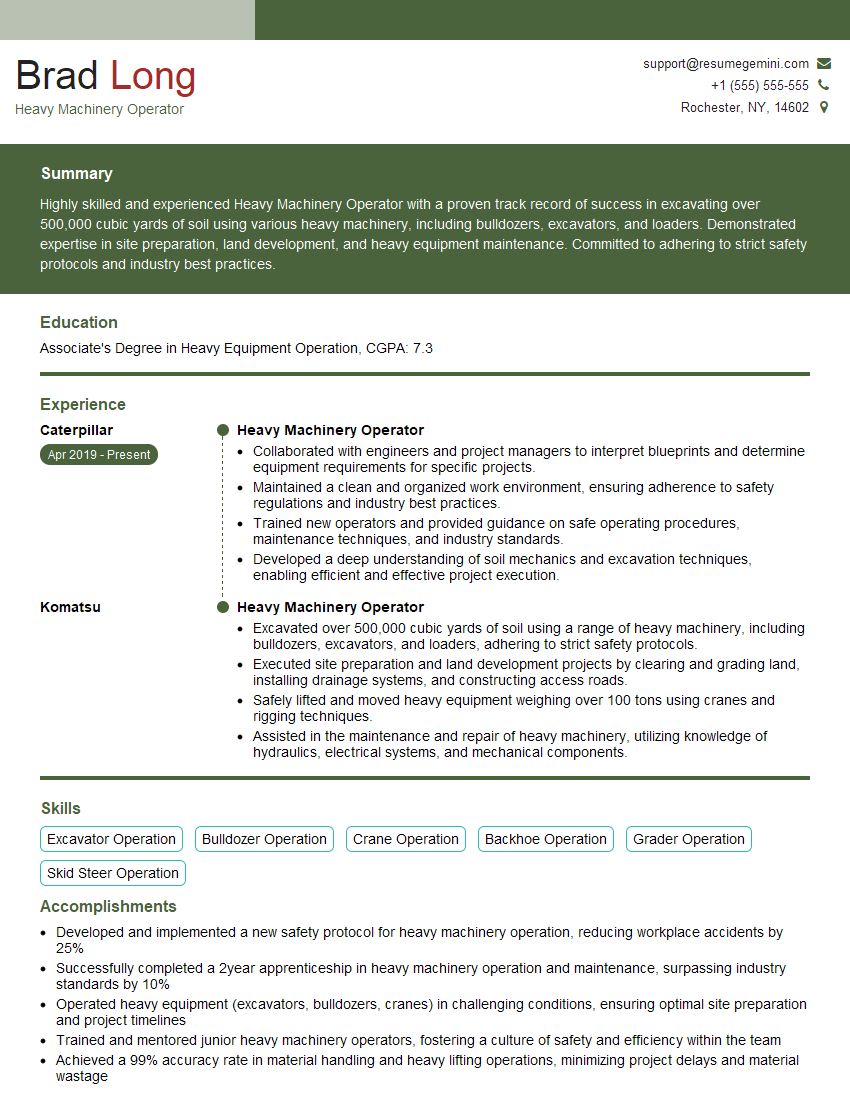

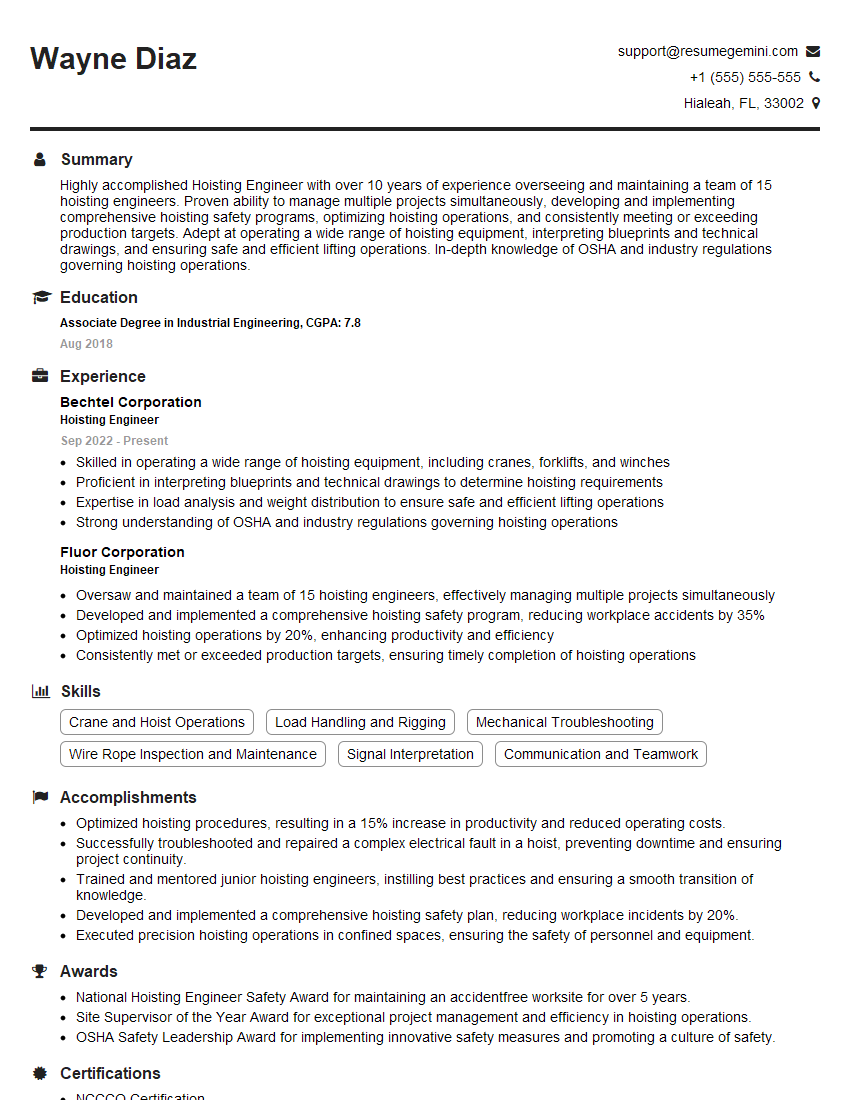

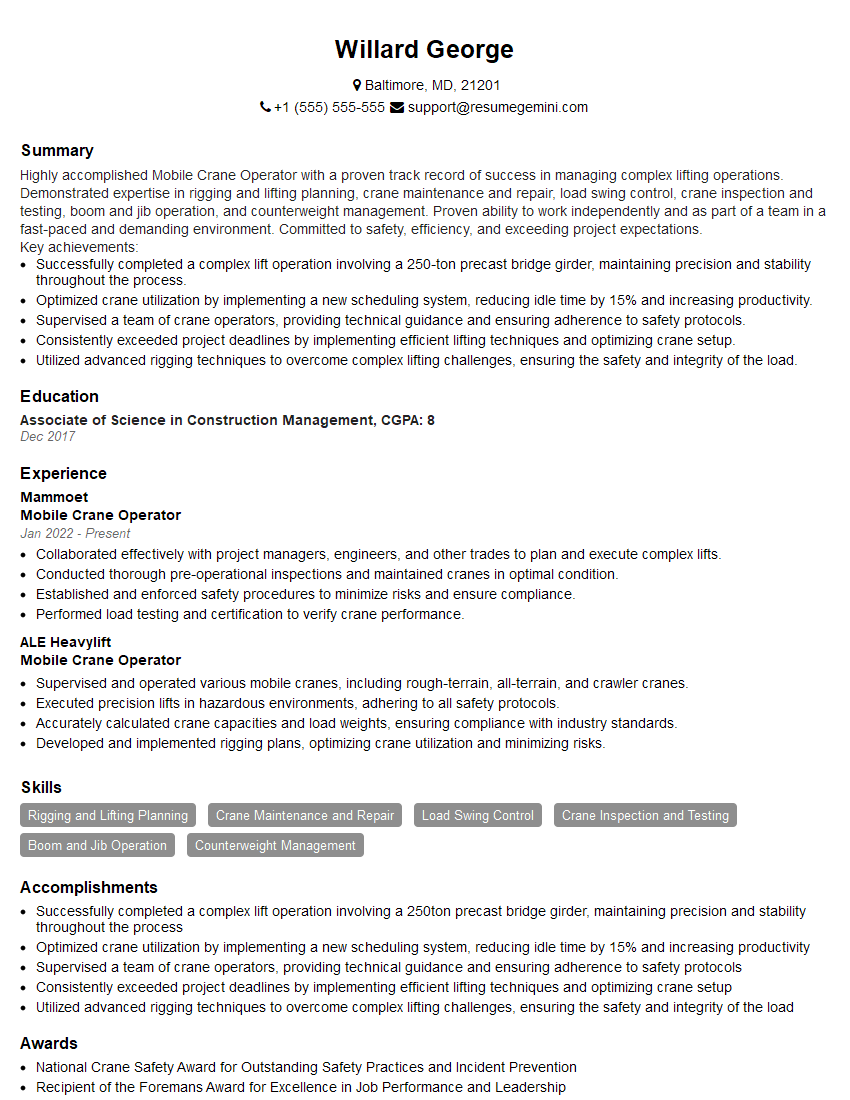

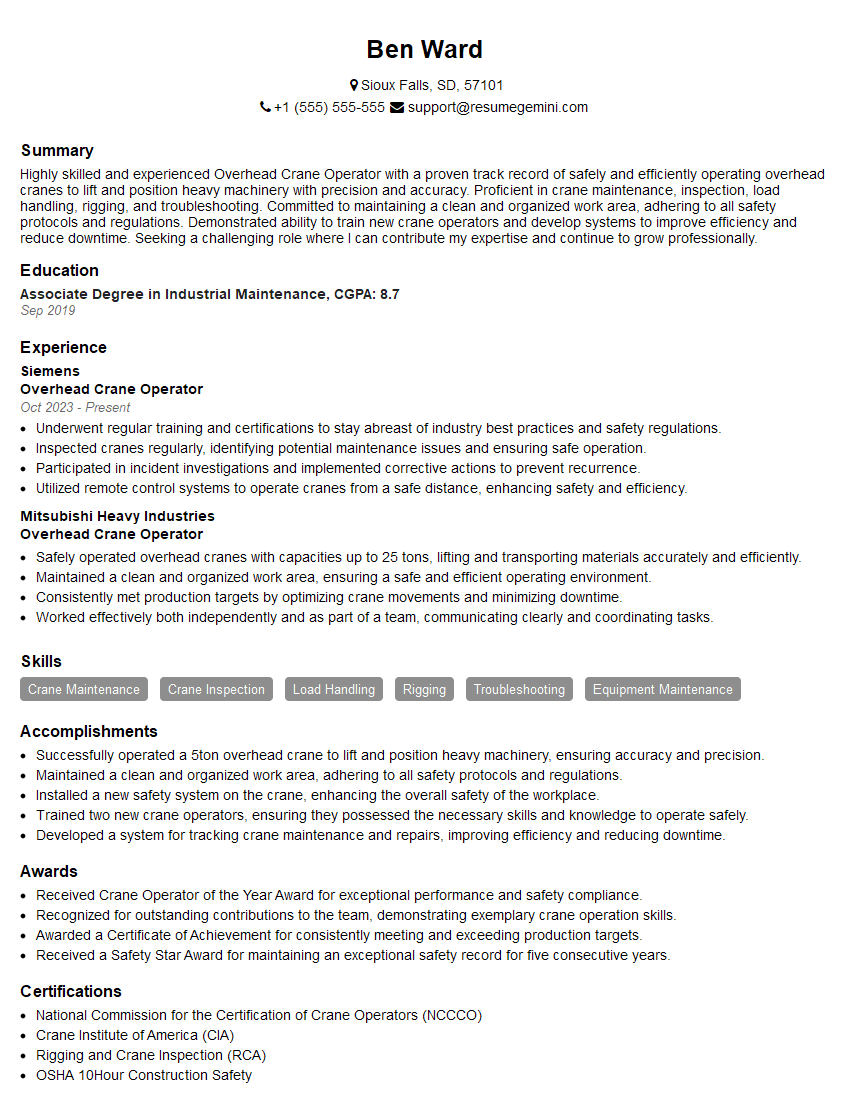

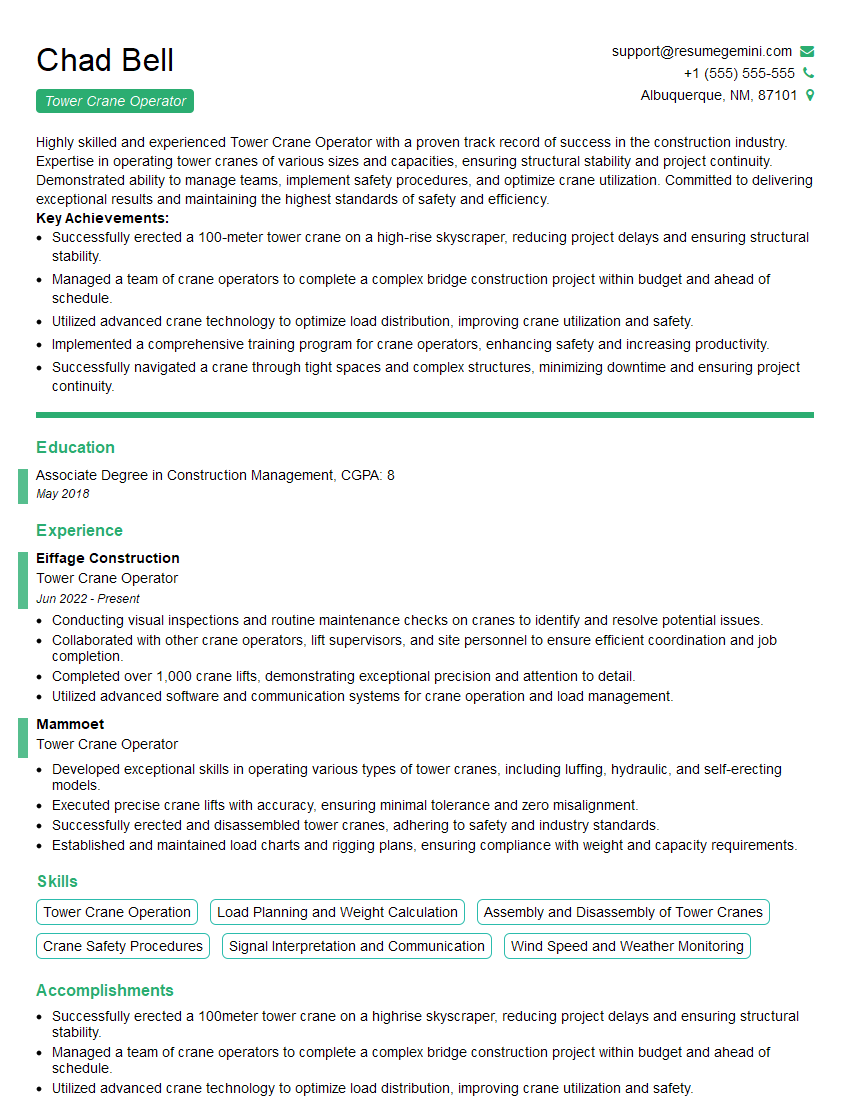

Mastering the operation of cranes and heavy machinery opens doors to rewarding and well-compensated careers in construction, logistics, and manufacturing. These roles are vital to infrastructure development and industrial productivity, offering excellent opportunities for career growth and advancement. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your qualifications. ResumeGemini provides examples of resumes tailored to Operating Cranes and Heavy Machinery roles to guide you in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good