Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Rigging and Safety Procedures interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Rigging and Safety Procedures Interview

Q 1. Explain the different types of rigging slings and their appropriate uses.

Rigging slings are the crucial link between the load and the lifting equipment. Choosing the right sling is paramount for safety and efficiency. Several types exist, each suited for specific applications:

- Eye-to-eye slings: These have eyes at both ends, making them versatile for various lifting configurations. Think of them as simple loops. They’re great for general lifting where the load is relatively evenly distributed.

- Endless slings: These are continuous loops, often made from round or flat webbing. Their continuous nature makes them less prone to slippage and ideal for lifting heavy, bulky items. Imagine a large, strong loop—that’s the essence of an endless sling.

- Choker slings: These are single-leg slings used when wrapping around a load. Caution is needed here, as the load can easily slip and the sling can experience significant stress at the choke point. Think of securing a log – this is where a choker might be used, but with extreme care.

- Bridle slings: These consist of two or more slings attached to a single lifting point. They are very useful in distributing weight evenly on an object and prevents the load from tilting.

- Chain slings: Durable and robust, chain slings are preferred for heavy lifting or in harsh environments, particularly where heat or abrasion is a concern. These are workhorses built for demanding jobs.

The choice depends heavily on the load’s shape, weight, and material, as well as the lifting environment. Always consult load charts and relevant safety regulations to determine the appropriate sling type and size.

Q 2. Describe the process of calculating the safe working load (SWL) of a rigging assembly.

Calculating the Safe Working Load (SWL) of a rigging assembly isn’t simply looking at the SWL of individual components. It’s a more complex process that requires understanding several factors.

First, you determine the SWL of each individual component – slings, shackles, hooks, etc. This information is typically found stamped on the equipment itself. Next, consider the angle of the lift. Lifting at an angle reduces the effective SWL. A common calculation involves using a trigonometric function (cosine) to account for the angle. For example, a 30-degree angle reduces the effective SWL significantly.

Another crucial consideration is the number of legs in the lift. A multi-leg sling distributes the load, increasing the overall SWL. The formula to calculate the total SWL for multi-leg slings is often available in the rigging equipment manuals. The SWL of a two-leg sling is not simply double the SWL of a single leg, it depends on the angle. So, a 60-degree angle in a two-leg lift configuration only offers 86.6% of the total SWL.

Finally, any additional factors like wear and tear, environmental conditions (extreme temperatures, corrosion), or damage must be accounted for. A thorough inspection before each lift is crucial. Always err on the side of caution; using a lower SWL than calculated is always recommended. Never exceed the lowest SWL of any component in your assembly.

Q 3. What are the key components of a pre-lift inspection?

A pre-lift inspection is a non-negotiable step for safe rigging operations. It’s a systematic check to ensure all equipment and procedures are in place. Key components include:

- Inspection of lifting equipment: This covers cranes, hoists, slings, shackles, hooks, and any other hardware involved. Check for any signs of wear, damage, corrosion, or defects. Each component should have a valid SWL tag.

- Examination of the load: Assess the load’s weight, dimensions, center of gravity, and any potential hazards. An unstable load can lead to disastrous consequences.

- Assessment of the lifting environment: Consider factors like ground conditions, overhead obstructions, weather, and the presence of personnel in the vicinity. Ensure the area is clear of obstacles and personnel.

- Review of the lifting plan: Ensure the plan details the correct lifting procedures, sequence, and any special considerations. A safe plan is a critical step.

- Verification of the rigging assembly: Double-check the correct assembly of all components, ensuring everything is properly secured and connected.

Documentation of the inspection is essential. Any issues identified should be rectified before proceeding. Remember, this is not just a checklist; it’s a crucial safety measure.

Q 4. How do you identify and mitigate potential hazards during a rigging operation?

Hazard identification and mitigation is an ongoing process throughout the rigging operation. Potential hazards can be broadly classified as:

- Equipment failures: This includes worn or damaged slings, broken hooks, malfunctioning cranes, etc. Regular inspections and maintenance are vital to mitigate this.

- Environmental hazards: Wind, rain, ice, uneven terrain, and overhead obstructions can all pose risks. Adapt the operation to the conditions or postpone the lift if the risks are too high.

- Human error: Incorrect rigging procedures, inadequate communication, and fatigue can lead to accidents. Proper training and clear communication protocols are crucial.

- Load instability: Improper load distribution, shifting center of gravity, or unexpected load movement can cause accidents. Secure the load correctly and monitor it throughout the lift.

Mitigation strategies include: using appropriate safety gear (hard hats, safety glasses, gloves), implementing traffic control measures, establishing clear communication channels, using redundant safety devices, and conducting thorough risk assessments before, during, and after the lift. Regularly assessing and controlling risks is paramount.

Q 5. What are the regulations and standards you adhere to in rigging operations?

Rigging operations are governed by numerous regulations and standards, varying by location and industry. Some key standards commonly adhered to include:

- OSHA (Occupational Safety and Health Administration) regulations: In the United States, OSHA sets stringent standards for workplace safety, including those relevant to rigging.

- ASME (American Society of Mechanical Engineers) standards: These provide guidance on the design, manufacturing, and safe operation of various lifting equipment.

- EN (European Norm) standards: These are widely adopted throughout Europe and cover various aspects of lifting and rigging safety.

- Manufacturer’s specifications and recommendations: It is crucial to consult and strictly adhere to the manufacturer’s recommendations and specifications for all rigging equipment. Every piece of equipment is unique and should be respected.

Staying updated on these regulations and standards is crucial. Regular training and certification programs are necessary to ensure compliance and maintain competency.

Q 6. Explain the importance of communication in a rigging team.

Effective communication is the cornerstone of safe rigging operations. It’s a shared responsibility to ensure everyone understands the plan, identifies potential hazards, and responds effectively during the lift.

Clear and concise communication involves: pre-lift briefings to ensure all team members are on the same page, using standardized hand signals, employing two-way radios for complex operations, designating a clear point of contact, implementing a system for reporting any issues or concerns, and providing concise and informative debriefings after the operation to discuss what went well and what could be improved. It might seem basic, but open, direct communication can prevent misunderstandings and avoid accidents.

Establishing a culture of safety where open communication is valued is essential. Everyone on the team should feel empowered to raise concerns and halt the operation if safety is jeopardized.

Q 7. Describe your experience with different types of lifting equipment (cranes, hoists, etc.).

My experience encompasses a wide range of lifting equipment, including various types of cranes (tower cranes, mobile cranes, overhead cranes), hoists (electric chain hoists, air hoists, hand-operated hoists), and specialized lifting equipment. I’ve worked with both large-scale construction projects and smaller-scale industrial settings.

For example, I’ve been involved in the rigging of heavy industrial machinery in a manufacturing plant using overhead cranes and chain hoists, carefully planning the lift paths to avoid any obstructions. I’ve also been responsible for rigging operations on large construction sites, using tower cranes to lift prefabricated structural components, requiring precise coordination and meticulous attention to safety protocols. My experience extends to the use of specialized lifting equipment like vacuum lifters for sensitive loads or air bags for delicate or unconventional objects. I am proficient in both planning, executing, and post-operation assessments of the lifting process for all the types of lifting equipment.

This experience has provided me with a comprehensive understanding of the capabilities and limitations of each equipment type, the necessary safety precautions, and the importance of adapting techniques to different scenarios.

Q 8. How do you ensure the proper use and maintenance of rigging hardware?

Proper use and maintenance of rigging hardware is paramount for safety. It’s not just about following a checklist; it’s about understanding the materials, their limitations, and how environmental factors affect their performance.

- Regular Inspections: Before every use, I meticulously inspect all hardware for damage: cracks, bends, corrosion, deformation, or wear. A simple visual check is the first line of defense. Think of it like a pre-flight check for an airplane – essential and non-negotiable.

- Documentation: A detailed log is kept, recording inspection dates, findings, and any maintenance performed. This allows us to track the history of each piece of equipment and predict potential issues before they become serious.

- Proper Storage: Rigging hardware should be stored in a dry, clean environment to minimize corrosion and damage. Improper storage can easily render equipment unusable or dangerous.

- Maintenance Schedule: A preventative maintenance schedule should be followed. This may involve lubrication, cleaning, or replacing worn parts. For instance, wire rope requires regular lubrication to prevent fraying and extend its lifespan. Ignoring this can be disastrous.

- Training: All team members receive thorough training on the proper use and inspection of rigging hardware, emphasizing the importance of identifying potential hazards.

For example, I once noticed a slight bend in a shackle during a pre-use inspection. This seemingly small imperfection could have caused catastrophic failure under load. By catching it early, we prevented a potential accident.

Q 9. What are the procedures for handling damaged or worn rigging equipment?

Damaged or worn rigging equipment is immediately removed from service. ‘Out of sight, out of mind’ is never an acceptable approach. There’s no room for compromise when it comes to safety.

- Clear Marking: Damaged equipment is clearly marked as unusable, often with tags and labels, to prevent accidental reuse.

- Detailed Reporting: A thorough report is filed documenting the type of damage, the location of the damage, and the circumstances under which the damage occurred. This helps with root cause analysis and prevents similar incidents in the future.

- Proper Disposal/Repair: Damaged equipment is either disposed of properly, following all relevant regulations, or sent for repair by a certified professional. Never attempt DIY repairs on critical rigging components – it’s simply too risky.

- Replacement: The damaged equipment is replaced with a verified, undamaged, and appropriately rated piece of equipment. The ‘fix it later’ mentality is a dangerous one.

Imagine working on a high-rise building and a shackle fails because it was previously damaged and overlooked. The consequences could be devastating. This highlights the critical importance of our strict procedures for handling damaged equipment.

Q 10. What is your experience with load charts and their application?

Load charts are the cornerstone of safe rigging practices. They provide critical information on the working load limit (WLL) of various pieces of equipment – ropes, chains, slings, etc. – under different conditions. Understanding and utilizing load charts correctly is not just good practice; it’s essential for life safety.

- Understanding WLL: I understand that the WLL is the maximum load a piece of equipment can safely handle. Exceeding this limit dramatically increases the risk of failure.

- Environmental Factors: Load charts often incorporate factors like temperature and material degradation. This means that the WLL can change based on environmental conditions; therefore, it’s essential to account for these factors.

- Safety Factor: Load charts usually incorporate a safety factor to account for unexpected loads or variations in material strength.

- Application: Before every lift, the load weight and configuration are carefully calculated to ensure they are within the WLL of all components used in the rigging system. If any component exceeds its WLL, an alternative approach needs to be developed that keeps everything within safe limits.

For instance, if we’re lifting a heavy component in extreme cold, I’ll consult the load chart to see how the reduced strength of the steel cable at lower temperatures impacts the WLL. We might need to use a higher rated piece of equipment to compensate.

Q 11. Describe your understanding of different hitching techniques and their safety implications.

Hitches – the way we attach ropes or slings to loads – are crucial for both load security and safety. Incorrect hitching can lead to slippage, load imbalance, and potentially catastrophic failure.

- Basic Hitches: I’m proficient in various hitching techniques, including clove hitches, bowlines, and round turns with a half-hitch. Each hitch serves a specific purpose and has its own strengths and weaknesses.

- Safety Implications: Understanding the load distribution and stability provided by each hitch is crucial. A poorly executed hitch can lead to the load shifting, causing instability, and potentially injuring workers or damaging equipment.

- Load Distribution: I always aim for even load distribution using the appropriate hitch and multiple attachment points where necessary, ensuring the load is secure and unlikely to shift or slip.

- Proper Knotting: All knots are securely tied, with tails properly secured to prevent loosening and potential slippage.

For example, using a bowline to create a loop for lifting a load provides a secure, non-sliping connection that can be easily adjusted. Conversely, an improperly tied clove hitch could easily slip under load.

Q 12. How do you account for environmental factors (wind, temperature) during rigging operations?

Environmental factors significantly impact rigging operations and must be carefully considered. Neglecting these factors can lead to accidents and equipment damage.

- Wind: High winds can significantly affect load stability and control. Wind speed and direction are always checked before commencing any rigging operation, and adjustments are made to mitigate the effects of the wind. This may involve using additional rigging equipment or delaying the operation until the wind subsides.

- Temperature: Temperature extremes can affect the strength of rigging materials, such as ropes and chains. High temperatures can weaken materials through heat stress, while low temperatures can make them brittle. The load charts must be consulted for the appropriate WLL under the prevailing temperature.

- Precipitation: Rain or snow can reduce friction and increase the risk of slippage. Appropriate precautions must be taken to protect equipment and personnel from the elements, and materials should be selected that can withstand the conditions.

- Visibility: Poor visibility, due to fog or darkness, can significantly impact the safety of rigging operations. Appropriate lighting and safety measures should be implemented.

For instance, if we’re lifting a load in a windy condition, we might use a more substantial crane and reduce the swing radius to minimize the risk of the load swinging uncontrollably.

Q 13. Explain the concept of load distribution and its importance in rigging.

Load distribution is the even dispersal of a load across multiple attachment points. It’s critical for preventing stress concentrations and ensuring the safe and stable lifting of the load. Uneven load distribution can overload individual components, leading to failure.

- Even Distribution: Proper load distribution requires careful planning and execution. The load must be balanced and centered, with appropriate rigging points used to ensure that the weight is evenly spread across all attachment points.

- Multiple Attachment Points: Using multiple attachment points for large or oddly shaped objects distributes the load more efficiently and prevents undue stress on any single point.

- Rigging Hardware Selection: The correct type and size of rigging hardware must be selected to accommodate the weight and distribution of the load. Using undersized hardware creates a significant risk.

- Inspections: Regular inspections during the lifting operation are crucial to confirm load stability and ensure the load remains evenly distributed.

Imagine trying to lift a heavy steel beam with a single point. The stress concentration at that single point would be enormous, increasing the risk of failure significantly. However, if we use multiple slings and distribute the weight evenly, the chances of failure are drastically reduced.

Q 14. What are your strategies for conflict resolution within the rigging team?

Conflict resolution is a critical skill within a rigging team, where safety relies on teamwork and clear communication. My strategy focuses on proactive communication, open dialogue, and a commitment to safety above all else.

- Open Communication: I foster an environment where team members feel comfortable voicing concerns and expressing differing opinions. This means actively listening to each individual’s perspective.

- Focus on Shared Goals: I remind the team of our shared goal – completing the job safely and efficiently. This helps to redirect conversations away from individual disagreements and towards collaborative solutions.

- Safety First: When a conflict arises, I emphasize safety as the overriding concern. Any disagreements must be resolved in a manner that ensures the safety of all involved.

- Mediation: If a conflict cannot be resolved directly by the involved parties, I will step in to mediate, facilitating a discussion that seeks common ground and a resolution that satisfies all parties.

- Documentation: Any significant conflicts or disagreements are documented, including the resolution and any actions taken to prevent similar issues in the future.

Once, a disagreement arose about the best lifting technique for a complex load. By fostering open dialogue and discussing the pros and cons of each approach, we found a solution that ensured the safety and efficiency of the lift. The focus remained on the safe execution of the task, resolving the conflict constructively and without jeopardizing the operation.

Q 15. How do you handle emergency situations during a rigging operation?

Handling emergencies in rigging demands immediate, decisive action. My first priority is always the safety of personnel. This means immediately halting the operation and ensuring everyone is clear of the hazard. Then, I would assess the situation, identifying the root cause of the emergency – be it equipment malfunction, human error, or unforeseen environmental factors.

For example, if a load starts to swing dangerously, my immediate response would be to signal the crane operator to stop immediately, using clear and unambiguous hand signals (I’ll detail these in a later answer). Once stopped, I’d carefully evaluate the situation, determine if the rigging is compromised, and implement corrective actions. This might involve re-rigging the load, securing it differently, or calling for specialized equipment. A detailed incident report, including root cause analysis and corrective actions, would be crucial for preventing future incidents.

In the event of a serious injury, I would prioritize first aid and immediate emergency services contact. My experience includes managing multiple scenarios involving equipment failure and near misses, always focusing on preventative measures and thorough post-incident investigations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with risk assessment and method statements in rigging.

Risk assessment and method statements are cornerstones of safe rigging. Before any lift, I meticulously conduct a risk assessment, identifying all potential hazards – equipment failures, environmental conditions, human factors, and load characteristics. This involves a systematic evaluation, often using a checklist, to ensure no aspect is overlooked.

Following the assessment, a comprehensive method statement is created. This document outlines the planned rigging procedure, including personnel assignments, equipment specifications, lifting techniques, and emergency procedures. It’s not just a plan; it’s a living document, regularly reviewed and updated as conditions change. It’s essentially a roadmap for the entire operation, ensuring everyone is on the same page and knows what to expect.

For example, in lifting a particularly heavy or oddly shaped piece of equipment, the method statement would detail the specific rigging configuration, including the type and number of slings, their attachment points, and the planned lifting trajectory. It would also identify potential hazards like overhead obstructions and the steps to mitigate them. This level of detail minimizes risks and ensures a smoother, safer operation.

Q 17. What is your experience with different types of knots used in rigging?

My experience encompasses a wide range of knots, each selected based on the specific rigging requirements. I’m proficient in various essential knots, including bowlines (for a secure loop that won’t slip), clove hitches (for quickly attaching a rope to a ring or hook), and figure-eights (for creating a secure stopper knot). I also have extensive experience with more specialized knots like the bowline on a bight (creating two loops from a single rope), and understand their specific applications and limitations.

The choice of knot is critical; a poorly tied knot can have catastrophic consequences. I always double-check every knot, ensuring it’s secure, properly seated, and free from any potential hazards. It’s not just about knowing the knots; it’s about understanding their strengths and weaknesses in different loading situations. For instance, I would never use a simple overhand knot for load-bearing applications due to its inherent instability under load. Practical experience has taught me the importance of using the right knot for the job and never compromising on safety.

Q 18. Describe the proper techniques for signaling crane operators.

Clear communication with the crane operator is paramount. We use a standardized system of hand signals, universally understood within the industry. These signals are unambiguous and cover all aspects of the lift, from hoisting and lowering to swinging and positioning the load. Each signal has a specific meaning, and I never rely on verbal communication when the load is in motion.

For example, a slow, upward sweeping motion with an open hand indicates a slow hoist, while a firm, downward motion indicates lowering. Swinging the load requires precise signals, ensuring the operator understands the direction and extent of the swing. My experience reinforces the critical importance of consistent, precise signaling. It’s not just about knowing the signals; it’s about communicating them clearly and confidently, even in challenging conditions.

Additionally, before each lift, a thorough pre-lift briefing is conducted with the crane operator, confirming load weight, center of gravity, and any potential hazards or special considerations. This collaborative approach is crucial for a successful and safe lift.

Q 19. How do you ensure the safety of personnel near rigging operations?

Ensuring personnel safety near rigging operations necessitates a multi-layered approach. This starts with establishing clear exclusion zones around the lifting area, using barriers or designated personnel to control access. Everyone within the zone must wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, and high-visibility clothing. Before any lift commences, a thorough risk assessment identifying potential hazards, such as falling objects or swinging loads, is crucial.

Training is another key aspect. All personnel involved, from riggers to crane operators and nearby workers, receive regular training on safe work practices around rigging operations. This includes understanding hand signals, emergency procedures, and recognizing potential hazards. Clear communication is essential; everyone must understand their roles and responsibilities.

Regular inspections of the work area and equipment are also critical. This helps identify potential problems early on, before they become serious hazards. For instance, ensuring that the ground is stable and free of obstructions is crucial to prevent accidents. A proactive approach to safety, combining training, exclusion zones, clear communication, and regular inspections, creates a much safer environment.

Q 20. What are your experience and understanding of different types of lifting beams?

My experience encompasses a wide variety of lifting beams, each designed for specific applications. I’m familiar with the common types: single-beam, double-beam, and spreader beams. Single-beam systems are simpler, used for relatively lighter loads and straightforward lifts. Double-beam systems provide greater stability and strength, suitable for heavier loads and longer spans.

Spreader beams are particularly useful for distributing loads across multiple attachment points, allowing for more controlled and safer lifting of bulky or irregularly shaped objects. I also have experience with specialized beams, like those designed for handling sensitive equipment or those that require specific configurations for unique load characteristics. Each type has its strengths and weaknesses; selection depends on factors like load weight, dimensions, and the specific needs of the project. The choice is critical; an improperly chosen beam can lead to equipment damage or even accidents.

For instance, attempting to lift a heavy, unbalanced load with a single-beam system could result in bending or failure. Selecting a correctly designed double-beam or spreader beam, with appropriate calculations for load distribution, is vital for safety and efficiency.

Q 21. What is your experience with load testing and certification of lifting equipment?

Load testing and certification of lifting equipment are crucial for safety. I’ve been directly involved in numerous load tests, observing the procedures and verifying compliance with relevant standards. This process involves applying a controlled load to the equipment, often exceeding the intended working load limit (WLL), to ensure it can withstand the expected stresses.

Thorough documentation of these tests is critical, including the load applied, the equipment’s response, and any observed anomalies. Certification is essential, ensuring the equipment is compliant with relevant safety standards and fit for its intended purpose. I understand the importance of maintaining accurate records and adhering strictly to the certification requirements. Out-of-certification equipment is never used, and any issues or defects are immediately reported and addressed.

For example, before a major lift involving a specific crane, we’d conduct a load test to verify its lifting capacity and ensure it’s in optimal working condition. These tests are not just a formality; they’re a critical safety measure that helps prevent catastrophic failures during actual operations. Regular load testing and meticulous record-keeping are integral parts of my approach to safe rigging.

Q 22. Describe your experience with using Personal Protective Equipment (PPE) during rigging operations.

Personal Protective Equipment (PPE) is paramount in rigging. It’s the first line of defense against hazards like falling objects, sharp edges, and crushing injuries. My experience encompasses consistent and meticulous use of PPE, tailored to the specific task. This includes hard hats, safety glasses or goggles offering side protection, high-visibility clothing, steel-toe boots with ankle support, and appropriate gloves—cut-resistant for handling wire rope and general-purpose for other tasks. For working at heights, a full-body harness with appropriate fall arrest systems is non-negotiable. I always inspect my PPE before each job, ensuring everything is in good working order and fits correctly. For instance, during a recent bridge construction project, I ensured every member of the rigging crew wore a properly fitted harness with a self-retracting lifeline when working above ground level. A single point of failure in PPE can lead to catastrophic consequences; therefore, proactive checks are essential.

Q 23. How do you plan for the safe movement of heavy loads in confined spaces?

Moving heavy loads in confined spaces requires meticulous planning and execution. Safety is paramount, and the confined space itself presents unique challenges. My approach begins with a thorough risk assessment, identifying potential hazards such as limited access, restricted visibility, and the risk of equipment colliding with walls or structures. We then develop a detailed lifting plan, specifying the exact path of the load, including clearances and potential obstacles. This plan will clearly outline the type of rigging gear to use, considering the weight, size, and shape of the load, and the space limitations. We’ll choose smaller, more maneuverable equipment if necessary and utilize equipment that can handle sharp turns or tight corners. The plan includes clear communication protocols between the crane operator, riggers, and spotters. Regular communication is crucial to ensure everyone is aware of the load’s position and any potential problems. For example, during the installation of a large piece of machinery in a factory, we carefully mapped the load’s path, using laser measurement tools and employing a smaller, more agile crane to navigate the restricted access.

Q 24. Explain your understanding of lockout/tagout procedures as they relate to rigging equipment.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization or startup of equipment during maintenance or repair, including rigging equipment. My understanding is that before any work commences on equipment, it must be de-energized, isolated, and locked out. This involves physically locking out the power source, preventing accidental activation. A tag is then placed on the lock, clearly indicating who performed the lockout, the date, and the reason. This process ensures that only authorized personnel can restore the power, preventing unintentional operation that could lead to serious injury or fatality. In the context of rigging, this applies to cranes, hoists, and other powered lifting equipment. Before maintenance or inspection, we lock out the power supply, preventing any unexpected movement. I personally ensure compliance by verifying the LOTO process and documenting all procedures in detailed reports.

Q 25. What is your experience with the use of lifting plans and rigging diagrams?

Lifting plans and rigging diagrams are essential tools for any rigging operation, especially for complex lifts. My experience involves creating, reviewing, and implementing these documents for various projects. A lifting plan outlines all aspects of a lift, including the load’s weight, dimensions, center of gravity, rigging configuration, crane specifications, and safety procedures. Rigging diagrams provide a visual representation of the planned rigging setup, clearly showing the points of attachment, angles, and the type of rigging hardware used. For instance, a recent project involved the installation of a large transformer. The lifting plan included calculations to determine the required crane capacity and the safe working load of each component of the rigging. The rigging diagram showed clearly the placement of shackles, slings, and other hardware, which was crucial in ensuring the lift was done correctly and safely. Using these plans allowed us to minimize risks and ensure the smooth and safe execution of every lift.

Q 26. How do you ensure compliance with relevant health and safety regulations?

Ensuring compliance with health and safety regulations is a top priority in my work. This involves understanding and adhering to relevant national and international standards and regulations, such as OSHA (in the US) or equivalent regulations in other countries. I stay updated on these regulations and ensure that all rigging operations are conducted according to the established safety guidelines. This involves reviewing permits, inspecting equipment regularly, and conducting thorough risk assessments before each job. It’s also about fostering a strong safety culture within the team. We always encourage communication, reporting any safety concerns, and providing regular training to improve the understanding and implementation of safety protocols. Compliance isn’t just about avoiding penalties; it’s about protecting lives and preventing accidents.

Q 27. Describe your problem-solving approach when facing unexpected issues during a rigging operation.

My problem-solving approach during unexpected issues is methodical and prioritizes safety. The first step is to immediately stop the operation and assess the situation. We identify the problem, evaluating the potential risks and determining the best course of action. This often involves consulting with other experienced riggers or engineers to get a second opinion, and exploring alternative solutions. For example, if a sling fails unexpectedly, the immediate response is to secure the load to prevent any further movement or dropping. Then, we determine why the failure occurred and ensure it doesn’t happen again. Detailed documentation is crucial, and thorough post-incident investigation helps to identify root causes and implement corrective actions to improve future safety procedures. My approach is always focused on safety and ensuring everyone remains safe and protected, and the situation is addressed without further complications.

Q 28. How do you stay updated with the latest industry best practices and regulations?

Staying updated is crucial in this ever-evolving field. I actively participate in professional organizations such as the Association of Crane & Rigging Professionals, attending conferences and workshops. I also regularly review industry publications, journals, and online resources to stay abreast of the latest safety standards and best practices. This includes reviewing updates to OSHA regulations and other relevant safety standards. Furthermore, ongoing training in new technologies and techniques keeps my skills sharp. Participating in training programs related to specific rigging equipment and safety procedures keeps my skillset relevant and my knowledge up to date. Continuous learning is fundamental to ensuring I always maintain best practices in safety and proficiency in rigging operations.

Key Topics to Learn for Rigging and Safety Procedures Interview

- Fundamental Rigging Principles: Understanding load capacity, center of gravity, and different rigging hardware (e.g., shackles, slings, wire ropes).

- Practical Application: Describe your experience with various rigging techniques for different loads and environments (e.g., lifting, moving, suspending heavy objects). Be prepared to discuss specific scenarios and problem-solving approaches.

- Safety Regulations and Standards: Demonstrate familiarity with relevant industry standards and regulations (OSHA, ANSI, etc.) and their practical application in rigging operations.

- Hazard Identification and Risk Assessment: Explain your methodology for identifying potential hazards associated with rigging activities and implementing effective risk mitigation strategies.

- Inspection and Maintenance of Rigging Equipment: Detail your experience with inspecting and maintaining rigging equipment, including identifying defects and ensuring safe operating conditions.

- Emergency Procedures: Describe your knowledge of emergency procedures related to rigging accidents, including rescue techniques and communication protocols.

- Knot Tying and Splicing: Showcase your proficiency in tying and splicing various knots relevant to rigging, highlighting their strengths and limitations.

- Communication and Teamwork: Explain how effective communication and teamwork are crucial for ensuring safety and efficiency during rigging operations.

- Lifting Plans and Documentation: Discuss your experience in developing and reviewing lifting plans, including detailed documentation and calculations.

- Working at Heights and Fall Protection: Describe your understanding of safety procedures and equipment used when working at heights during rigging operations.

Next Steps

Mastering Rigging and Safety Procedures is paramount for career advancement in this demanding field. It demonstrates your commitment to safety and your ability to handle complex tasks efficiently and responsibly. This expertise will significantly enhance your job prospects and open doors to more challenging and rewarding opportunities.

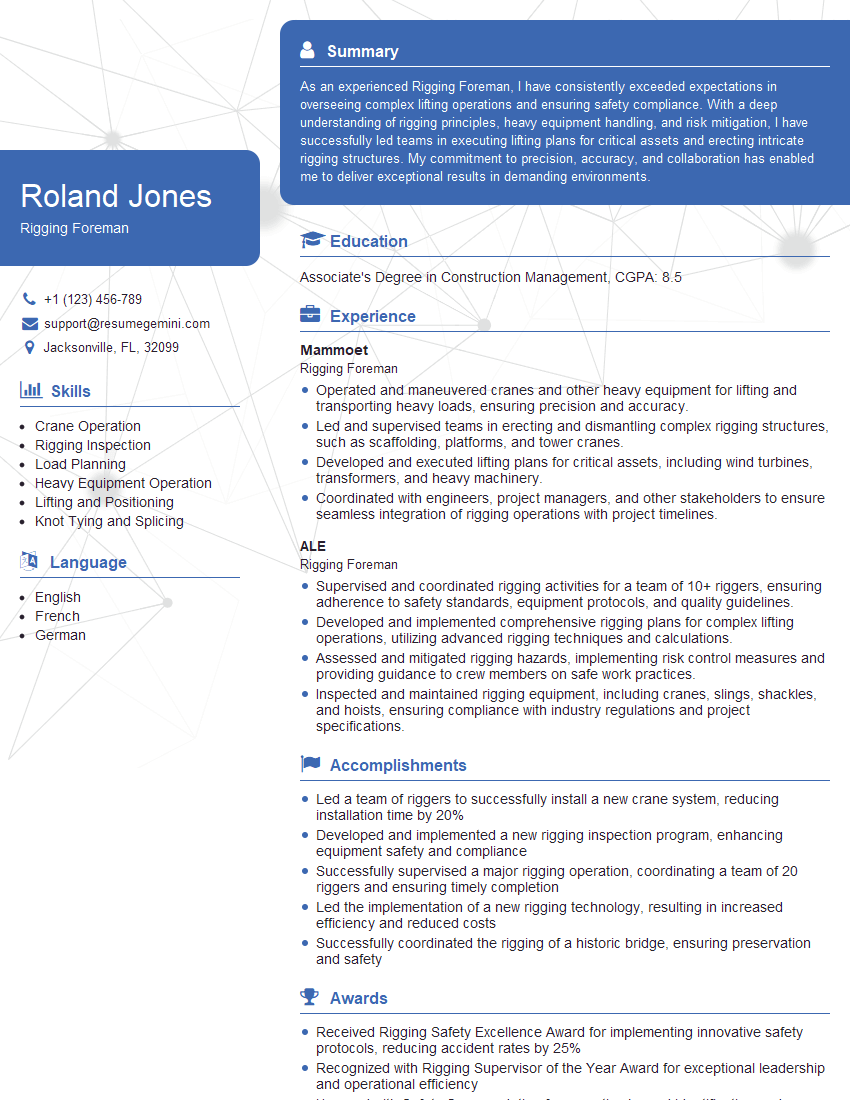

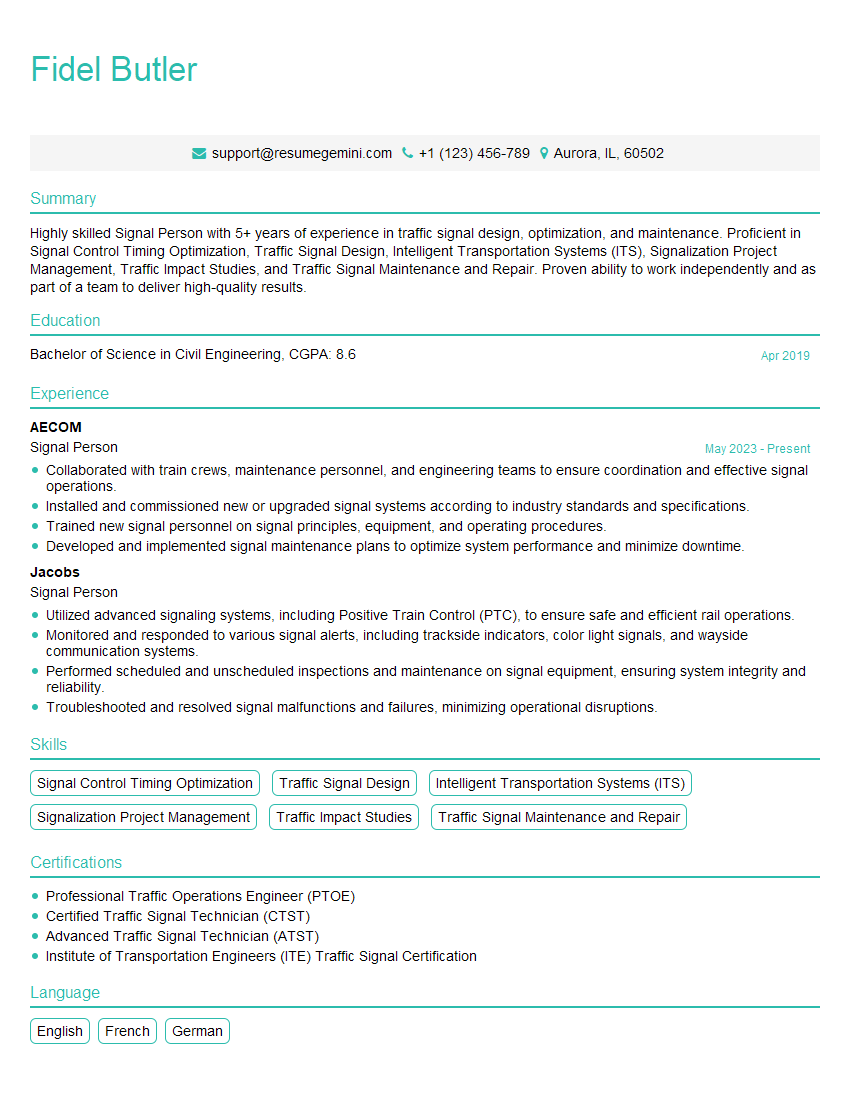

To maximize your chances of landing your dream job, crafting an ATS-friendly resume is essential. A well-structured resume that highlights your skills and experience will help your application stand out and get noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to the Rigging and Safety Procedures industry. Examples of resumes tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good