The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Operate vehicles and equipment safely interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Operate vehicles and equipment safely Interview

Q 1. Describe your experience operating heavy equipment.

My experience with heavy equipment spans over 10 years, encompassing a wide range of machines and operational contexts. I’ve operated excavators, bulldozers, loaders, and forklifts in various settings, from construction sites to demolition projects and even in challenging terrains like mountainous regions. This experience has provided me with a deep understanding of the nuances of each machine, their capabilities, and limitations. For instance, my work on a recent highway construction project involved operating an excavator to dig trenches, precisely following the designated plans and ensuring the safety of both myself and the crew. My proficiency extends beyond basic operation to include maintenance, troubleshooting, and adhering to strict safety protocols.

Q 2. What safety procedures do you follow when operating equipment?

Safety is paramount in my line of work. My safety procedures begin before I even approach the equipment. This includes a thorough pre-operational inspection, always verifying the stability of the ground and being aware of overhead obstructions and surrounding personnel. I always wear appropriate Personal Protective Equipment (PPE), including safety helmets, high-visibility clothing, steel-toe boots, and gloves. During operation, I maintain a safe distance from other equipment and workers, using hand signals or two-way radios for communication. I never operate under the influence of alcohol or drugs. My understanding of load capacity and stability is crucial; I never exceed weight limits and carefully assess the terrain to prevent tipping. In case of any unexpected incident, I know the precise emergency shutdown procedures for each piece of equipment. Post-operation, I secure the equipment properly to prevent unauthorized use or accidents.

Q 3. How do you perform pre-operational checks on equipment?

Pre-operational checks are a non-negotiable part of my routine. I use a standardized checklist for every piece of equipment. This checklist includes:

- Visual inspection: Checking for any visible damage to the machine, tires, hydraulic lines, or any other component.

- Fluid levels: Verifying engine oil, hydraulic fluid, coolant, and fuel levels are within the acceptable range.

- Tire pressure: Ensuring tires are properly inflated.

- Functional checks: Testing all controls, lights, brakes, and other essential systems to confirm they’re working correctly. This includes moving the equipment slightly and ensuring all movements are fluid and stable.

- Safety systems: Checking the functionality of safety features such as emergency stops, alarms, and seatbelts.

Q 4. Explain your understanding of load capacity and weight limits.

Understanding load capacity and weight limits is crucial for safe operation. Every piece of equipment has a specified load capacity—the maximum weight it can safely lift or carry. Exceeding this limit can lead to catastrophic equipment failure, serious injury, or death. I always check the manufacturer’s specifications to ensure I never exceed these limits. For example, before loading a forklift, I carefully weigh the items being moved and ensure the total weight is well below the forklift’s rated capacity. Similarly, when operating an excavator, I consider the weight of the load and the ground conditions to avoid tipping. I account for the weight distribution as well, to avoid any imbalance or overloading that might compromise stability.

Q 5. Describe your experience with different types of heavy equipment.

My experience encompasses a diverse range of heavy equipment. I’m proficient with excavators (both hydraulic and cable-operated), bulldozers, loaders (front-end loaders and skid steer loaders), forklifts (various capacities), and graders. Each machine requires a unique skill set and understanding of its capabilities. For instance, operating an excavator requires precise control for digging and trenching, while a bulldozer necessitates a different approach for earthmoving and leveling. My expertise extends to understanding the limitations of each machine, adapting my technique to varying terrain and project requirements. This versatile experience allows me to tackle a wide array of tasks effectively and safely.

Q 6. How do you handle unexpected equipment malfunctions?

Unexpected equipment malfunctions can occur. My response is always prioritized around safety. If a malfunction occurs, I immediately cease operation, shut down the equipment according to the established procedure, and secure the area. I then assess the situation, identifying the nature of the malfunction. Minor issues might be addressed using my troubleshooting skills and knowledge, but major issues require immediate reporting to the supervisor for professional repair. I communicate any problems clearly and concisely to my supervisor, providing as much detail as possible, without attempting any repairs beyond my skill level. Waiting for qualified personnel prevents further damage and ensures safety.

Q 7. What are the common causes of equipment accidents, and how can they be prevented?

Common causes of equipment accidents include operator error (e.g., exceeding weight limits, ignoring safety procedures, operating equipment under the influence of drugs or alcohol), mechanical failure (e.g., brake failure, hydraulic leaks), inadequate maintenance, and unsafe working conditions (e.g., poor site preparation, lack of communication). Prevention strategies involve:

- Thorough training and certification: Operators must be properly trained and certified to handle specific equipment.

- Regular equipment maintenance: Scheduled maintenance programs help identify and address potential issues before they lead to accidents.

- Strict adherence to safety procedures: Employees should follow all safety rules and regulations without exception.

- Regular safety inspections: Worksite inspections help identify and mitigate unsafe conditions.

- Effective communication: Clear communication between operators and ground personnel is essential to prevent accidents.

- Enforcing a drug-free workplace: Implement procedures to ensure that all operators are drug and alcohol free during operating hours.

Q 8. How do you ensure the safe transportation of materials?

Safe material transportation hinges on meticulous planning and execution. It’s not just about getting the materials from point A to point B; it’s about doing so without incident, damage, or injury. This involves several key steps:

- Proper Securing: Materials must be secured appropriately to prevent shifting or falling during transit. This means using the correct tie-downs, straps, or other securing devices, ensuring they’re rated for the weight and type of material being transported. For example, heavy steel beams require much stronger and more numerous tie-downs than a pallet of lighter boxes.

- Vehicle Suitability: The vehicle used must be appropriate for the load. A pickup truck is unsuitable for hauling a massive amount of gravel; a dump truck would be much safer. Overloading is a major safety hazard, potentially leading to vehicle instability and accidents.

- Route Planning: The chosen route should consider the weight and dimensions of the load, avoiding low bridges, narrow roads, or areas with difficult terrain. For oversized or overweight loads, special permits and escort vehicles might be required.

- Pre-Trip Inspection: Before any journey, a thorough inspection of the vehicle and its load is crucial. This checks for any issues with the vehicle’s condition, ensuring brakes, lights, and tires are functional, and that the load is secure.

- Defensive Driving: Safe driving practices are paramount. This includes maintaining a safe following distance, avoiding sudden braking or acceleration, and being extra vigilant for other road users.

Think of it like building a house: a weak foundation will lead to a collapse. Similarly, overlooking any of these steps can compromise safety and lead to accidents.

Q 9. Explain your knowledge of relevant safety regulations and standards.

My knowledge of safety regulations and standards is comprehensive and constantly updated. I’m familiar with OSHA (Occupational Safety and Health Administration) guidelines, specifically those relating to operating machinery, material handling, and personal protective equipment (PPE). These regulations cover aspects such as:

- PPE Usage: The mandatory use of safety helmets, high-visibility clothing, safety glasses, gloves, and hearing protection depending on the task and environment.

- Machine Guarding: Ensuring all moving parts of equipment are properly guarded to prevent accidental contact and injuries.

- Lockout/Tagout Procedures: Understanding and following procedures for safely de-energizing equipment before maintenance or repair to prevent accidental starts.

- Load Capacity Limits: Knowing and adhering to the weight limits of vehicles and equipment to prevent overloading and structural damage.

- Hazard Communication: Being aware of and understanding the hazards associated with the materials and equipment being used, and following proper handling and disposal procedures.

I also stay updated on industry-specific standards and best practices. Regular training and certifications ensure my knowledge remains current and relevant. Ignoring safety regulations is not just irresponsible but can lead to serious consequences, including accidents, fines, and legal repercussions.

Q 10. How do you maintain accurate records of equipment usage and maintenance?

Maintaining accurate equipment records is essential for effective maintenance, safety, and compliance. I typically utilize a combination of digital and physical methods:

- Digital Logs: Software or apps designed for equipment management allow for easy recording of usage hours, maintenance schedules, repairs performed, and any issues encountered. This data is readily accessible and easily shared with relevant personnel.

- Physical Logs/Inspection Checklists: I also maintain physical logs or checklists for daily equipment inspections, documenting pre-operation checks, noting any defects or irregularities, and tracking the completion of maintenance tasks. This provides a backup system and a physical record.

- Maintenance Schedules: All equipment has a scheduled maintenance plan based on manufacturer recommendations and usage. I adhere strictly to these schedules to prevent premature wear and tear and potential malfunctions.

- Repair Documentation: Thorough documentation is kept for any repairs performed, including the nature of the problem, the parts replaced, and the date and time of the repair. This aids in tracking maintenance history and identifying potential recurring problems.

Accurate record-keeping isn’t just about compliance; it’s a proactive approach to preventing equipment failure, optimizing maintenance schedules, and ultimately ensuring a safer working environment. Imagine trying to troubleshoot a malfunction without a proper record – it would be extremely difficult!

Q 11. Describe your experience with different types of terrain and working conditions.

My experience encompasses a wide range of terrains and working conditions, from level paved surfaces to rugged, uneven terrain, and from dry, sunny conditions to wet, muddy, or icy situations. I have operated equipment in both confined spaces and wide-open areas.

- Terrain Adaptation: Operating equipment on different terrains requires adjusting speed, technique, and safety precautions. For instance, navigating steep inclines requires slower speeds, careful maneuvering, and additional attention to braking. In muddy or icy conditions, reduced speeds, increased following distances, and potentially the use of tire chains are necessary.

- Environmental Considerations: Varying weather conditions necessitate adjustments in both operation and safety protocols. Poor visibility in rain or fog mandates extra caution, while extreme temperatures may affect the equipment’s performance or require additional protective measures.

- Confined Spaces: Working in confined spaces necessitates careful maneuvering to prevent damage to the equipment or the surrounding environment, and added awareness of potential hazards like low clearance or limited visibility.

Adaptability is key. Each environment presents unique challenges that require careful planning, risk assessment, and skillful adaptation to ensure safe and efficient operation.

Q 12. How do you communicate effectively with other workers on a job site?

Effective communication on a job site is paramount for safety and efficiency. I prioritize clear, concise, and respectful communication using a variety of methods:

- Hand Signals: In noisy environments, hand signals are indispensable for communicating with other workers, especially when operating heavy machinery. Standardized hand signals should be used and understood by all personnel.

- Two-Way Radios: Radios are crucial for maintaining contact, especially across large job sites. Clear and concise communication is important, avoiding jargon and using plain language.

- Pre-Job Briefings: Attending and participating in pre-job briefings ensures everyone is aware of the day’s tasks, potential hazards, and communication protocols.

- Direct Communication: When necessary, I approach individuals directly to clarify instructions or address concerns, ensuring understanding before proceeding.

Open and honest communication prevents misunderstandings, avoids accidents, and ensures everyone is working safely and efficiently towards the same goals. It’s like a well-orchestrated team; clear communication keeps everyone in sync.

Q 13. How do you handle challenging or stressful situations while operating equipment?

Handling challenging or stressful situations while operating equipment demands a calm, methodical approach. My strategy involves:

- Maintaining Focus: I prioritize maintaining focus on the task at hand, even under pressure. This involves deep breaths, eliminating distractions, and avoiding rushing.

- Risk Assessment: I quickly assess the situation, identifying potential hazards and developing a plan to mitigate them. This might involve adjusting my approach, requesting assistance, or temporarily halting operations.

- Seeking Assistance: If a situation is beyond my capabilities, I immediately seek help from a supervisor or more experienced colleague. Safety should never be compromised.

- Post-Incident Review: After a challenging situation, I conduct a post-incident review, analyzing what happened, identifying areas for improvement, and documenting lessons learned for future reference.

Think of it as a fire drill – a pre-planned response to an emergency. Having a structured approach to stress reduces panic and increases the likelihood of a safe resolution.

Q 14. What are your methods for preventing equipment damage?

Preventing equipment damage involves proactive maintenance, careful operation, and operator training. My methods include:

- Pre-Operational Checks: Thorough pre-operational checks are essential, identifying any potential issues before operation begins. This includes checking fluid levels, tire pressure, and the overall condition of the equipment.

- Proper Operation: Operating the equipment within its design limits, avoiding overloading or exceeding its capabilities, is crucial. This means understanding the equipment’s specifications and operating it according to manufacturer guidelines.

- Regular Maintenance: Adhering to scheduled maintenance procedures helps prevent breakdowns and extends the equipment’s lifespan. This includes regular lubrication, cleaning, and component inspections.

- Environmental Protection: Protecting equipment from harsh environmental conditions, such as extreme temperatures, excessive moisture, or dust, is critical. Proper storage and covering can help mitigate damage from these elements.

- Operator Training: Ensuring all operators receive adequate training and understand the safe operation and maintenance of the equipment is paramount. This prevents improper usage that can lead to damage.

Preventing damage is much more cost-effective than repairing it. Proactive measures save time, money, and reduce downtime. Think of it as preventative medicine: it’s much easier and cheaper to prevent a problem than to cure one.

Q 15. Describe your experience with preventative maintenance.

Preventative maintenance is crucial for ensuring the longevity and safe operation of any vehicle or equipment. It involves regularly scheduled inspections and servicing to identify and address potential problems before they lead to breakdowns or accidents. Think of it like a regular health checkup for your equipment – catching small issues early prevents major problems later.

- Visual Inspections: I routinely check for leaks, wear and tear on tires, belts, and hoses, and ensure all fluids (oil, coolant, hydraulic fluid) are at the correct levels. For example, a small crack in a hose might be easily fixed, but ignoring it could lead to a major fluid loss and system failure.

- Lubrication: Regular lubrication of moving parts is essential to reduce friction and wear. I meticulously follow manufacturer’s recommendations for lubrication schedules and types of grease or oil.

- Component Checks: This includes verifying the functionality of brakes, lights, and safety features. For example, on a forklift, ensuring the emergency stop works flawlessly is paramount.

- Record Keeping: Maintaining accurate records of all maintenance activities is vital for tracking issues, predicting potential problems, and demonstrating compliance with safety regulations. I use both digital and paper-based logs to document everything.

During my time operating heavy machinery at [Previous Employer Name], I implemented a new preventative maintenance schedule that reduced downtime by 15% and significantly improved safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you respond to emergency situations while operating equipment?

Responding to emergencies while operating equipment requires a calm, decisive approach, prioritizing safety above all else. My training emphasizes a systematic response, focusing on these key steps:

- Assess the Situation: Quickly identify the nature of the emergency (e.g., equipment malfunction, collision, fire).

- Secure the Area: Turn off the equipment, activate emergency lights/signals, and establish a safe perimeter to prevent further incidents or injuries. This might involve setting up cones or warning flags, depending on the location.

- Provide First Aid (if necessary): If anyone is injured, administer first aid according to my training and call for emergency medical services immediately.

- Contact Emergency Services: Report the incident to the relevant authorities and my supervisor, providing a clear and concise description of what happened.

- Document the Incident: Thoroughly document the details of the emergency, including the time, location, causes, and consequences, to aid in investigation and prevent future similar incidents.

For instance, during a near-miss incident involving a faulty hydraulic line on an excavator, I immediately shut down the machine, secured the area, and reported the issue to my supervisor. We then implemented a more rigorous inspection schedule to prevent future similar incidents.

Q 17. What is your experience with different types of fuel and lubrication systems?

My experience encompasses various fuel and lubrication systems, including diesel, gasoline, and hydraulic systems. Understanding the specific requirements of each fuel type and lubrication system is crucial for efficient and safe operation. Improper fuel or lubricant can lead to engine damage or equipment failure.

- Diesel Systems: I’m proficient in handling diesel fuel, understanding its properties and the need for proper filtration to prevent injector damage. I’m familiar with various diesel engine types and their maintenance.

- Gasoline Systems: I have experience with gasoline-powered equipment and understand the flammability risks and safety precautions associated with gasoline handling and storage.

- Hydraulic Systems: I’m well-versed in hydraulic fluid types, pressure monitoring, and leak detection. I know how to properly identify and address leaks, preventing potential equipment damage and safety hazards.

- Lubrication Systems: I understand the importance of using the correct type and grade of lubricant for each component. Improper lubrication can lead to premature wear and component failure.

I’ve worked with a wide range of equipment, from small gasoline-powered tools to large diesel-powered excavators, and in each case, I’ve prioritized the proper selection and maintenance of fuels and lubricants.

Q 18. How familiar are you with various types of attachments and their operation?

I am familiar with a range of attachments for various types of equipment, including but not limited to excavators, loaders, and forklifts. Each attachment requires specific operational knowledge to use safely and efficiently.

- Excavator Attachments: I have experience with various buckets (ditch cleaning, rock, general purpose), rippers, hydraulic hammers, and grapple attachments. Each attachment requires specific operating techniques to prevent damage to the equipment or the surrounding environment.

- Loader Attachments: I’m familiar with various buckets (general purpose, light material, heavy material), pallet forks, snow plows, and other attachments tailored to specific tasks. Understanding the weight capacity of each attachment is critical to prevent equipment overload.

- Forklift Attachments: I have experience with standard forklift forks, side-shifters, and other specialty attachments designed for handling different types of cargo. Proper attachment selection and secure fastening is crucial for safe material handling.

In a recent project, I efficiently utilized a hydraulic hammer attachment on an excavator to break up concrete for a demolition project, saving considerable time and resources compared to using manual methods.

Q 19. How do you ensure the stability of the equipment during operation?

Ensuring equipment stability during operation is paramount for safety and efficiency. My approach involves a multi-faceted strategy:

- Proper Ground Conditions: Before commencing operations, I always assess the ground conditions to ensure it’s stable and can support the weight of the equipment and its load. This often involves checking for soft ground, uneven surfaces, or potential hazards like underground utilities.

- Balanced Loads: I carefully distribute loads to maintain the equipment’s center of gravity, preventing tipping or instability. This includes understanding the load capacity limits of the equipment.

- Safe Operating Procedures: I always follow manufacturer-recommended safe operating procedures and adhere to all relevant safety regulations. This includes respecting speed limits, avoiding sharp turns, and maintaining a safe distance from obstacles.

- Terrain Awareness: I’m always aware of the terrain and adjust my operating techniques accordingly. This includes driving at slower speeds on uneven surfaces or inclines. For example, on a steep slope, I’d operate the equipment very slowly and use an appropriate travel path to mitigate the risk of tipping.

- Outriggers/Stabilizers (when applicable): When operating equipment equipped with outriggers or stabilizers, I always deploy them before performing elevated or heavy lifting tasks to ensure maximum stability.

For instance, I prevented a potential tipping incident by carefully distributing the load and choosing an appropriate travel path on an uneven terrain during a construction project.

Q 20. What are your experience with GPS systems or other technological aids?

I possess considerable experience utilizing GPS systems and other technological aids to enhance operational efficiency and precision. These technologies improve accuracy, safety, and productivity.

- GPS Guidance Systems: I am proficient in using GPS-guided systems for tasks such as grading, trenching, and other precision earthmoving operations. These systems allow for more accurate work, reducing waste and improving overall efficiency.

- Machine Monitoring Systems: I’m familiar with various machine monitoring systems that provide real-time data on fuel consumption, engine performance, and other operational parameters. This information is vital for preventative maintenance and optimizing equipment utilization.

- Digital Mapping & Surveying Software: I’m experienced in working with digital maps and surveying software to plan work areas, optimize routing, and ensure accurate execution of tasks.

In a recent project, using GPS guidance on a grader improved my accuracy in leveling a large area by 10%, significantly reducing the time and effort needed for rework.

Q 21. Describe your experience with site preparation and cleanup.

Site preparation and cleanup are crucial for ensuring a safe and efficient work environment. My experience covers all aspects of this process:

- Pre-Operation Site Assessment: Before any work begins, I thoroughly assess the site to identify potential hazards, including obstacles, uneven terrain, and underground utilities. This also involves planning the most efficient work route.

- Site Preparation: This includes tasks such as clearing debris, leveling the ground, and setting up safety barriers to protect personnel and equipment.

- Safe Material Handling: I adhere to safe material handling practices, ensuring materials are stored properly and moved efficiently to prevent accidents. This includes proper stacking, securing, and handling of materials.

- Cleanup & Waste Disposal: Following completion of work, I carefully clean up the site, removing debris, waste materials, and leftover materials according to environmental regulations. I’m knowledgeable in proper waste disposal procedures.

In a previous role, my meticulous site preparation and cleanup practices contributed to a flawless and accident-free project, saving both time and resources for the client.

Q 22. How familiar are you with the use of personal protective equipment (PPE)?

Personal Protective Equipment (PPE) is crucial for operating vehicles and equipment safely. My familiarity extends beyond simply knowing what PPE is; I understand its specific application based on the task and the potential hazards involved. This includes understanding the limitations of different PPE and ensuring it’s properly maintained and inspected before each use.

- Hard hats: Protecting against falling objects, impacts, and electrical hazards.

- Safety glasses or goggles: Protecting eyes from flying debris, chemicals, and impacts.

- Hearing protection: Mitigating noise-induced hearing loss from loud machinery.

- High-visibility clothing: Enhancing visibility in low-light conditions or around moving equipment.

- Gloves: Protecting hands from cuts, abrasions, chemicals, and extreme temperatures, varying by material and type.

- Safety boots: Protecting feet from crushing injuries, punctures, and slips.

- Respiratory protection: Protecting against inhaling harmful dusts, fumes, gases, or vapors, ranging from simple dust masks to specialized respirators.

For example, when operating a forklift in a warehouse, I would always wear a high-visibility vest, safety glasses, and steel-toe boots. If working with chemicals, I would add appropriate gloves and potentially a respirator, depending on the specific chemical’s hazards.

Q 23. How do you address equipment failures or breakdowns?

Addressing equipment failures or breakdowns follows a structured approach prioritizing safety and efficiency. My first step is always to ensure the safety of myself and others in the vicinity. This might involve shutting down the machine, securing the area, and warning others.

- Assessment: I carefully assess the nature and extent of the breakdown, identifying the specific malfunction and potential causes.

- Safety Precautions: I implement appropriate safety measures, such as using lockout/tagout procedures to prevent accidental restarts.

- Troubleshooting: I attempt to troubleshoot the problem using my knowledge and available resources, consulting manuals or contacting maintenance personnel if necessary.

- Reporting: I document the failure, including the time, location, nature of the problem, and any actions taken. This information is crucial for preventative maintenance and identifying recurring issues.

- Repair or Replacement: If the problem cannot be immediately resolved, I arrange for the equipment to be repaired or replaced, ensuring the work is done by qualified personnel.

For instance, if a hydraulic leak is discovered in an excavator, I would immediately shut down the machine, secure the area, and report the issue. I wouldn’t attempt a repair unless I had the training and expertise; instead, I’d contact the maintenance team.

Q 24. Explain your understanding of hydraulic systems in heavy machinery.

Hydraulic systems are integral to many heavy machinery operations. They use pressurized fluid to generate mechanical force, enabling the movement of components like lifting arms, buckets, and blades. My understanding encompasses the key components and their functions:

- Hydraulic pump: This converts mechanical energy (usually from an engine) into hydraulic energy (pressure).

- Hydraulic reservoir: Stores the hydraulic fluid and allows for cooling and settling.

- Hydraulic valves: Control the flow and direction of the fluid, directing it to different actuators.

- Hydraulic actuators (cylinders): Convert hydraulic energy into linear motion (pushing or pulling).

- Hydraulic fluid: The medium that transmits the pressure throughout the system.

Understanding hydraulic systems also includes knowledge of potential problems like leaks (leading to loss of pressure and malfunction), contamination (which can damage components), and overheating. I’m familiar with the safety precautions needed when working with hydraulic systems, such as avoiding contact with moving parts and using appropriate protective gear.

Q 25. How do you handle working in confined spaces with heavy equipment?

Working in confined spaces with heavy equipment requires meticulous planning and adherence to strict safety protocols. The confined space presents unique challenges, including limited access, poor ventilation, and potential hazards from the equipment itself.

- Permit-to-work systems: Ensuring proper authorization and risk assessments before entering the space.

- Atmospheric monitoring: Testing for oxygen levels, toxic gases, and other harmful substances.

- Ventilation: Implementing adequate ventilation to ensure safe air quality.

- Communication: Maintaining clear communication with personnel outside the confined space.

- Emergency procedures: Establishing clear emergency procedures for potential accidents or equipment malfunctions.

- Specialized equipment: Using appropriate equipment designed for confined space operation, including smaller and more maneuverable machines where possible.

For example, if operating a small excavator in a trench, I would ensure proper atmospheric monitoring and utilize a harness and lifeline to prevent falls. I’d also ensure that a spotter is present outside the trench to monitor my activities and assist in case of an emergency.

Q 26. Describe your experience with load securing procedures.

Load securing is paramount to prevent accidents and damage during transport. My experience involves understanding the different methods and choosing the appropriate techniques based on the type of load, transport vehicle, and journey conditions. This includes:

- Proper use of lashing straps, chains, and ropes: Ensuring the correct tension and securing points to prevent movement during transit.

- Understanding weight distribution: Distributing weight evenly to maintain balance and prevent instability.

- Appropriate load placement: Positioning the load correctly to optimize stability and prevent damage to the load or vehicle.

- Inspection and documentation: Thoroughly inspecting the secured load and documenting the securing procedure.

- Compliance with regulations: Adhering to relevant safety regulations and industry standards.

For example, when securing a pallet of bricks on a flatbed truck, I would use appropriate lashing straps, ensuring they are correctly tensioned and secured to approved anchor points. I would also ensure the pallet is evenly distributed and does not overhang the edges of the truck.

Q 27. How familiar are you with the different types of brakes and braking systems?

Different vehicles and equipment utilize various braking systems, and understanding their differences is critical for safe operation. My knowledge includes:

- Service brakes: The primary braking system used for normal stopping.

- Parking brakes: Used to hold the vehicle stationary when parked.

- Emergency brakes: Used in critical situations when the service brakes fail.

- Types of braking mechanisms: Drum brakes, disc brakes, air brakes, and hydraulic brakes, each with its strengths and weaknesses and requiring different maintenance and inspection schedules.

I understand the importance of regular brake inspections, checking for wear and tear, fluid levels, and proper functionality. I also know how to respond to brake failure scenarios, taking appropriate safety measures to bring the vehicle to a safe stop. For example, when operating a heavy truck with air brakes, I regularly check the air pressure and perform pre-trip inspections to ensure the braking system is functioning correctly.

Q 28. What are your experience with working at heights and using elevated work platforms?

Working at heights necessitates a high level of awareness and adherence to strict safety procedures. My experience with elevated work platforms (EWPs) involves:

- Pre-operational checks: Thoroughly inspecting the EWP before use to ensure it’s in safe working condition.

- Safe operating procedures: Following established procedures for operation, including proper leveling and securing.

- Harness and fall protection: Using appropriate harnesses and fall arrest systems to prevent falls.

- Awareness of environmental conditions: Considering wind speed, visibility, and other environmental factors that could affect safety.

- Load limits: Understanding and adhering to the weight limits of the platform.

For instance, when operating a scissor lift to perform maintenance on a high building, I would ensure the lift is properly leveled, my harness is securely fastened, and I am aware of any potential obstructions. I’d also regularly check the platform’s load capacity to ensure I am not exceeding it.

Key Topics to Learn for Operate vehicles and equipment safely Interview

- Vehicle Inspection and Maintenance: Understanding pre-operational checks, identifying potential hazards, and performing basic maintenance tasks. This includes knowing how to interpret warning lights and gauges.

- Safe Operating Procedures: Demonstrating knowledge of appropriate speed limits, safe following distances, hazard awareness (blind spots, pedestrian traffic), and emergency procedures. Practical application includes describing your experience adhering to company safety regulations.

- Load Securement and Transportation: Understanding the principles of safe load distribution, securing cargo to prevent shifting, and adhering to weight limits. Be prepared to discuss your experience with different types of cargo and securing methods.

- Defensive Driving Techniques: Explaining your understanding and application of defensive driving principles, anticipating potential hazards, and reacting safely to unexpected situations. This includes discussing your experience with adverse weather conditions.

- Equipment Operation and Safety: Demonstrating knowledge of specific equipment operation (forklifts, cranes, etc.), including safety protocols, emergency shut-off procedures, and limitations of the equipment. Be ready to discuss specific equipment you’ve operated and any relevant certifications.

- Regulations and Compliance: Understanding relevant safety regulations, permits, and licensing requirements for operating specific vehicles and equipment. Showcasing knowledge of relevant legislation demonstrates your commitment to safety.

- Accident Prevention and Reporting: Explaining your approach to accident prevention, including identifying and mitigating potential risks. Be prepared to discuss your experience reporting incidents and following established procedures.

Next Steps

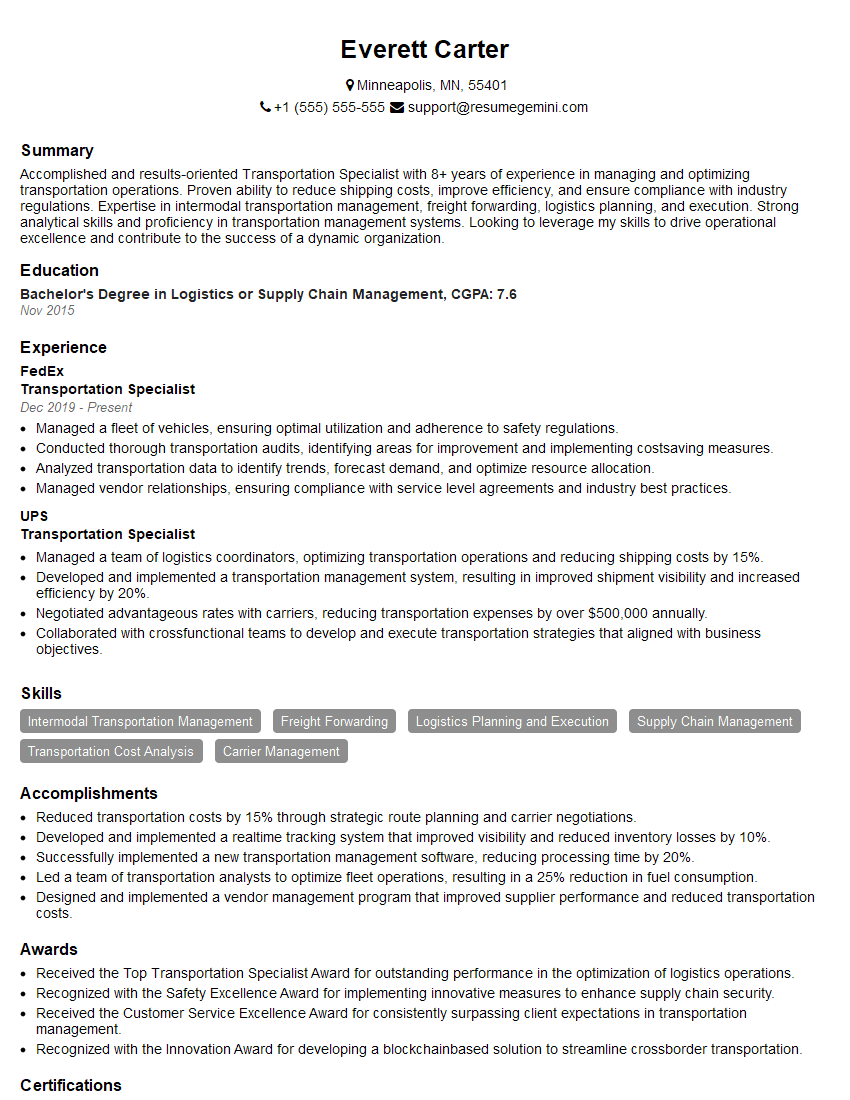

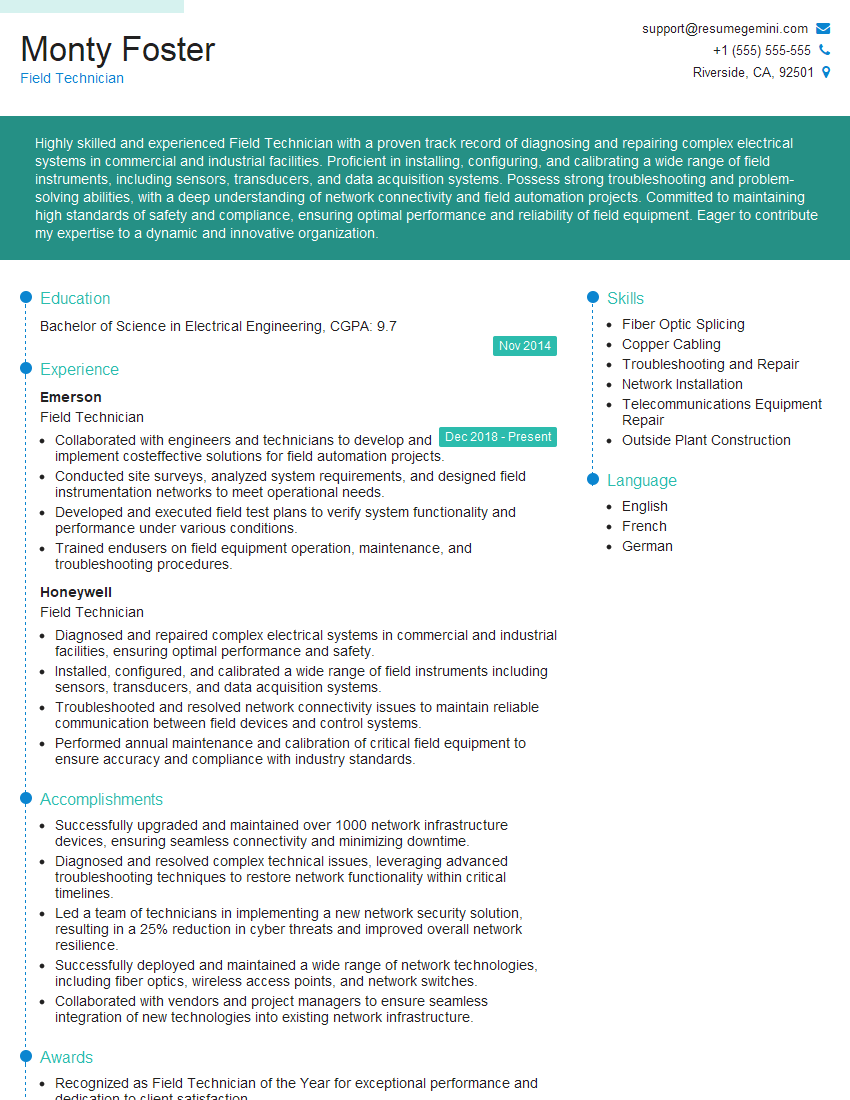

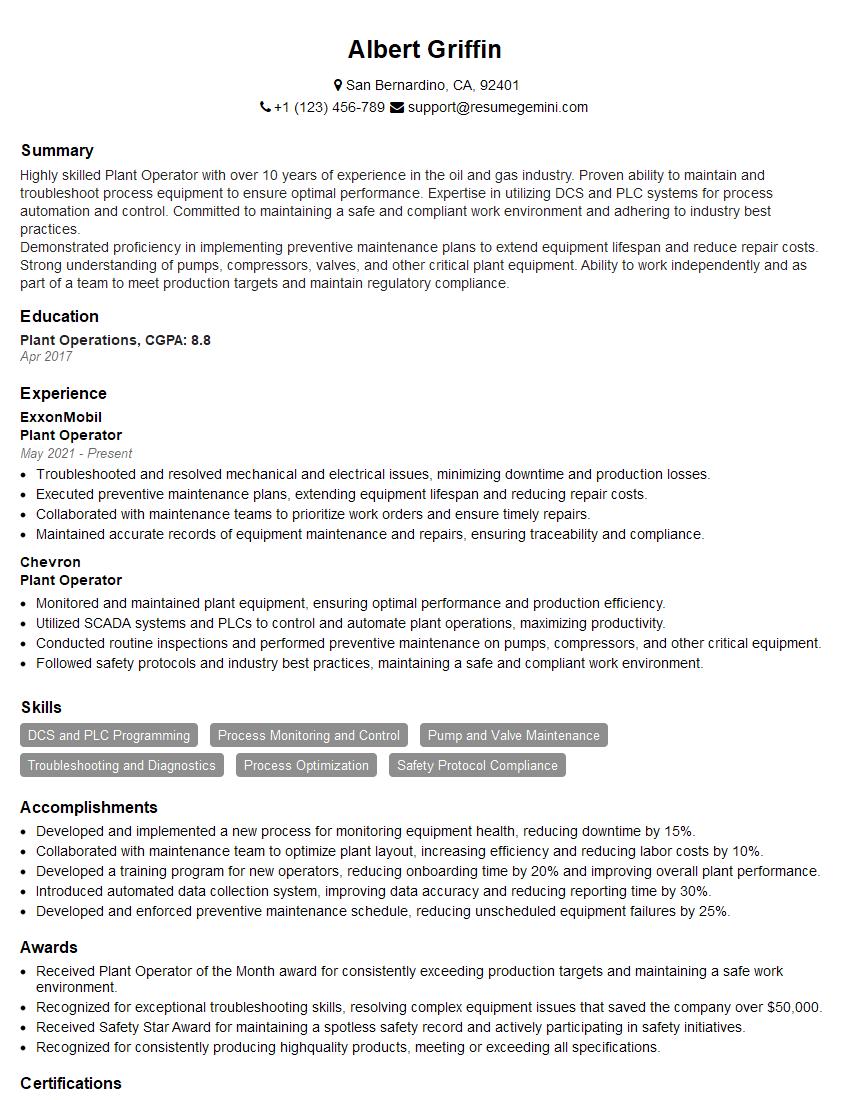

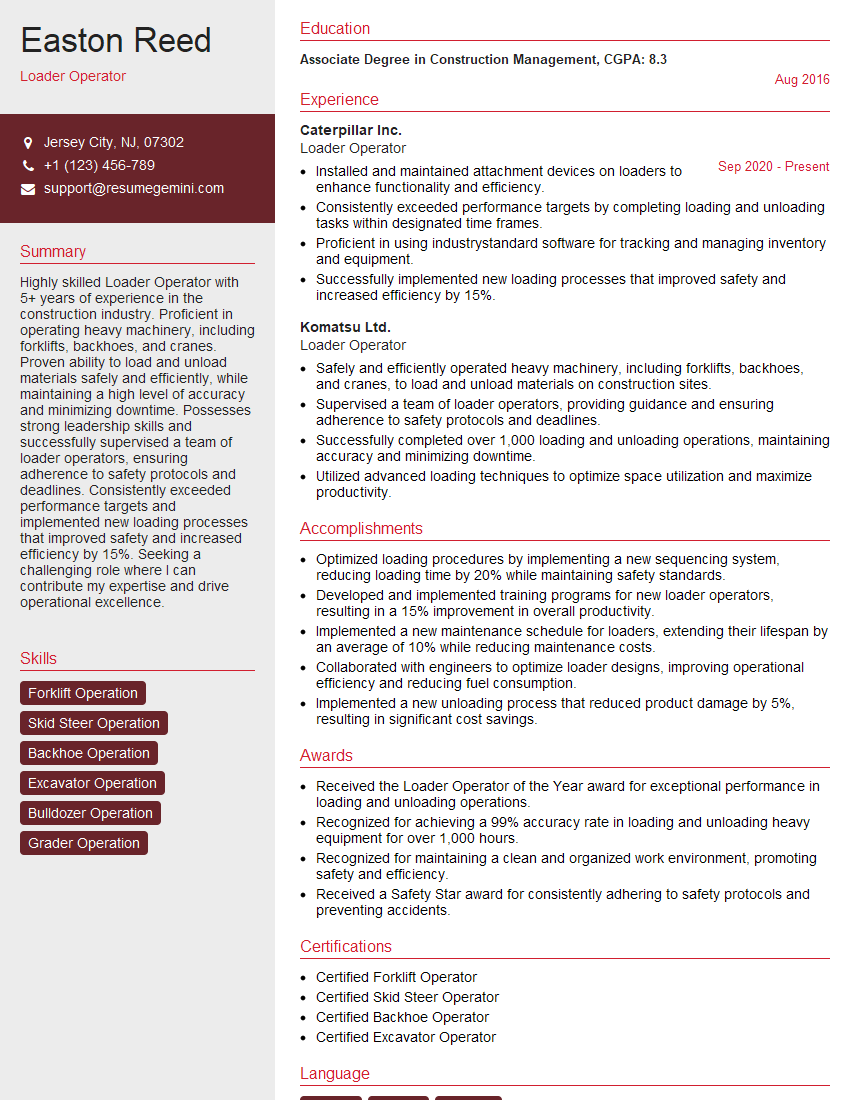

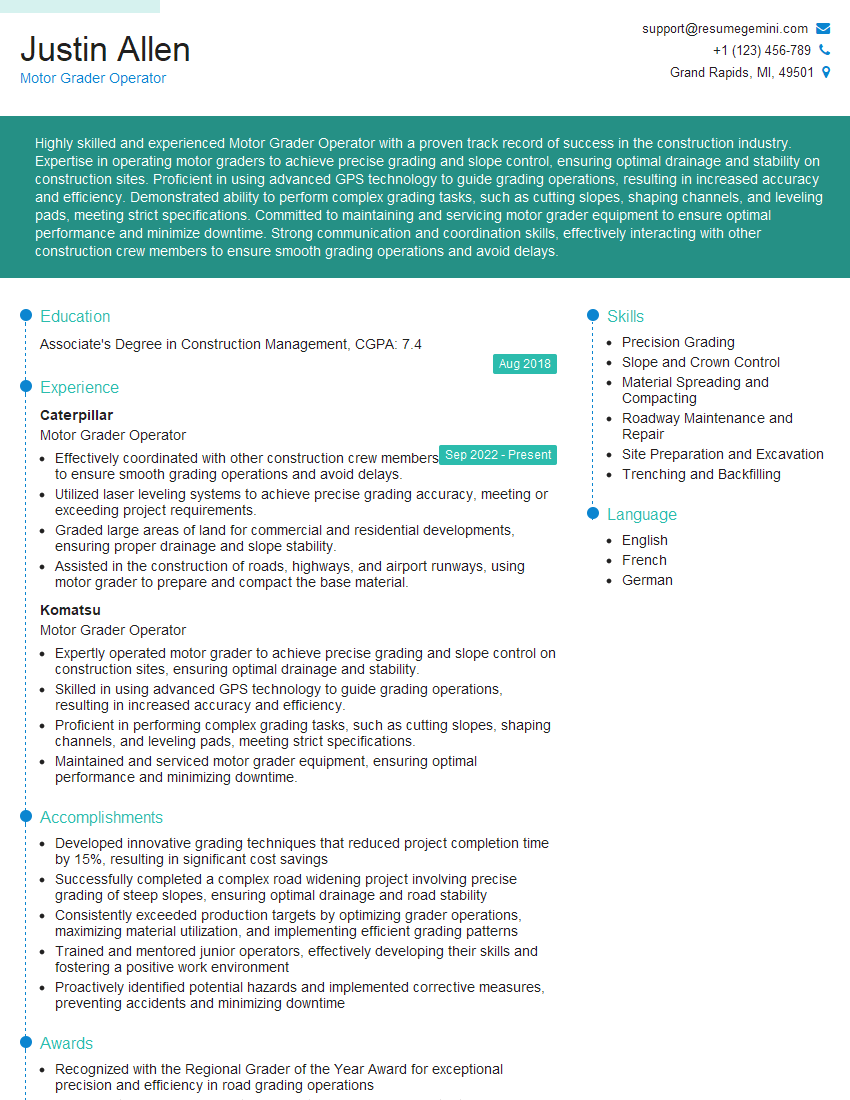

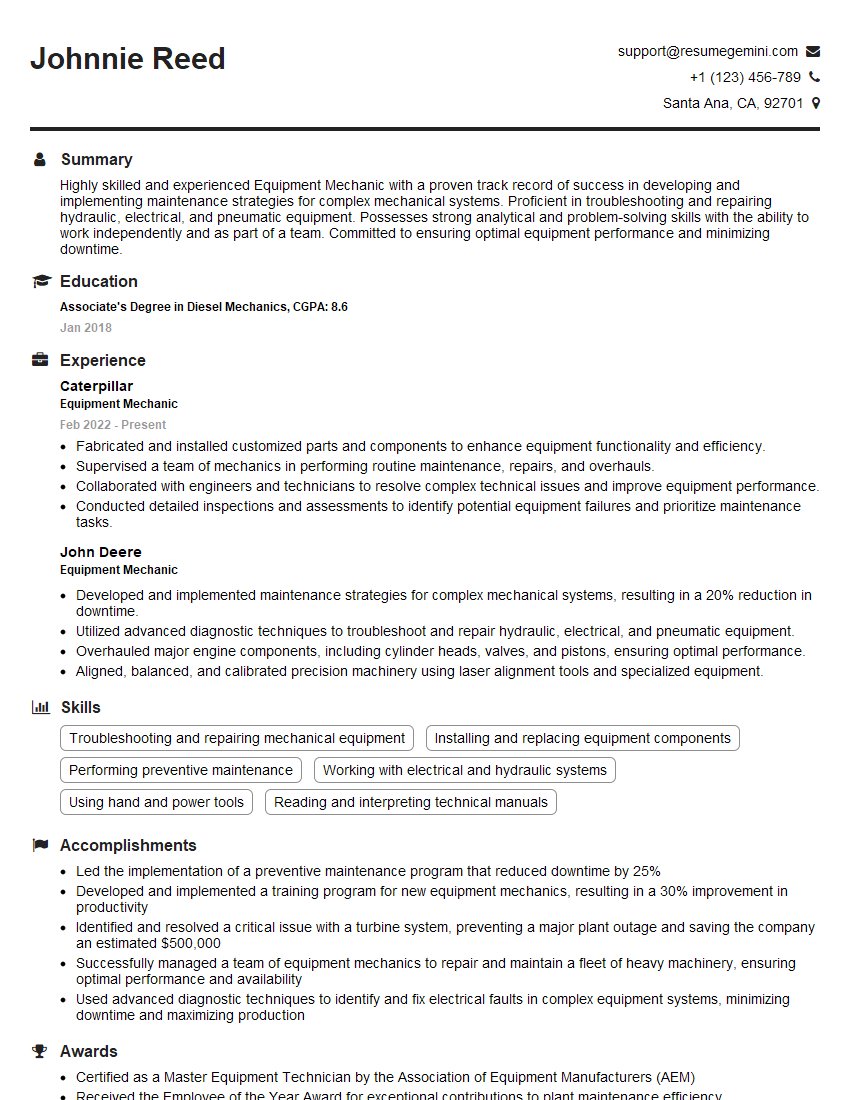

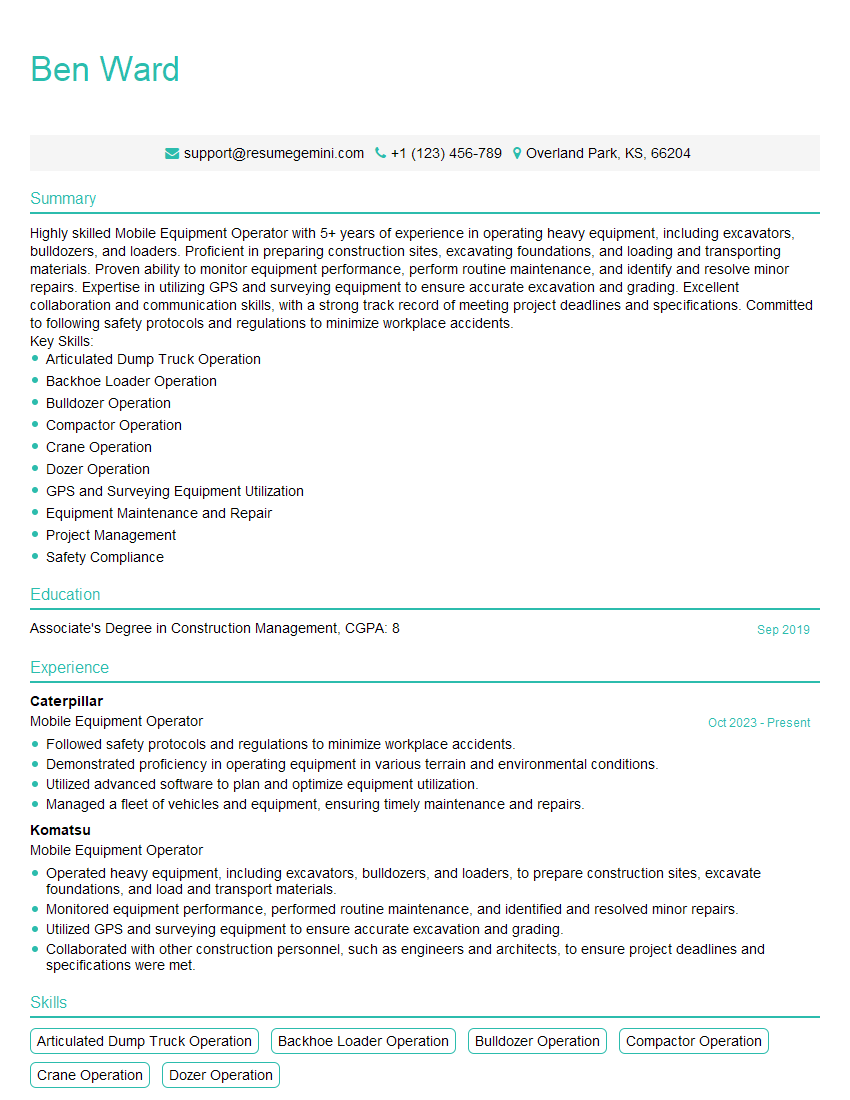

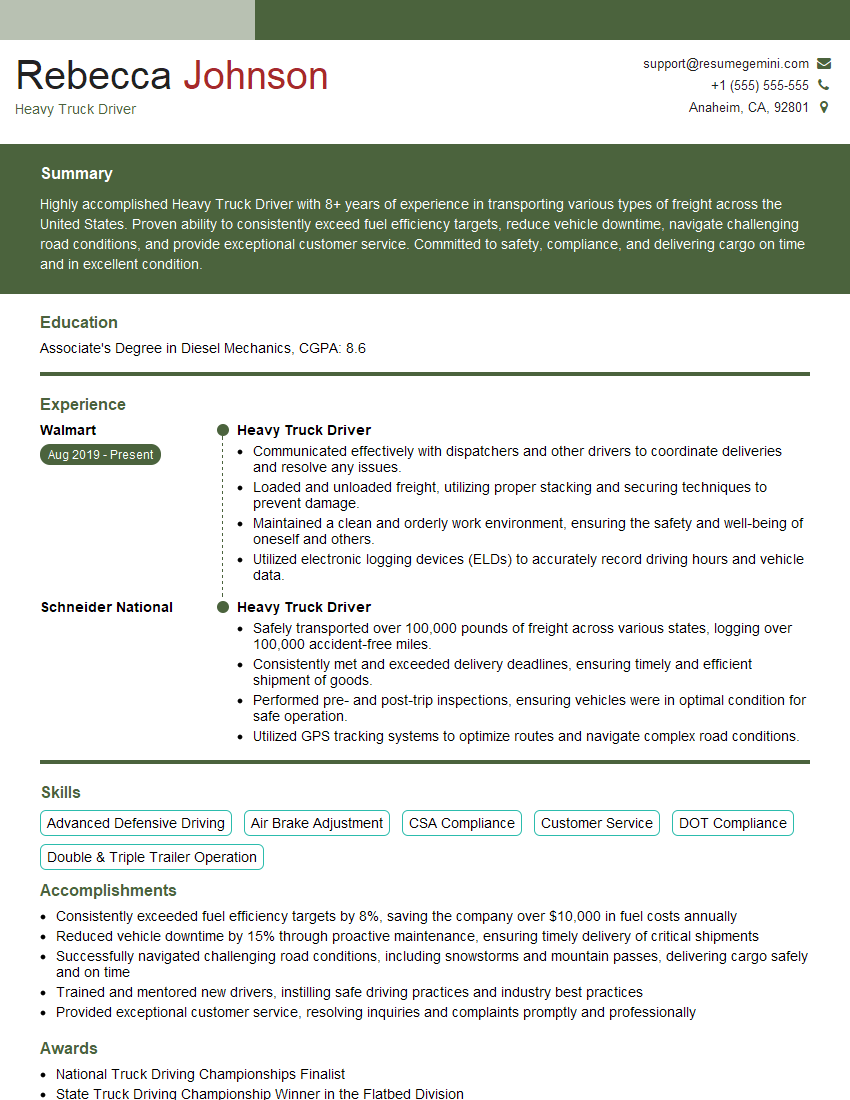

Mastering the safe operation of vehicles and equipment is crucial for career advancement in many fields. A strong understanding of safety procedures and regulations demonstrates responsibility and professionalism, opening doors to higher-paying roles and increased responsibility. To increase your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to “Operate vehicles and equipment safely” roles are available, providing you with a strong foundation for your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good