Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Knowledge of Production Scheduling Techniques interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Knowledge of Production Scheduling Techniques Interview

Q 1. Explain the difference between Finite Capacity Scheduling and Infinite Capacity Scheduling.

The core difference between Finite Capacity Scheduling (FCS) and Infinite Capacity Scheduling (ICS) lies in how they treat resource constraints. ICS assumes an unlimited supply of resources—labor, machines, materials—allowing you to schedule jobs without regard for capacity limitations. It’s a great starting point for creating a theoretical schedule, providing a high-level view of project timelines. However, it’s unrealistic for real-world production.

FCS, on the other hand, explicitly incorporates resource capacity constraints. It accounts for the limited availability of machines, workers, and materials, ensuring the schedule is feasible and achievable. This means the schedule realistically reflects the available resources and prevents overbooking.

Analogy: Imagine planning a party (your production). ICS is like creating a guest list without considering your venue size (resources). You might invite 100 people to a space that only holds 50. FCS, conversely, is like carefully planning your guest list based on the venue capacity, ensuring everyone has a place.

In practice, FCS is far more useful for accurate production planning, leading to better resource utilization and reduced lead times. ICS can be a useful tool during initial project planning or for high-level comparisons, but FCS is essential for execution.

Q 2. Describe your experience with Material Requirements Planning (MRP).

My experience with Material Requirements Planning (MRP) spans several projects across various manufacturing environments. I’ve used MRP systems to manage bill-of-materials (BOMs), schedule production orders, and optimize inventory levels. I’m proficient in analyzing MRP reports to identify potential bottlenecks or shortages and recommend corrective actions.

For example, in a previous role, we were facing delays in delivering a key component due to an unexpected supplier issue. Using the MRP system, I identified the impact this would have on downstream production. We quickly implemented a mitigation strategy involving expedited shipping and re-sequencing production orders to minimize the overall disruption. This involved collaborating with the purchasing department to find alternative suppliers and adjusting our production schedule to prioritize the affected product lines. The MRP system was crucial in providing the data transparency needed to make informed decisions.

I am familiar with both traditional MRP systems and more advanced systems that integrate with enterprise resource planning (ERP) software. I understand the importance of accurate data entry and regular system maintenance to ensure the accuracy of MRP outputs. My skills in this area extend to troubleshooting system issues and optimizing MRP parameters to improve the accuracy of forecasts and reduce inventory holding costs.

Q 3. How do you handle unexpected production delays or disruptions?

Handling unexpected production delays or disruptions requires a proactive and flexible approach. My strategy involves a series of steps:

- Immediate Assessment: First, I identify the root cause and extent of the disruption. This involves gathering data from the shop floor, talking to supervisors, and reviewing production reports.

- Impact Analysis: Using the production schedule and MRP system, I determine the impact of the delay on downstream processes and customer delivery dates.

- Rescheduling and Reprioritization: I utilize available capacity and flexibility to reschedule tasks and potentially re-prioritize orders based on criticality and customer commitments. This might involve using different scheduling algorithms (SPT for example, to prioritize the shortest jobs) to minimize overall delay.

- Communication: Clear and timely communication is key. I inform all relevant stakeholders – supervisors, customers, and purchasing – about the disruption and the steps being taken to address it.

- Continuous Monitoring: After implementing corrective actions, I continuously monitor the situation to assess effectiveness and make necessary adjustments. This includes tracking key performance indicators (KPIs) to measure the impact of the disruption and recovery efforts.

A recent example involved a machine breakdown. By quickly assessing the situation, we identified alternative machines that could handle the affected tasks. While some delays were unavoidable, minimizing their impact through proactive rescheduling and clear communication prevented larger, more costly setbacks.

Q 4. What are the key performance indicators (KPIs) you use to measure the effectiveness of a production schedule?

Measuring the effectiveness of a production schedule involves tracking several key performance indicators (KPIs). These KPIs provide a quantitative measure of schedule performance and identify areas for improvement. Some of the most important KPIs include:

- On-Time Delivery Rate: The percentage of orders delivered on or before their scheduled due date.

- Lead Time: The total time it takes to complete a product or order, from raw materials to finished goods. Shorter lead times are generally better.

- Throughput: The rate at which products or services are completed, usually measured as units per time period.

- Inventory Turnover Rate: How quickly inventory is used and replaced. A higher rate indicates efficient inventory management.

- Capacity Utilization: The percentage of available capacity being used. High utilization indicates efficient resource allocation but risks potential bottlenecks if too high.

- Production Efficiency: A ratio comparing actual output to planned output. This helps identify inefficiencies in the process.

- Work-in-Progress (WIP) Inventory: The amount of partially completed work. High WIP often suggests bottlenecks in the production process.

By regularly monitoring these KPIs, I can identify areas where the schedule needs adjustment or improvement, ensuring the production process remains efficient and meets customer demands.

Q 5. Explain your understanding of Advanced Planning and Scheduling (APS) software.

Advanced Planning and Scheduling (APS) software represents a significant advancement in production scheduling. It goes beyond basic MRP systems by offering more sophisticated functionalities, such as constraint-based scheduling, optimization algorithms, and what-if scenario analysis. APS software uses advanced algorithms to create optimized schedules that account for various constraints, including material availability, machine capacity, labor skills, and order due dates.

These systems often integrate seamlessly with ERP systems, providing a holistic view of the entire production process. Key features include:

- Capacity Planning: Accurately forecasts and manages resource capacity.

- Finite Capacity Scheduling: Creates realistic schedules that account for all resource constraints.

- Demand Management: Forecasts future demand and adjusts schedules accordingly.

- Optimization Algorithms: Uses sophisticated algorithms to find the most efficient schedule.

- What-If Analysis: Allows users to explore different scenarios and their impact on the schedule.

- Collaboration Tools: Facilitates communication and collaboration among different departments.

In my experience, APS software significantly improves scheduling accuracy, reduces lead times, and optimizes resource utilization. It allows for proactive problem-solving and minimizes disruptions. The ability to simulate various scenarios is invaluable in making informed decisions and mitigating potential risks.

Q 6. How do you prioritize tasks in a production schedule when faced with competing demands?

Prioritizing tasks in a production schedule with competing demands requires a structured approach. I typically use a combination of methods:

- Customer Priority: Orders from high-value or strategic customers are often given priority.

- Due Date: Jobs with imminent due dates are prioritized to avoid late deliveries.

- Criticality: Essential components or products for other production lines might take precedence.

- Profitability: Prioritizing high-margin orders can maximize overall profitability.

- Urgency: Orders with immediate deadlines or urgent requests from customers are prioritized.

- Scheduling Rules: Employing specific scheduling algorithms (like shortest processing time—SPT—or earliest due date—EDD) can help determine the optimal sequence of jobs.

A decision matrix can be helpful in visualizing and comparing different criteria. I also utilize the capabilities of advanced scheduling software to optimize task prioritization based on multiple parameters. Transparency and communication are crucial to ensure that all stakeholders understand the rationale behind the chosen priorities.

Q 7. Describe your experience with different scheduling algorithms (e.g., FIFO, LIFO, SPT).

I have extensive experience with various scheduling algorithms, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and SPT (Shortest Processing Time). Each has its strengths and weaknesses depending on the production environment and objectives.

- FIFO: Simple and easy to understand, but can lead to longer lead times if long jobs are queued ahead of shorter ones.

- LIFO: Can be useful for prioritizing recently arrived jobs, but might lead to longer wait times for older jobs.

- SPT: Minimizes the average completion time by prioritizing jobs with the shortest processing times. This is generally a good strategy to reduce lead time and work-in-progress.

- EDD (Earliest Due Date): Prioritizes jobs with the closest due dates, which is great for meeting deadlines and avoiding late deliveries but might not be optimal for throughput.

- Critical Ratio (CR): A more sophisticated method that considers both remaining time and processing time to prioritize jobs based on their urgency.

The choice of algorithm depends heavily on the specific context. For example, SPT might be ideal in a job shop with a variety of short jobs, while EDD is better suited for environments where meeting deadlines is paramount. In more complex situations, I often combine algorithms or use more advanced scheduling rules within APS software to optimize the schedule based on multiple criteria.

Q 8. How do you incorporate safety stock into your production plans?

Incorporating safety stock into production plans is crucial for mitigating the risks associated with demand variability and supply chain disruptions. Safety stock acts as a buffer, ensuring that you have enough inventory on hand to meet unexpected demand spikes or delays in receiving materials. The amount of safety stock depends on several factors, including demand variability, lead times, and service level targets.

How I incorporate it:

- Demand Forecasting: I begin by carefully analyzing historical demand data to predict future demand. This often involves using statistical forecasting methods to account for seasonality and trends.

- Lead Time Analysis: I assess the lead time for each component or product, considering potential delays from suppliers or internal processes. Longer lead times necessitate higher safety stock levels.

- Service Level Target: I determine the desired service level – the probability of meeting demand from existing stock. A higher service level (e.g., 99%) requires more safety stock than a lower one (e.g., 95%).

- Safety Stock Calculation: I use established formulas, often incorporating standard deviation of demand during lead time, to calculate the required safety stock. For instance, a simple formula might be:

Safety Stock = Z * σLwhere Z is the Z-score corresponding to the desired service level, and σL is the standard deviation of demand during lead time. - Regular Review and Adjustment: Safety stock levels aren’t static. I regularly review them, adjusting based on actual demand, lead time performance, and changes in the market.

Example: Imagine a manufacturing company producing widgets. If historical data shows a standard deviation of demand during lead time of 100 widgets, and they aim for a 95% service level (Z-score ≈ 1.645), their safety stock would be approximately 165 widgets (1.645 * 100).

Q 9. How do you balance production capacity with customer demand?

Balancing production capacity with customer demand is a constant challenge. It requires a delicate interplay of forecasting, capacity planning, and production scheduling. Overcapacity leads to wasted resources, while undercapacity results in unmet demand and lost revenue. The key is to find the sweet spot that optimizes resource utilization while meeting customer expectations.

My Approach:

- Demand Forecasting: Accurate demand forecasts are paramount. I use a variety of techniques, including time series analysis, moving averages, and exponential smoothing, to predict future demand.

- Capacity Planning: I assess the available production capacity, considering machine availability, labor hours, and other relevant constraints. This might involve analyzing machine run times, evaluating potential bottlenecks, and identifying opportunities for increased efficiency.

- Capacity-Demand Matching: I compare the forecasted demand with the available capacity. If demand exceeds capacity, I explore options such as increasing capacity (e.g., overtime, additional equipment), prioritizing high-demand items, or managing customer expectations through lead time communication.

- Production Scheduling: Once I have a clear understanding of demand and capacity, I develop a production schedule that optimizes resource allocation while meeting customer deadlines. Techniques like MRP (Material Requirements Planning) and Finite Capacity Scheduling are invaluable here.

- Continuous Monitoring and Adjustment: The production plan is not static. I continuously monitor actual production against the schedule and adjust the plan as needed to account for unexpected events such as machine breakdowns or material shortages.

Example: In a situation where demand outstrips capacity, I might prioritize fulfilling orders with the shortest lead times or those from key customers. I might also communicate potential delays to customers to manage their expectations.

Q 10. How do you handle bottleneck situations in production?

Bottlenecks significantly hinder production flow and limit overall output. Identifying and addressing bottlenecks is crucial for maximizing efficiency and meeting production targets. My approach is systematic and data-driven.

Handling Bottlenecks:

- Bottleneck Identification: I use various tools and techniques to pinpoint bottlenecks. This might involve analyzing production data, observing the production process, and using simulation software. Key metrics include cycle times, machine utilization, and work-in-progress inventory at each stage.

- Root Cause Analysis: Once a bottleneck is identified, I delve into the root causes. Is it due to insufficient machine capacity, skill shortages, material supply issues, or process inefficiencies?

- Solutions: Solutions depend on the root cause. Possible approaches include:

- Increasing Capacity: Adding more machines, upgrading existing equipment, or optimizing machine settings.

- Improving Process Efficiency: Streamlining workflows, reducing setup times, or implementing lean manufacturing principles.

- Restructuring Workflows: Re-allocating tasks or resources to better balance workload across different stages.

- Investing in Training: Upskilling employees to improve their efficiency and reduce error rates.

- Outsourcing: Subcontracting some of the workload to external suppliers.

- Monitoring and Evaluation: After implementing solutions, I continuously monitor the bottleneck to ensure that the implemented changes have effectively resolved the issue. I collect data to evaluate the effectiveness of the implemented solutions.

Example: If a particular machine is consistently the slowest step in the production process, I might explore options like upgrading the machine, adding a second machine, or re-designing the process to reduce its workload.

Q 11. What is your experience with production scheduling software (e.g., SAP, Oracle, etc.)?

I have extensive experience with several production scheduling software packages, including SAP ERP, Oracle SCM Cloud, and smaller, specialized systems. My experience spans from data entry and basic scheduling to advanced configuration and system optimization.

Specific Examples:

- SAP PP (Production Planning): I’ve used SAP PP to create and manage production orders, monitor capacity, and track material flows. I’m proficient in configuring routing and work center data, and utilizing MRP for material planning. I’ve also worked with the capacity requirements planning (CRP) functionalities.

- Oracle SCM Cloud: I’ve leveraged Oracle SCM Cloud for supply chain visibility, demand planning, and production scheduling, particularly in environments requiring sophisticated supply chain optimization across various manufacturing sites.

- Custom Solutions: In smaller companies, I’ve worked with custom-built scheduling systems, often integrating them with existing ERP and inventory management tools. This included designing and implementing reporting dashboards and data analysis solutions.

My experience includes both implementing these systems and optimizing their use within specific manufacturing contexts. I’m familiar with the challenges of data integration, master data maintenance, and user training.

Q 12. How do you ensure the accuracy of your production schedules?

Ensuring the accuracy of production schedules is critical. Inaccuracy can lead to delays, material shortages, and ultimately, dissatisfied customers. My approach focuses on data validation, process validation, and continuous improvement.

Accuracy Measures:

- Data Validation: Before scheduling, I meticulously validate the input data, including BOMs (Bill of Materials), routings, and capacity information. This involves checking for inconsistencies, errors, and completeness.

- Process Validation: I use simulation and what-if analysis to test the feasibility of the schedule. This identifies potential conflicts or capacity constraints that may have been missed during initial planning.

- Regular Monitoring and Adjustment: I continuously monitor the schedule against actual production data. Deviations are investigated, and corrective actions are taken promptly. This might involve adjusting the schedule, addressing process issues, or securing additional resources.

- Feedback Loops: I encourage feedback from shop floor personnel and other stakeholders to identify potential inaccuracies or improvements in the scheduling process.

- Key Performance Indicators (KPIs): I track KPIs such as on-time delivery, production efficiency, and inventory levels to assess the accuracy and effectiveness of the schedule.

Example: If a significant deviation occurs between planned and actual production time, I will investigate the reason—was there a machine breakdown? A material shortage? Or an unforeseen process issue? This analysis helps refine future schedules and improve accuracy.

Q 13. Explain your process for creating a production schedule from a bill of materials (BOM).

Creating a production schedule from a BOM (Bill of Materials) involves a multi-step process that translates the product design into a feasible production plan. This process often utilizes MRP (Material Requirements Planning) or similar techniques.

My Process:

- BOM Analysis: I start by thoroughly reviewing the BOM to understand the components needed for each product, their quantities, and the relationships between them.

- Routing Definition: I define the manufacturing process for each component and product, specifying the sequence of operations, machines required, and processing times. This involves creating routings that detail the production flow.

- Material Requirements Planning (MRP): I use MRP software or techniques to calculate the required quantities of materials and components based on the planned production schedule and the lead times involved. This ensures materials are available when needed.

- Capacity Planning: I analyze the capacity of each machine and work center to ensure that the schedule is feasible. This may involve adjusting the schedule to avoid overloading any particular resource.

- Scheduling: I use appropriate scheduling algorithms (e.g., priority scheduling, critical path scheduling) to allocate resources (machines, labor) and assign start and completion times for each operation. The choice of algorithm depends on the specific priorities and constraints.

- Schedule Validation: I validate the schedule to identify potential conflicts, bottlenecks, or capacity constraints. This often involves simulation and what-if analysis.

- Documentation and Communication: I document the finalized schedule and communicate it to relevant stakeholders—production personnel, procurement, and management—ensuring everyone understands their responsibilities.

Example: If the BOM indicates that Product A requires two components (Component X and Component Y), and the production plan is for 100 units of Product A, the MRP system will automatically calculate the required quantities of Component X and Component Y (200 units each assuming a 1:1 ratio).

Q 14. How do you communicate production schedule changes to relevant stakeholders?

Communicating production schedule changes effectively is critical to minimizing disruptions and ensuring everyone remains informed. My approach emphasizes clarity, timeliness, and appropriate channels.

Communication Strategy:

- Change Notification System: I implement a system for notifying stakeholders of changes promptly. This might involve email alerts, internal communication platforms, or even a dedicated production scheduling dashboard.

- Clear and Concise Communication: I ensure that communication is clear, concise, and easily understandable by all stakeholders. Technical jargon is minimized, and the impact of the changes is clearly explained.

- Targeted Communication: I tailor my communication to the specific needs of each stakeholder. For example, production personnel require detailed operational updates, while management might need a high-level overview of the impact on deadlines and resource allocation.

- Multiple Communication Channels: I utilize multiple communication channels, depending on the urgency and nature of the change. Email is suitable for routine updates, while immediate changes may require phone calls or face-to-face meetings.

- Documentation: All schedule changes are meticulously documented, including the reason for the change, the impacted areas, and the actions taken. This ensures traceability and facilitates future analysis.

- Feedback Mechanism: I establish a feedback mechanism to address any questions or concerns from stakeholders regarding the schedule changes.

Example: If a machine breakdown necessitates a schedule change, I would immediately inform the relevant personnel, update the schedule in the system, and send out email notifications explaining the delay and the revised schedule. Management would receive a summary highlighting the impact on key deadlines.

Q 15. Describe your experience with Lean manufacturing principles and their impact on scheduling.

Lean manufacturing principles fundamentally aim to eliminate waste and maximize efficiency throughout the production process. In scheduling, this translates to creating a pull system, rather than a push system. Instead of producing based on forecasts (push), we produce only what’s needed, when it’s needed (pull), minimizing inventory and maximizing responsiveness to customer demand.

My experience involves implementing Kanban systems to visualize workflow, using value stream mapping to identify bottlenecks, and employing 5S methodologies to create a more organized and efficient workspace. For example, in a previous role, implementing a Kanban system for a specific assembly line reduced lead times by 20% and inventory by 15% by making the flow of work more visible and manageable. This allowed for much more precise scheduling, leading to increased on-time delivery and reduced production costs.

- Reduced Lead Times: By streamlining processes and eliminating bottlenecks, lean principles enable faster production cycles.

- Improved Inventory Management: Just-in-time (JIT) inventory management significantly reduces storage costs and waste.

- Increased Flexibility: Lean systems are more adaptable to changes in demand and product specifications.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you utilize historical data to improve future production schedules?

Historical data is crucial for predictive scheduling. I utilize it in several ways. First, I analyze past production rates to establish realistic production targets. Second, I identify common bottlenecks and potential disruptions by examining historical downtime data and production issues. Third, I analyze demand patterns to forecast future needs. This involves using statistical techniques like moving averages and exponential smoothing to predict demand fluctuations. For example, if past data shows a predictable seasonal surge in demand, we can proactively adjust the schedule to avoid delays. Additionally, I use data analysis tools to identify trends in machine failures or material shortages, allowing for preventative maintenance scheduling and proactive procurement of materials.

Furthermore, I often use control charts to monitor key performance indicators (KPIs) like cycle time and defect rates. These charts help identify trends and anomalies that may indicate issues requiring attention before they significantly affect the schedule.

Q 17. What methods do you use for capacity planning?

Capacity planning involves determining if the available resources (machines, labor, materials) are sufficient to meet the production schedule. I utilize several methods:

- Theoretical Capacity Analysis: This involves calculating the maximum output possible given the available resources, accounting for machine speeds, available shifts, and other constraints.

- Simulation Modeling: I use simulation software to model different scenarios and assess the impact of changes to resources or schedules on overall capacity. This allows for ‘what-if’ analysis to optimize resource allocation.

- Historical Data Analysis: Analyzing historical production data reveals actual capacity utilization rates, helping to identify areas of under- or over-utilization.

- Bottleneck Analysis: Identifying the production steps with the lowest capacity helps prioritize improvement efforts. Addressing bottlenecks is often the most impactful way to increase overall capacity.

For instance, if simulation modeling shows a bottleneck at a specific machine during peak demand, we can explore options like adding another machine, improving the machine’s efficiency, or adjusting the workload distribution.

Q 18. How do you manage change requests to the production schedule?

Managing change requests requires a structured approach. I typically follow a process that involves:

- Impact Assessment: Analyzing the impact of the requested change on existing schedules and resource allocation. This might involve using Gantt charts or other scheduling tools to visually see the effect of the changes.

- Prioritization: Prioritizing requests based on factors like urgency, impact, and feasibility. A formal change control board might be involved to make decisions on high-impact requests.

- Rescheduling: If the change is approved, I use scheduling software to update the master production schedule, taking into account the change’s impact on resource availability and timelines.

- Communication: Keeping all relevant stakeholders informed about the changes and their implications. This ensures transparency and minimizes disruption.

This structured approach ensures that changes are handled efficiently while minimizing disruptions to overall production plans. A change management system with proper documentation is vital to maintain control and traceability.

Q 19. Describe a time you had to significantly revise a production schedule. What were the challenges, and how did you overcome them?

In a previous project, a major supplier experienced an unexpected production delay, impacting the delivery of a critical component for our flagship product. This threatened to significantly delay our production schedule and miss key deadlines. The challenge was not only to reschedule production but also to maintain customer confidence and minimize financial losses.

To overcome this, I immediately convened a cross-functional team involving production, procurement, and sales. We collaboratively explored several options, including:

- Identifying Alternative Suppliers: While sourcing from a new supplier carried its own risks, we found a backup supplier who could partially fill the gap.

- Reprioritizing Production: We focused production on the most critical products and slightly delayed less urgent orders. This helped to minimize the overall disruption.

- Negotiating Extended Deadlines with Key Customers: Open and honest communication with key clients allowed us to negotiate adjusted delivery timelines. This transparency helped maintain their trust and minimize potential penalties.

- Overtime and Shift Adjustments: We utilized overtime and adjusted shift patterns to accelerate production once the alternative components arrived.

Through this proactive and collaborative approach, we managed to minimize the impact of the supplier delay. The experience highlighted the importance of having contingency plans, strong supplier relationships, and a flexible production system.

Q 20. How familiar are you with different types of inventory management systems (e.g., FIFO, LIFO, JIT)?

I’m very familiar with various inventory management systems. Each has strengths and weaknesses depending on the context:

- FIFO (First-In, First-Out): This method prioritizes using the oldest inventory first. It minimizes waste from spoilage and obsolescence, particularly useful for perishable goods. It also provides a more accurate cost of goods sold calculation.

- LIFO (Last-In, First-Out): This prioritizes using the newest inventory first. It can be beneficial during periods of inflation as it results in a lower cost of goods sold, leading to lower tax liabilities. However, it can be less efficient for products with expiration dates.

- JIT (Just-In-Time): This system aims to minimize inventory holding costs by receiving materials only when needed for production. It requires strong supplier relationships and precise forecasting. JIT is highly efficient when implemented successfully, but disruptions can have significant repercussions.

The choice of inventory management system depends heavily on the nature of the product, the demand variability, and the cost of holding inventory. A thorough cost-benefit analysis is necessary to determine the most appropriate method.

Q 21. Explain your understanding of critical path analysis in relation to production scheduling.

Critical Path Analysis (CPA) is a project management technique used to identify the longest sequence of tasks in a project. In production scheduling, this longest sequence determines the shortest possible project duration. The tasks on the critical path are the most critical to timely completion; any delay on these tasks directly impacts the overall project timeline. Identifying the critical path allows us to focus resources and attention on the most crucial activities to avoid delays.

I utilize CPA during production scheduling by creating a network diagram representing the various tasks involved in manufacturing a product. Each task is assigned a duration, and the longest path through the network is identified as the critical path. This helps determine the minimum production time and helps prioritize task completion. For instance, if a specific machine is a bottleneck on the critical path, we might prioritize its maintenance or explore ways to reduce its processing time to shorten the overall production cycle.

Q 22. How do you ensure that your production schedule aligns with the overall business objectives?

Aligning the production schedule with business objectives is paramount. It’s not just about making products; it’s about making the right products, at the right time, and at the right cost to maximize profitability and meet market demands. This involves a close collaboration between production planning, sales forecasting, and the overall business strategy.

- Understanding Business Goals: First, we need a clear understanding of the company’s overarching goals – are we focusing on market share expansion, cost reduction, or new product launches? This dictates the priorities in our production schedule. For instance, if market share is the priority, the schedule will prioritize high-demand products, even if they have lower profit margins.

- Capacity Planning: We need to ensure that our production capacity aligns with the sales forecast and business objectives. This might involve investing in new equipment, optimizing existing processes, or strategically outsourcing certain tasks.

- Resource Allocation: Efficient resource allocation (materials, labor, equipment) is crucial. The schedule must optimize the use of these resources based on the business’s strategic priorities. If a new product launch is crucial, we might allocate more resources to its production, even if it temporarily reduces the output of other products.

- Performance Monitoring & Adjustment: Regular monitoring and comparison of actual production against the scheduled plan are critical. We need to analyze variances, identify bottlenecks, and make adjustments to the schedule as needed to ensure it remains aligned with the overall business objectives.

For example, in a previous role, we were launching a new flagship product. The business objective was to quickly capture significant market share. Therefore, the production schedule prioritized this new product, even if it meant temporarily slowing down production of some existing products. This resulted in exceeding the sales targets for the new product within the first quarter.

Q 23. How do you handle scheduling conflicts between different production lines or departments?

Scheduling conflicts between production lines or departments are common challenges. Effective conflict resolution requires a collaborative approach and sophisticated scheduling tools.

- Prioritization & Negotiation: Conflicts often arise due to limited resources or competing deadlines. We use a prioritization matrix based on factors like product demand, profitability, and delivery deadlines. This helps to negotiate and allocate resources effectively. Sometimes, it involves discussing trade-offs with various department heads.

- Buffer Time: Incorporating buffer time in the schedule provides flexibility to absorb unexpected delays or disruptions. This prevents a small delay in one area from cascading into major problems across the entire production process.

- Capacity Balancing: Analyzing the capacity of different production lines and departments helps identify potential bottlenecks. This can involve adjusting production volumes, optimizing workflows, or even investing in additional equipment to enhance overall capacity.

- Communication & Collaboration: Open communication and collaboration between departments is crucial. Regular meetings and use of shared scheduling software facilitates quick resolution of conflicts and prevents escalation.

For instance, in one scenario, the assembly line was facing delays due to a shortage of components from the machining department. Through collaboration, we realized the machining department was facing unexpected equipment downtime. We communicated the issue to the management team and prioritized the necessary maintenance and repair, while simultaneously adjusting the assembly line schedule to minimize disruption.

Q 24. What techniques do you use to improve the efficiency of the production schedule?

Improving production schedule efficiency involves leveraging various techniques that optimize resource utilization and minimize downtime.

- Lean Manufacturing Principles: Applying Lean principles, like eliminating waste (muda), identifying bottlenecks, and implementing just-in-time (JIT) inventory management significantly improves efficiency. JIT minimizes storage costs and reduces the risk of obsolescence.

- Advanced Planning and Scheduling (APS) Software: APS software utilizes advanced algorithms to optimize schedules, considering various constraints and variables. This provides a more accurate and efficient schedule compared to manual methods.

- Simulation and Modeling: Using simulation software allows us to test different scheduling scenarios, identify potential bottlenecks, and optimize resource allocation before implementing the schedule in real-time. This minimizes the risk of unforeseen problems.

- Process Optimization: Analyzing the production process to identify areas for improvement, like streamlining workflows, automating tasks, or improving material handling can greatly boost efficiency.

- Preventive Maintenance: Implementing a proactive preventive maintenance program helps minimize equipment downtime, avoiding unexpected disruptions to the production schedule.

In a past project, we implemented an APS system which resulted in a 15% reduction in lead times and a 10% increase in overall throughput. This was achieved by optimizing the sequence of production orders and reducing machine idle time.

Q 25. How do you measure the success of a production schedule?

Measuring the success of a production schedule goes beyond simply meeting deadlines. It involves evaluating various key performance indicators (KPIs).

- On-Time Delivery Rate: The percentage of orders delivered on or before their due date is a critical measure of schedule adherence.

- Lead Time: The time taken from order placement to product delivery is another important KPI. Reducing lead time enhances customer satisfaction and responsiveness.

- Throughput: The amount of product produced within a given time frame is a key indicator of productivity and efficiency.

- Inventory Turnover: How quickly inventory is used and replaced is crucial for optimizing inventory levels and minimizing storage costs. A higher turnover rate often indicates better schedule management.

- Production Cost: Monitoring and controlling production costs, while maintaining schedule adherence, is a significant indicator of overall efficiency and profitability. Variances from planned costs need to be investigated.

- Customer Satisfaction: This is ultimately the most crucial metric. A successful schedule results in satisfied customers receiving their orders on time and to specification.

By tracking and analyzing these KPIs, we can identify areas for improvement and fine-tune the production schedule for better performance. For example, consistently low on-time delivery rates might signal a need for better resource allocation or improved process efficiency.

Q 26. What are your preferred methods for visualizing production schedules (e.g., Gantt charts)?

Visualizing production schedules is crucial for understanding and managing the complexities of the production process. While Gantt charts are a staple, we use a combination of visualization methods to gain a comprehensive overview.

- Gantt Charts: These charts provide a visual representation of tasks, durations, and dependencies, making it easy to identify critical paths and potential bottlenecks. They are excellent for showing the overall schedule and progress.

- Kanban Boards: These are especially useful for visualizing the workflow and identifying work-in-progress (WIP). They help in managing the flow of work and minimizing bottlenecks in real-time.

- Drum-Buffer-Rope (DBR): This method, popular in Theory of Constraints, helps visualize the limiting factor (drum) in the production process and manage buffers around it to maintain a smooth flow. It’s particularly helpful for complex production systems.

- Process Flowcharts: These diagrams illustrate the sequence of steps in a production process. They help identify areas for improvement and streamline workflows.

- APS Software Dashboards: Many advanced scheduling systems offer customized dashboards that provide real-time data visualization, allowing managers to monitor progress, identify issues, and make timely adjustments.

The choice of visualization method depends on the complexity of the production process and the specific information we want to convey. Often, we use a combination of methods for a holistic view.

Q 27. Describe your experience with forecasting techniques used in production planning.

Accurate forecasting is the foundation of effective production planning. My experience encompasses various techniques, each with its strengths and limitations.

- Simple Moving Average: This is a straightforward method useful for stable demand patterns. It averages demand over a specific period to predict future demand. It’s easy to understand and implement but can be slow to respond to changes in demand.

- Exponential Smoothing: This method assigns weights to past data, giving more importance to recent data points. This makes it more responsive to changes in demand than simple moving average. It requires selecting an appropriate smoothing factor.

- ARIMA Models: These are sophisticated statistical models that analyze historical data to identify patterns and forecast future demand. They are better suited for complex, non-stationary data but require statistical expertise to implement and interpret.

- Qualitative Forecasting Methods: These methods, such as Delphi method or market research, incorporate expert opinions and qualitative factors like market trends and economic conditions. These are useful when historical data is limited or unreliable.

- Causal Forecasting: This method identifies factors influencing demand and uses regression analysis to build a predictive model. For example, we might relate demand to factors like advertising spending or economic indicators.

The choice of forecasting technique depends on factors like data availability, demand pattern stability, and the level of accuracy required. In practice, we often combine multiple methods to get a more robust and reliable forecast. In one instance, we used a combination of exponential smoothing and causal forecasting to predict demand for seasonal products, which resulted in significantly improved inventory management and reduced stockouts.

Key Topics to Learn for Knowledge of Production Scheduling Techniques Interview

- Demand Forecasting & Capacity Planning: Understanding different forecasting methods (e.g., moving average, exponential smoothing) and how to align production capacity with predicted demand. Practical application: Analyzing sales data to predict future needs and adjusting production lines accordingly.

- Scheduling Algorithms: Familiarity with various scheduling algorithms (e.g., FIFO, LIFO, shortest processing time, priority scheduling) and their strengths and weaknesses. Practical application: Choosing the optimal algorithm for a specific production environment to minimize lead times and maximize efficiency.

- Material Requirements Planning (MRP): Understanding the principles of MRP and how it’s used to manage inventory and ensure materials are available when needed. Practical application: Developing and implementing an MRP system to optimize material flow and prevent production delays.

- Production Control & Monitoring: Techniques for monitoring production progress, identifying bottlenecks, and taking corrective actions. Practical application: Using real-time data to track key performance indicators (KPIs) and make informed decisions to improve efficiency.

- Lean Manufacturing Principles: Applying lean methodologies (e.g., Kanban, 5S) to optimize production flow and minimize waste. Practical application: Implementing Kanban systems to manage work-in-progress and reduce inventory.

- Just-in-Time (JIT) Inventory Management: Understanding the principles of JIT and its impact on production scheduling. Practical application: Implementing JIT strategies to minimize inventory holding costs and improve responsiveness to customer demand.

- Software & Tools: Familiarity with common production scheduling software and tools (mention general categories, not specific software names). Practical application: Demonstrate understanding of how these tools aid in planning, execution, and analysis.

Next Steps

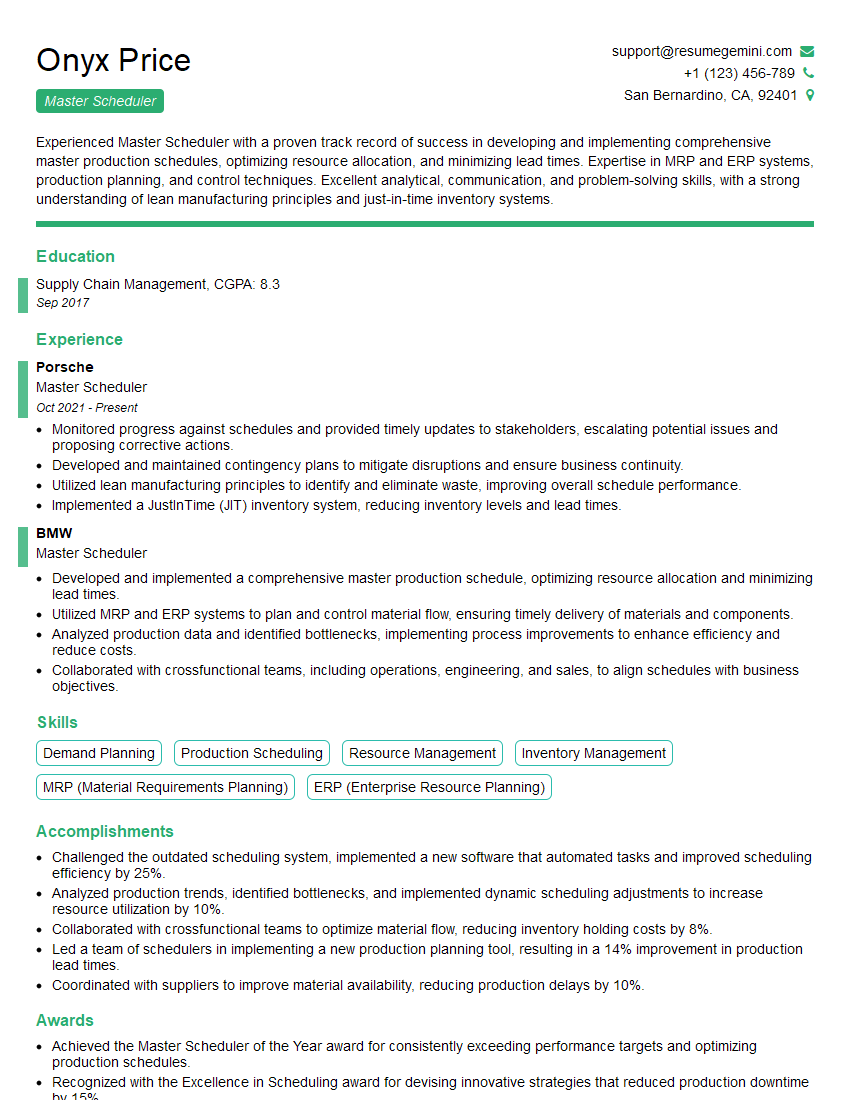

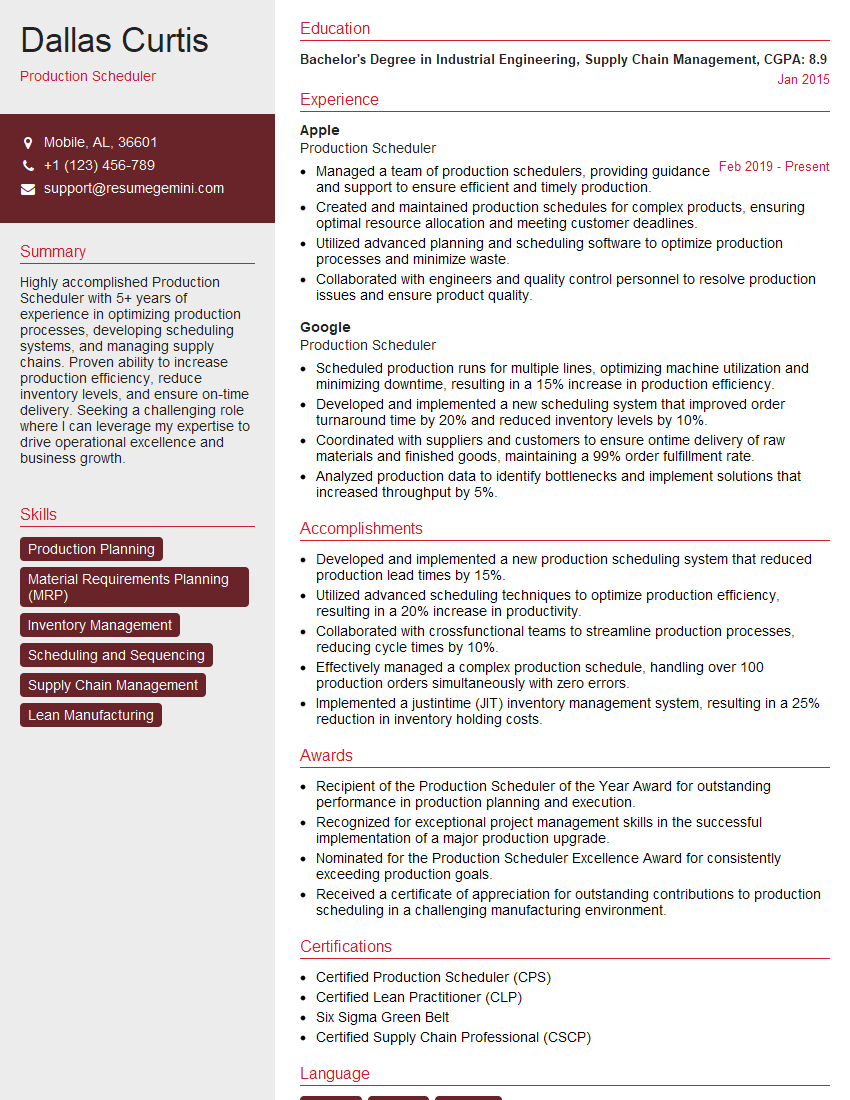

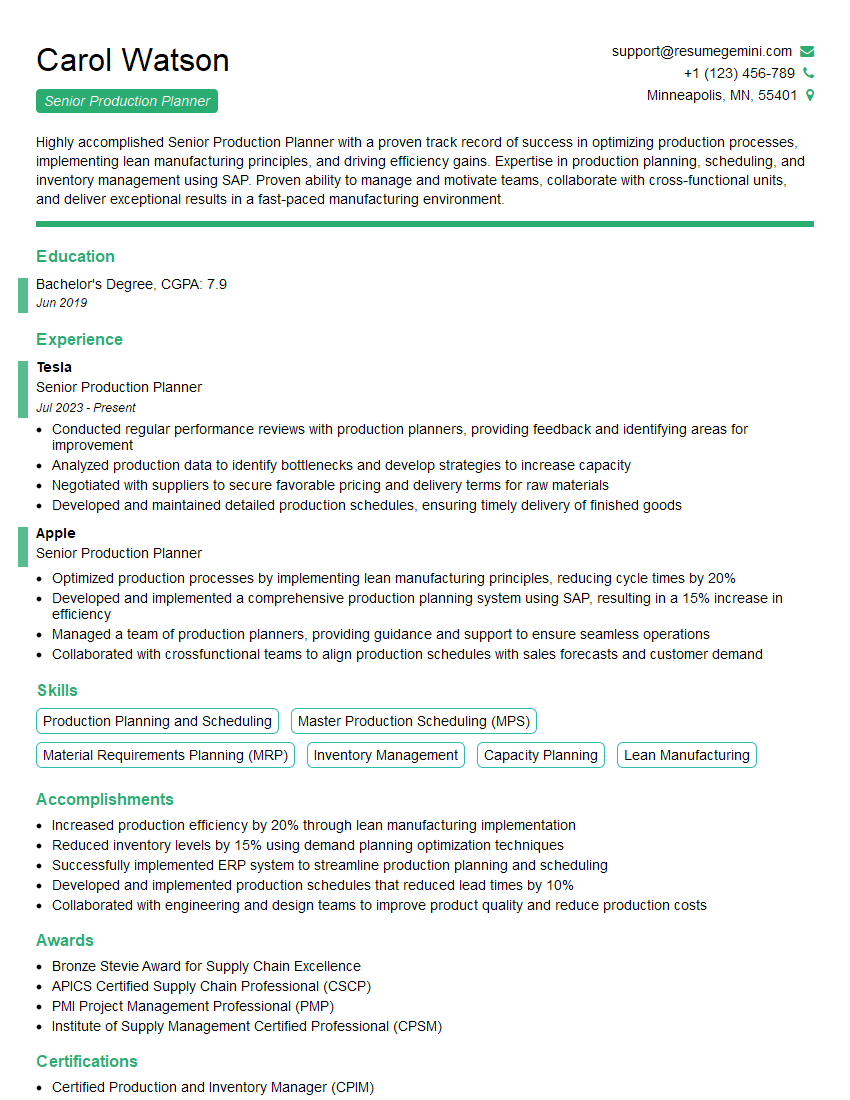

Mastering Knowledge of Production Scheduling Techniques is crucial for career advancement in manufacturing, operations management, and supply chain roles. It demonstrates a valuable skillset highly sought after by employers. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. This ensures your application gets noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They provide examples of resumes tailored to highlight expertise in Knowledge of Production Scheduling Techniques, giving you a significant advantage in your job search.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good