Are you ready to stand out in your next interview? Understanding and preparing for High-Volume Low-Pressure (HVLP) Spraying interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in High-Volume Low-Pressure (HVLP) Spraying Interview

Q 1. What are the advantages of HVLP spraying compared to other paint application methods?

HVLP spraying offers several key advantages over traditional methods like brush painting or conventional airless spraying. Primarily, it delivers a superior finish with significantly less overspray. Think of it like this: with a conventional sprayer, you might get a lot of paint misting into the air, wasting material and creating a messy environment. HVLP minimizes this waste.

- Reduced Overspray: This leads to less material waste and cleaner workspaces. You’ll use less paint and spend less time cleaning up.

- Improved Transfer Efficiency: A higher percentage of the paint reaches the surface being sprayed, resulting in cost savings.

- Superior Finish: HVLP produces a smoother, more even finish with less texture compared to other methods. This is because the paint particles are finer.

- Less Material Cleanup: Because of the reduced overspray, cleanup is much faster and easier.

- Better for the Environment: Less overspray means fewer volatile organic compounds (VOCs) released into the atmosphere.

For example, if you’re painting a delicate piece of furniture, HVLP’s precision and minimal overspray are invaluable. In larger-scale projects like painting a house, the cost savings from reduced material waste become very apparent.

Q 2. Explain the relationship between air pressure, fluid flow, and atomization in HVLP spraying.

The relationship between air pressure, fluid flow, and atomization in HVLP spraying is crucial for achieving a quality finish. It’s a delicate balance. HVLP stands for High Volume, Low Pressure, emphasizing that the system uses a large volume of air at relatively low pressure to atomize the paint.

Air Pressure: This is the force that pushes the air through the spray gun. Low pressure is key – typically ranging from 5 to 10 PSI (pounds per square inch) at the gun. Higher pressure results in excessive overspray and a rough finish. Too low, and the paint won’t atomize properly.

Fluid Flow: This refers to the rate at which the paint is fed through the nozzle. This is adjustable and depends on the viscosity of the paint and the desired coating thickness. Higher fluid flow produces a thicker coat, while lower flow produces a thinner coat.

Atomization: This is the process of breaking the paint into tiny droplets for even application. The low air pressure in HVLP creates a gentle, controlled atomization, preventing the paint from bouncing or splattering. The larger volume of air helps to create the fine mist that ensures a smoother finish.

Think of it like this: Imagine trying to water a plant. A high-pressure hose would splash water everywhere; a low-pressure hose with a wide opening delivers a gentle, even distribution. HVLP spraying works similarly.

Q 3. Describe the different types of HVLP spray guns and their applications.

Several types of HVLP spray guns cater to different needs. The choice depends on the project size, material being sprayed, and desired finish.

- Gravity-Feed Spray Guns: The paint is held in a cup above the gun, using gravity to feed the paint to the nozzle. These are excellent for smaller projects and detailed work due to their ease of handling and precision.

- Suction-Feed Spray Guns: The paint is drawn from a container below the gun via suction. These are more versatile for various paint viscosities and larger projects, as they can accommodate larger paint containers.

- Pressure-Feed Spray Guns: These guns use an external pressure pot or pump to feed the paint to the nozzle. This provides consistent paint flow, particularly beneficial for high-volume spraying.

For example, a detailer restoring a classic car would prefer a gravity-feed gun for precision and control. For painting a house exterior, a pressure-feed system would offer greater efficiency.

Q 4. How do you adjust the fluid flow and air pressure on an HVLP spray gun?

Adjusting fluid flow and air pressure on an HVLP spray gun involves manipulating specific controls on the gun itself. Most guns have easily accessible knobs or levers.

Fluid Flow Adjustment: A fluid needle valve usually controls this. Turning the valve clockwise generally decreases fluid flow, resulting in a thinner coat. Counterclockwise increases flow, creating a thicker coat. This adjustment is typically made before spraying, based on the material’s viscosity.

Air Pressure Adjustment: This is typically controlled by a regulator on the air compressor, often found on the air hose itself. The regulator allows you to fine-tune the pressure to the recommended PSI for the gun and material. It’s important to check the air pressure regularly.

It’s important to perform these adjustments in stages, testing on a scrap surface before applying paint to the actual project. This allows you to calibrate the spray pattern and flow before committing to the work itself.

Q 5. What are the common causes of orange peel in HVLP spraying, and how do you prevent them?

Orange peel, a textured finish resembling an orange peel, is a common problem in HVLP spraying, but easily preventable. Several factors contribute to this:

- Incorrect Air Pressure: Too high of air pressure causes the paint to atomize unevenly, leaving a textured surface.

- Too Much Paint: Excessive paint flow leads to thicker coats that don’t have time to level out properly.

- Incorrect Spray Distance: Spraying too close results in a heavier buildup of paint, leading to an uneven finish, while spraying too far away can result in a patchy appearance and insufficient coverage.

- High Viscosity Paint: Thick paint doesn’t atomize well, leading to a rough finish. Always thin the paint according to the manufacturer’s recommendations.

- Improper Gun Technique: Overlapping passes are important to ensure even coverage. If there are gaps between passes, an orange peel effect can occur.

Prevention: The key is to maintain the correct balance between air pressure, paint viscosity, and spray distance. Practice on scrap materials to perfect your technique and settings, ensuring smooth, consistent passes. Always thin the paint properly.

Q 6. How do you troubleshoot HVLP spray gun clogging?

A clogged HVLP spray gun is frustrating but usually fixable. Here’s a systematic approach:

- Identify the Clog: Determine if the clog is in the fluid nozzle, the air cap, or the fluid line.

- Disassemble Carefully: Consult your spray gun’s manual for disassembly instructions. Take photos as you go to help with reassembly.

- Clean the Components: Use the appropriate solvent for the paint you are using. Soak the clogged parts in the solvent, then gently clean them with a small brush or compressed air. You may need a fine needle for delicate cleaning.

- Inspect for Damage: Once clean, inspect the parts for damage or wear. Replace any damaged components.

- Reassemble and Test: Carefully reassemble the spray gun, following the reverse order of disassembly. Test on a scrap surface before resuming work.

Preventing clogs is just as important: Strain paint thoroughly before spraying, clean the gun immediately after use, and use the correct thinner.

Q 7. What safety precautions should be taken when using HVLP spray equipment?

Safety is paramount when using HVLP spray equipment. Here’s a checklist:

- Respiratory Protection: Always wear a respirator designed for spray painting to avoid inhaling paint fumes and particles.

- Eye Protection: Safety glasses or a face shield are essential to protect your eyes from paint splashes.

- Proper Ventilation: Work in a well-ventilated area or use a respirator with adequate ventilation. HVLP reduces overspray, but proper ventilation remains crucial.

- Fire Prevention: Paint is flammable. Ensure a fire extinguisher is nearby and avoid working near open flames.

- Clothing Protection: Wear long sleeves and pants to protect your skin from paint and solvents.

- Skin Protection: Wear gloves appropriate for the solvents used.

- Read the Safety Data Sheets (SDS): Familiarize yourself with the safety data sheets for the paints and solvents used, as they contain important safety information.

Remember, safety is not an option; it’s a non-negotiable requirement when working with spray equipment.

Q 8. Explain the importance of proper surface preparation before HVLP spraying.

Proper surface preparation is paramount to achieving a high-quality, long-lasting finish with HVLP spraying. Think of it like building a house – you wouldn’t start constructing walls on a shaky foundation, would you? Similarly, a poorly prepared surface will lead to an uneven, unsightly finish, regardless of how skilled you are with the spray gun.

This preparation involves several crucial steps:

- Cleaning: Removing all dirt, grease, dust, and any previous coatings is essential. Use appropriate solvents or detergents based on the substrate and existing coating. A thorough cleaning ensures the paint adheres properly.

- Sanding: Lightly sanding the surface creates a profile that improves adhesion. The level of sanding depends on the surface and the existing coating – a smooth surface might only need a light scuff, while a rougher surface might require more aggressive sanding. Always use appropriate grit sandpaper and avoid excessive sanding to prevent damaging the substrate.

- Priming (when necessary): A primer is often necessary, especially on porous materials like wood or bare metal. A primer acts as a bonding agent, providing a uniform surface for the topcoat and improving paint adhesion. It also helps to even out the color and hide imperfections.

- Masking: Carefully masking areas you don’t want to be painted is crucial for a neat and professional finish. Use high-quality painter’s tape and masking paper to protect surfaces.

For instance, when painting a wooden door, I’d start by cleaning it with a degreaser, then lightly sanding it with 220-grit sandpaper. After cleaning the sanding dust, I would apply a primer before applying the topcoat with my HVLP system. This ensures optimal adhesion and prevents peeling or chipping.

Q 9. What are the different types of HVLP spray nozzles, and when would you use each one?

HVLP spray nozzles come in various shapes and sizes, each designed for specific applications. The choice of nozzle significantly impacts the spray pattern, atomization, and overall finish.

- Round nozzles: These produce a circular spray pattern ideal for broad areas, providing even coverage. They’re great for large projects like fences or walls.

- Fan nozzles: These create an oval or rectangular pattern, perfect for covering wider areas efficiently with fewer passes. They’re useful for painting furniture or car bodies.

- High-pressure nozzles (though technically not ‘pure’ HVLP): Some HVLP systems incorporate nozzles that operate at slightly higher pressures than the standard HVLP range. These can be useful for applications requiring higher transfer efficiency for thicker materials or when needing to reach slightly more distance. However, these should still prioritize lower pressure to maintain the HVLP principle of reduced overspray.

For example, when painting a car, I would typically use a fan nozzle to efficiently cover the panels. However, for detailed areas like door handles, a smaller round nozzle would be more appropriate to achieve precise control and prevent paint build-up. The selection depends on the project and the desired finish.

Q 10. How do you clean and maintain an HVLP spray gun?

Cleaning and maintaining your HVLP spray gun is crucial for its longevity and performance. Neglecting this can lead to clogged nozzles, uneven finishes, and ultimately, damage to the equipment.

The cleaning process typically involves these steps:

- Immediate Cleaning: As soon as you finish spraying, flush the gun with the appropriate thinner or solvent recommended for your paint. This prevents the paint from drying inside the gun and causing blockages.

- Disassembly: Carefully disassemble the spray gun according to the manufacturer’s instructions. This allows for thorough cleaning of all components.

- Component Cleaning: Clean each component separately, using brushes, rags, and solvents to remove all traces of paint. Pay close attention to the nozzle, air cap, and fluid tip, as these are the most prone to clogging.

- Reassembly: Once all parts are clean and dry, reassemble the gun, ensuring all components are properly seated.

- Testing: Before storing, perform a test spray with thinner to ensure everything is working properly and there are no leaks.

Regular maintenance, such as lubricating moving parts as per the manufacturer’s instructions, also contributes to the extended lifespan of your HVLP spray gun. Think of it like changing the oil in your car; it prevents premature wear and tear and ensures peak performance.

Q 11. Describe the process of setting up an HVLP spray gun for a specific paint.

Setting up an HVLP spray gun for a specific paint requires careful consideration of several factors to ensure optimal results.

The process involves:

- Choosing the Correct Nozzle: Select the nozzle size and type appropriate for the paint’s viscosity and the project’s requirements (as detailed in question 2).

- Adjusting the Fluid Flow: The fluid flow is adjusted using the control knob on the spray gun. This setting determines the amount of paint that’s delivered with each trigger pull. The proper setting ensures consistent paint coverage without runs or sags. It usually takes practice and observation to find the right flow for a given paint.

- Adjusting the Air Pressure: The air pressure is crucial for atomization and transfer efficiency. Too low, and the paint won’t atomize properly; too high, and you’ll get excessive overspray and a rough finish. Most HVLP systems have pressure gauges and adjustments. Start by following the manufacturer’s recommendations for your specific gun and paint, and fine-tune according to your observation of the spray pattern. Experimentation and practice are vital for finding the optimal pressure.

- Paint Viscosity: The paint’s viscosity (thickness) plays a significant role. Too thick, and it won’t atomize properly; too thin, and you’ll get a poor finish. Thinners can be added to adjust the viscosity, but always follow the manufacturer’s recommendations.

- Test Spray: Before starting the main project, perform a test spray on a scrap piece of material to dial in the settings and ensure everything is working correctly.

For example, when spraying a high-viscosity lacquer, I might use a larger nozzle, reduce the air pressure slightly, and adjust the fluid flow accordingly to achieve a smooth and even finish. But for a thinner paint, I’d reduce nozzle size and increase airflow to avoid overspray.

Q 12. What are the environmental considerations related to HVLP spraying?

HVLP spraying, while offering many advantages, does have environmental considerations. The primary concern is overspray – the paint particles that miss the target surface.

These environmental impacts include:

- Air Pollution: Overspray contributes to air pollution, particularly in densely populated areas or enclosed spaces. Volatile Organic Compounds (VOCs) released from paints can have negative health effects and contribute to smog formation.

- Water Pollution: Paint runoff from cleaning or overspray can contaminate water bodies, impacting aquatic life.

- Waste Generation: The use of solvents and cleaning materials generates hazardous waste that needs proper disposal.

To mitigate these issues, it’s essential to practice responsible techniques: use low-VOC paints, minimize overspray using proper techniques and equipment, utilize appropriate respirators and safety measures to protect yourself from inhaling the paint particles, and properly dispose of waste materials in accordance with local regulations.

Q 13. How do you achieve a consistent finish using HVLP spraying?

Achieving a consistent finish with HVLP spraying depends on a combination of factors, all working in harmony.

Key elements include:

- Consistent Technique: Maintain a consistent distance from the surface and a steady, even motion. Avoid jerky movements or stopping abruptly, as this can cause build-up or uneven coverage.

- Proper Spray Gun Setup: Correctly adjusting the air pressure, fluid flow, and nozzle size for the specific paint is crucial, as detailed in question 4.

- Multiple Thin Coats: Applying several thin coats is always better than one thick coat. Thin coats allow the paint to level out and dry properly, minimizing runs, sags, and orange peel effects.

- Wet-on-Wet Technique (often but not always): For many paints, a wet-on-wet technique, where each subsequent coat is applied before the previous one dries completely, can help create a seamless transition and a smoother finish. Note: always check the paint manufacturer’s recommendations.

- Proper Ventilation: Ensuring adequate ventilation, especially when working indoors, helps prevent dust settling on wet paint and improves drying.

Think of it as baking a cake – you need the right ingredients (paint and equipment), the correct temperature (air pressure), and the right technique (even hand movements) to get a perfectly even result.

Q 14. Explain the concept of overspray and how to minimize it.

Overspray refers to the paint particles that don’t land on the intended surface and are dispersed into the air. It’s wasteful, creates environmental issues, and results in an unprofessional-looking finish.

Minimizing overspray involves several strategies:

- Optimal Air Pressure: Using the correct air pressure for the paint and nozzle is essential. Too high, and you’ll generate excessive overspray; too low, and you won’t achieve proper atomization.

- Correct Nozzle Selection: Choosing the appropriate nozzle size and type helps to focus the paint stream and reduce overspray.

- Proper Gun Technique: Maintain a consistent distance and speed while spraying. Avoid jerky movements or sudden stops. Practice smooth and even passes.

- Proper Ventilation: A well-ventilated area allows overspray particles to dissipate more effectively.

- Using a Containment System (if possible): Enclosing the spray area with plastic sheeting or using spray booths can significantly reduce overspray and keep it contained.

- Practice and Technique Refinement: The most significant factor is often skillful technique. Practice on scrap material to refine your technique and master the balance between adequate coverage and minimal overspray.

Imagine a garden hose – a forceful jet of water will spray everywhere, whereas a gentler, controlled stream will go exactly where you want it. The same principle applies to HVLP spraying. Practice makes perfect.

Q 15. What is the proper technique for applying multiple coats of paint using HVLP spraying?

Applying multiple coats with HVLP requires a methodical approach to ensure a smooth, even finish. Think of it like layering a cake – each layer needs to be properly set before the next is added.

First, ensure the previous coat is completely dry. Drying times vary depending on paint type, humidity, and temperature; always check the manufacturer’s instructions. If the previous coat isn’t dry, you’ll risk lifting or disturbing the underlying layers, creating an uneven, textured surface. Once dry, lightly sand with fine-grit sandpaper (e.g., 320-grit) to create a better surface for the next coat to adhere to. This removes any imperfections and improves adhesion. After sanding, wipe away any dust with a tack cloth. Then, apply the next coat using the same consistent technique as before – maintaining a consistent distance from the surface, even spray pattern, and controlled overlap.

For example, when painting a car door, I always start with the top edge and work my way down in smooth, overlapping strokes, ensuring that each pass overlaps the previous one by about 50%. This prevents streaking and ensures even coverage. Remember to always maintain a consistent distance and spray speed throughout the entire process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate viscosity of paint for HVLP spraying?

Paint viscosity is crucial for optimal HVLP spraying. Too thick, and the paint will be lumpy and uneven; too thin, and you’ll get runs and drips. The ideal viscosity allows for a smooth, even flow without clogging the gun. We typically use a Zahn cup to measure the viscosity. The ideal viscosity will depend on the paint type, the spray gun being used, and the application. Always refer to the paint manufacturer’s recommendations. Each paint type has a different ideal viscosity range, but generally, a viscosity within the 20-40 seconds range for a #4 Zahn cup is a good starting point for many applications. If you’re unsure, thin the paint with the appropriate thinner (recommended by the manufacturer) a little at a time and check the viscosity in between thinning. Remember, always test the paint’s viscosity before applying it to the project. This test can be done on a piece of scrap material.

For instance, with latex paints, I might add a small amount of water, testing regularly, until I achieve the ideal flow. For acrylic lacquers, the appropriate thinner would be used. Testing is key; you don’t want to over-thin the paint, as this might affect the durability and coverage of the final finish.

Q 17. What are the signs of a faulty HVLP spray gun?

Identifying a faulty HVLP spray gun requires careful observation and testing. There are several signs to watch out for. For instance, inconsistent spray patterns, including spitting, dry spraying, or uneven coverage, could indicate internal issues such as a clogged nozzle or worn-out air cap.

- Uneven spray pattern: This might signify a clogged nozzle, misaligned air cap, or a problem with the air pressure regulator.

- Spitting or dribbling: This usually points towards a clogged nozzle, dirty fluid passageways, or low air pressure.

- Insufficient atomization: If the paint is not atomizing properly and is leaving large droplets, it could be due to incorrect fluid pressure, excessive viscosity, or a worn-out air cap.

- Leaks: Fluid leaks usually indicate a worn-out seal, a cracked fluid cup, or improperly tightened connections.

- Inconsistent air pressure: If the air pressure fluctuates during spraying, it could indicate a problem with the compressor or air hose.

Troubleshooting involves systematically checking each component, cleaning the gun thoroughly, and replacing worn-out parts as needed. Regular maintenance, including cleaning after each use, helps prevent many of these issues.

Q 18. Describe your experience with different types of paint suitable for HVLP spraying.

My experience encompasses a wide range of paints suitable for HVLP spraying, including acrylic lacquers, water-based latex paints, and solvent-based enamels. Each paint type has its own characteristics and requires a slightly different approach to spraying.

- Acrylic Lacquers: These offer a fast drying time and excellent flow but require a well-ventilated area and proper safety precautions due to their solvent content.

- Water-Based Latex Paints: Environmentally friendly and easy to clean up, latex paints are ideal for many interior projects and offer good adhesion.

- Solvent-Based Enamels: These provide a durable and glossy finish but require more care in handling and disposal. Ventilation is critical.

I’ve found that understanding the specific properties of each paint type – its viscosity, drying time, and application requirements – is key to achieving a professional finish. For instance, I might use acrylic lacquer for a high-gloss car finish while choosing water-based latex for a kitchen cabinet project to minimize fumes and cleanup.

Q 19. How do you handle different types of surfaces (wood, metal, plastic) when using HVLP?

HVLP spraying adapts well to different surfaces; however, surface preparation is key for optimal results regardless of the material.

- Wood: Requires sanding to a smooth finish, filling any imperfections with wood filler, and applying a primer coat to ensure better paint adhesion and prevent the wood grain from showing through.

- Metal: Needs to be cleaned thoroughly to remove any rust, grease, or other contaminants. A rust-inhibiting primer is often recommended to prevent corrosion.

- Plastic: Often requires a dedicated plastic primer to promote adhesion, as many plastics can be slick and prevent paint from sticking properly.

The spray technique may need slight adjustment depending on the surface. For instance, I might use a slightly lighter coat on plastic to avoid runs and ensure good adhesion, while on wood, I may focus on ensuring even coverage to prevent the grain from showing through. Test spraying on a scrap piece of the same material is always a good idea to ensure that the paint and technique will work correctly.

Q 20. What are the benefits of using a spray booth for HVLP spraying?

A spray booth offers significant advantages for HVLP spraying, particularly in professional settings. It creates a controlled environment that minimizes overspray and ensures a cleaner, more professional finish.

- Containment of Overspray: The booth prevents paint from landing on unintended surfaces, saving cleanup time and reducing waste.

- Improved Air Quality: Ventilation systems within the booth extract paint fumes and dust, creating a safer and healthier work environment.

- Consistent Temperature and Humidity: A controlled environment helps ensure consistent paint drying and reduces the risk of imperfections due to environmental fluctuations.

- Better Lighting: Proper lighting within the booth allows for better visibility and facilitates a more even and precise application.

In a professional setting, a spray booth significantly improves efficiency and the quality of the finished product. The cost savings associated with reduced cleanup and less material waste, as well as the increased quality of work, make it an invaluable investment.

Q 21. Explain your experience with different HVLP spraying techniques (e.g., wet-on-wet, dry spraying).

My experience includes both wet-on-wet and dry spraying techniques. The choice depends on the paint type, desired finish, and the project’s complexity.

- Wet-on-Wet: This technique involves applying subsequent coats before the previous one is fully dry. It’s often used with fast-drying paints like lacquers and allows for a smoother, more flowing finish. However, it requires precision and skill to avoid runs and drips. This requires a higher level of skill and precision.

- Dry Spraying: Involves applying a very light coat, allowing each coat to dry completely before applying the next. This method is often preferred for thicker paints or projects that require multiple layers. It’s easier to control and reduces the risk of runs, but may result in a slightly less smooth finish if not enough coats are applied.

I’ve found that wet-on-wet is excellent for achieving a flawless finish with lacquers, while dry spraying is preferable for achieving high build with enamels or when working with more challenging surfaces or colors. The choice is guided by project-specific requirements and the properties of the paint used. I always test the technique on a scrap piece to perfect my application before starting the main project.

Q 22. Describe your troubleshooting experience with HVLP spray equipment malfunctions.

Troubleshooting HVLP spray equipment malfunctions requires a systematic approach. I begin by identifying the symptom – is the spray pattern uneven, is there insufficient atomization, is there clogging, or is the gun simply not spraying at all?

For instance, an uneven spray pattern often points to a clogged air cap or nozzle. I’d carefully disassemble the gun, cleaning each component thoroughly with the appropriate solvent. If the problem persists, I’d check the air filter for blockages, ensuring a consistent air pressure supply. Insufficient atomization could indicate low air pressure or a faulty air regulator. In this case, I’d check the air compressor’s pressure gauge and verify the regulator’s functionality. A gun not spraying at all might point to a complete clog, a problem with the fluid line, or a faulty trigger mechanism –requiring careful inspection and potential parts replacement.

I always keep a log of my troubleshooting steps and solutions to help me quickly diagnose similar problems in the future. This detailed record-keeping not only streamlines my work but also improves my understanding of common equipment malfunctions.

Q 23. How do you ensure proper ventilation when using HVLP spray equipment?

Proper ventilation is paramount when using HVLP spray equipment because the process produces overspray – fine paint particles that can be inhaled and are harmful to health. This is particularly crucial when working with solvents or paints containing volatile organic compounds (VOCs).

My approach focuses on a multi-layered strategy: first, I ensure the work area is well-ventilated, ideally with a dedicated ventilation system extracting air directly from the spray zone. In smaller spaces, I employ powerful exhaust fans strategically placed to create airflow. Secondly, I wear a respirator designed to filter out paint particles and VOCs. Thirdly, I prioritize working outdoors whenever feasible, leveraging natural airflow. And finally, I always follow the safety guidelines provided by the paint manufacturer and the equipment supplier.

Think of it like this: you wouldn’t cook a large meal indoors without a well-functioning exhaust hood. HVLP spraying is similar – adequate ventilation is essential for both health and safety.

Q 24. What are some common mistakes to avoid when using HVLP spray equipment?

Several common mistakes can significantly impact the quality of the HVLP spray finish and the overall efficiency. One frequent error is using improper air pressure. Too high a pressure leads to overspray and waste, while too low a pressure results in a poor finish with runs and sags. Another common mistake is holding the gun too close or too far from the surface, affecting both the evenness and thickness of the coat.

Also, incorrect fluid viscosity can create problems. Paint that’s too thick will clog the nozzle, while paint that’s too thin will produce a thin, uneven coat. Failing to properly prepare the surface – cleaning and sanding before application – is another critical oversight. It leads to poor adhesion and an overall unsatisfactory finish.

Finally, neglecting regular maintenance of the spray equipment – like cleaning the gun and air cap after each use – can lead to premature wear and tear and equipment malfunctions.

Q 25. Describe your experience with different HVLP spray gun manufacturers and models.

My experience encompasses a range of HVLP spray gun manufacturers and models, including Graco, Devilbiss, and Fuji. Each manufacturer offers unique features and strengths. For example, Graco is known for its durability and reliability in high-volume applications, while Devilbiss offers a wider variety of models catering to diverse needs. Fuji spray guns are often favored for their precise control and superior atomization.

I’ve worked extensively with various models from each brand, gaining experience with different nozzle sizes, fluid tips, and air caps. The choice of the appropriate gun often depends on the project’s scope – the size and type of surface being sprayed, the paint viscosity, and the desired finish quality. My experience allows me to recommend and utilize the best-suited model for any specific task, ensuring optimal results.

Q 26. How do you manage material waste during HVLP spraying?

Managing material waste is crucial for both environmental responsibility and cost-effectiveness. My approach involves several key steps. Firstly, I meticulously prepare the surface, ensuring the area to be sprayed is well-defined. This minimizes overspray and wasted material.

Secondly, I use the correct air pressure and gun distance for the specific paint and project. Optimizing these factors reduces overspray significantly. Thirdly, I use drop cloths or masking paper to protect areas not intended for painting. Fourthly, I collect any overspray or unused material properly, according to local regulations. I also maintain a close watch on the material usage throughout the process to identify and rectify any issues causing excessive waste promptly. Think of it like precision baking; accurate measurements and techniques are essential to minimize waste and optimize results.

Q 27. What is your understanding of different HVLP spray gun patterns (e.g., fan, round)?

HVLP spray guns utilize various spray patterns to achieve different application effects. The most common patterns are fan and round.

A fan pattern is ideal for large, flat surfaces. It produces a wide, even spray, ensuring efficient coverage. The width of the fan can typically be adjusted by turning a control on the spray gun, allowing for greater flexibility in application. Think of painting a wall – a fan pattern is perfect for creating a smooth, even coat quickly.

A round pattern is more suitable for detail work, such as painting trim, edges, or intricate designs. It offers precise control, enabling the user to apply paint accurately to small and hard-to-reach areas. Imagine painting the intricate details of furniture; a round pattern provides the necessary precision.

Understanding the nuances of each pattern is critical for creating a high-quality and professional finish.

Q 28. Describe your experience working with different paint finishes (e.g., gloss, matte, satin).

My experience encompasses a wide variety of paint finishes, including gloss, matte, and satin. Each finish requires a slightly different approach to achieve optimal results with HVLP spraying.

Gloss paints, with their high-shine appearance, demand meticulous application to avoid any imperfections, which are more visible due to the reflective nature of the finish. It usually requires multiple thin coats for a smooth, even surface.

Matte paints, known for their low sheen and ability to hide imperfections, offer more leeway in application. Even if there are minor inconsistencies, they’re usually less noticeable. However, the consistency of the application is still critical to prevent streaks or patches.

Satin paints fall between gloss and matte, exhibiting a subtle sheen. They provide a balance between durability and a softer look, requiring an even application as with other finishes to achieve a consistent sheen. The viscosity of the paint, air pressure, and spray distance will need careful adjustments for each finish to ensure the desired aesthetic outcome.

Key Topics to Learn for High-Volume Low-Pressure (HVLP) Spraying Interview

- Understanding HVLP Technology: Explore the fundamental principles of High-Volume Low-Pressure spraying, including air pressure, fluid flow, and atomization. Understand the advantages of HVLP over other spraying methods.

- Equipment Operation and Maintenance: Learn about different types of HVLP spray guns, compressors, and related equipment. Master the proper setup, cleaning, and maintenance procedures to ensure optimal performance and longevity.

- Material Selection and Application: Gain expertise in selecting appropriate paints, stains, and other coatings for different surfaces and applications. Understand the impact of material viscosity and spray techniques on the final finish.

- Spray Techniques and Patterns: Practice various spray techniques to achieve even coatings and avoid runs, drips, and overspray. Master controlling spray patterns to suit different projects and surface areas.

- Safety Procedures and Regulations: Familiarize yourself with relevant safety regulations and practices related to HVLP spraying, including personal protective equipment (PPE) and environmental considerations.

- Troubleshooting and Problem Solving: Develop the ability to identify and resolve common issues encountered during HVLP spraying, such as poor atomization, uneven coating, and equipment malfunctions.

- Practical Applications and Case Studies: Research diverse applications of HVLP spraying across various industries, such as automotive, furniture finishing, and industrial coating. Consider real-world scenarios and how you’d approach them.

Next Steps

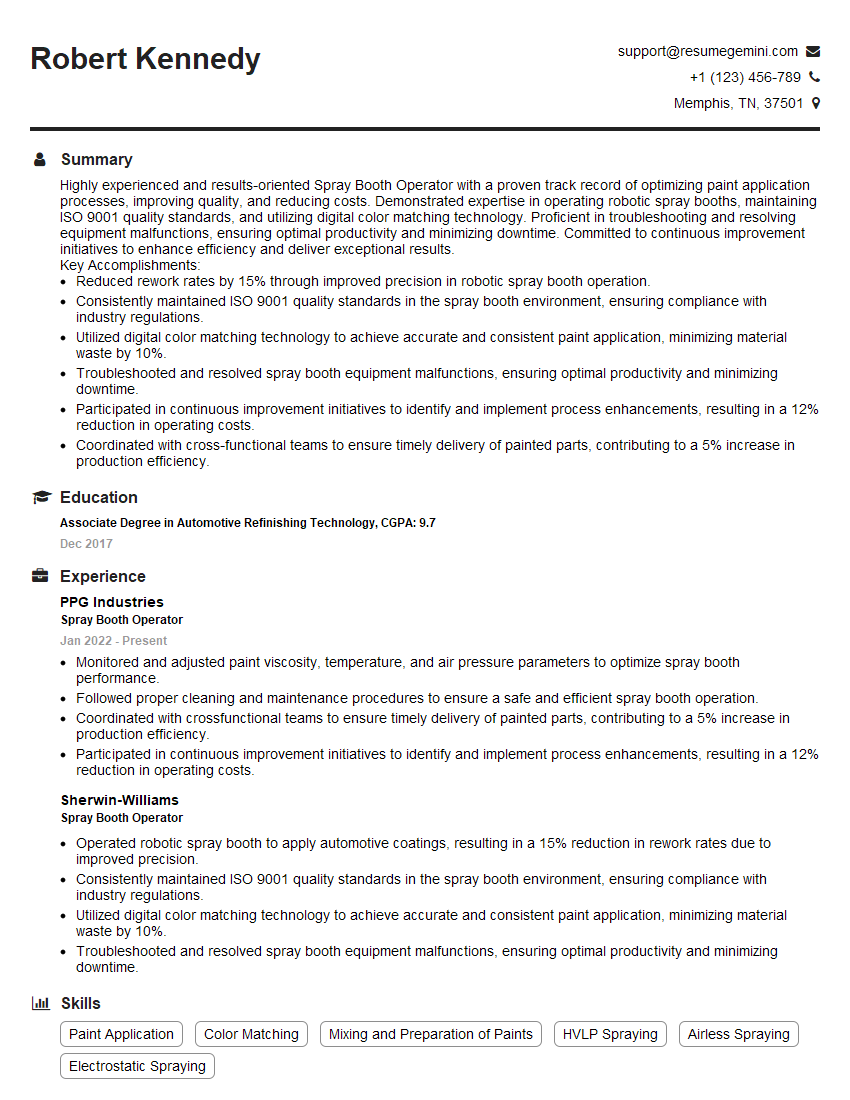

Mastering High-Volume Low-Pressure (HVLP) spraying opens doors to exciting career opportunities in a variety of sectors. A strong understanding of this technology showcases your practical skills and commitment to excellence, making you a highly competitive candidate. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to High-Volume Low-Pressure (HVLP) Spraying are available to guide you through the process. Invest time in creating a resume that reflects your expertise and you’ll significantly increase your chances of securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good