Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential HVAC and Refrigeration Systems Management interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in HVAC and Refrigeration Systems Management Interview

Q 1. Explain the difference between a heat pump and a furnace.

The key difference between a heat pump and a furnace lies in how they heat your space. A furnace generates heat by burning fuel (natural gas, propane, or oil) and then distributes that heated air through ductwork. Think of it as a big, controlled bonfire. It’s a one-way street: it only produces heat.

A heat pump, on the other hand, acts more like a refrigerator in reverse. It absorbs heat from the outside air (even in cold temperatures) and transfers it inside, using electricity. In the summer, it reverses the process, acting as an air conditioner. This makes it significantly more energy-efficient than a furnace, especially in milder climates.

In simpler terms: a furnace creates heat, while a heat pump moves heat.

Q 2. Describe the refrigeration cycle in detail.

The refrigeration cycle is a continuous process that involves four main components working together to transfer heat: the compressor, the condenser, the expansion valve, and the evaporator. Let’s follow the refrigerant as it cycles:

- Evaporation: In the evaporator, the low-pressure, low-temperature refrigerant absorbs heat from the space to be cooled (e.g., inside your refrigerator), changing from a liquid to a gas. This is where the cooling effect happens.

- Compression: The compressor raises the pressure and temperature of the refrigerant gas, making it hot.

- Condensation: The hot, high-pressure refrigerant gas flows into the condenser. Here, it releases heat to the surrounding environment (e.g., outside air for an air conditioner) and changes back into a liquid.

- Expansion: The high-pressure liquid refrigerant passes through the expansion valve, where the pressure dramatically drops, causing its temperature to decrease significantly. This now low-temperature liquid refrigerant goes back to the evaporator, restarting the cycle.

Imagine it like a water fountain: the pump (compressor) increases the pressure, the water sprays out (evaporation), the water falls back down and collects (condensation), and finally flows back up to the pump again (expansion).

Q 3. What are the common refrigerants used and their environmental impact?

Common refrigerants include R-134a, R-410A, R-32, and ammonia (NH3). The environmental impact varies greatly:

- R-134a and R-410A: These hydrofluorocarbons (HFCs) have a high global warming potential (GWP), meaning they contribute significantly to climate change, although less so than older refrigerants like R-22 (CFC).

- R-32: This hydrofluoroolefin (HFO) has a lower GWP than R-134a and R-410A, making it a more environmentally friendly alternative.

- Ammonia (NH3): A natural refrigerant with zero ozone depletion potential (ODP) and a very low GWP. However, it’s toxic and requires specialized handling.

The industry is moving towards refrigerants with lower GWPs to minimize environmental damage. Regulations are constantly evolving to phase out high-GWP refrigerants.

Q 4. How do you troubleshoot a malfunctioning compressor?

Troubleshooting a malfunctioning compressor requires a systematic approach. Safety is paramount; always disconnect the power before working on any electrical component.

- Check for power: Ensure the compressor is receiving power. Test the electrical connections and the circuit breaker.

- Listen for unusual sounds: A clicking sound might indicate a faulty starting capacitor. A loud knocking or rumbling sound suggests internal damage to the compressor.

- Check the refrigerant levels: Low refrigerant levels can lead to compressor failure. Use a refrigerant pressure gauge to check the high and low-side pressures. Significant deviations from the manufacturer’s specifications indicate a problem.

- Inspect the motor windings: Using a multimeter, check for continuity and resistance in the motor windings. Open or shorted windings mean a failed compressor.

- Examine the compressor oil: Discoloration or excessive contamination in the oil can indicate a problem within the compressor.

If you’re not experienced with refrigeration systems, it’s crucial to call a qualified technician. Attempting repairs without proper training can be dangerous.

Q 5. Explain the function of a condenser and evaporator in a refrigeration system.

The condenser and evaporator are the heat exchangers in a refrigeration system. They are essential for the heat transfer process.

The condenser releases heat from the high-pressure, high-temperature refrigerant to the surroundings. Think of it as a radiator—it dissipates the heat generated by the compressor. In an air conditioning system, this is typically outdoors.

The evaporator absorbs heat from the space being cooled. It’s where the low-pressure, low-temperature refrigerant absorbs heat, causing the surrounding air to cool. In your refrigerator, this is the cold coils at the back.

In essence, the condenser removes heat from the refrigerant, while the evaporator extracts heat from the environment to be cooled.

Q 6. What are the different types of HVAC systems?

HVAC systems vary depending on the application and climate. Common types include:

- Split systems: These are the most common type in residential buildings. They consist of an indoor air handler and an outdoor condenser unit connected by refrigerant lines.

- Packaged systems: All components (compressor, condenser, evaporator, and blower) are housed in a single unit. Often seen in smaller commercial buildings.

- Heat pumps: As discussed earlier, these systems can both heat and cool. Air-source heat pumps draw heat from the outside air, while geothermal heat pumps utilize the ground’s consistent temperature.

- VAV (Variable Air Volume) systems: These systems are common in larger commercial buildings, offering more precise temperature control in different zones.

- Chilled water systems: These use chilled water to cool buildings. A large chiller creates the chilled water, which is then circulated throughout the building.

The best system depends on factors such as building size, climate, and energy efficiency requirements.

Q 7. Describe your experience with various HVAC control systems.

Throughout my career, I’ve worked extensively with a range of HVAC control systems, from basic thermostats to advanced building automation systems (BAS). I have hands-on experience with:

- Programmable thermostats: I’ve installed, configured, and troubleshot numerous programmable thermostats, optimizing energy consumption and user comfort.

- Direct digital control (DDC) systems: I’m proficient in using DDC systems to monitor and control various HVAC equipment parameters (temperature, pressure, airflow), ensuring efficient operation and fault detection.

- Building automation systems (BAS): I’ve worked with several BAS platforms, integrating HVAC systems with other building systems (lighting, security) for centralized control and monitoring. I can efficiently program and troubleshoot complex automation sequences.

- Wireless control systems: I have experience integrating wireless sensors and actuators into HVAC systems for remote monitoring and control, enhancing system flexibility.

My experience encompasses both the design and implementation phases, allowing me to understand the intricacies of various control protocols and their impact on overall system performance. I’m always keen to learn about new technologies and methodologies in the field.

Q 8. How do you diagnose and repair a leaking refrigerant line?

Diagnosing a refrigerant leak involves a systematic approach. First, I’d visually inspect the entire system, looking for signs of oil or refrigerant stains, frost buildup in unexpected areas, or bubbling in the refrigerant lines. A leak detector, employing electronic sensors sensitive to refrigerant, is crucial for pinpointing the leak’s exact location. Different refrigerants require different detectors, so choosing the right one is paramount. Once the leak is located, I would carefully assess its severity. Small leaks might be repairable with specialized sealant, while larger leaks often necessitate replacing the damaged section of the line. This requires proper brazing or soldering techniques to ensure a leak-free seal, always remembering to evacuate and recover the refrigerant before commencing repairs, and then recharge the system according to manufacturer specifications. For example, I once encountered a leak in a residential unit traced to a corroded fitting hidden behind a wall. Careful removal of the wall section revealed the problem and allowed for the efficient repair.

Q 9. Explain the importance of regular HVAC maintenance.

Regular HVAC maintenance is paramount for several reasons. Firstly, it significantly extends the lifespan of your system. By proactively addressing minor issues before they escalate into major problems, you avoid costly replacements. Regular cleaning removes dust and debris that reduce efficiency and strain components. Secondly, maintenance ensures optimal efficiency. A well-maintained system operates at its peak, conserving energy and reducing utility bills. This translates directly to cost savings over time. Thirdly, regular servicing ensures safety. A malfunctioning system can pose hazards, from refrigerant leaks to carbon monoxide production. Professional maintenance helps detect and mitigate these risks. Imagine a scenario where a neglected air conditioner suddenly malfunctions during a heatwave. Regular maintenance could have prevented this costly and potentially dangerous situation. I routinely recommend annual maintenance checks for optimal system performance and safety.

Q 10. How do you interpret a psychrometric chart?

A psychrometric chart is a graphical representation of the thermodynamic properties of moist air. It’s a crucial tool for HVAC professionals. The chart plots various parameters like dry-bulb temperature (air temperature measured by a regular thermometer), wet-bulb temperature (air temperature after evaporative cooling), relative humidity (the amount of moisture in the air relative to its saturation capacity), enthalpy (total heat content), and specific volume (volume per unit mass of air). By knowing any two of these parameters, we can determine the rest from the chart. This helps in designing, analyzing, and troubleshooting HVAC systems. For example, I frequently use it to determine the necessary cooling load for a space given its dry-bulb temperature and relative humidity, or to assess the effectiveness of dehumidification strategies. Understanding how to read and interpret this chart is essential for optimizing HVAC system performance and ensuring occupant comfort.

Q 11. What safety precautions do you take when working with refrigerants?

Safety is paramount when working with refrigerants. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and respiratory protection. Refrigerants can be toxic and some are flammable. Proper ventilation is critical to prevent the buildup of harmful gases. Before working on a system, I ensure the power is turned off to prevent electrical hazards. Before opening any refrigerant lines, I use approved recovery and recycling equipment to capture the refrigerant and prevent its release into the atmosphere. This process is environmentally responsible and adheres to EPA regulations. I also follow all manufacturer’s guidelines and relevant safety standards. Never attempt to work with refrigerants without adequate training and understanding of the safety procedures involved. A failure to follow these procedures can lead to serious health consequences or environmental damage.

Q 12. Describe your experience with different types of ductwork.

My experience encompasses various ductwork types, including flexible, rigid, and high-velocity systems. Flexible ductwork, made of flexible materials like foil-faced fiberglass, is commonly used for residential applications due to its ease of installation and cost-effectiveness. However, it’s less efficient than rigid ductwork and prone to air leaks. Rigid ductwork, typically made of galvanized steel or aluminum, offers superior air tightness and durability, making it suitable for commercial and larger residential projects. High-velocity ductwork, characterized by smaller duct sizes and higher air velocities, is efficient for space-saving applications. The selection of ductwork depends on factors such as the building’s design, budget, and desired performance levels. For instance, in a recent project, we used rigid ductwork for the main distribution system and flexible ductwork for smaller branches to optimize both cost and efficiency.

Q 13. How do you calculate the heating and cooling load for a building?

Calculating heating and cooling loads requires a comprehensive approach. I typically utilize specialized software and industry-accepted methodologies like Manual J (for residential) or ASHRAE procedures (for commercial buildings). These methods consider several factors, including building size, climate data (temperature, humidity, solar radiation), insulation levels, window types, occupancy, lighting, and equipment heat gain. The calculations involve determining the heat loss during winter and heat gain during summer. This involves calculating transmission heat loads (through walls, roofs, windows), infiltration heat loads (due to air leakage), and internal heat gains (from occupants, lighting, and equipment). The final load calculations are used to size the HVAC equipment appropriately, ensuring adequate heating and cooling capacity for the building while optimizing energy efficiency. Accuracy in these calculations is crucial to avoid over- or under-sizing the system, which could result in discomfort and increased energy costs.

Q 14. What are the different types of air filters and their applications?

Air filters play a critical role in maintaining indoor air quality and protecting HVAC equipment. There are several types, each with specific applications. Fiberglass filters are the most common and inexpensive, offering basic filtration. Pleated filters offer greater surface area and better efficiency than fiberglass filters. HEPA (High-Efficiency Particulate Air) filters are designed for high-efficiency particulate removal and are ideal for environments requiring stringent air quality control, such as hospitals or cleanrooms. Electrostatic filters use static electricity to attract and trap dust particles. The choice of filter depends on the specific needs and environment. For instance, a home with allergies may benefit from a pleated or HEPA filter, while a standard office may require only a fiberglass filter. Regular filter replacement is essential to maintain peak system efficiency and air quality.

Q 15. Explain your understanding of building automation systems (BAS).

Building Automation Systems (BAS) are centralized control systems that manage and monitor a building’s various mechanical and electrical equipment, including HVAC systems. Think of it as a sophisticated nervous system for a building. A BAS uses sensors, controllers, and software to automate processes, optimize energy efficiency, and provide real-time monitoring of system performance. For example, a BAS can automatically adjust the temperature in different zones of a building based on occupancy, time of day, and weather conditions, all while collecting data for analysis and reporting.

My understanding encompasses the different types of BAS, including direct digital control (DDC) systems which are the most common, networked systems that offer centralized monitoring and control of multiple building systems, and supervisory control and data acquisition (SCADA) systems, which are often used in larger, more complex facilities. I’m proficient in using various BAS platforms including [mention specific platforms if you have experience with them, e.g., Tridium Niagara, Siemens, Johnson Controls] to program, troubleshoot, and optimize building automation strategies. I’ve used BAS to improve building energy efficiency by 15% in one project by implementing sophisticated scheduling and demand-based ventilation strategies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventative maintenance schedules.

Preventative maintenance schedules are crucial for ensuring the reliable and efficient operation of HVAC systems. I develop and implement comprehensive preventative maintenance (PM) schedules based on manufacturers’ recommendations, equipment age, and operating conditions. These schedules typically include tasks like filter changes, coil cleaning, lubrication of moving parts, and visual inspections for leaks or damage. A typical schedule would involve monthly, quarterly, and annual checks, with more frequent maintenance for heavily used systems or those in harsh environments.

In my experience, I’ve created and implemented PM schedules using computerized maintenance management systems (CMMS). This allowed me to track completed tasks, schedule future maintenance, and generate reports on system performance. For example, in one project, implementing a rigorous PM schedule resulted in a 20% reduction in emergency repair calls. This not only saves money but also minimizes downtime and ensures occupant comfort.

Q 17. How do you manage a team of HVAC technicians?

Managing a team of HVAC technicians requires strong leadership, communication, and technical expertise. I approach team management using a collaborative and supportive style. This includes regular team meetings to discuss ongoing projects, address challenges, and share best practices. Clear communication is paramount—ensuring everyone understands their roles, responsibilities, and the importance of safety. I foster a culture of continuous learning and professional development, encouraging technicians to participate in training programs and obtain relevant certifications.

I delegate tasks based on individual skills and experience, providing adequate supervision and support. I also focus on creating a positive and respectful work environment, promoting teamwork and open communication. For instance, I successfully mentored a junior technician who now excels in troubleshooting complex electrical issues within HVAC systems. Using performance reviews and feedback mechanisms keeps everyone engaged, accountable, and striving towards team goals.

Q 18. How do you handle emergency HVAC repairs?

Handling emergency HVAC repairs requires a rapid response and a systematic approach. My first step is to assess the situation quickly and accurately. This involves determining the nature of the problem, identifying the affected area, and assessing the level of urgency. Next, I prioritize the repair based on safety and impact, addressing critical issues immediately. I assign the most qualified technician for the job while coordinating with building management and occupants to minimize disruption.

Once the immediate problem is addressed, I conduct a thorough investigation to determine the root cause of the failure to prevent recurrence. This might involve reviewing maintenance records, conducting detailed inspections, and performing diagnostic testing. For example, during a recent emergency involving a chiller failure during a heatwave, my team quickly isolated the problem to a faulty compressor, replaced it, and restored cooling within four hours, preventing significant discomfort to building occupants. We then followed up with a comprehensive assessment to prevent similar future failures.

Q 19. What are the common causes of HVAC system failures?

HVAC system failures can stem from various causes, often linked to neglecting preventative maintenance or poor installation. Common causes include:

- Refrigerant Leaks: Leading to reduced cooling capacity and potential environmental damage.

- Faulty Components: Malfunctioning compressors, condensers, evaporators, or blowers.

- Electrical Issues: Short circuits, blown fuses, or faulty wiring leading to equipment shutdown or malfunction.

- Dirty Air Filters and Coils: Restricted airflow and reduced efficiency.

- Lack of Proper Maintenance: Accumulation of dirt, debris, and corrosion impacting performance.

- Improper Installation: Inadequate piping, wiring, or ductwork design resulting in leaks or inefficiencies.

Understanding these common causes allows for proactive maintenance and efficient troubleshooting. For example, regular filter changes can prevent many issues related to airflow restriction and component wear and tear.

Q 20. Describe your experience with troubleshooting electrical issues in HVAC systems.

Troubleshooting electrical issues in HVAC systems requires a solid understanding of electrical principles and safety procedures. This includes knowledge of circuit diagrams, voltage measurements, and the proper use of electrical testing equipment like multimeters and clamp meters. I always prioritize safety, following lockout/tagout procedures to de-energize circuits before working on them. I systematically check for issues like loose connections, damaged wires, blown fuses, faulty contactors, and problems with the control circuits.

My experience involves using schematic diagrams to trace wiring, employing multimeters to check voltage and continuity, and replacing faulty components. In one case, I traced an intermittent power failure in a rooftop unit to a corroded connection in the electrical panel, preventing a major system failure. Understanding the various components and control logic within HVAC systems is essential for diagnosing and resolving electrical problems effectively.

Q 21. How do you ensure energy efficiency in HVAC systems?

Ensuring energy efficiency in HVAC systems is a critical aspect of building management, both economically and environmentally. There are several strategies I employ, including:

- Regular Maintenance: This includes cleaning coils, changing filters, and lubricating moving parts to maximize efficiency. A dirty coil, for instance, can reduce efficiency by 20% or more.

- Optimized System Controls: Using BAS to schedule operations based on occupancy and weather conditions, reducing energy consumption during unoccupied periods or when natural ventilation is sufficient.

- Proper Sizing of Equipment: Ensuring the HVAC system is appropriately sized for the building’s heating and cooling loads prevents over- or under-capacity, improving efficiency.

- Energy-Efficient Equipment: Using high-efficiency components such as variable-speed drives (VSDs) on fans and pumps, modulating gas valves, and energy-efficient air handling units (AHUs).

- Building Envelope Improvements: Addressing issues like poor insulation and air leaks reduces the heating and cooling load on the HVAC system.

By implementing these strategies, I’ve successfully improved the energy efficiency of several buildings. For example, a project involving a comprehensive energy audit and subsequent upgrades resulted in a 30% reduction in energy consumption for the HVAC system.

Q 22. Explain your experience with different types of ventilation systems.

My experience encompasses a wide range of ventilation systems, from simple exhaust fans to sophisticated, energy-efficient designs. I’ve worked extensively with:

- Supply and Exhaust Ventilation: This is the most common type, involving bringing in fresh air and removing stale or contaminated air. I’ve designed and maintained systems in various settings, from office buildings where air quality is paramount to industrial facilities needing specialized fume extraction.

- Balanced Ventilation: This system ensures equal amounts of fresh air are supplied and exhausted, maintaining a constant pressure and preventing unwanted drafts. I’ve implemented this in sensitive environments like cleanrooms and operating theaters, where precise air control is essential.

- Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV): These systems recover heat or both heat and moisture from the exhaust air to preheat or precool the incoming fresh air, significantly improving energy efficiency. I’ve successfully integrated HRVs into residential and commercial projects, resulting in considerable energy savings for clients.

- Demand-Controlled Ventilation (DCV): DCV systems adjust ventilation rates based on occupancy and air quality sensors, optimizing energy use. I’ve worked on projects incorporating CO2 sensors and occupancy detectors to dynamically control ventilation, leading to cost reductions without compromising air quality.

In each project, I carefully consider factors like building design, occupancy levels, and environmental regulations to select the most appropriate and effective ventilation strategy.

Q 23. How do you handle customer complaints related to HVAC issues?

Handling customer complaints is a crucial aspect of this role. My approach prioritizes empathy, efficient problem-solving, and clear communication. I begin by actively listening to the customer, acknowledging their concerns, and asking clarifying questions to understand the issue completely.

Next, I investigate the problem systematically. This might involve inspecting the HVAC system, reviewing maintenance logs, or even using diagnostic tools to identify the root cause. I then explain my findings clearly and concisely to the customer, avoiding technical jargon and focusing on practical solutions.

Once a solution is agreed upon, I implement it efficiently and follow up with the customer to ensure their satisfaction. For example, if a customer complains about insufficient cooling, I might check the refrigerant levels, clean the condenser coils, or adjust the thermostat settings. If the problem requires more extensive repairs, I provide a detailed quote and timeline. Maintaining open communication throughout the process is vital to resolve the issue quickly and build trust.

Q 24. What are your preferred methods for documenting HVAC repairs and maintenance?

I utilize a combination of digital and physical documentation methods to ensure comprehensive and easily accessible records of all HVAC repairs and maintenance.

- Digital Documentation: I use customized software to log all service calls, including date, time, problem description, actions taken, parts replaced, and customer feedback. This allows for efficient searching and reporting. I also take digital photos of critical components before, during, and after repair to document the work performed and any pre-existing conditions.

- Physical Documentation: I maintain a detailed paper logbook at each job site. This contains handwritten notes, schematics, and diagrams relevant to the specific system. This acts as a backup and serves as a quick reference during subsequent service visits.

This dual approach ensures redundancy and accessibility, streamlining maintenance and troubleshooting in the future. For example, if a component fails months after a repair, the detailed documentation allows for rapid diagnosis and a swift resolution, minimizing downtime and customer inconvenience.

Q 25. Describe your experience with different types of chillers.

My experience with chillers includes various types, each with unique characteristics and applications:

- Reciprocating Chillers: These use multiple compressors to provide cooling. They are relatively simple and cost-effective, suitable for smaller applications. I’ve maintained several in smaller commercial buildings.

- Screw Chillers: These use rotating screws to compress the refrigerant. They’re known for high efficiency and reliability, often used in larger commercial and industrial settings. I have extensive experience troubleshooting and maintaining these in large office complexes and data centers.

- Centrifugal Chillers: These use a high-speed impeller to compress refrigerant. They’re highly efficient for large capacity cooling requirements, often found in very large buildings and industrial plants. I’ve worked on projects involving the commissioning and maintenance of these large systems.

- Absorption Chillers: These use heat as their power source, making them suitable for cogeneration or waste heat recovery systems. I’ve worked on projects integrating these into sustainable building designs.

My expertise extends to understanding their operational principles, troubleshooting malfunctions (like refrigerant leaks or compressor failures), and performing routine maintenance procedures to ensure optimal performance and longevity.

Q 26. Explain your understanding of different types of cooling towers.

Cooling towers are crucial for rejecting heat from HVAC systems. My knowledge spans several types:

- Open Cooling Towers: These are the most common type, using a water spray and airflow to evaporate water and dissipate heat. I’ve worked extensively with their maintenance, including cleaning, chemical treatment, and fan motor replacements.

- Closed Cooling Towers: These utilize a heat exchanger to separate the water from the air, minimizing water loss and reducing the risk of Legionella bacteria growth. I’ve installed and maintained these in applications requiring higher water conservation or enhanced hygiene.

- Mechanical Draft Cooling Towers: These utilize fans to induce airflow through the tower, providing higher cooling efficiency. I’ve managed the preventative maintenance of these systems in various settings.

- Natural Draft Cooling Towers: These rely on natural convection for airflow, requiring minimal energy input but occupying a larger footprint. I have experience assessing their suitability for specific projects.

Understanding the different types is critical for ensuring efficient operation, preventing scaling and corrosion, and maintaining water quality to avoid environmental issues and prevent bacterial growth.

Q 27. What are the regulations and safety standards you follow while working with HVAC systems?

Safety is paramount in HVAC work. I meticulously adhere to all relevant regulations and standards, including:

- OSHA (Occupational Safety and Health Administration) regulations: This covers aspects like fall protection, lockout/tagout procedures for electrical and mechanical equipment, proper handling of refrigerants, and use of personal protective equipment (PPE).

- EPA (Environmental Protection Agency) regulations: These cover the handling and disposal of refrigerants, minimizing environmental impact and preventing ozone depletion. I am certified to handle refrigerants according to EPA regulations.

- Local building codes: These dictate specific requirements for HVAC installations and maintenance within a given jurisdiction. I am familiar with and always compliant with local codes.

- Manufacturer’s guidelines: I always follow the specific instructions provided by equipment manufacturers for installation, maintenance, and troubleshooting.

Regular safety training, risk assessments, and adherence to these regulations are crucial to prevent accidents and ensure a safe working environment for myself and others.

Q 28. How do you stay updated on the latest advancements in HVAC technology?

Staying current in the rapidly evolving field of HVAC is essential. I employ a multi-pronged approach:

- Industry publications and journals: I regularly read publications like ASHRAE Journal to stay abreast of technological innovations and best practices.

- Professional development courses and workshops: I actively participate in training sessions and conferences focused on new technologies and energy-efficient design strategies. This helps me earn continuing education credits and keep my certifications current.

- Manufacturer training programs: I participate in training sessions provided by manufacturers on new equipment and technologies. This provides hands-on experience and ensures I’m proficient with the latest systems.

- Online resources and networking: I use online forums, webinars, and professional networking groups to connect with other professionals and learn about emerging trends.

This commitment to continuous learning allows me to incorporate cutting-edge technologies into my work, optimize system performance, and provide clients with the most up-to-date and efficient solutions. For example, recent training has broadened my expertise in Variable Refrigerant Flow (VRF) systems and building automation systems (BAS).

Key Topics to Learn for HVAC and Refrigeration Systems Management Interview

- System Design and Operation: Understanding the principles behind different HVAC and refrigeration systems (e.g., chillers, air handlers, heat pumps), including their components, functionalities, and interconnections. Practical application: Explain the design considerations for a large commercial building’s cooling system.

- Troubleshooting and Diagnostics: Mastering diagnostic techniques for identifying and resolving malfunctions in HVAC and refrigeration equipment. Practical application: Describe your approach to diagnosing a refrigeration system experiencing low cooling capacity.

- Refrigerant Handling and Safety: Deep understanding of refrigerant types, handling procedures, and safety regulations (EPA certifications are a plus!). Practical application: Explain the proper procedures for evacuating and charging a refrigeration system.

- Energy Efficiency and Sustainability: Knowledge of energy-efficient technologies and practices in HVAC and refrigeration. Practical application: Discuss strategies for optimizing energy consumption in a commercial refrigeration system.

- Control Systems and Automation: Familiarity with building automation systems (BAS) and programmable logic controllers (PLCs) used in HVAC and refrigeration control. Practical application: Explain how a BAS can be used to optimize building energy efficiency.

- Maintenance and Preventative Maintenance Programs: Developing and implementing effective maintenance schedules to extend equipment lifespan and minimize downtime. Practical application: Describe a preventative maintenance program you’ve designed or implemented.

- Budgeting and Cost Management: Understanding the financial aspects of HVAC and refrigeration systems, including budgeting, cost estimation, and project management. Practical application: Explain how to develop a budget for a HVAC system upgrade project.

- Teamwork and Leadership: Demonstrating effective communication, collaboration, and leadership skills within a team environment. Practical application: Describe a situation where you successfully led a team to solve a complex technical problem.

Next Steps

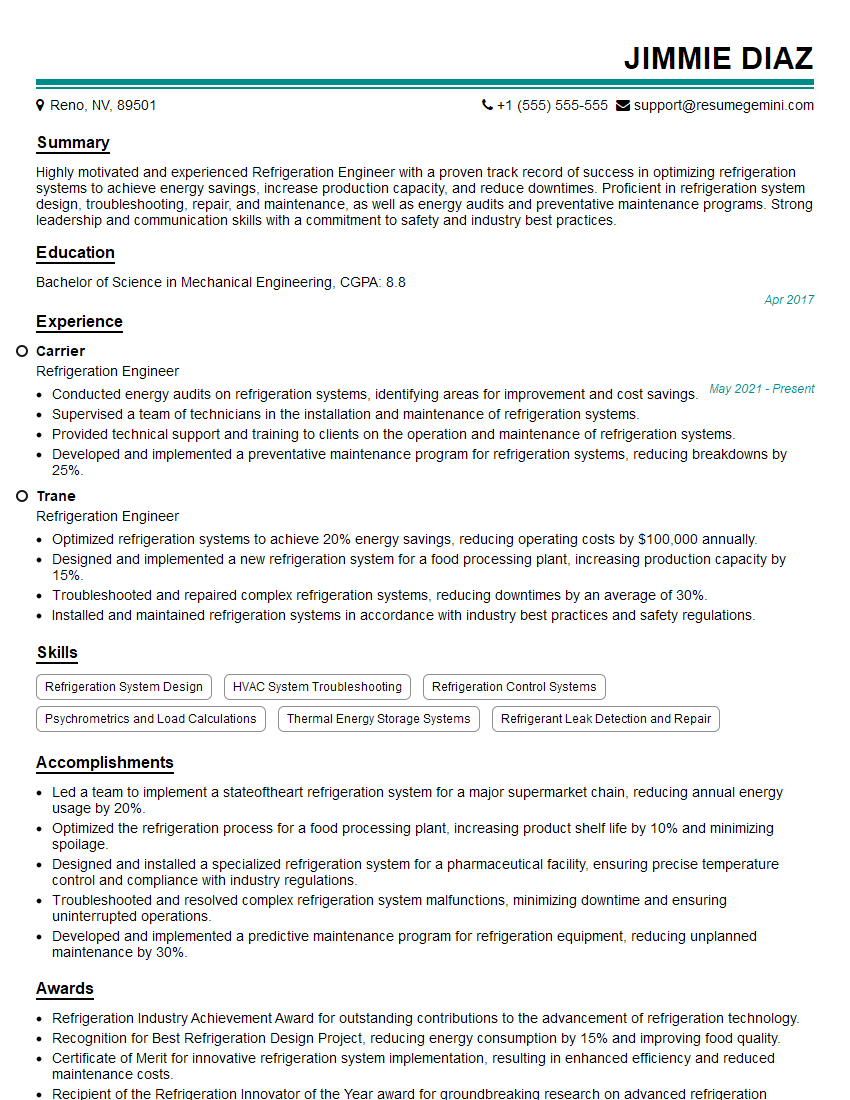

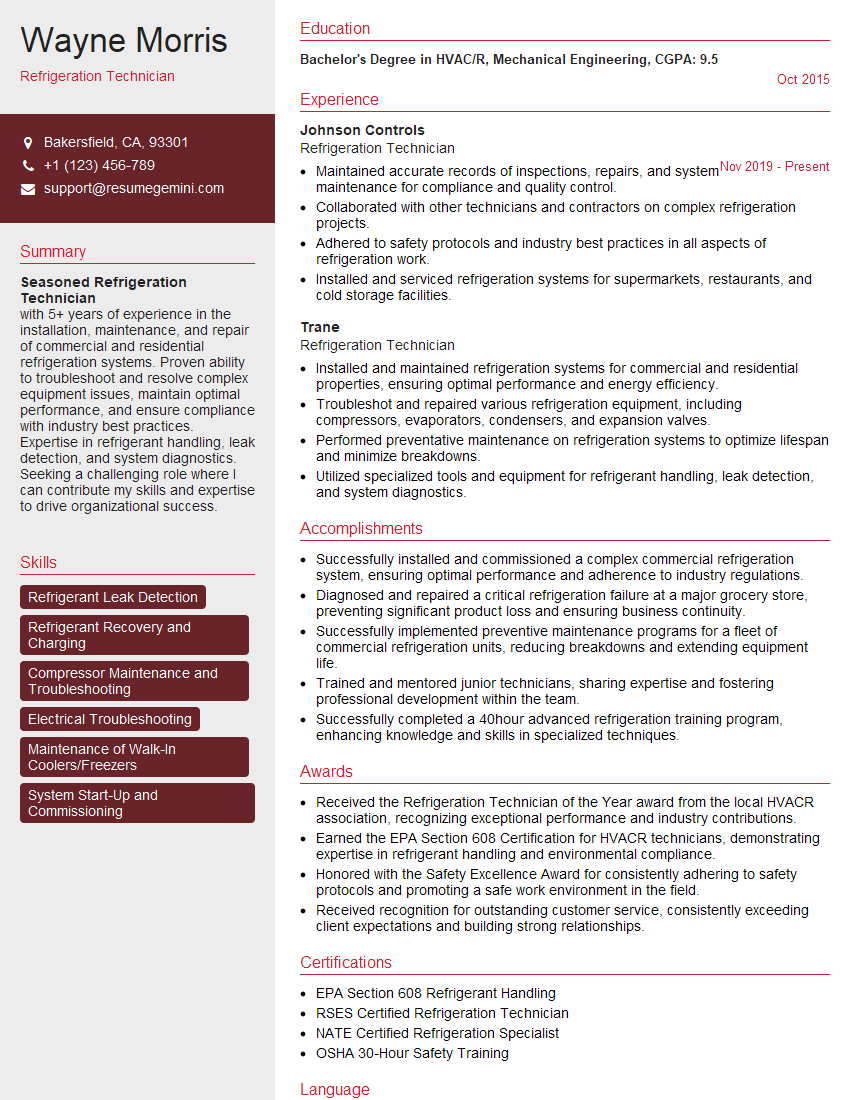

Mastering HVAC and Refrigeration Systems Management opens doors to rewarding careers with excellent growth potential. To maximize your job prospects, it’s crucial to create a professional, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your qualifications. Examples of resumes tailored to HVAC and Refrigeration Systems Management are available to help guide you in creating your perfect application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good