The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Expertise in Fruit Safety and Inspection interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Expertise in Fruit Safety and Inspection Interview

Q 1. Explain the importance of Good Agricultural Practices (GAP) in fruit production.

Good Agricultural Practices (GAPs) are a set of principles and practices that aim to ensure the safety and quality of fruits from the farm to the table. They encompass all aspects of fruit production, focusing on minimizing risks and maximizing beneficial outcomes for both consumers and the environment.

- Soil Health: GAPs emphasize maintaining healthy soil through practices like crop rotation, cover cropping, and avoiding excessive tillage. Healthy soil leads to healthier plants, less susceptibility to pests and diseases, and reduced need for chemical inputs.

- Water Management: Efficient and responsible water use is crucial. This includes implementing irrigation strategies that minimize water waste and prevent contamination. Water sources should be tested for pathogens and pollutants.

- Pest and Disease Management: GAPs promote Integrated Pest Management (IPM) strategies, focusing on preventive measures, biological control, and judicious use of pesticides only when absolutely necessary. This reduces reliance on harmful chemicals and protects beneficial insects and the environment.

- Harvesting and Handling: Proper harvesting techniques, including careful handling to prevent bruising and damage, are essential. Rapid cooling and appropriate storage conditions maintain fruit quality and safety.

- Worker Health and Safety: GAPs address worker safety, including the provision of personal protective equipment (PPE) and training on safe handling practices to prevent contamination.

For example, a farm following GAPs would meticulously track pesticide applications, ensuring they are used only when needed and at the correct dosage, and only authorized pesticides are used. They would also implement proper hygiene protocols for workers, requiring handwashing and the use of clean equipment.

Q 2. Describe the common pests and diseases affecting fruit crops and their control measures.

Fruit crops are susceptible to a wide range of pests and diseases, varying by region and specific crop. Effective control measures require careful monitoring and integrated strategies.

- Pests: Common fruit pests include aphids, mites, codling moths, and fruit flies. These can cause damage to leaves, stems, flowers, and fruit, reducing yield and quality. Control measures include biological control (e.g., introducing beneficial insects), using pheromone traps to monitor and disrupt mating cycles, and targeted pesticide applications.

- Diseases: Fungal diseases like powdery mildew, anthracnose, and brown rot are frequent issues, as are bacterial and viral diseases. Disease control involves removing infected plant material, promoting good air circulation, and employing resistant cultivars. Fungicides may be used as a last resort, strictly following label instructions.

For instance, in managing codling moths, a farmer might use pheromone traps to monitor moth populations and then strategically time insecticide applications to target the larval stage, minimizing environmental impact. In managing fungal diseases, preventative measures such as pruning and proper sanitation are critical. Regular visual inspections are vital for early detection and intervention.

Q 3. What are the key principles of Hazard Analysis and Critical Control Points (HACCP) in fruit processing?

Hazard Analysis and Critical Control Points (HACCP) is a systematic preventative approach to food safety. In fruit processing, it focuses on identifying and controlling potential hazards that could compromise the safety of the final product.

- Hazard Analysis: This involves identifying all potential hazards at each step of the processing, from raw material to finished product. These could include biological (bacteria, viruses), chemical (pesticides, cleaning agents), and physical (foreign objects) hazards.

- Critical Control Points (CCPs): These are specific points in the process where control is essential to prevent or eliminate a hazard or reduce it to an acceptable level. For example, pasteurization is a CCP for reducing microbial hazards in fruit juices.

- Establishing Critical Limits: For each CCP, a critical limit is set. This is the measurable value that must be met to ensure control is effective (e.g., a specific temperature for pasteurization).

- Monitoring: Regular monitoring at each CCP ensures that the critical limits are being met. This involves taking measurements and recording data.

- Corrective Actions: Procedures must be in place to address any deviations from critical limits. This might involve discarding a batch of product or adjusting processing parameters.

- Verification: Regular verification activities ensure the HACCP system is functioning effectively. This could involve auditing the process, testing for pathogens or residues, and reviewing records.

- Record Keeping: Thorough documentation is crucial. This includes recording all aspects of the HACCP plan, monitoring data, and corrective actions taken.

Think of it like building a bridge. HACCP is like the detailed blueprint and construction plan, ensuring every component (step in the process) is strong and safe to prevent collapse (food safety issues).

Q 4. How do you identify and manage potential food safety hazards during fruit harvesting?

Harvesting presents several potential food safety hazards. Careful management is key to minimizing risks.

- Field Sanitation: Maintaining clean fields and equipment reduces contamination from soil, wildlife, and previous crops. This might involve removing weeds, clearing debris, and regularly cleaning harvesting equipment.

- Worker Hygiene: Workers should follow strict hygiene protocols, including handwashing, wearing clean clothing, and avoiding activities that could contaminate the fruit (e.g., smoking or using tobacco).

- Pre-harvest Intervals (PHI): Adhering to PHI guidelines, the time between pesticide application and harvest, is crucial. This ensures residue levels are below legal limits.

- Proper Handling: Fruit should be handled gently to avoid bruising and damage, which can create entry points for microorganisms. Rapid cooling after harvest prevents microbial growth.

- Contamination Prevention: Prevention of contamination from wildlife (birds, rodents) and other sources (equipment, packaging) is crucial. Protective measures might include nets, rodent control, and appropriate packaging.

Imagine harvesting strawberries. If workers aren’t washing their hands regularly or if equipment isn’t cleaned, the risk of contamination increases substantially. Rapid cooling after harvest minimizes the chance of spoilage and bacterial growth.

Q 5. What are the different methods for detecting pesticide residues in fruits?

Detecting pesticide residues in fruits requires sensitive analytical techniques.

- High-Performance Liquid Chromatography (HPLC): This is a common method for separating and quantifying pesticides in fruit extracts. It is versatile and can detect a wide range of compounds.

- Gas Chromatography-Mass Spectrometry (GC-MS): This technique offers high sensitivity and specificity, enabling the detection and identification of even trace amounts of pesticides. It’s particularly useful for volatile pesticides.

- Enzyme-Linked Immunosorbent Assay (ELISA): This is a relatively rapid and cost-effective method for screening samples for the presence of specific pesticides. It’s less precise than HPLC or GC-MS but useful for initial screening.

- Liquid Chromatography-Mass Spectrometry (LC-MS): Combining the separation power of LC with the detection capabilities of MS, this technique provides high sensitivity and selectivity for pesticide analysis.

Each method has its strengths and weaknesses, and the choice depends on factors such as the types of pesticides being tested, the required sensitivity, and the available resources. A laboratory performing pesticide residue analysis will typically use a combination of these methods to ensure comprehensive testing.

Q 6. Explain the role of traceability in maintaining fruit safety throughout the supply chain.

Traceability is the ability to track a product through all stages of the supply chain, from farm to consumer. It’s vital for maintaining fruit safety.

- Lot Identification: Each batch or lot of fruit should be uniquely identified, allowing for tracking of its origin, processing steps, and distribution path. This enables swift identification and removal of contaminated products if necessary.

- Record Keeping: Detailed records should be maintained throughout the supply chain, including harvest dates, processing details, storage conditions, and distribution information. This facilitates efficient tracking in case of issues.

- Information Sharing: Effective communication between all parties in the supply chain (farmers, processors, distributors, retailers) is essential for accurate tracking and timely responses to any problems.

- Technology: Technologies such as barcodes, RFID tags, and blockchain can enhance traceability, enabling real-time tracking and management of fruit throughout the supply chain.

If a foodborne illness outbreak is linked to a particular batch of fruit, traceability allows rapid identification of the source, enabling quick recall and prevention of further illness. Without traceability, identifying the source would be much more difficult and time-consuming.

Q 7. Describe your experience with various fruit inspection methods (visual, physical, chemical).

My experience encompasses a wide range of fruit inspection methods, ensuring comprehensive assessment of safety and quality.

- Visual Inspection: This involves careful examination of the fruit for external defects, such as bruises, discoloration, signs of pest damage, or decay. It is the first line of defense and often reveals obvious issues.

- Physical Inspection: This may include measuring fruit size, weight, and firmness, assessing internal quality by cutting open samples, and checking for foreign materials. Physical tests help quantify aspects of quality and identify hidden problems.

- Chemical Inspection: This involves laboratory testing to detect pesticide residues, microbial contamination, and other chemical contaminants. Methods include HPLC, GC-MS, and ELISA, as discussed previously.

In a typical day, I might visually inspect a batch of apples for bruises and discoloration. I may then conduct a physical test, determining the firmness of a sample, while a chemical analysis would check for pesticide residues. Combining these methods allows a comprehensive assessment of the fruit’s safety and quality, ensuring it meets standards before reaching consumers.

Q 8. How do you handle a situation where contaminated fruit is discovered in a shipment?

Discovering contaminated fruit in a shipment is a serious matter requiring immediate and decisive action. The first step is to immediately isolate the affected shipment to prevent further contamination. This involves physically separating it from other produce and preventing any cross-contamination. Next, we conduct a thorough investigation to determine the source and extent of the contamination. This might involve lab testing to identify the contaminant (bacteria, pesticides, etc.), reviewing transport records to trace the fruit’s journey, and inspecting the growing and packing facilities. Based on the findings, we’ll determine the appropriate course of action: disposal of the contaminated fruit (following all relevant environmental regulations), notification of relevant authorities (e.g., food safety agencies), and potentially a product recall. Throughout this process, meticulous record-keeping is crucial for transparency and accountability.

For example, if we find E. coli contamination in a shipment of blueberries, we’d immediately isolate the batch, collect samples for lab testing, and trace the blueberries back to the farm and packing plant to identify the point of contamination. This might involve reviewing sanitation records, inspecting equipment, and interviewing personnel. Depending on the severity of the contamination and the potential for public health risk, we may need to initiate a recall, notifying retailers and consumers to return the product.

Q 9. What are the regulations and standards related to fruit safety in your region/country?

Fruit safety regulations vary by region, but generally encompass several key areas. In many countries, these regulations involve adherence to Good Agricultural Practices (GAPs), which cover aspects from soil health and water management to pest control and harvesting techniques. There are usually strict limits on pesticide residues, and regular inspections are carried out by government agencies to ensure compliance. Specific regulations often exist regarding packaging, labeling (including accurate information on origin and contents), and transportation to maintain the cold chain and prevent spoilage or contamination. Furthermore, traceability systems are often mandated, allowing for the easy tracking of fruit from farm to consumer in case of a problem. Penalties for non-compliance can range from fines to product seizures and business closures. For instance, in my region, the maximum allowable levels of specific pesticides on imported fruit are clearly defined, and exceeding these limits results in shipment rejection and potential legal action.

Q 10. How familiar are you with GlobalGAP and other international fruit safety certifications?

I am very familiar with GlobalGAP (Good Agricultural Practices) and other international fruit safety certifications such as GRASP (GlobalG.A.P. Risk Assessment on Social Practices), and Rainforest Alliance. GlobalGAP is a widely recognized standard for good agricultural practices and covers various aspects, including environmental protection, worker welfare, and food safety. It ensures that fruits are grown and handled in a way that minimizes risks to both the environment and human health. These certifications offer assurances to consumers and retailers about the safety and sustainability of the product. Understanding these certifications is essential for importing and exporting fruit, as many markets require them for entry. Furthermore, familiarity with these standards helps in benchmarking our own practices and identifying areas for improvement.

For example, a farm certified under GlobalGAP will have documented procedures for pest control that minimize the use of harmful chemicals, ensuring compliance with relevant regulations. This documentation is audited regularly to maintain the certification.

Q 11. Describe your experience with food safety auditing and reporting procedures.

I have extensive experience conducting food safety audits and preparing detailed reports. These audits involve a thorough examination of all aspects of the fruit production and handling process, from farm to consumer. This includes reviewing documentation such as HACCP (Hazard Analysis and Critical Control Points) plans, Standard Operating Procedures (SOPs), and records of sanitation and pest control measures. The physical inspection encompasses the production facilities, equipment, and storage areas, assessing hygiene levels, temperature control, and other critical factors. The audit report summarizes findings, highlighting any areas of non-compliance or potential risks. This report is crucial for corrective actions, improving operations, and demonstrating compliance to customers and regulatory agencies. I usually follow a standardized checklist to ensure comprehensive coverage and consistency across audits.

For instance, a recent audit I conducted revealed inconsistencies in the temperature logging system at a cold storage facility. My report detailed this finding, recommending system upgrades and staff retraining to maintain proper cold chain integrity.

Q 12. How would you investigate a complaint about unsafe fruit?

Investigating a complaint about unsafe fruit requires a systematic approach. First, I would thoroughly document the complaint, including details such as the type of fruit, the alleged problem (e.g., presence of foreign objects, spoilage, pesticide residue), the date of purchase, and contact information. Then, I would collect samples of the implicated fruit for laboratory analysis to confirm the alleged issue. Simultaneously, I would trace the fruit back through the supply chain, examining records from the retailer, distributor, importer, and grower to pinpoint the potential source of the problem. I would interview relevant personnel at each stage of the chain to gather information. Depending on the nature and severity of the complaint, I would determine the appropriate course of action: This could range from corrective actions at the farm level to a wider product recall if a significant safety issue is identified. Throughout this process, maintaining open communication with the complainant is essential.

Q 13. What are the key indicators of fruit spoilage or deterioration?

Key indicators of fruit spoilage or deterioration vary depending on the type of fruit but often include visible changes in appearance, texture, and smell. These can include:

- Changes in color: Browning, discoloration, or the appearance of mold.

- Changes in texture: Softening, shriveling, or becoming slimy.

- Off-odors: Sour, fermented, or putrid smells.

- Presence of mold or other microbial growth: Visible fuzzy patches or slimy areas.

- Excessive bruising or damage: Physical injury to the fruit can lead to spoilage.

For example, a banana that turns brown and soft is clearly spoiled, while strawberries with visible mold should be discarded immediately. These visual cues should always be considered alongside temperature monitoring and traceability data, which provides comprehensive insights into the fruit’s condition.

Q 14. Explain the importance of proper sanitation and hygiene practices in fruit handling.

Proper sanitation and hygiene practices are paramount in fruit handling to prevent contamination and ensure food safety. This begins with maintaining hygiene at the growing stage, including proper cleaning of equipment and tools. During harvesting, care must be taken to avoid introducing contaminants through dirty hands or handling practices. Packing houses and storage facilities should be regularly cleaned and disinfected to eliminate bacteria and other pathogens. Workers should be trained on proper hygiene protocols, such as handwashing and the use of protective clothing. Maintaining the cold chain is vital to slow down microbial growth and extend shelf life. Regular inspections and monitoring are necessary to ensure adherence to these practices. Think of it like a chain: one weak link (poor hygiene) can compromise the entire process, leading to foodborne illness.

Q 15. How do you ensure the accuracy and reliability of fruit quality testing results?

Ensuring accurate and reliable fruit quality testing hinges on a multi-pronged approach. It starts with meticulously calibrated equipment and validated testing methods. For example, we use refractometers regularly calibrated against known standards to measure the soluble solids content, a key indicator of ripeness and quality. We also employ standardized procedures for sample preparation and handling to minimize bias. This includes representative sampling—avoiding damaged fruit or areas with decay—and adherence to precise protocols for measuring pH, titratable acidity, and other parameters. Beyond instrumentation, regular internal audits and participation in proficiency testing programs, where we compare our results to those of other labs, help us identify and correct any systemic errors or drifts in accuracy. Finally, maintaining detailed records of all calibration checks, test results, and any deviations from standard operating procedures provides a complete audit trail ensuring traceability and accountability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data analysis and reporting in relation to fruit safety.

Data analysis and reporting are critical to identifying trends and improving fruit safety. My experience involves using statistical software packages like R and SPSS to analyze large datasets from various inspections. This allows us to identify correlations between factors like growing conditions, handling practices, and the incidence of spoilage or contamination. For example, I recently used regression analysis to demonstrate a strong correlation between temperature fluctuations during transport and the prevalence of fungal growth in a particular batch of strawberries. This data was then used to recommend improvements in cold chain management to the grower and shipper. My reports clearly communicate the findings, including visualizations like charts and graphs to enhance understanding and facilitate decision-making. The final report is tailored to the specific audience, whether it be a grower, regulatory agency, or internal management team.

Q 17. How do you maintain accurate records of fruit inspections and findings?

Maintaining accurate records is paramount for traceability and regulatory compliance. We utilize a combination of electronic and paper-based systems. Electronic databases store detailed information about each inspection, including date, time, location, type of fruit, inspector’s name, and specific findings. The information is linked to sample IDs and images. For example, our database tracks each batch of apples inspected, linking it to its origin farm and subsequent processing steps. This enables quick identification of the source of any contamination or quality issue. Paper records, such as inspection checklists and photographs of defects, serve as backup and are securely archived. Regular backups of the electronic database ensure data security and recovery capabilities.

Q 18. What are your strategies for effective communication about fruit safety concerns?

Effective communication about fruit safety concerns involves tailoring the message to the audience and using clear, non-technical language. For growers, communication focuses on practical steps to improve practices. With consumers, it’s about educating them on proper fruit handling and storage. For regulatory bodies, it’s about meeting reporting obligations and ensuring compliance. I leverage multiple communication channels, including formal reports, presentations at industry conferences, and informal meetings with stakeholders. A recent example involved explaining a salmonella outbreak in a batch of imported mangoes to the public health officials, providing clear and concise information on the affected batches and outlining the steps taken to contain the spread. Visual aids like infographics help simplify complex information, especially for public communication.

Q 19. Explain your understanding of different types of fruit packaging and their impact on safety.

Fruit packaging significantly impacts safety and shelf life. Different materials offer varying levels of protection against physical damage, microbial contamination, and atmospheric influences. Modified atmosphere packaging (MAP), for example, extends the shelf life of fruits by controlling the gaseous environment within the package. However, MAP requires careful consideration of gas composition to avoid harming the fruit. Rigid containers like plastic crates offer good protection during transport but may not be as effective in maintaining quality over extended storage periods. Flexible packaging like plastic bags is cost-effective but provides less protection. Choosing the appropriate packaging involves careful evaluation of factors like fruit type, intended shelf life, transportation conditions, and environmental impact. For instance, selecting a breathable bag for avocados allows them to continue ripening after harvest, while a sealed MAP package is more suitable for maintaining the crispness of apples.

Q 20. How do you stay updated with the latest regulations and best practices in fruit safety?

Staying updated is crucial in this rapidly evolving field. I actively participate in professional organizations such as the International Association for Food Protection (IAFP) and attend conferences and workshops. I subscribe to relevant scientific journals and industry newsletters to remain abreast of new research findings and regulatory changes. I regularly review updates from government agencies like the FDA and USDA, paying close attention to changes in food safety standards and guidelines. Online resources, such as databases of scientific publications and regulatory documents, are also valuable tools. For example, I recently completed a training course on the latest technologies in pathogen detection, which improved my ability to assess and manage fruit safety risks.

Q 21. Describe a situation where you had to troubleshoot a fruit safety issue. What was your approach?

During a large-scale inspection of imported grapes, we detected unusually high levels of pesticide residues in a specific shipment. My approach involved a systematic investigation. First, we confirmed the initial findings with repeat testing. Second, we traced the origin of the grapes to a specific vineyard and reviewed their pesticide application records. Third, we collaborated with the importing company and the relevant regulatory authorities to isolate the affected shipment and prevent its entry into the market. Fourth, we investigated the vineyard’s application practices and identified a deviation from approved protocols. Fifth, we provided recommendations to the vineyard on appropriate corrective actions, including retraining staff and reviewing their pesticide management system. The issue was resolved efficiently by using a collaborative, data-driven approach. This case highlighted the importance of effective record-keeping, traceability, and strong collaboration with stakeholders to address fruit safety concerns.

Q 22. What are the potential risks associated with different fruit preservation methods?

Different fruit preservation methods, while extending shelf life, introduce varying risks. For example, canning, while effective, can lead to spoilage if not properly sterilized, resulting in botulism – a potentially fatal illness. Improper freezing can cause freezer burn, reducing quality and potentially creating areas susceptible to microbial growth. Dehydration, if not done to a sufficiently low water activity, may not inhibit microbial growth. Finally, chemical preservatives, while effective, can introduce health concerns if used improperly or exceed safe levels. The key is to select the method best suited to the fruit and to meticulously follow safety protocols.

- Canning: Risk of botulism if improper sterilization.

- Freezing: Risk of freezer burn and subsequent microbial growth.

- Dehydration: Risk of insufficient water activity reduction, leading to spoilage.

- Chemical Preservatives: Risks associated with exceeding safe usage levels.

Q 23. How do you ensure that fruit storage and transportation conditions maintain safety?

Maintaining safe storage and transportation conditions for fruit requires a multi-pronged approach. Temperature control is paramount; fruits have optimal temperature ranges to prevent spoilage and microbial growth. We use refrigerated trucks and storage facilities maintaining these precise temperatures. Proper ventilation is equally critical, preventing the buildup of ethylene gas, which can accelerate ripening and decay. Furthermore, careful handling minimizes physical damage, reducing entry points for pathogens. Hygiene standards must be rigorously enforced, ensuring clean surfaces and equipment to prevent cross-contamination. Finally, comprehensive documentation, including temperature logs and handling records, ensures traceability and accountability. For instance, a shipment of highly perishable berries requires a cold chain maintained throughout its journey – from the orchard to the processing plant and eventually to the consumer. Any breach in this cold chain is documented and investigated.

Q 24. What are the key microbial hazards associated with various fruit types?

Microbial hazards vary considerably depending on the fruit type and its handling. For example, Salmonella and E. coli are more commonly associated with fruits that come into contact with soil or fecal matter during growth or harvesting, such as berries and leafy greens. Molds like Aspergillus and Penicillium are a concern for many fruits, especially if they are damaged or improperly stored. Listeria monocytogenes can survive in refrigerated conditions, posing a risk to soft fruits. Yersinia enterocolitica is another potential hazard associated with various fruits. The risk is significantly heightened with improper hygiene during harvesting, processing, and handling. For example, contaminated water used in washing can introduce pathogens into the fruit.

Q 25. How do you handle discrepancies between laboratory results and visual inspection findings?

Discrepancies between lab results and visual inspection require a thorough investigation. Visual inspection is a first line of defense, but it has limitations; some pathogens are invisible to the naked eye. When a discrepancy arises, we first re-examine the sample, ensuring proper sampling and preparation techniques were followed. We may re-test the sample using different laboratory methods to confirm the initial result. If discrepancies persist, we carefully investigate the entire process, from harvesting to testing, looking for procedural errors or environmental factors that could explain the variance. Thorough documentation of each step helps in isolating the root cause. A detailed root cause analysis might reveal issues with sanitation protocols or equipment malfunctioning. For example, a visual inspection deemed a batch of apples acceptable, yet lab testing revealed high levels of E.coli. A subsequent investigation uncovered a minor leak in a sanitation system during the washing stage.

Q 26. Describe your experience with using different equipment and technologies for fruit safety inspection.

My experience encompasses a wide range of equipment and technologies. I am proficient in using near-infrared (NIR) spectroscopy for rapid, non-destructive analysis of fruit composition and quality parameters relevant to safety, like sugar content and water activity. I’ve also used hyperspectral imaging to detect bruises and defects not visible to the naked eye, helping to identify areas where microbial contamination is more likely. We employ sophisticated microbiological testing equipment, including automated colony counters and PCR (polymerase chain reaction) systems, for sensitive and accurate pathogen detection. I am also familiar with X-ray imaging systems to identify internal defects and foreign materials which can aid in safety assessment.

Q 27. What are your strengths and weaknesses when it comes to maintaining fruit safety standards?

My strengths lie in my meticulous attention to detail, my systematic approach to problem-solving, and my proactive approach to preventing safety issues. I consistently adhere to established protocols, and I’m adept at interpreting data from various sources to make informed decisions. However, like everyone, I have areas for improvement. One area I’m actively working on is enhancing my communication skills in conveying complex technical information to non-technical audiences. Another area is staying abreast of the latest advancements in fruit safety technologies and integrating them into my workflow. Constant learning and self-improvement are crucial in this field.

Q 28. How do you prioritize tasks and manage time effectively during a busy fruit inspection period?

During busy periods, effective prioritization is crucial. I use a combination of techniques to manage my workload. First, I identify critical tasks based on risk assessment—high-risk fruits and critical control points receive top priority. Then, I employ time-management strategies like creating detailed schedules, utilizing checklists, and breaking down large tasks into smaller, manageable ones. I also prioritize tasks based on urgency and their impact on consumer safety. Regular communication with stakeholders, including producers, processors, and regulatory agencies, keeps everyone informed, reduces delays, and ensures collaboration. For example, prioritizing the inspection of a large shipment of highly perishable mangoes that is showing signs of early spoilage would take precedence over a routine inspection of a stable commodity.

Key Topics to Learn for Expertise in Fruit Safety and Inspection Interview

- Good Agricultural Practices (GAPs): Understanding and applying principles of GAPs to ensure fruit safety from farm to market. This includes sanitation, pest management, and worker hygiene.

- Hazard Analysis and Critical Control Points (HACCP): Applying HACCP principles to identify and control potential hazards throughout the fruit production and processing chain. Practical application includes developing and implementing HACCP plans.

- Foodborne Illness Prevention: Knowledge of common foodborne pathogens affecting fruit and the preventative measures to minimize risk. This includes understanding sanitation procedures and temperature control.

- Pest and Disease Management: Understanding integrated pest management (IPM) strategies and effective disease control methods for various fruit types. Practical application involves identifying pests and diseases and implementing appropriate control measures.

- Post-Harvest Handling and Storage: Knowledge of proper techniques for handling, packing, and storing fruit to maintain quality and safety. This includes understanding optimal temperature and humidity levels.

- Regulations and Compliance: Familiarity with relevant food safety regulations and industry standards (e.g., FDA, USDA). Practical application involves ensuring compliance with these regulations throughout the supply chain.

- Inspection Techniques and Procedures: Understanding the methods and procedures used for inspecting fruit for quality, safety, and compliance with regulations. This includes visual inspection, testing, and documentation.

- Traceability and Record Keeping: Understanding the importance of traceability systems and accurate record keeping to track fruit throughout the supply chain. This includes documenting inspection findings and other critical data.

Next Steps

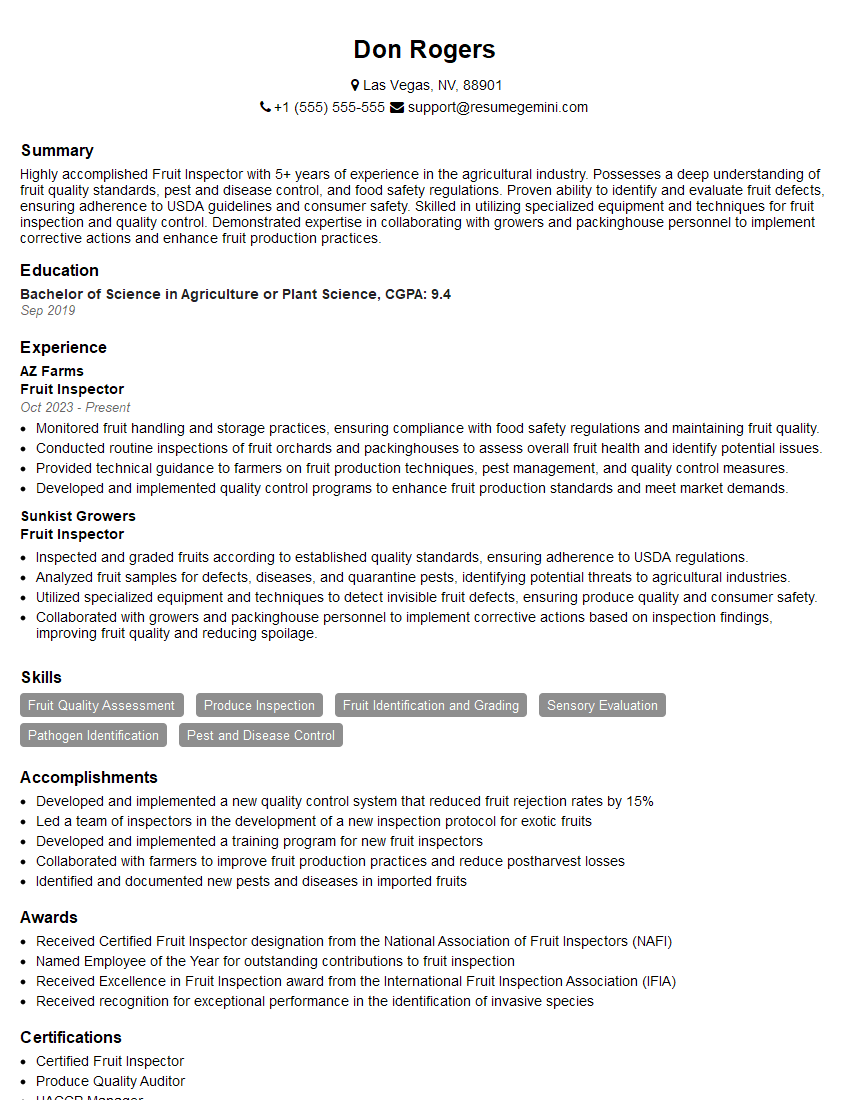

Mastering Expertise in Fruit Safety and Inspection opens doors to rewarding careers in the food industry, offering opportunities for growth and specialization. To maximize your job prospects, focus on creating a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your expertise. Examples of resumes tailored to Expertise in Fruit Safety and Inspection are available to guide you. Take the next step towards your dream career – build a compelling resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good