The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Understanding of Plating Parameters interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Understanding of Plating Parameters Interview

Q 1. Explain the relationship between current density and plating thickness.

The relationship between current density and plating thickness is directly proportional. Think of it like this: current density is the rate at which metal ions are deposited onto the substrate. A higher current density means more metal ions are being deposited per unit area per unit time, resulting in a thicker plating in a given time. Conversely, a lower current density leads to a thinner plating.

For example, if you double the current density, you’ll roughly double the plating thickness (assuming other parameters remain constant). However, this relationship isn’t perfectly linear; at extremely high current densities, factors like hydrogen evolution and inefficient metal deposition can reduce plating efficiency and hinder thickness increase. The formula, while simplified, illustrates the relationship: Thickness ∝ (Current Density x Time). In practice, precise control of current density is crucial for achieving the desired plating thickness, whether it’s a thin, decorative layer or a thick, functional coating.

Q 2. What are the effects of temperature on plating efficiency?

Temperature significantly influences plating efficiency. Generally, increasing the temperature boosts the rate of chemical reactions within the plating bath. This means that metal ions are more readily reduced and deposited onto the cathode (the part being plated). Higher temperatures increase the mobility of ions in the solution, allowing for faster deposition.

However, excessively high temperatures can have negative consequences. It can lead to increased hydrogen evolution (the release of hydrogen gas, which can cause poor plating quality), increased evaporation of the plating solution, and potential degradation of the plating bath’s components. Finding the optimal temperature is a balancing act, often determined through experimentation and knowledge of the specific plating solution chemistry. The sweet spot is usually determined empirically for the specific bath composition.

Q 3. Describe the different types of plating solutions and their applications.

Plating solutions are tailored to the specific metal being deposited and the desired properties of the final coating. Some common types include:

- Cyanide baths: Often used for plating precious metals like gold, silver, and cadmium. They offer good throwing power (ability to plate uniformly on complex shapes) but are highly toxic and require careful handling and disposal.

- Acid baths: Commonly used for plating metals like nickel, copper, and chromium. They generally provide faster plating rates and better control over the plating process than cyanide baths but may have limitations in throwing power.

- Sulfate baths: Used for a variety of metals, including nickel, copper, and zinc. They’re often preferred for their lower toxicity compared to cyanide baths and good throwing power.

- Chloride baths: Employed for metals like gold and tin. They’re known for their brightness and are sometimes preferred for electronic applications.

- Alkaline baths: Used for plating zinc and other metals. They provide good throwing power and are often less aggressive than acid baths.

The choice of plating solution depends heavily on the application. For example, a cyanide gold bath might be used for jewelry due to its excellent corrosion resistance and decorative qualities, while an acid copper bath might be selected for printed circuit boards for its conductivity and solderability.

Q 4. How do you control the pH of a plating bath?

pH control is critical for maintaining the optimal performance of a plating bath. The pH affects the solubility of metal ions, the rate of plating reactions, and the overall quality of the deposited metal. Deviation from the ideal pH can lead to poor plating, such as roughness, pitting, or reduced efficiency.

pH is controlled by the addition of acids or bases. For example, if the pH is too high (alkaline), an acid like sulfuric acid can be added to lower it. Conversely, if the pH is too low (acidic), a base like sodium hydroxide can be added to raise it. Regular monitoring using a pH meter is crucial, along with careful additions of acid or base to achieve and maintain the desired pH range. Automatic pH control systems are often employed in industrial electroplating settings to ensure consistent and reliable plating quality.

Q 5. What are the common causes of pitting in electroplating?

Pitting, the formation of small holes or cavities in the plating, is a common defect with several possible causes:

- Impurities in the plating solution: Contaminants like dust, grease, or other metallic ions can interfere with the uniform deposition of metal, leading to pitting.

- Poor surface preparation: An inadequately cleaned or prepared substrate can result in localized areas where plating does not adhere properly, leading to pits.

- Uneven current distribution: If the current density is not uniform across the surface, some areas may receive insufficient metal deposition resulting in pits.

- Gas evolution: Hydrogen evolution at the cathode can sometimes lead to the formation of pits, especially at high current densities.

- Insufficient agitation: Poor mixing of the plating solution can cause localized depletion of metal ions leading to pits.

Preventing pitting requires meticulous attention to detail, including thorough surface preparation, regular filtration of the plating bath, proper control of current density, and adequate agitation. Identifying the root cause is key to effective remediation.

Q 6. Explain the importance of pre-treatment processes in plating.

Pre-treatment processes are essential for ensuring a strong bond between the plating and the substrate. They remove contaminants, imperfections, and oxides from the surface, creating a clean and receptive surface for plating. This leads to better adhesion, improved plating quality, and longer-lasting coatings.

Common pre-treatment steps include:

- Cleaning: Removing oils, greases, and other contaminants using solvents, detergents, or alkaline cleaners.

- Degreasing: Employing solvents or electrolytic methods to remove stubborn oily residues.

- Pickling: Using acid solutions to remove oxides and other surface impurities.

- Activation: Treating the surface to improve its receptivity to the plating process. For example, this might involve a brief immersion in an acid solution.

Think of it like preparing a wall before painting. You wouldn’t paint directly onto a dirty, dusty wall, right? Similarly, proper surface preparation in plating ensures a smooth, even, and durable finish.

Q 7. How do you measure and control the concentration of plating solution components?

Measuring and controlling the concentration of plating solution components is vital for maintaining consistent plating quality and efficiency. Different methods are used depending on the specific component.

Methods include:

- Titration: A widely used chemical method to determine the concentration of specific ions in the solution.

- Spectrophotometry: Measures the absorbance of light by the solution to determine the concentration of certain components.

- Atomic Absorption Spectroscopy (AAS): A highly sensitive technique for determining the concentration of metal ions.

- Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES): Another highly sensitive technique for determining the concentration of multiple elements in the solution.

Concentration control often involves adding fresh chemicals to replenish depleted components and maintaining the desired concentrations. Regular analysis and adjustment are crucial for optimal plating performance and consistent quality.

Q 8. What are the safety precautions involved in handling plating chemicals?

Handling plating chemicals requires meticulous safety precautions due to their potential toxicity and corrosiveness. Think of them like handling strong acids or bases in a chemistry lab – extreme care is essential.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves (nitrile or neoprene are preferred), safety glasses or goggles, a lab coat, and sometimes a respirator, depending on the chemicals involved. Never underestimate the importance of eye protection – a splash of chromic acid, for example, can cause serious damage.

- Ventilation: Plating processes often generate harmful fumes. Ensure adequate ventilation in the plating area, ideally using a dedicated exhaust system. Working in a well-ventilated space is crucial to prevent inhalation of hazardous vapors.

- Spill Procedures: Develop and practice spill response plans. Know how to neutralize spills safely using appropriate materials and dispose of them properly, following all local and national regulations. Spills should never be taken lightly.

- Proper Handling and Storage: Chemicals should be stored in their original containers, properly labeled and in a designated area away from incompatible substances. Follow the manufacturer’s safety data sheets (SDS) diligently. Mixing the wrong chemicals can lead to dangerous reactions.

- Emergency Procedures: Familiarize yourself with emergency procedures, including eye washes, safety showers, and contacting emergency services in case of accidents. Be aware of the location and proper use of all safety equipment.

Remember, safety is paramount in electroplating. A moment of carelessness can lead to serious consequences. Always prioritize safety and adhere to established safety protocols.

Q 9. Describe the different types of anodes used in electroplating.

The choice of anode in electroplating is critical as it dictates the metal being deposited and influences the plating process’s efficiency and quality. Think of the anode as the source of the metal ions that will be plated onto the cathode (the part being plated).

- Insoluble Anodes: These anodes, such as lead, graphite, or platinum, don’t dissolve into the plating bath. They act primarily as current conductors and oxygen evolution occurs at their surface. They are often used in processes where the metal ions are replenished by adding metal salts to the solution. Lead anodes are commonly used in chromic acid plating, for instance.

- Soluble Anodes: These anodes, made of the same metal being deposited (e.g., a copper anode for copper plating), dissolve into the plating bath, replenishing the metal ions as they are consumed during plating. This ensures a consistent concentration of metal ions in the solution and provides a more stable plating process. For example, a nickel anode is used in nickel plating baths.

The selection of an anode type depends on the specific plating process and the desired characteristics of the plated layer. An insoluble anode might be chosen for its cost-effectiveness or resistance to corrosion, while a soluble anode is preferred for maintaining a stable plating bath composition.

Q 10. How do you troubleshoot a plating bath with low plating efficiency?

Low plating efficiency in an electroplating bath means that less metal is being deposited than expected for the given amount of current passed. It’s like getting less mileage than promised from a car – something’s not working efficiently.

Troubleshooting low plating efficiency involves a systematic approach:

- Check the bath composition: Ensure the correct concentrations of metal salts, additives, and pH are maintained. Deviation from optimal concentrations can drastically reduce efficiency. Analyze the bath using standard analytical techniques to verify the concentrations.

- Assess the anode condition: A poorly maintained or passivated anode can hinder efficient metal ion generation. Clean the anode and ensure proper contact with the electrical circuit. In the case of soluble anodes, check for the appropriate dissolution rate.

- Inspect the cathode surface: A dirty or poorly prepared cathode surface can lead to poor adhesion and lower efficiency. The surface must be thoroughly cleaned and pre-treated before plating. Insufficient cleaning can impede the deposition process.

- Examine the current density: Too high or too low current density can negatively impact efficiency. Optimize current density for the specific plating bath and the geometry of the part being plated. Using a higher current density may increase the plating speed but could decrease the quality. A lower current density could increase quality but decreases the plating speed.

- Analyze the bath temperature: The temperature significantly influences the plating process. Maintain the specified temperature range. Temperature deviations often lead to defects and reduce efficiency.

- Check for impurities: Impurities in the plating bath can inhibit the deposition process. Regularly filter the bath to remove particulate matter and consider purifying the bath if contamination is suspected. Impurities can either come from the materials themselves or be introduced from the environment.

By systematically investigating these aspects, you can identify and rectify the cause of low plating efficiency, restoring the bath to its optimal performance. Remember to record all measurements and observations for future reference.

Q 11. Explain the concept of throwing power in electroplating.

Throwing power in electroplating refers to the ability of a plating bath to produce a uniform coating thickness on a complex-shaped workpiece, even in areas that are difficult to reach or have varying current densities. Imagine painting a house – good throwing power means you get even coverage even in hard-to-reach corners.

Good throwing power is essential for achieving consistent plating quality across the entire surface of the part. It is influenced by several factors:

- Bath Composition: The type and concentration of additives in the plating bath significantly affect throwing power. Certain additives enhance throwing power by reducing the polarization at the cathode, enabling uniform deposition.

- Current Density: Lower current densities generally improve throwing power. However, very low current densities can result in slower deposition rates.

- Geometry of the Workpiece: The shape and size of the workpiece play a role. Parts with deep recesses or sharp edges may experience less uniform plating. Consider using fixtures or other methods to improve the uniformity of the electric field.

- Bath Conductivity: Higher bath conductivity generally leads to better throwing power. Conductivity can be affected by temperature and the concentration of ions.

Understanding and controlling the factors that affect throwing power is crucial for achieving high-quality, uniform electroplated coatings on complex parts. Optimization of throwing power is a key consideration in electroplating process development and industrial applications.

Q 12. How do you control the brightness of a plated surface?

Controlling the brightness of a plated surface is a critical aspect of electroplating, affecting both the aesthetics and the corrosion resistance of the plated layer. Brightness is often achieved by manipulating the plating bath’s composition and operating parameters.

Several methods are used to control brightness:

- Brighteners: These are organic additives introduced into the plating bath to enhance the brightness of the deposited metal. They work by modifying the crystal structure of the deposited layer, leading to a smoother and more reflective surface. The type and concentration of brighteners are carefully chosen based on the plating metal and the desired level of brightness.

- Current Density: The current density applied to the cathode can influence the brightness of the deposit. Often, a specific range of current densities is needed to achieve optimal brightness. Too high or too low current density can lead to dull or burnt deposits.

- Agitation: Agitation of the plating bath, through stirring or air bubbling, promotes uniform deposition and can improve brightness. Agitation helps to eliminate concentration gradients near the cathode, resulting in smoother surface finishing.

- Temperature: The temperature of the plating bath also affects the brightness. Maintaining the optimal temperature range is crucial for ensuring a bright and uniform deposit.

- pH Control: Careful pH control can enhance the brightness of the deposited layer. Deviation from the ideal pH can lead to dull or pitted surfaces.

The precise combination of these factors will determine the final brightness. Experience and careful experimentation are crucial for optimizing brightness in a particular electroplating process.

Q 13. What are the common defects encountered in electroplating and their causes?

Electroplating, while a precise process, is prone to several defects. These defects can significantly affect the quality and performance of the plated layer. Identifying the cause of these defects is crucial for corrective action.

- Pitting: Small holes or depressions in the plated surface. Causes include impurities in the plating bath, poor surface preparation of the workpiece, or insufficient agitation.

- Burning: A dark, unevenly deposited area, usually caused by excessively high current density.

- Nodules: Small, protruding bumps on the surface, often caused by excessive current density or impurities.

- Treeing: A dendritic or fern-like growth on the surface, resulting from high current density or contaminated solutions.

- Roughness: An uneven, textured surface, due to poor surface preparation, high current density, or improper bath composition.

- Blistering: Formation of blisters or bubbles under the plated layer, typically caused by trapped hydrogen or other gases.

- Poor Adhesion: The plated layer separates or peels off from the substrate, usually caused by inadequate surface preparation, or incompatibility between the substrate and the plating metal.

Careful attention to bath composition, surface preparation, current density, and operating parameters is vital in preventing these defects and ensuring high-quality electroplating.

Q 14. Describe the process of stripping a plated layer.

Stripping a plated layer involves removing the deposited metal from the substrate. This is often necessary for rework, analysis, or reclaiming valuable metals. The process is essentially the reverse of plating, but the choice of stripping method depends on the plated metal and the substrate material.

Several methods are used for stripping:

- Chemical Stripping: This involves immersing the plated part in a chemical solution that dissolves the plated metal. The choice of stripping solution depends on the plated metal; for instance, a cyanide-based solution might be used to strip silver or copper, while other solutions are used for other metals. Safety precautions are paramount here; these solutions are typically highly corrosive.

- Electrochemical Stripping: This method involves using an electrochemical cell to remove the plated metal. The plated part is made the anode and current is passed through the cell. The plated metal dissolves and goes into the solution. This method is more controlled than chemical stripping and allows for more precise removal.

- Mechanical Stripping: This method uses abrasive techniques such as grinding, sanding, or blasting to remove the plated layer. It is suitable for thicker coatings and is less precise than chemical or electrochemical methods but doesn’t necessarily require specialized chemical solutions.

Choosing the right stripping method requires careful consideration of the plated metal, the substrate, and the desired level of precision. Safety is always a major concern when working with stripping solutions, so appropriate PPE and handling procedures should always be followed.

Q 15. What are the environmental considerations in electroplating?

Electroplating, while offering numerous benefits, presents significant environmental challenges. The primary concern revolves around the hazardous nature of the chemicals used in plating baths. These often include heavy metals like chromium, nickel, cadmium, and cyanide, which are highly toxic and can contaminate water sources if not properly managed. Another issue is the generation of wastewater containing these heavy metals and other byproducts. This wastewater requires careful treatment before disposal to prevent environmental damage. Furthermore, the energy consumption associated with the electroplating process contributes to greenhouse gas emissions. Responsible electroplating operations must adhere to strict environmental regulations, implement waste minimization strategies (like using less toxic chemicals and recycling bath solutions), and invest in wastewater treatment technologies to mitigate these environmental impacts.

For example, a chromium plating facility might employ a closed-loop system to minimize the amount of chromium-containing wastewater generated. They might also use advanced treatment methods, like ion exchange or reverse osmosis, to remove chromium from wastewater before discharge.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the quality of a plating bath over time?

Maintaining a plating bath’s quality over time is crucial for consistent plating results. This involves regular monitoring and adjustment of key parameters. These parameters include the concentration of the metal ions (e.g., nickel, copper), pH level, conductivity, and the concentration of additives like brighteners and leveling agents. Regular analysis using techniques like atomic absorption spectroscopy (AAS) or inductively coupled plasma optical emission spectrometry (ICP-OES) is necessary to track the concentrations of these components.

As the plating process continues, metal ions are depleted from the bath and impurities accumulate. To maintain the bath’s quality, you need to replenish the metal ions with fresh plating salts, and periodically remove impurities through filtration or other purification methods. Regularly adjusting the pH and other parameters ensures optimal plating performance. Failing to maintain the bath can lead to poor plating quality, such as dull finishes, pitting, or reduced adhesion.

Think of it like baking a cake: you need to follow the recipe precisely and use fresh ingredients. If you neglect this, the final product will be compromised. Similarly, if you don’t maintain your plating bath, the quality of your plated parts will suffer.

Q 17. Explain the difference between electroplating and electroless plating.

Electroplating and electroless plating are both techniques used to deposit a metallic layer onto a substrate, but they differ significantly in their mechanisms. Electroplating utilizes an electric current to drive the deposition process. The substrate acts as the cathode (negative electrode) in an electrolytic cell, and the metal to be plated is dissolved from the anode (positive electrode) and deposited onto the cathode. A direct current (DC) power source is essential.

In contrast, electroless plating is an autocatalytic process that doesn’t require an external electric current. Instead, it relies on a chemical reducing agent to reduce metal ions in the solution to their metallic form, causing them to deposit onto the substrate. The substrate’s surface acts as a catalyst for this chemical reaction. Electroless plating is often used for applications where uniform coating is critical, even in intricate parts.

Imagine electroplating like painting with an electrically charged brush, where the electricity pushes the paint (metal) onto the surface. Electroless plating is more akin to a chemical reaction where the metal spontaneously deposits on the surface, coating even complex geometries equally well.

Q 18. What are the advantages and disadvantages of different plating metals?

Different plating metals offer unique advantages and disadvantages depending on the application’s specific requirements.

- Chrome: Offers excellent corrosion resistance, hardness, and a shiny finish. However, it is toxic and requires careful handling.

- Nickel: Provides good corrosion resistance, ductility, and can be easily polished. It’s often used as an undercoat for other metals.

- Copper: Excellent electrical conductivity, easily plated, and relatively inexpensive. It can be easily corroded if not protected by a topcoat.

- Gold: Outstanding corrosion resistance, excellent electrical conductivity, and highly inert. It’s expensive.

- Silver: High electrical conductivity and reflectivity, but susceptible to tarnishing.

The choice of plating metal depends on factors such as the desired properties (corrosion resistance, conductivity, aesthetics), cost considerations, and environmental regulations. For example, a decorative part might be plated with chrome for its shine and corrosion resistance, while a circuit board might use gold for its excellent conductivity.

Q 19. How do you determine the appropriate plating thickness for a given application?

Determining the appropriate plating thickness hinges on the specific application’s demands. The required thickness is dictated by the functional and aesthetic requirements of the part. For corrosion protection, a thicker plating layer offers greater resistance. For electrical conductivity, a thinner layer might suffice. In decorative applications, the desired aesthetic qualities, like the shine of chrome, determine the appropriate thickness.

Industry standards and specifications often provide guidelines for minimum plating thicknesses for various applications. For instance, a certain minimum thickness might be specified for a part exposed to harsh environmental conditions to ensure adequate corrosion protection. Calculating the precise thickness often involves considering factors like the substrate material, the plating metal, the expected service life, and the anticipated environmental conditions. Testing and simulations can help refine the estimated thickness.

Imagine needing to coat a pipe to prevent rust. A thin layer might work for indoor use, but a significantly thicker coat would be necessary if the pipe is outside and exposed to harsh weather. The same applies to determining plating thickness for any part.

Q 20. Describe the different types of plating equipment and their functions.

Electroplating equipment varies depending on the scale of operation and the specific plating process. Common components include:

- Plating tanks: These vessels hold the plating bath and the parts to be plated. Materials like polypropylene or stainless steel are often used.

- Rectifiers: These DC power supplies provide the current needed for electroplating. Their capacity depends on the size of the plating tank and the current density required.

- Heating and cooling systems: Maintaining the optimal bath temperature is crucial for consistent plating quality. Heaters and chillers control the temperature.

- Filtration systems: These remove impurities and solid particles from the plating bath, maintaining its quality.

- Agitation systems: These ensure uniform distribution of metal ions and additives within the plating bath, resulting in a more uniform coating.

- Anodes: These are made of the plating metal and dissolve during the process, replenishing the metal ions in the bath.

Larger-scale commercial plating operations may incorporate automated systems for handling parts, controlling parameters, and monitoring the plating process. Small-scale operations may utilize simpler, manually controlled setups.

Q 21. How do you perform a quality control check on a plated part?

Quality control checks on plated parts are essential to ensure they meet the required specifications. These checks typically involve visual inspection for defects like pitting, porosity, or uneven coating. Furthermore, measurements of plating thickness are performed using techniques like magnetic thickness gauges, microscopes, or X-ray fluorescence spectroscopy. These techniques measure the thickness of the plated layer to ensure it meets the predetermined standards. Adhesion tests can also be performed to assess how well the plating layer adheres to the substrate. This is vital as poor adhesion can lead to premature failure of the part.

In addition to these physical tests, corrosion resistance tests might be performed to evaluate the plating’s ability to protect the underlying substrate from corrosion. This could involve salt spray testing or other accelerated corrosion tests. The specific tests conducted depend on the application’s requirements and the plating metal used. Regular quality control checks help identify any problems early on, allowing for timely adjustments to the plating process.

Imagine building a car. You wouldn’t just assemble parts without checking for quality. Similarly, performing quality control checks is essential in electroplating to ensure the final product meets the required specifications.

Q 22. Explain the role of additives in plating solutions.

Additives in plating solutions are crucial for controlling the plating process and improving the quality of the deposited layer. They aren’t just there to make things work; they’re carefully chosen to fine-tune the process for specific results. Think of them as the secret ingredients in a perfect recipe. These additives can influence several key aspects of the plating process.

- Brightness agents: These improve the smoothness and reflectivity of the plated surface. Imagine the difference between a dull, matte finish and a brilliantly shiny one – that’s the work of brightness agents. They often work by altering the crystal growth habit of the metal deposit.

- Stress reducers: Internal stresses can build up in the plated layer, potentially causing cracking or peeling. Stress reducers help to minimize these stresses, leading to a more durable and stable coating.

- Levelers: These additives promote uniform thickness across the plated part, particularly in areas with complex geometries. Without levelers, thicker deposits might form in recesses, while high points remain thin.

- Carriers: Some additives serve as carriers for other components, improving their solubility or distribution in the plating bath.

- Buffers: Buffers help to maintain the pH of the plating bath within a stable range, crucial for consistent and reliable plating results. A change in pH can drastically alter the plating process.

For example, in nickel plating, saccharin is a common brightness agent, while certain organic compounds act as levelers. The precise choice of additives depends heavily on the desired properties of the plated layer and the specific metal being deposited.

Q 23. What are the different methods for analyzing plating solutions?

Analyzing plating solutions is critical for maintaining consistent plating quality. Regular analysis helps identify potential problems before they significantly impact production. Several methods are employed, each targeting different aspects of the solution’s composition.

- Titration: This classic chemical technique determines the concentration of specific components, such as metal ions. For example, we might titrate to determine the concentration of nickel ions in a nickel sulfamate bath.

- Spectrophotometry: This method uses light absorption to measure the concentration of certain substances. It’s particularly useful for determining the concentration of organic additives, which are often difficult to analyze by other methods.

- Atomic Absorption Spectroscopy (AAS): AAS is a very sensitive technique for measuring the concentration of metal ions. It provides highly accurate data on the metal content of the bath. It’s indispensable for monitoring metal ion depletion during the plating process.

- pH Measurement: Simple yet essential, pH measurement ensures the plating bath is within the optimal range for consistent plating. A simple pH meter is used for this measurement.

- Conductivity Measurement: This indicates the overall ionic strength of the solution, providing an indirect measure of the total dissolved solids. Changes in conductivity can indicate the buildup of impurities or depletion of key components.

The choice of analytical methods depends on the specific plating process and the information needed. Often, a combination of techniques is used to provide a comprehensive analysis.

Q 24. How do you calculate the plating time required to achieve a specific thickness?

Calculating plating time requires understanding Faraday’s Law of Electrolysis, which relates the amount of metal deposited to the current, time, and metal’s electrochemical equivalent. The basic formula is:

Thickness (in µm) = (Current Density (A/dm²) * Plating Time (s) * Atomic Weight (g/mol) ) / (Valency * Density (g/cm³) * 96485 (C/mol))Let’s break this down:

- Thickness: The desired thickness of the plated layer.

- Current Density: The amount of current applied per unit area of the workpiece (usually expressed in Amperes per square decimeter).

- Plating Time: The duration of the plating process (in seconds).

- Atomic Weight: The atomic weight of the plating metal (found on a periodic table).

- Valency: The number of electrons transferred per metal ion in the plating reaction.

- Density: The density of the plating metal.

- 96485 (C/mol): Faraday’s constant.

Example: To deposit a 25 µm thick layer of nickel (Atomic Weight = 58.7 g/mol, Density = 8.9 g/cm³, Valency = 2) at a current density of 2 A/dm², we’d rearrange the formula to solve for plating time:

Plating Time (s) = (Thickness * Valency * Density * 96485) / (Current Density * Atomic Weight)Substituting the values, we get the required plating time. Remember that this is a simplified calculation; factors like current efficiency (the percentage of current actually contributing to plating) can influence the actual time needed.

Q 25. Describe the impact of agitation on plating uniformity.

Agitation plays a vital role in ensuring uniform plating. It’s like stirring a pot of soup – without proper mixing, you end up with uneven seasoning. Similarly, in electroplating, without agitation, the metal ions near the surface of the workpiece get depleted quickly, leading to uneven plating thickness.

Benefits of Agitation:

- Improved Uniformity: Agitation ensures a continuous supply of metal ions to the cathode (workpiece), preventing depletion and promoting a uniform thickness across the entire surface.

- Increased Plating Rate: A constant supply of fresh metal ions means a higher rate of deposition.

- Reduced Pitting and Nodules: Agitation minimizes the formation of pits and nodules, resulting in a smoother surface finish.

- Better Dispersion of Additives: Agitation ensures that additives are evenly distributed throughout the plating bath, allowing them to function effectively across the entire surface of the workpiece.

Methods of Agitation: Various methods exist, including air agitation, mechanical stirring, and solution filtration. The choice depends on the plating solution, tank size, and the desired level of uniformity. Insufficient agitation can lead to poor-quality plating, while excessive agitation can cause problems such as the inclusion of air bubbles in the deposit.

Q 26. What are the different types of plating racks and their selection criteria?

Plating racks are essential for holding parts during the electroplating process. They need to be carefully chosen to ensure uniform plating and prevent damage to the parts. Different types of racks cater to various needs and geometries.

- Barrel Plating Racks: These are used for small, similar-shaped parts, such as screws or nuts. The parts are loaded into a rotating barrel, which ensures they are evenly exposed to the plating solution.

- Hook-Type Racks: Individual parts are hung from hooks on a rack. This is suitable for larger, irregularly shaped items that need individual attention.

- Tray-Type Racks: Parts are placed in trays, which are then immersed in the plating solution. This is a simple method for plating many similar parts.

- Jigs: These are customized racks designed for specific parts, ensuring optimal contact and uniform plating. They are particularly useful for intricate or large components.

Selection Criteria:

- Part Geometry: The rack should be designed to hold the parts securely and ensure even plating across all surfaces.

- Material Compatibility: The rack material shouldn’t react with the plating solution or cause contamination.

- Conductivity: The rack material should be electrically conductive to allow for efficient current transfer.

- Ease of Loading/Unloading: The design should allow for efficient loading and unloading of parts.

- Durability: The rack must withstand the repeated use and harsh conditions of the plating process.

Improper rack selection can lead to uneven plating, short circuits, or damage to the parts.

Q 27. How would you address a problem with poor adhesion of the plated layer?

Poor adhesion of the plated layer is a serious problem. A poorly adhered coating will quickly peel or flake off, rendering the plating process ineffective. Addressing this issue requires a systematic approach.

Troubleshooting Steps:

- Surface Preparation: This is the most critical step. The substrate must be thoroughly cleaned to remove any oils, oxides, or other contaminants that could hinder adhesion. Methods include degreasing, acid etching, and mechanical polishing. Insufficient cleaning is a frequent cause of poor adhesion.

- Pre-plating Treatments: Pre-plating treatments, such as electroless nickel plating or zincate immersion, can improve the bonding between the substrate and the plating layer. These treatments often help to create a more receptive surface for the subsequent plating.

- Plating Solution Analysis: Problems within the plating bath, such as impurities or incorrect pH, can affect adhesion. Regular analysis is crucial to identify and rectify such issues.

- Plating Parameters: Incorrect plating parameters, such as current density or temperature, can lead to poor adhesion. Optimizing these parameters is essential for achieving a strong bond.

- Substrate Material: The compatibility of the substrate material with the plating process should be considered. Some materials might require special surface treatments to ensure good adhesion.

Each of these aspects should be carefully examined when troubleshooting poor adhesion. A thorough investigation, often involving microscopic examination of the interface between the substrate and the plated layer, is necessary to pinpoint the exact cause.

Q 28. Explain the importance of proper waste management in electroplating.

Proper waste management in electroplating is not just an environmental responsibility; it’s essential for maintaining a safe and compliant operation. Electroplating generates various hazardous wastes, including heavy metal-containing solutions, spent chemicals, and sludge.

Importance of Proper Waste Management:

- Environmental Protection: Heavy metals and other chemicals in electroplating waste can contaminate soil and water sources, causing harm to ecosystems and human health. Proper waste management helps to minimize environmental impact.

- Legal Compliance: Strict regulations govern the discharge and disposal of electroplating waste. Failure to comply can lead to heavy fines and legal repercussions.

- Worker Safety: Many electroplating chemicals are toxic, posing risks to workers. Proper handling and disposal procedures are vital to protecting worker health and safety.

- Cost Savings: Efficient waste management can reduce disposal costs and improve the overall efficiency of the operation. Recycling or reclaiming valuable materials from waste is a cost-effective strategy.

Waste Management Strategies: Strategies include:

- Waste Minimization: Implementing process improvements to reduce the generation of waste in the first place.

- Recycling and Reclamation: Recovering valuable metals and chemicals from spent solutions.

- Treatment: Treating waste solutions to remove or reduce the concentration of hazardous substances before disposal.

- Proper Disposal: Disposing of waste in accordance with all applicable regulations and using licensed waste disposal facilities.

A comprehensive waste management plan, including proper training for workers, is crucial for responsible and safe electroplating practices.

Key Topics to Learn for Understanding of Plating Parameters Interview

- Electrolyte Composition and its Impact: Understand the role of different ions, additives, and their concentration on plating quality, efficiency, and deposit properties. Explore the theoretical principles behind conductivity, throwing power, and current efficiency.

- Current Density and its Effects: Learn how current density influences plating rate, deposit structure (e.g., fine-grained vs. coarse-grained), and stress development. Discuss practical applications of varying current density for specific plating applications.

- Temperature Control and its Significance: Analyze the impact of temperature on reaction kinetics, plating rate, and deposit morphology. Understand how to control temperature effectively and its implications for process optimization and consistency.

- pH Control and its Influence: Explore the importance of pH in maintaining the stability of the electrolyte and its effect on plating efficiency, deposit quality, and overall process control. Discuss methods for pH adjustment and monitoring.

- Agitation and its Role: Understand the effects of different agitation methods (e.g., air agitation, mechanical agitation) on mass transport, uniformity of the deposit, and overall plating efficiency. Discuss practical considerations for choosing appropriate agitation techniques.

- Troubleshooting Common Plating Issues: Develop problem-solving skills to address common issues such as pitting, burning, poor adhesion, and variations in plating thickness. Learn to identify root causes and implement corrective actions.

- Safety Precautions and Environmental Considerations: Familiarize yourself with safety protocols related to handling chemicals, electrical equipment, and waste disposal in plating processes. Understand the environmental regulations and best practices for responsible plating operations.

Next Steps

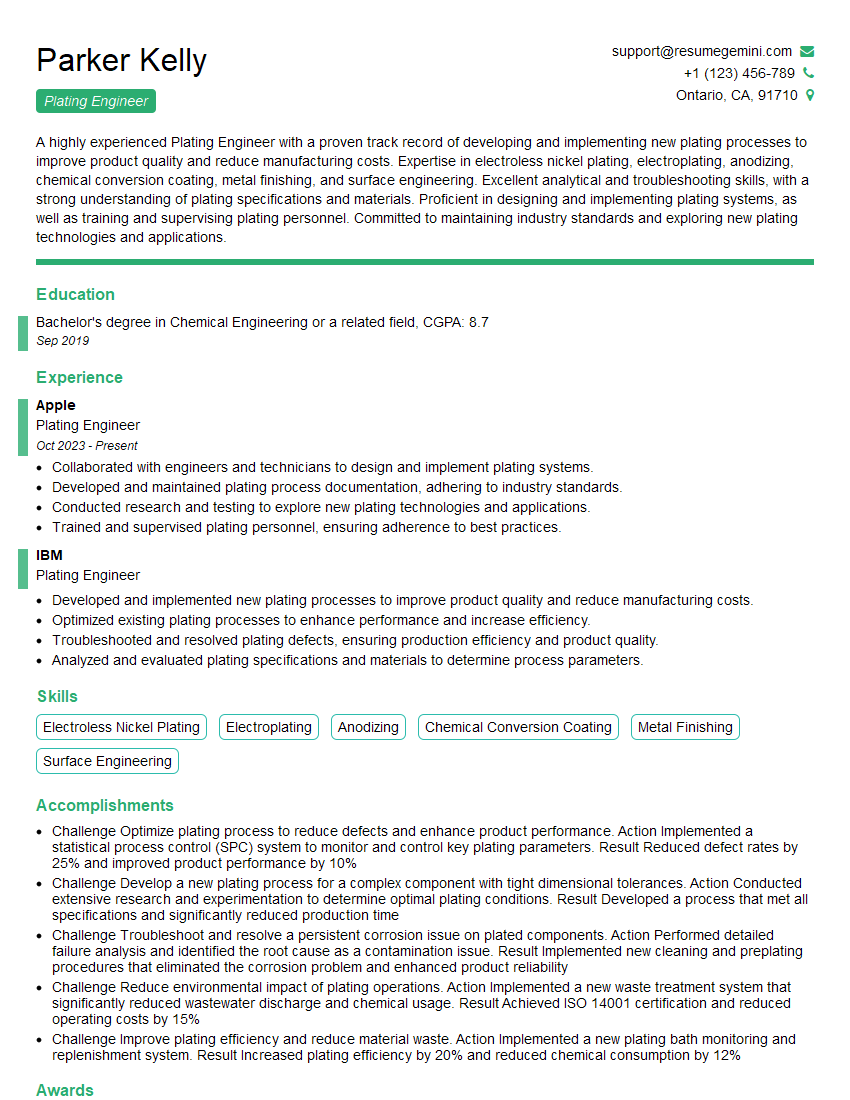

Mastering the understanding of plating parameters is crucial for career advancement in materials science, manufacturing, and related fields. A strong grasp of these concepts demonstrates your technical expertise and problem-solving abilities, making you a highly desirable candidate. To elevate your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Understanding of Plating Parameters to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good