Cracking a skill-specific interview, like one for OSHA 29 CFR 1926.1002, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in OSHA 29 CFR 1926.1002 Interview

Q 1. Define the Hazard Communication Standard (HCS) as per OSHA 29 CFR 1926.1002.

OSHA 29 CFR 1926.1002, the Hazard Communication Standard (HCS), is a crucial regulation designed to protect workers from the health hazards associated with exposure to hazardous chemicals in the construction industry. Think of it as a comprehensive communication system ensuring everyone on a job site knows what dangers they might face and how to avoid them. It mandates that employers must provide employees with information about the hazards of chemicals used in the workplace and train them on how to handle them safely.

Q 2. Explain the role of the Safety Data Sheet (SDS) in hazard communication.

The Safety Data Sheet (SDS) is the cornerstone of the HCS. Imagine it as the chemical’s detailed instruction manual. It provides comprehensive information about a hazardous chemical, including its physical and chemical properties, potential health hazards, safe handling procedures, emergency response measures, and more. Employers must ensure SDSs are readily accessible to all employees who may handle the chemical. If a worker needs to know how to safely use a specific chemical, the SDS is their go-to resource.

Q 3. What are the key elements of a proper SDS?

A proper SDS contains sixteen standardized sections as per the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). These sections cover a wide range of information, including identification of the substance, hazards identification (health hazards, physical hazards, environmental hazards), composition/information on ingredients, first-aid measures, fire-fighting measures, accidental release measures, handling and storage, exposure controls/personal protection, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, transport information, regulatory information, and other information. Each section is critical to understanding and managing the risks associated with the chemical.

Q 4. How are labels used to communicate hazards under OSHA 29 CFR 1926.1002?

Labels are the first line of defense in hazard communication. They act as quick, visual warnings directly on the chemical containers. Think of them as the chemical’s ‘stop sign’ or warning label. OSHA mandates that all containers of hazardous chemicals be labeled with specific information, including the product identifier, signal word (danger or warning), hazard statements describing the specific hazards, precautionary statements explaining how to handle the chemical safely, and the supplier’s identification. This ensures workers are alerted to potential dangers before they even begin handling the chemical.

For example, a container of highly corrosive acid will display a skull and crossbones pictogram along with signal words and hazard/precautionary statements explaining the dangers of skin contact and the proper PPE needed.

Q 5. What are the employer’s responsibilities regarding hazard communication?

Employers have a wide array of responsibilities under OSHA 29 CFR 1926.1002. These include developing and implementing a written hazard communication program, obtaining SDSs for all hazardous chemicals used on the job site, ensuring proper labeling of containers, providing training to employees on hazard communication, ensuring that containers of hazardous chemicals are properly labeled, providing employees with access to SDSs, and maintaining records of their hazard communication program. Failure to fulfill these responsibilities can lead to serious penalties and, more importantly, put workers at risk.

For instance, an employer must develop a written hazard communication program which includes a list of all the hazardous chemicals used on the jobsite, the methods they use to inform employees about chemical hazards, and the process for providing employee training. The employer must then provide training to workers that is tailored to the hazards present on the worksite. This training should be done before the employees work with any hazardous chemicals.

Q 6. What are the employee’s rights under the Hazard Communication Standard?

Employees have the right to know about the hazards of the chemicals they work with. This includes access to SDSs, training on chemical hazards and safe handling practices, and the right to a safe working environment. Employees should not hesitate to ask questions about chemicals they use and should report any concerns regarding potential hazards to their supervisor. The HCS empowers workers to protect their own safety and health. For example, an employee has the right to receive training before handling any hazardous chemicals and the right to refuse work they feel is unsafe due to inadequate hazard communication.

Q 7. Describe the different routes of exposure to hazardous chemicals.

Hazardous chemicals can enter the body through various routes of exposure: Inhalation (breathing in fumes, vapors, mists, or dusts), Skin Absorption (direct contact with the skin), Ingestion (accidental swallowing), and Eye Contact (direct contact with the eyes). Understanding these routes is vital for implementing appropriate safety measures. For example, working with a solvent that releases harmful vapors requires adequate ventilation and respiratory protection (Inhalation). Handling a corrosive chemical mandates using appropriate gloves and protective clothing to prevent skin absorption. This understanding of exposure routes facilitates the creation of effective safety protocols, such as using proper PPE and following safe handling procedures.

Q 8. Explain the importance of training employees on hazard communication.

Training employees on hazard communication is paramount to ensuring a safe and healthy work environment. It’s not just about compliance with OSHA 29 CFR 1926.1002; it’s about protecting your workforce. Effective hazard communication training empowers employees to identify, understand, and avoid potential chemical hazards. This prevents accidents, injuries, illnesses, and potential legal liabilities. Think of it like this: you wouldn’t send someone to fight a fire without fire safety training; similarly, you can’t expect workers to handle hazardous chemicals without proper training.

The training equips them with the knowledge to read and understand Safety Data Sheets (SDSs), recognize hazard labels, and follow appropriate safety precautions. It also fosters a culture of safety awareness, encouraging employees to proactively identify and report potential hazards.

Q 9. How do you ensure that all employees receive appropriate hazard communication training?

Ensuring all employees receive appropriate hazard communication training requires a multi-pronged approach. First, training must be provided before an employee handles hazardous chemicals. The training must be readily available and understandable – using simple language and avoiding excessive technical jargon. It should cover all relevant hazards in the workplace, including specific chemicals and processes. We use a combination of methods: interactive training modules, hands-on demonstrations, and regular refresher courses.

Documentation is key. We maintain records of each employee’s training, including the date, the content covered, and proof of completion. This ensures accountability and allows us to track training effectiveness. We also conduct regular audits to verify that employees understand and apply the training. For example, we might perform unannounced observations to see how workers handle chemicals or quiz them on SDS information.

Q 10. What are the requirements for maintaining SDSs and labels?

Maintaining SDSs and labels is a critical component of a successful hazard communication program. SDSs must be readily accessible to employees at all times, either in a central location or electronically. They must be kept up-to-date, reflecting any changes in the chemical’s composition or hazards. Labels must be affixed to all containers of hazardous chemicals, clearly indicating the chemical’s identity, hazards, and precautions.

We use a labeling system that follows the Globally Harmonized System (GHS) standards, ensuring consistency and clarity. Our SDSs are kept in both physical and digital formats to allow easy access. We conduct regular checks to ensure labels are legible, undamaged, and accurately reflect the contents. If a container is transferred to a secondary container, a new label with all the required information must be attached.

Q 11. How do you handle a chemical spill?

Handling chemical spills requires a swift and well-coordinated response to minimize risks. The first step is to immediately evacuate the area, ensuring that no one comes into contact with the spilled chemical. Then, we activate our emergency response plan, which includes contacting emergency services if necessary.

Next, we assess the situation, determining the type and quantity of spilled chemical and the potential hazards involved. The appropriate personal protective equipment (PPE) must be donned before any cleanup begins. This might include respirators, gloves, eye protection, and specialized clothing. We then contain the spill using absorbent materials like spill pads or booms to prevent further spreading. Finally, the spilled chemical is cleaned up according to the SDS recommendations. The area is then thoroughly cleaned and ventilated before personnel are allowed to return.

Q 12. What are the requirements for communicating hazards in non-English languages?

OSHA mandates hazard communication in a language understood by all employees. If non-English speakers are employed, we must provide training and SDSs in their native language. Simply providing a translated version of the SDS isn’t enough; it must be professionally translated to ensure clarity and accuracy. We often use certified translation services to guarantee correctness.

Labels must also be in the language(s) understood by the workers. Pictures and pictograms, which are universally understood, are also vital components, supplementing the written language and further reducing miscommunication. We conduct training sessions in the employees’ native languages, ensuring comprehension and participation.

Q 13. How do you evaluate the effectiveness of your hazard communication program?

Evaluating the effectiveness of our hazard communication program involves a continuous process of monitoring, auditing, and feedback. We track the number of reported incidents, near misses, and any related injuries or illnesses. We regularly audit our SDS storage systems, the labels on containers, and conduct spot-checks to verify that employees are properly using PPE and following procedures.

Employee feedback is critical. We conduct regular surveys and safety meetings to gather input and assess their understanding of the program. We use this feedback to identify areas for improvement and update our training materials or procedures as needed. For example, if employees report difficulty understanding a particular SDS, we might revise it or provide additional clarification.

Q 14. Explain the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system for classifying and communicating chemical hazards. It aims to provide a standardized approach to hazard communication, making it easier for workers worldwide to understand the risks associated with chemicals, regardless of the country of origin or manufacturer. The GHS uses a consistent set of hazard pictograms, signal words, and hazard statements to clearly communicate the risks.

The system reduces confusion caused by differing national standards and facilitates international trade of chemicals. Key aspects of GHS include: classification of chemicals based on their hazards; standardized hazard labels including pictograms, signal words, hazard statements and precautionary statements; and Safety Data Sheets (SDSs) with a consistent format containing detailed information about the chemical’s hazards and safe handling practices. Adopting the GHS ensures that our hazard communication program aligns with global best practices, enhancing worker safety and streamlining our processes.

Q 15. What are the differences between the old HCS and the GHS?

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) significantly updated the old Hazard Communication Standard (HCS). The old HCS was a patchwork of different labeling and classification systems, leading to inconsistencies across industries and countries. GHS aimed to create a globally consistent approach. Key differences include:

- Pictograms: GHS introduced standardized pictograms for quick hazard identification, replacing the previous system’s less consistent labeling.

- Hazard Classification: GHS uses a more comprehensive and standardized system for classifying chemical hazards, expanding the number of hazard classes and categories.

- Signal Words: GHS uses standardized signal words (‘Danger’ and ‘Warning’) to indicate the severity of a hazard, unlike the previous more varied system.

- Safety Data Sheets (SDS): GHS mandates a 16-section SDS format, improving consistency and ease of information retrieval compared to the older Material Safety Data Sheets (MSDS).

- Labeling Requirements: GHS mandates a more detailed and consistent label format, including specific elements like pictograms, signal words, and hazard statements.

Think of it like updating from a handwritten recipe book (old HCS) with varying formats and ingredients to a professionally published cookbook (GHS) with standardized recipes and units of measurement – far easier to understand and follow consistently.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do pictograms communicate hazard information under GHS?

GHS pictograms are graphical symbols representing specific hazard classes. They’re designed for immediate visual understanding, regardless of language. Each pictogram has a distinct shape and symbol, conveying the type of hazard. For example:

- Flame: Indicates flammability.

- Exclamation mark: Signals irritant, health hazard, or other less severe hazards.

- Corrosion: Represents corrosive chemicals.

- Gas cylinder: Warns of gases under pressure.

- Skull and crossbones: Indicates acute toxicity.

- Exploding bomb: Signifies explosives.

- Environment: Alerts to environmental hazards.

- Health hazard: Indicates various health hazards (carcinogen, mutagen, etc.).

Imagine walking into a lab; seeing a skull and crossbones immediately tells you to proceed with extreme caution, regardless of your native language.

Q 17. Explain the different hazard classes under GHS.

GHS classifies chemicals into various hazard classes, each with subcategories. Some key classes include:

- Physical Hazards: Explosives, flammables, oxidizers, gases under pressure, self-reactive substances, pyrophorics, self-heating substances, water-reactive substances, corrosives.

- Health Hazards: Acute toxicity (oral, dermal, inhalation), skin corrosion/irritation, serious eye damage/eye irritation, respiratory sensitization, skin sensitization, germ cell mutagenicity, carcinogenicity, reproductive toxicity, specific target organ toxicity (single or repeated exposure), aspiration hazard.

- Environmental Hazards: Aquatic toxicity (acute or chronic).

This classification system allows for a thorough hazard assessment, ensuring appropriate safety measures are implemented based on the specific nature of the chemical’s hazards.

Q 18. How are signal words used in GHS?

GHS uses two signal words to communicate the relative severity of hazards: ‘Danger’ and ‘Warning’.

- Danger: Indicates a high degree of hazard and signifies immediate and potentially severe health effects or a high probability of serious physical hazards.

- Warning: Indicates a moderate degree of hazard and may still involve serious health effects or physical hazards but with a lesser probability of severe effects or a less immediate threat.

Think of it like traffic signals; ‘Danger’ is a red light, requiring immediate attention and cessation of activity, while ‘Warning’ is a yellow light, cautioning slower approach and careful consideration.

Q 19. What are the requirements for employee training under GHS?

GHS mandates comprehensive employee training on all aspects of the hazard communication program. Training must cover:

- Hazard identification: How to recognize and understand the hazards of chemicals in the workplace.

- SDS use: How to locate, understand, and interpret SDS information.

- Labeling systems: How to understand and interpret chemical labels, including pictograms, signal words, and hazard statements.

- Appropriate safety measures: Handling, storage, use, and emergency procedures for chemicals.

- Emergency procedures: Actions to take in the event of an accident or spill.

Training must be provided initially and whenever a new chemical is introduced or whenever changes occur in the hazard communication program. Employers must ensure employees understand their role in hazard prevention and mitigation.

Q 20. Describe your experience with developing and implementing a hazard communication program.

In my previous role, I was responsible for developing and implementing a comprehensive hazard communication program for a construction site. This involved:

- Chemical Inventory: Conducting a thorough inventory of all hazardous chemicals present on the site.

- SDS Collection and Organization: Gathering and organizing all relevant SDSs, ensuring they were readily accessible to employees.

- Labeling System Implementation: Ensuring all containers were properly labeled according to GHS requirements.

- Training Program Development and Delivery: Creating and delivering a comprehensive training program to educate employees about hazard identification, SDS interpretation, and safety procedures.

- Program Updates and Maintenance: Regularly reviewing and updating the program to reflect changes in chemicals, processes, or regulatory requirements.

- Record Keeping: Maintaining detailed records of all aspects of the program, including employee training records, chemical inventories, and SDS updates.

This resulted in a significant improvement in workplace safety, reducing incidents involving chemical exposure and promoting a culture of safety awareness among workers. We had a 30% reduction in chemical-related incidents after implementation.

Q 21. How do you ensure compliance with OSHA 29 CFR 1926.1002?

Ensuring compliance with OSHA 29 CFR 1926.1002 requires a multi-faceted approach:

- Proactive Hazard Identification: Regularly assessing and identifying all hazardous chemicals on the worksite.

- Comprehensive Training: Providing thorough and ongoing training to all employees.

- Accurate Labeling and SDS Management: Ensuring that all containers are properly labeled and that up-to-date SDSs are readily accessible.

- Regular Inspections: Conducting regular inspections to verify compliance with all requirements of the standard.

- Record Keeping: Maintaining detailed records of all aspects of the hazard communication program.

- Staying Updated: Regularly reviewing and updating the program to reflect changes in chemicals, processes, or regulatory requirements.

Compliance is not a one-time event but an ongoing process requiring vigilance and commitment to maintaining a safe work environment. Regular audits and employee feedback are crucial to identifying gaps and ensuring continuous improvement.

Q 22. What are some common violations related to hazard communication?

Common violations related to hazard communication under OSHA 29 CFR 1926.1002 often stem from a lack of comprehensive programs or failure to adhere to established procedures. These include:

- Failure to provide adequate Safety Data Sheets (SDSs): This could involve missing SDSs altogether, having outdated SDSs, or not making them readily accessible to employees. For instance, keeping SDSs locked away in a supervisor’s office is a violation.

- Lack of proper labeling of hazardous chemicals: Containers without proper labels, or labels that are illegible or incomplete (missing hazard pictograms, signal words, etc.), are frequently cited violations. Imagine a chemical container with just a handwritten name – that’s insufficient.

- Inadequate employee training: Employees must receive training on the hazards of the chemicals they handle and how to work safely with them. Simply having a training document signed isn’t enough; it must demonstrate understanding.

- Insufficient hazard communication program: The entire hazard communication program needs to be well-documented and regularly updated. This includes written procedures, employee training records, and a list of hazardous chemicals present in the workplace.

- Failure to update the hazard communication program when new chemicals are introduced or when changes are made to existing chemicals: This requires proactive review and updating of all relevant materials.

Q 23. How would you address a non-compliant situation related to hazard communication?

Addressing a non-compliant situation regarding hazard communication requires a multi-step approach. First, I would conduct a thorough assessment to identify the specific violations. This involves reviewing existing SDSs, labels, training records, and the overall hazard communication program. Then:

- Immediate corrective action: This could involve immediately labeling improperly labeled containers, providing missing SDSs, or halting work with hazardous chemicals until corrective measures are in place.

- Employee training: Retraining might be necessary to ensure employees understand the hazards associated with the chemicals and the appropriate safety procedures. I would also make sure the training is documented.

- Program update: The hazard communication program would need to be updated to reflect the corrective actions and ensure ongoing compliance. This might involve revising the chemical inventory, updating SDSs, and creating new training materials.

- Documentation: Meticulous documentation of all corrective actions, training records, and program updates is crucial to demonstrate compliance to OSHA.

- Follow-up inspections: Regular inspections would be conducted to ensure that the corrective actions are effective and that the program remains compliant.

Throughout this process, open communication with employees is essential. Creating a culture of safety where employees feel comfortable reporting concerns is key to preventing future violations.

Q 24. Describe your experience with conducting hazard assessments.

My experience with conducting hazard assessments involves a systematic approach, typically following a hierarchical process. I begin by identifying all potential hazards in the workplace through walkthroughs, reviewing previous incident reports, and consulting with workers. Then:

- Hazard identification: I create a comprehensive list of all potential hazards, including physical (noise, slips, trips, falls), chemical (exposure to hazardous substances), biological (bacteria, viruses), ergonomic (repetitive movements), and psychosocial (stress, violence) hazards.

- Risk assessment: I evaluate the likelihood and severity of each hazard, typically using a matrix approach, which considers the probability of occurrence and the potential consequences. This helps prioritize hazards based on their risk level.

- Control measures: I develop and implement control measures based on the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, and PPE). This might involve redesigning workstations, implementing safety procedures, or providing personal protective equipment (PPE).

- Monitoring and review: Once control measures are implemented, ongoing monitoring is critical to ensure their effectiveness. Regular hazard assessments are scheduled to review the effectiveness of controls and identify any emerging hazards.

I’ve conducted these assessments in various settings, including construction sites, manufacturing facilities, and offices, adapting my approach based on the specific environment and hazards present. This approach ensures a safe and healthy work environment. For example, in a construction project, I’d pay close attention to fall hazards, while in a chemical lab, my focus would be on chemical exposures and appropriate handling procedures.

Q 25. How do you manage changes to chemicals in the workplace?

Managing changes to chemicals in the workplace requires a proactive and documented approach. Whenever a new chemical is introduced or a change occurs to an existing chemical (e.g., a new supplier, a new formulation), the following steps must be taken:

- Obtain the new SDS: The SDS from the supplier must be obtained immediately. It must be reviewed to identify any changes in hazards, handling requirements, or control measures.

- Update the chemical inventory: The chemical inventory must be updated to reflect the change, noting the new chemical or the revised information for the existing chemical.

- Update labels: Containers of the chemical must be properly labeled to reflect any changes in hazard information. This might involve replacing old labels with new ones.

- Employee training: Employees who handle the chemical must receive updated training to cover any changes in hazards or handling procedures.

- Update the hazard communication program: The hazard communication program should be updated to reflect these changes, including revised training materials and updated SDSs.

- Document all changes: All changes should be documented, including the date of the change, the nature of the change, and the actions taken to address it.

This rigorous approach ensures that employees are always aware of the potential hazards associated with the chemicals they are working with and that appropriate control measures are in place.

Q 26. How do you maintain records related to hazard communication?

Maintaining records related to hazard communication is critical for demonstrating compliance. This involves keeping detailed records of:

- Safety Data Sheets (SDSs): SDSs must be readily accessible to employees. They should be stored in a designated location and updated as needed. A system for tracking versions and ensuring employees have access to the most current SDS is essential.

- Chemical inventory: A detailed list of all hazardous chemicals present in the workplace, including the location of storage, should be maintained. This list should be regularly reviewed and updated.

- Labels: Ensure that all containers of hazardous chemicals are properly labeled and that labels are legible and up-to-date. Take photos of the labels to keep on file.

- Employee training records: Detailed training records for all employees who handle hazardous chemicals should be maintained. This should include the date of training, the topics covered, and the names of the trainees.

- Hazard assessments: Records of all hazard assessments, including the methodology used, the hazards identified, and the control measures implemented, should be retained.

- Program updates: Documentation of all changes made to the hazard communication program, including updates to SDSs, training materials, or chemical inventory, is also important.

These records should be stored securely and maintained for a period of time as defined by OSHA and company policy. Digital record-keeping and a well-organized system are highly recommended.

Q 27. Explain your understanding of the responsibilities of a Safety Data Sheet (SDS) author.

The responsibilities of a Safety Data Sheet (SDS) author are significant. They are legally responsible for ensuring the accuracy and completeness of the SDS. This includes:

- Accurate identification of hazards: The SDS author must accurately identify all the known hazards associated with the chemical, including physical, health, and environmental hazards.

- Complete composition information: The author must provide complete information on the chemical’s composition, including the identity and concentration of all components.

- Appropriate hazard statements: The SDS must include appropriate hazard statements, using standardized language and pictograms as defined by Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

- Appropriate precautionary measures: The SDS must provide clear and concise guidance on appropriate precautionary measures to minimize the risks associated with the handling, storage, and disposal of the chemical.

- Compliance with regulations: The SDS author must ensure that the SDS complies with all relevant local, national, and international regulations.

The author needs a strong understanding of toxicology, chemistry, and relevant regulations to fulfil this role. They might be an employee of the chemical manufacturer or a specialized consultant.

Q 28. How do you ensure the accuracy and completeness of SDSs?

Ensuring the accuracy and completeness of SDSs requires a multi-faceted approach:

- Thorough review process: A rigorous review process involving multiple individuals with expertise in toxicology, chemistry, and regulatory compliance is crucial. This cross-check minimizes errors.

- Use of standardized templates: Using a standardized template ensures that all the necessary information is included and presented consistently.

- Regular updates: SDSs must be regularly updated to reflect any new information on hazards, handling, or regulatory requirements. Changes in the composition or intended use of the chemical necessitate updates.

- Verification of data sources: All information provided in the SDS should be verified from reliable sources, such as scientific literature, toxicological studies, and regulatory databases.

- Internal and external audits: Regular internal and external audits can help identify any inconsistencies or gaps in the SDS.

By adhering to these practices, the SDS author can help ensure that employees have access to accurate and up-to-date information to work safely with hazardous chemicals. Think of it like building a house – a solid foundation, consistent construction, and regular inspections ensure a safe and strong structure.

Key Topics to Learn for OSHA 29 CFR 1926.1002 Interview

- Hazard Communication: Understanding the requirements for labeling, safety data sheets (SDS), and employee training related to hazardous materials in construction.

- Employee Training: Practical application of training methods and documentation to ensure workers understand and follow safety protocols concerning hazardous materials.

- Exposure Monitoring and Control: Methods for monitoring employee exposure to hazardous substances, including air monitoring techniques and implementation of engineering and administrative controls.

- Personal Protective Equipment (PPE): Selecting, using, and maintaining appropriate PPE for different hazards covered under the standard, including respirators and other specialized equipment.

- Medical Surveillance: Understanding the requirements for medical evaluations and the role of medical professionals in protecting worker health from hazardous substance exposure.

- Recordkeeping: Properly maintaining records of training, monitoring, and medical surveillance to comply with OSHA regulations.

- Emergency Response: Developing and implementing procedures for handling spills, leaks, and other emergencies involving hazardous materials.

- Compliance Procedures: Understanding the steps involved in ensuring compliance with OSHA 29 CFR 1926.1002, including inspections, audits, and corrective actions.

- Practical Problem Solving: Analyzing hypothetical scenarios involving hazardous material exposure and applying your knowledge to devise effective solutions.

Next Steps

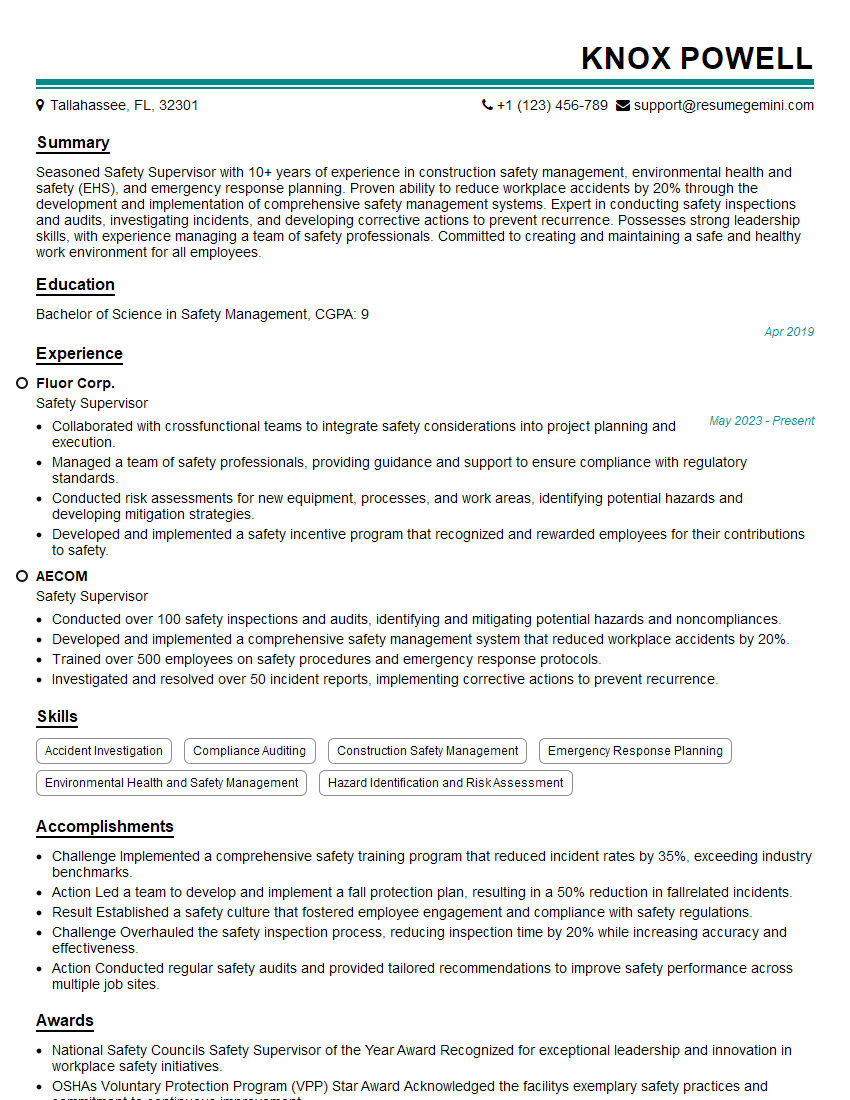

Mastering OSHA 29 CFR 1926.1002 demonstrates a crucial commitment to workplace safety, significantly enhancing your value to any construction or related employer. This knowledge translates directly into higher earning potential and more advanced career opportunities. To maximize your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise. Examples of resumes tailored to showcasing OSHA 29 CFR 1926.1002 knowledge are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good