Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Food Handling Procedures interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Food Handling Procedures Interview

Q 1. Describe the proper handwashing procedure.

Proper handwashing is the cornerstone of food safety. It’s a simple yet incredibly effective way to prevent the spread of harmful bacteria and viruses. Think of your hands as potential carriers – they touch everything! Thorough handwashing minimizes this risk.

- Wet your hands with warm water.

- Apply soap – enough to create a good lather.

- Scrub your hands vigorously for at least 20 seconds. This includes the backs of your hands, between your fingers, and under your nails. Think of singing the “Happy Birthday” song twice.

- Rinse your hands thoroughly under warm running water.

- Dry your hands using a clean towel or air dryer.

Imagine preparing a salad – if you haven’t washed your hands properly after handling raw chicken, you could easily contaminate the lettuce. Always wash your hands before starting any food preparation, after touching raw meat or poultry, after using the restroom, and after handling garbage.

Q 2. Explain the temperature danger zone for food.

The temperature danger zone for food is the range where bacteria multiply rapidly, increasing the risk of foodborne illness. This critical zone is between 40°F (4°C) and 140°F (60°C). Think of it as the ‘bacterial breeding ground.’

Foods left in this range for more than two hours should be discarded. This is because bacteria double their numbers every 20 minutes within this temperature range. For example, leaving a cooked chicken casserole at room temperature for several hours allows bacteria to multiply exponentially, potentially leading to food poisoning.

Q 3. What are the key principles of HACCP?

HACCP, or Hazard Analysis and Critical Control Points, is a preventative food safety management system. It’s a systematic approach to identifying and controlling biological, chemical, and physical hazards in food production. Instead of simply reacting to problems, HACCP proactively prevents them.

- Hazard Analysis: Identify potential hazards that could contaminate food.

- Critical Control Points (CCPs): Determine the steps in the food production process where these hazards can be prevented, eliminated, or reduced to safe levels.

- Critical Limits: Establish measurable limits for each CCP to ensure safety.

- Monitoring: Regularly monitor CCPs to ensure they remain within critical limits.

- Corrective Actions: Define actions to take if a CCP deviates from critical limits.

- Verification: Regularly verify the effectiveness of the HACCP plan.

- Record Keeping: Maintain thorough records of all HACCP activities.

For instance, in a restaurant, a CCP might be the internal temperature of cooked chicken. The critical limit would be 165°F (74°C). Monitoring involves using a thermometer to check the temperature, and corrective action might include discarding undercooked chicken.

Q 4. How do you prevent cross-contamination?

Cross-contamination occurs when harmful bacteria or other pathogens transfer from one food to another. It’s a silent threat, often invisible, yet incredibly dangerous. Preventing it requires diligence and careful practices.

- Separate raw and cooked foods: Use separate cutting boards, utensils, and containers for raw meats, poultry, seafood, and ready-to-eat foods.

- Wash hands thoroughly: Wash your hands before and after handling different foods, especially raw meats.

- Clean and sanitize surfaces: Regularly clean and sanitize countertops, cutting boards, and other food contact surfaces.

- Proper storage: Store raw meats below cooked foods in the refrigerator to prevent dripping.

- Cook foods to safe internal temperatures: Ensure food is cooked to the appropriate temperature to kill harmful bacteria.

Imagine preparing a steak and a salad simultaneously. Using the same cutting board for both without cleaning it in between could easily transfer bacteria from the raw steak to the salad, causing cross-contamination.

Q 5. What are the common foodborne illnesses and their prevention?

Numerous foodborne illnesses exist, caused by bacteria, viruses, or parasites. Some common ones include Salmonella (often from poultry), E. coli (often from undercooked beef), Listeria (often from soft cheeses and deli meats), and Norovirus (often spread through contaminated surfaces or food handlers).

Prevention hinges on proper food handling practices: cooking food to safe internal temperatures, proper handwashing, preventing cross-contamination, and keeping food at safe temperatures (outside the danger zone). Refrigerating perishable foods promptly is also critical. Regular cleaning and sanitation of equipment and surfaces are vital. If you suspect a foodborne illness, seek medical attention immediately.

Q 6. Explain FIFO and its importance in food storage.

FIFO stands for ‘First-In, First-Out.’ It’s a crucial inventory management system for food storage, ensuring that older items are used before newer ones. This minimizes the risk of spoilage and reduces waste.

Imagine your refrigerator – labeling items with dates and placing older items in front helps ensure that you use them first. Proper rotation is key. Ignoring FIFO can lead to spoiled food and potential foodborne illnesses. For example, an older container of milk might be hidden behind newer ones, and it could spoil unnoticed, leading to waste and potential health issues. Implementing a FIFO system is essential for any food service establishment.

Q 7. Describe the proper procedures for cleaning and sanitizing food contact surfaces.

Cleaning and sanitizing food contact surfaces are crucial for preventing cross-contamination. Cleaning removes visible soil and food residue, while sanitizing kills most of the remaining harmful microorganisms.

- Cleaning: Wash the surface with hot, soapy water, scrubbing thoroughly to remove all visible debris.

- Rinsing: Rinse the surface with clean water to remove all soap residue.

- Sanitizing: Apply a food-grade sanitizer according to the manufacturer’s instructions. Allow the surface to air dry.

Different sanitizing methods exist, including chlorine solutions, iodine solutions, and quaternary ammonium compounds. It’s essential to follow the instructions carefully and ensure proper contact time for effective sanitization. Think of it like this: cleaning is like washing your dishes, while sanitizing is like adding a final rinse to ensure they’re completely germ-free.

Q 8. What are the different types of food thermometers and how are they used?

Food thermometers are essential tools for ensuring food safety by accurately measuring internal temperatures. Different types cater to various needs. Let’s explore a few:

- Thermocouple Thermometers: These are fast-reading, highly accurate, and durable. They use a sensor that reacts quickly to temperature changes, making them ideal for checking the temperature of meat during cooking. Imagine using one to ensure your Thanksgiving turkey reaches a safe internal temperature of 165°F (74°C).

- Digital Thermometers: These are user-friendly with easy-to-read displays. They are commonly used in various food settings, from home kitchens to restaurants, because of their convenience and accuracy. You’d likely find one of these in your home for checking the temperature of your milk for your morning coffee.

- Instant-Read Thermometers: These provide quick temperature readings, making them perfect for checking multiple items or fast-cooking foods. Think of using one to verify the temperature of a steak immediately after removing it from the pan.

- Bimetallic Dial Thermometers: These are generally less expensive but can be slower to react and less accurate than digital or thermocouple thermometers. They are often used for ovens or refrigerators to monitor temperature ranges.

Proper use involves inserting the thermometer into the thickest part of the food, avoiding bones and fat, and waiting for the reading to stabilize. Always follow the manufacturer’s instructions for cleaning and sanitizing.

Q 9. How do you identify and handle potentially hazardous foods?

Potentially Hazardous Foods (PHFs) are foods that are particularly susceptible to bacterial growth and can cause foodborne illness if not handled properly. These include foods that are high in protein and moisture, such as meat, poultry, fish, eggs, dairy products, and cooked rice or beans.

Identifying them is relatively straightforward; they’re often the foods requiring refrigeration. Handling them correctly involves adhering to the four key principles of food safety: Clean, Separate, Cook, and Chill.

- Clean: Wash hands, surfaces, and utensils thoroughly.

- Separate: Keep raw foods separate from cooked foods to prevent cross-contamination.

- Cook: Cook foods to their safe internal temperatures, using a food thermometer to ensure accuracy.

- Chill: Refrigerate perishable foods promptly to slow bacterial growth. Aim for a refrigerator temperature of 40°F (4°C) or below.

For example, imagine you’re preparing a chicken salad. Raw chicken is a PHF. Following the steps above means ensuring your hands and surfaces are clean, keeping the raw chicken separate from other ingredients, cooking the chicken thoroughly to 165°F (74°C), and quickly refrigerating the finished salad.

Q 10. What are the proper storage requirements for different food types?

Proper food storage varies greatly depending on the food type and its susceptibility to spoilage. The goal is to maintain food safety and quality by preventing bacterial growth and maintaining optimal conditions.

- Refrigerated Foods (PHFs): Store at 40°F (4°C) or below. Use the FIFO (First-In, First-Out) method, placing newer items behind older items to ensure older food gets used first. Properly wrap or seal foods to prevent cross-contamination.

- Frozen Foods: Maintain a freezer temperature of 0°F (-18°C) or below. Avoid repeatedly freezing and thawing foods as this negatively impacts quality and safety.

- Dry Goods: Store in a cool, dry, and well-ventilated area. Protect them from pests and moisture.

- Canned Goods: Store in a cool, dry place, away from direct sunlight and heat. Inspect cans for dents, bulges, or leaks before use.

Imagine a restaurant kitchen. They’ll have designated areas for refrigerated items, freezers, and dry storage, each carefully maintained at the correct temperature and designed to minimize cross-contamination. Their storage practices are crucial to prevent foodborne illnesses.

Q 11. Explain the importance of proper food labeling and dating.

Proper food labeling and dating are critical for ensuring food safety and preventing waste. Accurate labeling helps consumers and food handlers make informed decisions about food quality and safety.

- Labels: Should clearly identify the food product, ingredients, and allergen information (as required by law). They also need to show the weight, net contents, manufacturer’s name and address, and nutritional information.

- Dating: ‘Use-By’ dates indicate when food is at its peak quality. ‘Sell-By’ dates are for retailers to manage stock rotation. Food may still be safe to consume after these dates but will likely decrease in quality.

Consider a pre-packaged salad. The label clearly states the ingredients, allergens, and a ‘Use-By’ date, allowing consumers to understand the food’s safety and quality before purchase. This ensures transparent food handling throughout the supply chain.

Q 12. Describe the procedures for receiving and inspecting food deliveries.

Receiving and inspecting food deliveries is a crucial step in maintaining food safety. Thorough inspections prevent contaminated or spoiled food from entering your facility.

Procedures typically include:

- Temperature checks: Immediately check the temperature of refrigerated or frozen foods using a thermometer. Reject any deliveries that don’t meet the required temperatures.

- Visual inspection: Examine packaging for damage, leaks, or signs of pest infestation. Check for any unusual odors or discoloration of the food itself.

- Verification: Ensure that the delivered items match the order quantities and specifications outlined in the purchase order. Check expiration dates.

- Documentation: Maintain detailed records of deliveries, including temperature readings, inspection results, and any rejected items.

Imagine a restaurant receiving a shipment of fresh seafood. The chef carefully checks the temperature of the ice, inspects the fish for freshness, compares the delivery slip to the order, and documents everything. This process prevents spoiled seafood from reaching the menu.

Q 13. How do you manage food waste effectively?

Effective food waste management is vital for both economic and environmental reasons. Strategies for minimizing food waste include:

- Accurate Forecasting: Predict food needs accurately to reduce overstocking.

- Proper Storage: Implement effective storage practices to extend the shelf life of foods. FIFO method for perishable items is critical.

- Employee Training: Educate staff on food waste reduction techniques.

- Donation: Donate surplus food to local charities or food banks.

- Composting: Compost food scraps to reduce landfill waste.

A large-scale caterer can effectively manage food waste by precisely forecasting order volumes, storing ingredients properly, training staff to minimize waste in food preparation, and donating any surplus to shelters. These combined steps reduce financial losses and the environmental impact of discarded food.

Q 14. What are the guidelines for handling allergens?

Handling allergens requires stringent procedures to prevent cross-contamination and protect customers with allergies. The big 8 allergens are milk, eggs, peanuts, tree nuts, soy, wheat, fish, and shellfish.

- Clear Labeling: Ensure all food items are clearly labeled with allergen information.

- Dedicated Equipment: Use separate equipment and utensils for handling allergenic foods to avoid cross-contamination.

- Food Preparation Areas: Designate separate preparation areas for allergenic foods, if possible.

- Staff Training: Thoroughly train staff on allergen awareness, handling procedures, and the importance of avoiding cross-contamination.

- Communicating with Customers: Establish clear communication procedures with customers to discuss dietary needs and allergen concerns.

Imagine a bakery handling both wheat-based products and gluten-free items. They’ll employ separate mixing bowls, ovens, and storage areas to prevent cross-contamination. Staff will be specifically trained on the risks of cross-contamination and follow stringent cleaning protocols. Menu descriptions will clearly indicate the presence of allergens.

Q 15. Explain the importance of personal hygiene in food handling.

Personal hygiene is paramount in food handling because it directly impacts the safety and quality of the food we consume. Contamination from our hands, hair, or clothing can easily introduce pathogens like bacteria, viruses, or parasites into food, leading to foodborne illnesses. Think of it like this: your hands are constantly touching surfaces, and those surfaces can harbor unseen microorganisms. If you don’t wash your hands properly, you’re essentially transferring those microorganisms to the food you’re preparing.

- Handwashing: Frequent and thorough handwashing with soap and water for at least 20 seconds, especially after using the restroom, handling raw meat, or touching potentially contaminated surfaces, is crucial.

- Clean Clothing: Wearing clean, preferably dedicated food-handling attire, including hairnets, aprons, and gloves, prevents hair or clothing fibers from contaminating food.

- Wound Care: Any open wounds or cuts on hands or arms must be covered with waterproof bandages to prevent contamination.

- Avoiding Touching Face: Refraining from touching your face, particularly your eyes, nose, and mouth, while handling food helps prevent the spread of germs.

In a professional kitchen, adhering to strict hygiene protocols ensures consistent food safety and protects both consumers and employees from potential health risks. Neglecting hygiene can result in severe consequences, ranging from minor illnesses to outbreaks of food poisoning, leading to reputational damage and potential legal issues.

Career Expert Tips:

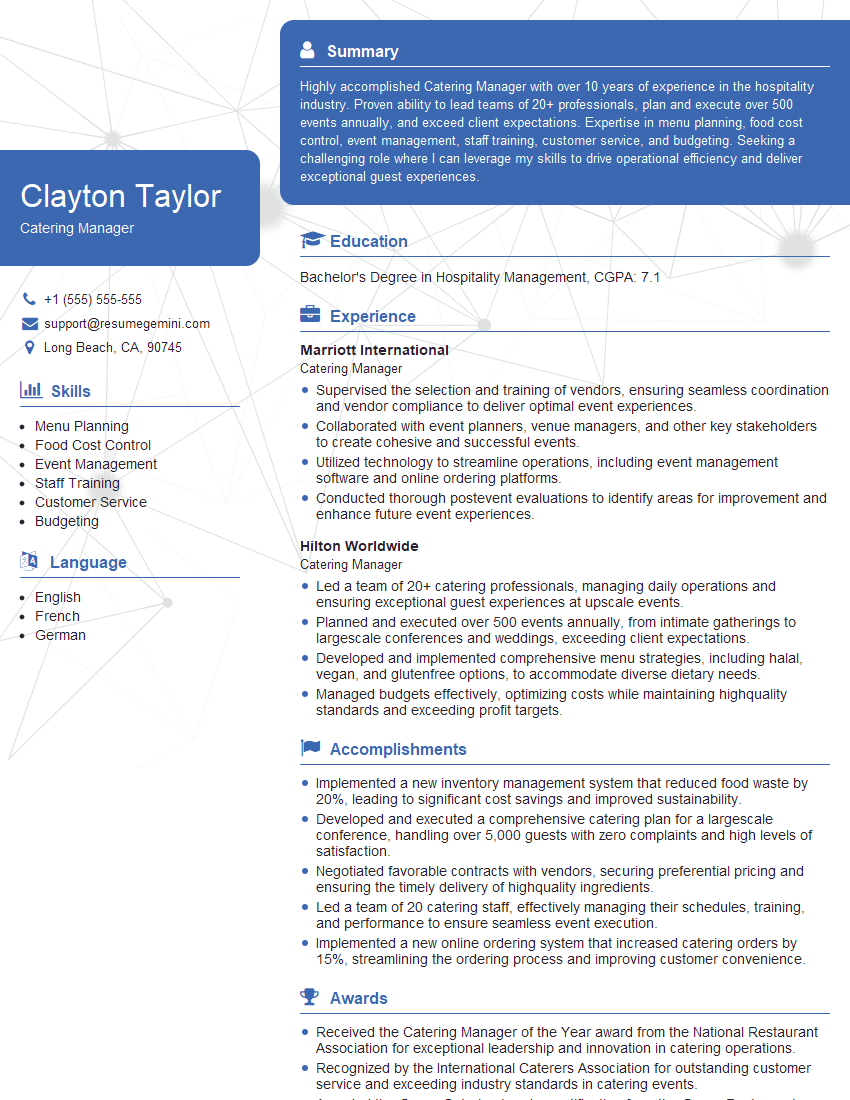

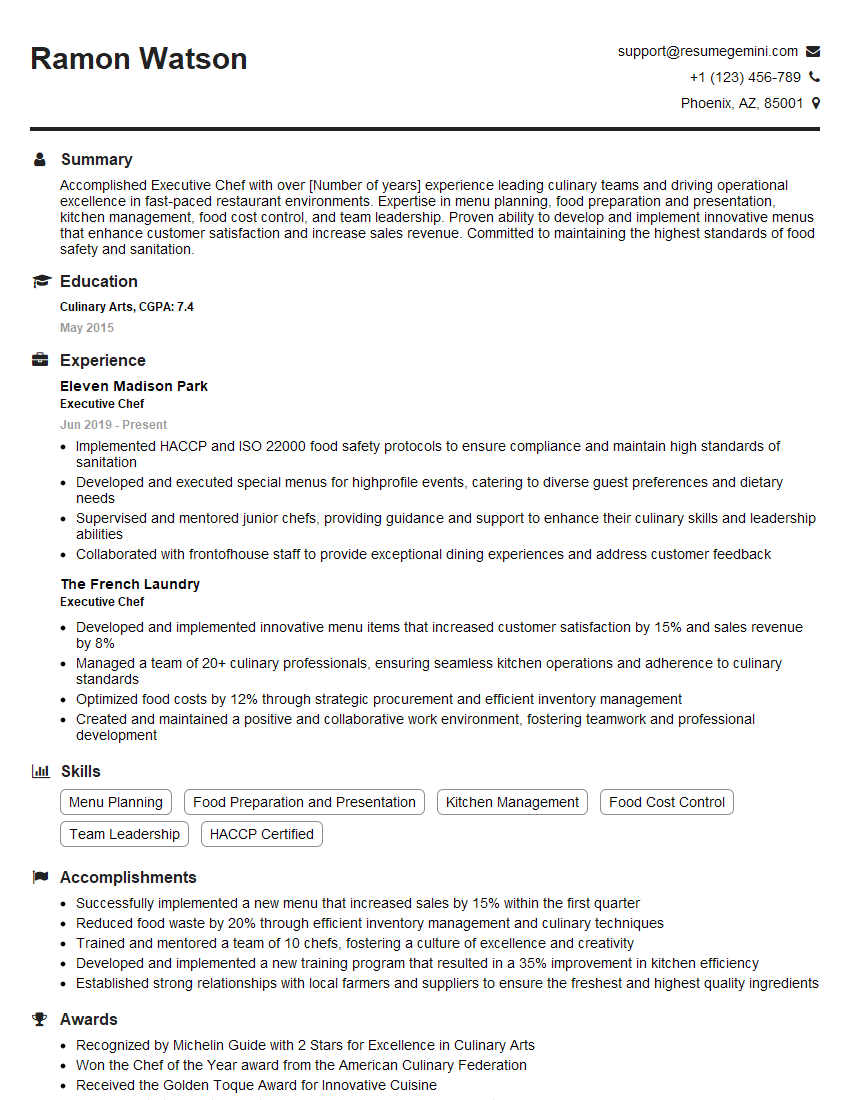

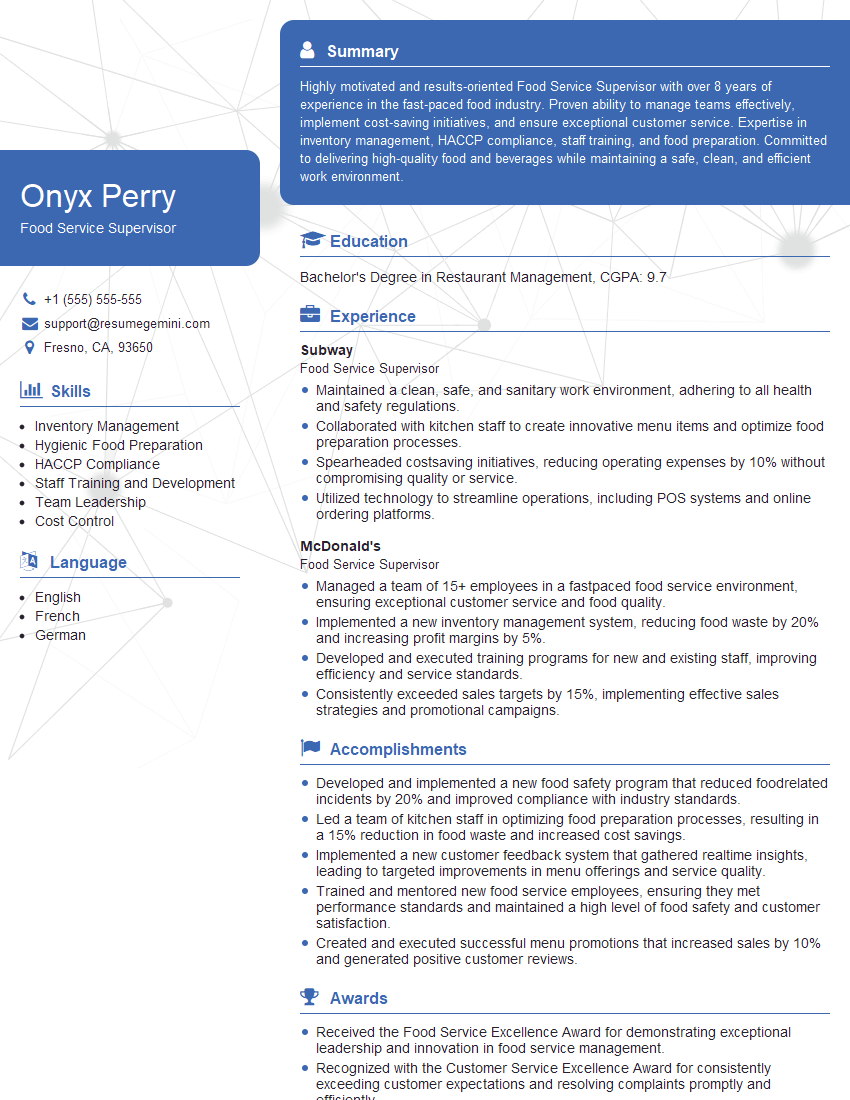

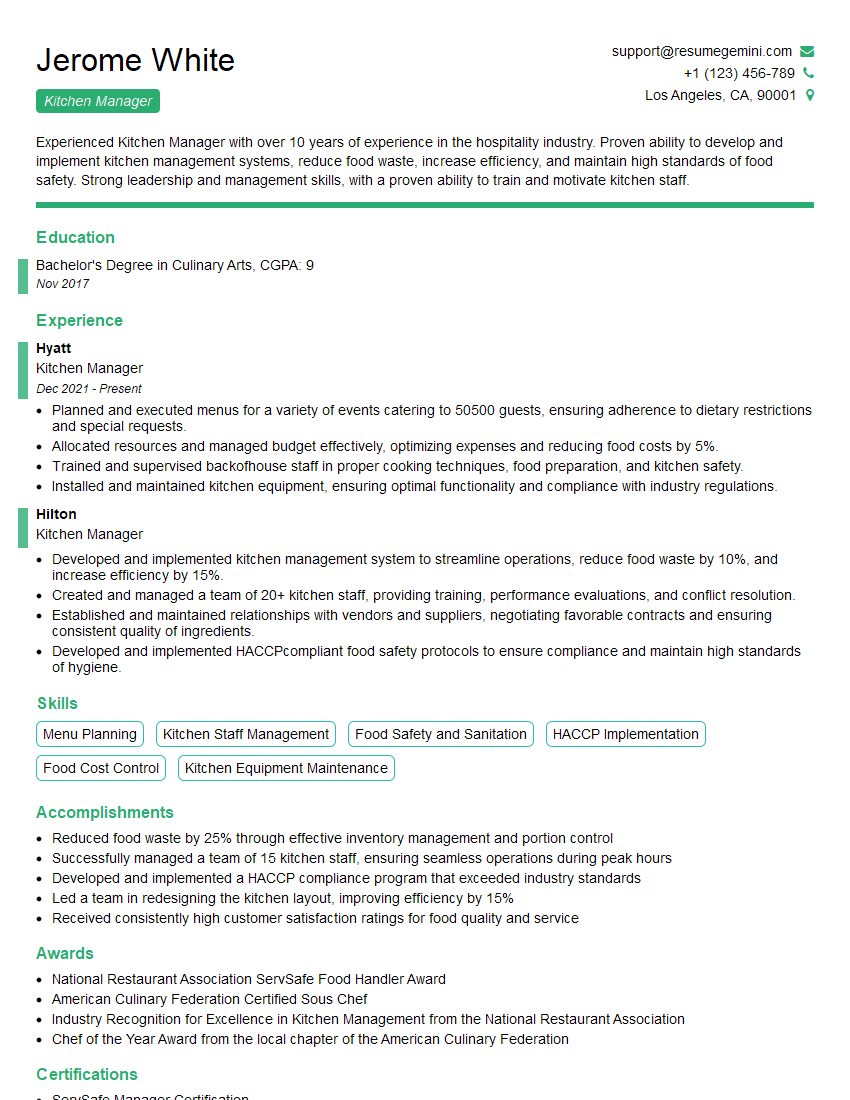

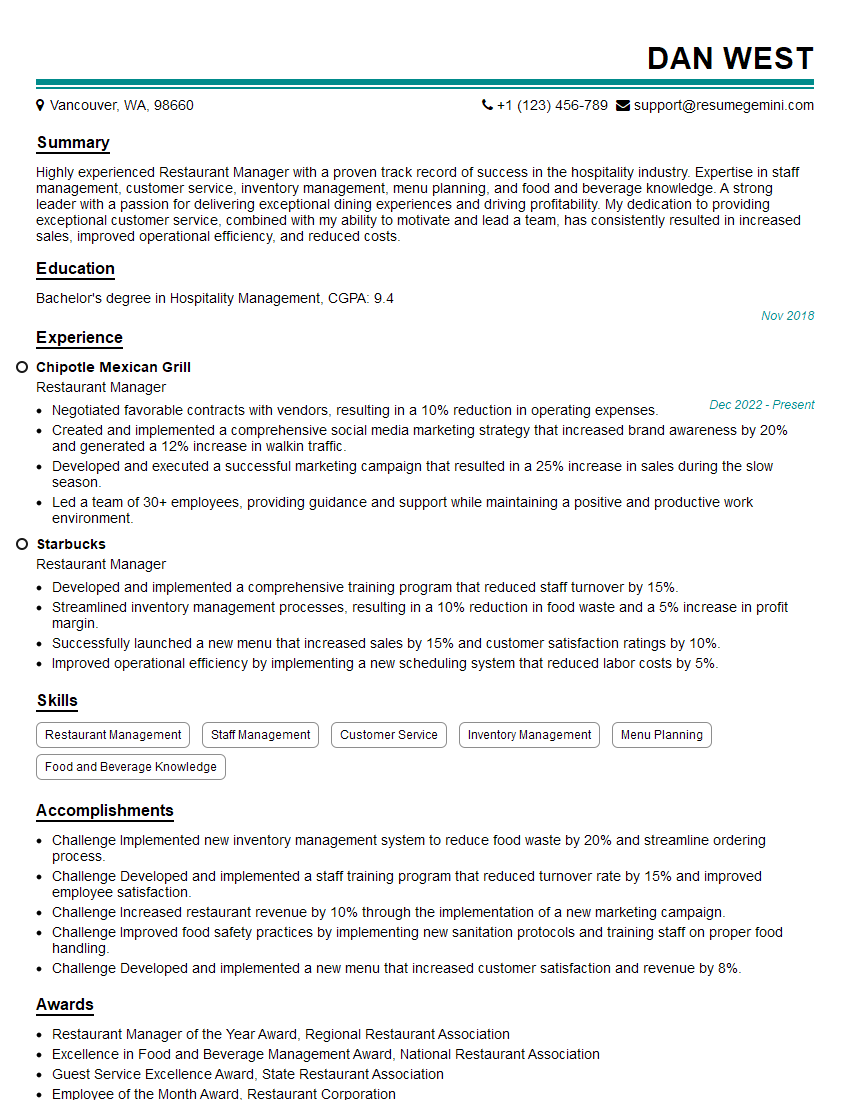

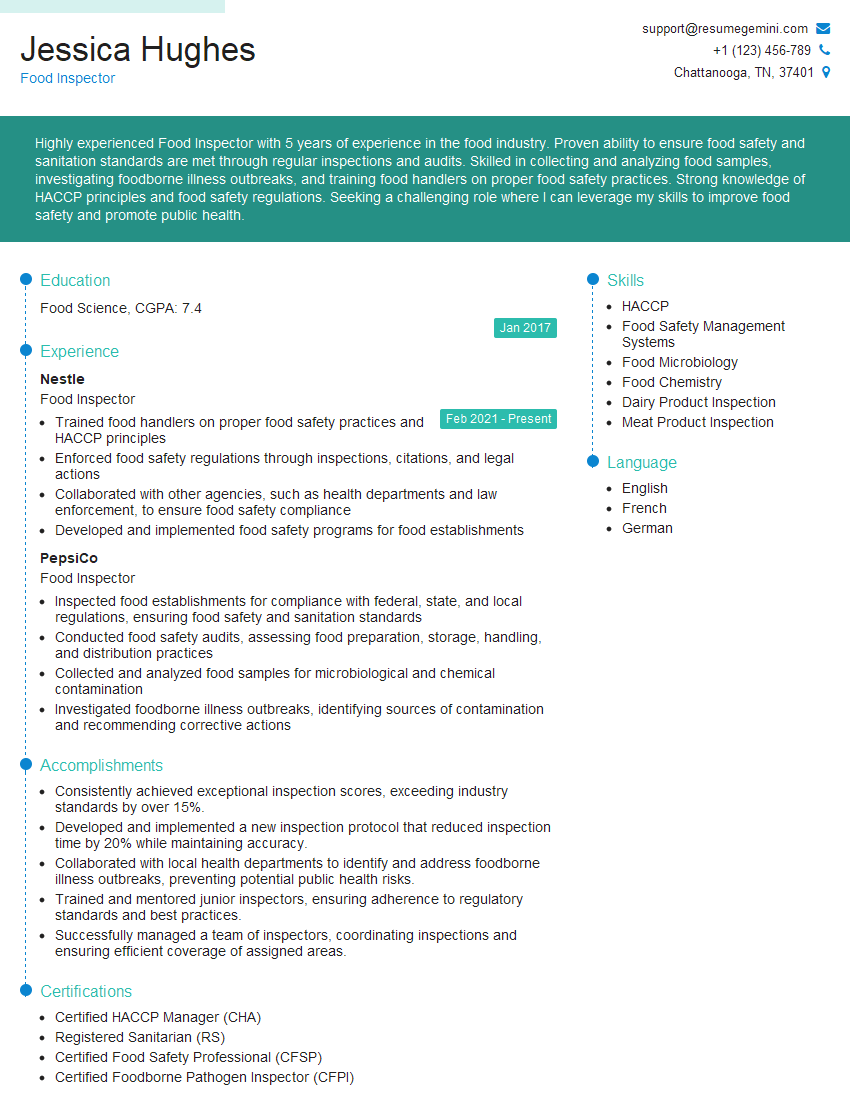

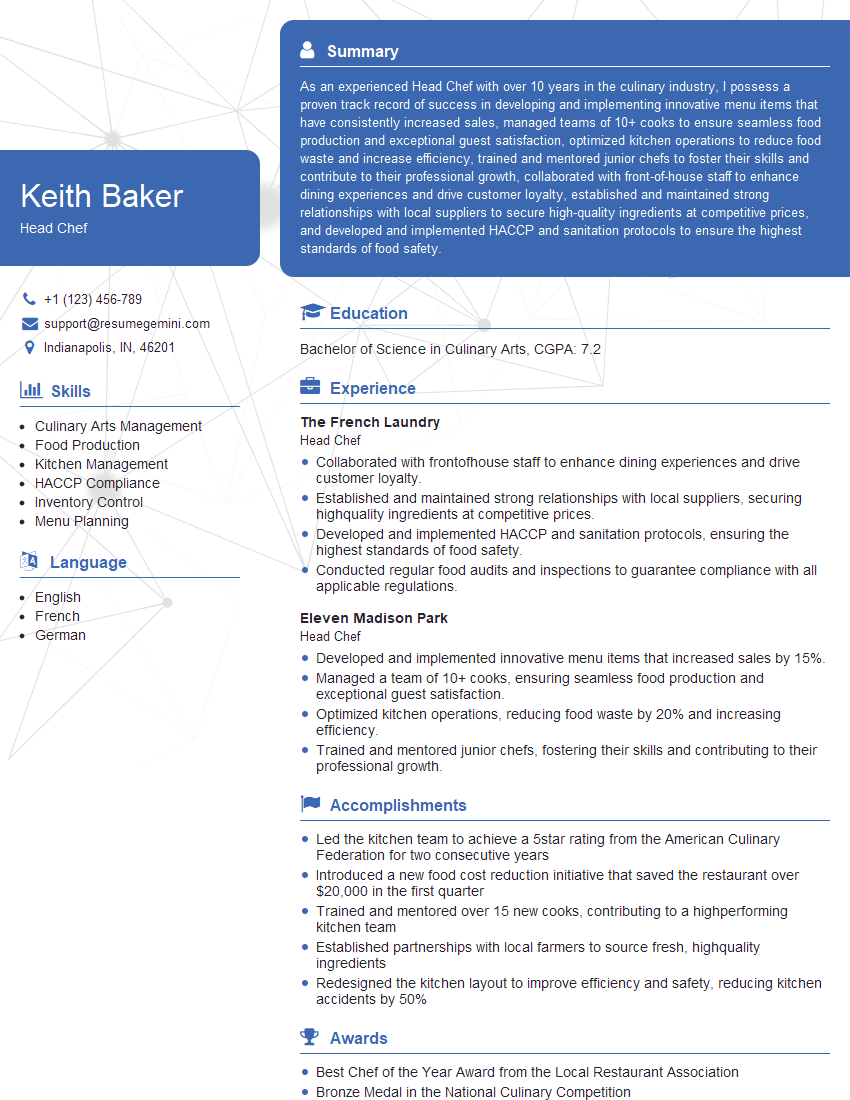

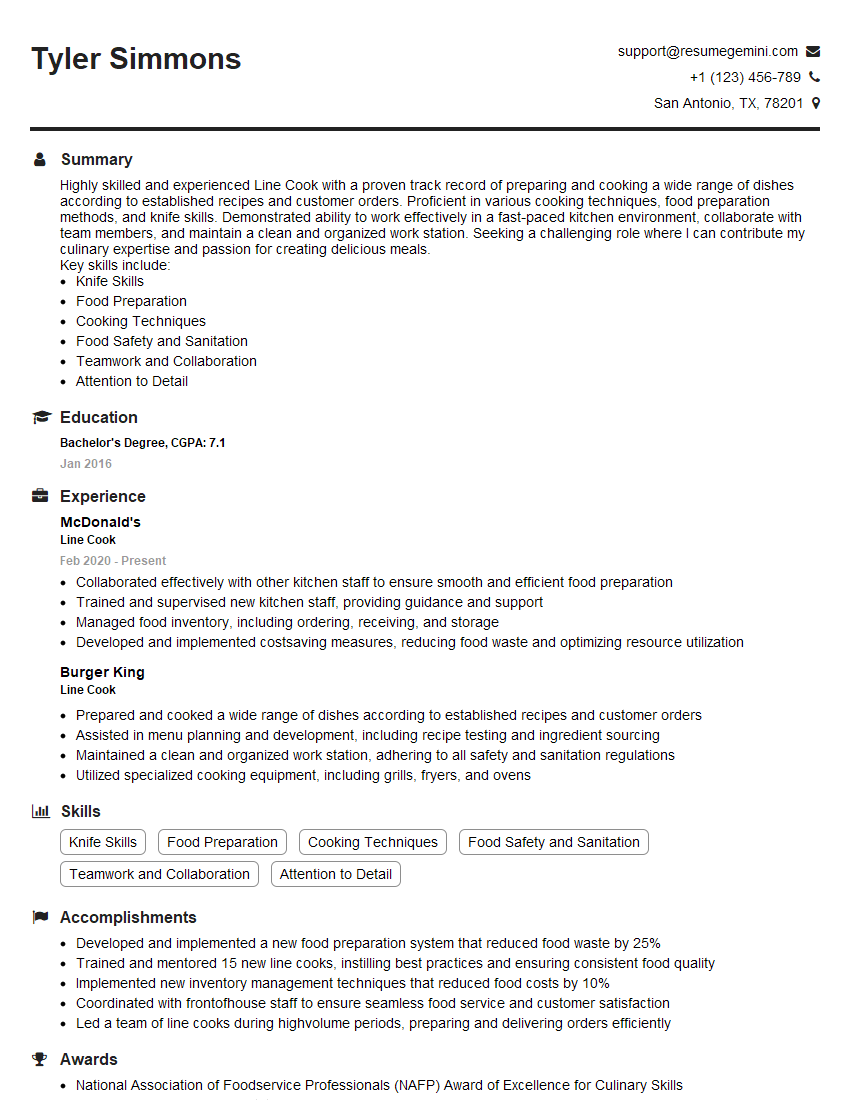

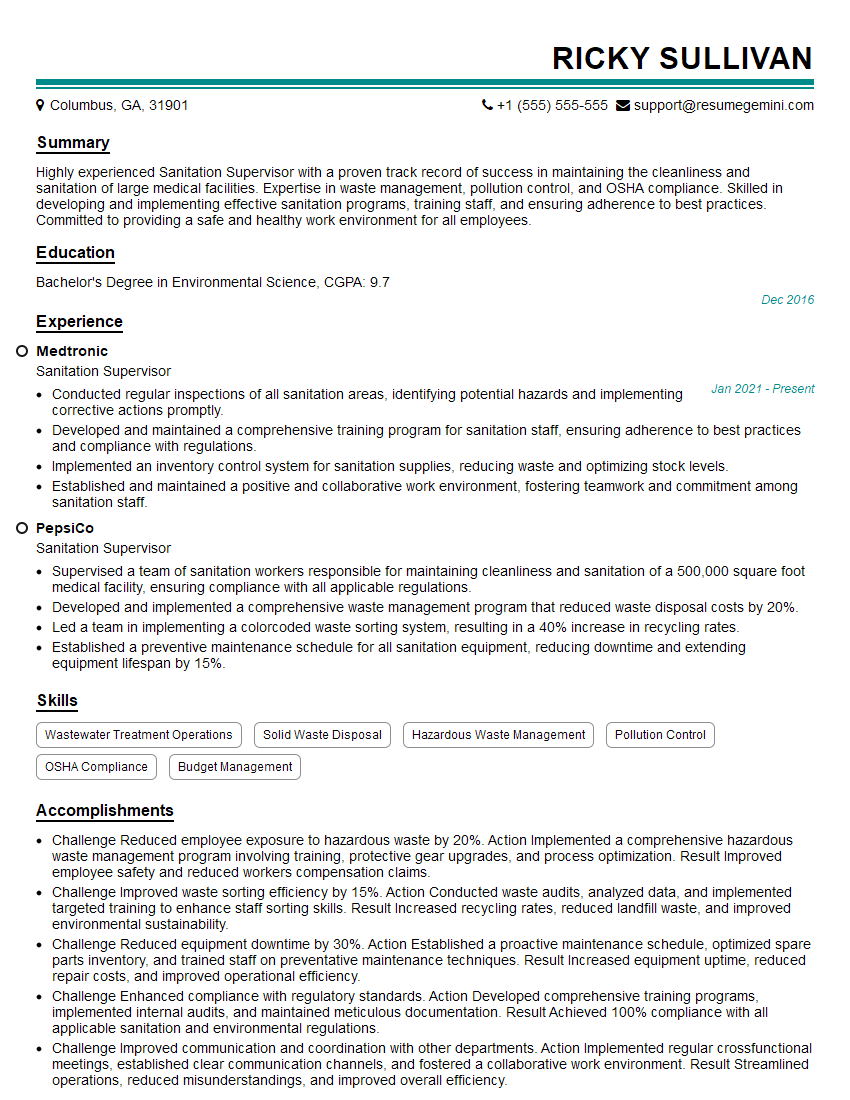

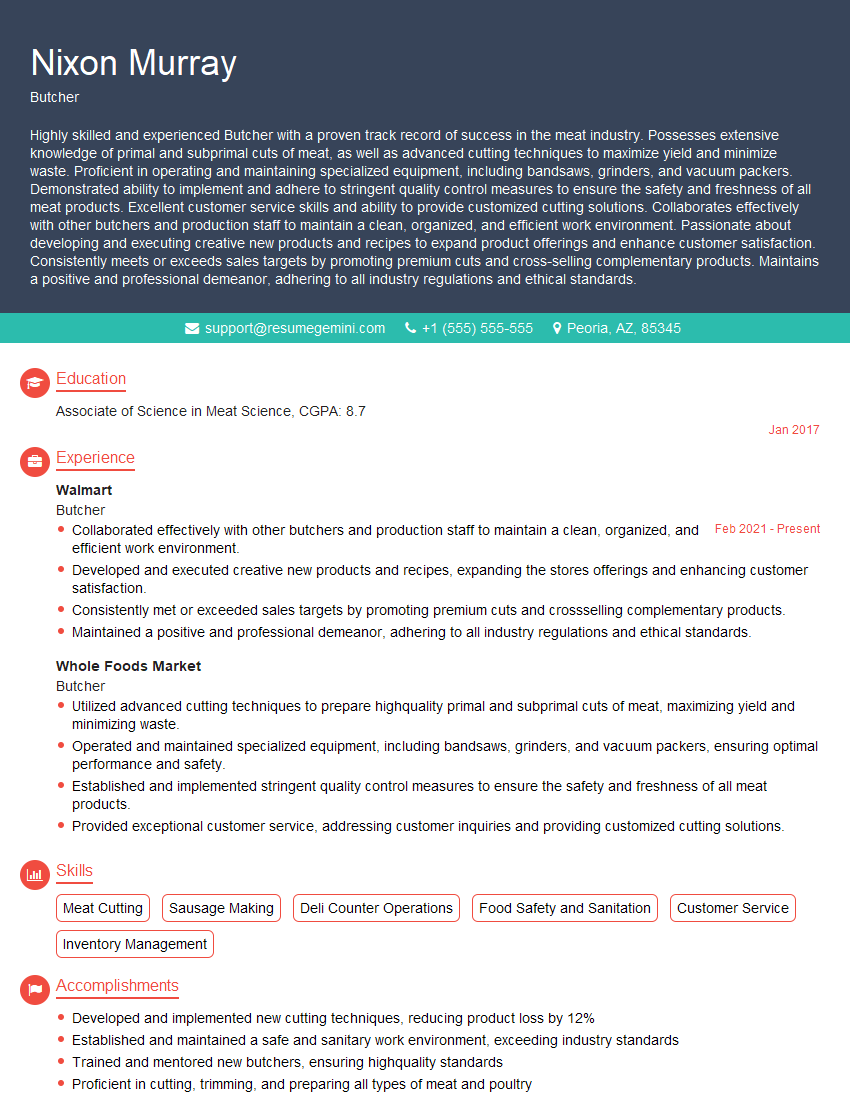

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and respond to a food safety emergency?

Identifying and responding to a food safety emergency requires a swift and systematic approach. The first step is recognizing potential hazards. This could include observing signs of spoilage (e.g., unusual odor, discoloration, slime), detecting pest infestations, or experiencing equipment malfunction (e.g., refrigerator failure).

My response would follow a structured protocol:

- Immediate Action: Isolate the affected food, equipment, or area to prevent further contamination. If a customer reports feeling unwell after consuming a dish, promptly record details such as symptoms, the dish consumed, and the time of consumption.

- Assessment & Investigation: Determine the extent of the problem. This might involve checking temperature logs, inspecting food storage areas, or interviewing staff.

- Notification: Depending on the severity, notify relevant authorities (e.g., health department) and inform management immediately. If a customer has experienced a foodborne illness, apologize, assure them you take the matter seriously, and collect their contact details.

- Corrective Actions: Implement corrective actions to prevent recurrence. This might include deep cleaning and sanitizing the affected area, discarding contaminated food, repairing faulty equipment, or revising food handling procedures. We should document all actions taken.

- Documentation: Meticulous documentation is essential for traceability and accountability. This should include details of the incident, steps taken, and any corrective actions implemented.

For instance, if the refrigerator breaks down, I’d immediately transfer temperature-sensitive foods to backup refrigeration, notify management and potentially initiate a recall if the food was compromised, and document the entire event. This systematic approach minimizes risks and ensures a prompt resolution, protecting public health and maintaining the facility’s reputation.

Q 17. What is your experience with food safety audits?

I have extensive experience with food safety audits, having participated in numerous audits across various facilities, from small restaurants to large-scale food processing plants. I am familiar with various audit standards, including those aligned with HACCP (Hazard Analysis and Critical Control Points), ISO 22000, and SQF (Safe Quality Food).

My role in these audits has encompassed preparation, conducting self-assessments, correcting any identified deficiencies, and implementing preventative measures. I am adept at identifying potential hazards, reviewing documentation such as temperature logs and staff training records, and ensuring compliance with regulatory requirements. For example, during one audit, we identified a lapse in proper handwashing procedures. Through corrective actions and staff retraining, we successfully addressed the issue and subsequently achieved a positive audit outcome. My experience extends to addressing auditor feedback, implementing improvements, and maintaining an audit-ready environment. The continuous improvement cycle is crucial in ensuring long-term food safety compliance.

Q 18. Describe your experience with implementing and maintaining a food safety management system.

I’ve been involved in the implementation and maintenance of food safety management systems (FSMS) for over [Number] years. My experience includes designing, documenting, and implementing systems based on HACCP principles, ensuring all aspects from procurement to service are covered.

My approach involves a detailed risk assessment identifying critical control points (CCPs) in the food handling process. For example, temperature control during cooking and storage is a critical CCP. We monitor these points meticulously and establish corrective actions for deviations. Maintaining accurate records, conducting regular staff training, and implementing a robust internal auditing program are essential components of our FSMS. I have experience using various software to support food safety tracking and reporting. For example, we use software to record temperatures, trace ingredients, and manage employee training records. This system allows us to react promptly to issues and demonstrate continuous improvement.

The success of any FSMS lies in consistent monitoring, ongoing staff training, and a culture of food safety within the organization. Regular internal audits ensure that all procedures are consistently followed and potential problems are identified and addressed before they escalate.

Q 19. How do you train staff on proper food handling procedures?

Staff training on proper food handling procedures is a crucial aspect of maintaining food safety. My approach is multifaceted, combining various methods to ensure effective knowledge transfer and skill development.

- Interactive Training Sessions: I conduct interactive training sessions using a combination of lectures, demonstrations, and hands-on practice. These sessions cover topics ranging from personal hygiene to proper food storage, cooking temperatures, and handling of different food types.

- Role-Playing and Simulations: Role-playing scenarios help staff learn how to respond to various food safety emergencies, such as equipment malfunctions or suspected contamination. This hands-on training promotes a more complete understanding of critical procedures.

- Visual Aids and Manuals: Visual aids, such as diagrams, flowcharts, and videos, supplement training sessions, aiding comprehension and retention. Comprehensive manuals summarizing key procedures are provided to all staff members for ongoing reference.

- Regular Refresher Courses: Regular refresher courses ensure that knowledge and skills remain up-to-date and that any changes to regulations or procedures are communicated effectively.

- Assessments and Feedback: Formal assessments and ongoing feedback mechanisms are used to evaluate staff understanding and identify areas needing further training.

I believe that effective training is an investment in food safety and staff development. It leads to a reduction in foodborne illnesses, maintains a positive working environment, and protects the reputation of the establishment.

Q 20. What are the different types of food preservation methods?

Food preservation methods aim to extend the shelf life of food products and prevent spoilage. Various methods exist, each with its own principles and applications.

- Low Temperature Preservation: This includes refrigeration (slowing microbial growth), freezing (inhibiting microbial activity), and chilling (rapid cooling to prevent bacterial growth).

- High Temperature Preservation: This involves methods such as canning (heating food to kill microorganisms and sealing it in airtight containers), pasteurization (brief heating to reduce the number of microorganisms), and sterilization (high-temperature heating to completely eliminate microorganisms).

- Water Reduction Preservation: Methods such as drying (removing water to inhibit microbial growth), dehydration (removing water through artificial means), and smoking (combining drying and the antimicrobial effects of smoke) are commonly used.

- Chemical Preservation: This involves using substances such as salt, sugar, vinegar, or chemical preservatives to inhibit microbial growth. Pickling (using vinegar or brine) is an example.

- Irradiation Preservation: Exposure to ionizing radiation kills microorganisms and extends shelf life. This is used less frequently for food that consumers directly eat.

- Other Methods: High-pressure processing, modified atmosphere packaging (MAP), and fermentation are also important food preservation techniques.

The choice of preservation method depends on factors like the type of food, desired shelf life, and the availability of resources and technology.

Q 21. Explain the difference between cleaning and sanitizing.

While both cleaning and sanitizing are crucial for maintaining food safety, they are distinct processes. Cleaning removes visible soil, food residue, and other debris, while sanitizing reduces the number of microorganisms to safe levels. Think of cleaning as the first step, preparing the surface for sanitization, which is the final stage of ensuring hygiene.

- Cleaning: This involves physically removing dirt and debris using detergents, water, and appropriate tools, such as brushes, sponges, or cloths. Effective cleaning requires proper rinsing to eliminate detergent residue.

- Sanitizing: This is achieved using approved sanitizers, such as chlorine solutions, iodine, or quaternary ammonium compounds, to kill or reduce the number of microorganisms remaining after cleaning. Sanitizing requires adherence to specific concentration and contact time instructions based on the sanitizer used.

For example, cleaning a cutting board involves washing it with hot, soapy water and scrubbing to remove food particles. Sanitizing then involves rinsing the board and immersing it in a sanitizing solution for the recommended contact time to kill any remaining bacteria. This two-step process ensures optimal hygiene and minimizes the risk of cross-contamination.

Q 22. Describe the correct methods for thawing frozen food.

Thawing frozen food safely is crucial to prevent bacterial growth. Never thaw food at room temperature, as this allows bacteria to multiply rapidly. There are three safe methods:

- Refrigerator Thawing: This is the safest method. Place the food in the refrigerator, allowing ample time for it to thaw completely. Larger items may require several days. This slow thaw minimizes bacterial growth.

- Cold Water Thawing: Submerge the food in a leak-proof bag in cold water, changing the water every 30 minutes to maintain a cold temperature. This method is faster than refrigerator thawing but still prevents rapid bacterial growth. Ensure the food is completely submerged to prevent uneven thawing.

- Microwave Thawing: Microwave thawing is the fastest method but requires careful monitoring to avoid uneven cooking and bacterial growth in areas that may heat up faster. Follow the manufacturer’s instructions and cook the food immediately after thawing.

Example: A large turkey breast should be thawed in the refrigerator for at least 24 hours per 5 pounds. Smaller items, like individual portions of meat, can be thawed in cold water in a couple of hours. Always check the food is completely thawed before cooking to ensure even cooking and safety.

Q 23. What is your understanding of food spoilage indicators?

Food spoilage indicators are visual, olfactory, or textural changes that signal a food product is no longer safe or suitable for consumption. These indicators can include:

- Off-odors: Sour, rancid, or putrid smells.

- Changes in color: Discoloration, dullness, or unusual spots.

- Changes in texture: Slimy, sticky, or unusually soft surfaces. For example, slimy chicken or mushy vegetables.

- Visible mold or bacterial growth: Any fuzzy or slimy growth is a clear indication of spoilage.

- Uncharacteristic taste: Sour, bitter, or metallic flavors not expected for the product.

Recognizing these indicators is essential for preventing foodborne illnesses. Remember, even if a food looks and smells alright, but has been stored improperly for an extended time, it may not be safe to eat. When in doubt, throw it out!

Q 24. How do you manage pests in a food handling environment?

Pest management in a food handling environment is paramount to prevent contamination and maintain hygiene. A multi-pronged approach is necessary:

- Good Sanitation Practices: Regularly cleaning and sanitizing all surfaces, equipment, and storage areas. This includes removing food debris that attracts pests.

- Proper Storage: Storing food in airtight containers, off the floor, and away from walls to prevent pest access.

- Regular Inspections: Conducting frequent inspections to identify any signs of pest activity, such as droppings, tracks, or nesting materials.

- Pest Control Measures: Employing professional pest control services for regular treatments and monitoring. This should be conducted in a manner that doesn’t compromise food safety.

- Exclusion Techniques: Sealing cracks and gaps in walls, floors, and doors to prevent pest entry.

Example: In a restaurant setting, this could include daily cleaning of floors, regular emptying of trash cans, using sealed containers for storage, and monthly inspections by a professional pest control service.

Q 25. Explain the importance of documentation in food handling.

Documentation in food handling is critical for traceability, accountability, and compliance with regulations. Comprehensive records demonstrate adherence to food safety standards and allow for effective investigation in case of incidents.

- Temperature Logs: Recording temperatures of refrigerators, freezers, and cooking equipment at regular intervals to ensure safe storage and cooking temperatures are maintained.

- Delivery Receipts: Tracking the origin and delivery dates of all food products.

- Preparation Records: Documenting preparation methods, ingredients used, and the date and time of preparation.

- Employee Training Records: Maintaining records of employee training on food safety procedures.

- Pest Control Records: Keeping records of all pest control treatments and inspections.

Example: If there is a foodborne illness outbreak, detailed records allow for quick identification of the source of contamination and prevent further incidents.

Q 26. Describe your experience with food recall procedures.

I have extensive experience with food recall procedures, having participated in several during my career. A food recall is a coordinated effort to remove a potentially unsafe food product from the market. My role typically involves:

- Identifying the affected product: Pinpointing the specific batch, lot, or product line involved in the recall.

- Tracing the product: Tracking the distribution chain to determine where the product was shipped and sold.

- Notification: Collaborating with regulatory agencies and retailers to notify consumers and initiate the product removal process.

- Coordination: Working with the production team to halt production, investigate the cause of contamination and implement corrective actions to prevent future occurrences.

- Documentation: Maintaining detailed records of all recall activities.

Effective communication and swift action are vital during a recall. The goal is to minimize the risk to public health and maintain consumer confidence.

Q 27. How do you ensure compliance with all relevant food safety regulations?

Ensuring compliance with food safety regulations requires a proactive and comprehensive approach. This involves:

- Staying Updated: Regularly reviewing and updating knowledge on current food safety regulations and best practices (e.g., HACCP, GMP).

- Implementing Systems: Establishing and maintaining robust food safety management systems, such as Hazard Analysis and Critical Control Points (HACCP).

- Training: Providing regular training to all employees on food safety procedures, hygiene practices, and regulatory compliance.

- Audits and Inspections: Conducting regular internal audits and cooperating fully with external inspections by regulatory agencies.

- Record Keeping: Maintaining accurate and complete records of all food safety-related activities.

Compliance is not merely a checklist; it’s a commitment to food safety and public health. It requires continuous monitoring, improvement, and a culture of safety within the organization.

Q 28. What are your strengths and weaknesses related to food handling?

My strengths in food handling include a deep understanding of food safety regulations, strong attention to detail, and the ability to effectively manage teams to maintain high hygiene standards. I’m also adept at problem-solving and quickly adapting to changing situations, such as handling unexpected contamination issues.

One area I am working to improve is my proficiency in using advanced statistical software for analyzing food safety data. While I understand the data analysis principles, I’m actively seeking opportunities to enhance my skills in this specific area to further refine our food safety processes.

Key Topics to Learn for Food Handling Procedures Interview

- Personal Hygiene and Sanitation: Understanding the importance of handwashing, proper attire, and preventing cross-contamination. Practical application includes describing your own hygiene practices and how you’d handle a situation with a coworker not following protocol.

- Temperature Control: Mastering safe temperature ranges for food storage, preparation, and service. Think about how you would ensure food is kept at the correct temperature throughout the entire process, from receiving to serving.

- Food Storage and Rotation: Implementing FIFO (First-In, First-Out) methods to minimize food waste and prevent spoilage. Be prepared to explain how you’d organize a refrigerator or storage area for optimal food safety and rotation.

- Preventing Cross-Contamination: Identifying and avoiding cross-contamination risks between raw and cooked foods, and different food types. Consider how you would handle cleaning and sanitizing procedures to prevent cross-contamination effectively.

- Foodborne Illness Prevention: Recognizing common foodborne illnesses and understanding the steps to prevent their transmission. This includes understanding safe cooking temperatures and proper handling of potentially hazardous foods.

- Cleaning and Sanitizing Procedures: Knowing the proper methods and chemicals to effectively clean and sanitize food contact surfaces and equipment. Be ready to describe your approach to cleaning and sanitizing, and the importance of following established protocols.

- Allergen Awareness and Management: Understanding common food allergens and how to prevent cross-contamination and ensure safe food handling for individuals with allergies. Consider scenarios where you’d handle allergen information and prevent allergic reactions.

- Waste Management and Disposal: Safe and proper disposal of food waste to maintain hygiene and prevent pest infestation. This includes understanding local regulations and best practices for waste handling.

Next Steps

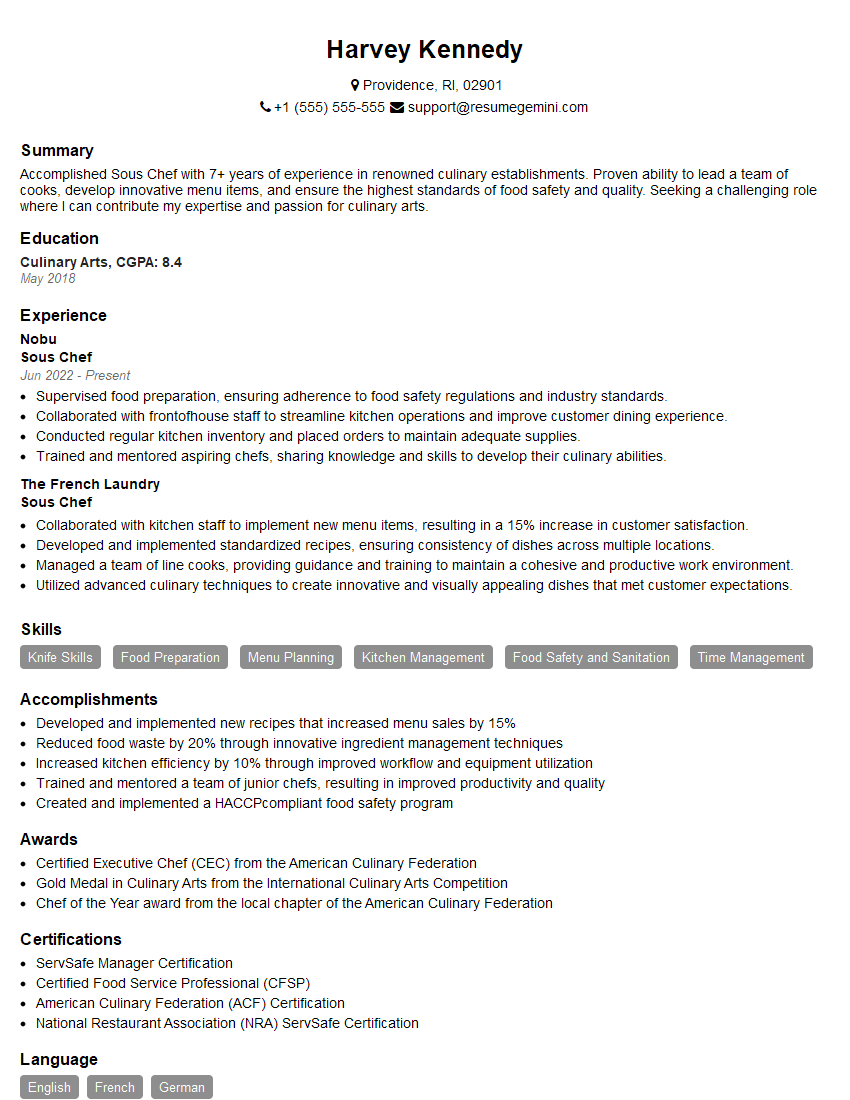

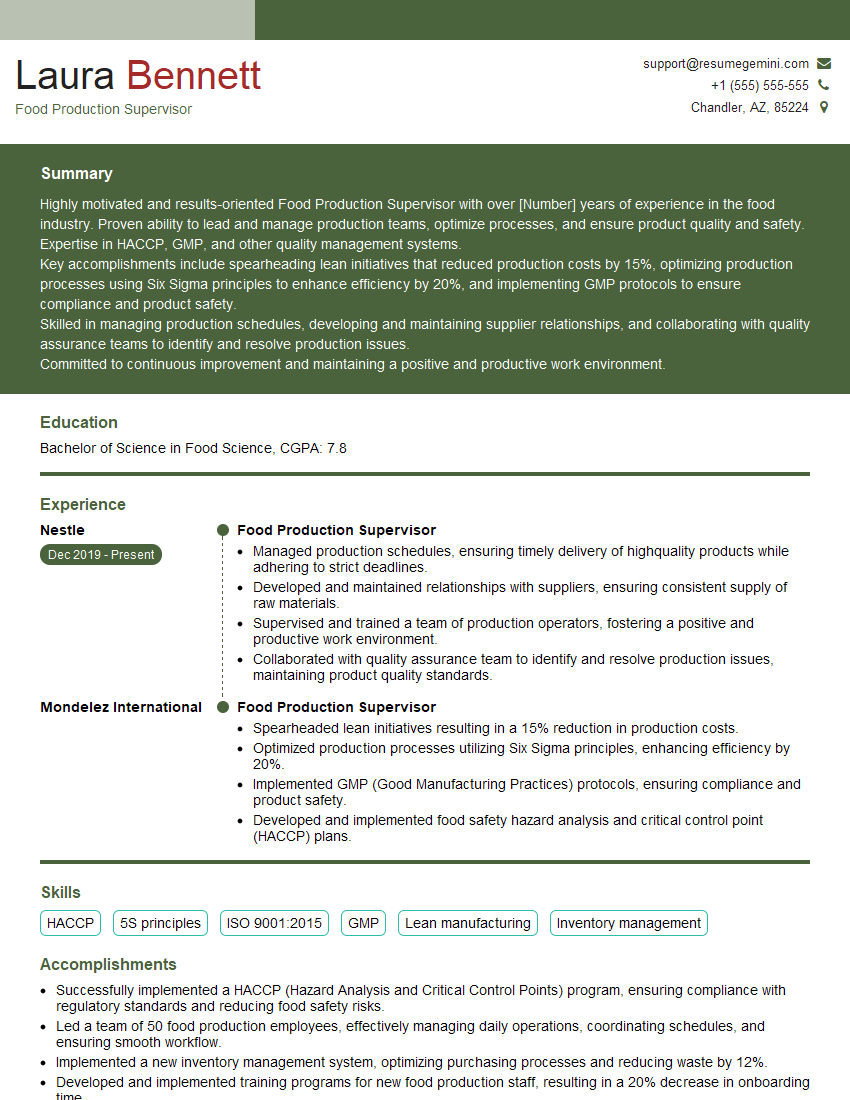

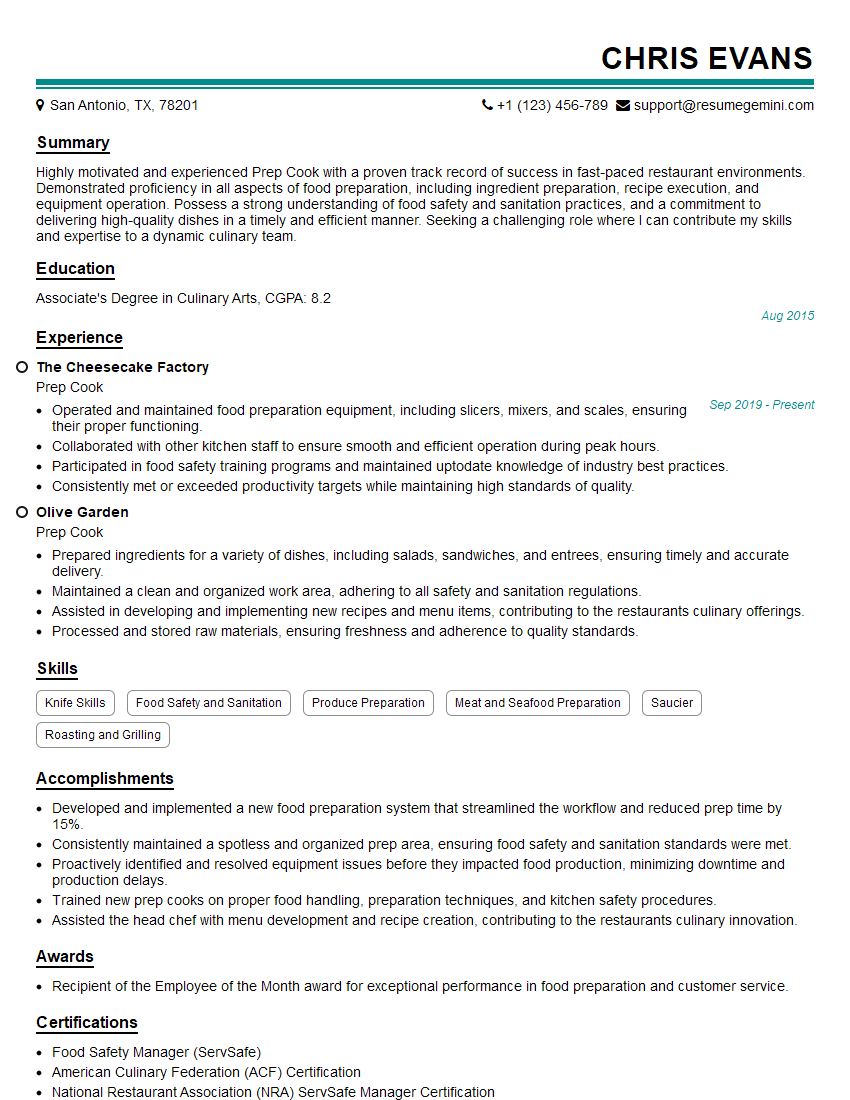

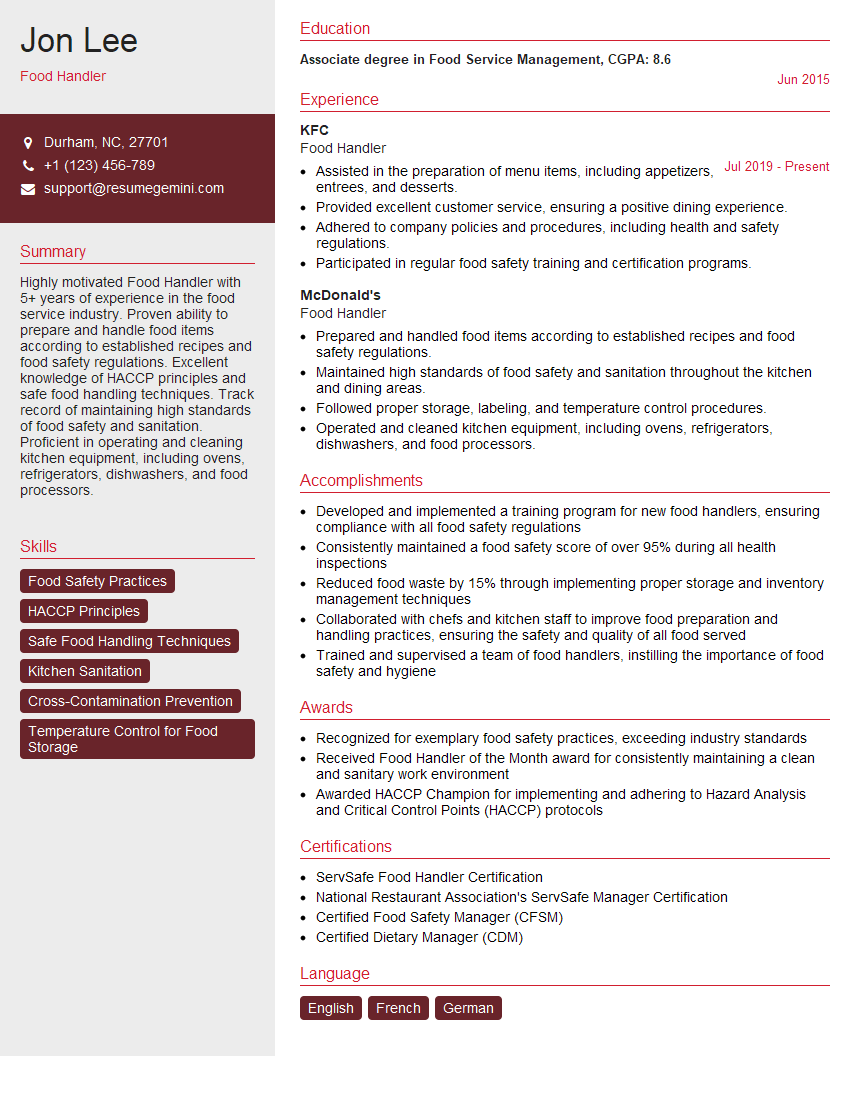

Mastering food handling procedures is crucial for career advancement in the food industry, demonstrating your commitment to safety and quality. A strong resume is your key to unlocking opportunities. Creating an ATS-friendly resume significantly increases your chances of getting noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and effective resume. We provide examples of resumes tailored to Food Handling Procedures to guide you in creating your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good