Preparation is the key to success in any interview. In this post, we’ll explore crucial Knowledge of Cargo Handling Procedures interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Knowledge of Cargo Handling Procedures Interview

Q 1. Explain the different types of cargo handling equipment.

Cargo handling equipment varies greatly depending on the type of cargo and the location. We can broadly categorize them into:

- Lifting Equipment: This includes cranes (container cranes, gantry cranes, mobile harbor cranes), forklifts, and reach stackers. These are essential for moving heavy containers and pallets.

- Material Handling Equipment: This category encompasses conveyors (belt conveyors, roller conveyors), stackers, and pallet jacks, used for moving cargo efficiently within warehouses and terminals.

- Specialized Equipment: This group includes specialized equipment tailored to specific cargo types. For example, we have specialized cranes for handling oversized or heavy-lift cargo, and equipment for handling liquid cargo (like pumps and pipelines).

- Transportation Equipment: This includes trucks, trailers, and rail cars that move cargo between ports, terminals, and inland destinations.

For example, imagine unloading a container ship. Giant container cranes lift the containers from the ship’s hold and place them on chassis, ready for transport. Smaller forklifts then maneuver the containers within the terminal for further processing.

Q 2. Describe the process of loading and unloading containers from a vessel.

Loading and unloading containers from a vessel is a complex, coordinated process. It typically involves these steps:

- Planning and Preparation: This involves reviewing the cargo manifest, assigning container locations (stowage plan), and coordinating with stevedores (the workers who load and unload cargo).

- Vessel Arrival and Berthing: The vessel arrives at the designated berth, and the mooring lines are secured.

- Crane Operations: Container cranes lift containers from the ship’s hold or deck and place them onto waiting chassis or directly onto the terminal. The process is reversed for loading.

- Chassis Transportation: Once the container is on a chassis (a wheeled frame), it’s transported to a designated location within the terminal for customs inspection, delivery, or storage.

- Container Handling and Stacking: Reach stackers and other equipment move containers within the terminal yard, stacking them efficiently to maximize space.

- Departure: After unloading and loading are complete, the vessel departs the port.

Think of it like a giant, highly organized game of Tetris, where each container must be placed in the right spot to maintain balance and stability. Safety and efficiency are paramount throughout the entire process.

Q 3. What are the safety regulations related to cargo handling?

Safety is paramount in cargo handling. Regulations vary by country but commonly include:

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including safety helmets, high-visibility clothing, safety shoes, and gloves.

- Training and Certification: Operators of cargo-handling equipment must be properly trained and certified. Regular refresher training is essential.

- Safe Lifting Practices: Strict adherence to safe lifting techniques is crucial to prevent accidents. This includes using appropriate equipment and ensuring proper load securing.

- Emergency Procedures: Clear emergency procedures must be in place, including protocols for fire, spills, and other potential incidents.

- Regular Inspections: Cargo handling equipment undergoes regular inspections to ensure it is in safe working condition.

- Environmental Regulations: Regulations cover the handling of hazardous materials and environmental protection.

Failure to comply with these regulations can lead to serious accidents, fines, and damage to reputation. For instance, a poorly secured load could fall and cause injury or damage, while improper handling of hazardous materials could lead to environmental contamination.

Q 4. How do you ensure the security of cargo during transit?

Cargo security during transit relies on a multi-layered approach:

- Container Sealing and Locking: Containers are sealed and locked to prevent unauthorized access. Seals are tamper-evident, allowing detection of any breaches.

- Security Surveillance: Ports and terminals employ various surveillance systems, including CCTV cameras and security personnel, to monitor activity.

- Cargo Inspection: Random inspections and checks are carried out to detect contraband or illicit goods.

- Access Control: Strict access control measures restrict entry to authorized personnel only.

- Electronic Tracking: GPS tracking devices can monitor the location and movement of containers throughout their journey.

- Insurance: Cargo insurance provides financial protection against loss or damage.

Imagine a shipment of high-value electronics. Multiple layers of security, from container seals to GPS tracking, work together to minimize the risk of theft or damage. This reduces financial losses and maintains trust between shippers and carriers.

Q 5. What are the different methods of cargo stowage?

Cargo stowage involves arranging cargo within a vessel to ensure stability, safety, and efficient use of space. Methods include:

- Unit Load Stowage: This method uses standardized units like containers or pallets for efficient stacking and handling.

- Bulk Stowage: This method is used for loose cargo, such as grain or ore, and requires careful consideration of weight distribution.

- Breakbulk Stowage: This involves manually handling individual pieces of cargo, such as bags or boxes. It’s less efficient than unit load but necessary for certain goods.

- Weight Distribution: Careful weight distribution is crucial to prevent instability. Heavier items are often placed lower down in the vessel.

- Securing Cargo: Cargo must be securely fastened to prevent shifting during transit, using lashing or other methods.

Proper stowage is essential for preventing cargo damage, vessel instability, and even accidents. For example, improperly stowed cargo in a container ship could shift during a storm, leading to damage or even causing the vessel to list (tilt).

Q 6. Explain the importance of proper documentation in cargo handling.

Proper documentation is crucial for smooth and efficient cargo handling. Key documents include:

- Bill of Lading: This is a contract of carriage between the shipper and the carrier, detailing the terms of shipment and serving as proof of ownership.

- Packing List: This document lists the contents of each package, providing detailed information about the cargo.

- Commercial Invoice: This document outlines the sale of goods between buyer and seller, detailing the value and description of the goods.

- Certificate of Origin: This verifies the country of origin of the goods.

- Customs Documents: These documents are required for customs clearance and vary depending on the regulations of the importing and exporting countries.

Without accurate documentation, there would be significant delays in customs clearance, potential disputes over cargo ownership, and difficulty tracking cargo throughout its journey. Think of it like the instruction manual for a complex machine – all parts need to be accounted for and understood.

Q 7. How do you handle damaged or lost cargo?

Handling damaged or lost cargo involves a systematic process:

- Investigation and Documentation: Thoroughly investigate the cause of the damage or loss, documenting everything with photographs and witness statements.

- Notification of Stakeholders: Inform relevant parties, including the shipper, carrier, and insurer.

- Damage Assessment: Assess the extent of the damage or loss, determining the value of the affected goods.

- Claims Process: File a claim with the insurer and/or carrier, providing all necessary documentation to support the claim.

- Resolution: Work with the involved parties to reach a resolution, which may involve compensation, replacement goods, or other solutions.

For example, if a container of furniture is damaged during transit, the process starts with documenting the damage, taking photos, and reporting it to the carrier and insurer. The claim process then follows, ideally leading to compensation or replacement of the damaged furniture.

Q 8. What are the common challenges faced in cargo handling?

Cargo handling presents numerous challenges, often interconnected and dependent on factors like cargo type, transportation mode, and geographical location. Think of it like a complex puzzle with many pieces that need to fit perfectly.

- Time Sensitivity: Perishable goods like fruits and vegetables have strict time limits, demanding swift handling to prevent spoilage. A delay can lead to significant financial losses.

- Damage and Loss: Improper handling, inadequate securing, or accidental damage can result in costly repairs or total loss of cargo. Imagine a shipment of delicate electronics being mishandled – the consequences can be devastating.

- Security Concerns: Theft, pilferage, and smuggling are constant threats, requiring robust security measures throughout the entire handling process. Think about high-value goods like jewelry or pharmaceuticals needing extra protection.

- Documentation and Compliance: Meeting regulatory requirements for customs, insurance, and other documentation can be complex and time-consuming. Failing to comply can result in hefty fines and delays.

- Capacity and Congestion: Ports and terminals can experience congestion, leading to delays in unloading, storage, and loading. Picture a busy port during peak season – the sheer volume of cargo can create bottlenecks.

- Weather Conditions: Extreme weather events can disrupt operations and cause damage to cargo and infrastructure. A storm can delay shipments for days or even weeks.

- Technological Limitations: Lack of advanced technology or inefficient systems can hinder efficiency and increase the risk of errors. Investing in modern tracking and management systems is crucial.

Q 9. How do you manage cargo inventory?

Effective cargo inventory management is crucial for efficiency and accuracy. It’s like keeping a meticulous record of every item in a large warehouse. We employ several strategies:

- Barcode/RFID Tracking: Each cargo unit is tagged with a unique identifier, allowing real-time tracking throughout its journey. This system helps us locate specific items quickly and accurately.

- Warehouse Management Systems (WMS): Software solutions that manage inventory levels, track location, and optimize storage space. This allows us to visualize the entire inventory in real-time and identify potential bottlenecks.

- Regular Stocktaking: Physical checks of inventory are conducted periodically to verify accuracy and identify discrepancies between physical stock and recorded data. This ensures our records match reality.

- First-In, First-Out (FIFO) Method: Perishable goods are managed according to FIFO, ensuring the oldest items are shipped first to prevent spoilage. This is especially critical for food items.

- Data Analysis: Regular analysis of inventory data helps identify trends, predict demand, and optimize storage strategies. This allows us to improve efficiency and minimize waste.

Q 10. Describe your experience with different types of cargo (e.g., hazardous materials, perishable goods).

My experience encompasses a broad range of cargo types, each requiring specialized handling techniques. It’s like having different recipes for different dishes.

- Hazardous Materials (Hazmat): Handling hazmat requires strict adherence to regulations, including proper labeling, packaging, and transportation procedures. For instance, we follow the IMDG code for sea transport of dangerous goods, and the IATA regulations for air transport. Safety is paramount, and specialized training is mandatory for personnel.

- Perishable Goods: These goods require temperature-controlled environments and rapid transit to maintain quality. We utilize refrigerated containers and monitor temperature throughout the journey. We also work closely with logistics providers who can ensure smooth and fast transit.

- Oversized or Heavy Lift Cargo: These require specialized equipment and handling techniques to ensure safe movement and prevent damage. We work with heavy-lift specialists for planning and execution, and we utilize specialized lifting equipment like cranes and heavy-duty trucks.

- General Cargo: This covers a wide array of items, from clothing to furniture. While less demanding than other types, proper packing and securing are essential to prevent damage during transit.

Q 11. Explain the role of a bill of lading in cargo handling.

The Bill of Lading (B/L) is a crucial document in cargo handling; it’s like the passport for your cargo. It acts as a contract of carriage, a receipt for the goods, and a document of title.

- Contract of Carriage: It outlines the agreement between the shipper and the carrier, specifying the terms of transportation, including the origin, destination, and agreed-upon charges.

- Receipt for Goods: It confirms that the carrier has received the goods in the stated condition and quantity. Any discrepancies need to be noted clearly.

- Document of Title: It represents legal ownership of the goods, allowing the holder to claim them upon arrival. This is crucial for transferring ownership and facilitating financial transactions.

Without a properly executed B/L, the entire shipment can be delayed or even jeopardized. It’s a critical legal document throughout the entire shipping process.

Q 12. What are Incoterms and how do they affect cargo handling?

Incoterms (International Commercial Terms) are standardized trade terms published by the International Chamber of Commerce (ICC). They define the responsibilities of the buyer and seller in an international transaction, affecting cargo handling significantly. Think of them as a set of rules that determine who does what and when.

Different Incoterms allocate responsibilities for things like delivery, insurance, and customs clearance. For example, FOB (Free On Board) means the seller is responsible for delivering the goods to the port of shipment, while CIF (Cost, Insurance, and Freight) places responsibility on the seller for insurance and freight to the port of destination. Choosing the right Incoterms is crucial as it impacts costs, risks, and insurance requirements, consequently affecting the handling procedures and responsibilities of all parties involved.

Q 13. How do you manage delays in cargo handling?

Delays in cargo handling are inevitable sometimes, but effective management is key. It’s like navigating a traffic jam – you need a plan.

- Proactive Communication: Maintaining open communication with all stakeholders (shippers, carriers, customers) is essential to promptly address any potential delays.

- Contingency Planning: Having alternative plans in place for potential disruptions, such as alternate transportation routes or storage facilities, can minimize the impact of delays.

- Root Cause Analysis: Investigating the cause of the delay helps to identify areas for improvement and prevent future occurrences.

- Documentation and Reporting: Keeping accurate records of delays, their causes, and the actions taken helps in tracking performance and improving processes.

- Negotiation and Problem Solving: Working collaboratively with all involved parties to find solutions, potentially including renegotiating delivery schedules or finding alternative transportation options, helps to mitigate losses and maintain relationships.

Q 14. What is the importance of proper cargo securing?

Proper cargo securing is paramount for safety and preventing damage during transit. Think of it as building a strong foundation for a house. If it’s not secure, the whole structure can collapse.

- Preventing Shifting and Damage: Secure cargo prevents shifting during transportation, which can cause damage to the goods themselves and to the vehicle or vessel carrying them.

- Ensuring Stability and Safety: Secure cargo contributes to the overall stability of the transport unit, reducing the risk of accidents.

- Meeting Legal and Insurance Requirements: Proper securing is often a legal requirement and is essential for insurance claims in case of damage or loss.

- Reducing Losses: By preventing damage and loss, proper securing helps to reduce financial losses for both shippers and carriers. It minimizes the risk of expensive repairs or complete write-offs.

The methods used depend on the type of cargo and transport mode; some involve using lashing straps, blocking and bracing, or specialized containers.

Q 15. Describe your experience with customs regulations and procedures.

My experience with customs regulations and procedures is extensive, spanning over 10 years in international cargo handling. I’ve worked with customs agencies globally, including the U.S. Customs and Border Protection (CBP), European Union customs, and various Asian customs authorities. I’m proficient in navigating the complexities of import and export documentation, including Harmonized System (HS) code classification, certificates of origin, and other required permits. I understand the nuances of different customs processes and have a proven track record of ensuring timely and compliant clearance of goods. For example, I successfully navigated a complex situation involving the import of specialized medical equipment into Japan, requiring meticulous documentation and adherence to stringent regulatory requirements. This involved understanding specific Japanese import regulations and working closely with both the Japanese Customs office and our client.

I have a deep understanding of various customs duties, tariffs, and taxes, and I’m adept at minimizing compliance risks and potential delays by ensuring all documentation is accurate and complete before submission. I frequently conduct training sessions for colleagues on updates and changes within customs regulations, emphasizing proactive risk management.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with international regulations?

Ensuring compliance with international regulations is paramount in cargo handling. My approach is multifaceted and proactive. It begins with a thorough understanding of the specific regulations governing the origin, transit, and destination of the cargo. This involves meticulous research, utilizing resources like the World Trade Organization (WTO) guidelines and specific country-specific regulations. We use a robust system of checks and balances throughout the entire process, starting from the initial booking of the cargo. This includes verifying documentation, ensuring accurate HS codes are assigned, and confirming all necessary permits are obtained.

Regular audits and training sessions for our staff reinforce compliance procedures. We stay updated on changes in international trade laws and regulations through industry publications, seminars, and affiliations with relevant professional organizations. Further, we maintain a close working relationship with customs brokers and other regulatory bodies, fostering open communication and timely resolution of any potential compliance issues. A recent instance involved updated sanctions on specific materials. We implemented immediate changes across our processes to ensure 100% compliance by utilizing updated classification lists and verifying documentation against the sanctions lists before shipment.

Q 17. How do you handle cargo claims and disputes?

Handling cargo claims and disputes requires a methodical and diplomatic approach. My experience involves thoroughly investigating each claim, gathering all relevant documentation—Bills of Lading, insurance policies, cargo manifests, and any other supporting evidence. The process starts with a thorough assessment of the claim to determine the validity and liability. This often involves communication with involved parties—shippers, carriers, insurers, and customs officials. I employ strong negotiation skills to reach mutually acceptable resolutions. Documentation and communication logs are meticulously maintained throughout the entire process.

For example, I successfully negotiated a settlement for a damaged shipment of perishable goods. Through careful documentation and a structured negotiation strategy, I secured fair compensation for the client while minimizing the financial impact on our company. In cases where negotiation fails, I have experience escalating the matter through mediation or arbitration, adhering to established legal procedures. A key aspect is maintaining accurate record keeping, which serves as critical evidence should legal action become necessary.

Q 18. What is your experience with different transportation modes (sea, air, land)?

I possess extensive experience across all major modes of transportation: sea, air, and land. My expertise in sea freight encompasses containerization, bulk shipping, and break-bulk cargo handling. I understand the complexities of ocean bills of lading, Incoterms, and the various challenges related to port operations and marine insurance. In air freight, I’m familiar with different aircraft types, their capacity limitations, and the specific requirements for handling sensitive or hazardous materials. Experience with air waybills and the regulations surrounding air cargo security is essential. Land transport, primarily trucking, involves knowledge of trucking regulations, route optimization, and the safe handling of cargo during land transportation. I am proficient in tracking shipments across all three modes, employing technologies such as GPS tracking and shipment management systems. For instance, I once orchestrated the seamless transfer of time-sensitive pharmaceuticals from an air shipment to a trucking delivery system to meet a critical deadline for a client in a remote area.

Q 19. Describe your proficiency with cargo handling software and systems.

I’m proficient in various cargo handling software and systems, including Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and various customs clearance software. I’m adept at utilizing these systems for tracking shipments, managing inventory, generating reports, and ensuring seamless communication with stakeholders. My experience includes working with systems such as SAP GTS, Oracle Transportation Management, and various specialized logistics platforms. I’m capable of configuring these systems to meet specific business requirements and integrating them with other enterprise resource planning (ERP) systems. I’m also comfortable with data analysis using these systems to identify trends, improve operational efficiencies, and reduce costs.

For example, I implemented a new TMS to streamline our shipping processes, resulting in a 15% reduction in transit times and a 10% reduction in shipping costs. I am also proficient in utilizing data analytics within these systems to predict potential delays and proactively address them.

Q 20. Explain your understanding of cargo weight and balance.

Cargo weight and balance is crucial for safe and efficient transportation, particularly in air and sea freight. Understanding center of gravity, weight distribution, and load stability is essential to prevent accidents and ensure compliance with safety regulations. In air freight, improper weight and balance can lead to structural damage or even crashes. Sea freight requires careful consideration to ensure stability and prevent shifting during transit, potentially damaging the cargo or the vessel. I possess a thorough understanding of calculating weight and balance, using specialized software and manual calculations when necessary. I’m familiar with the regulations and procedures related to weight and balance documentation required by various regulatory bodies.

For instance, I had to carefully manage the weight and balance of an oversized and overweight piece of equipment being shipped by air. This required precise calculations to ensure it met the aircraft’s weight limits and the center of gravity was within acceptable parameters. It involved close coordination with the airline and specialized handling equipment providers.

Q 21. How do you manage cargo storage in a warehouse?

Managing cargo storage in a warehouse involves optimizing space utilization, ensuring safety, and maintaining efficient inventory management. My approach involves implementing a well-defined warehouse layout that accounts for the types and sizes of cargo being stored. This includes proper racking systems, appropriate aisle widths, and designated areas for different cargo categories. We utilize a WMS to track inventory levels, manage stock rotation (FIFO/LIFO), and streamline picking and packing processes. Safety measures, such as clear signage, fire prevention systems, and proper handling equipment, are in place to minimize risks. Regular inspections and maintenance of the warehouse facility are crucial. Furthermore, security procedures are implemented to prevent theft or damage to stored goods.

For example, I recently implemented a new warehouse layout and upgraded our WMS resulting in a 20% increase in storage capacity and a 10% reduction in order fulfillment time. We also successfully maintained a 99.9% inventory accuracy rate through implementing the new WMS.

Q 22. What are the environmental concerns related to cargo handling?

Environmental concerns in cargo handling are significant and multifaceted. They stem from the sheer volume of goods moved globally and the processes involved. Key issues include:

- Air Pollution: Diesel emissions from trucks, ships, and handling equipment contribute to smog and respiratory problems. The constant movement of cargo generates significant greenhouse gases.

- Water Pollution: Accidental spills of cargo, particularly hazardous materials, can contaminate waterways. Runoff from ports and storage areas can also carry pollutants into the ocean.

- Noise Pollution: The constant activity in ports and transportation hubs creates significant noise pollution, impacting nearby communities and wildlife.

- Waste Generation: Packaging materials, from cardboard to plastic pallets, generate substantial waste. Improper disposal leads to landfill issues and environmental degradation.

- Climate Change: The transportation of goods, particularly by air and sea, accounts for a substantial portion of global greenhouse gas emissions.

Mitigating these concerns requires a multi-pronged approach, including investing in cleaner technologies (e.g., electric vehicles, alternative fuels), implementing stricter regulations for waste management, optimizing transportation routes to reduce fuel consumption, and promoting sustainable packaging options.

Q 23. Describe your experience with cargo tracking and tracing systems.

I have extensive experience with various cargo tracking and tracing systems, ranging from simple spreadsheet-based tracking to sophisticated, integrated systems like those offered by major logistics providers. In my previous role, we utilized a system that integrated GPS tracking on containers, real-time data updates on vessel locations and estimated times of arrival (ETAs), and automated notifications for delays or exceptions. This allowed us to proactively address potential problems, improve delivery times, and provide enhanced transparency to clients. For example, we used this system to successfully track a shipment of perishable goods across multiple continents, adjusting the transportation route when a port strike occurred to avoid spoilage. My experience also includes working with barcode and RFID technologies for individual package tracking within containers, ensuring accurate inventory management and minimizing loss or damage.

Q 24. How do you prioritize tasks in a fast-paced cargo handling environment?

Prioritization in a fast-paced cargo handling environment is crucial. I utilize a combination of methods to ensure tasks are completed efficiently and effectively. My approach typically involves:

- Urgency and Importance Matrix: I classify tasks based on urgency (immediate, short-term, long-term) and importance (critical, important, less important). This helps identify high-priority tasks requiring immediate attention.

- Time Management Techniques: I employ techniques such as time blocking and the Pomodoro Technique to allocate specific time slots for different tasks, optimizing focus and productivity.

- Collaboration and Communication: Open communication with team members and stakeholders is essential. This helps to identify potential bottlenecks and adjust priorities as needed. For instance, I might adjust the unloading schedule for a container of time-sensitive medicine to expedite the process.

- Contingency Planning: It’s vital to anticipate potential delays or disruptions. Having a backup plan allows for smoother operations when unforeseen events occur.

This multifaceted strategy ensures that critical tasks are addressed promptly, minimizing disruptions and maximizing efficiency in a dynamic operational environment.

Q 25. What are your strategies for improving efficiency in cargo handling operations?

Improving efficiency in cargo handling hinges on several key strategies:

- Process Optimization: Analyzing existing workflows and identifying bottlenecks, redundancies, or areas for automation is key. This might involve streamlining documentation processes, implementing optimized loading/unloading procedures, or adopting new technologies.

- Technology Integration: Utilizing real-time tracking systems, automated gate systems, and warehouse management systems (WMS) significantly enhances efficiency and transparency.

- Improved Communication and Collaboration: Real-time communication between all stakeholders (shippers, carriers, customs, etc.) ensures smooth transitions and minimizes delays.

- Staff Training and Development: Well-trained staff are better equipped to handle tasks efficiently and safely. This includes providing specialized training on new technologies or procedures.

- Data Analytics: Using data analysis to identify trends, inefficiencies, and areas for improvement enables a data-driven approach to optimize processes and reduce costs.

For example, in a previous role, we implemented a new WMS, which resulted in a 15% reduction in processing time and a significant improvement in inventory accuracy.

Q 26. Explain your experience with different types of cargo containers.

My experience encompasses a wide range of cargo containers, including:

- Standard 20ft and 40ft containers: These are the most common types, used for a variety of goods.

- High Cube containers: These offer increased height for bulky items.

- Refrigerated containers (reefers): These maintain a controlled temperature for perishable goods.

- Open-top containers: These have removable roofs for oversized cargo.

- Flatrack containers: These have a low-profile design for heavy and oversized equipment.

- Tank containers: These are designed for the transport of liquids and gases.

Understanding the specific characteristics of each container type is crucial for safe and efficient handling. For instance, the weight distribution and securing of reefer containers requires special attention due to their unique features. Furthermore, knowing the proper handling procedures for hazardous materials containers is vital for safety.

Q 27. How do you identify and mitigate risks in cargo handling?

Risk identification and mitigation in cargo handling is a critical aspect of ensuring safety and operational efficiency. My approach involves:

- Hazard Identification: This involves systematically identifying potential hazards throughout the cargo handling process, including handling equipment malfunction, improper storage, security breaches, and weather-related incidents. Methods include risk assessments, checklists, and safety audits.

- Risk Assessment: Once hazards are identified, assessing their likelihood and potential impact is key. This helps prioritize mitigation efforts.

- Mitigation Strategies: Developing and implementing appropriate controls to minimize the identified risks. This might involve implementing safety protocols, investing in protective equipment, enhancing security measures, or adopting improved handling techniques.

- Contingency Planning: Creating plans to handle unforeseen circumstances, such as equipment failure or severe weather, is essential. For instance, we would prepare alternative loading bays in case of port congestion.

- Regular Monitoring and Review: Continuously monitoring safety performance, identifying areas for improvement, and regularly reviewing risk assessments help maintain a proactive approach to safety management.

For example, I once identified a potential risk of equipment failure leading to cargo damage. We implemented a preventive maintenance program resulting in a significant decrease in equipment-related incidents.

Q 28. What is your experience with different types of cargo handling equipment maintenance?

My experience with cargo handling equipment maintenance covers a wide range of machinery, including:

- Forklifts: Regular maintenance involves checks of hydraulic systems, tire pressure, and engine performance. Preventive maintenance schedules and operator training are crucial.

- Container Cranes: These require specialized maintenance, encompassing inspections of hoisting mechanisms, electrical systems, and structural components. Regular lubrication and inspections are critical to prevent accidents.

- Straddle Carriers: Similar to container cranes, these require meticulous maintenance of their lifting and moving mechanisms. Regular inspections and adherence to manufacturer guidelines are essential.

- Automated Guided Vehicles (AGVs): Maintenance involves software updates, battery checks, and sensor calibration. Preventative measures are paramount to maintain efficiency and prevent downtime.

I am familiar with both preventive and corrective maintenance strategies. Preventive maintenance, involving scheduled inspections and servicing, minimizes breakdowns and extends the lifespan of equipment. Corrective maintenance addresses equipment failures as they occur. Effective maintenance management is critical for minimizing downtime, enhancing safety, and ultimately optimizing operational efficiency.

Key Topics to Learn for Knowledge of Cargo Handling Procedures Interview

- Cargo Types and Characteristics: Understanding different cargo types (dry bulk, liquid bulk, breakbulk, containers), their handling requirements (temperature control, weight limits, hazardous materials), and associated documentation.

- Handling Equipment and Technology: Familiarity with various equipment (cranes, forklifts, conveyor belts, automated systems), their safe operation, and maintenance. Understanding the application of technology in cargo tracking and management (RFID, GPS).

- Safety Regulations and Procedures: Knowledge of international and local safety regulations (IMDG Code, SOLAS), risk assessment methodologies, and emergency response procedures for cargo handling operations.

- Cargo Stowage and Securing: Understanding principles of efficient and safe cargo stowage, including weight distribution, stability considerations, and securing methods to prevent damage or shifting during transit.

- Documentation and Logistics: Proficiency in handling shipping documents (Bill of Lading, packing lists, certificates of origin), understanding import/export procedures, and the role of logistics in the overall cargo handling process.

- Inventory Management and Tracking: Understanding methods for tracking cargo throughout the handling process, managing inventory levels, and minimizing losses or damages.

- Problem-Solving in Cargo Handling: Ability to identify and troubleshoot potential problems related to cargo handling, such as damage, delays, or safety concerns, and develop effective solutions.

Next Steps

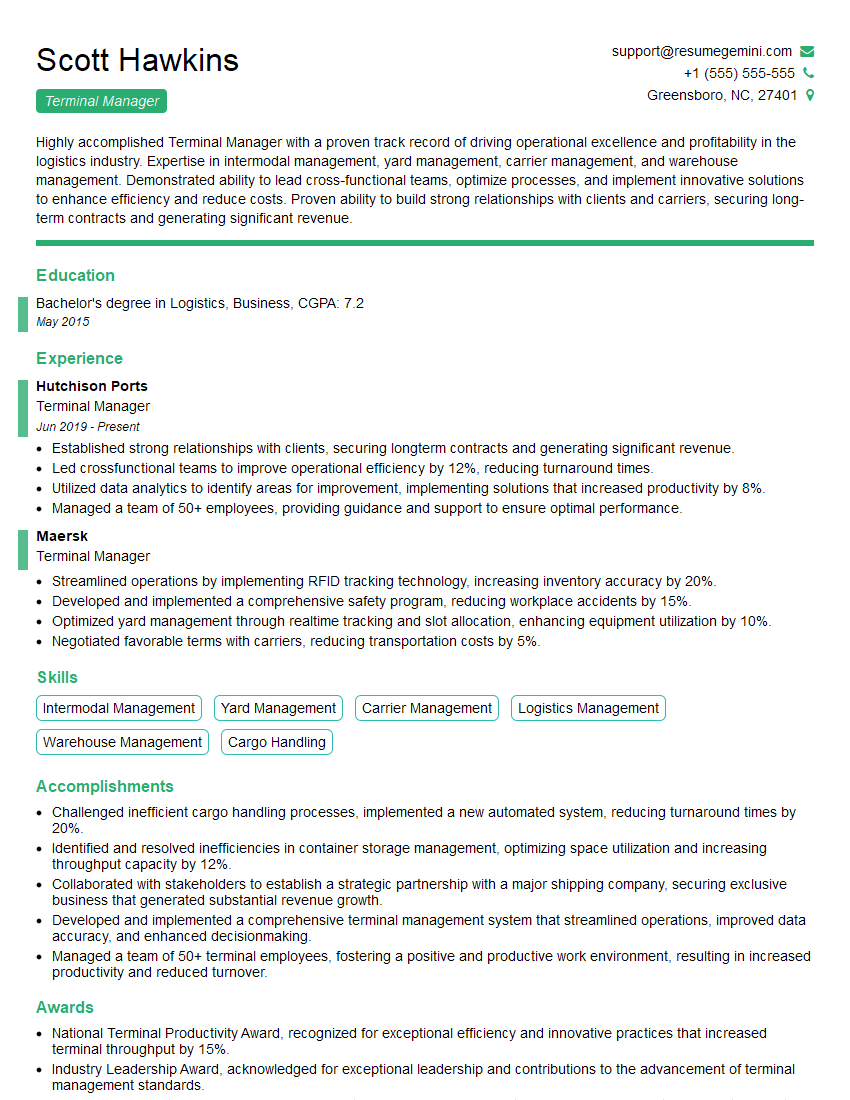

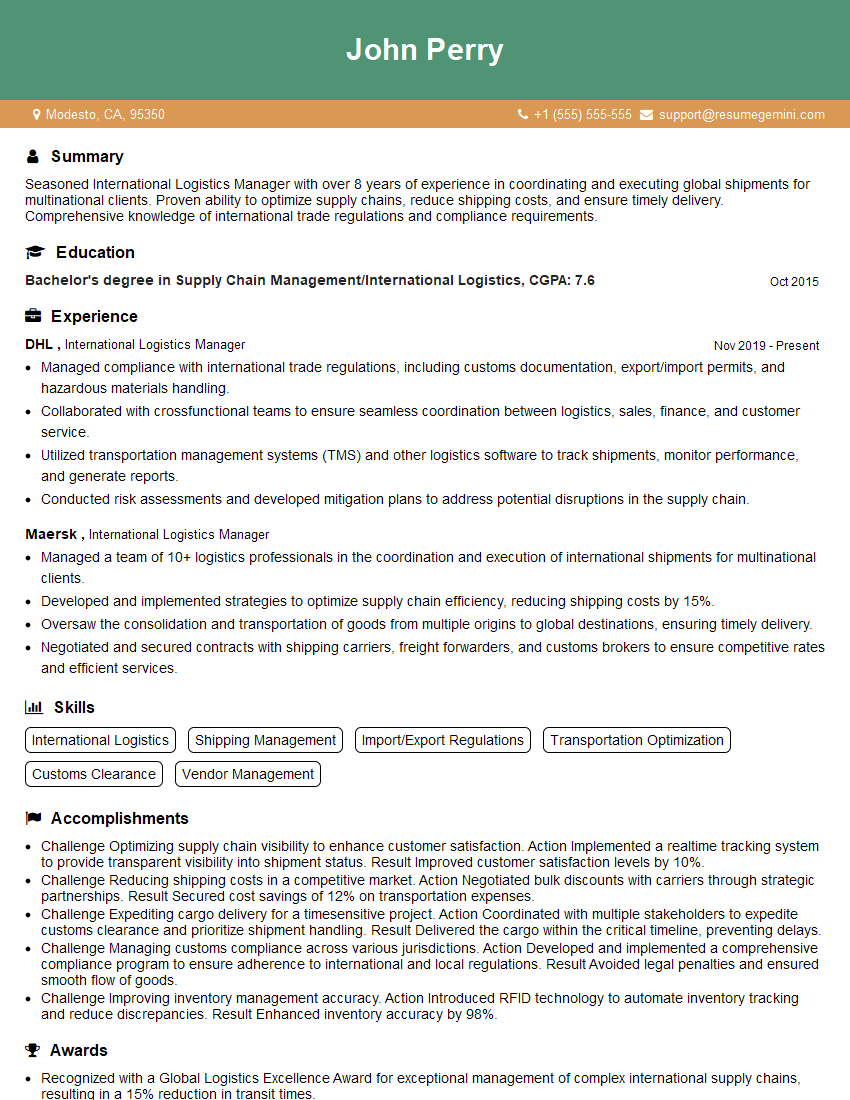

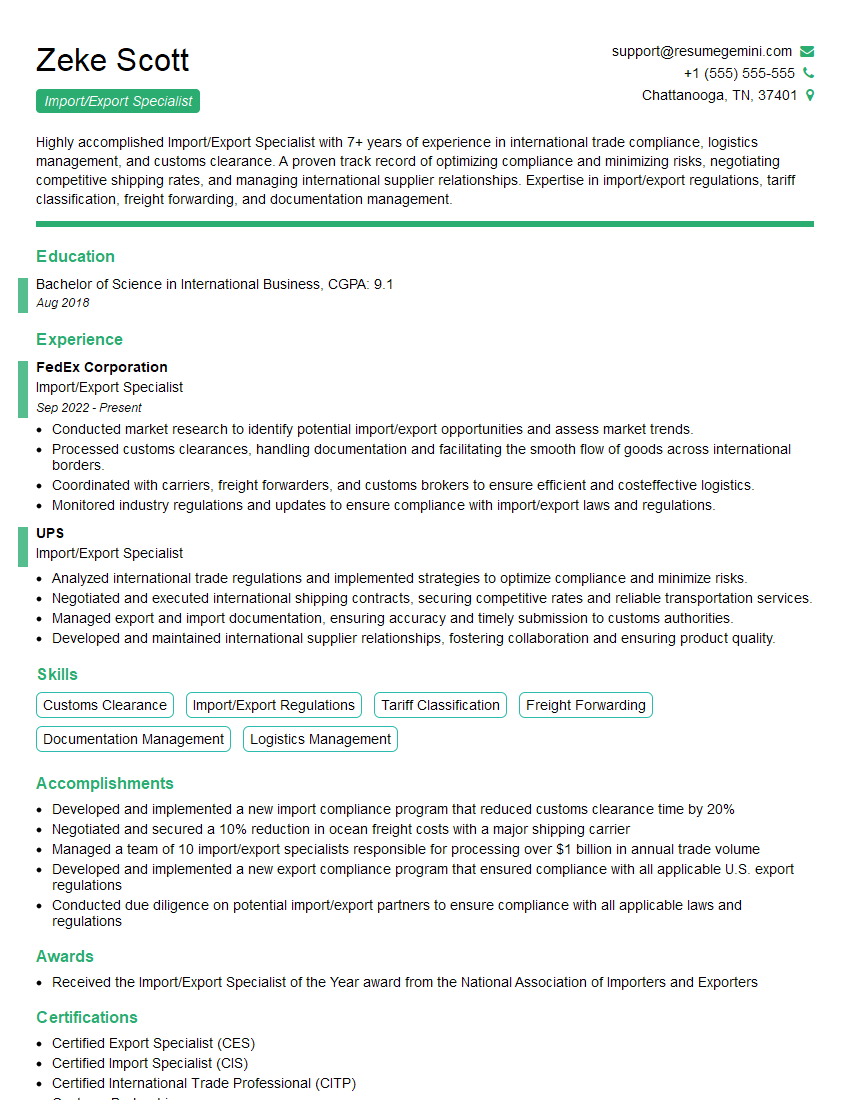

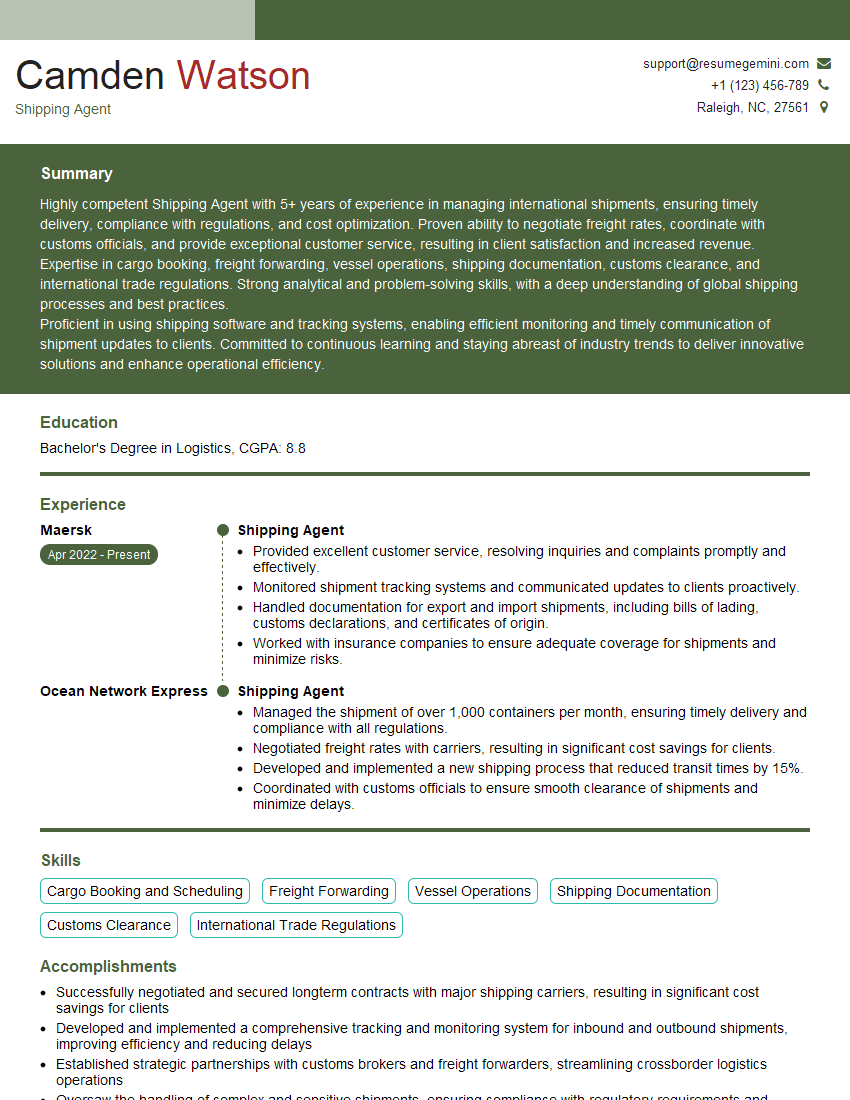

Mastering Knowledge of Cargo Handling Procedures is crucial for career advancement in the logistics and shipping industries. A strong understanding of these procedures demonstrates your competence and opens doors to higher-paying roles and greater responsibility. To significantly enhance your job prospects, it’s vital to create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific demands of this field. Examples of resumes tailored to showcasing Knowledge of Cargo Handling Procedures are available to guide you. Invest time in crafting a strong resume—it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good