Are you ready to stand out in your next interview? Understanding and preparing for Use ladders, scaffolding, and other equipment interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Use ladders, scaffolding, and other equipment Interview

Q 1. Describe the different types of ladders and their appropriate uses.

Ladders come in various types, each designed for specific applications. Choosing the right ladder is crucial for safety and efficiency.

- Step Ladders: These self-supporting ladders are ideal for shorter tasks where you need a stable platform. Think of painting a wall in your living room or changing a lightbulb.

- Extension Ladders: These are adjustable in height, making them versatile for taller jobs. Imagine needing to reach the roof to clean gutters.

- Straight Ladders: These are used for accessing higher points, often leaning against a wall or structure. Consider using one to clean high windows.

- Articulating Ladders (Multi-position ladders): These can be configured into various positions – A-frame, extension, or scaffold, offering flexibility. This is a great choice for DIY projects requiring different angles.

- Platform Ladders: These offer a larger working platform, enhancing stability and convenience. Perfect for more involved tasks like installing exterior lights or cleaning high windows.

The key is selecting a ladder type that matches the task’s height, stability requirements, and your comfort level. Always prioritize safety over convenience.

Q 2. Explain the importance of regular ladder inspections.

Regular ladder inspections are paramount for preventing accidents. A damaged ladder is a dangerous ladder. Think of it like your car – regular maintenance is essential.

Inspections should check for:

- Cracks or breaks in the rails, steps, or stiles: Even small cracks can weaken the ladder’s structure.

- Loose rivets, bolts, or welds: These can cause sudden failure.

- Damaged or worn feet: These provide essential grip and stability.

- Bent or damaged sections: A bent rail might seem minor, but it compromises the ladder’s strength.

- Signs of corrosion or rot (for wooden ladders): Wood decay weakens the ladder significantly.

Regular inspections – ideally before each use – can identify issues early, allowing for repairs or replacement, saving lives and preventing costly accidents.

Q 3. What are the key safety precautions when using a ladder?

Ladder safety is non-negotiable. It’s about more than just reaching the top; it’s about getting down safely too.

- Proper setup: Ensure the ladder is on a stable, level surface. Use ladder stabilizers where appropriate.

- Angle of inclination: The base should be one-fourth the working height away from the wall. This creates the correct angle.

- Three-point contact: Always maintain three points of contact (two hands and one foot, or two feet and one hand) on the ladder.

- Avoid overloading: Never exceed the ladder’s weight capacity.

- Use caution on slippery surfaces: Use rubber feet or non-slip mats if necessary.

- Never overreach: Stay centered on the ladder. If you need to reach further, move the ladder.

- Wear appropriate footwear: Avoid wearing slippery shoes.

- Secure the ladder: If possible, secure the ladder at the top using appropriate straps or hooks.

Remember, a moment of carelessness can have devastating consequences. Prioritize safety at all times.

Q 4. How do you determine the appropriate ladder length for a specific task?

Determining the correct ladder length is crucial. It’s not just about reaching the top but ensuring safe working space.

The rule of thumb is to extend the ladder 3 feet above your working height. This provides a safe margin for reaching and descending without overreaching. For instance, if you need to work at a height of 10 feet, you’ll need a ladder that extends to at least 13 feet.

Always consider the angle of inclination mentioned earlier. A longer ladder might seem like an easy choice, but an improper angle will lead to instability.

If unsure, always err on the side of caution and choose a longer ladder rather than risking a fall.

Q 5. What are the common causes of ladder accidents?

Ladder accidents often stem from preventable causes.

- Improper setup: Using a ladder on an unstable surface, incorrect angle of inclination, or not using stabilizers.

- Overreaching: Reaching too far to the side while on the ladder.

- Overloading: Exceeding the ladder’s weight limit.

- Slippery conditions: Working on wet or oily surfaces.

- Faulty equipment: Using a damaged or poorly maintained ladder.

- Lack of training and awareness: Insufficient knowledge about proper ladder safety procedures.

Many accidents are preventable through proper training, regular inspection, and adherence to safety guidelines. Remember, prevention is always better than cure.

Q 6. Describe the different types of scaffolding systems.

Scaffolding systems provide a stable and secure working platform at heights. They vary widely in design and application.

- Independent Tied Scaffolding: This free-standing system is often used for exterior work, providing excellent stability.

- Suspended Scaffolding: This type hangs from a structure, often used for exterior building maintenance or renovations.

- Tube and Clamp Scaffolding: Highly versatile, this system uses tubes and clamps to create custom configurations, offering significant flexibility.

- System Scaffolding (Pre-engineered): These pre-fabricated systems are quicker to erect and dismantle but offer less flexibility.

- Mobile Scaffold Towers (Rollers): These wheeled units provide mobility for interior work.

Choosing the correct scaffolding system depends on the job’s complexity, height, location, and access requirements. Proper planning is essential before starting any scaffolding work.

Q 7. Explain the process of erecting and dismantling scaffolding safely.

Erecting and dismantling scaffolding safely is critical. It’s a step-by-step process requiring careful attention to detail and adherence to safety standards.

Erecting:

- Planning: Assess the job site, plan the scaffolding’s layout and components, and check the ground conditions.

- Base Preparation: Ensure a stable and level base. Consider using base plates or cribbing.

- Assembly: Follow the manufacturer’s instructions precisely, ensuring proper connections and bracing.

- Inspection: Thoroughly inspect the erected structure for stability and any potential hazards.

Dismantling:

- Planning: Plan the dismantling process meticulously, working from the top down.

- Removal of Materials: Carefully remove materials systematically and in a controlled manner.

- Lowering of Components: Use appropriate lowering systems to avoid dropping components.

- Final Inspection: Conduct a final inspection to ensure complete removal and the safety of the area.

Always adhere to relevant safety regulations and ensure proper training for all personnel involved. Never rush the process – safety should always be prioritized.

Q 8. What are the safety regulations and standards related to scaffolding use?

Scaffolding safety regulations and standards are crucial for preventing accidents. They vary slightly by region but generally cover design, erection, use, and dismantling. Key aspects include ensuring the scaffolding is designed by a competent person for the specific task and load, using appropriate materials in good condition, providing adequate access and egress, and maintaining a safe working distance from power lines. Regulations often mandate regular inspections by competent personnel, the use of proper tie-ins and base plates to ensure stability, and the provision of guardrails and toe boards to prevent falls. For example, OSHA (in the US) and similar organizations worldwide have detailed standards that cover things like maximum spans, the correct type of scaffolding for the job (e.g., system scaffold, tube and clamp, etc.), and requirements for fall protection.

- Design Calculations: These must be performed to ensure the scaffold can withstand the anticipated loads.

- Inspection Documentation: Meticulous records of inspections are vital to demonstrate compliance and track the scaffold’s condition.

- Training Certification: Workers must receive appropriate training and certification before working on or around scaffolding.

Q 9. How do you ensure the stability of scaffolding during use?

Ensuring scaffold stability is paramount. It begins with proper ground preparation – a level and firm base is essential. The scaffold must be correctly erected according to the manufacturer’s instructions and relevant regulations. This includes using appropriate base plates, ensuring proper bracing, and tying the scaffold securely to the structure. Regular inspections are critical, checking for any signs of instability, such as loose connections, uneven loading, or damage to components. The scaffold should never be overloaded; weight limits should be clearly defined and strictly adhered to. Think of it like building a house – a strong foundation and careful construction are key to its stability. Overloading one area could compromise the entire structure.

- Plumb and Level Checks: Frequent checks ensure the scaffold remains vertical and horizontal.

- Tie-in points: Secure connections to the building are essential for preventing sway or collapse.

- Load Distribution: Heavy materials should be evenly distributed across the scaffold.

Q 10. What are the potential hazards associated with scaffolding work?

Scaffolding work presents several potential hazards. Falls are the most significant, accounting for a high percentage of accidents. Other risks include being struck by falling objects (tools, materials), electrocution (contact with power lines), and collapse of the scaffolding itself. Additionally, there’s the risk of slips, trips, and falls on the scaffold platform, and the potential for injuries from working at heights.

- Fall Protection: Absence of adequate fall protection is a major contributor to accidents.

- Material Handling: Improper handling of materials can lead to dropped objects.

- Scaffold Instability: Poor erection or maintenance increases the chance of collapse.

- Weather Conditions: Working in high winds or rain significantly increases the risk.

Q 11. Describe your experience with fall protection equipment.

I have extensive experience with a variety of fall protection equipment, including full-body harnesses, lanyards, shock-absorbing lanyards, self-retracting lifelines (SRLs), and anchor points. I’m proficient in selecting the appropriate equipment for different tasks and ensuring it’s properly inspected and maintained before each use. I’ve used these systems on numerous scaffolding projects, ensuring workers are protected from falls. For instance, on a recent high-rise project, we used SRLs anchored to the building structure, providing continuous fall protection for workers as they moved around the scaffold.

- Harness Inspection: Checking for any wear and tear, damage, or defects is crucial.

- Anchor Point Selection: Choosing structurally sound anchor points is vital.

- System Integration: Correct integration of all components of the fall protection system is essential for effectiveness.

Q 12. Explain the different types of fall arrest systems and their applications.

Fall arrest systems are categorized into several types, each suited for specific applications. Full-body harnesses are the foundation, distributing forces across the body in case of a fall. Lanyards connect the harness to an anchor point; shock-absorbing lanyards mitigate impact forces during a fall. Self-retracting lifelines (SRLs) automatically retract the lifeline and provide constant connection, ideal for movement. Horizontal lifelines provide protection along a horizontal plane. The choice depends on the work environment and the nature of the task. For example, SRLs are perfect for workers who need to move around a scaffold, whereas a fixed lanyard might be suitable for working in one confined location.

- SRLs: Best for dynamic work involving frequent movement.

- Fixed Lanyards: Suitable for stationary work.

- Horizontal Lifelines: Ideal for multiple workers along a line.

Q 13. How do you perform a pre-use inspection of fall protection equipment?

A pre-use inspection of fall protection equipment is critical. I always start by visually inspecting the harness for tears, cuts, fraying, or any signs of damage to stitching or buckles. I check the lanyards for wear, cuts, and proper functioning of shock absorbers (if applicable). I test the SRL’s retraction mechanism to ensure it functions smoothly and locks securely. I inspect all connection points (carabiners, snaps, etc.) and make sure they are free of defects and properly closed. The anchor point is checked for its structural integrity and ability to support the required load. Any doubt about the condition of any component leads to its immediate removal from service.

- Documentation: All inspections must be thoroughly documented.

- Training: Workers must be trained in how to conduct these inspections.

- Regular Maintenance: Equipment should be inspected regularly, even if not in use.

Q 14. What are the limitations of different types of fall protection systems?

Each fall protection system has limitations. SRLs have limited travel distance; exceeding this can lead to insufficient shock absorption during a fall. Fixed lanyards restrict movement and are unsuitable for dynamic tasks. Horizontal lifelines require proper installation and may not be suitable for every work environment. The effectiveness of any system relies heavily on proper installation, maintenance, and user training. Environmental conditions (e.g., extreme temperatures) can also impact the performance of certain materials. For example, a lanyard exposed to excessive UV radiation might weaken over time. Careful consideration of these factors is vital in choosing the appropriate system and ensuring safe working practices.

- Travel Distance Limitations: Understanding the limitations of SRLs is essential.

- Environmental Factors: Consider the impact of temperature and UV exposure.

- Material Degradation: Regular inspection is needed to detect wear and tear.

Q 15. How do you rescue someone who has fallen from height?

Rescuing someone who has fallen from a height is a critical situation demanding immediate and coordinated action. The first priority is ensuring the safety of both the rescuer and the fallen person. Never attempt a rescue without proper training and equipment.

The steps generally involve:

- Assess the situation: Check the victim’s condition, the stability of the surrounding area, and potential hazards like further falls or unstable structures.

- Secure the scene: Isolate the area to prevent further accidents. Alert emergency services immediately – providing accurate location and details of the incident.

- Stabilize the victim: Provide first aid if qualified to do so, focusing on preventing further injury. Immobilize the victim’s neck and spine if there are any indications of spinal injury.

- Rescue the victim: Employ appropriate rescue techniques, potentially using harnesses, ropes, and specialized equipment. This could involve a lowering system or a controlled descent depending on the circumstances. Teamwork and communication are key.

- Evacuate the victim: Once secured, carefully remove the victim from the scene, using appropriate equipment such as a stretcher. Ensure a safe path and consider the victim’s injuries during transport.

Example: Imagine someone falling off a scaffold. Before approaching, I’d ensure the scaffold is stable and wouldn’t collapse further. I’d then call emergency services while simultaneously assessing the victim’s injuries. If I was trained and equipped for a rescue, I would use appropriate equipment like a harness and rope system to lower the individual safely to the ground.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the procedures for working at height in adverse weather conditions?

Working at height in adverse weather conditions significantly increases the risk of accidents. Strong winds, heavy rain, ice, and snow can compromise equipment stability and create slippery surfaces. The procedures are much stricter than in normal weather. The overriding principle is: If it’s too dangerous to work, it’s too dangerous to work.

Here’s a breakdown:

- Risk Assessment: A thorough risk assessment is paramount. It should consider specific weather forecasts, wind speeds, precipitation, and potential lightning strikes. It may lead to postponing work altogether.

- Appropriate Equipment: Wind-resistant equipment and additional safety measures are crucial. This may involve using heavier-duty scaffolding or securing equipment more firmly.

- Weather Monitoring: Continuous monitoring of weather conditions is essential. Work should be stopped immediately if conditions deteriorate beyond acceptable limits, defined in the risk assessment.

- Protective Clothing: Suitable high-visibility clothing, waterproof gear, and appropriate footwear are mandatory. This protects workers from the elements and enhances visibility.

- Communication: Clear communication among workers and supervisors is critical in maintaining safety and awareness of changing weather conditions.

Example: If high winds are predicted, we would postpone work on a high-rise building using a boom lift until the wind speed falls below a predetermined safe threshold specified in our risk assessment. Similarly, work would halt immediately if heavy rain made the working surface dangerously slippery.

Q 17. Explain the importance of risk assessment before working at height.

A risk assessment is the cornerstone of safe work at height. It’s a systematic examination to identify potential hazards and implement control measures to mitigate risks. It’s not just a box-ticking exercise; it’s a proactive approach to preventing accidents. Think of it as a detailed plan to keep everyone safe.

The importance lies in:

- Identifying Hazards: It helps pinpoint specific dangers associated with the task, such as unstable surfaces, equipment malfunctions, or environmental factors.

- Evaluating Risks: It assesses the likelihood and severity of potential accidents, determining the overall level of risk.

- Implementing Controls: Based on the risk assessment, appropriate control measures can be implemented, such as selecting suitable equipment, providing training, and establishing safe work procedures.

- Minimizing Accidents: By identifying and mitigating risks, a risk assessment drastically reduces the chances of accidents, injuries, and fatalities.

- Legal Compliance: A comprehensive risk assessment demonstrates compliance with health and safety regulations, protecting the company and its workers from legal repercussions.

Example: Before erecting a scaffold, a risk assessment would consider the ground stability, the type and condition of the scaffolding components, the weather forecast, and the training level of the workers. This informs decisions about securing the scaffold, using appropriate personal protective equipment (PPE), and establishing communication protocols.

Q 18. How do you identify and mitigate potential hazards associated with working at height?

Identifying and mitigating hazards associated with working at height is a continuous process. It involves a multi-faceted approach encompassing careful planning, proper training, and vigilant observation.

Hazard Identification: This involves a thorough review of the worksite, considering:

- Environmental factors: Weather conditions, ground stability, obstructions.

- Equipment: Condition of ladders, scaffolds, harnesses, and other equipment.

- Human factors: Worker fatigue, lack of training, poor communication.

- Task-specific hazards: Specific risks related to the task being performed at height.

Hazard Mitigation: Once hazards are identified, control measures are implemented to reduce the risk, including:

- Eliminating hazards: If possible, remove the hazard entirely. For example, if a task can be completed from the ground, that is preferred.

- Engineering controls: Use of safety equipment like guardrails, fall arrest systems, and secure platforms.

- Administrative controls: Establish safe work procedures, provide thorough training, implement permit-to-work systems, and regular inspections.

- Personal protective equipment (PPE): Provide and ensure the correct use of PPE like harnesses, helmets, and safety footwear.

Example: If working on a roof, a hazard might be a lack of edge protection. Mitigation might involve installing a temporary guardrail system before workers begin the task.

Q 19. Describe your experience with using powered access equipment (e.g., scissor lifts, boom lifts).

I have extensive experience operating various powered access equipment, including scissor lifts, boom lifts, and articulated boom lifts. My experience spans various construction sites and industrial settings, encompassing both indoor and outdoor environments.

My experience includes:

- Pre-operational checks: Thoroughly inspecting the machine for any damage or defects before each use.

- Safe operation: Following manufacturer’s instructions and adhering to all relevant safety regulations.

- Working at height: Performing tasks such as painting, welding, and inspections from elevated positions safely and efficiently.

- Confined space operation: Operating equipment in confined spaces, taking necessary precautions to ensure stability and safety.

- Maintenance and reporting: Reporting any mechanical issues or needed maintenance.

Example: On a recent project, I used a boom lift to install HVAC equipment on a multi-story building. I performed pre-operational checks, ensured the ground was stable, and communicated clearly with ground personnel during the operation.

Q 20. What are the safety procedures for operating powered access equipment?

Safety procedures for operating powered access equipment are crucial to prevent accidents. They are built around a framework of pre-operational checks, safe operating practices, and post-operational procedures.

Key safety procedures include:

- Pre-operational checks: A thorough inspection of the machine’s hydraulics, controls, safety devices, and tires before each use. This should be documented.

- Ground conditions: Assessing the stability of the ground, ensuring a level surface free from obstructions.

- Safe working load: Never exceeding the machine’s safe working load capacity. This information is clearly marked on the machine.

- Operator training and certification: Only trained and certified operators should operate the equipment.

- Safe operation: Following the manufacturer’s instructions, maintaining three points of contact when ascending or descending, avoiding sudden movements.

- Environmental factors: Considering wind speed, rain, and other weather conditions. Work may need to be suspended in adverse weather.

- Emergency procedures: Understanding and practicing emergency procedures, including evacuation plans in case of malfunction.

- Post-operational checks: Lowering the platform safely, securing the equipment, and performing a final check for any damage.

Example: Before operating a scissor lift, I’d check the hydraulic fluid level, ensure the emergency stop button functions correctly, and inspect the platform for any damage before allowing anyone to use it.

Q 21. How do you ensure the safe operation of powered access equipment in confined spaces?

Operating powered access equipment in confined spaces presents unique challenges due to limited maneuverability and potential obstructions. Safety is paramount, demanding extra caution and careful planning.

Key considerations include:

- Space assessment: Determining if the equipment can safely fit into the space, considering height, width, and turning radius. Consider the potential for entanglement with obstructions.

- Equipment selection: Choosing the right equipment – a smaller, more maneuverable machine might be necessary for a confined space.

- Stability: Ensuring the equipment’s stability is paramount. Uneven surfaces or obstructions can compromise this. Outriggers may need to be used.

- Ventilation and oxygen levels: In enclosed spaces, adequate ventilation is critical to prevent oxygen deficiency. Oxygen levels should be monitored.

- Emergency access: Ensuring a clear escape route in case of emergency. The machine’s emergency controls must be easily accessible.

- Communication: Maintaining clear communication with ground personnel is critical.

Example: When using a boom lift in a narrow basement, I would first assess the space thoroughly, ensuring there’s sufficient clearance for the equipment to operate safely. I’d use outriggers for stability and establish a clear communication system with a ground crew to guide the lift and ensure safety.

Q 22. What are the emergency procedures if a powered access equipment malfunctions?

If a powered access platform malfunctions, the priority is immediate and controlled shutdown. This typically involves activating the emergency stop button, which is usually prominently displayed and easily accessible from the platform. Following this, we must ensure everyone on the platform safely exits. This could mean using the emergency descent mechanism (if available and safe to use) or, if necessary, using a secondary rescue plan such as an external rescue system or the fire department. Communication is crucial; someone should immediately contact the relevant supervisor and/or emergency services. The malfunction should be thoroughly investigated afterwards, with attention paid to identifying the root cause to prevent future incidents. This investigation often involves inspecting the equipment’s maintenance logs and working with manufacturers or service technicians. For instance, during a recent job, a scissor lift’s hydraulic system failed. Following emergency shutdown, we used the manual lowering system, ensuring that all personnel were clear of the lift before descending. We subsequently reported the incident and the lift was taken out of service pending inspection and repair.

Q 23. Describe your experience with using other height access equipment (e.g., aerial work platforms).

I have extensive experience operating various height access equipment, including scissor lifts, boom lifts (both articulating and telescopic), and cherry pickers. My experience spans diverse construction and maintenance projects, ranging from building façade repairs to overhead electrical work. I am proficient in pre-use inspections, understanding load limits, and operating controls safely and effectively. For example, on a recent project involving the installation of signage on a high building, I utilized a telescopic boom lift to precisely position the signage. This involved carefully calculating the reach and load capacity to ensure the stability of the lift and the safety of the team. Each equipment type has its own unique operating procedures, and I’m comfortable adapting my approach to each situation while adhering to safety protocols. I am also familiar with different types of controls, both manual and electronic, and comfortable working in various weather conditions while adhering to safety precautions.

Q 24. What training and certifications do you hold related to working at height?

I hold several certifications relevant to working at height, including a valid PASMA (Preferred Access for Scaffolding and Mobile Access Towers) certificate for scaffolding and tower erection and dismantling, and a IPAF (International Powered Access Federation) PAL card for operating powered access equipment. Furthermore, I’ve completed comprehensive training in fall protection systems, including the proper use of harnesses, lanyards, and anchor points. My training also covers risk assessment methodologies specific to work at height, ensuring that I’m capable of identifying and mitigating potential hazards before starting any task. My certifications are all up-to-date and I participate in regular refresher courses to stay abreast of industry best practices and evolving safety regulations.

Q 25. How do you communicate effectively with colleagues when working at height?

Effective communication is paramount when working at height. We utilize a combination of visual signals (hand signals), verbal communication (using clear and concise language), and two-way radios to ensure everyone understands instructions and potential hazards. Before commencing any task, we always conduct a thorough risk assessment and safety briefing to discuss potential hazards and the procedures for dealing with them. We use a system of acknowledgment and confirmation for all instructions. For instance, if one team member is directing the positioning of a boom lift, they’ll use hand signals to indicate movement, while another will verbally confirm the instructions. This layered approach minimizes miscommunication and enhances overall safety. In high-noise environments, we might resort to written instructions or rely heavily on visual communication.

Q 26. Describe a time you had to deal with a safety issue while working at height.

During a scaffolding project, I noticed a section of the scaffolding showing signs of significant wear and tear. It wasn’t immediately apparent to others, but my experience allowed me to identify the potential for collapse. I immediately halted work on that section, reported the issue to my supervisor, and we jointly decided to reinforce that area before continuing. It was a costly delay but avoided a potentially serious accident. This situation highlighted the importance of regular inspections, attention to detail, and prioritizing safety over deadlines. We subsequently implemented a more rigorous inspection procedure for all scaffolding projects, including pre-shift and post-shift checks and scheduled intermediate inspections.

Q 27. How do you stay updated on the latest safety regulations and best practices for working at height?

I stay updated on safety regulations and best practices through several channels. I regularly review publications from organizations like the HSE (Health and Safety Executive) and OSHA (Occupational Safety and Health Administration), depending on the regional regulations. I also attend industry conferences and workshops to learn about new technologies and safety procedures. My IPAF and PASMA certifications require ongoing training and recertification to maintain validity, keeping me informed about changes to standards. Further, I actively participate in internal safety meetings and training sessions to share knowledge and best practices within my team. Keeping abreast of these developments ensures I’m always working within the most current safety guidelines.

Q 28. What are your strategies for maintaining a safe work environment when using ladders, scaffolding, and other equipment?

Maintaining a safe work environment involves a multi-pronged approach. This begins with thorough pre-task planning, including a detailed risk assessment. Regular inspections of all equipment – ladders, scaffolding, and powered access platforms – are essential, checking for damage, wear, and proper setup. We ensure that all equipment is properly maintained and regularly serviced according to the manufacturer’s recommendations. All team members receive comprehensive training on the safe use and limitations of all equipment, and we emphasize proper PPE (Personal Protective Equipment) use – hard hats, safety harnesses, and appropriate footwear. Effective communication and teamwork are equally important for ensuring everyone remains aware of potential hazards and adheres to established safety protocols. Furthermore, we always ensure that adequate fall protection is in place, and we never take shortcuts that compromise safety.

Key Topics to Learn for Use ladders, scaffolding, and other equipment Interview

- Safety Regulations and Procedures: Understanding and applying OSHA (or relevant regional) safety regulations for working at heights, including proper equipment inspection, fall protection, and emergency procedures.

- Equipment Selection and Setup: Knowing how to choose the appropriate ladder, scaffold, or other equipment based on the job requirements, load capacity, and work environment. This includes safe setup and dismantling procedures.

- Types of Ladders and Scaffolds: Familiarity with different types of ladders (extension, step, etc.) and scaffolds (single, double, rolling, etc.), their uses, limitations, and potential hazards.

- Fall Protection Systems: Understanding various fall protection systems (harnesses, lifelines, anchor points) and their proper application to minimize fall risks while using ladders and scaffolding.

- Practical Application: Being able to describe scenarios where you’ve used this equipment, highlighting your decision-making process regarding safety and efficiency. Include examples demonstrating your problem-solving skills in challenging situations.

- Troubleshooting and Maintenance: Understanding common equipment problems, how to identify them, and basic maintenance procedures to ensure equipment is in safe working condition. This includes recognizing signs of wear and tear.

- Working with Different Materials: Demonstrate knowledge of how to safely and effectively use ladders and scaffolding when working with various materials (e.g., brick, wood, metal).

Next Steps

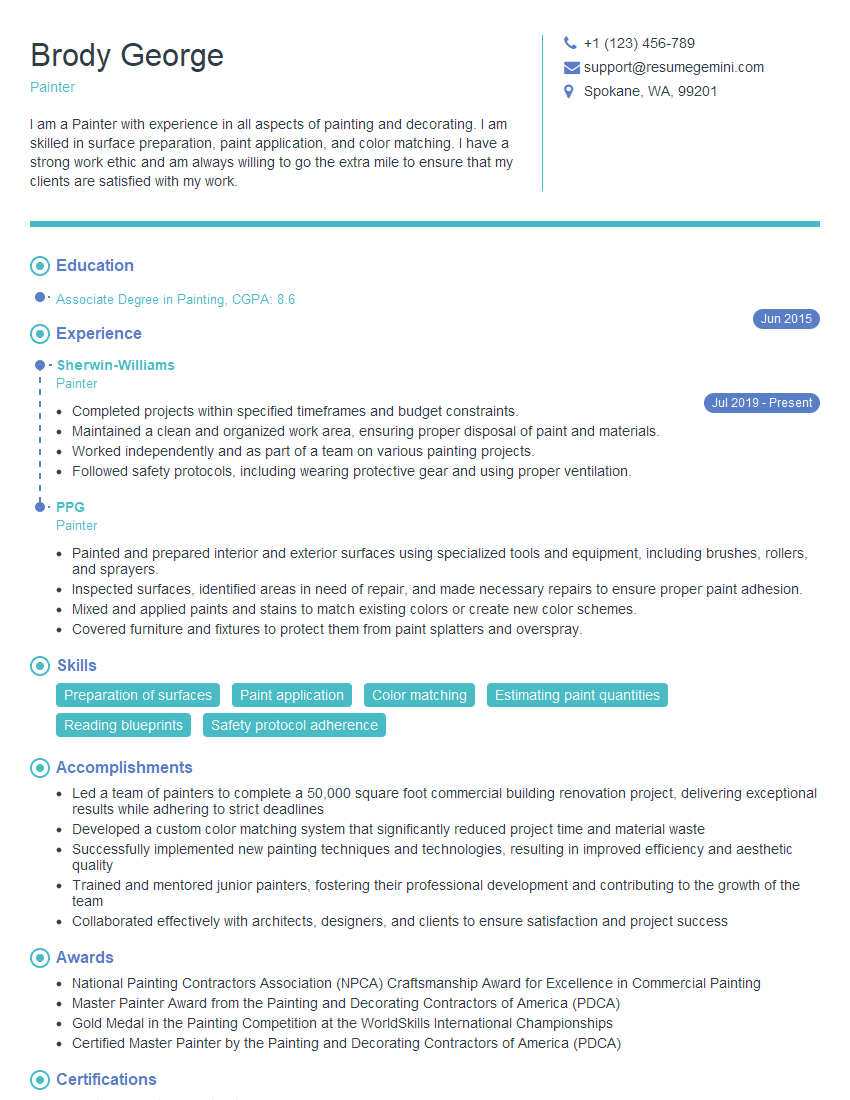

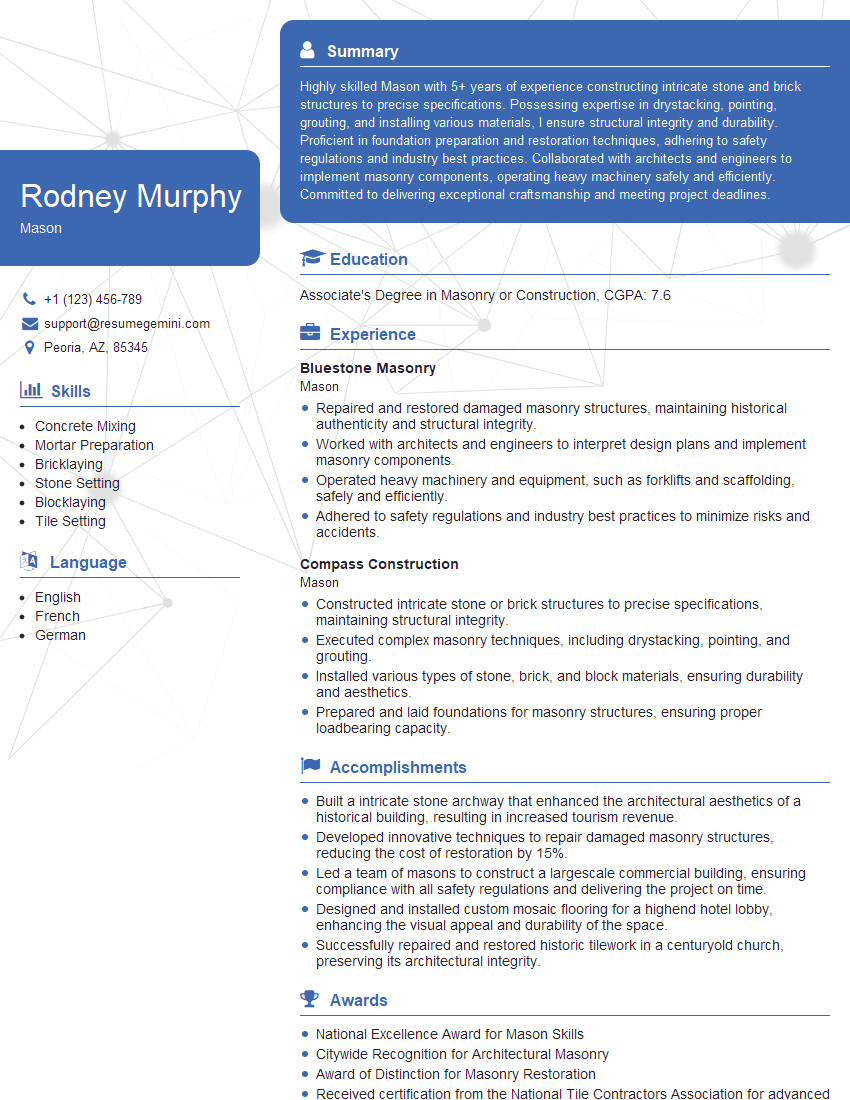

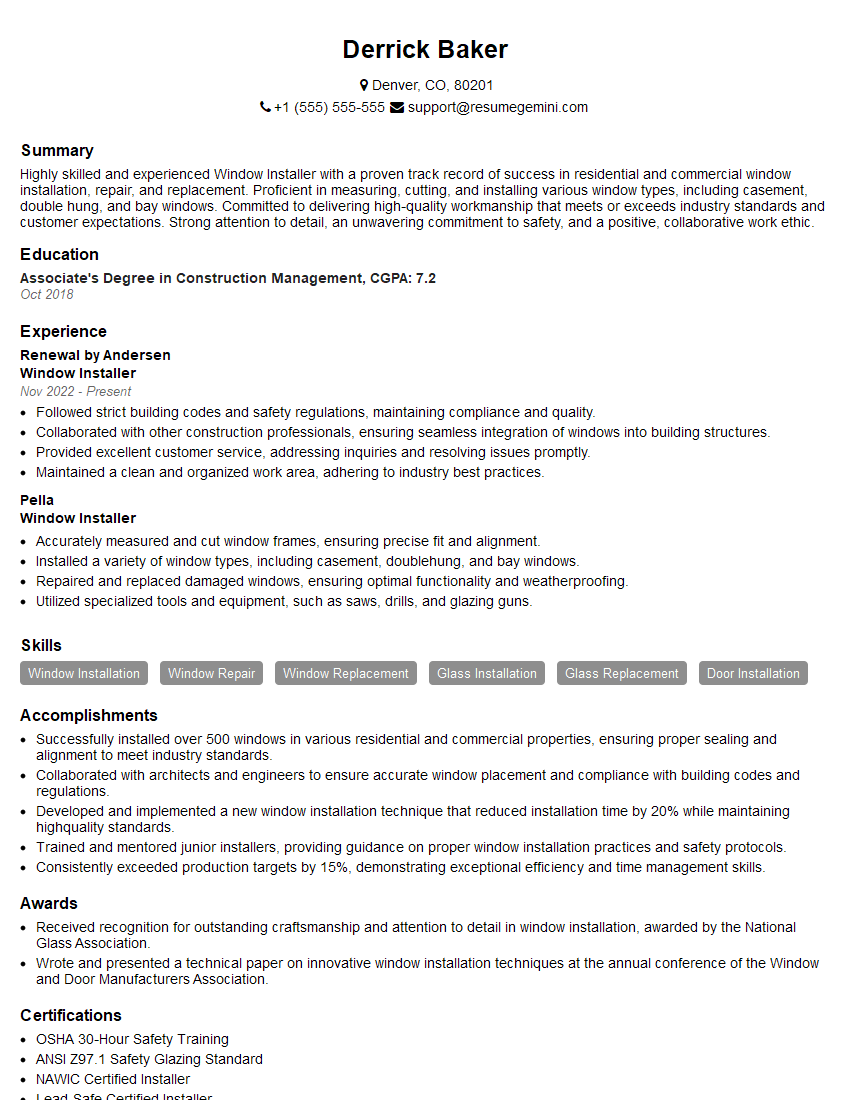

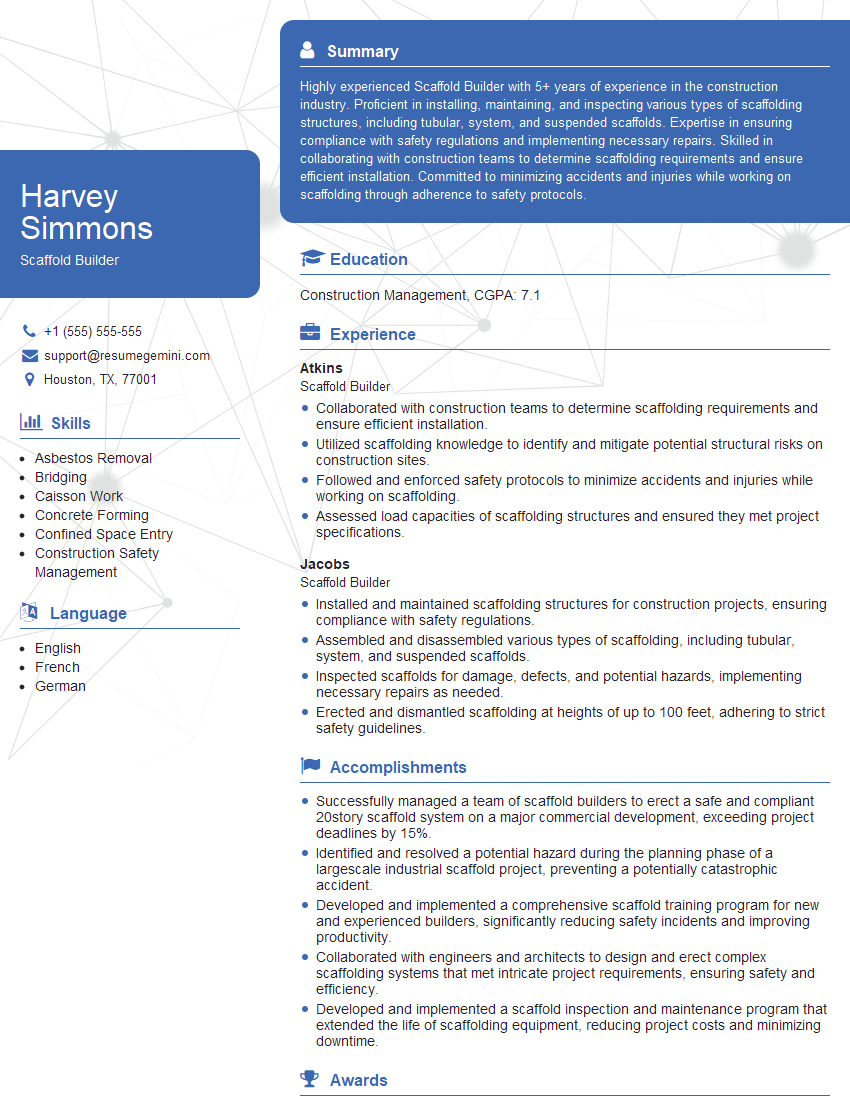

Mastering the safe and efficient use of ladders, scaffolding, and other equipment is crucial for career advancement in construction and related fields. It demonstrates a commitment to safety and a high level of technical skill, both highly valued by employers. To increase your job prospects, create an ATS-friendly resume that highlights your expertise in these areas. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to highlight experience with ladders, scaffolding, and other equipment are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good