Preparation is the key to success in any interview. In this post, we’ll explore crucial Wastewater Treatment and Environmental Compliance interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Wastewater Treatment and Environmental Compliance Interview

Q 1. Describe the different types of wastewater treatment processes.

Wastewater treatment processes are designed to remove pollutants and contaminants from wastewater before it’s discharged into the environment. They can be broadly categorized into three levels: primary, secondary, and tertiary.

- Primary Treatment: This is a physical process that removes large solids and grit through screening, sedimentation (settling tanks), and sometimes flotation. Think of it as a basic cleaning – the large, visible stuff gets taken out. An example is a grit chamber removing sand and gravel.

- Secondary Treatment: This is a biological process that uses microorganisms to break down dissolved and suspended organic matter. Common methods include activated sludge processes (explained in detail in the next question), trickling filters (where wastewater trickles over a bed of media coated with microorganisms), and lagoons (large ponds where natural processes break down pollutants). This stage is like a deeper clean, removing the less visible but still harmful organic materials.

- Tertiary Treatment: This is an advanced treatment step that removes remaining pollutants like nutrients (nitrogen and phosphorus), pathogens, and other specific contaminants. Methods include filtration, disinfection (using chlorine, UV, or ozone), and advanced oxidation processes. This is the final polishing stage, ensuring the water is as clean as possible before discharge.

The specific treatment process chosen depends on factors such as the type and volume of wastewater, the receiving water quality standards, and the budget.

Q 2. Explain the activated sludge process and its key parameters.

The activated sludge process is a highly effective secondary treatment method that uses aerobic (oxygen-requiring) bacteria to break down organic matter in wastewater. Imagine it as a tiny ecosystem within a tank. Wastewater is mixed with a mixture of these bacteria (the ‘activated sludge’) and air is pumped in to keep them alive and active.

Key parameters monitored and controlled include:

- Dissolved Oxygen (DO): Essential for aerobic bacteria to thrive. Levels are constantly monitored and adjusted by controlling aeration.

- Mixed Liquor Suspended Solids (MLSS): The concentration of microorganisms in the aeration tank. Maintaining the right MLSS is vital for effective treatment.

- Mixed Liquor Volatile Suspended Solids (MLVSS): Represents the active biomass within the MLSS. It is used to estimate the amount of active bacteria.

- Sludge Retention Time (SRT): The average time the microorganisms remain in the system. A longer SRT allows more complete degradation of organic matter but can lead to excess sludge production.

- Food-to-Microorganism Ratio (F/M): The ratio of influent organic matter to the biomass concentration. It dictates the rate of organic matter removal.

- pH: A measure of acidity/alkalinity. Optimal pH range ensures optimal bacterial activity.

Controlling these parameters ensures optimal performance of the activated sludge process. For instance, if the DO is too low, the bacteria become inactive leading to poor treatment efficiency. Regular monitoring and adjustments keep the process running smoothly and effectively.

Q 3. What are the common pollutants found in wastewater?

Wastewater contains a diverse range of pollutants, which can be broadly classified as:

- Organic Matter: This includes biodegradable substances like fats, oils, grease, carbohydrates, and proteins from domestic and industrial sources. These consume oxygen as they decompose, potentially depleting oxygen levels in receiving waters (causing eutrophication).

- Nutrients: Nitrogen and phosphorus from fertilizers, detergents, and human waste can cause excessive algal growth, leading to eutrophication and harmful algal blooms.

- Pathogens: Bacteria, viruses, and parasites from human and animal waste pose a serious threat to public health if not properly removed.

- Inorganic Matter: Salts, heavy metals (lead, mercury, cadmium), and other inorganic chemicals from industrial discharges can be toxic to aquatic life.

- Suspended Solids: These are solid particles that remain suspended in the wastewater, such as sand, silt, and other insoluble materials.

- Toxic Substances: Various chemicals like pesticides, pharmaceuticals, and industrial byproducts can have harmful effects on the environment and human health.

The specific pollutants present will vary considerably depending on the source of the wastewater. For example, wastewater from a food processing plant will have high levels of organic matter, while wastewater from a metal finishing facility might contain heavy metals.

Q 4. How do you monitor and control the effluent quality?

Effluent quality monitoring and control are crucial to ensure compliance with discharge permits and protect receiving water bodies. This involves a multi-faceted approach:

- Regular Sampling and Analysis: Wastewater samples are collected at various points within the treatment plant and from the final effluent. These are analyzed for a range of parameters, including suspended solids, BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), nutrients, pH, and specific pollutants relevant to the type of wastewater.

- Process Control Strategies: Real-time monitoring of key operational parameters (as mentioned in the activated sludge process) allows for adjustments to treatment processes to maintain optimal performance. Automated control systems are often used for efficient management.

- Data Analysis and Interpretation: Trends in effluent quality data help identify issues and potential problems. Statistical process control (SPC) techniques can be used to monitor variations and predict potential issues.

- Corrective Actions: If effluent quality doesn’t meet standards, corrective actions are implemented. This might involve adjustments to chemical dosages, cleaning of equipment, or even upgrades to treatment processes.

For instance, if BOD levels are consistently high, it might indicate a problem in the biological treatment stage, requiring adjustments to aeration or the addition of more microorganisms.

Q 5. What are the regulatory requirements for wastewater discharge?

Regulatory requirements for wastewater discharge vary depending on location and the type of wastewater, but generally involve obtaining a discharge permit from the relevant environmental agency. These permits specify limits for various pollutants in the effluent. These limits are often based on water quality standards designed to protect receiving water bodies and human health.

Common requirements include:

- Permitting: Obtaining a National Pollutant Discharge Elimination System (NPDES) permit (in the US) or equivalent permits in other countries before discharging treated wastewater.

- Effluent Limitations: Meeting specific limits for various pollutants, such as BOD, COD, suspended solids, nutrients, and specific toxic substances.

- Monitoring and Reporting: Regular monitoring of effluent quality and submitting regular reports to the regulatory agency.

- Compliance Inspections: Undergoing regular inspections by the regulatory agency to ensure compliance with permit conditions.

- Spill Prevention Control and Countermeasures (SPCC) Plans: Developing and implementing plans to prevent accidental spills or releases of pollutants.

Non-compliance can result in significant penalties, including fines and legal action. Therefore, effective wastewater treatment and compliance monitoring are essential for any wastewater treatment facility.

Q 6. Explain the importance of effluent disinfection.

Effluent disinfection is a crucial step in wastewater treatment to eliminate or reduce the number of harmful pathogens (bacteria, viruses, and parasites) before discharge. This protects public health and the environment.

The primary reason for disinfection is to prevent the spread of waterborne diseases. Pathogens can cause various illnesses, from mild gastrointestinal problems to serious conditions like cholera and typhoid fever. Disinfection significantly reduces this risk. Different methods are used depending on the specific context:

- Chlorination: The most common method, using chlorine gas or hypochlorite solutions to kill pathogens. However, chlorine can react with organic matter to form disinfection byproducts (DBPs), some of which are potentially harmful.

- Ultraviolet (UV) Disinfection: Uses UV light to damage the DNA of pathogens, preventing their replication. It’s a chemical-free method but less effective against some viruses and parasites than chlorine.

- Ozone Disinfection: Ozone is a powerful oxidizing agent that kills pathogens. It doesn’t form harmful DBPs but is more expensive than chlorine.

The choice of disinfection method depends on factors such as cost, effectiveness against specific pathogens, potential formation of DBPs, and local regulations. Proper disinfection is a vital part of ensuring safe and environmentally sound wastewater discharge.

Q 7. Describe different types of wastewater treatment plant sludge management.

Sludge management is a critical aspect of wastewater treatment plant operations. Sludge is the semisolid material that’s separated from the wastewater during treatment. It contains a high concentration of organic matter, nutrients, and potentially harmful substances. Therefore, it requires careful handling and disposal.

Different methods exist:

- Anaerobic Digestion: Sludge is broken down in the absence of oxygen by microorganisms, producing biogas (methane and carbon dioxide) that can be used for energy generation. This reduces sludge volume and produces a valuable energy source.

- Aerobic Digestion: Similar to anaerobic digestion, but in the presence of oxygen. It requires more energy but produces less odor and is suitable for smaller plants.

- Land Application: Sludge is applied to land as a fertilizer, but requires careful monitoring to avoid nutrient overload and potential contamination. This is only suitable if regulations allow and the sludge is deemed safe.

- Incineration: Sludge is burned at high temperatures to reduce its volume and destroy pathogens. This method is effective but can generate air emissions that require control.

- Landfilling: Sludge is disposed of in landfills, but requires careful management to prevent environmental contamination. This method should be the last resort due to space limitations and environmental concerns.

- Dewatering: Reducing the water content of sludge to make it easier to handle and transport. This may involve processes such as belt filter presses or centrifuges.

The best sludge management method depends on factors such as sludge characteristics, available resources, regulatory requirements, and cost. Many plants utilize a combination of methods for optimal resource recovery and environmental protection.

Q 8. How do you troubleshoot problems in a wastewater treatment plant?

Troubleshooting in a wastewater treatment plant (WWTP) is a systematic process. It begins with identifying the problem – is it a decrease in effluent quality, an operational malfunction, or an increase in energy consumption? Once identified, we move to a diagnostic phase. This involves checking operational parameters like flow rates, dissolved oxygen (DO) levels, pH, and sludge volume index (SVI). We look at the performance of each unit process, from the preliminary treatment stages (screening, grit removal) to the secondary treatment (activated sludge, trickling filters) and tertiary treatment (disinfection, filtration). For example, a sudden drop in DO in the aeration tank might indicate a problem with the aerators themselves, a malfunction in the blower system, or an unexpectedly high organic load. A high SVI suggests issues with sludge settling and potentially problems within the activated sludge process, needing investigation into the microbial community’s health. Data logging and historical trends are crucial; comparing current readings to historical averages helps pinpoint deviations. If the issue persists, further investigation might involve lab testing of influent and effluent samples to analyse parameters like BOD, COD, and nutrient levels. This could reveal deficiencies in the treatment process that demand adjustments to operational strategies or maintenance activities. Ultimately, effective troubleshooting is a blend of experience, methodical investigation, and a solid understanding of the WWTP’s processes.

Q 9. What is the role of biological nutrient removal in wastewater treatment?

Biological nutrient removal (BNR) is a crucial part of modern wastewater treatment, focusing on removing nitrogen and phosphorus, key pollutants causing eutrophication in receiving waters (leading to algal blooms and oxygen depletion). The process harnesses the power of microorganisms. In a typical BNR system, the nitrogen cycle is manipulated through nitrification (conversion of ammonia to nitrate by aerobic bacteria) and denitrification (conversion of nitrate to nitrogen gas by anaerobic bacteria). Phosphorus removal often involves the use of biological enhanced phosphorus removal (EBPR) bacteria, which accumulate phosphorus within their cells under anaerobic conditions and release it under aerobic conditions. This accumulated phosphorus is then removed with the excess sludge. Imagine it like a controlled biological recycling process: microorganisms consume nitrogen and phosphorus, reducing their concentration in the wastewater. The effectiveness of BNR is influenced by several factors, including dissolved oxygen levels, the availability of carbon sources for denitrification, and the appropriate balance of aerobic and anaerobic zones within the treatment system. For example, insufficient aeration could hinder nitrification, while a lack of readily available organic carbon sources could limit denitrification. Proper process monitoring and control are essential to ensure optimal nutrient removal.

Q 10. Explain the concept of BOD and COD.

BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) are both indicators of the amount of organic matter present in wastewater. They represent the amount of oxygen consumed during the breakdown of organic material, but they differ in their approach. BOD measures the oxygen consumed by aerobic microorganisms during the biological oxidation of organic matter over a specific time period (typically 5 days at 20°C – BOD5). It reflects the biodegradable organic matter. COD, on the other hand, measures the oxygen equivalent required for chemical oxidation of all organic matter present in the sample, regardless of whether it’s biodegradable. Strong oxidizing agents are used to oxidize organic compounds. COD provides a quicker and more complete measure of organic matter than BOD. Think of it like this: BOD represents the amount of food available to microorganisms, while COD represents the total amount of food available, including things microorganisms can’t readily digest. A high BOD or COD indicates a significant pollution load in wastewater. For instance, industrial wastewater often exhibits much higher BOD and COD values compared to domestic wastewater. Monitoring BOD and COD is vital in assessing the effectiveness of treatment processes and maintaining compliance with discharge permits.

Q 11. What are the different types of wastewater treatment plant aeration systems?

Aeration systems are essential in wastewater treatment, providing the oxygen necessary for aerobic microorganisms to effectively break down organic matter. There are several types:

- Surface Aerators: These use rotating or other mechanisms to introduce air into the wastewater at the surface, creating turbulence and oxygen transfer. They are simpler and less energy-intensive for smaller plants.

- Diffused Aeration Systems: These employ air diffusers located at the bottom of the aeration tank. Fine bubbles rising through the liquid maximize oxygen transfer efficiency, but they’re more energy intensive than surface aerators. Subtypes include fine-bubble diffusers and membrane diffusers. Membrane diffusers are increasingly preferred due to their high oxygen transfer efficiency and reduced clogging.

- Mechanical Aerators: These use rotating impellers or other mechanical devices to mix the wastewater and transfer oxygen from the air. They are efficient at mixing but can be susceptible to clogging and require regular maintenance.

The choice of aeration system depends on factors such as plant size, wastewater characteristics, energy costs, and maintenance requirements. For example, large treatment plants often utilize diffused aeration for its high oxygen transfer efficiency, while smaller plants may find surface aerators more cost-effective.

Q 12. Describe the principles of membrane filtration in wastewater treatment.

Membrane filtration is an advanced wastewater treatment process used for enhanced removal of suspended solids, bacteria, viruses, and other pollutants. It involves forcing wastewater through a semi-permeable membrane with tiny pores, separating the treated water (permeate) from the retained solids (concentrate). Several types of membrane filtration exist, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis, each with different pore sizes and capabilities. Microfiltration removes larger particles, ultrafiltration removes smaller particles and some dissolved organic matter, nanofiltration removes even smaller molecules, and reverse osmosis removes dissolved salts and other small molecules. The process relies on pressure to drive water through the membrane. Imagine it like a very fine sieve, but at a microscopic level, allowing only water and very small dissolved molecules to pass through while retaining solids and larger contaminants. Membrane filtration is effective in achieving high-quality effluent, making it suitable for water reuse applications or meeting stringent discharge standards. Regular cleaning and replacement of membranes are critical for optimal performance and to prevent fouling, which is the buildup of material on the membrane surface that reduces its permeability.

Q 13. How do you maintain compliance with environmental regulations?

Maintaining compliance with environmental regulations is paramount in wastewater treatment. It involves a multi-faceted approach starting with a thorough understanding of applicable regulations. This includes federal, state, and local permits and discharge limits for various parameters like BOD, COD, suspended solids, nutrients, and pH. A robust monitoring program is critical. This involves regularly collecting samples and analyzing them for key parameters, documenting all results meticulously. Operational records such as flow rates, aeration levels, chemical dosages, and maintenance logs are equally important in demonstrating compliance. Any deviations from permit limits must be promptly addressed and investigated, identifying root causes and implementing corrective actions. Regular facility inspections and audits are also vital to identify potential compliance issues before they escalate. Internal training and staff competency are also key to ensure everyone understands the regulations and their roles in maintaining compliance. A proactive approach, involving anticipating potential issues and incorporating preventive measures, is far more efficient than reacting to violations.

Q 14. What are the common environmental permits required for wastewater treatment?

The specific environmental permits required for a wastewater treatment plant vary depending on location, plant size, and the type of wastewater treated. However, some common permits include:

- National Pollutant Discharge Elimination System (NPDES) Permit (in the US): This is a fundamental permit for discharging treated wastewater into surface waters. It outlines discharge limits and monitoring requirements.

- State-Specific Discharge Permits: Many states have their own permits alongside or in addition to NPDES permits, often specifying more detailed requirements.

- Air Permits: These may be necessary if the plant uses equipment that emits pollutants into the air, such as boilers or aeration systems.

- Solid Waste Permits: These are required for handling and disposing of sludge (biosolids) generated during treatment.

- Other Permits: Depending on location and specific circumstances, additional permits might be required related to aspects such as hazardous waste management, groundwater protection, or construction activities.

It’s crucial to work with regulatory agencies to determine the exact permits needed and ensure all requirements are met to prevent penalties and ensure environmental protection.

Q 15. Explain the importance of safety protocols in a wastewater treatment plant.

Safety protocols in a wastewater treatment plant are paramount, not just for worker well-being but also for environmental protection and operational efficiency. Think of it like this: a single lapse in safety can lead to a major incident with significant environmental and economic consequences.

Our protocols cover several key areas:

- Personal Protective Equipment (PPE): This includes everything from respirators and gloves to specialized suits depending on the task. We have strict rules about proper use and disposal of PPE to avoid contamination.

- Lockout/Tagout Procedures (LOTO): These procedures ensure machinery is safely shut down and prevented from accidental start-up during maintenance. A failure to observe LOTO can result in serious injury or equipment damage.

- Confined Space Entry Procedures: Many tasks involve entering confined spaces, such as tanks or manholes. We follow stringent procedures, including atmospheric monitoring and rescue plans, to prevent asphyxiation or exposure to hazardous gases.

- Emergency Response Plans: Detailed emergency plans are in place for various scenarios, including chemical spills, equipment failures, and fires. Regular drills ensure staff are well-prepared to respond effectively.

- Hazard Communication & Training: We provide thorough training to all employees on the hazards associated with their work and the appropriate safety procedures. Regular refresher courses are also conducted.

In my experience, a proactive and well-enforced safety program is not just a regulatory requirement but a critical element of successfully managing a wastewater treatment facility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with SCADA systems in wastewater treatment.

SCADA (Supervisory Control and Data Acquisition) systems are integral to modern wastewater treatment. Imagine it as the central nervous system of the plant, allowing for real-time monitoring and control of all processes. My experience spans several years working with various SCADA platforms, from data acquisition and process automation to alarm management and reporting.

I’ve been involved in:

- Data Acquisition: Configuring SCADA to collect real-time data from various sensors, including flow meters, level sensors, and analyzers. This data provides crucial insights into plant performance and identifies potential issues early on.

- Process Control: Using SCADA to automate various treatment processes, such as aeration control, chemical dosing, and sludge management, optimizing efficiency and reducing manual intervention. For example, I worked on a project where we implemented automated control of aeration based on dissolved oxygen levels, resulting in significant energy savings.

- Alarm Management: Setting up and managing alarm systems to alert operators to abnormal conditions, ensuring timely responses to prevent process upsets and potential environmental incidents.

- Reporting and Data Analysis: Using SCADA data to generate reports for regulatory compliance and performance evaluation. This includes trend analysis to identify patterns and optimize plant operations.

For example, in a previous role, I utilized a SCADA system to remotely monitor and control the chemical feed for our phosphorus removal system, significantly reducing operator intervention and minimizing potential errors in dosing.

Q 17. How do you handle unexpected spills or emergencies?

Unexpected spills or emergencies are always a serious concern in wastewater treatment. Our response follows a well-defined protocol that prioritizes safety, environmental protection, and regulatory compliance.

The steps typically involve:

- Immediate Response: Isolate the spill and prevent further spread. This might involve shutting down equipment or deploying containment booms. Safety of personnel is always the top priority.

- Assessment and Notification: Assess the extent of the spill and the potential environmental impact. Notify relevant authorities, such as the environmental protection agency, immediately. This often involves filling out specific incident reports.

- Containment and Cleanup: Employ appropriate containment and cleanup methods, such as absorbent materials or vacuum trucks, depending on the nature of the spill. This may require specialized equipment and expertise.

- Environmental Monitoring: Monitor the affected area to assess the environmental impact and ensure cleanup efforts are effective. This often involves collecting samples for laboratory analysis.

- Investigation and Corrective Actions: Conduct a thorough investigation to determine the root cause of the spill and implement corrective actions to prevent recurrence. This might involve upgrading equipment, improving procedures, or enhancing training.

- Documentation: Maintain meticulous records of the incident, including response actions, environmental monitoring data, and corrective actions taken. This is crucial for regulatory reporting and future reference.

For example, during a recent chemical spill, we swiftly deployed our emergency response team, contained the spill using absorbent booms, and notified the relevant authorities within the required timeframe. A thorough investigation later revealed a faulty valve, which was promptly replaced.

Q 18. What is your experience with wastewater sampling and analysis?

Wastewater sampling and analysis are crucial for monitoring treatment plant performance, ensuring regulatory compliance, and identifying potential problems. My experience encompasses all aspects of this process, from sample collection and preservation to laboratory analysis and data interpretation.

I am proficient in:

- Sample Collection: Following standard operating procedures for collecting representative samples from various points throughout the treatment process, ensuring proper preservation techniques to maintain sample integrity.

- Laboratory Analysis: Performing various laboratory analyses, including BOD, COD, TSS, ammonia, nitrates, phosphates, and many others. I also understand the limitations and potential sources of error in each test.

- Data Interpretation: Analyzing laboratory results to assess treatment plant performance, identify operational issues, and make informed decisions regarding process adjustments.

- Quality Control: Maintaining rigorous quality control procedures to ensure the accuracy and reliability of laboratory results. This includes running blanks and standards, as well as participating in proficiency testing programs.

In a previous role, I identified a decrease in effluent quality based on routine sampling and analysis. Further investigation revealed a malfunction in our biological treatment process, which was promptly addressed, preventing potential environmental violations and operational disruptions.

Q 19. Explain your understanding of the Clean Water Act (or relevant local legislation).

The Clean Water Act (CWA) in the United States is a cornerstone of environmental protection, establishing a framework for regulating water pollution. It sets water quality standards, regulates the discharge of pollutants into navigable waters, and provides funding for wastewater treatment infrastructure improvements. Similar legislation exists in other countries, often with comparable goals.

My understanding encompasses:

- National Pollutant Discharge Elimination System (NPDES) permits: These permits are required for any discharge of pollutants into navigable waters. They specify the types and amounts of pollutants that can be discharged, and plants must regularly monitor their discharges and submit reports to demonstrate compliance.

- Water quality standards: The CWA sets water quality standards, which define the acceptable levels of various pollutants in water bodies. Wastewater treatment plants must ensure that their discharges meet these standards.

- Enforcement mechanisms: The CWA outlines various mechanisms for enforcing compliance, including inspections, penalties for violations, and citizen lawsuits.

- Funding mechanisms: The CWA provides funding for wastewater treatment infrastructure improvements through various grant programs.

Understanding the CWA is not simply about complying with regulations; it’s about acting as a responsible steward of our environment. This understanding guides our operational practices, investment decisions, and ensures the long-term sustainability of our wastewater treatment efforts.

Q 20. Describe your experience with wastewater treatment plant design or upgrades.

My experience in wastewater treatment plant design and upgrades is extensive. I’ve worked on various projects, from minor modifications to large-scale expansions. It’s a multifaceted process involving engineering, regulatory compliance, and financial considerations.

My contributions have included:

- Process Optimization: Analyzing existing treatment processes to identify areas for improvement, such as increasing efficiency, reducing energy consumption, or improving effluent quality. This often involves using simulation software and data analysis to explore different scenarios.

- Equipment Selection: Specifying and selecting appropriate equipment for various treatment processes, considering factors such as capacity, efficiency, reliability, and cost-effectiveness.

- Design Development: Contributing to the design of new treatment facilities or upgrades to existing facilities, ensuring compliance with all applicable regulations and standards.

- Construction Oversight: Overseeing construction to ensure that the project is completed on time and within budget, and that the design specifications are met.

- Commissioning and Startup: Participating in the commissioning and startup of new or upgraded facilities, ensuring that all systems are functioning properly.

For example, on one project, I led the upgrade of a municipal wastewater treatment plant, incorporating advanced technologies such as membrane bioreactors to improve effluent quality and reduce energy consumption. The project resulted in significant environmental improvements and cost savings for the municipality.

Q 21. What are the different types of industrial wastewater treatment processes?

Industrial wastewater treatment processes vary considerably depending on the specific industry and the nature of the wastewater generated. However, several common processes are frequently employed.

These include:

- Physical Treatment: This involves methods like screening, sedimentation, and filtration to remove large solids and suspended particles. Think of it like a multi-stage sieve, progressively removing larger and then smaller particles.

- Chemical Treatment: This uses chemicals to precipitate or neutralize pollutants. For example, coagulation and flocculation are used to remove suspended solids, while neutralization adjusts the pH to acceptable levels.

- Biological Treatment: This employs microorganisms to break down organic pollutants. Common methods include activated sludge, trickling filters, and anaerobic digestion. This is like using nature’s own cleanup crew to break down contaminants.

- Advanced Treatment: This is used for particularly challenging wastewater streams requiring advanced techniques, such as membrane filtration (microfiltration, ultrafiltration, reverse osmosis), activated carbon adsorption, or advanced oxidation processes. This stage targets removing very specific contaminants or achieving higher quality treated water.

The choice of processes depends on the characteristics of the wastewater (flow, strength, type of pollutants), environmental regulations, and economic considerations. For example, a food processing plant might employ a combination of physical, chemical, and biological treatment to remove organic matter, fats, oils, and grease, while a pharmaceutical plant might require more advanced treatment methods to remove specific chemical compounds.

Q 22. How do you manage and dispose of hazardous waste?

Hazardous waste management in wastewater treatment is critical for environmental protection and worker safety. It starts with proper segregation at the source. We identify hazardous waste streams – things like heavy metals from industrial discharges, solvents, or certain chemicals – and store them separately in clearly labeled containers to prevent cross-contamination.

Disposal methods depend heavily on the waste’s characteristics. For example, certain heavy metals might be removed using technologies like chemical precipitation, then the resulting sludge is handled as hazardous waste, often requiring specialized treatment and disposal in licensed facilities. This could involve incineration, solidification/stabilization, or landfilling in a secured hazardous waste landfill, always following all relevant regulations like those set by the EPA.

We maintain meticulous records of every step of the process – from generation to final disposal – to ensure full compliance. This documentation is essential for audits and helps us continually improve our practices. Think of it like a detailed recipe for hazardous waste, ensuring each ingredient (waste type) is carefully measured and processed according to the correct formula (regulations).

Q 23. Explain your understanding of life cycle assessment (LCA) related to wastewater.

Life Cycle Assessment (LCA) in wastewater treatment examines the environmental impact of a wastewater treatment process across its entire lifecycle. This means we assess the impacts from the raw materials used in construction and operation (energy, chemicals) through treatment, sludge management, and even the end-of-life disposal of treatment plant equipment.

The four main phases are Goal and Scope definition, Inventory Analysis (quantifying resource use and emissions), Impact Assessment (evaluating the environmental consequences of those impacts), and finally Interpretation of results. For instance, we might use LCA to compare the environmental performance of different sludge treatment methods – anaerobic digestion versus incineration – by analyzing energy consumption, greenhouse gas emissions, and potential water pollution from each process. The findings help us select the most environmentally sound option.

LCA gives us a holistic view, allowing us to identify areas for improvement, such as minimizing energy use, optimizing chemical usage, and selecting sustainable materials. It’s a powerful tool for driving sustainable practices within wastewater treatment.

Q 24. Describe your experience with conducting environmental impact assessments.

I have extensive experience conducting Environmental Impact Assessments (EIAs). EIAs are crucial for predicting and mitigating the potential environmental consequences of projects, such as building a new wastewater treatment plant or expanding an existing one. The process typically involves:

- Identifying potential impacts: We assess potential effects on air and water quality, noise levels, and the surrounding ecosystem.

- Data collection and analysis: This includes environmental surveys, water quality testing, and stakeholder consultations.

- Impact prediction: We use models and data to forecast the likely effects of the project.

- Mitigation strategy development: This involves designing ways to minimize or avoid negative impacts – for example, using noise reduction technologies or implementing advanced wastewater treatment to minimize discharges.

- Report preparation and review: The EIA culminates in a detailed report, which is often subject to regulatory review.

For example, in one project, our EIA identified the potential for increased nutrient loading into a nearby river due to the new plant’s discharge. This led us to recommend and implement advanced nutrient removal technologies to mitigate this impact, ensuring environmental protection.

Q 25. How do you ensure the accuracy and reliability of environmental monitoring data?

Accuracy and reliability in environmental monitoring are paramount. We employ a multi-pronged approach:

- Calibration and validation: All monitoring equipment is regularly calibrated and validated against certified standards, ensuring accurate readings. We use traceable standards and participate in proficiency testing programs.

- Quality control/quality assurance (QA/QC): We implement rigorous QA/QC procedures, including duplicate samples, blank samples, and spike samples, to detect and correct for errors. This also includes proper chain of custody procedures.

- Data management: Data is electronically recorded, managed, and stored securely using validated software systems that ensure data integrity and traceability. We follow specific protocols to minimize data entry errors.

- Analyst competency: Our team of analysts are highly skilled and undergo regular training. This ensures competent sample handling, analysis, and reporting.

- Method validation: We validate the methods used for each parameter to ensure they are suitable and accurate for the specific matrix.

Regular internal and external audits review our entire data management system, ensuring we maintain the highest quality standards. This commitment to data quality leads to confident decision-making and effective environmental management.

Q 26. Explain your experience with environmental audits and inspections.

I have extensive experience with environmental audits and inspections, both internal and external. Internal audits allow us to proactively identify and correct deficiencies in our environmental management system (EMS) before regulatory agencies do. These audits cover everything from waste management practices to monitoring procedures and compliance with permits and regulations.

External audits and inspections, conducted by regulatory bodies, are a critical part of ensuring compliance. These can be announced or unannounced and involve a thorough review of our documentation, facilities, and operational procedures. I have worked collaboratively with regulatory inspectors, providing them with all necessary data and addressing any identified deficiencies promptly and effectively. A well-prepared company, with clear documentation and a robust EMS, will fare much better during external audits. Clear, accurate record-keeping is your best friend.

Q 27. Describe your experience with environmental reporting and documentation.

Environmental reporting and documentation is crucial for demonstrating compliance, identifying areas for improvement, and communicating our environmental performance to stakeholders. I have experience preparing a wide range of reports including:

- Compliance reports: These reports document our adherence to environmental regulations and permits.

- Environmental monitoring reports: These summarize our monitoring data and highlight any trends or concerns.

- Annual environmental reports: These provide a comprehensive overview of our environmental performance over the past year.

- Incident reports: These document any environmental incidents, detailing the cause, response, and corrective actions.

All reporting follows strict guidelines to ensure accuracy, completeness, and consistency. We utilize software systems to manage and generate reports efficiently, further ensuring consistency and reducing the risk of errors. Transparency and accuracy are key – stakeholders want and deserve clear, easily understandable reports.

Q 28. What strategies do you use for improving the efficiency and sustainability of wastewater treatment processes?

Improving the efficiency and sustainability of wastewater treatment is a constant pursuit. Strategies we employ include:

- Energy optimization: Implementing energy-efficient technologies like variable speed drives on pumps and using renewable energy sources where feasible. This reduces our carbon footprint and operating costs.

- Process optimization: Using advanced process control systems to optimize treatment processes, leading to better effluent quality and reduced energy consumption.

- Sludge management optimization: Optimizing sludge treatment strategies, potentially using anaerobic digestion to produce biogas, a renewable energy source.

- Resource recovery: Exploring the recovery of valuable resources from wastewater, such as phosphorus or energy.

- Water reuse: Implementing wastewater reuse programs where appropriate, reducing reliance on fresh water sources.

- Automation and digitization: Implementing advanced sensors and monitoring systems that provide real-time data, enabling proactive maintenance and process optimization. This also increases operational efficiency.

By integrating these strategies, we move toward a more sustainable and efficient wastewater treatment system, minimizing environmental impact and maximizing resource recovery.

Key Topics to Learn for Wastewater Treatment and Environmental Compliance Interview

- Wastewater Treatment Processes: Understanding primary, secondary, and tertiary treatment methods, including their chemical and biological principles. Consider the practical application of each process in different plant designs and scales.

- Environmental Regulations and Compliance: Familiarize yourself with relevant federal, state, and local regulations (e.g., Clean Water Act, NPDES permits). Practice applying these regulations to hypothetical scenarios and problem-solving.

- Water Quality Monitoring and Analysis: Master the techniques for sampling, analyzing, and interpreting water quality data. Understand the significance of various parameters (BOD, COD, TSS, nutrients, etc.) and their implications for treatment efficacy and environmental impact.

- Instrumentation and Process Control: Gain a working knowledge of the instrumentation used in wastewater treatment plants (sensors, meters, SCADA systems). Understand how these systems are used to monitor and control treatment processes effectively.

- Sludge Management and Disposal: Learn about various sludge treatment methods (thickening, digestion, dewatering) and disposal options, including their environmental implications and cost considerations. Explore the practical challenges and solutions related to sludge management.

- Health and Safety Regulations: Understand OSHA regulations and best practices for working in a wastewater treatment environment, including personal protective equipment (PPE) and hazard mitigation strategies.

- Sustainability and Optimization: Explore energy efficiency strategies, resource recovery options (biogas, biosolids), and other sustainability initiatives within wastewater treatment. Consider the role of data analysis and process optimization in achieving environmental and economic goals.

- Troubleshooting and Problem-solving: Develop your ability to identify and troubleshoot common operational issues in wastewater treatment plants. Practice applying your knowledge to solve realistic problems efficiently and effectively.

Next Steps

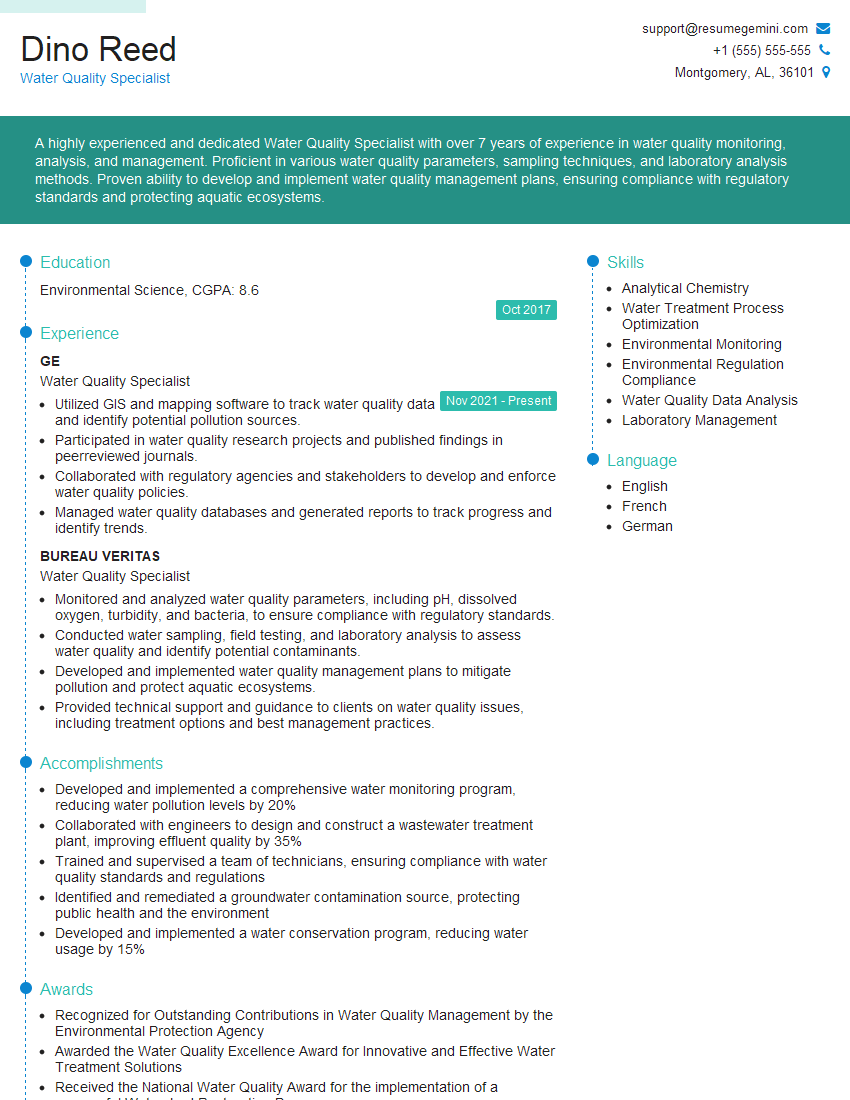

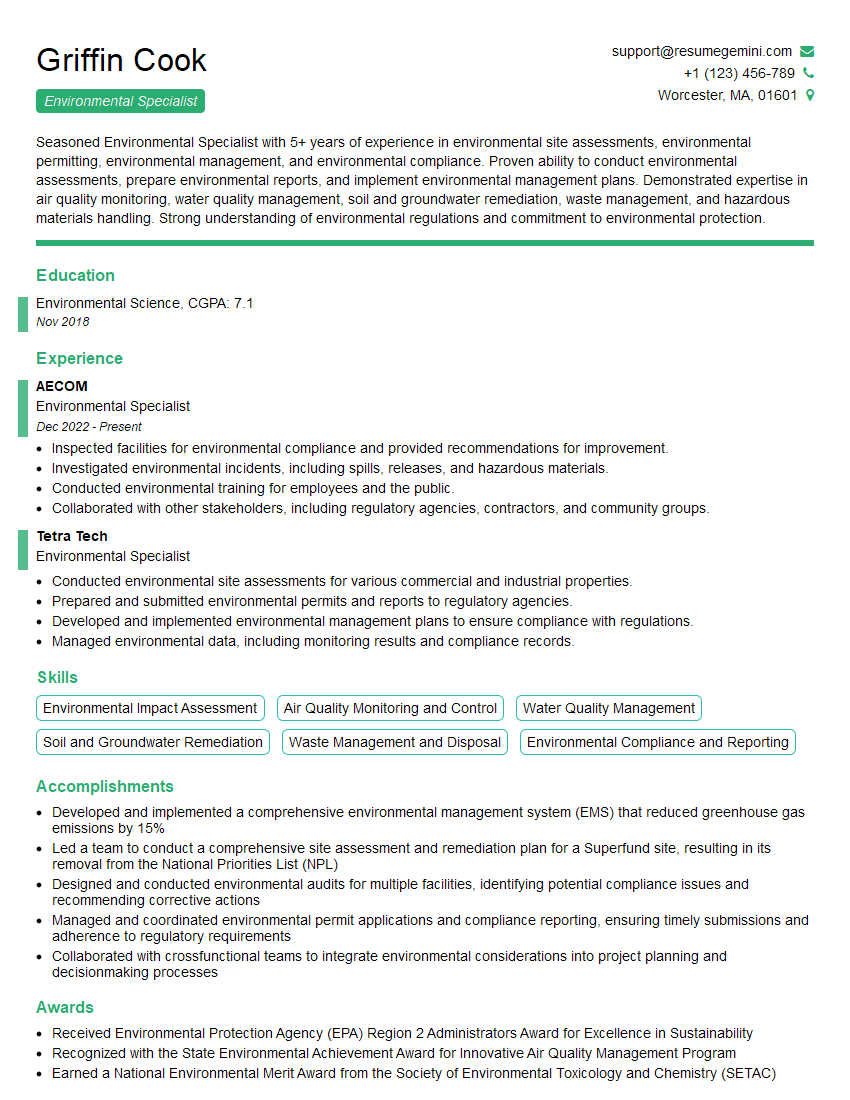

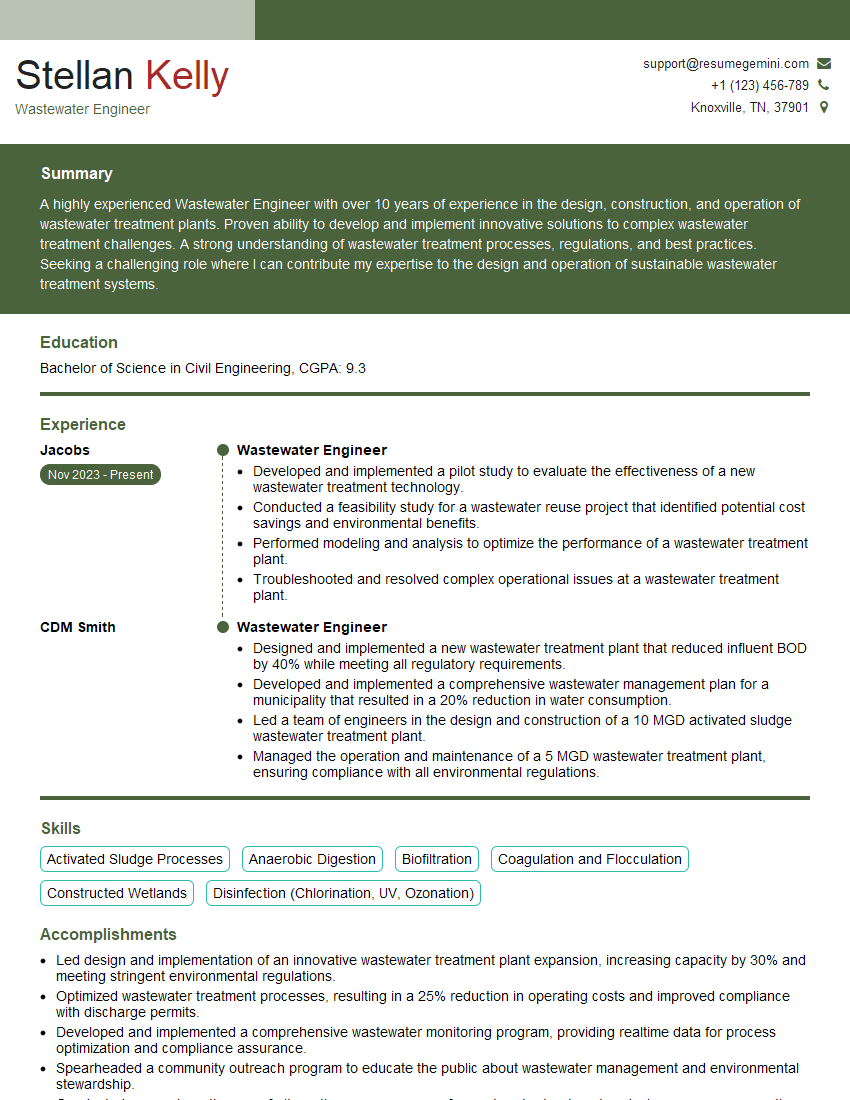

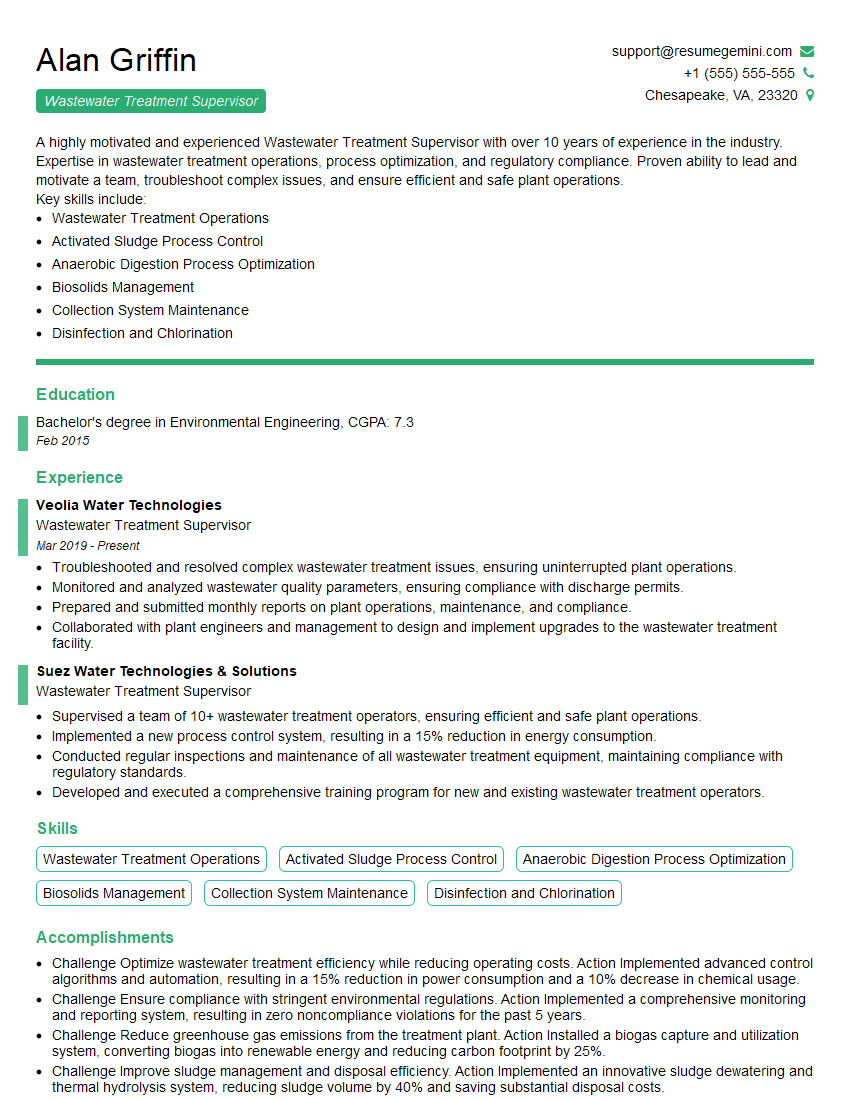

Mastering Wastewater Treatment and Environmental Compliance opens doors to a rewarding career with significant impact. Demonstrating your expertise through a strong resume is crucial for securing your dream role. Creating an ATS-friendly resume increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Wastewater Treatment and Environmental Compliance are provided to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good