Unlock your full potential by mastering the most common Dye Penetrant Testing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Dye Penetrant Testing Interview

Q 1. Explain the principles of dye penetrant testing.

Dye penetrant testing (DPT) is a widely used non-destructive testing (NDT) method that relies on the principle of capillary action to detect surface-breaking flaws in various materials. Imagine a sponge absorbing water – a liquid penetrant is drawn into surface-breaking cracks and defects. Then, a developer is applied which draws the penetrant out of the flaw and makes it visible, allowing inspectors to identify the location and approximate size of the defect.

Essentially, DPT works by applying a low-viscosity liquid that readily flows into surface cracks. Once the penetrant has had sufficient time to dwell, excess penetrant is removed and a developer is applied to pull the penetrant out of the cracks and make the indications visible. These indications (the visible penetrant) will reveal the location and size of the surface breaking cracks or defects.

Q 2. Describe the different types of dye penetrant methods (e.g., visible, fluorescent).

There are two main types of dye penetrant methods: visible and fluorescent.

- Visible dye penetrants: These use a brightly colored dye (often red) that contrasts sharply with the part being inspected, making it easily visible to the naked eye after the developer is applied. Think of it like spilling red juice on a white tablecloth – the stain is highly visible.

- Fluorescent dye penetrants: These use a dye that glows brightly under ultraviolet (UV) light. This method offers increased sensitivity, especially for very fine cracks, as the fluorescence makes the indications stand out even more dramatically than the visible dye method. Imagine using a blacklight to reveal hidden writing – the fluorescent penetrant functions similarly.

Within each category, there are further sub-classifications based on the penetrant’s sensitivity and the method of cleaning (e.g., water washable, post-emulsifiable). The choice of method depends on the material being tested, the type of flaw expected, and the level of sensitivity required.

Q 3. What are the limitations of dye penetrant testing?

Dye penetrant testing has several limitations:

- Only detects surface-breaking flaws: DPT cannot detect subsurface defects or flaws that don’t reach the surface of the part. Think of a crack hidden beneath another layer of material; DPT won’t see it.

- Surface finish limitations: Porous materials, excessively rough surfaces, or parts with deep recesses can interfere with the testing process. The penetrant might not be able to properly penetrate the flaws or be effectively removed.

- Part cleanliness crucial: Contamination on the surface (oils, grease, coatings) will mask defects and produce false negatives. Thorough pre-cleaning is essential.

- Environmental conditions: Temperature and humidity can affect the results. Extremely cold or hot temperatures, for example, can slow or accelerate the process.

- Subjective interpretation: The interpretation of indications can be somewhat subjective, requiring experienced inspectors to accurately identify and classify defects.

It’s essential to understand these limitations to avoid misinterpretations and ensure appropriate application of the technique.

Q 4. What are the five steps involved in dye penetrant testing?

The five steps of dye penetrant testing are:

- Pre-cleaning: Removing all oils, grease, dirt, and other contaminants from the surface to be tested. This is crucial for accurate results.

- Penetrant application: Applying the penetrant evenly over the surface, allowing it to dwell for a specified time to enter any surface-breaking flaws.

- Excess penetrant removal: Removing excess penetrant from the surface without disturbing the penetrant already inside the flaws. Methods include wiping, rinsing, or emulsifying.

- Developer application: Applying the developer to draw the penetrant from the flaws to the surface, making the indications visible.

- Inspection: Examining the surface for indications (blemishes or areas of penetrant concentration) that reveal the presence, location, and size of flaws.

Following these steps precisely is vital for accurate and reliable test results.

Q 5. Explain the importance of pre-cleaning in dye penetrant testing.

Pre-cleaning is the most critical step in dye penetrant testing. Any residual oil, grease, paint, or other contaminant on the part’s surface will block the penetrant from entering cracks and flaws. This can lead to false negatives, where defects are missed, and compromise the integrity of the testing process. Imagine trying to find a leak in a pipe that’s covered in mud – you wouldn’t be able to see the leak. Similarly, contaminants on a part’s surface will obscure cracks and other surface defects.

Thorough pre-cleaning ensures the penetrant can effectively penetrate any surface-breaking flaws, providing accurate and reliable results. Different cleaning methods are used depending on the type of contamination and the material of the part. These include solvent cleaning, aqueous cleaning, and abrasive cleaning.

Q 6. Describe different types of penetrants and their applications.

Penetrants are classified based on their properties and method of removal:

- Water-washable penetrants: These are easily removed with water, making them convenient and environmentally friendly. They are suitable for many applications but may offer slightly lower sensitivity than other types.

- Post-emulsifiable penetrants: These require an emulsifier to help remove the excess penetrant. The emulsifier breaks down the penetrant, making it easier to remove with water. This offers a balance between ease of use and high sensitivity.

- Solvent-removable penetrants: These are removed using a solvent. This method offers very high sensitivity, particularly useful for detecting very fine cracks, but requires careful handling due to the use of solvents.

- Lipophilic penetrants: These penetrants have a strong affinity for oils and greases and are particularly useful when testing parts with oily or greasy surfaces. These often require a stronger solvent cleaner.

The selection of the appropriate penetrant depends on several factors, including the material being tested, the type of flaw being sought, and environmental considerations. For instance, water-washable penetrants are preferred when environmental concerns are high, while solvent-removable penetrants might be chosen for their superior sensitivity when inspecting critical components.

Q 7. What are the different types of developers and their properties?

Developers are used to draw the penetrant out of the flaws, making them visible to the inspector. They come in various forms:

- Dry developers: These are powders applied by dusting or spraying. They are simple to use but may offer lower sensitivity than other types.

- Wet developers: These are liquid developers that are sprayed or dipped onto the part. They offer better sensitivity than dry developers and provide more uniform coverage.

- Water-washable developers: These are easily cleaned with water, making them environmentally friendly and convenient.

The choice of developer depends on the type of penetrant used, the sensitivity required, and practical considerations like ease of cleanup. For example, a wet developer might be chosen for its increased sensitivity, while a dry developer might be used in situations where speed and simplicity are prioritized. Properties of developers include their ability to draw penetrant to the surface effectively, their drying time, and their compatibility with the penetrant used.

Q 8. How do you select the appropriate penetrant, developer, and cleaning agent for a specific application?

Selecting the right penetrant, developer, and cleaner for dye penetrant testing (DPT) is crucial for accurate results. It depends heavily on the material being tested, the type of discontinuity expected, and the environmental conditions. Think of it like choosing the right tools for a specific job – a hammer won’t work for every task.

- Penetrant Selection: Consider the material’s porosity and surface finish. A low-viscosity penetrant is ideal for fine cracks in smooth surfaces, while a high-viscosity penetrant is better for porous materials or larger discontinuities. The penetrant type (visible, fluorescent, water-washable, etc.) depends on the sensitivity required and the available inspection equipment. For instance, fluorescent penetrants offer higher sensitivity in low-light conditions.

- Developer Selection: The developer’s role is to draw the penetrant out of the discontinuities, making them visible. The choice depends on the penetrant type and the surface being tested. A wet developer works quickly but might blur fine indications, while a dry developer offers better resolution but takes longer. For example, a dry developer might be preferred for inspecting intricate parts with fine cracks.

- Cleaning Agent Selection: The cleaner removes excess penetrant from the surface before applying the developer. It must effectively remove the penetrant without damaging the part or leaving residue that could interfere with the test. The choice depends on the penetrant type and the material. A solvent cleaner is often used for oil-based penetrants, while water-based cleaners are suitable for water-washable penetrants. It’s crucial to avoid cleaners that might attack the surface of the part.

In summary, a thorough understanding of the materials, the type of defects expected, and the testing environment is essential to select appropriate materials.

Q 9. Explain the process of interpreting dye penetrant test results.

Interpreting dye penetrant test results requires careful observation and attention to detail. Imagine you’re searching for hidden clues – every detail matters.

- Visual Inspection: After the developer has dried, carefully examine the part’s surface under appropriate lighting conditions (ambient lighting for visible penetrants and UV-A light for fluorescent penetrants). Look for indications such as bleeds, cracks, seams, or other discontinuities.

- Indication Identification: Distinguish between relevant indications (surface-breaking discontinuities) and non-relevant indications (false indications). False indications might result from surface contamination, improper cleaning, or damage during handling.

- Indication Evaluation: Assess the size, shape, location, and extent of the indications. This helps determine the severity and nature of the defect. A small, isolated indication might be less critical than a long, continuous indication.

- Documentation: Record the findings meticulously, including photographs, sketches, and written descriptions of the indications. This allows for tracking and comparison over time.

It is often beneficial to compare results with established acceptance criteria outlined in relevant codes and standards. Experience plays a crucial role in accurate interpretation.

Q 10. What are the indications of surface discontinuities in dye penetrant testing?

Surface discontinuities show up in dye penetrant testing as indications, which are essentially visual signs of the defect. These indications vary in shape and appearance depending on the nature of the discontinuity.

- Cracks: Appear as fine, linear indications often exhibiting a sharp, well-defined outline.

- Porosity: Shows up as numerous small, interconnected indications across the surface.

- Seams: May manifest as long, continuous indications reflecting the seam’s geometry.

- Inclusions: Can be seen as localized, irregular indications, often with a slightly diffused outline.

- Lack of Fusion: This shows as a line of indications reflecting an incomplete weld or bond.

The size and shape of the indication are crucial in determining the severity of the defect. It’s important to differentiate between a small, insignificant surface irregularity and a large, potentially critical crack.

Q 11. How do you document and report the findings of a dye penetrant test?

Proper documentation and reporting are critical in dye penetrant testing, ensuring that the test results are clear, unambiguous, and readily understood by others. Consider it the essential record of the investigation.

- Test Part Identification: Clearly identify the part being tested, including its part number, material, and other relevant details.

- Test Method: Specify the type of penetrant, developer, cleaner used, and the test procedure followed.

- Test Results: Detailed descriptions of any indications found, including their location, size, shape, and orientation. Photographs and sketches are beneficial for better understanding.

- Interpretation: State the significance of the observed indications in terms of their acceptability or non-acceptability based on applicable codes, standards or company specifications.

- Inspector’s Signature and Date: The report must be signed and dated by the qualified inspector who performed the test, confirming their responsibility.

The report should be formatted clearly and concisely, with all information organized logically to enhance readability and understanding. Often, standardized forms or templates facilitate consistency and completeness.

Q 12. What are the safety precautions you must take during dye penetrant testing?

Safety is paramount during dye penetrant testing. Penetrants, developers, and cleaners can be hazardous if mishandled. Proper safety protocols are essential to prevent injuries and health issues.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety glasses, and respirators as required by the Material Safety Data Sheets (MSDS) of the specific chemicals used.

- Ventilation: Work in a well-ventilated area to minimize exposure to fumes and vapors. If local exhaust ventilation isn’t sufficient, use respirators appropriate for the specific chemicals.

- Skin Protection: Avoid skin contact with penetrants, developers, and cleaners. Immediately wash any skin contact with soap and water.

- Waste Disposal: Dispose of used penetrants, developers, and cleaners according to local environmental regulations and the relevant MSDS.

- Fire Safety: Many penetrant materials are flammable; ensure no ignition sources are present during the testing process.

Regular safety training and adherence to established safety procedures are vital to mitigate potential hazards.

Q 13. Explain the difference between visible dye penetrant and fluorescent dye penetrant.

The main difference between visible dye penetrant and fluorescent dye penetrant lies in how the indications are made visible. It’s like the difference between a brightly colored marker and a highlighter.

- Visible Dye Penetrant: Uses a brightly colored dye that is visible under normal white light. These penetrants are less sensitive than fluorescent penetrants and are suitable for detecting larger discontinuities.

- Fluorescent Dye Penetrant: Employs a dye that glows brightly under UV-A light. This significantly enhances the sensitivity of the test, allowing for the detection of smaller and finer discontinuities. They’re particularly valuable for detecting tiny cracks that might be missed with visible dye penetrants.

The choice between visible and fluorescent penetrants depends on the required sensitivity and the size of the defects expected. Fluorescent penetrants are generally preferred when high sensitivity is needed for detecting very fine cracks.

Q 14. How do you ensure proper cleaning to avoid false indications?

Proper cleaning is absolutely essential to avoid false indications in dye penetrant testing. Incomplete cleaning can lead to misleading results, potentially resulting in costly errors. Think of it as cleaning a crime scene; you don’t want to contaminate the evidence.

- Appropriate Cleaning Agent: Choose a cleaner compatible with both the penetrant and the test part material. Ensure that the cleaner effectively removes all excess penetrant without damaging the part’s surface or leaving residue.

- Thorough Cleaning: Use the recommended cleaning method (e.g., wiping, spraying, immersion) to completely remove excess penetrant from the part’s surface. Pay close attention to crevices and hard-to-reach areas.

- Multiple Cleaning Stages: In many cases, multiple cleaning stages might be necessary to ensure complete penetrant removal. This might include several wiping stages with clean solvents.

- Inspection After Cleaning: Before applying the developer, visually inspect the cleaned surface to check for any remaining penetrant. If any residue remains, repeat the cleaning process.

Careful and thorough cleaning is crucial for ensuring accurate and reliable test results.

Q 15. What are the common causes of false indications in dye penetrant testing?

False indications in dye penetrant testing, meaning indications that appear to be flaws but aren’t, are a common challenge. These can stem from several sources, broadly categorized as procedural errors, material properties, and environmental factors.

- Improper cleaning: Residual cleaning agents or contaminants can mask cracks or create false indications that mimic flaws. Imagine trying to find a small scratch on a muddy car – the mud itself could hide or mimic other imperfections.

- Excess penetrant: Too much penetrant can create surface bleed, obscuring actual discontinuities. Think of painting a wall – too much paint will run and create uneven areas, masking the actual wall surface.

- Incomplete removal of penetrant: If the penetrant isn’t thoroughly removed, it can be mistaken for a crack. This is like not completely wiping away spilled ink – it might look like a mark rather than a stain.

- Improper development: Insufficient or excessive developer application can affect the indication visibility, leading to either missed cracks or false indications. Think of developing a photo – you need the right amount of developer for a clear picture.

- Surface irregularities: Rough surfaces, scratches, or machining marks can trap penetrant, mimicking flaws. A textured surface might retain dye even where there’s no crack.

- Water marks or contamination: These can create false indications. Imagine a water droplet resembling a tiny crack.

Careful adherence to the chosen testing method and meticulous attention to each step are crucial to minimize false indications. Regular calibration and maintenance of equipment also plays a vital role.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle and store dye penetrant materials?

Proper handling and storage of dye penetrant materials are critical to ensure the test’s reliability and the safety of personnel. The manufacturer’s instructions should always be followed diligently.

- Storage conditions: Penetrants and developers should be stored in a cool, dry place, protected from direct sunlight and extreme temperatures. Exposure to heat or freezing can alter their properties, impacting the test results.

- Container integrity: Ensure containers are tightly sealed to prevent evaporation and contamination. Leaking containers not only waste material but can also create safety hazards.

- Shelf life: Check the expiration dates of all materials. Expired penetrants and developers might not perform as intended, leading to inaccurate results or false indications.

- Compatibility: Never mix different brands or types of penetrants, developers, or cleaners without confirming their compatibility with the manufacturer. Mixing incompatible chemicals can lead to unexpected reactions and potentially hazardous conditions.

- Cleanliness: Maintain cleanliness around the storage area. Contamination can negatively affect the test outcome. For example, dust settling on a penetrant can cause false indications.

Regularly inspect materials for signs of degradation, such as discoloration or unusual viscosity. Proper storage practices extend the usable life of these materials and help guarantee accurate test results.

Q 17. Explain the importance of proper technique to avoid false results.

Proper technique in dye penetrant testing is paramount. A single misstep can lead to false indications or missed flaws, compromising the integrity of the inspection and potentially causing safety hazards.

- Thorough cleaning: The surface must be meticulously cleaned to remove any dirt, oil, or grease that might mask flaws. If a surface isn’t completely clean, the penetrant might not reach the cracks.

- Controlled penetrant application: The penetrant should be applied evenly to ensure full surface coverage. Uneven application can lead to incomplete penetrant entry and false negatives.

- Proper dwell time: Adhering to the manufacturer’s recommended dwell time is crucial. Insufficient dwell time may prevent penetrant from reaching all discontinuities, while excessive dwell time can cause bleed-out.

- Effective removal of excess penetrant: Thorough removal of excess penetrant is key. Residual penetrant can create false indications. This step requires precision and attention to detail.

- Careful developer application: The developer should be applied consistently and evenly to draw the penetrant out of surface-breaking flaws. Improper developer application can mask or create false indications.

- Inspection under proper lighting: Inspection should be done under appropriate lighting conditions. Poor lighting can hinder detection of subtle indications.

Consistently following standardized procedures and using proper equipment is essential. Training and certification help to standardize these procedures, reducing the likelihood of errors and improving the reliability of the test.

Q 18. Describe the various levels of certification in dye penetrant testing (e.g., Level I, II, III).

Dye penetrant testing certification levels typically follow a hierarchical structure, such as Level I, II, and III. These levels represent increasing responsibility and expertise.

- Level I: This level involves performing dye penetrant testing under direct supervision of a Level II or III technician. Individuals at this level are trained to follow specific procedures and recognize indications, but they don’t typically interpret the results or make critical decisions.

- Level II: Level II technicians perform dye penetrant testing independently and interpret the results. They are responsible for planning the inspection, selecting appropriate materials and techniques, and evaluating the indications. They usually don’t develop or approve procedures.

- Level III: Level III technicians are the most experienced and possess the highest level of expertise. They are responsible for developing and approving test procedures, interpreting complex results, and training Level I and II personnel. They also handle complex troubleshooting and resolving discrepancies.

The specific requirements and responsibilities for each level may vary depending on the certifying organization and the industry. However, the core principle remains consistent: higher levels represent increased proficiency and responsibility.

Q 19. What are the relevant industry standards and codes for dye penetrant testing?

Several industry standards and codes govern dye penetrant testing, ensuring consistency and quality across various applications and sectors. Adherence to these standards is crucial for producing reliable results.

- ASTM E1417: This standard covers the practice for liquid penetrant testing. It’s widely used and provides comprehensive guidelines on all aspects of the testing method.

- ISO 3452-1: This international standard specifies the requirements for liquid penetrant testing.

- ASME Section V, Article 6: This code covers the use of liquid penetrant testing in the context of boiler and pressure vessel inspections.

- Military standards (MIL-STD): Various military standards provide specifications for dye penetrant testing in military applications. Specific standards may apply depending on the application.

These standards specify requirements for materials, procedures, equipment, personnel qualifications, and interpretation of results, ensuring consistency and reliability of the testing process. Following these standards is critical for maintaining the integrity of the inspection and avoiding legal issues.

Q 20. How do you calibrate and maintain dye penetrant testing equipment?

Calibrating and maintaining dye penetrant testing equipment is essential to ensure accurate and reliable results. Neglecting this can compromise the test’s integrity and potentially lead to costly errors.

- Ultraviolet (UV) lamps: UV lamps used in fluorescent penetrant testing need regular calibration to ensure they emit the required intensity and wavelength. This is typically done using a calibrated radiometer.

- Penetrant and developer dispensing equipment: These devices should be inspected and cleaned regularly to prevent cross-contamination and ensure accurate dispensing. Any malfunction should be promptly addressed.

- Cleaning equipment: Cleaning equipment, such as ultrasonic cleaners and pressure washers, should be maintained according to the manufacturer’s instructions to ensure their effectiveness.

- Temperature and humidity control: The environment in which the test is performed must be properly controlled, particularly temperature and humidity, as these factors can significantly influence the test results. Regular monitoring and logging are crucial.

Maintaining detailed records of calibration and maintenance activities is crucial for traceability and compliance with industry standards. These records also offer invaluable insights into equipment performance over time.

Q 21. What are the environmental factors that affect dye penetrant testing?

Environmental factors can significantly influence the outcome of dye penetrant testing. These factors need to be carefully controlled and considered to ensure reliable results.

- Temperature: Extreme temperatures can affect the viscosity of penetrants and developers, influencing their penetration and bleed-out characteristics. Ideally, the testing environment should be controlled to maintain a consistent temperature within the manufacturer’s recommended range.

- Humidity: High humidity can affect the drying process, potentially causing problems with penetrant removal or developer application. Lower humidity can also lead to quicker evaporation of penetrants.

- Air currents: Drafts and air currents can interfere with the drying and development processes, leading to inconsistencies in the results. A still environment is preferred.

- Contamination: Dust, dirt, or other airborne contaminants can compromise the cleanliness of the test surface, leading to false indications. A clean environment is therefore critical.

- Sunlight: Direct sunlight can interfere with the inspection process, especially when using fluorescent penetrants. The inspection should be conducted in a shaded area or under controlled lighting conditions.

It’s crucial to control and monitor environmental conditions during the test to ensure accurate and consistent results. These environmental factors are often overlooked but can significantly affect the test’s reliability.

Q 22. Explain how to interpret different types of discontinuities shown in a dye penetrant inspection.

Interpreting discontinuities in dye penetrant inspection involves understanding the indication’s shape, size, and location. Think of it like a detective examining a crime scene; the clues (indications) tell a story about the defect.

- Surface Cracks: These appear as sharp, distinct lines or branching patterns. The length and sharpness depend on the crack’s severity. Think of a spiderweb crack on a windshield – that’s a clear indication of a surface crack.

- Porosity: Shows up as numerous small, often clustered indications. Imagine a sponge – the many tiny holes are analogous to porosity in a material.

- Seams/Inclusions: These are often linear or irregular and may appear as a string of indications. They represent flaws embedded within the material. Visualize a sewing seam – that’s a simplified illustration.

- Lack of Fusion: Shows as a lack of penetration along a weld line. The dye won’t penetrate where the weld didn’t fuse properly, leaving a gap in the indication.

- Shrinkage Cracks: These tend to be irregular and can be found near weld joints or castings, reflecting the material shrinking during cooling.

The size and shape of the indication help determine the severity of the defect. Always refer to the relevant acceptance standards for your specific application to judge whether the discontinuity is acceptable or requires repair.

Q 23. Describe the process for performing a dye penetrant test on a specific material (e.g., aluminum, steel).

Performing a dye penetrant test, regardless of the material (aluminum or steel), involves a series of steps. Let’s imagine we’re inspecting an aluminum aircraft component:

- Pre-cleaning: Thoroughly clean the surface to remove any dirt, oil, or other contaminants that could block penetration. This is crucial for accurate results. We’d typically use a solvent cleaner followed by a thorough rinse and dry.

- Penetrant Application: Apply the dye penetrant evenly to the surface, ensuring complete coverage. Allow the penetrant to dwell for the recommended time (specified by the penetrant manufacturer) to allow it to seep into any surface-breaking discontinuities.

- Excess Penetrant Removal: Remove excess penetrant using the appropriate method – either water wash (for water-washable penetrants) or an emulsifier followed by a thorough water wash (for post-emulsifiable penetrants). This step is vital; otherwise, you’ll have excessive background dye, making it hard to see indications.

- Developer Application: Apply the developer evenly to the surface. The developer draws the trapped penetrant out of the discontinuities, making them visible. Common developers include wet developers, dry developers, and aerosol developers.

- Inspection: Carefully examine the surface for indications of penetrant bleed-out. Proper lighting is essential during inspection.

- Cleaning: Finally, clean the part thoroughly to remove all traces of penetrant and developer.

The specific dwell times, penetrant type, and cleaning methods will depend on the material’s characteristics, the type of discontinuity expected, and the applicable standards. Always consult the relevant material specifications and the dye penetrant manufacturer’s instructions.

Q 24. How would you troubleshoot a problem with incomplete dye penetration?

Incomplete dye penetration is a common problem, often resulting from inadequate cleaning or improper application. Troubleshooting this involves a systematic approach:

- Verify Cleaning: Ensure the surface was properly cleaned before penetrant application. Insufficient cleaning will prevent penetrant from entering the discontinuities. Recheck the cleaning process, focusing on the removal of all oils, grease, and other contaminants.

- Check Penetrant Dwell Time: Confirm that the penetrant was allowed to dwell for the manufacturer’s recommended time. Insufficient dwell time prevents the penetrant from reaching the depths of the flaws.

- Examine Penetrant Application: Ensure the penetrant was applied evenly. Uneven application can leave some areas untreated. Review the penetrant application technique, ensuring complete and even coverage across the surface.

- Inspect for Surface Porosity or Coatings: Very porous materials or coatings can block penetrant entry. Consider using a different penetrant or pre-treatment to facilitate penetration.

- Check for Penetrant Compatibility: Ensure the penetrant is compatible with the material being tested. The wrong penetrant may not properly penetrate certain materials.

By systematically checking each step, you can pinpoint the cause of incomplete penetration and adjust your procedure for better results.

Q 25. How would you troubleshoot a problem with excessive background dye?

Excessive background dye indicates a problem with the excess penetrant removal step. Here’s how to address it:

- Review Emulsifier Application (if applicable): If using a post-emulsifiable penetrant, ensure the emulsifier was properly applied and allowed to dwell for the recommended time. Insufficient emulsification will leave excess penetrant on the surface.

- Check Water Wash Thoroughness: Verify that the part was thoroughly rinsed after emulsification or with a water-washable penetrant. Insufficient rinsing leaves residual dye, leading to high background.

- Examine Rinse Techniques: Employ appropriate rinsing techniques to prevent smearing. High-pressure water jets can help remove excess dye without causing smearing. Ensure that there’s sufficient water flow and pressure for effective rinsing.

- Consider Water Quality: Inconsistent water quality can negatively impact rinsing. If using tap water, ensure it is soft and relatively free of mineral deposits that could interfere with the rinsing process. Consider using deionized water for improved rinsing results.

- Check for Penetrant Degradation: Penetrant could be degraded, leading to difficulties in removal. Verify the penetrant’s expiration date and storage conditions. Degraded penetrant will likely be harder to remove and thus, increase background dye.

Addressing these points helps minimize background dye and improve the clarity of the indications.

Q 26. How do you determine the sensitivity of a dye penetrant test?

Dye penetrant test sensitivity refers to its ability to detect small discontinuities. Determining this involves several factors:

- Penetrant Type: Different penetrants have varying sensitivities; some are designed for detecting fine cracks, while others are better suited for larger defects. Consult the penetrant’s specifications for its sensitivity level.

- Testing Standards: Adherence to relevant standards (e.g., ASTM E1417, ISO 3452) provides a framework for evaluating sensitivity. These standards often incorporate test blocks with known discontinuities of various sizes to assess the detection capabilities of a given penetrant and procedure.

- Visual Acuity of Inspector: The inspector’s ability to discern small indications significantly influences sensitivity. Regular eye exams and proper lighting are essential.

- Environmental Conditions: Ambient conditions can impact the test. A clean, well-lit environment is crucial for optimum sensitivity.

- Calibration and Validation: Periodic calibration and validation of testing procedures and equipment are necessary to maintain consistent sensitivity over time. This involves using test blocks with known discontinuities to ensure the testing process remains reliable and sensitive.

Ultimately, the sensitivity is a complex measure encompassing these aspects and is implicitly assessed through adherence to standards and successful detection of known flaws in calibration tests.

Q 27. Describe the difference between water washable and post-emulsifiable penetrants.

The key difference between water-washable and post-emulsifiable penetrants lies in how excess penetrant is removed:

- Water-Washable Penetrants: These are directly removed with water. Think of it as simply rinsing off the excess dye. They are convenient and faster but generally less sensitive than post-emulsifiable penetrants.

- Post-Emulsifiable Penetrants: These require an emulsifier to help remove the excess penetrant. The emulsifier breaks down the penetrant, making it water-washable. This process is like using soap to dissolve grease; the emulsifier helps the penetrant mix with water for easier removal. They typically offer better sensitivity because they can penetrate into tighter discontinuities.

The choice depends on the application. Water-washable penetrants are suitable for many applications where speed and simplicity are important, while post-emulsifiable penetrants are often preferred when higher sensitivity is needed.

Q 28. What are some common applications of dye penetrant testing in different industries?

Dye penetrant testing has widespread applications across various industries:

- Aerospace: Detecting cracks and other flaws in aircraft components is critical for safety. Dye penetrant testing is essential for maintaining airworthiness.

- Automotive: Used in engine blocks, axles, and other critical parts, ensuring vehicle safety and reliability.

- Manufacturing: Quality control in various manufacturing processes uses this method to check for surface flaws in welds, castings, and forgings.

- Power Generation: Inspection of turbine blades and other components in power plants to ensure their integrity and safe operation.

- Medical Devices: Assuring the quality and safety of medical implants and tools.

In essence, any industry dealing with components where surface flaws can compromise safety or functionality can benefit from dye penetrant testing as a valuable non-destructive testing method.

Key Topics to Learn for Dye Penetrant Testing Interview

- Fundamentals of Dye Penetrant Testing: Understand the basic principles, including the process steps (pre-cleaning, penetrant application, dwell time, removal, developer application, inspection, and post-cleaning).

- Types of Dye Penetrant Systems: Familiarize yourself with different penetrant types (visible dye, fluorescent dye, water-washable, post-emulsifiable, lipophilic), their applications, and limitations.

- Penetrant Inspection Techniques: Master various inspection methods and understand how to interpret results accurately. This includes understanding the impact of lighting, surface preparation, and environmental factors.

- Defect Detection and Interpretation: Learn to identify different types of surface-breaking defects (cracks, porosity, seams) and accurately interpret indications. Understand the difference between relevant and non-relevant indications.

- Process Variables and Control: Grasp the importance of controlling environmental factors and process parameters to ensure reliable and repeatable results. Know how to troubleshoot common issues and maintain quality control.

- Safety and Regulations: Understand relevant safety procedures, handling of chemicals, and disposal of waste materials. Familiarize yourself with industry standards and regulations (e.g., ASTM standards).

- Practical Applications and Case Studies: Review real-world applications of dye penetrant testing across various industries (aerospace, automotive, manufacturing). Be prepared to discuss scenarios and problem-solving approaches.

- Limitations of Dye Penetrant Testing: Recognize the limitations of the method and understand when it’s appropriate and inappropriate to use. Know what other Non-Destructive Testing (NDT) methods could be used as complements.

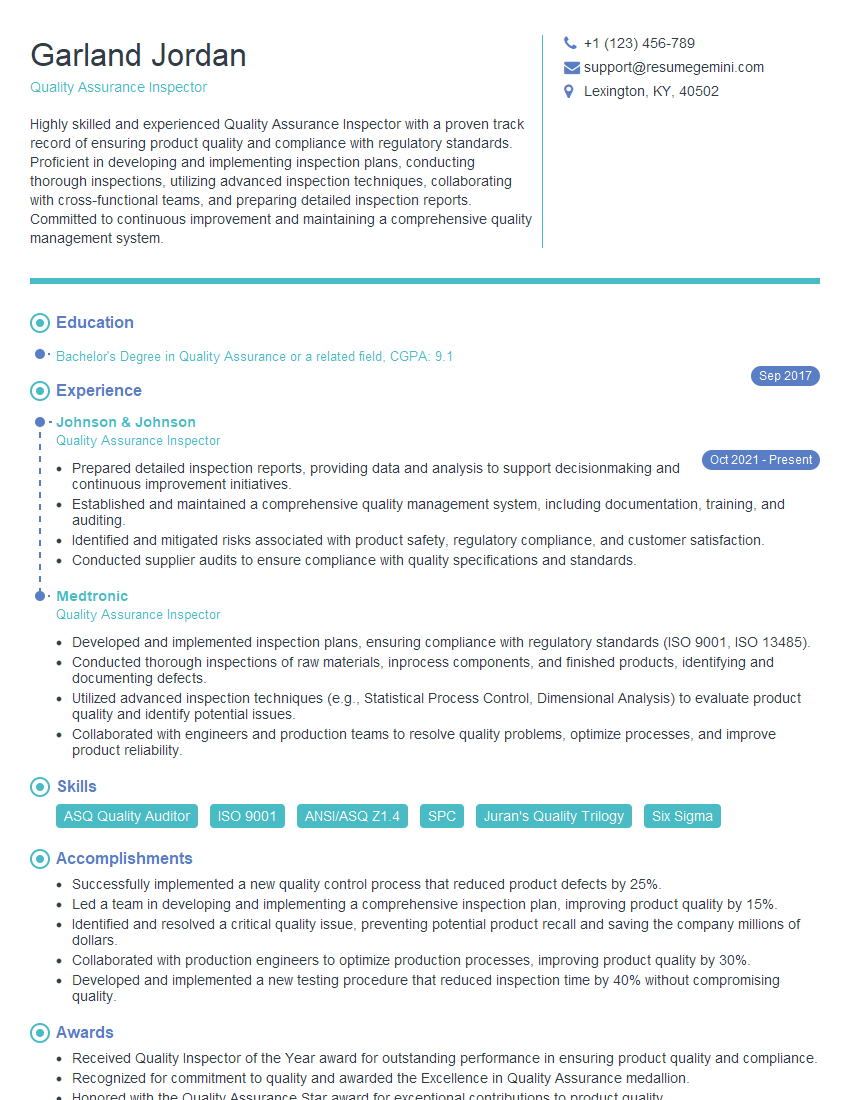

Next Steps

Mastering Dye Penetrant Testing opens doors to exciting career opportunities in various industries. A strong understanding of this NDT method is highly valued, making you a competitive candidate. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications shine. Examples of resumes tailored to Dye Penetrant Testing are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good