Unlock your full potential by mastering the most common Knowledge of ISO 90012015 Standard interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Knowledge of ISO 90012015 Standard Interview

Q 1. Explain the key principles of ISO 9001:2015.

ISO 9001:2015 is built upon seven key principles that guide organizations in establishing and maintaining a robust Quality Management System (QMS). These principles aren’t just theoretical; they’re practical guidelines for improving efficiency and customer satisfaction. Let’s explore them:

- Customer focus: Understanding and meeting customer needs and expectations is paramount. This involves actively seeking customer feedback and adapting processes to consistently deliver value.

- Leadership: Leaders must create and maintain a quality-oriented culture. This includes setting clear objectives, providing resources, and fostering a climate of continuous improvement.

- Engagement of people: Empowering employees at all levels is crucial. A skilled and motivated workforce is essential for achieving quality objectives. This means providing training, open communication, and opportunities for growth.

- Process approach: Managing processes effectively is key. Processes should be clearly defined, documented, monitored, and improved to ensure consistent outputs.

- Improvement: Continuous improvement is a cornerstone of ISO 9001:2015. Regular evaluation and improvement of processes ensure the QMS remains effective and efficient.

- Evidence-based decision making: Decisions should be based on data analysis and objective evidence, not just assumptions. This ensures decisions are well-informed and lead to better outcomes.

- Relationship management: Building strong relationships with suppliers and other stakeholders contributes to a stable and reliable supply chain and ensures shared quality goals.

For example, a manufacturing company might use customer surveys to understand preferences, then adapt its product design and manufacturing processes accordingly. This exemplifies both customer focus and a process approach.

Q 2. Describe the PDCA cycle and its role in a QMS.

The PDCA cycle, or Plan-Do-Check-Act cycle, is a foundational model for continuous improvement. It’s a systematic approach to identifying problems, implementing solutions, and monitoring their effectiveness. Think of it as a continuous loop of learning and improvement.

- Plan: Identify the problem, set objectives, and develop a plan to address the issue. This involves analyzing the current situation, defining goals, and outlining the steps to achieve those goals.

- Do: Implement the plan. This is the execution phase where the planned changes are put into practice.

- Check: Monitor the results and compare them to the planned objectives. This involves data collection, analysis, and identifying any deviations from the plan.

- Act: Take action based on the results of the check phase. This might involve standardizing successful changes, refining the process, or abandoning the initiative if it proves ineffective.

In a QMS, the PDCA cycle is used throughout. For example, if a defect rate increases, the PDCA cycle could be used to investigate the root cause, implement corrective actions (Do), monitor the effectiveness of those actions (Check), and then implement permanent improvements to the process (Act).

Q 3. What are the requirements for establishing, implementing, maintaining, and improving a QMS?

Establishing, implementing, maintaining, and improving a QMS involves a comprehensive approach. ISO 9001:2015 outlines specific requirements, emphasizing a structured and systematic approach. These requirements cover:

- Understanding the context of the organization: This involves identifying internal and external issues that can affect the QMS. Examples include regulatory requirements, market conditions, and organizational culture.

- Leadership and commitment: Top management must demonstrate commitment to the QMS by setting objectives, providing resources, and ensuring the system is effectively implemented.

- Planning: Establishing quality objectives, determining necessary processes, and specifying the resources required for the QMS are crucial steps.

- Support: Providing resources, including infrastructure, personnel, and work environment, ensures the QMS can function effectively.

- Operation: Planning and controlling operational processes, including product and service realization, are essential for consistent quality.

- Performance evaluation: Regularly monitoring, measuring, analyzing, and evaluating the performance of the QMS is critical for identifying areas for improvement.

- Improvement: Implementing actions to address deficiencies and continuously enhance the effectiveness of the QMS. This includes corrective actions for nonconformities and preventive actions to avoid future problems.

Imagine a software company implementing ISO 9001:2015. They’d map their software development processes, define quality metrics, implement regular code reviews, and gather customer feedback to ensure consistent high quality.

Q 4. How does risk-based thinking apply to ISO 9001:2015?

Risk-based thinking is integrated throughout ISO 9001:2015. It’s not an add-on, but a fundamental approach to proactively identifying and managing risks that could negatively impact the organization’s ability to meet customer requirements and achieve its quality objectives. This involves:

- Identifying risks: This involves systematically identifying potential threats and opportunities that can impact the QMS. These could be related to processes, resources, or external factors.

- Analyzing risks: Evaluating the likelihood and potential impact of each identified risk. This allows prioritization of the most significant risks.

- Evaluating risks: Determining the acceptability of risks and deciding whether actions are needed to mitigate potential negative impacts.

- Addressing risks: Implementing actions to address risks. This could include developing preventive controls or contingency plans.

- Monitoring and reviewing risks: Regularly monitoring and reviewing the effectiveness of risk mitigation actions. Risk assessments should be updated as conditions change.

For example, a pharmaceutical company might identify the risk of contamination in its manufacturing process. By implementing strict cleaning protocols and regular quality checks, they can mitigate the likelihood and impact of this risk.

Q 5. What are the requirements for internal audits under ISO 9001:2015?

Internal audits are a crucial part of the ISO 9001:2015 QMS. They provide an objective assessment of the effectiveness of the QMS by verifying that processes are being followed, requirements are met, and improvements are being implemented. Requirements include:

- Planning: Defining the scope, objectives, and criteria of the audit. This also includes identifying the audit team members and their competencies.

- Conducting the audit: Gathering evidence through interviews, document reviews, and observations to assess the effectiveness of the QMS.

- Reporting: Documenting audit findings, including nonconformities and opportunities for improvement. The report should be objective and factual.

- Follow-up: Tracking the implementation of corrective actions to address any identified nonconformities.

- Competence of auditors: Auditors should possess the necessary knowledge, skills, and experience to conduct effective audits.

A well-planned internal audit might involve reviewing documented procedures, interviewing employees, and observing processes firsthand. The process should be objective, transparent, and documented in detail. The goal is to identify strengths and weaknesses, ultimately leading to improvements.

Q 6. Explain the importance of management review in a QMS.

Management review is a high-level process that ensures the QMS remains effective and fit for purpose. It provides an opportunity for top management to evaluate the performance of the QMS, identify areas for improvement, and make strategic decisions. Its importance lies in:

- Ensuring the QMS is effective: Regularly reviewing performance ensures that the QMS is meeting its objectives and delivering expected results.

- Identifying areas for improvement: Analyzing performance data allows for proactive identification of areas needing improvement.

- Strategic decision making: Management review provides a platform for top management to make informed decisions regarding the QMS and the organization’s strategic direction.

- Demonstrating top management commitment: Active participation in management reviews shows commitment to the QMS and continuous improvement.

- Ensuring continual improvement: The cycle of planning, implementation, monitoring, and review leads to a culture of continual improvement.

Imagine a manufacturing company analyzing customer satisfaction data during a management review. Low satisfaction scores might trigger a review of product design or customer service procedures, showcasing the process’s impact.

Q 7. Describe your experience conducting internal audits.

Throughout my career, I’ve conducted numerous internal audits across various industries, including manufacturing, software development, and healthcare. My experience encompasses both planning and executing audits, and reporting findings. I’ve used a variety of auditing techniques including document review, observation, and interviews.

For instance, in a recent audit of a manufacturing facility, I identified a gap in their calibration process for critical measuring equipment. This nonconformity posed a risk to product quality. My report detailed the gap, including supporting evidence, and recommended corrective actions. I also worked with the facility management to ensure that the corrective actions were implemented and verified their effectiveness through follow-up.

I consistently focus on objectivity, impartiality, and thorough documentation. My approach emphasizes not just identifying nonconformities, but also recognizing areas of strength and potential opportunities for improvement. It’s about helping organizations strengthen their QMS and build a culture of continuous improvement.

Q 8. How would you handle a nonconformity identified during an audit?

Discovering a nonconformity during an audit is a critical moment. The first step is to understand the nature and scope of the issue. This involves careful documentation, including the specific clause of ISO 9001:2015 that’s not being met, the evidence of nonconformity, and its potential impact.

Next, we need to establish the root cause using appropriate tools like 5 Whys or Fishbone diagrams. This investigation is crucial for preventing recurrence. Once the root cause is identified, we initiate a corrective action to address the immediate nonconformity, focusing on restoring compliance.

Finally, we develop and implement a preventive action to prevent similar nonconformities in the future. This might involve updating procedures, providing additional training, or investing in new equipment. The effectiveness of both corrective and preventive actions needs to be verified and documented. For example, if a nonconformity was found in a welding process due to inconsistent training, the corrective action would be retraining, and the preventive action would be updating the training program to ensure consistency and incorporating regular competency assessments.

Q 9. Explain the concept of corrective actions and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are crucial elements of a robust Quality Management System (QMS). Corrective action addresses existing nonconformities to ensure immediate compliance, while preventive action targets potential issues to avoid future nonconformities. Imagine a leaky faucet (nonconformity): corrective action is fixing the leak; preventive action is regularly checking all faucets to prevent future leaks and perhaps even investing in better quality faucets.

The CAPA process typically involves: identifying the nonconformity, analyzing the root cause(s), implementing corrective actions, verifying the effectiveness of corrective actions, implementing preventive actions, and verifying the effectiveness of preventive actions. Each step needs to be carefully documented, with clear responsibilities and deadlines.

Q 10. Describe your experience with implementing corrective actions.

In my previous role, we had a recurring issue with late delivery of a specific product. Through a thorough root cause analysis involving interviews, data analysis, and process mapping, we discovered the bottleneck was in the procurement of a key component. The corrective action involved expediting the current order and engaging a secondary supplier. The preventive action included negotiating longer-term contracts with both suppliers, improving inventory management techniques, and implementing a more robust risk assessment process for critical components.

We documented all the actions taken, the responsible parties, and the deadlines. We then verified the effectiveness of the actions by monitoring delivery times for the next several months. The results showed a significant improvement in on-time delivery, demonstrating the success of the implemented CAPA process.

Q 11. How do you ensure continuous improvement within a QMS?

Continuous improvement is the cornerstone of ISO 9001:2015. It’s about constantly striving to enhance the effectiveness of the QMS. This involves systematically reviewing processes, gathering data on performance, identifying areas for improvement, implementing changes, and measuring the results. A key tool for this is the Plan-Do-Check-Act (PDCA) cycle.

This cycle is a continuous loop: Plan (define objectives and actions); Do (implement the plan); Check (monitor and measure results); Act (evaluate results and implement further changes if needed). Management review meetings, internal audits, and customer feedback analysis are crucial mechanisms for driving this continuous improvement. For instance, regularly analyzing customer satisfaction surveys can identify areas where processes need refinement or new products/services need to be developed to meet evolving customer expectations.

Q 12. What are the key differences between ISO 9001:2015 and previous versions?

ISO 9001:2015 introduced significant changes compared to previous versions, shifting the focus from documentation to a risk-based approach. Key differences include: a stronger emphasis on risk-based thinking, the adoption of a process approach (not just procedures), a greater focus on leadership commitment, and a more integrated approach to quality management. The term ‘quality manual’ is less important; documented information is now the focus. The structure of the standard also changed, adopting a high-level structure to align with other ISO management systems. Previous versions were more prescriptive and focused on documentation as an end itself, while the 2015 version prioritizes the effectiveness of the QMS in achieving business goals.

Q 13. Explain the importance of documented information in a QMS.

Documented information is the backbone of a functioning QMS. It provides evidence that processes are being controlled and that the organization is meeting its quality objectives. This includes records, procedures, work instructions, and other forms of information. Documented information is not just about compliance; it facilitates communication, process control, and improvement.

For example, documented procedures ensure everyone follows the same steps for a particular task, leading to consistent quality. Records of customer feedback help to identify areas for improvement. The documented information helps to ensure consistency and traceability throughout the QMS which facilitates audits and demonstrates compliance.

Q 14. How do you manage documented information effectively?

Effective management of documented information necessitates a structured approach. This starts with determining what information needs to be documented and why. We need a system to control its creation, review, update, storage, and retrieval. This system should incorporate version control to prevent the use of outdated documents. We may use a document management system (DMS) – this would be a software program to manage the storage and retrieval of documents in a controlled manner. Access controls should be in place to limit access to authorized personnel only. Regular reviews are essential to ensure the accuracy and relevance of the documented information.

For instance, a well-defined document control procedure helps ensure that all versions are properly identified and that obsolete documents are removed from circulation, and a regular document review process can help keep all documents up-to-date, accurate and relevant.

Q 15. Describe your understanding of process approach within ISO 9001:2015.

ISO 9001:2015 emphasizes a process approach, meaning that organizations should understand and manage their interconnected processes to achieve their objectives. Think of it like a well-oiled machine: each part (process) plays a crucial role, and their smooth interaction leads to the desired outcome (meeting customer requirements and improving the organization).

Instead of focusing on individual tasks, the process approach focuses on optimizing the flow of activities from start to finish. This involves identifying all processes, defining their inputs and outputs, understanding their interactions, and measuring their effectiveness. A clear process map visually showing the flow, responsibilities, and interdependencies is vital.

For example, in a manufacturing company, a process might be ‘Order Fulfillment,’ encompassing activities like order entry, production planning, manufacturing, quality control, packaging, and shipping. Understanding and managing this process as a whole, rather than each individual activity in isolation, significantly enhances efficiency and quality.

- Planning: Defining the process, its scope, and required resources.

- Implementation: Carrying out the process according to the defined plan.

- Monitoring: Tracking the process performance and identifying areas for improvement.

- Review and Improvement: Regularly reviewing the process effectiveness and making adjustments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of leadership in establishing and maintaining a QMS.

Leadership plays a paramount role in establishing and maintaining a Quality Management System (QMS). Top management must demonstrate commitment to quality by actively participating in establishing the QMS, ensuring its ongoing suitability, adequacy, and effectiveness. This isn’t just lip service; it requires tangible actions.

- Setting the Quality Policy: Leaders define the organization’s commitment to quality, setting the tone and direction for the entire organization.

- Resource Allocation: They must provide the necessary resources (financial, human, technological) to support the QMS.

- Promoting a Quality Culture: Leaders foster a culture where quality is valued and everyone is empowered to identify and solve quality problems. This includes open communication and employee involvement.

- Accountability: Leaders are responsible for ensuring the QMS is effective and meets its objectives. They should regularly review the performance of the QMS and take corrective actions as needed.

Imagine a ship captain: the captain sets the course, allocates resources (crew, fuel), maintains the ship (QMS), and ensures the crew (employees) works together towards a safe and successful voyage (achieving organizational objectives). The captain’s leadership directly impacts the voyage’s success – similarly, top management’s leadership is pivotal to a successful QMS.

Q 17. How do you ensure the effectiveness of the QMS?

Ensuring QMS effectiveness is an ongoing process involving continuous monitoring, measurement, analysis, and improvement. It’s not a one-time event but a continuous cycle.

- Internal Audits: Regularly scheduled audits assess the conformity of the QMS with the established requirements and identify areas for improvement. These audits should be planned, documented, and followed up.

- Management Review: A periodic review by top management evaluates the QMS’s performance, suitability, and effectiveness. This is a critical opportunity to identify trends, address issues, and make strategic decisions.

- Monitoring and Measurement: Regularly monitoring key performance indicators (KPIs) provides insights into the QMS’s effectiveness. This includes tracking customer satisfaction, defect rates, and process cycle times.

- Corrective Actions: A robust system for identifying and addressing nonconformities and corrective actions is crucial. This ensures that problems are addressed promptly and effectively preventing recurrence.

- Preventive Actions: Proactively identifying potential problems and implementing measures to prevent them is vital. This is a proactive approach to continuous improvement.

Think of it like maintaining a garden: regular checks (internal audits), pruning (corrective actions), and fertilizing (preventive actions) ensure the garden (QMS) thrives and produces the best results.

Q 18. What are the key performance indicators (KPIs) you would use to measure QMS performance?

The specific KPIs used to measure QMS performance will depend on the organization’s context and objectives. However, some common and effective KPIs include:

- Customer Satisfaction: Measured through surveys, feedback forms, and complaint analysis. High customer satisfaction indicates a well-functioning QMS.

- Defect Rate: The percentage of nonconforming products or services. A low defect rate shows effective process control and quality assurance.

- Process Cycle Time: The time taken to complete a process. Reducing cycle time improves efficiency and customer responsiveness.

- On-Time Delivery Rate: The percentage of orders delivered on time. This reflects the organization’s ability to meet customer expectations.

- Internal Audit Findings: The number and severity of audit findings identify areas needing attention and improvement within the QMS.

- Employee Satisfaction: Engaged employees contribute to a more effective QMS. Measuring employee satisfaction helps gauge the organizational culture surrounding quality.

By tracking these KPIs, organizations can monitor the QMS’s performance, identify trends, and focus improvement efforts where they are most needed. Data visualization tools can significantly help in this monitoring and analysis.

Q 19. Describe your experience with ISO 9001:2015 certification audits.

I have extensive experience with ISO 9001:2015 certification audits, both as an auditee and an auditor. As an auditee, I’ve been involved in preparing for and undergoing several certification audits. This involved meticulous documentation review, process mapping, internal audits, and corrective actions. We meticulously prepared all our documentation and procedures and successfully achieved certification.

As an auditor, I have conducted numerous audits for various organizations across different sectors. My role involves evaluating the organization’s QMS against the ISO 9001:2015 standard, identifying conformity and nonconformities, and reporting my findings. I focus on a risk-based approach, identifying areas of higher risk and dedicating more audit time to those.

I am proficient in understanding audit procedures, interpreting audit findings, and communicating effectively with auditees. I’m adept at building rapport with auditees, ensuring a collaborative and productive audit environment.

Q 20. How do you handle customer complaints related to quality issues?

Handling customer complaints related to quality issues requires a systematic and empathetic approach. The goal is to resolve the issue, retain customer trust, and learn from the experience to prevent similar issues in the future.

- Acknowledge and Empathize: Promptly acknowledge the complaint, express empathy for the customer’s frustration, and assure them that their concerns are being taken seriously.

- Investigate Thoroughly: Conduct a thorough investigation to determine the root cause of the problem. This may involve collecting data, interviewing relevant personnel, and reviewing records.

- Implement Corrective Actions: Take corrective actions to address the immediate problem and prevent recurrence. This might involve replacing a defective product, issuing a refund, or modifying a process.

- Communicate the Resolution: Keep the customer informed about the progress of the investigation and the actions being taken to resolve the issue. This open communication rebuilds trust.

- Analyze and Improve: After resolving the issue, analyze the root cause and implement preventative actions to avoid similar problems in the future. This is crucial for continuous improvement of the QMS.

For example, if a customer received a defective product, a prompt apology, a replacement, and a follow-up call demonstrates a commitment to customer satisfaction, turning a negative experience into a positive one.

Q 21. Explain your experience with root cause analysis techniques.

Root cause analysis (RCA) is crucial for understanding the underlying reasons behind quality issues. It goes beyond simply addressing symptoms to identify and eliminate the root causes, preventing recurrence. I have experience using various RCA techniques, including:

- 5 Whys: A simple yet effective technique where you repeatedly ask ‘why’ to uncover the root cause. It’s iterative and helps drill down to the core problem.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps brainstorm potential causes categorized by category (e.g., People, Machines, Methods, Materials, Environment, Measurement). It’s excellent for group discussions.

- Pareto Analysis: This statistical method identifies the vital few causes contributing to the majority of problems. Focusing on these key causes is the most effective use of resources.

- Fault Tree Analysis (FTA): A deductive approach that works backward from the undesirable event to identify its potential causes. It’s helpful for complex problems.

The choice of technique depends on the complexity of the problem and the resources available. Regardless of the chosen technique, thorough documentation and a structured approach are essential. The goal is not just to find a root cause but to develop effective corrective and preventive actions based on the findings.

For instance, if a machine repeatedly malfunctions, the 5 Whys might reveal that the root cause is inadequate maintenance, leading to the implementation of a preventive maintenance schedule. A fishbone diagram could similarly reveal the same issue with other potential contributors more clearly visualized.

Q 22. Describe your experience with using statistical process control (SPC).

Statistical Process Control (SPC) is a powerful tool for monitoring and improving processes by using statistical methods to identify variations and prevent defects. My experience involves implementing and interpreting control charts, such as X-bar and R charts, and using them to track key process parameters. For example, in a previous role manufacturing circuit boards, we used SPC to monitor the soldering process. We tracked the number of solder defects per board, plotting the data on a control chart. When points fell outside the control limits, it signaled a potential problem, prompting us to investigate the root cause (e.g., faulty equipment, operator error). This allowed for timely corrective actions, reducing defects and improving overall product quality. Beyond simple control charts, I’m also familiar with advanced techniques like capability analysis (Cp, Cpk) to assess the process’s ability to meet specifications and process behavior charts to identify patterns and trends.

I’ve also utilized SPC in identifying and reducing waste in a lean manufacturing environment. By tracking cycle times and defect rates, we could visually pinpoint bottlenecks and areas for improvement. This data-driven approach allowed for continuous improvement based on factual evidence rather than assumptions.

Q 23. How do you ensure the competency of personnel involved in the QMS?

Ensuring competency of personnel within a Quality Management System (QMS) is paramount to its success. This involves a multi-faceted approach. First, we need to clearly define roles and responsibilities, ensuring each individual understands their contribution to the overall quality objectives. Next, we implement a robust training program tailored to specific roles and responsibilities. This training goes beyond simple awareness; it includes practical application and competency assessments. For example, in a previous role, we used a blended learning approach combining online modules with hands-on workshops and on-the-job training. We then conducted assessments – both written and practical – to validate their understanding and skills. The training is regularly updated to reflect any changes in processes, standards, or regulations.

Furthermore, ongoing competency development is crucial. We use performance reviews, regular feedback sessions, and opportunities for further professional development to maintain and enhance skills. Documentation of all training and competency assessments is meticulously maintained as part of our audit trail. Finally, we promote a culture of continuous learning, where employees are encouraged to seek out opportunities for improvement and knowledge sharing. We believe investing in our team’s skills leads to improved product quality and overall organizational effectiveness.

Q 24. Explain your understanding of supply chain management within the context of ISO 9001:2015.

Within the ISO 9001:2015 framework, supply chain management is critical. The standard emphasizes the need to control external providers and ensure that procured products and services meet specified requirements. This involves selecting suppliers based on their ability to consistently meet quality requirements, monitoring their performance, and managing any risks associated with their performance. This goes beyond simply checking incoming materials; it requires proactive engagement with suppliers.

Effective supply chain management under ISO 9001:2015 requires establishing clear communication channels with suppliers. This includes defining quality requirements in purchase orders and contracts, ensuring they have the necessary quality management systems in place, and conducting regular audits or reviews of their processes. It’s also important to document all interactions and agreements with suppliers. For instance, we might use supplier scorecards to track performance metrics such as on-time delivery, defect rates, and responsiveness. This allows for objective evaluation and helps identify areas for improvement in the supplier relationships.

Furthermore, managing risks associated with the supply chain, such as disruptions or quality issues, is vital. This may involve creating contingency plans, diversifying supply sources, or implementing robust change control procedures. In summary, a well-managed supply chain under ISO 9001:2015 is essential for ensuring the consistent quality of products and services.

Q 25. Describe your experience with implementing a QMS in a specific industry.

I have extensive experience implementing QMS in the medical device industry. This involved a thorough understanding of the stringent regulatory requirements, including FDA regulations (21 CFR Part 820) and ISO 13485. The implementation followed a phased approach, starting with a gap analysis to assess the existing system against the requirements of ISO 9001:2015 and ISO 13485. This identified areas needing improvement and facilitated the development of a comprehensive implementation plan.

Key aspects included establishing a robust document control system, creating and implementing procedures for design control, risk management, and corrective and preventative actions (CAPA). Employee training was extensive, focusing on the specific requirements of the medical device industry. We conducted internal audits to verify compliance and performed mock regulatory inspections to prepare for external audits. The successful implementation resulted in certification to both ISO 9001:2015 and ISO 13485, demonstrating our commitment to producing safe and effective medical devices. This involved significant collaboration across various departments – engineering, manufacturing, quality assurance, and regulatory affairs – to ensure a fully integrated and effective QMS. Regular management reviews were held to monitor progress, address challenges, and ensure continual improvement of the system.

Q 26. How would you handle a conflict between different departments regarding quality issues?

Conflicts between departments regarding quality issues are common. My approach is to facilitate a collaborative problem-solving process. This starts with clearly defining the issue and gathering information from all involved parties. I ensure everyone feels heard and their concerns are acknowledged. The next step involves identifying the root cause of the conflict, which often lies in differing perspectives, interpretations of standards, or conflicting priorities.

Once the root cause is identified, I would facilitate a brainstorming session to generate potential solutions. This will be a collaborative effort, involving representatives from each department. We would evaluate the proposed solutions based on feasibility, effectiveness, and impact on other processes. The agreed-upon solution would be documented, along with assigned responsibilities and timelines for implementation. Finally, we would monitor the effectiveness of the solution and make necessary adjustments. This process, centered around collaboration and transparency, ensures a fair and equitable resolution that strengthens interdepartmental relationships and improves the overall quality management system. Mediation, if necessary, would be employed to ensure a neutral and productive resolution.

Q 27. What are your strengths and weaknesses in relation to quality management?

My strengths lie in my ability to systematically analyze complex problems, develop effective solutions, and communicate clearly with diverse teams. I’m adept at implementing and maintaining QMS, leading audits, and facilitating continuous improvement initiatives. I thrive in challenging environments and am comfortable making data-driven decisions. I’m also a strong advocate for teamwork and collaboration.

An area for development is my delegation skills. While capable of handling multiple tasks simultaneously, I sometimes find it challenging to fully trust others to perform certain duties to my exact standards. I am actively working on overcoming this by implementing clear delegation procedures and providing more comprehensive training to empower my team members. I believe this proactive approach will allow me to leverage team strengths more effectively and enhance overall efficiency.

Q 28. Where do you see yourself in 5 years in relation to your quality management career?

In five years, I envision myself in a leadership position within a quality management organization, possibly leading a team or overseeing a large-scale QMS implementation. I want to continue developing my expertise in advanced quality methodologies and expanding my knowledge of industry best practices. I also aim to contribute to the development of innovative quality management solutions that enhance efficiency and drive organizational success. My goal is to become a recognized expert in the field, mentoring others, and contributing to the advancement of quality management principles.

Key Topics to Learn for Your ISO 9001:2015 Standard Interview

Ace your interview by mastering these core concepts and their practical applications. Remember, understanding the “why” behind the standard is just as important as knowing the “what”.

- Understanding the Context of ISO 9001:2015: Delve into the purpose and principles of the standard. Focus on its role in achieving customer satisfaction and continuous improvement.

- The Quality Management System (QMS): Explore the structure and implementation of a QMS. Understand how different elements interact and contribute to overall effectiveness.

- Risk-Based Thinking: Learn how to identify, analyze, and address potential risks and opportunities within a QMS. Practice applying risk assessment methodologies.

- Internal Audits & Corrective Actions: Understand the process of conducting internal audits, identifying nonconformities, and implementing effective corrective actions. Practice describing real-world scenarios.

- Management Review: Familiarize yourself with the purpose and process of management reviews and their role in driving continuous improvement within the organization.

- Document Control & Records Management: Understand the importance of controlled documentation and the process of maintaining accurate records. Consider the practical challenges and solutions.

- Process Approach: Grasp the importance of a process-oriented approach to quality management. Practice explaining how different processes interact and contribute to the overall system.

- Continuous Improvement (PDCA Cycle): Master the Plan-Do-Check-Act cycle and its application in a real-world context within a QMS. Be prepared to discuss examples.

Next Steps: Unlock Your Career Potential

Mastering the ISO 9001:2015 standard significantly enhances your value to potential employers, demonstrating your commitment to quality and your ability to contribute to a robust QMS. To maximize your job prospects, it’s crucial to present your skills effectively.

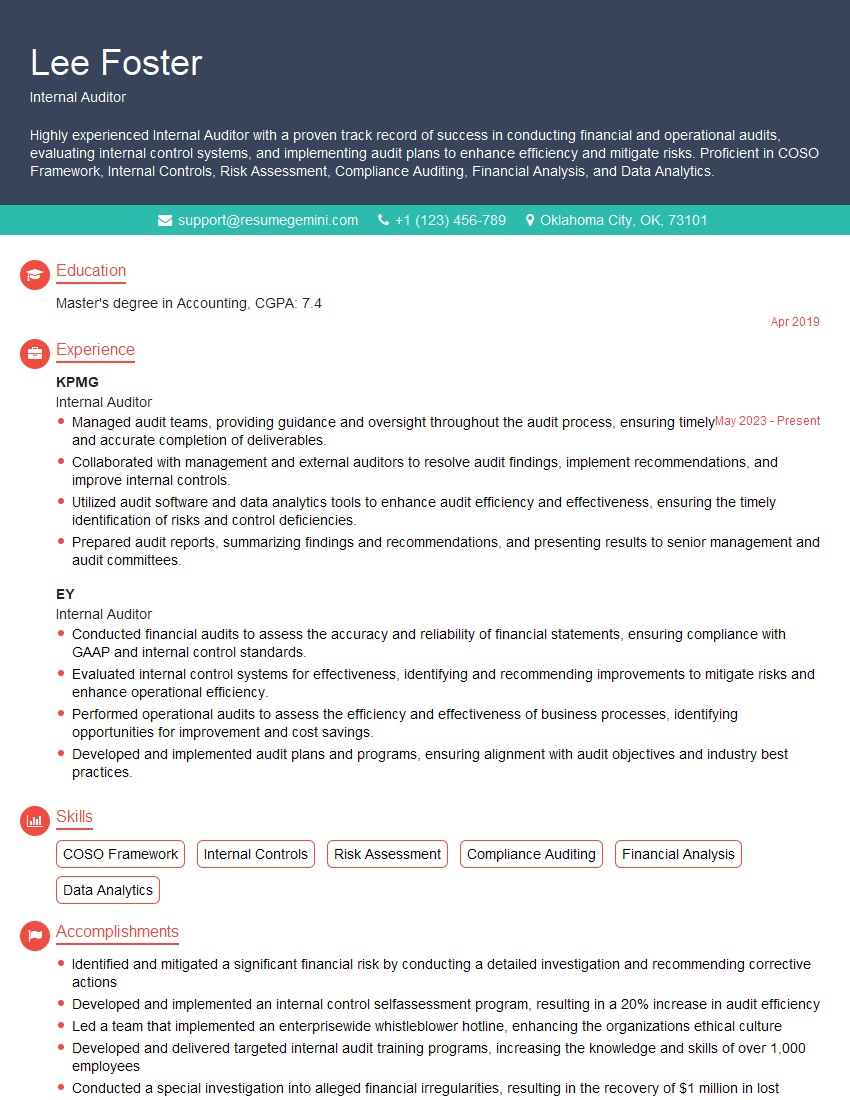

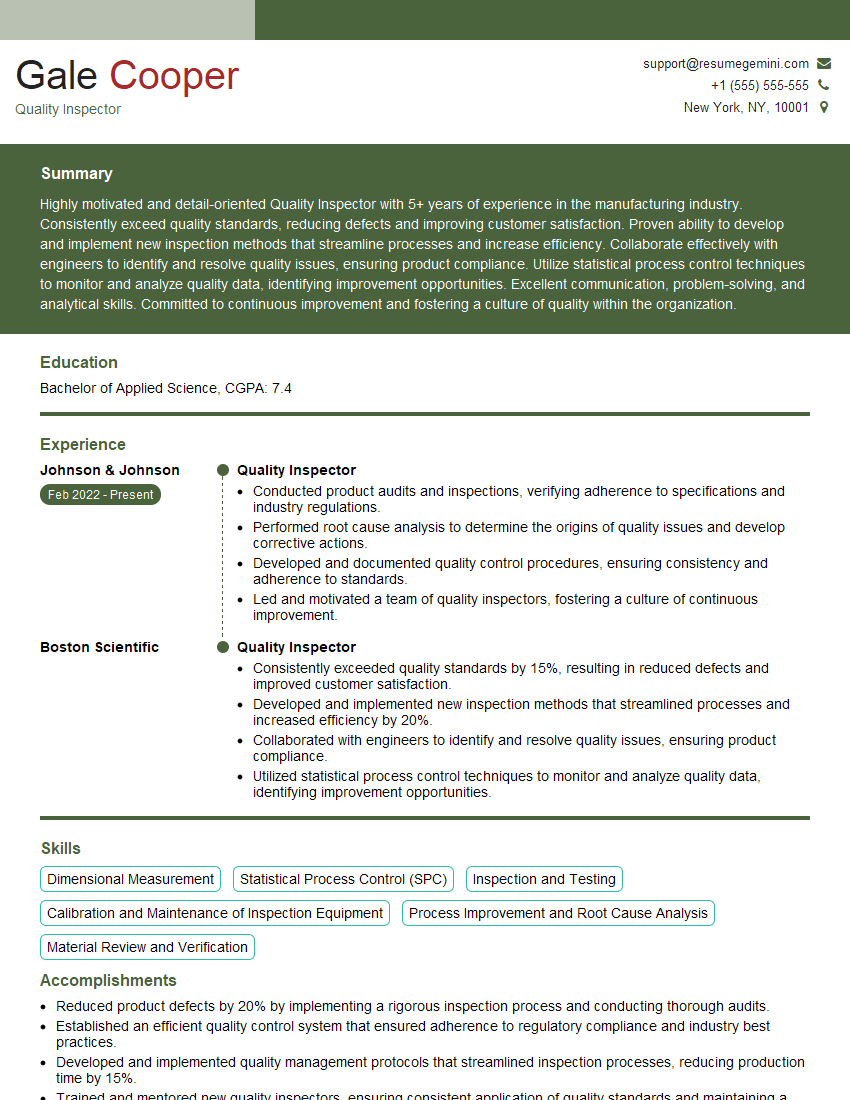

Crafting an ATS-friendly resume is key to getting your application noticed. This ensures your qualifications are highlighted effectively by applicant tracking systems used by many organizations. ResumeGemini is a trusted resource for creating compelling and effective resumes. They offer examples of resumes tailored specifically for candidates with expertise in ISO 9001:2015, allowing you to showcase your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good