Preparation is the key to success in any interview. In this post, we’ll explore crucial Maintain inventory of equipment and materials interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Maintain inventory of equipment and materials Interview

Q 1. Explain the different inventory management methods you are familiar with (FIFO, LIFO, etc.).

Inventory management methods dictate how the cost of goods sold and the value of remaining inventory are calculated. Different methods impact financial statements and tax liabilities. Here are some common ones:

- FIFO (First-In, First-Out): This assumes that the oldest items in your inventory are sold first. Imagine a bakery – the oldest croissants are sold before the freshly baked ones. This method generally results in a higher net income during periods of inflation because the cost of goods sold is lower (older, cheaper items).

- LIFO (Last-In, First-Out): This method assumes the newest items are sold first. Think of a stack of plates – you’d use the top ones first. LIFO results in a lower net income during inflation because the cost of goods sold is higher (newer, more expensive items). It’s less commonly used now due to tax regulations in many countries.

- Weighted-Average Cost: This method calculates the average cost of all items in inventory and assigns that average cost to each item sold. It simplifies calculations but may not reflect the true cost of goods sold as accurately as FIFO or LIFO.

- Specific Identification: This method tracks the cost of each individual item. It’s ideal for high-value, unique items like jewelry or specialized equipment, but can be cumbersome for large inventories.

The choice of method depends on factors like industry regulations, tax implications, and the nature of the inventory itself. For example, a grocery store might use FIFO for perishable goods, while a hardware store might use weighted-average cost for nuts and bolts.

Q 2. How do you track inventory levels accurately?

Accurate inventory tracking is crucial for efficient operations. It involves a multi-pronged approach:

- Regular Stock Takes (Physical Counts): Manually counting items at regular intervals provides a snapshot of what’s physically present. This is essential for identifying discrepancies and verifying data accuracy.

- Barcode/RFID Scanning: Using barcodes or RFID tags on items and integrating them with a scanning system significantly speeds up the counting process and reduces human error. Real-time data updates offer immediate visibility into inventory levels.

- Inventory Management Software: Software solutions automate many processes, including tracking incoming and outgoing items, generating reports, and setting alerts for low stock levels. They provide a centralized database ensuring consistency and reducing manual data entry errors.

- Cycle Counting: Instead of a complete stocktake, this involves regularly counting smaller sections of your inventory. It’s a more efficient way to maintain accuracy over time (discussed further in answer 7).

- Point of Sale (POS) Integration: Linking your inventory system to your POS system provides real-time updates on sales and reduces the chances of discrepancies arising from sales not being properly reflected in inventory records.

Combining these methods provides a robust system for accurate inventory tracking. For example, I’ve implemented a system using barcode scanning integrated with inventory software, along with monthly cycle counts, to maintain inventory accuracy within a 1% margin of error.

Q 3. Describe your experience with inventory software and systems.

I’ve extensive experience with various inventory management systems, both cloud-based and on-premise. I am proficient in software such as Fishbowl Inventory, Zoho Inventory, and NetSuite. My experience includes implementing, configuring, and training staff on these systems. In my previous role, I oversaw the migration from a spreadsheet-based system to a cloud-based solution, which dramatically improved efficiency and reduced errors. This involved data migration, user training, and ongoing system optimization. I’m comfortable working with various functionalities, including:

- Demand forecasting: Using historical data to predict future demand.

- Automated ordering: Setting reorder points and automatically generating purchase orders.

- Reporting and analytics: Generating reports on inventory levels, turnover rates, and other key metrics.

- Integration with other systems: Connecting the inventory system with ERP, accounting, and e-commerce platforms.

My experience extends to customizing reports and workflows to meet specific business needs. I understand the importance of selecting the right software based on the scale and complexity of the inventory, the company’s IT infrastructure, and budget constraints.

Q 4. What are the key performance indicators (KPIs) you use to measure inventory performance?

Several KPIs are crucial for assessing inventory performance. These provide insights into areas needing improvement. Here are some key ones:

- Inventory Turnover Rate: This shows how many times inventory is sold and replaced over a period. A higher turnover rate generally indicates efficient inventory management.

Inventory Turnover = Cost of Goods Sold / Average Inventory Value - Days of Inventory on Hand (DOH): This metric represents the average number of days it takes to sell existing inventory. Lower DOH is typically better, indicating faster sales and reduced storage costs.

DOH = (Average Inventory / Cost of Goods Sold) * Number of Days - Stockout Rate: The percentage of times an item is out of stock when demanded. A low stockout rate indicates effective inventory planning.

- Holding Cost: The total cost associated with storing inventory, including warehousing, insurance, and obsolescence. Minimizing this cost is a key goal.

- Inventory Accuracy: The percentage of inventory records that match the physical count. High accuracy reflects a well-managed system.

By monitoring these KPIs regularly, I can identify trends, pinpoint areas needing attention, and make data-driven decisions to optimize inventory management. For example, a consistently low inventory turnover rate might indicate overstocking of certain items, prompting a review of forecasting accuracy and sales strategies.

Q 5. How do you handle inventory discrepancies?

Inventory discrepancies—differences between recorded inventory and physical counts—require a systematic approach to investigation and resolution:

- Identify the Discrepancy: Start by pinpointing the specific items or areas where discrepancies exist. Review stocktake data, software records, and any relevant transaction records.

- Investigate the Cause: Determine the root cause. Possible reasons include data entry errors, theft, damage, misplacement, or inaccurate counting procedures. Involve relevant staff in the investigation.

- Adjust Records: Once the cause is identified and confirmed, adjust inventory records to reflect the actual physical count. This might involve writing off damaged or lost goods.

- Implement Corrective Actions: Address the root cause to prevent future discrepancies. This may involve improving data entry procedures, enhancing security measures, or providing additional training for staff involved in inventory management.

- Documentation: Maintain thorough documentation of the entire process, including the discrepancy, the investigation, the corrective actions, and the final resolution.

For example, if a significant discrepancy was due to a faulty barcode scanner, I would replace the scanner and conduct a recount of the affected inventory to ensure accuracy. A thorough investigation ensures discrepancies are resolved efficiently and prevent future errors.

Q 6. How do you prevent stockouts and overstocking?

Preventing stockouts and overstocking requires a proactive approach integrating forecasting, demand planning, and effective inventory management techniques:

- Accurate Demand Forecasting: Using historical data, market trends, and sales forecasts to predict future demand. This forms the basis for ordering decisions.

- Safety Stock Levels: Maintaining a buffer of inventory to account for unexpected demand spikes or supply chain disruptions. The optimal safety stock level depends on factors like lead time and demand variability.

- Reorder Points: Setting trigger points for reordering inventory. This ensures that orders are placed before stock levels fall too low, preventing stockouts.

- Economic Order Quantity (EOQ): Calculating the optimal order quantity that minimizes total inventory costs, considering ordering costs and holding costs.

- Regular Inventory Reviews: Periodically reviewing inventory levels, sales data, and forecasting accuracy to identify potential issues and adjust strategies as needed.

- Supplier Relationship Management: Establishing strong relationships with suppliers to ensure reliable supply and timely delivery.

A combination of these techniques allows for a balanced inventory strategy, minimizing the risk of both stockouts and overstocking. For example, in a previous role, we implemented a new forecasting model that reduced stockout rates by 15% while simultaneously decreasing inventory holding costs by 10%.

Q 7. Explain your experience with cycle counting.

Cycle counting is a more efficient inventory management technique compared to a full annual stocktake. It involves counting a small portion of your inventory regularly, rather than everything at once. This approach offers several advantages:

- Improved Accuracy: Counting smaller sections more frequently minimizes the impact of errors and allows for quicker correction.

- Reduced Downtime: Disruption to operations is reduced since only parts of the inventory are counted at any given time.

- Increased Efficiency: Focusing on smaller sections allows for better organization and faster counting.

- Proactive Issue Identification: Regular counts help to identify discrepancies or slow-moving items early on, enabling prompt corrective action.

Typically, a cycle counting schedule is developed based on item criticality, value, and movement frequency. High-value or fast-moving items are counted more often. In my experience, using a cycle counting system combined with barcode scanning increased inventory accuracy to over 99%, significantly reducing the time and resources needed for annual stocktakes. A well-structured cycle counting plan, alongside thorough training, is essential for its success.

Q 8. Describe your process for conducting a physical inventory count.

Conducting a physical inventory count is a crucial process for verifying the accuracy of our inventory records against the actual physical stock. It’s like taking a snapshot of our warehouse at a specific point in time. My process involves several key steps:

- Planning and Preparation: This includes defining the scope (entire warehouse, specific area), scheduling the count (minimizing disruption to operations), assembling a team, and providing them with clear instructions and necessary equipment (barcode scanners, counting sheets, clipboards).

- Team Briefing: Before we start, I ensure everyone understands the counting methodology, location assignments, and the importance of accuracy. We discuss handling discrepancies and reporting procedures.

- Counting and Verification: We use a two-person count system for each location, with one person counting and the other verifying. This minimizes errors. For high-value or sensitive items, we may use additional checks or involve supervisors.

- Data Entry and Reconciliation: Once counted, the data is entered into our inventory management system. This step is meticulously checked for accuracy against the physical count sheets. Any discrepancies are investigated immediately.

- Reporting and Analysis: A final report detailing variances and any identified issues is generated. This report helps us understand where our inventory management needs improvement and informs future strategies.

For example, in a previous role, we implemented a cycle counting system alongside our annual physical inventory. This involved counting a smaller portion of the inventory regularly, making the annual count less daunting and more accurate because we addressed discrepancies more frequently.

Q 9. How do you manage obsolete or damaged inventory?

Managing obsolete or damaged inventory is critical for maintaining efficiency and minimizing losses. My approach is multi-faceted:

- Identification and Categorization: We regularly review our slow-moving or non-moving items. Damage is assessed through regular inspections. Items are categorized as obsolete, repairable, or scrap.

- Disposition Strategies: Obsolete items are evaluated for potential sale (e.g., through online marketplaces or auctions), donation to charity, or responsible disposal according to environmental regulations. Repairable items are sent for repair or refurbishment. Scrap materials are disposed of ethically and sustainably.

- Inventory Write-Downs/Write-offs: We follow proper accounting procedures for writing down or writing off obsolete or damaged inventory, accurately reflecting the loss in our financial records. Proper documentation is essential for auditing purposes.

- Preventive Measures: We implement strategies to minimize obsolescence and damage through improved forecasting, better storage conditions, and enhanced handling procedures.

For instance, I once successfully negotiated a deal with a recycling center to dispose of obsolete electronic components, recovering a portion of the cost while adhering to environmental regulations.

Q 10. How do you ensure inventory accuracy?

Ensuring inventory accuracy is paramount. It relies on a combination of robust processes and technology:

- Regular Cycle Counting: Instead of one large annual count, we perform frequent, smaller counts of different sections of inventory. This makes discrepancies easier to find and correct promptly.

- Barcode Scanning and RFID Technology: Utilizing barcode scanners or RFID tags automates the counting process, minimizing human error. Real-time tracking provides immediate visibility into stock levels.

- Inventory Management System (IMS): We use a sophisticated IMS to track inventory movements, maintain accurate records, and generate reports. Proper training for all personnel using the system is crucial.

- Regular Audits: Internal and potentially external audits verify the accuracy of our inventory data and ensure compliance with company policies and regulations.

- Employee Training: Properly trained staff are key to accurate inventory management. Training on proper handling, storage, and documentation procedures is crucial.

In a past project, we implemented a new IMS which reduced our inventory discrepancies by 30% within the first six months through enhanced accuracy and better tracking capabilities.

Q 11. What is your experience with forecasting inventory needs?

Forecasting inventory needs is crucial for avoiding stockouts and minimizing excess inventory. My approach utilizes a combination of techniques:

- Historical Data Analysis: We analyze past sales data, identifying trends and seasonality to predict future demand. This involves examining factors such as sales volume, growth rates, and product lifecycles.

- Market Research and Trend Analysis: Staying updated on market trends and competitor activities provides valuable insight into potential changes in demand. This helps anticipate shifts in customer preferences.

- Sales Forecasting Tools: We employ software solutions that utilize statistical models and machine learning to refine our forecasts. This can help identify outliers or unusual patterns that would otherwise be missed.

- Collaboration with Sales and Operations: Regular communication with sales and operations teams helps incorporate their knowledge and insights into our forecasts. Their real-time understanding of market demands is invaluable.

- Safety Stock Calculation: We maintain a safety stock to account for unexpected fluctuations in demand or lead times. This safety net is crucial for preventing stockouts.

In my previous role, we implemented a more sophisticated forecasting model that improved our forecast accuracy by 15%, resulting in significant cost savings by reducing waste and preventing stockouts.

Q 12. How do you optimize storage space for maximum efficiency?

Optimizing storage space is vital for efficiency and cost reduction. This involves a systematic approach:

- Space Planning and Layout: We carefully plan the warehouse layout, considering factors such as product size, weight, frequency of access, and storage methods (shelving, racking, palletizing).

- Efficient Storage Methods: We use appropriate storage solutions to maximize space utilization. This includes utilizing vertical space with high-bay racking and implementing lean storage techniques.

- Inventory Organization: Proper organization minimizes wasted space and improves picking efficiency. Items are organized logically, taking into account frequency of use and product categories.

- Regular Decluttering and Maintenance: We regularly clear out obsolete or damaged items, ensuring the warehouse remains uncluttered and accessible. Maintenance of the storage system is crucial to prevent damage.

- Technology Integration: Implementing warehouse management systems (WMS) can optimize space utilization through dynamic slot allocation and real-time tracking of inventory location.

For example, by implementing a new racking system and reorganizing our warehouse, we were able to increase our storage capacity by 20% without increasing floor space.

Q 13. Explain your experience with inventory reporting and analysis.

Inventory reporting and analysis is crucial for making informed business decisions. My experience encompasses various aspects:

- Report Generation: I generate regular reports on key inventory metrics, such as inventory turnover rate, stock levels, and carrying costs. Reports are customized based on the needs of different stakeholders (management, sales, operations).

- Data Analysis and Interpretation: I analyze inventory data to identify trends, potential problems, and areas for improvement. This involves using statistical methods and visual aids (charts, graphs) to present findings clearly.

- KPI Tracking: We closely monitor key performance indicators (KPIs) related to inventory management, such as inventory turnover, fill rate, and order fulfillment time. These KPIs guide our improvement efforts.

- Forecasting and Budgeting: Inventory reports and analysis contribute to accurate sales forecasting and budgeting, ensuring sufficient funds are allocated for inventory purchases and storage.

- Decision Support: The insights from inventory analysis inform strategic decisions about procurement, pricing, and inventory optimization strategies.

In a past role, my analysis of inventory data revealed a seasonal demand pattern that allowed us to adjust procurement strategies and reduce carrying costs significantly.

Q 14. How do you handle returns and damaged goods?

Handling returns and damaged goods requires a systematic and efficient process:

- Return Authorization: A clear return authorization process is in place to streamline the return process. This involves verifying the reason for the return and ensuring compliance with company policies.

- Inspection and Assessment: Returned or damaged goods are inspected to assess their condition. This helps determine whether they can be resold, repaired, or disposed of.

- Inventory Updates: The inventory management system is updated to reflect the returned or damaged goods. This ensures accuracy of inventory records.

- Quality Control: Procedures are in place to identify the root cause of returns and damaged goods. This helps prevent similar issues in the future through improved quality control and handling procedures.

- Disposal/Recycling: Damaged goods that cannot be repaired or resold are disposed of responsibly, in accordance with environmental regulations.

For example, we implemented a system for tracking returns that helped us identify a pattern of damaged goods due to improper packaging. Addressing this issue significantly reduced return rates and improved customer satisfaction.

Q 15. Describe your experience with implementing new inventory management systems.

Implementing a new inventory management system is a significant undertaking requiring careful planning and execution. It’s not just about choosing the right software; it’s about integrating it seamlessly into existing workflows and ensuring user adoption. My approach begins with a thorough needs assessment, identifying pain points in the current system and defining clear objectives for the new one. This includes analyzing current processes, data accuracy, and reporting capabilities. For example, in a previous role, we transitioned from a spreadsheet-based system to a cloud-based ERP solution. This involved data migration, extensive user training, and a phased rollout to minimize disruption. We prioritized key features like real-time stock visibility and automated reporting first, then gradually introduced more advanced functionalities. Post-implementation, we conducted regular performance reviews, gathering feedback from users to make necessary adjustments and ensure the system meets ongoing needs. We used key performance indicators (KPIs) like order fulfillment time and inventory accuracy to measure success.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage inventory across multiple locations?

Managing inventory across multiple locations requires a centralized system with real-time data synchronization. This ensures consistent information across all sites, preventing stockouts in one location while another has excess. I’ve used both cloud-based solutions and enterprise resource planning (ERP) systems that offer this capability. A crucial aspect is establishing clear communication channels between locations. This could involve daily inventory updates, automated alerts for low stock levels, and regular stock reconciliation processes. For instance, in a previous role managing a retail chain with numerous branches, we implemented a system that automatically transferred stock from locations with surpluses to those experiencing shortages. This dramatically reduced stockouts and optimized our inventory levels. We also used barcoding and RFID technology (discussed further in question 7) to improve tracking accuracy across locations.

Q 17. How do you prioritize tasks when managing inventory?

Prioritizing inventory management tasks involves a combination of urgency and importance. I use a method similar to the Eisenhower Matrix (urgent/important), categorizing tasks based on their impact on business operations and potential consequences of delay. For example, tasks involving critical parts needed for urgent production runs or addressing immediate stockouts take precedence. Regular stock replenishment orders for high-demand items are given a high priority to prevent shortages. Less critical tasks, such as inventory audits or system maintenance, are scheduled accordingly. Using a task management tool helps visualize deadlines, dependencies, and progress, allowing for effective time allocation. Regular reviews and adjustments to the priority list are essential to maintain efficiency and adapt to changing circumstances.

Q 18. How do you handle emergency inventory situations?

Handling emergency inventory situations requires quick thinking and decisive action. The first step is accurate assessment of the problem – what’s missing, how critical is it, and what are the consequences of the shortage? Once the situation is understood, I immediately identify alternative sources, whether through expedited orders from existing suppliers, sourcing from secondary vendors, or even reallocating stock from other locations. Transparent communication with relevant stakeholders (production, sales, etc.) is critical to manage expectations and minimize disruption. After the immediate crisis is resolved, a thorough root cause analysis is performed to prevent similar incidents in the future. This might involve reviewing safety stock levels, refining forecasting models, or improving communication processes. For instance, in one instance, a critical component unexpectedly ran out due to a supplier delay. We expedited an order from a backup supplier and implemented a new vendor relationship management strategy to diversify our supply chain.

Q 19. What are the common challenges you face in inventory management?

Common challenges in inventory management include inaccurate forecasting leading to overstocking or stockouts, human error in data entry, inefficient processes, lack of real-time visibility, and managing obsolete or slow-moving inventory. Other challenges involve maintaining data integrity across multiple systems, dealing with damaged or lost goods, and adapting to fluctuating demand. These challenges often intersect and need holistic solutions. For example, poor data entry can lead to inaccurate forecasting, resulting in unnecessary storage costs or production delays. To overcome these challenges, I emphasize process standardization, regular audits, robust data management practices, and the use of technology like barcode scanning and RFID (discussed further below) to enhance accuracy and efficiency.

Q 20. How do you collaborate with other departments to manage inventory effectively?

Effective inventory management relies heavily on collaboration with other departments. Close communication with purchasing ensures timely procurement of materials, while coordination with production manages the flow of goods throughout the manufacturing process. Sales and marketing input helps with demand forecasting, enabling better inventory planning. For example, I would work closely with the purchasing department to negotiate favorable terms with suppliers, ensuring a stable supply of materials at competitive prices. Regular meetings and shared reporting dashboards are vital in maintaining transparency and aligning efforts across departments. Open communication and a shared understanding of inventory goals are essential for success. Regular meetings, shared dashboards, and collaborative problem-solving approaches are key here.

Q 21. Describe your experience with barcode scanning and RFID technology.

Barcode scanning and RFID technology are invaluable tools for improving inventory accuracy and efficiency. Barcode scanning is widely used for tracking individual items, automating data entry, and streamlining the receiving and shipping processes. RFID (Radio-Frequency Identification) offers a more advanced solution, enabling the tracking of multiple items simultaneously without line-of-sight. This is particularly useful for managing large volumes of items or in environments with challenging physical conditions. In a previous role, we implemented RFID tags on pallets of goods, significantly improving the speed and accuracy of inventory counting and location tracking. The data collected allowed for real-time monitoring of inventory levels, improving forecasting and reducing stockouts. While RFID technology can be more expensive than barcodes, the increase in efficiency and accuracy often justifies the investment.

Q 22. How do you ensure the security of inventory?

Ensuring inventory security is paramount to prevent loss, theft, and damage. It’s a multi-faceted approach involving physical security measures, robust record-keeping, and procedural controls.

- Physical Security: This includes secure storage facilities with access controls (like key card systems or surveillance cameras), regular inventory counts and spot checks, and proper handling procedures to prevent damage. For example, we might store high-value equipment in locked cages within a secured warehouse.

- Access Control: Limiting access to authorized personnel only, through systems like user-based logins for inventory management software and clearly defined responsibility for specific items. This ensures only those needing access have it, minimizing the risk of theft or accidental damage.

- Record Keeping: Accurate and up-to-date records are crucial. Any movement of inventory – from receiving to dispatch – needs to be documented. This creates an audit trail to identify discrepancies and potential security breaches.

- Regular Audits: Periodic physical inventory counts are essential to verify records against actual stock levels. This helps identify discrepancies, whether due to theft, damage, or inaccurate record-keeping.

By combining these elements, we establish a strong security posture that protects our inventory investment.

Q 23. How do you maintain inventory records?

Maintaining accurate inventory records is the backbone of efficient inventory management. I utilize a combination of manual and automated systems to ensure data integrity and accessibility.

- Inventory Management System (IMS): We use a dedicated software solution that tracks every item, from its acquisition to its eventual disposal. This system provides real-time visibility into stock levels, allowing us to make informed decisions about ordering and allocation.

- Barcode/RFID Technology: Barcodes or RFID tags are attached to items, enabling quick and accurate scanning during receiving, transfers, and shipments. This significantly reduces the risk of manual data entry errors.

- Regular Reconciliation: Physical counts are conducted regularly to cross-verify against the IMS data. This helps identify and correct any discrepancies caused by errors or theft. Discrepancies are investigated thoroughly to identify root causes and prevent future occurrences.

- Data Backup and Security: Regular data backups and robust security measures are in place to protect against data loss or corruption. The system is also designed to ensure data accuracy and integrity using check digits and other validation methods.

The key is to maintain a systematic approach that integrates both manual and automated processes, ensuring data accuracy and timely updates.

Q 24. What is your experience with data analysis related to inventory?

Data analysis is crucial for optimizing inventory management. I have extensive experience using inventory data to identify trends, predict future demand, and improve operational efficiency.

- Demand Forecasting: I use historical data, market trends, and seasonality to predict future demand, optimizing inventory levels and minimizing stockouts or overstocking. Techniques such as moving averages and exponential smoothing are employed.

- ABC Analysis: This method categorizes inventory based on its value and consumption rate (A – high value/high consumption, B-medium, C-low). This allows us to focus on managing high-value items more closely, preventing losses and optimizing storage.

- Turnover Rate Analysis: Analyzing the turnover rate (how quickly inventory is sold) helps identify slow-moving or obsolete items that require attention and potentially pricing adjustments or disposal.

- Reporting and Dashboards: I utilize data visualization tools to create insightful reports and dashboards that track key performance indicators (KPIs) such as inventory turnover, stock levels, and order fulfillment rates. This allows for proactive identification of potential problems.

By leveraging data analysis, we can make data-driven decisions that lead to significant improvements in inventory management.

Q 25. How do you identify and address slow-moving inventory?

Slow-moving inventory ties up capital and reduces profitability. Identifying and addressing it requires a proactive approach.

- ABC Analysis (as mentioned above): Focuses resources on high-value, slow-moving items first.

- Inventory Age Analysis: Identify items that have been in stock for an extended period. We track the age of each item in stock to identify potential candidates for review.

- Market Research: Investigate the reasons for slow movement. Is there a decrease in demand? Is the pricing competitive? Is there a problem with the product itself?

- Price Adjustments: Consider discounting slow-moving items to stimulate sales. This might involve temporary promotional pricing or bundle deals.

- Product Disposition: If demand is unlikely to recover, consider liquidating obsolete or damaged items through sales, donations, or recycling. We have a clear process for disposing of obsolete inventory in an environmentally sound manner.

A combination of these strategies helps free up space, reduce storage costs, and improve cash flow.

Q 26. How do you contribute to cost reduction in inventory management?

Cost reduction in inventory management is a continuous process. My contributions focus on optimizing inventory levels, reducing storage costs, and minimizing waste.

- Demand Forecasting Accuracy: Improved forecasting minimizes overstocking, reducing storage costs and minimizing the risk of obsolescence.

- Efficient Ordering Procedures: Streamlining the procurement process and negotiating favorable terms with suppliers reduce acquisition costs.

- Optimized Storage: Effective warehouse layout and space utilization minimize storage expenses.

- Waste Reduction: Implementing measures to prevent damage and spoilage reduces losses and improves inventory accuracy.

- Technology Implementation: Using inventory management software and automation technologies reduces labor costs and improves efficiency.

By focusing on these areas, we can significantly reduce overall inventory costs and improve profitability.

Q 27. Explain your understanding of just-in-time inventory management.

Just-in-time (JIT) inventory management is a strategy that aims to minimize inventory holding costs by receiving materials only when they are needed for production or sale. The goal is to reduce storage space and holding costs, and improve cash flow.

- Reduced Inventory Levels: JIT minimizes the amount of inventory held at any given time. This lowers storage costs and reduces the risk of obsolescence.

- Improved Efficiency: The system requires efficient production and supply chain processes to ensure timely delivery of materials.

- Flexibility: While efficient, JIT requires flexibility to respond to unexpected changes in demand or supply.

However, JIT can be vulnerable to supply chain disruptions. A well-planned JIT system requires close coordination between the company and its suppliers and a robust contingency plan for potential disruptions.

Q 28. Describe a time you had to solve a challenging inventory problem.

In a previous role, we faced a critical shortage of a key component due to an unforeseen supplier delay. This threatened to halt production and significantly impact our deadlines.

- Problem Identification: We quickly identified the root cause – a supplier factory experiencing a temporary shutdown due to an unexpected equipment failure.

- Emergency Response: We immediately contacted alternative suppliers to source the component. This required quickly assessing their capacity and reliability.

- Negotiation and Expediting: We negotiated expedited shipping to receive the component as quickly as possible. This involved paying a premium for faster delivery, but the alternative of halting production was far costlier.

- Production Adjustments: We temporarily adjusted production schedules to utilize existing inventory while awaiting the shipment of the replacement components. This involved prioritization and careful planning.

- Root Cause Analysis and Prevention: After resolving the immediate issue, we conducted a thorough analysis to identify weaknesses in our supply chain and implement preventive measures to mitigate similar risks in the future. This included diversifying suppliers and implementing better communication protocols.

While challenging, this experience highlighted the importance of a robust contingency plan and the ability to adapt quickly to unexpected disruptions. We successfully mitigated the impact of the delay, minimizing the overall disruption to operations.

Key Topics to Learn for Maintain inventory of equipment and materials Interview

- Inventory Management Systems: Understanding different inventory management methods (FIFO, LIFO, weighted average cost), and the strengths and weaknesses of each. Practical application includes choosing the right system for a specific business context.

- Data Accuracy and Reconciliation: The importance of accurate data entry, regular stocktaking, and reconciling physical inventory with recorded inventory. Practical application includes developing procedures to minimize discrepancies and identify causes of errors.

- Inventory Control Techniques: Exploring techniques like ABC analysis (prioritizing high-value items), cycle counting, and using software for inventory tracking. Practical application includes implementing and optimizing these techniques to reduce waste and improve efficiency.

- Ordering and Procurement Processes: Understanding the process of ordering new materials and equipment, including lead times, minimum order quantities, and vendor relationships. Practical application includes optimizing the ordering process to minimize stockouts and storage costs.

- Reporting and Analysis: Generating reports on inventory levels, turnover rates, and cost of goods sold. Practical application includes interpreting these reports to identify areas for improvement and make data-driven decisions.

- Equipment Maintenance and Tracking: Understanding preventative maintenance schedules, tracking equipment repairs and replacements, and ensuring compliance with safety regulations. Practical application includes creating and maintaining an effective equipment maintenance program.

- Waste Reduction and Optimization: Identifying and minimizing inventory waste through strategies such as improved forecasting, efficient storage, and minimizing obsolescence. Practical application includes implementing strategies to reduce waste and improve overall efficiency.

Next Steps

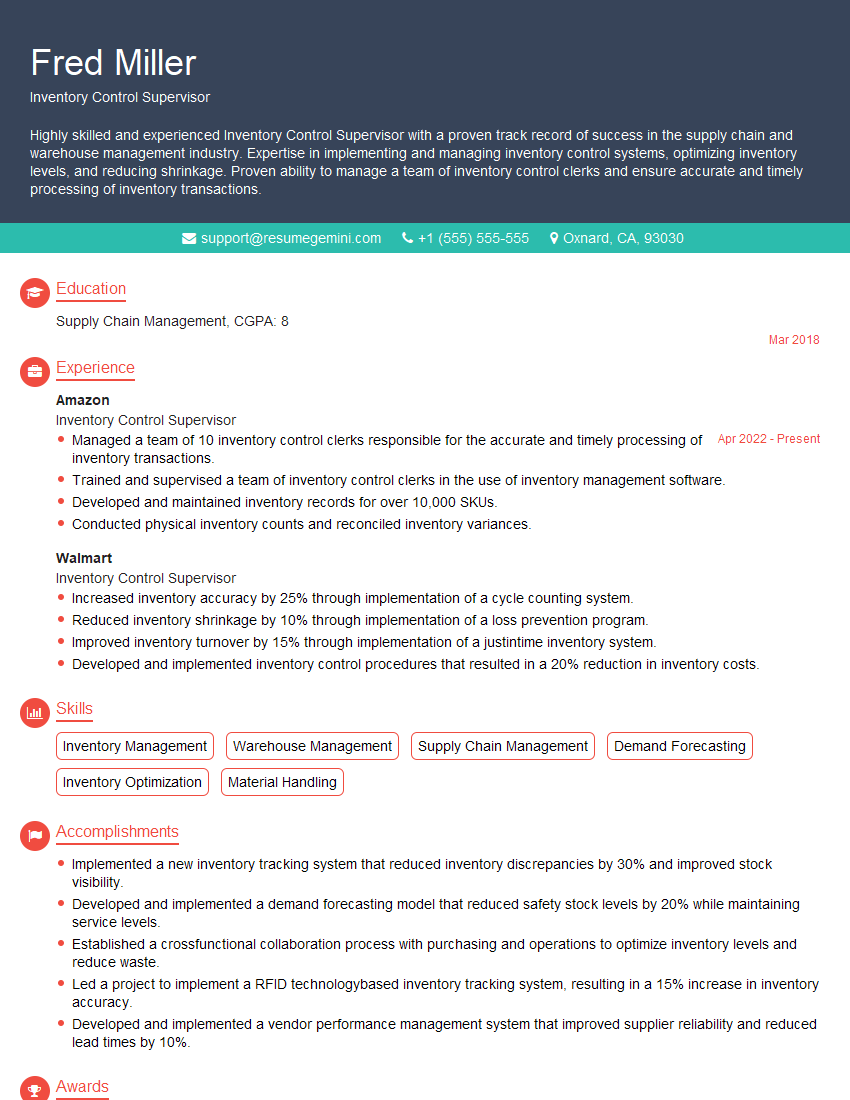

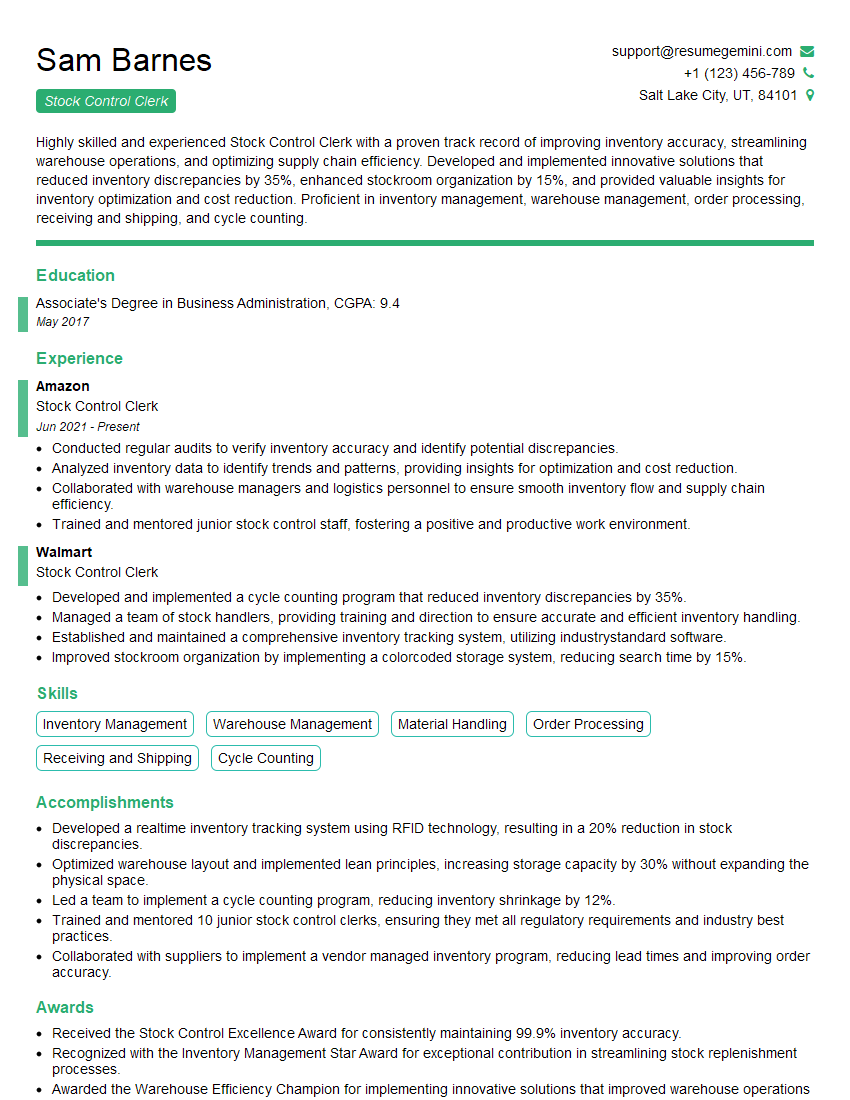

Mastering inventory management is crucial for career advancement in logistics, supply chain, and operations. It demonstrates your ability to be efficient, organized, and detail-oriented – highly valued skills in any industry. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that will catch the eye of recruiters. Examples of resumes tailored to showcasing expertise in maintaining inventory of equipment and materials are available to help guide your resume creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good