Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Visual Grading interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Visual Grading Interview

Q 1. Explain the difference between subjective and objective visual grading.

The core difference between subjective and objective visual grading lies in the degree of quantifiable measurement. Subjective grading relies heavily on the inspector’s judgment and interpretation. It’s often based on general descriptions like ‘good,’ ‘fair,’ or ‘poor,’ making it susceptible to individual biases and inconsistencies. Think of judging the ‘aesthetic appeal’ of a handcrafted item – beauty is in the eye of the beholder. Objective grading, on the other hand, uses standardized scales and defined criteria. It minimizes personal interpretation by assigning numerical values or specific categories to observable defects. For instance, measuring the number of scratches per square inch on a polished surface is objective. The result is more consistent and reproducible.

Q 2. Describe your experience with different types of visual grading scales (e.g., numerical, categorical).

My experience encompasses a wide range of visual grading scales. Numerical scales, like a 1-to-10 rating system where 10 represents perfect condition, offer a degree of precision. However, the interpretation of the numerical values can still vary among inspectors. Categorical scales are often more robust. They divide the graded items into predefined categories based on the severity of defects. For example, a scale could classify defects as ‘Minor,’ ‘Moderate,’ ‘Major,’ and ‘Critical.’ I’ve also worked with scales combining numerical and categorical approaches, assigning a numerical value within each category. For example, a ‘Moderate’ defect could be further sub-categorized as ‘Moderate 1,’ ‘Moderate 2,’ and ‘Moderate 3’ based on size or impact. This hybrid approach can be advantageous in balancing precision and ease of interpretation.

Q 3. How do you ensure consistency in visual grading across multiple inspectors?

Consistency is paramount in visual grading. We achieve this through several key strategies. First, rigorous training is crucial. Inspectors undergo extensive training on the specific grading scale, defect definitions, and proper inspection techniques. This includes hands-on practice with sample items and standardized procedures. Second, we implement regular calibration exercises using standardized samples. This allows us to identify and address any inconsistencies in interpretation among the inspectors. Third, clear, well-defined criteria are fundamental. Detailed documentation, including images and descriptions of each defect category, minimizes ambiguity and maximizes consistency. Finally, statistical process control (SPC) techniques are used to monitor the grading process, identifying trends and potential sources of variation. Regular audits and reviews further reinforce consistent application of the grading standards.

Q 4. What are the common challenges faced in visual grading, and how do you overcome them?

Common challenges in visual grading include subjectivity, as mentioned earlier, fatigue, which can lead to inconsistencies over long inspection periods, and lighting variations which can significantly affect the perception of defects. To overcome these, we employ a combination of solutions. Standardized lighting conditions, using calibrated light sources, mitigate lighting variations. Regular breaks and shift changes are implemented to address fatigue. The use of objective scales and regular calibration exercises minimize the impact of subjectivity. We also utilize digital imaging and image analysis software in certain cases to provide an objective record of the defects and reduce human error.

Q 5. Describe your experience with different types of visual defects (e.g., scratches, discoloration, dents).

My experience includes evaluating a wide range of visual defects. Scratches are graded based on their length, depth, and number. Discoloration is assessed based on its extent, intensity, and uniformity. Factors considered include the type of discoloration (e.g., staining, fading). Dents are evaluated based on their size, depth, and location. The impact of the dent on the overall functionality or aesthetics of the item is also factored in. Other common defects include pitting, cracks, blisters, and inclusions (foreign material embedded in the product). For each defect type, detailed criteria, including images and descriptions, are used for consistent evaluation.

Q 6. How do lighting and environmental conditions affect visual grading accuracy?

Lighting and environmental conditions significantly influence visual grading accuracy. Insufficient lighting can mask minor defects, while excessive lighting can create glare, obscuring or distorting the appearance of defects. Ambient light variations can lead to inconsistencies. Temperature and humidity can also affect the material properties, influencing the appearance of defects. To mitigate these effects, we maintain controlled environments during inspections, using standardized lighting sources with consistent intensity and color temperature. The environment is carefully regulated to minimize temperature and humidity fluctuations. This provides consistent lighting conditions throughout the inspection process, crucial for accurate and repeatable results.

Q 7. What are the best practices for documenting visual grading results?

Best practices for documenting visual grading results involve a combination of methods. Detailed reports, including the grading scale used, specific defect descriptions, and numerical or categorical grades assigned to each defect, are essential. Photographs or digital images of the defects are incorporated into the documentation, offering visual evidence to support the grading. The use of standardized forms ensures consistency in information collection and reduces ambiguity. Digital databases provide efficient storage and retrieval of grading results, allowing for easy access and analysis. Traceability is critical, ensuring that the inspector’s identity, date, and time of inspection are accurately recorded alongside the grading results. This detailed documentation provides a comprehensive record of the grading process and is crucial for quality control, dispute resolution, and continuous improvement.

Q 8. Explain your experience with using magnification tools in visual grading.

Magnification tools are essential in visual grading, allowing for the detailed inspection of features often invisible to the naked eye. My experience spans various tools, from simple magnifying glasses and jeweler’s loupes to sophisticated stereo microscopes and digital microscopes with integrated imaging capabilities. The choice of tool depends heavily on the material being graded and the level of detail required. For instance, inspecting the surface finish of a precision-engineered part might require a stereo microscope providing high magnification and depth perception, while assessing minor imperfections on a textile might only need a strong magnifying glass. I’m proficient in using these tools to accurately assess surface defects, color variations, and dimensional inconsistencies, meticulously documenting findings with photographs or digital images when necessary.

For example, while grading a batch of ceramic tiles, I used a digital microscope to identify microscopic cracks that were undetectable to the naked eye. This allowed for the rejection of tiles that would likely fail in service. In another instance, I used a stereo microscope to examine the intricate details of a printed circuit board (PCB), ensuring the soldering was free of defects and that the component placement was accurate.

Q 9. How do you handle disagreements on grading decisions with colleagues?

Disagreements in visual grading are inevitable, given the subjective nature of some assessments. My approach focuses on collaborative problem-solving and a commitment to objective evaluation. First, we revisit the grading criteria and standards, ensuring we are both interpreting them consistently. This often involves reviewing the established grading guidelines and referencing any relevant standards or specifications. If a discrepancy persists, we thoroughly examine the sample together, using the appropriate magnification tools. Often, a second opinion from a senior grader might be sought. If the difference still cannot be resolved, we may use objective measurements from calibrated instruments to assist with the decision. The goal is always to reach a consensus that aligns with established quality control practices. Open communication and a mutual respect for each other’s expertise are key to resolving these situations professionally and constructively.

Q 10. Describe your experience with different types of materials and their unique visual grading requirements.

My experience encompasses a wide range of materials, each presenting unique visual grading challenges. For instance, grading textiles requires assessing factors like fabric weave, color consistency, and the presence of imperfections like knots or broken threads. This often involves using different lighting conditions to highlight subtle variations in color or texture. Grading plastics involves inspecting for surface scratches, discoloration, and variations in thickness or clarity. The techniques and tools used for grading metals differ again, focusing on surface finish, the presence of pitting or corrosion, and dimensional accuracy. This might involve using specialized tools like surface roughness meters in addition to visual inspection. I have developed a keen eye for the subtle nuances of various materials and have adapted my techniques accordingly, always maintaining a high standard of consistency and accuracy.

For example, while grading a batch of injection-molded plastic parts, I identified a subtle variation in gloss across different areas which was imperceptible without using a controlled light source. This indicated a potential problem in the molding process, leading to improved process control. While grading woven fabrics, I used specialized lighting to highlight imperfections that weren’t visible under typical lighting conditions.

Q 11. What software or tools have you used for image analysis and visual grading?

Throughout my career, I’ve utilized a variety of software and tools for image analysis and visual grading. These include dedicated image analysis software packages offering features like image enhancement, measurement tools, and defect detection algorithms. Specific examples include ImageJ (for basic analysis and measurement), and specialized software provided by microscope manufacturers. I have also used digital microscopes with integrated image capture and analysis capabilities, greatly streamlining the process of documenting findings and sharing them with colleagues. In addition, I’m proficient in using various photo editing software to standardize lighting and enhance image clarity for more detailed analysis. The selection of software is influenced by the material being examined and the specific analysis tasks involved.

Q 12. How do you ensure the accuracy and reliability of your visual grading assessments?

Ensuring accuracy and reliability is paramount in visual grading. This is achieved through a multi-faceted approach. First, strict adherence to established grading standards and protocols is crucial. Second, I regularly participate in inter-laboratory comparisons and proficiency testing to ensure my grading results are consistent with industry benchmarks. Regular calibration and maintenance of all equipment, including microscopes and measuring devices, are also essential for consistent and reliable results. Maintaining detailed records of each grading session, including images and notes, creates a traceable audit trail, further enhancing the reliability of my assessments. Moreover, continuous professional development and participation in relevant training keeps me updated with the latest techniques and best practices.

Q 13. Explain your approach to training new visual graders.

Training new visual graders is a structured process involving both theoretical and practical components. It begins with a thorough review of the relevant grading standards, including detailed explanations of acceptable and unacceptable characteristics. Hands-on training involves working alongside experienced graders, observing their techniques, and participating in grading sessions under supervision. I use a combination of techniques, including shadowing, guided practice, and feedback sessions, to help trainees develop the necessary skills and judgment. I emphasize the importance of consistent lighting and controlled viewing conditions, as these significantly influence the accuracy of grading. Regular assessments and feedback sessions are crucial to monitor progress and address any areas needing improvement. The goal is to foster a solid understanding of grading protocols and to develop a keen eye for detail, ensuring consistency and accuracy across all graders.

Q 14. Describe your experience with statistical process control (SPC) in visual grading.

Statistical Process Control (SPC) plays a vital role in ensuring consistent and reliable visual grading. By tracking key metrics, like the number of defects per unit or the percentage of rejected items, we can identify trends and patterns that indicate potential process issues. Control charts are invaluable tools in this context; they allow for the early detection of deviations from expected values, enabling timely corrective actions. I have extensive experience in applying SPC principles to visual grading processes, identifying and addressing sources of variation that might affect grading consistency. This ensures the entire grading process remains within established quality control limits, maintaining the overall quality and reliability of our assessments.

For example, if we observe a sudden increase in the number of rejected parts, an SPC chart would highlight this deviation. This might lead to an investigation into the manufacturing process or a review of the grading process itself, leading to identification and resolution of the root cause.

Q 15. How do you handle a large volume of samples requiring visual grading within tight deadlines?

Handling a large volume of samples within tight deadlines requires a strategic approach. It’s not just about speed, but maintaining accuracy. My strategy involves a combination of efficient workflow management and potentially leveraging technology where appropriate.

- Prioritization and Batching: I categorize samples based on urgency and similarity, processing batches of similar items to optimize workflow. This minimizes context switching and improves efficiency.

- Teamwork and Delegation: If the volume necessitates, I coordinate with colleagues, assigning tasks based on individual strengths and expertise. Clear communication and standardized grading protocols are crucial for consistency.

- Technology Integration: Automated image analysis software can assist with pre-screening or objective measurements, allowing me to focus on the more nuanced aspects of visual grading requiring human expertise.

- Process Optimization: Continuous evaluation of the grading process helps identify bottlenecks. For example, refining the grading criteria or improving sample handling can significantly reduce processing time without compromising quality.

For instance, in a recent project involving thousands of textile samples, we implemented a system of pre-sorting by color category, followed by parallel grading within each category. This improved efficiency by approximately 30% compared to a linear processing approach.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) you use to measure your effectiveness in visual grading?

Key Performance Indicators (KPIs) for visual grading must reflect both speed and accuracy. I use a combination of quantitative and qualitative measures:

- Grading Speed: Samples graded per hour or per day, measured over consistent periods. This helps track efficiency trends.

- Accuracy Rate: This is crucial. It involves comparing my grading results with those of a highly experienced grader or a reference standard. A high percentage agreement demonstrates consistent, accurate grading.

- Defect Detection Rate: This measures how effectively I identify imperfections. This KPI can be broken down by defect type for a more detailed analysis.

- Rework Rate: The percentage of samples requiring re-grading due to initial errors provides valuable feedback for improving the process.

- Client Satisfaction: Feedback from clients regarding the accuracy and timeliness of my grading is essential. This qualitative data provides a real-world perspective.

Regularly monitoring these KPIs provides insights into personal performance, identifies areas for improvement, and helps justify the resources dedicated to visual inspection.

Q 17. How do you stay updated on the latest advancements in visual grading techniques?

Staying current in visual grading requires continuous learning. I utilize several strategies:

- Professional Organizations: Membership in relevant organizations provides access to conferences, workshops, and publications featuring the latest research and techniques.

- Industry Publications and Journals: Regularly reviewing industry-specific publications keeps me abreast of new technologies and methodologies.

- Online Courses and Webinars: Numerous online resources offer specialized training in visual grading, color science, and related fields.

- Networking with Colleagues: Sharing experiences and best practices with other graders through professional networks offers valuable insights and perspectives.

- Vendor Demonstrations: Attending demonstrations of new equipment or software from vendors provides hands-on experience with the latest advancements.

For instance, I recently completed a course on advanced digital imaging techniques for material analysis which significantly improved my ability to detect subtle surface imperfections.

Q 18. Describe a time when you had to make a difficult grading decision.

I once had to grade a batch of ceramic tiles where a small number exhibited a subtle variation in glaze consistency – barely noticeable to the naked eye. The client’s specifications were extremely strict, and the difference didn’t clearly fall into the defined “acceptable” or “unacceptable” categories.

My approach involved:

- Careful Documentation: I meticulously photographed each tile, noting the variation in lighting conditions to eliminate bias.

- Reference Samples: I compared the tiles to reference samples provided by the client, analyzing the subtle differences under various lighting conditions.

- Expert Consultation: I discussed the ambiguous cases with a senior colleague, leveraging their experience to reach a consensus.

While it was time-consuming, this systematic approach ensured consistency and minimized the risk of making a subjective judgment that could have impacted client satisfaction. The outcome was a clear, defensible grading report that satisfied the client.

Q 19. Explain your understanding of colorimetric analysis and its application in visual grading.

Colorimetric analysis is a scientific method for measuring and quantifying color. It involves using instruments like spectrophotometers to determine the spectral reflectance or transmittance of a material. This data is then used to calculate color coordinates (like L*a*b*) which provides an objective representation of the color. This is very different from subjective visual assessment.

In visual grading, colorimetric analysis plays a crucial role in:

- Objective Color Assessment: It eliminates the subjectivity inherent in human color perception, creating a standard for comparing colors across different samples or batches.

- Color Matching: It assists in matching colors for consistency across a product line.

- Defect Detection: Variations in color can indicate defects or inconsistencies in the manufacturing process. Colorimetric analysis can objectively identify these variations.

- Metamerism Identification: Colorimetric analysis can detect metamerism – two colors appearing identical under one light source but different under another. This is essential for ensuring consistent color perception across different environments.

For example, in the textile industry, colorimetric analysis ensures consistent dye lots by quantifying the color of each batch, preventing subjective discrepancies.

Q 20. How do you identify and classify different types of surface imperfections?

Identifying and classifying surface imperfections requires a systematic approach, often combined with magnification aids (microscopes, loupes). Classification is usually material-specific, but general categories exist:

- Scratches: Linear imperfections caused by abrasion. Classified by depth, length, and direction.

- Dents or Indentations: Depressions in the surface, characterized by their size, depth, and shape.

- Cracks: Breaks in the material, categorized by their length, width, and branching patterns.

- Pits or Pores: Small holes or cavities in the surface.

- Discoloration: Uneven or abnormal color variations, described by their size, intensity, and location.

- Foreign Material: Inclusion of unwanted substances in the material.

- Bubbles: Voids or air pockets trapped within the material.

Detailed descriptions and photographic documentation are vital for accurate classification and reproducibility of results. Using standardized grading scales or reference images enhances consistency across different graders.

Q 21. What are the potential consequences of inaccurate visual grading?

Inaccurate visual grading can have significant consequences, impacting various aspects of a business:

- Financial Losses: Accepting defective products can lead to customer complaints, returns, warranty claims, and potential legal action. Rejecting acceptable products can lead to unnecessary waste and loss of revenue.

- Reputational Damage: Consistent quality is essential for maintaining customer trust. Inaccurate grading can damage a company’s reputation and erode customer loyalty.

- Safety Concerns: In some industries (e.g., aerospace, automotive), defects can pose safety risks. Inaccurate grading could lead to hazardous products reaching the market.

- Manufacturing Inefficiencies: Incorrect grading can disrupt the manufacturing process, leading to delays, rework, and increased production costs.

- Legal Liabilities: In cases of product liability, inaccurate grading can make a company responsible for damages caused by defective products.

Therefore, accuracy in visual grading is not just about meeting a standard; it’s crucial for safeguarding a company’s financial stability, reputation, and legal standing.

Q 22. How do you use visual grading to identify root causes of defects?

Visual grading, at its core, is about meticulously examining a product or material to identify defects. To pinpoint root causes, we don’t just identify the defect; we analyze its characteristics to understand its origin. This involves a systematic approach. For instance, if I’m inspecting a batch of printed circuit boards and notice a recurring discoloration in a specific area, I wouldn’t simply flag it as ‘discoloration.’ Instead, I’d analyze:

- Location: Is the discoloration consistently in the same area on each board? This might point to a problem with a specific machine component or process step at that location.

- Pattern: Does the discoloration follow a specific pattern (e.g., circular, linear)? This can hint at the type of defect – perhaps a faulty nozzle in a printing process or a localized heating issue.

- Severity: How widespread is the discoloration? A few instances might indicate a minor issue, while widespread occurrences signal a major problem needing immediate attention.

By documenting these observations meticulously, we can use this data to create a hypothesis about the root cause. This hypothesis is then verified through further investigation, possibly involving process engineers or quality control specialists. For example, if the discoloration points to a specific soldering station, we might check the temperature settings, solder paste consistency, or even the mechanical alignment of the station itself. The key is to move beyond simple defect identification to a deeper understanding of *why* the defect occurred.

Q 23. Describe your experience with implementing and improving visual grading procedures.

In my previous role at Acme Manufacturing, we were experiencing high defect rates in our injection molding process. The existing visual grading procedures were inconsistent and lacked standardization. To improve this, I implemented a multi-pronged approach:

- Standardization of Procedures: We created a detailed, step-by-step visual grading guide with clear images and descriptions of acceptable and unacceptable characteristics. This ensured everyone used the same criteria.

- Improved Training: I developed and delivered comprehensive training sessions on the new procedures, emphasizing consistent application and proper documentation. We incorporated practical exercises and feedback sessions to reinforce learning.

- Implementation of a Digital Grading System: We transitioned from paper-based record-keeping to a digital system. This enabled us to track defects more efficiently, analyze trends, and generate reports for continuous improvement. The system also included image capture functionality, allowing for easy review and comparison of defects.

- Regular Audits and Calibration: I implemented a system of regular internal audits to assess the consistency of grading across different graders. We also regularly calibrated our visual grading tools and reference standards to maintain accuracy.

These changes led to a significant reduction in defect rates, improved consistency in grading, and better data-driven decision-making within the company.

Q 24. What are your strengths and weaknesses as a visual grader?

My strengths as a visual grader include exceptional attention to detail, a methodical and systematic approach, and a strong aptitude for pattern recognition. I possess excellent hand-eye coordination and am comfortable working for extended periods with minimal breaks while maintaining focus. I am also adept at communicating my findings clearly and concisely, both verbally and in writing, and I’m always keen to learn and improve my skills.

However, like everyone, I have areas for improvement. Sometimes, prolonged periods of intense visual scrutiny can lead to eye fatigue, affecting my accuracy. I am actively working to mitigate this through regular breaks, employing visual relaxation techniques, and ensuring adequate lighting in my workspace. Another area is proactively seeking feedback – though I believe in my abilities, consistently reviewing my work with colleagues can uncover potential biases or oversights. Continuous improvement is essential in this role.

Q 25. How do you maintain a high level of focus and attention to detail during visual grading tasks?

Maintaining focus during visual grading is crucial. Think of it like a marathon, not a sprint. I employ several strategies to stay sharp:

- Regular Breaks: I take short, frequent breaks to rest my eyes and mind. Even a few minutes every hour can make a huge difference.

- Ergonomic Setup: A properly configured workspace with good lighting, comfortable seating, and appropriate magnification tools helps avoid physical strain and maintain focus.

- Mindfulness Techniques: Simple techniques like deep breathing exercises can help center my attention and reduce mental fatigue.

- Variety of Tasks: Where possible, I try to vary my tasks throughout the day, switching between different types of visual grading to prevent monotony.

- Self-Checks and Quality Control: Periodically, I conduct self-checks on my work to ensure accuracy and identify any potential patterns of errors. This is a form of active monitoring to identify personal dips in concentration.

By proactively managing my energy and attention, I can sustain a high level of accuracy and efficiency throughout my workday.

Q 26. How do you handle stressful situations that might impact your visual grading performance?

Stressful situations, such as tight deadlines or high-pressure environments, can undeniably affect visual grading performance. My approach involves a combination of proactive strategies and responsive techniques:

- Proactive Stress Management: I prioritize sufficient sleep, a healthy diet, and regular exercise to build resilience to stress. I also engage in activities outside of work to help me relax and de-stress.

- Time Management: I use time management techniques like prioritizing tasks and breaking down large jobs into smaller, manageable chunks. This helps to prevent feeling overwhelmed.

- Clear Communication: If I’m facing a challenging situation, I communicate openly with my supervisor or team to discuss the challenges and seek support.

- Responsive Techniques: During stressful moments, I employ deep breathing exercises or step away from the task for a few minutes to clear my head. I also double-check my work to make sure I am not making errors due to the pressure.

By addressing both the root causes and the symptoms of stress, I strive to maintain consistency and accuracy even under pressure.

Q 27. Explain your experience with working under strict quality standards and regulations.

Throughout my career, I’ve consistently worked under stringent quality standards and regulations, including ISO 9001 and industry-specific guidelines. I understand the importance of compliance and have a proven track record of adhering to these standards. My experience includes:

- Understanding and Applying Regulations: I have a thorough understanding of relevant regulations and their implications for visual grading processes. I can interpret specifications and apply them consistently.

- Documentation and Traceability: I am meticulous in documenting my findings, ensuring complete traceability of defects and corrective actions. This includes clear, accurate labeling and detailed records.

- Calibration and Validation: I’m familiar with procedures for calibrating visual grading tools and validating grading methodologies to ensure accuracy and reliability. This includes participating in regular audits and calibration checks.

- Continuous Improvement: I proactively participate in continuous improvement initiatives aimed at enhancing quality management systems and reducing defect rates. I actively look for ways to improve processes based on identified weaknesses or trends.

My commitment to quality and regulatory compliance ensures consistent, reliable, and accurate visual grading results.

Q 28. Describe your experience with using visual aids and reference standards in visual grading.

Visual aids and reference standards are indispensable tools for maintaining consistency and accuracy in visual grading. My experience includes using a range of tools and standards, such as:

- Microscopes: For examining very fine details or defects that are not readily visible to the naked eye.

- Magnifying Glasses: For closer inspection of larger components or areas of interest.

- Color Charts: To ensure consistency in identifying color variations or deviations.

- Reference Samples: Samples of products that represent the acceptable quality range against which graded parts are compared. This is particularly useful for detecting subtle variations in texture or finish.

- Digital Imaging Systems: These systems can capture high-resolution images of defects, allowing for detailed analysis and comparison, and also facilitating easier training and standardization.

I am proficient in selecting and using the appropriate visual aids and reference standards for each specific grading task. I also understand the importance of maintaining and calibrating these tools to ensure accurate and reliable results. The use of these tools isn’t simply about magnification or comparison; it’s about systematic and standardized evaluation that minimizes bias and improves accuracy and consistency.

Key Topics to Learn for Visual Grading Interview

- Understanding Visual Grading Principles: Grasp the core concepts behind visual grading, including the assessment criteria and the overall goals of the process. Explore different grading scales and their applications.

- Practical Application in Various Contexts: Learn how visual grading is applied across different industries (e.g., image processing, medical imaging, quality control). Consider examples where visual assessment is crucial and how it informs decision-making.

- Calibration and Consistency: Understand the importance of achieving consistent grading across different assessors. Explore methods for calibrating visual grading systems and minimizing subjective bias.

- Quantitative & Qualitative Analysis: Learn to balance quantitative metrics (e.g., numerical scores) with qualitative descriptions of visual characteristics. Practice articulating both objective and subjective assessments.

- Handling Ambiguity and Uncertainty: Discuss approaches for managing ambiguous cases and situations where visual assessment is challenging. Develop strategies for dealing with inconsistencies or uncertainties in the visual data.

- Technological Tools & Software: Familiarize yourself with any relevant software or tools commonly used in visual grading processes. Understanding the technical aspects demonstrates practical experience.

- Problem-Solving & Decision-Making: Practice analyzing visual data and making informed decisions based on your assessment. Be prepared to articulate your reasoning and justify your grading choices.

Next Steps

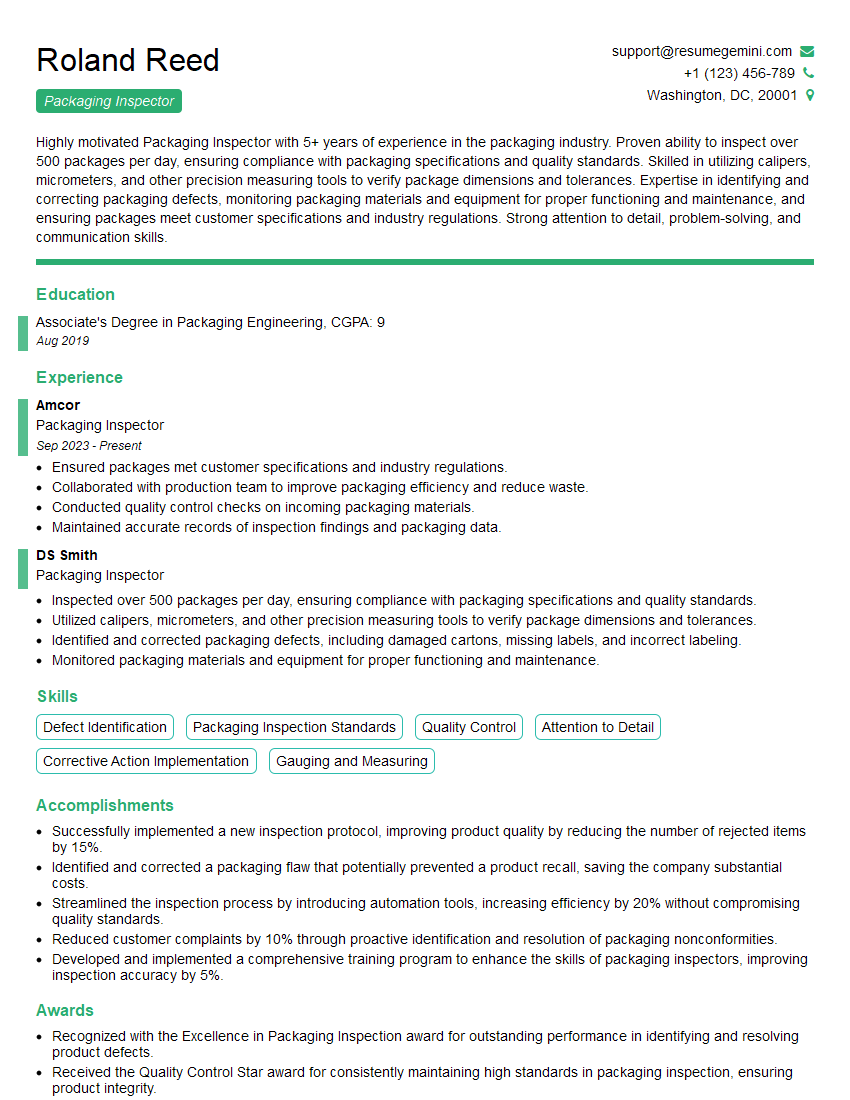

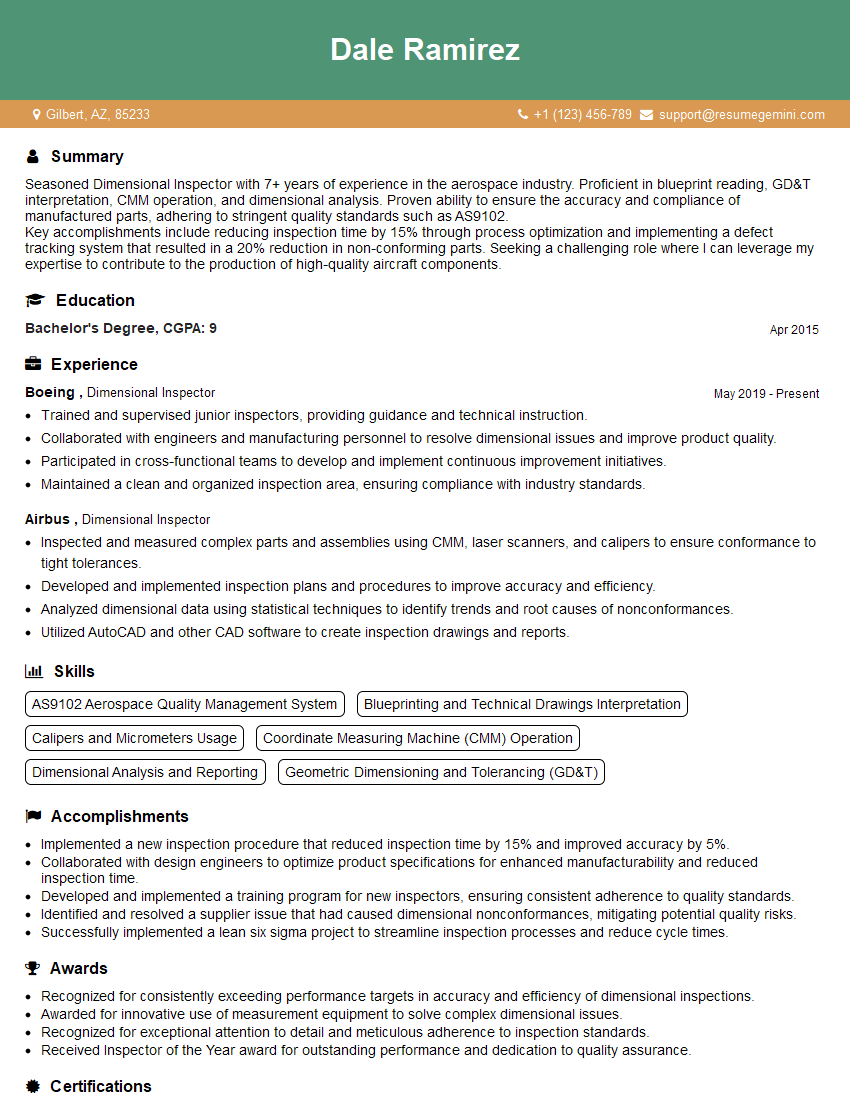

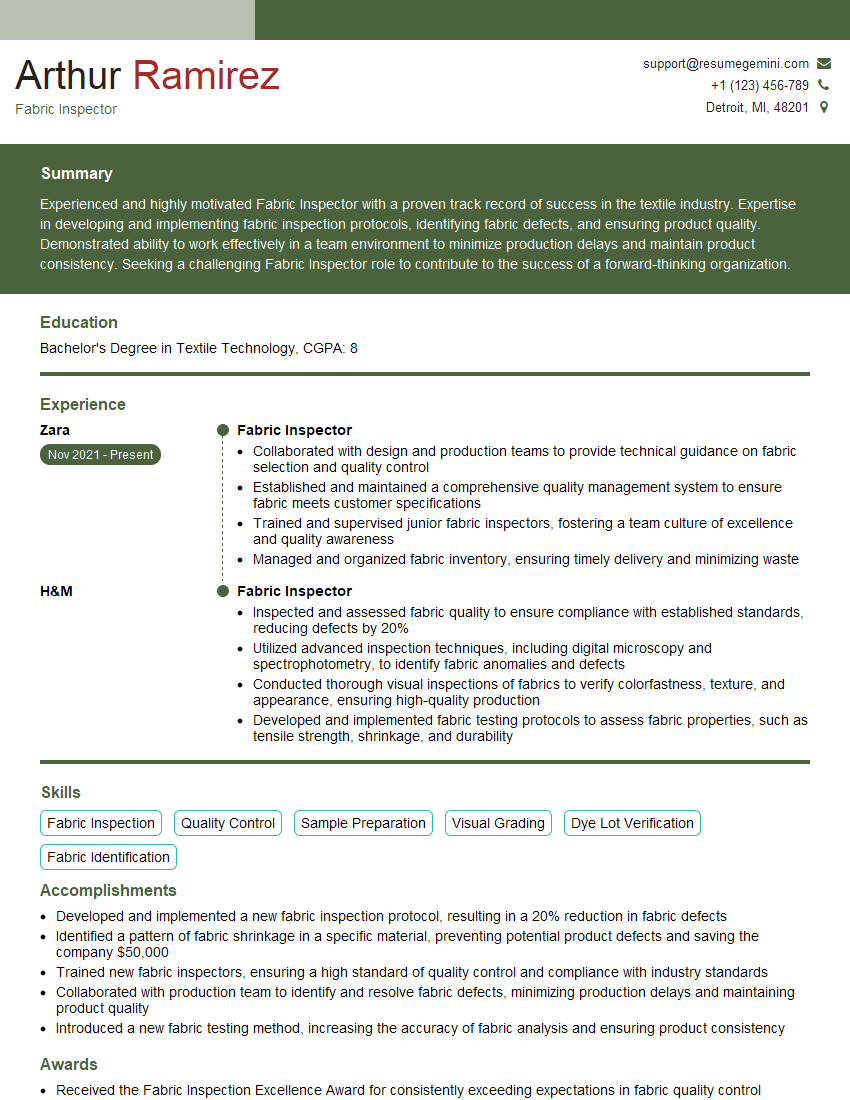

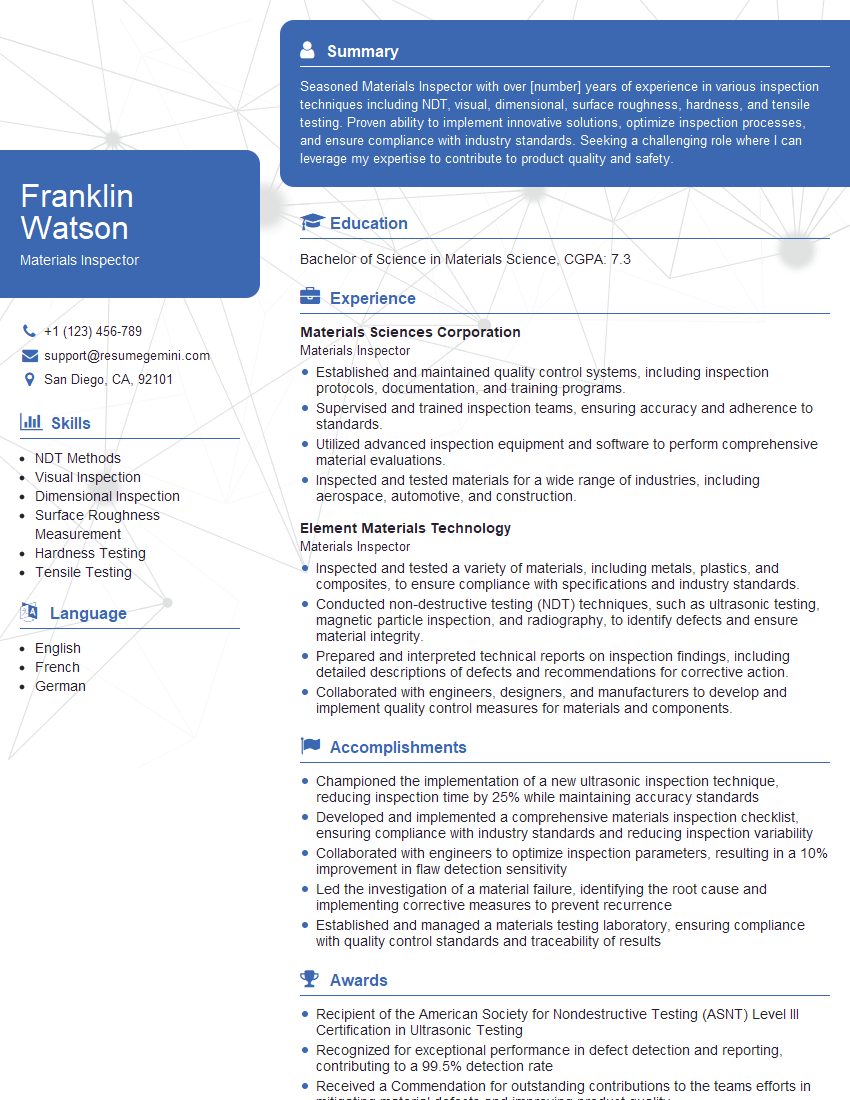

Mastering visual grading opens doors to exciting career opportunities in diverse fields requiring precise and consistent visual assessment. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your visual grading skills and experience. Examples of resumes specifically tailored for Visual Grading positions are available to further guide your resume creation. Invest time in crafting a compelling resume; it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good