The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Fish Roe HACCP Procedures interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Fish Roe HACCP Procedures Interview

Q 1. Describe the seven principles of HACCP.

HACCP, or Hazard Analysis and Critical Control Points, is a preventative food safety management system. It’s based on seven principles that guide the identification and control of biological, chemical, and physical hazards in food production.

- Principle 1: Conduct a Hazard Analysis: Identify potential hazards that could occur at each step of the fish roe processing. This involves reviewing the entire production process from sourcing to distribution.

- Principle 2: Determine Critical Control Points (CCPs): Identify the specific steps in the process where control is essential to prevent or eliminate hazards or reduce them to acceptable levels. These are your CCPs.

- Principle 3: Establish Critical Limits: Set measurable limits for each CCP. For example, a critical limit might be a maximum temperature for storage (e.g., 4°C).

- Principle 4: Establish Monitoring Procedures: Develop a system for regularly checking and recording the CCPs to ensure they stay within the critical limits. This often involves using temperature probes, visual inspections, and documentation.

- Principle 5: Establish Corrective Actions: Define what steps will be taken if a CCP deviates from the critical limit. This might include discarding a batch, adjusting equipment, or retraining staff.

- Principle 6: Establish Verification Procedures: Implement ways to confirm that the HACCP plan is working effectively. This might include internal audits, environmental monitoring, and product testing.

- Principle 7: Establish Record-Keeping and Documentation Procedures: Keep thorough records of all HACCP activities, including hazard analyses, CCPs, monitoring data, corrective actions, and verification results. This is crucial for traceability and accountability.

Think of it like building a house – you wouldn’t start construction without blueprints (hazard analysis), a strong foundation (CCPs), and regular inspections (monitoring) to ensure the building meets specifications.

Q 2. Explain the critical control points (CCPs) in fish roe processing.

In fish roe processing, several steps are critical control points. These vary slightly depending on the type of roe and processing method, but generally include:

- Raw Material Receiving and Handling: Ensuring the fish are fresh, properly handled to minimize microbial growth, and free of contaminants. This involves checking temperature, assessing the fish’s condition, and verifying the supplier’s practices.

- Cleaning and Sorting: Removing impurities and ensuring consistent roe quality. Contamination during this stage could lead to issues.

- Processing (e.g., Salting, Pasteurization): Applying appropriate treatments to eliminate or reduce hazards like pathogens and spoilage organisms. This is crucial for food safety.

- Packaging: Selecting appropriate packaging materials that protect the roe from contamination and maintain its quality. Contaminated packaging material can lead to a hazard.

- Cooling and Storage: Maintaining appropriate temperatures throughout the process, preventing microbial growth and extending shelf life. Temperature abuse is a critical hazard.

- Distribution and Transportation: Ensuring appropriate temperature control during transit to prevent spoilage and contamination.

Each of these steps presents potential hazards, and they necessitate precise controls to ensure that the fish roe is safe and of high quality for consumers.

Q 3. How do you monitor and verify CCPs in fish roe production?

Monitoring and verification of CCPs in fish roe production are essential for maintaining food safety and product quality. It involves a combination of methods:

- Temperature Monitoring: Using calibrated thermometers and data loggers to continuously record temperatures at various stages of the process, including during processing, storage, and transportation. This is critical for preventing bacterial growth.

- Visual Inspection: Regularly inspecting the roe for any signs of spoilage, discoloration, or contamination. Trained personnel should conduct these inspections.

- Microbiological Testing: Periodically sampling the roe to test for the presence of pathogens. Frequency depends on risk assessment and regulatory requirements.

- Metal Detection: Using metal detectors to ensure that no metal fragments are present in the final product. This can be particularly critical for automated packaging lines.

- pH Measurement: Monitoring pH levels, especially important for certain processing methods to prevent bacterial growth.

- Documentation: Meticulously recording all monitoring data, including dates, times, and results. This creates a clear audit trail for traceability and regulatory compliance.

Verification includes reviewing the monitoring data, checking equipment calibration, performing internal audits, and conducting regular staff training to ensure compliance.

Q 4. What are the common hazards associated with fish roe?

Fish roe, due to its high moisture content and nutrient richness, is susceptible to several hazards:

- Microbial Hazards: Bacteria such as Listeria monocytogenes, Salmonella, and E. coli can cause serious illnesses if present. This necessitates stringent hygienic practices.

- Parasites: Certain parasites can infest fish, potentially contaminating the roe. Proper handling and processing steps (like freezing) can mitigate this risk.

- Chemical Hazards: Heavy metals, pesticides, and other toxins can accumulate in fish and subsequently in the roe. Careful sourcing and supplier selection are essential.

- Physical Hazards: Bone fragments, glass shards, or other foreign materials can contaminate the roe. Metal detectors and thorough visual inspections are necessary.

- Histamine: Improper handling and storage can lead to histamine formation, causing scombrotoxin poisoning (a type of food poisoning). Strict temperature control is vital.

Understanding these hazards is paramount in designing effective control measures.

Q 5. Describe your experience with fish roe allergen control.

Fish roe allergen control is a crucial aspect of food safety. Many fish roes are processed in facilities that also handle other allergenic products like nuts or shellfish. My experience includes:

- Allergen Management Plan: Developing and implementing a comprehensive allergen management plan to prevent cross-contamination. This includes defining and documenting procedures for cleaning, sanitation, and equipment changeover.

- Segregation and Labeling: Ensuring physical separation of fish roe from other allergenic products throughout the production process. Clear and accurate allergen labeling is crucial for informing consumers.

- Traceability: Implementing a robust traceability system to identify the source of ingredients and to easily trace the movement of products through the process. This is essential for allergen recall situations.

- Supplier Verification: Confirming that suppliers are compliant with allergen control requirements. This often involves audits of supplier facilities.

- Staff Training: Providing comprehensive training to all personnel on allergen awareness, handling procedures, and the importance of preventing cross-contamination.

Careful attention to these details is fundamental in preventing allergic reactions and ensuring consumer safety.

Q 6. How do you manage temperature control during fish roe processing and storage?

Temperature control is paramount in fish roe processing and storage. Maintaining the cold chain is vital to prevent microbial growth and maintain product quality. This involves:

- Rapid Cooling: Immediately cooling the roe after processing to prevent bacterial proliferation. This might involve ice baths or blast chillers.

- Storage Temperatures: Maintaining the appropriate storage temperature (usually below 4°C) throughout the entire process, using refrigerated storage facilities and cold chain transportation.

- Temperature Monitoring: Regularly monitoring temperatures using calibrated thermometers and data loggers. These devices should be strategically placed to accurately capture temperature variations.

- Equipment Maintenance: Ensuring that refrigeration equipment is regularly maintained and calibrated to maintain consistent temperatures. Any malfunctions should be addressed immediately.

- Emergency Procedures: Developing procedures to handle temperature deviations or equipment failures to minimize the risk of product spoilage or bacterial growth.

Consistent monitoring, effective equipment, and well-trained personnel are crucial for successful temperature control.

Q 7. What are the legal requirements for fish roe safety in your region?

Legal requirements for fish roe safety vary by region, but generally align with international food safety standards (such as those set by the Codex Alimentarius Commission). In my region (Please insert your region here), key legal requirements would include:

- Compliance with HACCP Regulations: Implementing and maintaining a HACCP plan that meets all regulatory requirements. This often includes mandatory HACCP certification.

- Good Manufacturing Practices (GMP): Adhering to strict sanitation and hygiene standards throughout the production process to prevent contamination.

- Labeling Regulations: Meeting all labeling requirements, including accurate ingredient lists, nutritional information, and allergen declarations.

- Traceability Requirements: Maintaining a robust traceability system to track the source of ingredients and the movement of products through the supply chain. This is essential for effective recall procedures if contamination occurs.

- Regular Inspections: Undergoing regular inspections from regulatory authorities to ensure compliance with all relevant laws and regulations.

Staying current on these regulations is crucial for compliance and minimizing legal risks. It is advisable to consult the appropriate regulatory bodies and regularly review updates to food safety legislation. Failure to meet these requirements can lead to sanctions, fines, or product recalls.

Q 8. Explain your experience with traceability systems in fish roe production.

Traceability in fish roe production is paramount for ensuring food safety and consumer confidence. It’s a system that allows us to track a product’s journey from the moment the fish is harvested to when it reaches the consumer. This involves meticulous record-keeping at every stage. My experience involves implementing and managing traceability systems using both manual and automated methods.

In one project, we used a batch-coding system where each batch of roe received a unique identifier linked to detailed records including the source of the fish (farm, wild-caught location), harvest date, processing details (temperature, time, equipment), and storage conditions. This information is readily accessible through a dedicated database, enabling rapid identification of any batch affected in case of a problem. We also incorporated RFID tagging in later stages of the process to further enhance accuracy and efficiency.

Another crucial aspect is ensuring traceability extends beyond our own facility. This includes collaboration with suppliers to obtain comprehensive information about their operations and maintaining close relationships with distribution channels to track the movement of our products. This comprehensive approach minimizes disruptions during a recall and assists regulatory investigations.

Q 9. How do you handle a fish roe recall situation?

Handling a fish roe recall is a critical situation requiring immediate and decisive action. My approach involves a structured process, prioritizing speed and accuracy to minimize health risks and reputational damage.

- Immediate Notification: First, we notify relevant regulatory agencies, such as the FDA (in the US) or the EFSA (in Europe), and our distribution partners.

- Batch Identification: We use our traceability system to pinpoint the affected batches and isolate them immediately.

- Recall Strategy: A comprehensive recall plan is implemented, including detailed communication protocols for retailers and consumers. We outline the recall scope, identification of implicated products, and return procedures.

- Communication: Open and transparent communication with customers, stakeholders, and regulatory bodies is vital. Clear and concise messaging is crucial, avoiding ambiguity.

- Root Cause Analysis: After the immediate recall, a thorough investigation is undertaken to determine the root cause of the issue. This involves reviewing all stages of production to identify potential points of contamination or failure. Corrective actions are then implemented to prevent future recurrences.

- Documentation: Every step of the recall process is meticulously documented for regulatory compliance and future reference.

Think of it like a carefully orchestrated emergency response, involving clear communication, quick action, and thorough investigation to minimize harm.

Q 10. What are the key microbiological parameters monitored in fish roe?

Microbiological monitoring of fish roe is crucial to prevent foodborne illnesses. Key parameters include:

- Total Viable Count (TVC): Measures the total number of aerobic bacteria present. High TVC indicates potential spoilage or the presence of pathogens.

- Coliforms: Indicator organisms suggesting fecal contamination. Their presence points to poor hygiene practices.

- Escherichia coli (E. coli): A specific coliform, often used as an indicator of fecal contamination and a potential pathogen.

- Salmonella spp.: A significant foodborne pathogen that can cause severe illness.

- Listeria monocytogenes: Another serious pathogen that can survive and multiply under refrigeration, posing a significant risk in ready-to-eat products like fish roe.

- Staphylococcus aureus: Can produce toxins that cause food poisoning, even if the bacteria are killed during processing.

These parameters are monitored throughout the production process, from raw material inspection to finished product testing, to ensure that the product meets safety standards.

Q 11. Describe your experience with GMP (Good Manufacturing Practices) in a seafood processing environment.

My experience with GMPs in seafood processing is extensive. GMPs are fundamental to ensuring consistent product quality and safety. I’ve been involved in developing and implementing GMP programs in multiple seafood processing facilities, covering all aspects from facility design and equipment maintenance to personnel hygiene and sanitation procedures.

In a recent project, we implemented a comprehensive GMP program encompassing employee training on hygiene protocols, regular equipment sanitation checks using ATP bioluminescence testing (which quickly assesses surface cleanliness), and strict adherence to documented standard operating procedures (SOPs). We also implemented a robust pest control program to minimize the risk of contamination. This systematic approach led to a significant reduction in product defects and enhanced our overall food safety profile.

Regular audits and internal inspections are key components of a well-functioning GMP program, enabling ongoing monitoring of adherence to standards and providing opportunities for improvement.

Q 12. How do you validate cleaning and sanitization procedures for fish roe processing equipment?

Validation of cleaning and sanitization procedures is critical for preventing cross-contamination and ensuring food safety. This involves a multi-step process:

- Defining Procedures: Detailed SOPs must be developed outlining the cleaning and sanitization process for each piece of equipment. This includes the cleaning agents used, contact times, and rinsing procedures.

- Monitoring: We use a variety of methods to monitor the effectiveness of our cleaning and sanitization procedures. This can include visual inspections, ATP bioluminescence testing (measuring residual organic matter), and microbiological testing (swabbing surfaces to detect the presence of bacteria).

- Challenge Testing: To ensure efficacy, we perform challenge studies. A known concentration of microorganisms is applied to the equipment’s surface, and then the cleaning and sanitization process is followed. Subsequent microbiological testing verifies the process’s ability to eliminate the microorganisms.

- Documentation: All procedures, test results, and corrective actions are meticulously documented to maintain a complete audit trail.

A validated cleaning and sanitization process ensures that equipment is free from harmful microorganisms, preventing cross-contamination and ensuring that our final product meets the highest food safety standards.

Q 13. Explain your experience with fish roe shelf-life studies.

Fish roe shelf-life studies are essential for determining the optimal storage conditions and packaging to ensure product quality and safety. These studies involve storing samples of fish roe under various conditions (temperature, packaging type) and monitoring their quality over time.

We use various methods to assess quality, including sensory evaluation (looking at texture, color, and odor), microbiological testing (tracking changes in microbial counts), and chemical analysis (measuring indicators of spoilage, like histamine levels). These studies allow us to determine the shelf life under specific conditions and set appropriate expiration dates. For example, we might find that roe stored at -20°C in modified atmosphere packaging (MAP) has a significantly longer shelf life compared to roe stored at 4°C in standard packaging.

The data obtained from these studies informs product labeling, storage recommendations, and overall product management strategies.

Q 14. What are the common causes of spoilage in fish roe?

Spoilage in fish roe can be caused by various factors, impacting both its safety and quality. Key contributors include:

- Microbial Growth: Bacteria, yeasts, and molds can proliferate under favorable conditions (temperature, moisture), leading to off-flavors, odors, and potential health hazards.

- Enzyme Activity: Enzymes present in the roe itself can break down its components, causing undesirable changes in texture, color, and flavor. This process is accelerated at higher temperatures.

- Oxidation: Exposure to air can lead to oxidation of lipids (fats) within the roe, resulting in rancidity and off-flavors.

- Improper Handling and Processing: Poor hygiene practices during harvest, processing, and storage can introduce contaminants and facilitate microbial growth.

- Temperature Abuse: Fluctuations or inadequate temperature control during storage and distribution can greatly accelerate spoilage.

Understanding these causes is essential for implementing effective control measures to extend shelf life and maintain the quality and safety of fish roe.

Q 15. How do you identify and prevent cross-contamination in fish roe processing?

Cross-contamination in fish roe processing is a major concern, as it can lead to serious food safety issues. It occurs when harmful bacteria or other pathogens from one source transfer to the fish roe, contaminating the product. Preventing this requires a multi-faceted approach focusing on strict hygiene practices and facility design.

- Spatial Separation: Raw and processed areas should be completely separate, with dedicated equipment and workflows for each. Imagine two entirely different kitchens: one for preparing raw fish and another strictly for handling the processed roe. This minimizes the risk of pathogens moving between stages.

- Equipment Sanitation: Thorough cleaning and sanitization of all equipment after each use is crucial. This includes knives, cutting boards, processing machinery, and even the work surfaces. We use validated sanitation procedures, often involving multiple steps with chemical sanitizers and thorough rinsing, to ensure all residual contaminants are eliminated.

- Personnel Hygiene: Employees must follow strict handwashing protocols and wear appropriate protective clothing, such as hairnets, gloves, and aprons. Regular training on proper hygiene practices is essential and often includes visual aids and practical demonstrations.

- Airflow Control: In some processing facilities, controlled airflow prevents the spread of airborne contaminants. This is particularly important where open processing methods are used.

- Traceability: Maintaining detailed records of all ingredients, equipment, and personnel involved in the processing chain is vital for tracking down the source of any contamination if it does occur.

For example, if we detect Salmonella in a batch, traceability helps us identify the exact point of contamination, whether it was during harvesting, transportation, or processing, allowing for swift corrective action and preventing future incidents.

Career Expert Tips:

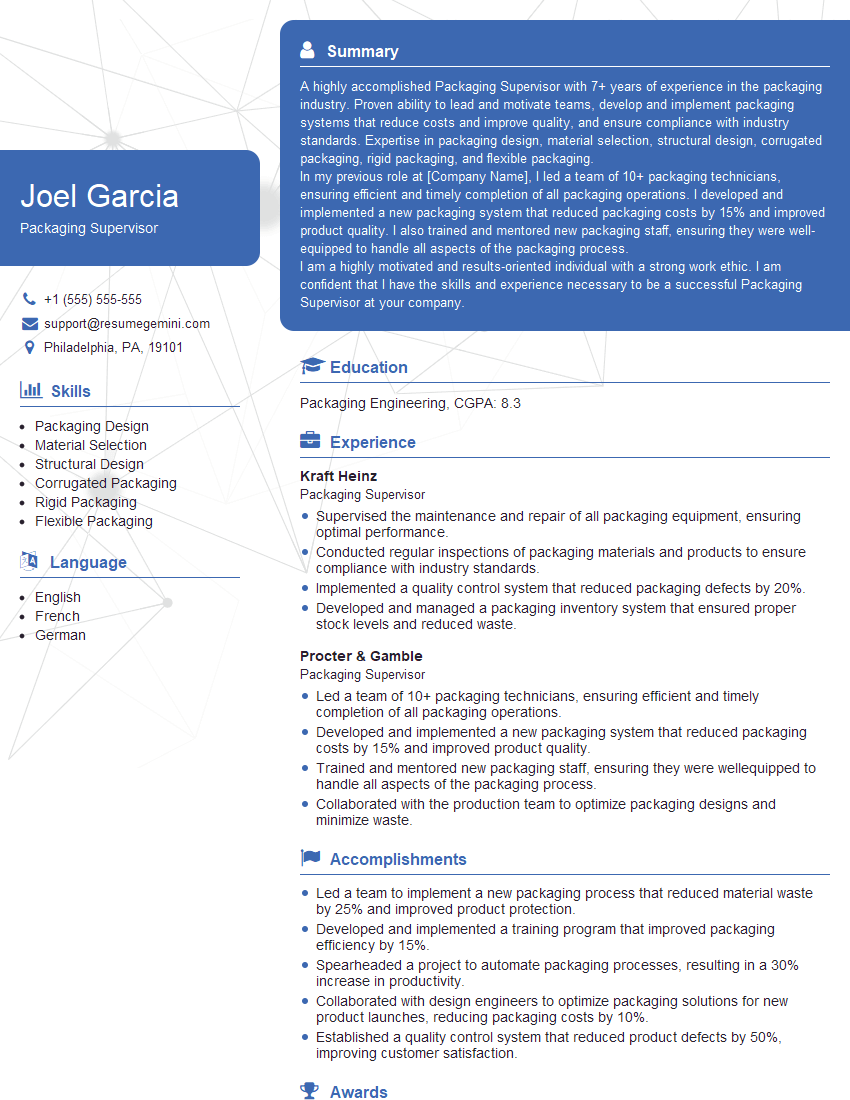

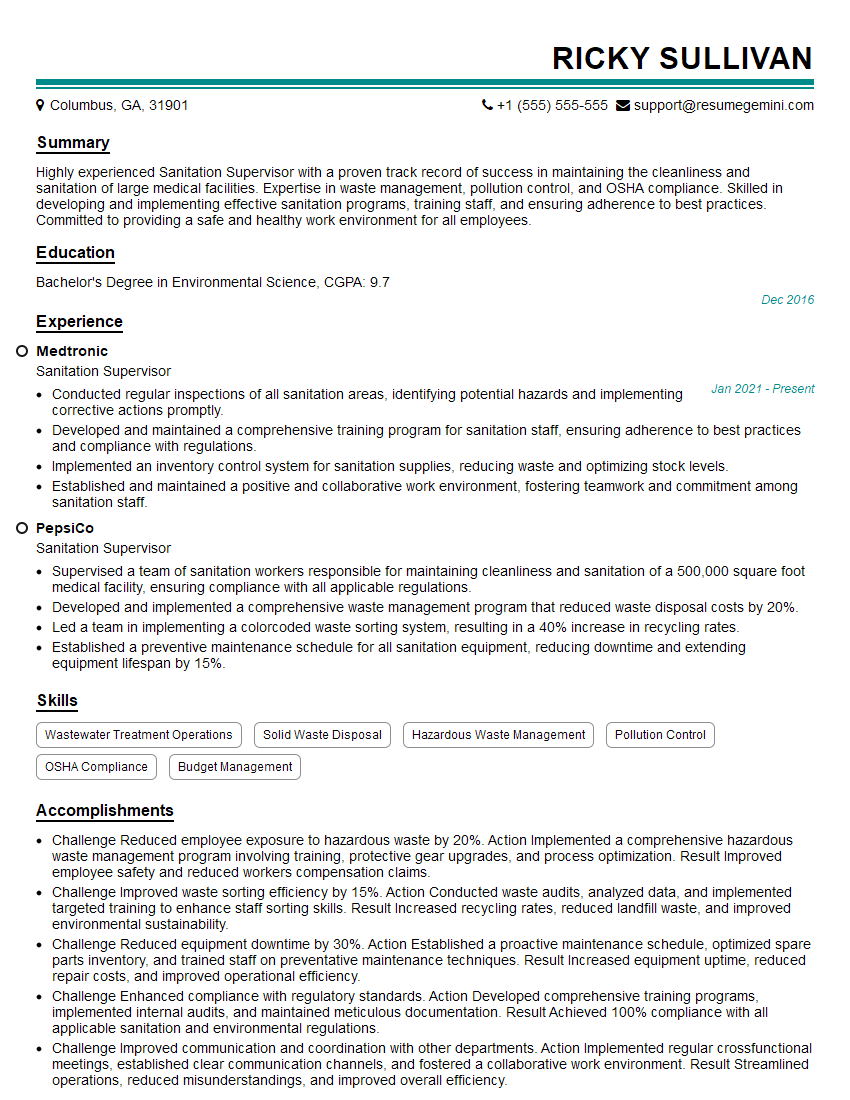

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with internal audits related to HACCP in fish roe processing?

I have extensive experience conducting internal audits for HACCP compliance in fish roe processing plants. These audits are critical to ensuring our systems are effective and compliant with regulations. My role typically involves reviewing documents, observing processes, interviewing personnel, and verifying the effectiveness of the implemented controls.

- Document Review: I examine HACCP plans, Standard Operating Procedures (SOPs), training records, and sanitation logs to confirm that they are comprehensive, up-to-date, and followed consistently.

- Process Observation: I observe the actual processing operations to ensure that practices align with the written procedures. This involves checking temperatures, sanitation procedures, and employee compliance with the protocols.

- Personnel Interviews: I conduct interviews with employees at various levels to assess their understanding of HACCP principles and their ability to apply these principles during their work.

- Verification of Controls: I validate the effectiveness of critical control points (CCPs) by reviewing data like temperature logs, microbial testing results, and allergen controls. This demonstrates that our processes are actually preventing hazards.

For instance, I recently discovered a minor discrepancy in temperature monitoring during the pasteurization process during an internal audit. This led to immediate corrective actions, including improved training and upgraded equipment calibration protocols. The issue was resolved promptly, preventing potential problems.

Q 17. Describe your experience with developing and implementing HACCP plans.

I’ve been involved in the development and implementation of numerous HACCP plans for fish roe processing. This involves a systematic approach, working closely with the processing teams to analyze hazards, identify CCPs, and establish monitoring procedures.

- Hazard Analysis: We meticulously identify biological, chemical, and physical hazards that could contaminate the fish roe at each stage of production, from harvesting to packaging. This often involves brainstorming sessions and reviewing industry best practices.

- Critical Control Point (CCP) Identification: We determine which steps in the process are crucial to controlling identified hazards. For example, pasteurization is a key CCP for controlling pathogens like Listeria and Salmonella.

- Critical Limits Establishment: For each CCP, we define specific measurable limits that must be met. This might include temperature ranges, time limits, and pH values.

- Monitoring Procedures: We establish methods for regularly monitoring each CCP to ensure that critical limits are met. This often involves automated monitoring systems and regular manual checks.

- Corrective Actions: We develop procedures for taking corrective actions if any critical limits are not met. This could involve rejecting a batch, repeating a process, or adjusting parameters.

- Verification Procedures: We implement methods to verify that the HACCP plan is effective, such as internal audits, microbial testing, and regular review of records.

For example, I helped a client implement a new high-pressure processing (HPP) system as a CCP to reduce the risk of pathogens while maintaining product quality. The success of this implementation was verified through regular microbial testing and documented in our audit trails.

Q 18. Explain how you would investigate a fish roe food safety incident.

Investigating a fish roe food safety incident requires a thorough and systematic approach. The goal is to identify the root cause, implement corrective actions, and prevent recurrence.

- Immediate Containment: The first step is to isolate the affected product and prevent further distribution. This may involve recalling the product from the market.

- Traceback Investigation: We trace the affected product back through the entire supply chain to identify the source of the contamination. This may involve reviewing records, interviewing personnel, and sampling ingredients.

- Root Cause Analysis: We conduct a thorough analysis to determine the root cause of the incident, identifying failures in the HACCP plan or other procedures.

- Corrective Actions: We develop and implement corrective actions to address the root cause. This might involve improving sanitation practices, upgrading equipment, or revising the HACCP plan.

- Verification: We verify that the corrective actions are effective in preventing future incidents. This may involve retesting and monitoring.

- Documentation: A comprehensive report documenting the entire investigation process, including findings, corrective actions, and verification results, is prepared and kept for records.

For instance, if a Listeria outbreak is linked to our product, we would conduct thorough environmental sampling of the facility, review processing records to identify potential weaknesses in our sanitation protocols, and potentially re-train our staff on hygienic practices.

Q 19. What are your strategies for preventing Listeria monocytogenes in fish roe?

Listeria monocytogenes is a serious concern in fish roe processing, as it can survive and grow even under refrigeration. Preventing its presence requires a multi-pronged approach that focuses on eliminating the bacteria from the environment and preventing its growth in the product.

- Good Manufacturing Practices (GMPs): Implementing strict GMPs is essential. This includes maintaining a clean and sanitary processing environment, controlling temperatures, and preventing cross-contamination.

- Sanitation: Rigorous sanitation programs are critical. This involves using validated cleaning and sanitizing agents effective against Listeria and ensuring thorough cleaning of all surfaces and equipment. Sanitation verification methods, including ATP bioluminescence testing, confirm the effectiveness of our cleaning.

- Temperature Control: Maintaining low temperatures throughout the entire processing chain is vital. This includes proper refrigeration during storage, transportation, and display.

- Pasteurization: Pasteurization or other appropriate lethality treatments are often used to eliminate Listeria. The effectiveness of this step is crucial and requires accurate monitoring and validation.

- Supplier Control: Selecting and verifying the safety and quality of raw materials from reputable and certified suppliers is vital in preventing contamination.

For example, we might implement a regular environmental swabbing program to monitor for the presence of Listeria in our facility and trigger preventative actions before contamination occurs.

Q 20. How do you ensure the effectiveness of your HACCP plan?

Ensuring the effectiveness of a HACCP plan is an ongoing process, not a one-time event. It requires consistent monitoring, verification, and improvement.

- Regular Monitoring: Continuous monitoring of CCPs is essential. This involves regularly checking temperature, pH, and other critical parameters and documenting the results.

- Internal Audits: Conducting regular internal audits to assess compliance with the HACCP plan is crucial. These audits should be thorough, objective, and documented.

- Microbial Testing: Regular microbial testing of the finished product and environmental samples is necessary to verify the effectiveness of the controls in preventing pathogens.

- Record Keeping: Accurate and complete record-keeping is essential. This allows for traceability and helps identify trends and potential issues.

- Management Review: Regular management reviews of the HACCP plan are needed to evaluate its effectiveness and make necessary adjustments.

- Corrective Actions: A system for identifying and correcting deviations from the HACCP plan is essential. This should include documented corrective actions, preventive actions, and verifications that these actions were effective.

For instance, if our temperature logs show deviations outside the critical limits at a CCP, we would investigate the root cause, implement corrective actions (such as equipment maintenance or staff retraining), and then monitor the CCP closely to verify the effectiveness of those actions.

Q 21. Describe your understanding of the role of preventive controls for human food.

Preventive controls for human food are critical for ensuring food safety. They represent a proactive approach, focusing on preventing hazards rather than just reacting to them after they occur. This is a significant shift from traditional reactive approaches.

- Hazard Analysis and Risk-Based Preventive Controls: This is the cornerstone of preventive controls. It involves identifying hazards, assessing their risks, and implementing control measures to minimize those risks. This includes considering biological, chemical, and physical hazards.

- Supply-Chain Program: Having robust controls for suppliers is key. This involves verifying that suppliers have adequate food safety programs in place and regularly reviewing supplier performance data.

- Good Agricultural Practices (GAPs): For produce, implementing GAPs is crucial. This includes ensuring proper harvesting, handling, and storage practices to minimize contamination.

- GMPs: Maintaining high standards of GMPs throughout the entire production process is essential. This involves controlling the environment, implementing sanitation procedures, and training employees on proper food safety practices.

- Monitoring and Verification: Regular monitoring of preventive controls, including documentation and record-keeping, is necessary. Verification activities confirm the effectiveness of these controls.

The preventive controls approach is vital because it helps ensure food safety from farm-to-fork. For example, in fish roe processing, having a robust supply-chain program that verifies the safety of the raw material significantly reduces the risk of contamination.

Q 22. How do you manage supplier relationships to ensure safe fish roe sourcing?

Managing supplier relationships for safe fish roe sourcing is paramount. It’s like building a strong foundation for a house – if the foundation is weak, the whole structure is at risk. We begin by rigorously vetting potential suppliers, evaluating their HACCP plans, and conducting on-site audits to assess their facilities and practices. This involves examining their hygiene standards, temperature control methods, traceability systems, and raw material sourcing. We verify that they adhere to the same stringent quality and safety standards as we do. We establish clear communication channels, regularly reviewing their performance metrics, including microbiological testing results and incident reports. We also insist on documented evidence of their compliance with relevant food safety regulations. This proactive approach ensures the safety and quality of our raw materials from the very beginning.

For example, we might require suppliers to provide detailed traceability records, showing the origin of their fish roe, harvest dates, and handling procedures. If a supplier fails to meet our standards, we work with them to implement corrective actions. If improvements aren’t made, we may discontinue our relationship, prioritizing the safety of our consumers above all else.

Q 23. What are your experience with different types of fish roe processing (e.g., pasteurization, freezing)?

My experience encompasses various fish roe processing methods, each with its own advantages and challenges. Pasteurization, a heat treatment, is effective in eliminating harmful bacteria like Listeria monocytogenes and Salmonella. However, it can affect the texture and flavor of some roe types. We carefully control the pasteurization parameters – time and temperature – to ensure effective microbial reduction while minimizing quality degradation. Freezing is another crucial method, particularly for preserving the roe’s quality for extended periods. Proper freezing techniques, such as rapid freezing, help maintain the texture and prevent ice crystal formation that can damage the roe’s structure. We use blast freezers to achieve this rapid freezing. Other methods like salting and smoking are also utilized, depending on the specific type of roe and the desired final product. The choice of processing method depends on various factors, including the type of fish roe, its intended shelf life, and the desired final product characteristics.

Q 24. Explain your understanding of food safety regulations specific to fish roe.

Fish roe falls under stringent food safety regulations, varying slightly depending on the country and region. Generally, these regulations cover critical control points throughout the entire supply chain, from harvesting to retail. This includes requirements for Good Manufacturing Practices (GMPs), Hazard Analysis and Critical Control Points (HACCP) plans, traceability systems, labeling requirements, and microbiological limits. For instance, regulations often specify maximum permissible levels of histamine, a biogenic amine that can cause food poisoning if present in high concentrations. Compliance with these regulations is not merely a legal obligation but a commitment to consumer safety and public health. We conduct regular internal audits and external inspections to ensure our operations align with all applicable regulations. Staying informed about changes and updates to these regulations is crucial, ensuring continued compliance.

Q 25. What methods do you use to ensure proper labeling and packaging of fish roe?

Proper labeling and packaging are vital for maintaining fish roe quality and safety, and for providing consumers with accurate information. Our labels clearly state the product name, ingredients, net weight, origin, best-before date, storage instructions, and any potential allergens. We comply with all relevant labeling regulations, ensuring the information is easily visible and understandable. Packaging materials are carefully selected to protect the product from contamination, damage, and spoilage. We use high-quality materials that maintain the integrity of the roe, whether it’s vacuum-sealed pouches or modified atmosphere packaging (MAP). Traceability is also integrated into our packaging system – each package is uniquely identifiable, enabling us to trace the product’s journey from origin to consumer, assisting with potential recall management.

Q 26. Describe your experience with training employees on HACCP principles in a fish roe processing facility.

Training employees on HACCP principles is crucial. We conduct regular training sessions, covering all aspects of the HACCP plan, including hazard identification, critical control point determination, monitoring, corrective actions, and record-keeping. We use a combination of classroom instruction, hands-on training, and interactive workshops. The training is tailored to the specific roles of our employees, ensuring that everyone understands their responsibilities in maintaining food safety. For example, production line workers receive detailed training on proper hygiene practices, temperature monitoring, and defect detection. Management personnel receive training on overseeing the HACCP system and responding to potential deviations. We use quizzes and practical assessments to evaluate employee understanding and competence. This ensures our workforce is equipped to maintain the highest safety standards.

Q 27. How do you ensure the accuracy and reliability of your food safety testing methods?

Ensuring the accuracy and reliability of food safety testing methods is paramount. We use accredited laboratories for our testing, selecting those with proven expertise in fish roe analysis. We utilize standardized methods and procedures, ensuring consistency and comparability of results. We maintain detailed records of all testing activities, including sample collection, analysis methods, and results. We participate in proficiency testing programs to verify the accuracy and reliability of our laboratory’s results. Regular calibration and maintenance of testing equipment are also vital. Furthermore, we have clear protocols for investigating and resolving any discrepancies in test results, involving internal and external experts as needed. This multi-faceted approach ensures that our testing program is robust, reliable, and provides accurate information to support our food safety management system.

Q 28. How would you handle a discrepancy between your HACCP plan and actual production practices?

Handling discrepancies between our HACCP plan and actual production practices requires a systematic approach. First, we identify and document the discrepancy. Then, we conduct a root cause analysis to determine the reason for the deviation. This might involve interviewing employees, reviewing production records, and inspecting equipment. Once the root cause is identified, we implement corrective actions to address the issue and prevent recurrence. These actions could range from retraining employees, modifying equipment, or revising the HACCP plan itself. We document all corrective actions taken, and monitor the effectiveness of these actions. Finally, we review and update the HACCP plan to reflect the lessons learned, ensuring that it accurately reflects our actual production practices and remains a valuable tool for maintaining food safety. This systematic approach ensures continuous improvement and enhances the effectiveness of our HACCP system.

Key Topics to Learn for Your Fish Roe HACCP Procedures Interview

- Hazard Analysis: Identifying biological, chemical, and physical hazards specific to fish roe processing, from harvest to final product.

- Critical Control Points (CCPs): Determining the steps in the process where control is essential to prevent or eliminate hazards. Examples include temperature control during processing and storage.

- Critical Limits: Establishing measurable parameters (e.g., temperature, pH, time) for each CCP to ensure safety.

- Monitoring Procedures: Detailing the methods for regularly checking CCPs to ensure critical limits are met. This includes record-keeping and documentation.

- Corrective Actions: Defining procedures to follow when critical limits are not met, including deviations and their resolution.

- Verification Procedures: Explaining how the effectiveness of the HACCP plan is regularly verified. This could involve internal audits, product testing, or supplier audits.

- Record-Keeping and Documentation: Understanding the importance of meticulous record keeping to demonstrate compliance and traceability throughout the process.

- Good Manufacturing Practices (GMPs): Demonstrating knowledge of GMP principles relevant to fish roe handling, sanitation, and hygiene.

- Allergen Control: Understanding and implementing procedures to manage allergens in fish roe processing and labeling.

- Traceability: Explaining how the system tracks fish roe from origin to consumer, facilitating recalls if necessary.

Next Steps

Mastering Fish Roe HACCP Procedures demonstrates a commitment to food safety and quality, significantly enhancing your prospects in the seafood industry. This expertise is highly valued by employers and can lead to increased responsibility and career advancement. To maximize your chances of landing your dream job, it’s crucial to have a resume that effectively showcases your skills and experience. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini is a trusted resource to help you build a compelling and effective resume. They offer examples of resumes tailored to Fish Roe HACCP Procedures to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good