Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Building Electrical Design interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Building Electrical Design Interview

Q 1. Explain the NEC (National Electrical Code) and its relevance to building electrical design.

The National Electrical Code (NEC) is a nationally recognized standard for the safe installation of electrical wiring and equipment in buildings. Think of it as the rulebook for electrical safety in construction. It’s crucial for building electrical design because it dictates the minimum requirements for safety, ensuring that electrical systems are installed correctly to prevent fires, shocks, and other hazards. It covers everything from conductor sizing and grounding to overcurrent protection and arc-fault protection. Ignoring the NEC can lead to serious legal and safety consequences, potentially resulting in building permits being denied or even causing injury.

For example, the NEC specifies the minimum size of conductors for a given load to prevent overheating and fire hazards. It also dictates the type of grounding system required depending on the building type and location. Compliance with the NEC is essential for all electrical design professionals.

Q 2. Describe your experience with different types of electrical load calculations.

My experience with electrical load calculations encompasses various methods, including the simple addition of individual loads (for simpler projects), the more complex power factor considerations (vital for industrial settings with significant motor loads), and demand factor calculations (used to account for the unlikely event of all loads operating simultaneously).

I’ve worked with both residential and commercial projects, employing different techniques based on project specifics. For instance, a high-rise residential building necessitates a detailed load calculation considering different apartment types, while a small commercial space might require a simpler approach. I also have expertise in using software like ETAP or SKM PowerTools to perform complex load flow studies and simulations, ensuring a robust and reliable electrical system design.

Understanding load calculations is essential for properly sizing service equipment, distribution panels, and conductors. Inaccuracies can lead to system overloading, potentially causing equipment failure, fires, or even injuries. A meticulously executed load calculation is, therefore, the cornerstone of a safe and efficient electrical design.

Q 3. How do you determine the appropriate size of conductors for a given load?

Determining the appropriate conductor size is crucial for preventing overheating and ensuring safe operation. It’s done using the NEC tables in conjunction with the calculated load. First, we determine the total load current, incorporating factors like demand factors and power factors. Next, we consult the NEC tables to find the minimum conductor size that can safely carry that current, considering the ambient temperature and the type of insulation used. Other factors, like voltage drop, can necessitate using a larger conductor than strictly required by the current-carrying capacity alone. For instance, long runs might require larger conductors to mitigate voltage drop.

For example, if a load calculation reveals a current of 50 amps, we wouldn’t simply select a 50-amp conductor. We’d consult the NEC tables, accounting for the installation method (e.g., conduit, open wiring), and choose a conductor with an ampacity greater than 50 amps to ensure a safety margin. This margin is critical, as a conductor operating near its full capacity is more prone to overheating. This approach is further refined using software tools that provide accurate calculations, considering all factors.

Q 4. What are the different types of grounding systems, and when would you use each?

Grounding systems are crucial for safety, protecting against electrical shocks and preventing equipment damage. The most common types are:

- Grounding Electrode System (GES): This system uses a grounding electrode, such as a ground rod, to connect the electrical system to the earth. It’s commonly used in residential applications and smaller commercial buildings.

- Equipment Grounding Conductor (EGC): This is a separate conductor that runs alongside the circuit conductors and connects the metallic parts of equipment to the grounding electrode. It provides a low-resistance path for fault currents to flow to ground.

- Grounding Grid System: This system employs a network of interconnected grounding electrodes, often used in larger buildings or facilities with complex electrical systems. This method provides more robust grounding and effectively disperses fault currents.

The choice of grounding system depends on several factors, including the building size, type of electrical system, and local soil conditions. Larger buildings often utilize a grounding grid to enhance safety and reliability, while smaller buildings might use a simpler GES. Local codes and regulations further influence the final choice. Proper grounding is non-negotiable in electrical design as it’s a cornerstone of electrical safety.

Q 5. Explain your understanding of voltage drop calculations and their importance.

Voltage drop calculations determine the reduction in voltage between the source and the load. It’s critical because excessive voltage drop can impair equipment performance, reduce efficiency, and even cause equipment failure. Think of it like water pressure in a pipe; if the pipe is too long or too narrow, the water pressure (voltage) will drop significantly at the end.

We calculate voltage drop using formulas that consider conductor length, current, conductor material, and temperature. Acceptable voltage drop levels are specified in the NEC, usually around 3% for branch circuits and 5% for feeders. If the calculated voltage drop exceeds these limits, we need to increase the conductor size or adjust the circuit layout to minimize the voltage drop. This often involves increasing the conductor size, which might be a more expensive solution, but ensures optimal equipment performance.

Neglecting voltage drop calculations can lead to motor overheating, reduced lighting levels, and other operational issues. It’s therefore an essential calculation in every electrical design project.

Q 6. How do you design a lighting system to meet specific illumination levels?

Designing a lighting system starts with determining the required illumination level, typically expressed in foot-candles or lux, based on the building’s function and the occupants’ needs. For example, a hospital operating room needs significantly higher illumination than a residential hallway. Then we select appropriate luminaires (light fixtures) and light sources (LEDs, fluorescent, etc.) based on their efficiency, color temperature, and light distribution characteristics.

Next, we calculate the number and placement of luminaires to achieve the desired illumination level, often utilizing lighting design software. Factors like room dimensions, ceiling height, wall reflectance, and fixture spacing are considered. Energy efficiency is a crucial consideration, and we often incorporate energy-saving techniques like daylight harvesting or occupancy sensors. The final design ensures not only adequate lighting but also an aesthetically pleasing and comfortable environment.

The lighting design process always considers the overall energy consumption and aims to balance adequate illumination with energy efficiency. This balance is crucial for both economic and environmental reasons.

Q 7. Describe your experience with power distribution systems in buildings.

My experience with power distribution systems in buildings spans various scales and complexities. From designing simple panelboards for small commercial spaces to developing intricate distribution schemes for large industrial facilities, I have worked extensively on this aspect of electrical design. This involves selecting appropriate transformers, switchboards, and panelboards based on the calculated loads and system requirements.

In larger projects, I use sophisticated software to perform power flow studies and short-circuit calculations to ensure system reliability and safety under fault conditions. The design needs to account for redundancy, ensuring that the system can operate even with component failures. For instance, a critical facility might require multiple transformers and redundant paths to ensure uninterrupted power supply. My focus is always on safety, reliability, and cost-effectiveness. A well-designed distribution system is the backbone of a functional and safe building, and designing it requires careful planning and detailed calculations.

Q 8. What are your preferred software tools for electrical design (e.g., AutoCAD, Revit)?

My preferred software tools for electrical design are Revit and AutoCAD. Revit’s BIM (Building Information Modeling) capabilities are invaluable for complex projects, allowing for seamless coordination with other MEP disciplines and better clash detection. Its strong parameterization helps in creating accurate and easily modifiable drawings. AutoCAD, on the other hand, remains essential for detailed drawings, particularly for smaller projects or when specific details require precise control beyond what Revit readily provides. I also utilize specialized software for short-circuit and arc flash calculations, typically ETAP or SKM PowerTools.

Q 9. Explain the process of creating electrical drawings and specifications.

Creating electrical drawings and specifications is a multi-stage process. It begins with a thorough understanding of the project requirements, including the building’s intended use, load calculations, and the client’s specific needs. Next, I develop a schematic diagram, illustrating the overall power distribution system. This is followed by the creation of detailed drawings – floor plans showing outlet locations, lighting layouts, and conduit routing; riser diagrams showing vertical runs of wiring; and single-line diagrams showing the main power distribution. Simultaneously, detailed specifications are drafted, outlining equipment requirements, material selection (e.g., wire gauge, conduit type), and installation methods. Throughout, rigorous quality control checks ensure accuracy and compliance. Think of it like building a house – the schematic is the blueprint, the detailed drawings are the construction plans, and the specifications are the detailed material and labor lists.

Q 10. How do you ensure compliance with building codes and regulations?

Compliance with building codes and regulations is paramount. I ensure this by referencing the relevant codes (e.g., NEC in the US, IEC internationally) throughout the design process. This includes verifying that all equipment is listed and labeled by a Nationally Recognized Testing Laboratory (NRTL), ensuring proper grounding and bonding, adhering to safety distances, and meeting requirements for emergency power systems. I also utilize code-checking software to automate certain aspects of compliance verification. Regular internal reviews and potentially third-party audits further solidify compliance. Ignoring codes isn’t just a matter of fines; it’s a matter of safety and potentially catastrophic consequences.

Q 11. Describe your experience with short circuit and arc flash hazard calculations.

I have extensive experience performing short-circuit and arc flash hazard calculations using industry-standard software like ETAP or SKM PowerTools. These calculations are critical for designing safe and reliable electrical systems. Short-circuit calculations determine the maximum fault current a system can experience, enabling the selection of appropriate protective devices like circuit breakers. Arc flash studies, on the other hand, analyze the potential energy released during an arc flash incident, which is crucial for determining appropriate personal protective equipment (PPE) for electricians working on the system. For example, a recent project involved a large industrial facility. The short-circuit calculations helped size the switchgear and protective devices, while the arc flash study ensured the electrical workers had the necessary PPE, minimizing potential injury.

Q 12. How do you coordinate electrical design with other MEP disciplines?

Coordination with other MEP disciplines (Mechanical, Electrical, Plumbing) is achieved through regular meetings, model coordination using BIM software, and thorough review of drawings. For instance, in Revit, we can integrate models from different disciplines, identifying clashes early on. This collaborative approach prevents conflicts, such as conduit routing through HVAC ducts or pipe penetrations interfering with electrical equipment. Clear communication and a shared understanding of project goals are key. A successful project isn’t just about individual expertise; it’s about team effort.

Q 13. What are your strategies for managing electrical projects within budget and schedule?

Managing electrical projects within budget and schedule requires meticulous planning and execution. This starts with a detailed budget breakdown, considering all aspects – labor, materials, equipment, and software. Regular progress tracking, using tools like Gantt charts and project management software, helps monitor progress against the timeline. Value engineering, identifying cost-effective alternatives without compromising safety or performance, is a crucial strategy. Proactive communication with the client and contractors ensures transparency and allows for timely adjustments if necessary. My approach mirrors a conductor’s orchestra – each element is crucial, and skillful management ensures a harmonious outcome.

Q 14. Explain your experience with different types of electrical protection devices.

My experience encompasses various electrical protection devices, including circuit breakers (molded-case, air circuit breakers), fuses, ground fault circuit interrupters (GFCIs), arc fault circuit interrupters (AFCIs), and surge protection devices (SPDs). I understand the application of each device and their selection based on factors like fault current, voltage rating, and the specific hazard being mitigated. For example, GFCIs are essential in wet locations to protect against electric shock, while AFCIs protect against arc faults in residential settings. SPD selection depends on the anticipated surge levels, protecting sensitive equipment from voltage spikes. Each device serves a specific purpose, and understanding their capabilities is crucial for a safe and reliable electrical system.

Q 15. How do you handle design changes and revisions during a project?

Design changes are inevitable in building electrical projects. My approach prioritizes clear communication and meticulous documentation. We start by formally documenting all change requests, including their impact on the schedule, budget, and the overall design. This often involves a change order process, which outlines the modifications and their associated costs.

For example, if a client decides to add a new server room after initial design completion, we’ll meticulously assess the increased power requirements, cable routing needs, and potential impact on existing systems. This includes creating updated schematics, load calculations, and potentially revising the panel schedules. Each change is reviewed with the client and stakeholders to ensure complete understanding and agreement before implementation. We utilize version control software to track changes to drawings and specifications, ensuring that all parties have access to the most current version. This methodical process minimizes errors and ensures a smooth project completion, even with design revisions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your approach to troubleshooting electrical problems in buildings.

Troubleshooting electrical problems requires a systematic approach. I begin by prioritizing safety – always de-energizing circuits before any direct work. Then, I gather information: interviewing occupants to understand the nature of the problem, reviewing building documentation (plans, schematics, maintenance logs), and visually inspecting the affected area. This often includes using tools like multimeters to measure voltage, current, and resistance.

For instance, if a circuit breaker keeps tripping, I might first check for overloads by assessing the connected loads. If the overload is ruled out, I would investigate potential short circuits, checking for faulty wiring, damaged insulation, or malfunctioning appliances. I use a systematic process of elimination, starting with the most likely causes and progressively moving to more complex issues. Detailed documentation of the problem, troubleshooting steps, and solution is crucial for future reference. Proper documentation also protects both the client and myself from potential liability issues.

Q 17. What are your experiences with different types of power generation systems?

My experience encompasses various power generation systems, including traditional grid-tied systems, backup generators (diesel and natural gas), and renewable energy sources like solar photovoltaic (PV) and wind.

I’ve designed systems incorporating grid-tied power as the primary source, with backup generators providing power during outages. This requires careful consideration of transfer switches, automatic load shedding capabilities, and compliance with relevant codes and regulations. I have also worked on projects integrating solar PV systems, necessitating understanding of array sizing, inverter selection, and interconnection with the grid or battery storage. Each system requires unique design considerations related to safety, reliability, and efficiency. For example, a large commercial building might require a comprehensive system combining grid power, solar PV, and a large-capacity generator, while a smaller residential building could use a simpler system relying primarily on grid power with a smaller generator for backup.

Q 18. How do you select appropriate lighting fixtures for different spaces?

Selecting lighting fixtures involves considering several factors: the space’s function, ambiance desired, energy efficiency, and budget.

For example, a hospital operating room needs bright, shadow-free lighting with high color rendering index (CRI) for accurate color perception during surgery. This would necessitate specialized surgical lighting fixtures with precise control. In contrast, a restaurant might require dimmable fixtures to create a warm and inviting atmosphere, potentially using track lighting or pendant lights depending on the design. Always considering the specific needs and the overall design aesthetic is crucial. I utilize lighting design software to simulate lighting levels and assess glare, ensuring the final design meets both functional and aesthetic requirements. Energy-efficient options like LED lighting are usually prioritized, and luminaire selection is also guided by life cycle cost analysis to balance initial costs with long-term energy savings and maintenance.

Q 19. Explain your familiarity with energy-efficient lighting design practices.

Energy-efficient lighting design focuses on minimizing energy consumption without compromising illumination quality.

Key practices include utilizing high-efficiency lighting sources (LEDs), optimizing lighting levels based on occupancy sensors and daylight harvesting, and implementing proper lighting controls. For example, incorporating daylight sensors to dim or turn off artificial lights when sufficient natural light is available. We often design systems with occupancy sensors to automatically switch off lights in unoccupied spaces, thus saving a significant amount of energy. Moreover, understanding the differences between color temperatures (Kelvin) and color rendering index (CRI) is critical for selecting appropriate light sources that meet both energy efficiency and aesthetic needs. Thorough lighting calculations using software like DIALux or Relux are essential to ensure compliance with energy codes and client expectations.

Q 20. What is your understanding of the requirements for emergency lighting systems?

Emergency lighting systems are crucial for ensuring safe evacuation during power outages. Codes like the International Building Code (IBC) specify requirements for illumination levels, battery backup duration, and testing procedures.

Design considerations include providing adequate illumination levels in pathways, exits, and assembly areas. The system must have sufficient battery backup to function for a minimum duration, typically 90 minutes, and must be regularly tested to ensure reliability. We need to consider the types of emergency lighting fixtures appropriate for different locations; exit signs, emergency lights, and pathway lighting are all part of a comprehensive system. Regular testing and maintenance are crucial to ensuring compliance with codes and the safety of occupants. This often includes documentation of testing procedures and results, which are critical for auditing and ensuring continued compliance.

Q 21. Explain the design considerations for fire alarm and security systems.

Fire alarm and security systems are integrated safety systems requiring careful design and coordination with other building systems.

Fire alarm systems involve strategically placing detectors (smoke, heat, etc.) and notification appliances (bells, horns, strobes). The design must ensure adequate coverage and redundancy, adhering to NFPA standards. Similarly, security systems encompass CCTV cameras, access control systems, and intrusion detection devices. Integration with the fire alarm system is often necessary, ensuring coordination during emergencies. This means considering power requirements, cable routing, and the overall system architecture. For example, the placement of cameras must consider blind spots and optimal viewing angles, while access control systems require considerations for user authentication, door hardware, and integration with other building management systems (BMS). All designs need thorough documentation including system schematics, device specifications, and emergency procedures.

Q 22. Describe your experience with building automation systems (BAS).

Building Automation Systems (BAS) are crucial for optimizing building performance and energy efficiency. My experience encompasses designing, implementing, and commissioning BAS across various building types, from commercial offices to industrial facilities. I’m proficient in various protocols like BACnet, Modbus, and LonWorks, and have worked with leading BAS platforms like Tridium Niagara and Schneider Electric EcoStruxure. For example, in a recent project for a large office complex, I integrated a BAS to control HVAC systems, lighting, and security, resulting in a 15% reduction in energy consumption. This involved programming logic controllers, configuring network communication, and developing user interfaces for monitoring and control. My expertise extends to integrating smart devices and IoT sensors into the BAS for enhanced data analytics and predictive maintenance, ensuring a future-proof system.

I’ve also tackled challenges involving legacy system integration, where I’ve successfully migrated older systems onto modern platforms, improving functionality and reliability while minimizing disruption.

Q 23. How do you ensure the safety of electrical workers during construction?

Ensuring electrical worker safety is paramount. My approach is multi-faceted and starts with meticulous planning. This includes developing comprehensive safety plans that comply with all relevant regulations (like OSHA in the US or equivalent local standards). We use Lockout/Tagout procedures rigorously to prevent accidental energization during maintenance or repair. All workers are provided with appropriate Personal Protective Equipment (PPE), including insulated gloves, safety glasses, and arc flash suits where necessary. Regular safety training and toolbox talks are crucial for reinforcing best practices and addressing potential hazards. I also insist on thorough site inspections to identify and mitigate potential hazards like exposed wiring or inadequate lighting. For example, I implemented a system of daily site safety checks that involved using a checklist and daily briefings with the electricians to anticipate and discuss potential problems. This proactive approach reduces risks and fosters a culture of safety.

Q 24. What are your experiences with different types of wiring methods?

My experience spans various wiring methods, each with its strengths and weaknesses. I’m familiar with conduit wiring (rigid metal conduit (RMC), intermediate metal conduit (IMC), electrical metallic tubing (EMT)), which offers excellent protection against physical damage. I also have extensive experience with cable tray systems, particularly effective for large-scale installations and providing flexibility for future expansion. I’ve worked with both open and enclosed cable tray systems, selecting the appropriate type based on the environment and required level of protection. Furthermore, I have experience with raceway systems, understanding the various types and their applications. For example, in a recent hospital project, I specified the use of RMC for critical areas due to its high level of protection against fire and impact, while using EMT for less demanding areas to reduce costs.

I’m also experienced with less common but equally important methods such as surface-mounted wiring, often necessary in renovations or where conduit installation is impractical. The selection of the wiring method is always driven by the project’s specific needs, considering factors such as cost, safety, accessibility, and aesthetics.

Q 25. Describe your knowledge of different types of transformers and their applications.

Transformers are essential components in electrical systems. My understanding covers various types, including step-up transformers (increasing voltage), step-down transformers (decreasing voltage), isolation transformers (providing electrical isolation), and autotransformers (single winding). I understand the different transformer designs, such as core type and shell type, and their respective characteristics. Applications vary widely; for instance, step-down transformers are used to reduce high-voltage transmission lines to safer levels for building distribution. Isolation transformers are often used in sensitive medical equipment to prevent ground loops and improve safety. In a recent project, we used multiple step-down transformers to distribute power across different sections of a large industrial facility, each transformer sized to meet the specific load requirements of its respective area.

My knowledge extends to the selection criteria, considering factors like voltage rating, power rating, efficiency, and environmental considerations. I also understand the importance of proper transformer protection devices, such as fuses and circuit breakers, to protect against overloads and short circuits.

Q 26. How do you perform a site survey for an electrical design project?

A thorough site survey is critical for accurate electrical design. It begins with a review of the architectural plans and specifications to understand the building’s layout, occupancy, and intended use. On-site, I conduct a physical inspection, documenting existing electrical infrastructure, service entrances, and potential constraints. I identify locations for equipment like switchboards, panelboards, and transformers, considering accessibility and code compliance. I carefully assess the load requirements of different areas, taking into account lighting, power outlets, HVAC systems, and specialized equipment. I also note the site’s geographical location and environmental conditions, which can influence design decisions. For example, seismic zones require special considerations for equipment mounting and cable routing. I record all relevant data—measurements, photos, and observations—and create detailed site survey reports, including any significant challenges or opportunities that may affect the design.

Q 27. Explain your approach to managing electrical design documentation.

Effective management of electrical design documentation is crucial for project success. I utilize a structured approach, employing a combination of digital and physical documentation. My system relies on a central, organized digital repository, typically utilizing Building Information Modeling (BIM) software. This allows for collaborative design, version control, and easy access to updated drawings, specifications, and calculations. Detailed drawings (single-line diagrams, wiring diagrams, panel schedules) are created using CAD software, adhering to industry standards. Specifications are written concisely, clearly outlining requirements for materials and equipment. Calculations, including load calculations and short-circuit analysis, are documented thoroughly and are traceable. Furthermore, I maintain a robust filing system for physical documents, ensuring accessibility and compliance with project archiving requirements. Regular reviews and updates are crucial to maintain accuracy and reflect any changes made during the project’s lifecycle.

Q 28. Describe your understanding of the life cycle costs associated with building electrical systems.

Understanding life cycle costs is fundamental to responsible electrical design. It’s more than just initial capital costs; it encompasses all expenses throughout the system’s lifespan, including installation, operation, maintenance, and eventual replacement. Factors like energy efficiency, equipment lifespan, and maintenance requirements heavily influence these costs. For example, selecting high-efficiency transformers and lighting fixtures reduces operational costs over time. Specifying durable materials reduces maintenance and replacement expenses. I incorporate life cycle costing analysis into my design process, evaluating different options and quantifying their long-term implications. This helps clients make informed decisions, balancing initial investment with long-term savings and operational efficiency. Life cycle cost analysis allows for optimization, providing sustainable solutions that are both cost-effective and environmentally responsible.

Key Topics to Learn for Building Electrical Design Interview

- Power Systems Design: Understanding three-phase power distribution, load calculations, voltage drop analysis, and protective device coordination. Practical application includes designing power distribution systems for various building types (residential, commercial, industrial).

- Lighting Design: Knowledge of illumination levels, lighting controls (dimmer switches, occupancy sensors), energy-efficient lighting technologies (LEDs), and emergency lighting systems. Practical application includes creating efficient and effective lighting plans that meet building codes and client requirements.

- Electrical Codes and Standards: Familiarity with relevant building codes (NEC, IEC etc.) and industry standards. Practical application includes ensuring designs comply with all safety regulations and best practices.

- Fire Alarm and Life Safety Systems: Understanding the design and installation of fire alarm systems, emergency lighting, and other life safety systems. Practical application includes designing systems that ensure occupant safety in case of emergencies.

- Building Information Modeling (BIM): Proficiency in using BIM software (Revit, AutoCAD) for electrical design and coordination with other disciplines (MEP). Practical application includes collaborating effectively with other building professionals using a centralized model.

- Electrical Drawings and Documentation: Ability to create clear, concise, and accurate electrical drawings and specifications. Practical application includes communicating design intent effectively to contractors and other stakeholders.

- Energy Efficiency and Sustainability: Understanding sustainable design principles and incorporating energy-efficient solutions into electrical designs. Practical application includes minimizing energy consumption and reducing environmental impact.

- Troubleshooting and Problem-Solving: Ability to identify and resolve electrical system issues effectively. Practical application includes analyzing design challenges and implementing solutions that meet functional and aesthetic needs.

Next Steps

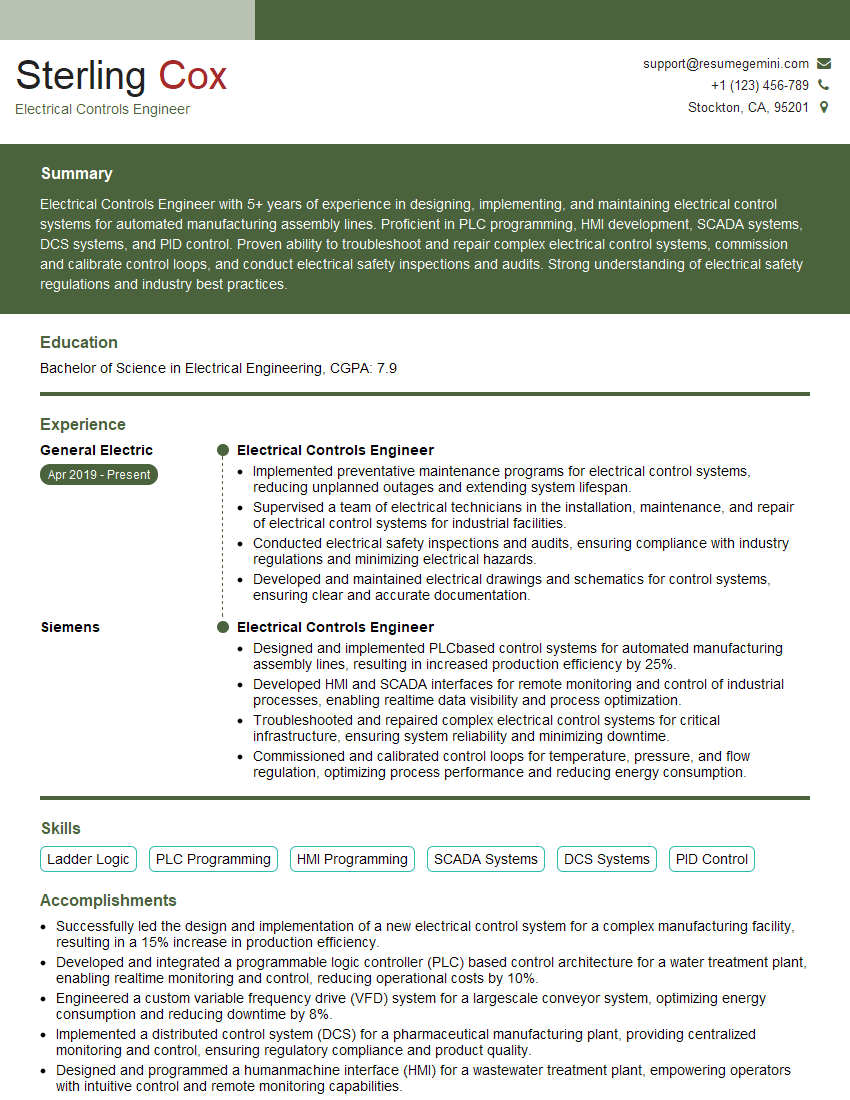

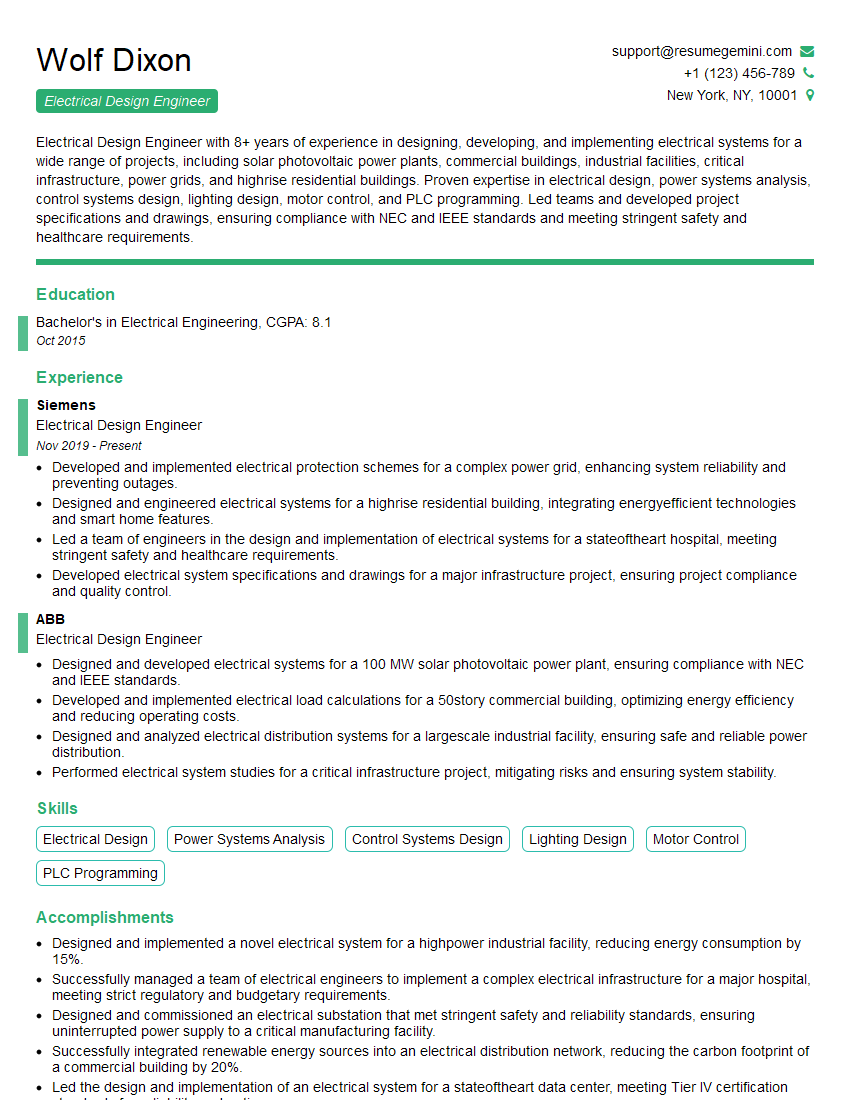

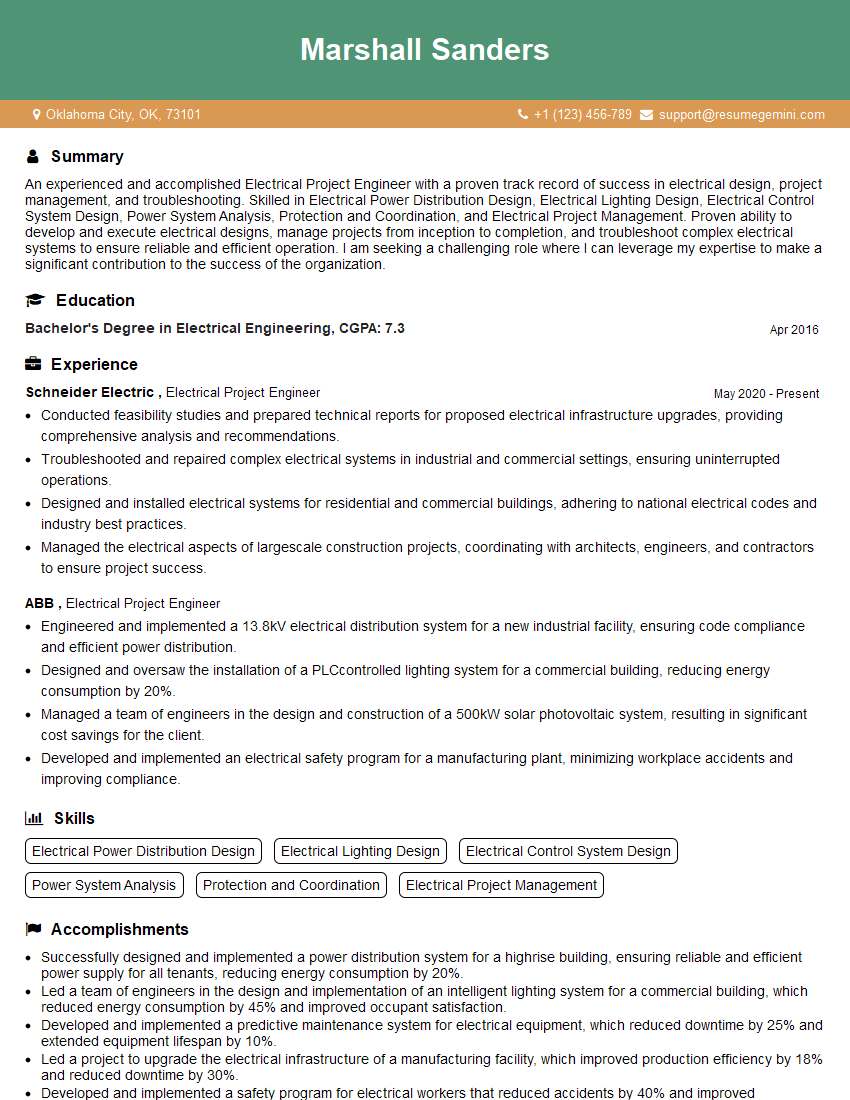

Mastering Building Electrical Design is crucial for career advancement, opening doors to specialized roles and higher earning potential. A well-crafted resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for applicant tracking systems, significantly increases your chances of getting your application noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to Building Electrical Design, ensuring your application stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good