Cracking a skill-specific interview, like one for Specialized Cargo Handling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Specialized Cargo Handling Interview

Q 1. Explain the different types of specialized cargo.

Specialized cargo encompasses a wide range of goods requiring specific handling and transportation methods due to their unique characteristics. These can be broadly categorized, though there’s often overlap:

- Hazardous Materials (Hazmat): These include substances that pose risks to health, safety, and the environment. Examples include flammable liquids, explosives, corrosive chemicals, and radioactive materials. Each requires specific packaging, labeling, and transportation regulations (e.g., IATA, IMDG).

- Oversized and Heavy-Lift Cargo: These are goods exceeding standard dimensional or weight limits, often requiring specialized equipment like heavy-lift cranes, specialized trailers, and even ships. Think of wind turbine blades, large industrial machinery, or construction components.

- Temperature-Sensitive Cargo: This includes pharmaceuticals, perishables (food, flowers), and other goods requiring precise temperature control during transit to maintain quality and prevent spoilage. This often involves refrigerated containers and meticulous monitoring.

- Live Animals: Transporting animals necessitates specialized containers, ventilation, and careful consideration of their well-being, including access to food and water. This requires adherence to strict animal welfare regulations.

- Project Cargo: This category typically involves the transportation of large and complex industrial equipment or infrastructure components. Each project has unique logistical challenges requiring detailed planning and coordination.

- Perishable Goods: These goods are subject to rapid deterioration, requiring careful temperature control, quick transit times, and sometimes specialized packaging (fresh produce, seafood, dairy products).

The classification of cargo is crucial for selecting appropriate handling procedures, documentation, and insurance coverage.

Q 2. Describe your experience handling hazardous materials.

My experience with hazardous materials spans over 15 years, encompassing the full spectrum from initial assessment to final delivery. I’ve been directly involved in the transportation of various classes of hazardous materials, including Class 1 (explosives), Class 3 (flammable liquids), and Class 9 (miscellaneous hazardous materials). This included meticulous adherence to regulations like the International Air Transport Association (IATA) Dangerous Goods Regulations and the International Maritime Dangerous Goods (IMDG) Code.

A memorable project involved the transport of a large shipment of lithium-ion batteries. We had to ensure the batteries were properly packaged and labeled according to UN standards, complete detailed shipping documents, and coordinate with specialized carriers equipped to handle the inherent risks associated with these materials. The entire process involved rigorous risk assessment, safety training for personnel, and constant monitoring throughout the journey to prevent incidents.

My experience also extends to incident response. I’ve been involved in developing emergency response plans and conducting training exercises to ensure our team can effectively handle potential hazardous materials spills or accidents. This preparedness is paramount to ensure the safety of personnel and the environment.

Q 3. What are the key considerations for securing oversized cargo?

Securing oversized cargo demands meticulous planning and the use of specialized equipment. Key considerations include:

- Accurate Weight and Dimensions: Precise measurements are crucial to determine the appropriate transportation method and securing mechanisms. This often involves on-site surveys.

- Route Planning: The route must be carefully planned to accommodate the cargo’s size and weight, considering bridge clearances, road width restrictions, and potential obstacles. This often involves obtaining necessary permits.

- Load Distribution: Even weight distribution is vital to prevent instability and damage. This requires expertise in load balancing and the use of specialized techniques.

- Securing Mechanisms: Appropriate straps, chains, and other securing devices must be used, ensuring they are correctly tensioned and secured to prevent shifting during transit. Calculations regarding load capacity are critical.

- Proper Documentation: Detailed documentation is essential, including weight, dimensions, securing methods, and the route plan. This documentation is required for insurance purposes and compliance with regulations.

- Escort Vehicles: In many cases, escort vehicles are needed to ensure safe passage and compliance with highway regulations.

For example, securing a large wind turbine blade requires specialized trailers, crane assistance for loading and unloading, and multiple securing points to prevent shifting or damage during transport. Careful planning and execution are essential to avoid costly delays and potential safety issues.

Q 4. How do you manage temperature-sensitive cargo?

Managing temperature-sensitive cargo involves a multi-faceted approach. The key is maintaining the prescribed temperature range throughout the entire supply chain:

- Pre-shipment Checks: Verifying the functionality of refrigeration units and confirming that the required temperature is achieved before loading.

- Container Selection: Choosing appropriate refrigerated containers (reefers) with adequate insulation and monitoring capabilities.

- Temperature Monitoring: Continuous temperature monitoring is crucial, often utilizing electronic data loggers that record temperature fluctuations throughout the journey. These loggers provide irrefutable evidence of proper temperature maintenance.

- Transit Planning: Optimizing transit routes and minimizing transit times to reduce exposure to temperature variations.

- Emergency Procedures: Having contingency plans in place to address potential equipment malfunctions or unexpected delays that could compromise temperature control.

- Documentation: Detailed records of temperature readings, container inspections, and any deviations from the prescribed temperature range are essential for compliance and potential claim resolution.

For instance, pharmaceuticals often require extremely precise temperature control, and a failure to maintain these standards could render the entire shipment useless. In such cases, real-time monitoring and proactive communication are vital.

Q 5. Explain the process of customs clearance for specialized cargo.

Customs clearance for specialized cargo is often more complex than for standard goods due to the specific requirements and regulations governing various cargo types. The process typically involves:

- Pre-Arrival Documentation: Submitting all necessary documentation to customs authorities well in advance of arrival, including commercial invoices, packing lists, bills of lading, certificates of origin, and any specific permits or licenses required for the specific type of cargo (e.g., import permits for hazardous materials).

- Cargo Inspection: Customs authorities may conduct physical inspections of the cargo to verify its contents and compliance with regulations.

- Duty and Tax Payment: Calculating and paying any applicable duties, taxes, and fees.

- Compliance Verification: Ensuring compliance with all relevant import and export regulations, including those related to safety, security, and environmental protection.

- Release of Cargo: Once all requirements are met, customs authorities release the cargo for onward transportation or delivery.

For example, importing hazardous materials often requires additional documentation, such as Material Safety Data Sheets (MSDS), and might involve stricter inspection procedures. Effective communication with customs authorities is key to ensuring a smooth and timely clearance process.

Q 6. What are the regulations surrounding the transport of perishable goods?

Regulations surrounding the transport of perishable goods prioritize maintaining product quality and safety throughout the supply chain. Key aspects include:

- Temperature Control: Maintaining the appropriate temperature range throughout transit is paramount. Regulations often specify acceptable temperature fluctuations and monitoring requirements.

- Packaging and Handling: Proper packaging is essential to protect the goods from damage and spoilage. Regulations might specify packaging materials and handling procedures to ensure product integrity.

- Hygiene and Sanitation: Maintaining hygienic conditions throughout the handling and transportation process is vital to prevent contamination and spoilage. Regulations often detail cleaning and disinfection procedures.

- Transit Time: Minimizing transit time is important to reduce the risk of spoilage. Regulations might specify maximum transit times for certain types of perishable goods.

- Documentation: Maintaining detailed records of temperature, handling, and transit time is often a regulatory requirement.

For example, transporting fresh seafood requires adherence to strict temperature controls and hygienic practices, often with specific documentation requirements to trace the product’s journey and maintain its safety.

Q 7. How do you handle cargo damage claims?

Handling cargo damage claims requires a systematic approach to ensure a fair and efficient resolution:

- Documentation: Thorough documentation is crucial. This includes photos, videos, and detailed descriptions of the damage, along with all relevant shipping documents. The condition of the goods upon receipt must be meticulously documented.

- Investigation: A thorough investigation is necessary to determine the cause of the damage. This might involve examining the packaging, transportation methods, and handling procedures.

- Liability Determination: Determining who is liable for the damage is a crucial step. This often involves reviewing the terms and conditions of the contract of carriage and relevant insurance policies.

- Claim Submission: Filing a formal damage claim with the appropriate party, providing all necessary documentation and supporting evidence.

- Negotiation and Settlement: Negotiating a fair settlement with the liable party. This might involve discussions regarding compensation for the damaged goods.

For example, if damage occurs during transit, determining whether the damage was caused by improper packaging, rough handling, or unforeseen circumstances is key to establishing liability and a fair settlement. Insurance policies often play a critical role in mitigating the financial impact of damage claims.

Q 8. Describe your experience with different modes of transportation (air, sea, land).

My experience spans all major modes of transportation – air, sea, and land – each presenting unique challenges and opportunities in specialized cargo handling. Air freight excels in speed and time-sensitivity, crucial for perishable goods or urgent deliveries. I’ve managed shipments of pharmaceuticals requiring temperature-controlled containers and intricate documentation. Sea freight, while slower, offers cost-effectiveness for large volumes, which I’ve leveraged for transporting heavy machinery and oversized project cargo, focusing on efficient containerization and secure lashing techniques to prevent damage. Finally, land transportation, including trucking and rail, provides flexibility for shorter distances and last-mile delivery. I’ve overseen the logistics for time-sensitive deliveries of automotive parts using optimized routing and real-time tracking to minimize delays. Each mode requires a different approach, from meticulous documentation to specialized handling equipment and risk mitigation strategies.

- Air Freight Example: Successfully managed the air freight of a high-value, temperature-sensitive pharmaceutical shipment from India to the US, adhering to stringent regulatory compliance and maintaining the product’s integrity throughout the journey.

- Sea Freight Example: Coordinated the transport of oversized wind turbine components across the Atlantic, requiring detailed planning for load securing, port handling, and customs clearance.

- Land Freight Example: Optimized the trucking routes for just-in-time delivery of automotive parts to assembly plants, reducing transit times and minimizing inventory costs.

Q 9. What software or systems are you familiar with for managing cargo?

I’m proficient in several software and systems for cargo management. These include Transportation Management Systems (TMS) such as Blue Yonder and Oracle Transportation Management, which facilitate route optimization, shipment tracking, and documentation. I’m also experienced with Warehouse Management Systems (WMS) like SAP EWM and Manhattan Associates, enabling efficient inventory control and order fulfillment. Furthermore, I’m comfortable using Electronic Data Interchange (EDI) for seamless communication and data exchange with partners, and have experience with various Customs brokerage software to handle import/export documentation. My familiarity extends to specialized software for tracking temperature-sensitive goods and managing hazardous materials.

Example TMS function: Route optimization algorithms consider factors like distance, traffic conditions, and delivery deadlines to determine the most efficient route.Q 10. How do you prioritize cargo shipments in a high-pressure environment?

Prioritizing cargo in high-pressure environments requires a systematic approach. I utilize a multi-criteria decision-making framework considering factors such as:

- Urgency: Time-sensitive shipments, such as perishable goods or those with strict deadlines, receive top priority.

- Value: High-value goods necessitate extra care and attention, prioritizing secure handling and faster transit.

- Risk: Shipments with inherent risks, such as hazardous materials or fragile items, require specialized handling and close monitoring.

- Customer Importance: Prioritize shipments from key clients or those with specific contractual obligations.

I employ a combination of Kanban boards, workflow management tools, and clear communication with the team to maintain transparency and ensure efficient allocation of resources. In situations with conflicting priorities, I use a decision matrix to weigh the different factors and make informed choices, often involving consultation with stakeholders.

Q 11. Explain your understanding of Incoterms.

Incoterms, or International Commercial Terms, are a set of standardized trade terms published by the International Chamber of Commerce (ICC). These terms define the responsibilities of the buyer and seller in an international transaction, specifying which party is responsible for costs, risks, and documentation at different stages of the shipment. Understanding Incoterms is crucial for preventing misunderstandings and disputes. For example, ‘FOB’ (Free On Board) indicates the seller’s responsibility ends once the goods are loaded onto the vessel, while the buyer assumes responsibility thereafter. ‘CIF’ (Cost, Insurance, and Freight) designates that the seller pays for the cost of the goods, insurance, and freight to the port of destination. Incorrect interpretation of Incoterms can lead to significant financial and logistical issues. I have extensive experience in applying the correct Incoterms to contracts, ensuring clear delineation of responsibility and minimizing potential risks.

- Example: Selecting the appropriate Incoterm for a shipment of delicate machinery to a remote location, considering factors such as insurance requirements and the buyer’s capacity to handle customs clearance.

Q 12. How do you ensure the security of sensitive cargo?

Securing sensitive cargo requires a multi-layered approach encompassing physical security measures, procedural controls, and technological safeguards. This starts with thorough risk assessment to identify vulnerabilities and potential threats. Physical security includes utilizing secure warehousing facilities with access controls, employing tamper-evident seals and containers, and potentially utilizing GPS tracking and alarm systems. Procedural controls involve rigorous vetting of personnel, implementing strict inventory management, and maintaining detailed documentation of every step of the process. Technological safeguards involve utilizing advanced tracking systems, blockchain technology for transparent and immutable records, and encryption for sensitive data transmission. Compliance with relevant regulations and industry best practices is paramount. I’ve been involved in developing and implementing comprehensive security plans for high-value and sensitive cargo shipments, including pharmaceuticals and high-tech equipment.

Q 13. What is your experience with cargo tracking and tracing systems?

My experience with cargo tracking and tracing systems is extensive. I’m proficient in using GPS tracking devices, RFID tagging, and various software platforms that provide real-time visibility into a shipment’s location and status. These systems are crucial for monitoring the progress of shipments, anticipating potential delays, and responding proactively to unforeseen circumstances. This includes utilizing platforms that integrate with TMS and WMS to provide a holistic view of the supply chain. I’ve used this information to optimize routes, resolve delivery issues, and provide timely updates to clients. The ability to accurately track and trace cargo is essential for ensuring on-time delivery, reducing costs, and improving customer satisfaction. For example, real-time tracking alerted me to an unexpected road closure, enabling me to reroute the shipment and avoid significant delay.

Q 14. Describe your experience with cargo insurance.

Cargo insurance is a critical aspect of specialized cargo handling, mitigating potential financial losses due to damage, theft, or loss during transit. I understand various types of cargo insurance policies, including all-risks coverage, specific perils coverage, and liability insurance. Selecting the appropriate policy depends on the nature of the cargo, the mode of transport, and the specific risks involved. I’m familiar with the claims process and have experience in working with insurance providers to resolve claims effectively. My role often includes negotiating favorable insurance terms, ensuring adequate coverage for the value of the goods, and ensuring the policy aligns with the Incoterms used in the sales contract. Failing to secure appropriate insurance can result in substantial financial consequences in case of unforeseen events, which highlights its importance in risk management.

Q 15. How do you handle discrepancies between shipping documents and cargo received?

Discrepancies between shipping documents and received cargo are a common challenge in specialized cargo handling. They can range from minor inconsistencies like slightly differing quantities to major issues involving damaged or missing items. Our process begins with a meticulous pre-delivery inspection. This involves a thorough check against the Bill of Lading (B/L), packing lists, and other relevant documentation. We meticulously verify the number of packages, their condition, and markings against the documented specifications. Any discrepancies are immediately documented using a detailed discrepancy report, which includes photos and signatures from all involved parties.

For example, if the B/L indicates 10 crates of delicate scientific equipment but only 9 are received, we immediately initiate a damage claim procedure with the carrier and investigate the potential cause of the missing crate. This might involve tracking the shipment’s journey, reviewing handling records at various ports, or investigating potential theft. We also engage with the shipper and consignee to find a resolution, which may involve replacement, compensation, or a negotiated agreement. The aim is always to maintain transparency and work collaboratively to rectify the issue and avoid delays.

The entire process is rigorously documented and carefully managed according to established procedures and international best practices. This ensures accountability, facilitates insurance claims if necessary, and minimizes disruption to the supply chain.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the challenges associated with handling project cargo?

Handling project cargo presents unique challenges due to its often oversized, heavy, and complex nature. These challenges include:

- Oversized Dimensions and Weight: Project cargo frequently exceeds standard container sizes and weight limits, requiring specialized transportation methods like heavy-lift vessels, multi-modal transport, and bespoke rigging solutions. This adds complexity to planning and execution.

- High Value and Sensitivity: Project cargo often comprises high-value equipment or machinery sensitive to damage. Extra care is needed in handling, securing, and protecting the cargo throughout the transportation process. Specialized packaging, climate control, and insurance are crucial.

- Complex Logistics and Permits: Obtaining necessary permits, navigating complex customs regulations, and coordinating multiple modes of transport across different jurisdictions adds layers of logistical complexity. Detailed route planning and proactive communication are vital.

- Just-in-Time Delivery Requirements: Project cargo shipments often have stringent deadlines to meet project timelines. Delays can have significant financial implications, highlighting the critical need for precise scheduling and risk mitigation strategies.

For instance, transporting a large wind turbine requires coordinating specialized vessels, securing necessary permits for oversized loads, and employing skilled riggers for precise loading and unloading. The entire process demands meticulous planning, risk assessment, and seamless coordination among various stakeholders to ensure timely and safe delivery.

Q 17. How do you optimize cargo loading and unloading processes?

Optimizing cargo loading and unloading involves strategic planning and the utilization of efficient technologies and practices. This starts with pre-planning the loading sequence to minimize movement and maximize space utilization within containers or vessels. We use sophisticated software that simulates the loading process, optimizing weight distribution and preventing instability. This is particularly crucial for specialized cargo with specific weight and balance requirements.

Efficient unloading necessitates clear communication with receiving parties, ensuring smooth handover processes and minimal wait times. We deploy specialized equipment like cranes, forklifts, and other handling machinery suited for specific cargo types, alongside trained personnel to minimize damage risk and expedite the process. Furthermore, the use of barcode scanning and RFID tracking allows for real-time inventory updates, improving accuracy and reducing potential delays during the unpacking phase.

For example, loading a container of delicate glassware would involve careful placement, utilizing appropriate cushioning and bracing materials, and precisely documenting the location of each item. Unloading would similarly require cautious handling and meticulous checks to ensure no damage has occurred during transit.

Q 18. What are your strategies for managing delays in cargo transportation?

Managing delays in cargo transportation requires proactive measures and contingency planning. The first step is identifying the cause of the delay: whether it’s port congestion, weather disruptions, customs clearance issues, or equipment failure. Once the cause is determined, we implement the appropriate response. This could range from rerouting the shipment, utilizing alternative transportation modes, expediting customs procedures, or negotiating with the carrier for faster processing.

Transparent communication with all stakeholders (shippers, consignees, carriers, and customs authorities) is paramount. Regular updates are provided to keep everyone informed of the situation and potential solutions. Proactive risk management involves establishing contingency plans, such as having alternative shipping routes or storage solutions ready should a delay occur. Detailed documentation of all communication and actions taken throughout the delay helps to facilitate any necessary claims or adjustments.

For instance, if a shipment is delayed due to a port strike, we might explore using a nearby port or air freight as a temporary solution. We would immediately inform the client and provide alternative solutions while exploring all possible measures to get the cargo moving again.

Q 19. Explain your understanding of various types of cargo packaging.

Cargo packaging is crucial for protecting goods during transit. Different cargo types necessitate different packaging strategies. Common types include:

- Wooden Crates and Pallets: These offer robust protection for heavy or fragile items. They’re often customized to fit specific cargo dimensions and provide shock absorption.

- Corrugated Cardboard Boxes: Cost-effective for lighter and less fragile goods. Different grades of cardboard offer varying levels of protection.

- Steel Drums and Barrels: Ideal for liquids, powders, or granular materials, providing excellent containment and protection from damage.

- Flexible Intermediate Bulk Containers (FIBC): Also known as ‘big bags,’ these are cost-effective for bulk handling and offer good protection from moisture.

- Specialized Packaging: This category includes custom-designed packaging for sensitive equipment, incorporating climate control, anti-vibration features, and other protective elements.

Choosing the right packaging type considers factors such as the fragility of the cargo, environmental conditions during transit, and the handling procedures involved. Proper packaging minimizes damage, reduces insurance costs, and ensures that the goods reach their destination in perfect condition.

Q 20. How do you ensure compliance with international shipping regulations?

Ensuring compliance with international shipping regulations is a critical aspect of specialized cargo handling. We maintain a thorough understanding of regulations concerning hazardous materials (IMO regulations), customs procedures, import/export controls, and environmental protection. This involves meticulous documentation, accurate classification of goods, and adherence to all applicable safety protocols.

We utilize specialized software to manage documentation and track compliance requirements. This includes ensuring correct labeling, preparing necessary certificates (e.g., phytosanitary certificates for agricultural products), and adhering to all security standards. Regular training and updates for our personnel ensure they are always aware of the latest regulatory changes and best practices. Our company undergoes regular audits to guarantee our processes align with all relevant international and national standards.

Non-compliance can lead to severe penalties, delays, and even seizure of cargo. Therefore, proactive compliance is not only crucial for legal reasons, but it also safeguards the smooth and efficient movement of goods.

Q 21. Describe your experience with different types of cargo containers.

My experience encompasses a wide range of cargo containers, including:

- Standard Dry Containers: The most common type, suitable for general cargo requiring protection from the elements.

- Refrigerated Containers (Reefer Containers): Maintain a controlled temperature, essential for transporting perishable goods.

- Open-Top Containers: Have a removable top, allowing for easy loading of oversized cargo.

- Flatrack Containers: A flat platform without walls or a roof, suitable for exceptionally large or heavy equipment.

- Tank Containers: Specifically designed for liquid or gaseous cargo, with various sizes and material compositions.

- Hazardous Materials Containers: Meet stringent safety regulations for the transportation of dangerous goods.

Selecting the appropriate container type is crucial for efficient and safe transport. For example, transporting a large piece of machinery would likely necessitate a flatrack or open-top container, while sensitive electronics might require a climate-controlled reefer container. The choice is always dictated by the specific requirements of the cargo and its intended journey.

Q 22. How do you handle cargo theft or loss situations?

Cargo theft and loss are serious concerns in specialized cargo handling. My approach is multifaceted, prioritizing prevention and mitigation. Prevention starts with robust security measures, including comprehensive risk assessments tailored to the specific cargo’s value and vulnerability. This includes selecting secure transportation routes, utilizing GPS tracking and tamper-evident seals, and employing trained security personnel. In the unfortunate event of theft or loss, a swift and thorough investigation is launched. This involves collaborating with law enforcement, insurance providers, and all parties involved in the shipment’s journey. We meticulously document all aspects, from initial receipt to final destination, using digital chain-of-custody tracking. Detailed records of handling, storage, and transportation are critical for insurance claims and identifying potential weaknesses in our security protocols. For example, if a shipment of high-value pharmaceuticals goes missing, we’d analyze GPS data to pinpoint the last known location, review CCTV footage from relevant locations, and interview all personnel who handled the shipment to trace the route and identify any anomalies. We then use this information to refine our security measures to prevent similar incidents.

Q 23. What is your experience with weight and balance calculations for aircraft cargo?

Weight and balance calculations are paramount for air freight, especially with specialized cargo, to ensure safe and efficient flight operations. My experience encompasses using specialized software and manual calculation methods to determine the center of gravity (CG) of the aircraft and its payload. This process involves meticulously recording the weight and location of each item within the aircraft’s cargo compartment. Specialized cargo often requires careful consideration due to its unique dimensions and weight distribution – for instance, oversized or oddly shaped equipment requires precise placement to maintain balance. I am proficient in utilizing software like Air Weight & Balance Calculator to calculate weight and balance based on several factors: Aircraft Type, Cargo Manifest, Fuel Quantity, Crew weight, and passenger weight. Any deviation from acceptable limits necessitates a recalculation, potential cargo rearrangement, or possibly a change in flight plan to ensure the aircraft remains within its operational limits. For example, shifting a heavy piece of machinery slightly forward might be necessary to bring the center of gravity within the acceptable range.

Q 24. How do you manage documentation and paperwork for specialized cargo?

Managing documentation for specialized cargo is crucial for compliance, traceability, and efficient handling. My approach utilizes a digital system that integrates all documentation related to a shipment, from the initial booking request to the final delivery receipt. This includes commercial invoices, packing lists, certificates of origin, hazardous materials declarations (if applicable), and other relevant permits or licenses. I ensure that all documents are accurate, complete, and readily accessible to all relevant parties throughout the supply chain. Digitalization allows for seamless sharing and tracking of documents, minimizing delays and improving transparency. For instance, using a cloud-based system allows real-time updates on a shipment’s status, including documentation status, accessible to all parties involved including the shipper, consignee, and customs officials. This not only helps in efficient tracking but also improves regulatory compliance.

Q 25. Explain your understanding of different types of cargo handling equipment.

Specialized cargo handling relies on a variety of equipment tailored to specific cargo types and operational needs. My experience includes working with:

- Forklifts: Essential for moving palletized and containerized goods, including different capacities and attachments for various cargo types.

- Overhead Cranes: Critical for handling heavy or oversized items like machinery and industrial equipment.

- Specialized Lifting Devices: Including vacuum lifters, magnetic lifters, and slings for delicate or oddly-shaped items.

- Conveyors and Rollers: Used for efficient movement of lighter goods across distances.

- Container Handling Equipment: Reach stackers and straddle carriers for handling maritime containers.

- Temperature-Controlled Containers and Vehicles: Essential for pharmaceuticals, perishable goods, and other temperature-sensitive cargo.

The selection of appropriate equipment is crucial for both efficiency and safety, matching the equipment’s capabilities with the specific requirements of the cargo.

Q 26. How do you maintain safety standards while handling specialized cargo?

Maintaining safety standards is paramount in specialized cargo handling, where the cargo itself often presents unique hazards. My approach is a combination of rigorous training, adherence to safety protocols, and the implementation of appropriate safety equipment. This includes ensuring personnel are trained in the safe handling of various cargo types, including hazardous materials, understanding relevant safety regulations, and using appropriate personal protective equipment (PPE). Regular safety audits and inspections are conducted to identify potential hazards and ensure compliance. For example, handling a shipment of hazardous chemicals would involve ensuring the team is trained on handling such materials, and properly equipped with respirators and protective suits. We also ensure all equipment is regularly maintained and inspected to prevent malfunctions. This proactive approach minimizes risks and ensures a safe working environment.

Q 27. Describe your problem-solving skills in a complex cargo handling situation.

I approach complex cargo handling situations with a structured problem-solving methodology. A recent example involved a time-sensitive shipment of a large, delicate piece of scientific equipment which was damaged during transit. My first step was to gather all relevant information – assessing the damage, reviewing transportation documentation, and interviewing those involved in the handling process. Next, I analyzed the information to pinpoint the likely cause of the damage – a lack of proper cushioning during transport. To solve this, I coordinated with the shipper to implement improved packaging and secured alternative, more specialized transportation with a carrier experienced in handling such sensitive equipment. Finally, I communicated with all parties involved, ensuring transparency and coordination. This incident emphasized the importance of proactive risk assessment, thorough communication, and the need for flexibility in resolving unexpected challenges.

Key Topics to Learn for Specialized Cargo Handling Interview

- Understanding Different Cargo Types: Learn the unique handling requirements for various specialized cargo, including hazardous materials, oversized/heavy lift cargo, perishable goods, and live animals. Consider the regulations and safety protocols for each.

- Logistics and Supply Chain Management: Explore the intricacies of planning and executing the movement of specialized cargo, from origin to destination. Focus on route optimization, documentation, and risk mitigation strategies.

- Cargo Securing and Packaging Techniques: Master the techniques for safely securing and packaging different types of specialized cargo to prevent damage during transit. This includes understanding appropriate lashing methods, bracing techniques, and material choices.

- Customs Regulations and Documentation: Gain a thorough understanding of international and national regulations governing the import and export of specialized cargo. Practice completing relevant documentation accurately and efficiently.

- Safety Procedures and Risk Management: Familiarize yourself with the safety protocols and risk assessment procedures specific to handling specialized cargo. Understand how to identify and mitigate potential hazards.

- Technology in Specialized Cargo Handling: Explore the role of technology in modern cargo handling, including tracking systems, automated handling equipment, and data analytics for efficient operations.

- Problem-Solving and Decision-Making: Prepare to discuss scenarios involving unforeseen challenges during cargo handling, such as delays, damage, or emergency situations. Highlight your ability to make quick, informed decisions under pressure.

Next Steps

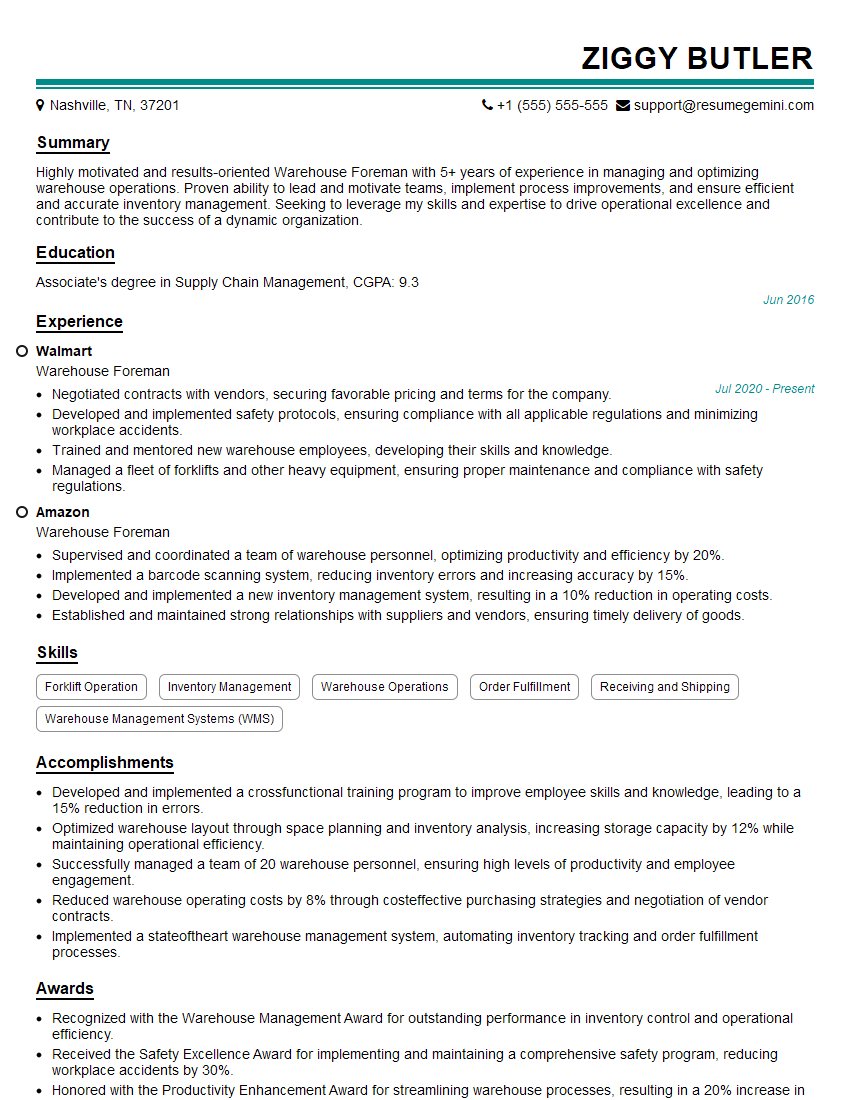

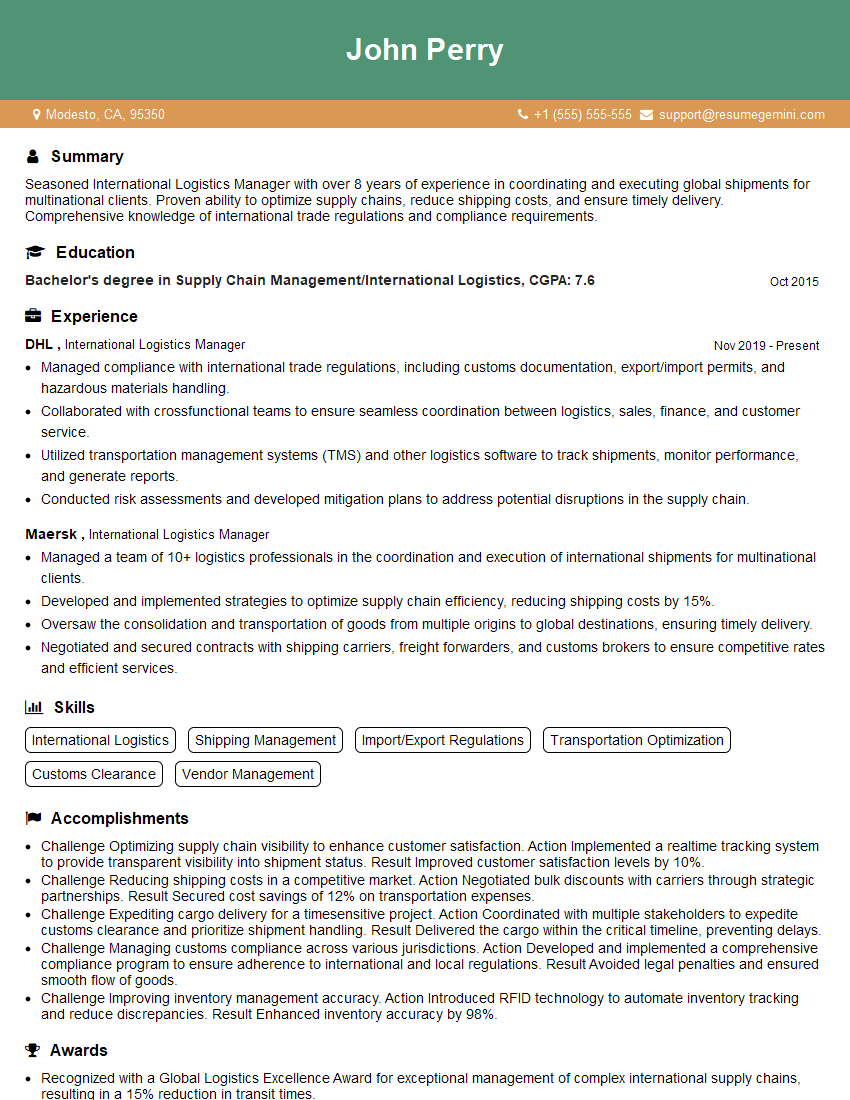

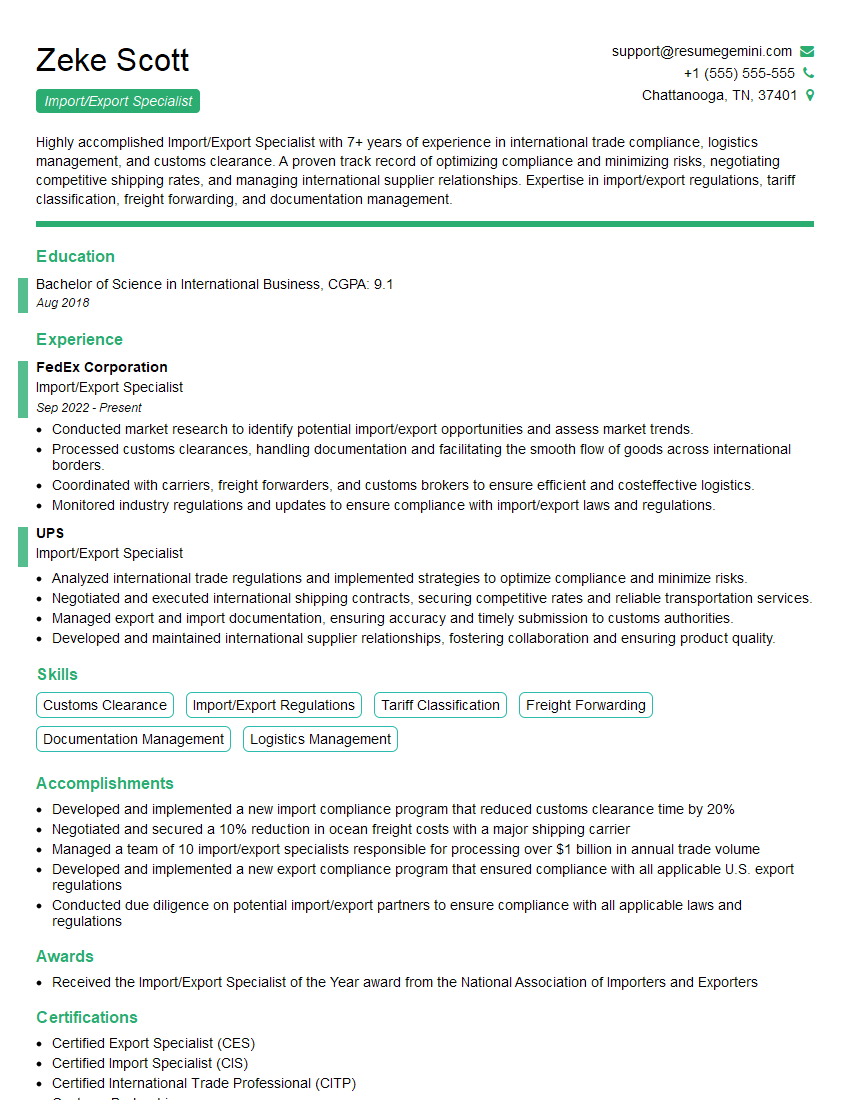

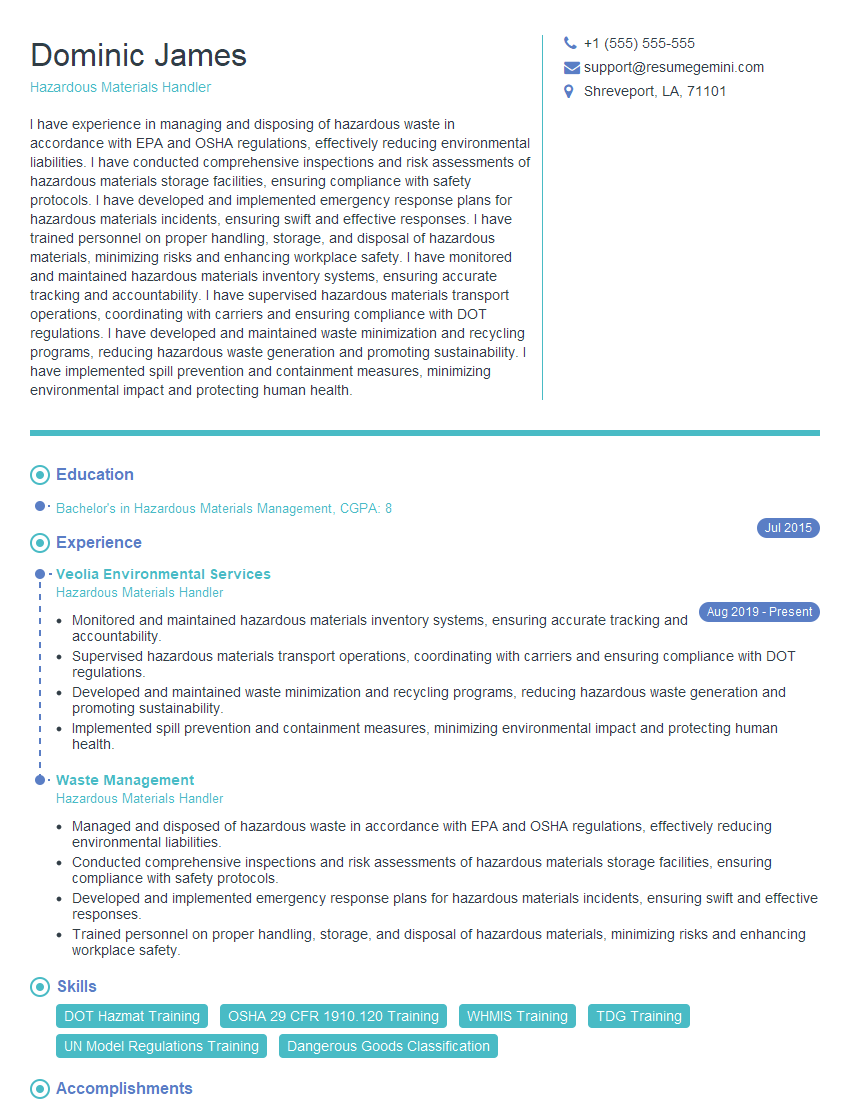

Mastering specialized cargo handling opens doors to exciting career opportunities with significant growth potential in a dynamic and globally connected industry. To maximize your chances of landing your dream job, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. We provide examples of resumes tailored to Specialized Cargo Handling to guide you through the process, helping you present yourself as the ideal candidate. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good