Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Knowledge of Food and Beverage Industry Standards interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Knowledge of Food and Beverage Industry Standards Interview

Q 1. Explain the principles of HACCP.

HACCP, or Hazard Analysis and Critical Control Points, is a preventative food safety system based on identifying and controlling biological, chemical, and physical hazards in food production. Instead of reacting to contamination, HACCP focuses on preventing it from ever occurring.

- Hazard Analysis: Identifying potential hazards throughout the production process – from raw materials to finished product. This involves brainstorming potential dangers like bacterial contamination (Salmonella, E.coli), chemical contamination (pesticides), or physical hazards (glass shards).

- Critical Control Points (CCPs): Determining the steps in the process where these hazards can be controlled or eliminated. For example, cooking temperature is a CCP for bacterial contamination; metal detection is a CCP for physical hazards.

- Critical Limits: Establishing measurable limits for each CCP. For instance, a CCP for cooking might require an internal temperature of 165°F (74°C) to be held for a certain duration.

- Monitoring: Regularly checking that the CCPs are operating within the established critical limits. This might involve temperature monitoring, visual inspection, or using testing equipment.

- Corrective Actions: Defining procedures to follow when a CCP deviates from its critical limits. For instance, if the cooking temperature drops, a corrective action might be to reheat the product to the required temperature.

- Verification: Confirming that the HACCP plan is working effectively. This could include regular audits, reviewing records, and implementing improvements.

- Record Keeping: Maintaining detailed records of all aspects of the HACCP plan, including hazard analysis, CCP monitoring, corrective actions, and verification activities.

Example: In a canning factory, a CCP might be the sterilization process. The critical limit would be the temperature and duration of sterilization necessary to eliminate Clostridium botulinum spores. Monitoring involves checking the temperature and time of each batch. Corrective action might include discarding a batch if the sterilization parameters weren’t met.

Q 2. Describe your experience with GMP (Good Manufacturing Practices).

My experience with GMPs spans over ten years, encompassing various roles within the food and beverage industry. I’ve been involved in developing, implementing, and auditing GMP programs across different manufacturing facilities. This includes ensuring adherence to standards regarding sanitation, personnel hygiene, equipment maintenance, and raw material handling. I have a strong understanding of the principles and practical applications of GMP, including:

- Sanitation Procedures: Developing and implementing comprehensive sanitation programs, including cleaning and sanitizing equipment and facilities, following established protocols, and verifying the effectiveness of these protocols using ATP testing.

- Personnel Hygiene: Training employees on proper hygiene practices, such as handwashing, wearing protective clothing, and preventing contamination through proper handling techniques.

- Equipment Maintenance: Overseeing the preventative maintenance and calibration of equipment, ensuring proper functioning and preventing contamination caused by malfunctioning machinery.

- Raw Material Handling: Implementing procedures to control the receipt, storage, and handling of raw materials, ensuring that they are stored properly, protected from contamination, and appropriately rotated (FIFO).

- Pest Control: Collaborating with pest control services to implement measures to prevent pest infestations and contamination.

In a previous role, I successfully implemented a new sanitation program that reduced contamination rates by 30%, leading to a significant decrease in product recalls and an improved company reputation. My experience has equipped me with the skills to identify and rectify GMP deficiencies, contributing to a robust and compliant food safety system.

Q 3. What are the key differences between FDA and USDA regulations?

The FDA (Food and Drug Administration) and USDA (United States Department of Agriculture) both regulate food safety, but their jurisdictions differ. The FDA regulates most food products except for meat, poultry, and some egg products. The USDA regulates these latter products, along with certain aspects of the production and processing of agricultural products.

- FDA: Focuses on a wide range of foods, including fruits, vegetables, dairy products, seafood, processed foods, and dietary supplements. Their regulations cover areas such as food additives, labeling, sanitary conditions of facilities, and preventing the spread of foodborne illnesses.

- USDA: Primarily focuses on meat, poultry, and egg products from farm to table. They oversee slaughterhouses, processing plants, and distribution of these specific products. Their regulations heavily emphasize the humane treatment of animals and the safety and wholesomeness of meat and poultry.

Key Differences: The specific regulations, inspection procedures, and enforcement mechanisms differ between the two agencies. For instance, the USDA employs a rigorous inspection system in slaughterhouses, while the FDA relies on a Hazard Analysis and Critical Control Point (HACCP) system and periodic inspections for many food facilities. Understanding these differences is crucial for ensuring compliance depending on the specific type of food product being manufactured or handled.

Q 4. How do you ensure food safety throughout the supply chain?

Ensuring food safety throughout the supply chain requires a multi-faceted approach involving collaboration, traceability, and robust safety protocols at each stage. This involves:

- Supplier Audits: Regularly auditing suppliers to ensure they adhere to appropriate food safety standards, including GMPs and HACCP principles. This includes verifying their sanitation practices, pest control measures, and overall food safety management systems.

- Traceability Systems: Implementing robust traceability systems that allow for the tracking of food products from farm to table. This allows for rapid identification and removal of contaminated products from the market in case of a recall.

- Transportation and Storage: Maintaining proper temperature control during transportation and storage to prevent the growth of harmful bacteria. This includes using refrigerated trucks and storage facilities, along with monitoring temperatures at key points in the supply chain.

- Receiving and Inspection: Implementing procedures for inspecting incoming raw materials and ingredients to ensure they meet quality and safety standards. This includes visual inspection, temperature checks, and potentially microbiological testing.

- Communication and Collaboration: Establishing clear communication channels between all parties in the supply chain to ensure timely identification and resolution of any food safety issues. This involves sharing information about potential hazards, recall notifications, and other relevant matters.

For example, a proactive approach might involve real-time temperature monitoring throughout the supply chain, providing immediate alerts if deviations from safe temperatures occur. This allows for swift intervention and prevents spoilage or bacterial growth.

Q 5. What is your experience with food allergen management?

My experience with food allergen management is extensive, covering the entire spectrum from ingredient sourcing to finished product labeling. I’ve worked with companies to establish and maintain comprehensive allergen control programs, minimizing cross-contamination risks and ensuring compliance with regulations.

- Allergen Identification and Control: Identifying all potential allergens present in ingredients and finished products (e.g., milk, eggs, peanuts, soy, wheat, tree nuts, fish, shellfish). Implementing controls to prevent cross-contamination at all stages of production. This involves dedicated equipment, separate processing lines, and thorough cleaning and sanitizing procedures.

- Supplier Management: Working with suppliers to ensure they provide accurate allergen information and follow appropriate allergen control procedures in their own operations.

- Labeling Compliance: Ensuring accurate and compliant allergen labeling on all finished products, following all applicable regulations (e.g., FDA’s labeling requirements).

- Training and Awareness: Providing training to all employees on allergen awareness, safe handling practices, and the importance of preventing cross-contamination. This includes regular refresher training.

- Documentation and Record Keeping: Maintaining detailed records of all allergen-related activities, including supplier certifications, cleaning logs, and testing results.

In one instance, I helped a food manufacturing facility implement a new allergen control program which significantly reduced the risk of allergen cross-contamination, leading to a positive impact on consumer safety and the company’s overall reputation. The implementation involved a comprehensive review of existing processes, retraining of personnel, and updates to cleaning and sanitation procedures.

Q 6. Explain your understanding of food labeling regulations.

Food labeling regulations are complex and vary depending on the country and specific product. My understanding encompasses both the legal requirements and the practical implications of ensuring compliant labeling. Key aspects include:

- Product Name: The product name must be clear and not misleading.

- Net Weight/Volume: The net weight or volume of the product must be accurately declared.

- Ingredient List: Ingredients must be listed in descending order of weight, with allergens clearly identified.

- Nutrition Facts Panel: This panel must provide information on serving size, calories, macronutrients, and micronutrients, following FDA guidelines (in the US).

- Manufacturer Information: The name and address of the manufacturer or distributor must be included.

- Allergen Statements: Clear statements must indicate the presence of major food allergens (as mentioned previously).

- Other Declarations: Depending on the product, other declarations might be required, such as country of origin, warnings, and handling instructions.

Non-compliance can result in significant penalties. Accurate and comprehensive labeling not only protects consumers but also avoids legal issues and protects the company’s reputation. I am adept at navigating these regulations and ensuring that the labeling of any product is complete and compliant.

Q 7. Describe your experience with food traceability systems.

My experience with food traceability systems involves implementing and managing systems that track food products throughout their lifecycle. Effective traceability is vital for both food safety and responding to potential contamination incidents. This includes:

- Lot Numbering and Tracking: Assigning unique lot numbers to each batch of raw materials and finished products to trace their origin and movement. This allows for tracking of specific batches involved in contamination incidents.

- Database Management: Utilizing database systems to store and manage traceability data, allowing for efficient retrieval of information during investigations or recalls.

- Barcode and RFID Technology: Implementing barcode and/or RFID technology to improve the efficiency and accuracy of tracking and data collection.

- Software Integration: Integrating traceability systems with other enterprise resource planning (ERP) and supply chain management systems to provide a holistic view of the food product’s journey.

- Recall Management: Utilizing traceability data to effectively manage product recalls, identifying and isolating affected batches quickly and efficiently.

In a previous role, I helped design and implement a new traceability system which reduced the time needed to identify and isolate contaminated products during a recall by 50%, significantly reducing losses and damage to reputation.

Q 8. How do you handle food recalls?

Handling a food recall is a critical process requiring swift action and meticulous attention to detail. It’s not just about removing the product from shelves; it’s about protecting public health and maintaining consumer trust. My approach follows a structured protocol, starting with immediate investigation to identify the root cause of the recall. This involves reviewing production records, testing samples, and tracing the affected product’s distribution chain.

Once the root cause is identified, we initiate a formal recall, notifying regulatory bodies like the FDA (in the US) or equivalent agencies in other countries. Simultaneously, we work with our distribution network to effectively remove the problematic products from the market. Clear and concise communication is paramount – we create transparent communication strategies for consumers, retailers, and internal teams, providing updates regularly. Finally, a thorough post-recall analysis is crucial. This helps to determine the effectiveness of our response, identify areas for improvement in our processes, and prevent future incidents.

For example, in a previous role, we faced a recall due to a labeling error on a batch of organic granola bars. Our immediate response included halting production, initiating the recall process, and issuing a public statement clearly explaining the situation and outlining the actions taken. We meticulously tracked the returned products, conducted root cause analysis to improve our labeling process and prevent future errors, and conducted post-recall surveys to assess consumer confidence.

Q 9. What is your experience with microbiological testing?

Microbiological testing is fundamental to ensuring food safety. My experience encompasses a wide range of tests, from standard plate counts for bacteria like E. coli and Salmonella to more advanced techniques like PCR (Polymerase Chain Reaction) for detecting pathogens in complex food matrices. I’m proficient in interpreting results and determining appropriate actions based on findings.

I have extensive experience with methods like the enumeration of aerobic mesophilic bacteria, coliforms, E. coli, Staphylococcus aureus, and Listeria monocytogenes. I’m also familiar with various techniques for analyzing fungal counts, yeast, and mold. Understanding the limitations of each test is crucial, and I ensure the selected methods align with the specific needs of the product and the regulatory requirements. In my previous role, we used rapid methods for pathogen detection to minimize delays in production and response time during quality control checks.

For instance, using rapid PCR methods allowed us to quickly identify and isolate a batch contaminated with Salmonella during routine testing, preventing a larger scale contamination and potential recall. This highlights the importance of proactive microbiological testing in maintaining product safety and compliance.

Q 10. Describe your experience with sensory evaluation of food products.

Sensory evaluation is a critical aspect of product development and quality control, providing valuable insights into consumer perception. My experience involves conducting both descriptive analysis (trained panelists assessing specific attributes) and affective tests (consumer panels evaluating overall liking). I understand the importance of controlling the sensory testing environment to minimize bias and ensure reliable results. This includes managing sample presentation, using appropriate scoring scales, and analyzing data using appropriate statistical methods.

I’ve worked extensively with sensory panels to assess various attributes like taste, texture, aroma, appearance, and mouthfeel. For example, in one project, we used a trained sensory panel to profile the aroma of different coffee blends, identifying key volatile compounds that influenced consumer preference. This data directly influenced the formulation and marketing of our new coffee products. Understanding consumer preferences through sensory analysis is key to developing successful products that meet market demands.

Moreover, I’m proficient in using statistical software (e.g., R, SPSS) to analyze sensory data and determine statistically significant differences between products. This rigorous data analysis is crucial for drawing meaningful conclusions and making informed decisions about product development and quality.

Q 11. What is your experience with quality control procedures?

Quality control (QC) procedures are the cornerstone of maintaining consistent product quality and safety. My experience encompasses all facets of QC, from raw material inspection to finished product testing. This includes implementing HACCP (Hazard Analysis and Critical Control Points) plans, conducting regular audits, and developing and maintaining Standard Operating Procedures (SOPs). A key aspect of my approach is a proactive, preventative mindset, rather than simply reacting to problems.

My experience includes developing and implementing QC plans for various food products, ranging from baked goods to ready-to-eat meals. I’m proficient in using various quality control tools, such as control charts and statistical process control (SPC) techniques, to monitor processes and identify deviations. For example, using control charts to track the weight of packaged products helps to immediately detect any deviations from the target weight, preventing the production of out-of-specification products. This proactive approach is crucial in avoiding significant losses and maintaining product quality.

Implementing and maintaining a robust QC system is vital for upholding food safety and regulatory compliance. My work emphasizes documentation, training of personnel, and continuous improvement in QC processes to constantly strive for higher quality and safety standards.

Q 12. How do you ensure product consistency?

Ensuring product consistency requires a multi-faceted approach, encompassing rigorous control throughout the entire production process. This starts with standardized recipes and procedures. Thorough raw material specifications and sourcing are essential, as variations in raw material quality can directly affect the final product. In addition to this, robust quality control measures are implemented at various stages of production, using precise equipment and well-trained personnel.

Process parameters must be meticulously monitored and controlled. This includes factors like temperature, time, and humidity during processing. Regular calibration and maintenance of processing equipment are also crucial. Statistical Process Control (SPC) is a powerful tool used to monitor process variability and identify potential issues before they lead to significant inconsistency. Regular audits and review of SOPs ensure that everyone is following protocols correctly.

For example, in my previous role, we implemented a system of continuous monitoring of temperature and humidity levels during the drying phase of our granola bar production. This allowed us to maintain consistent texture and prevent spoilage, resulting in a more consistent final product. Implementing such detailed procedures helps ensure each bar is consistently delicious and safe to eat.

Q 13. Explain your understanding of food preservation techniques.

Food preservation techniques aim to extend the shelf life of food products while maintaining their quality and safety. My understanding encompasses a broad range of methods, from traditional techniques to modern technologies. These can be broadly categorized into:

- Thermal Processing: This includes methods like pasteurization (heat treatment to kill microorganisms) and sterilization (more intense heat treatment to eliminate all microorganisms).

- Non-thermal Processing: This encompasses techniques such as high-pressure processing (HPP), irradiation, and pulsed electric fields (PEF), all of which aim to inactivate microorganisms without the use of high heat.

- Low-Moisture Preservation: This includes methods like drying (removing water to inhibit microbial growth), freezing (reducing water activity to prevent microbial growth), and concentration (removing water to increase the concentration of solids).

- Chemical Preservation: This utilizes substances like preservatives (e.g., sodium benzoate, sorbic acid) to inhibit microbial growth.

- Modified Atmosphere Packaging (MAP): This involves altering the gas composition within the package (e.g., increasing CO2, reducing O2) to slow down microbial growth and extend shelf life.

Selecting the appropriate preservation technique depends on various factors, such as the type of food, its desired shelf life, and the desired quality attributes. For example, pasteurization is commonly used for milk and juices, while freezing is frequently employed for fruits and vegetables. Understanding the effectiveness and limitations of each technique is crucial for selecting the optimal approach.

Q 14. Describe your experience with food packaging materials and regulations.

Food packaging materials and regulations are critically important in maintaining product safety and quality, as well as conveying accurate information to consumers. My experience involves selecting appropriate packaging materials based on product characteristics, shelf life requirements, and regulatory compliance. I’m knowledgeable about various materials such as plastics, paperboard, glass, and metal, as well as different packaging technologies like modified atmosphere packaging (MAP) and vacuum packaging.

I am familiar with relevant food safety regulations and labeling requirements, ensuring that all packaging materials comply with international standards, such as FDA regulations in the US or EU regulations in Europe. This includes understanding regulations related to food contact materials, ensuring that the materials used are safe for contact with food and do not leach harmful substances. Proper labeling is crucial, and I ensure that all necessary information such as ingredients, nutritional information, allergen warnings, and best-before dates is accurately presented on the packaging.

For example, in a past project involving the development of a new line of organic snacks, we chose compostable packaging to align with our brand’s sustainability goals. This required careful selection of materials that were compliant with food safety regulations and had the necessary barrier properties to ensure product freshness. This demonstrates a holistic approach to packaging, combining quality, safety, and sustainability considerations.

Q 15. How do you manage food waste?

Managing food waste is crucial for both ethical and economic reasons. It involves a multi-pronged approach focusing on prevention, reduction, and recovery.

- Prevention: Accurate forecasting of demand, precise portioning, and effective inventory management are key. For example, using predictive analytics to understand peak demand periods and adjusting production accordingly minimizes surplus.

- Reduction: Implementing FIFO (First-In, First-Out) inventory systems ensures older products are used first. Regular stock rotation and staff training on proper storage techniques reduce spoilage. Creative recipe development can also utilize ‘ugly’ produce that would otherwise be discarded.

- Recovery: Composting organic waste diverts it from landfills and creates valuable fertilizer. Donating surplus food to food banks or charities is another vital recovery method. Some companies even process food waste into animal feed.

In my previous role, we implemented a comprehensive food waste management program that included staff training, improved inventory control software, and partnerships with local charities. This resulted in a 25% reduction in food waste within six months.

Career Expert Tips:

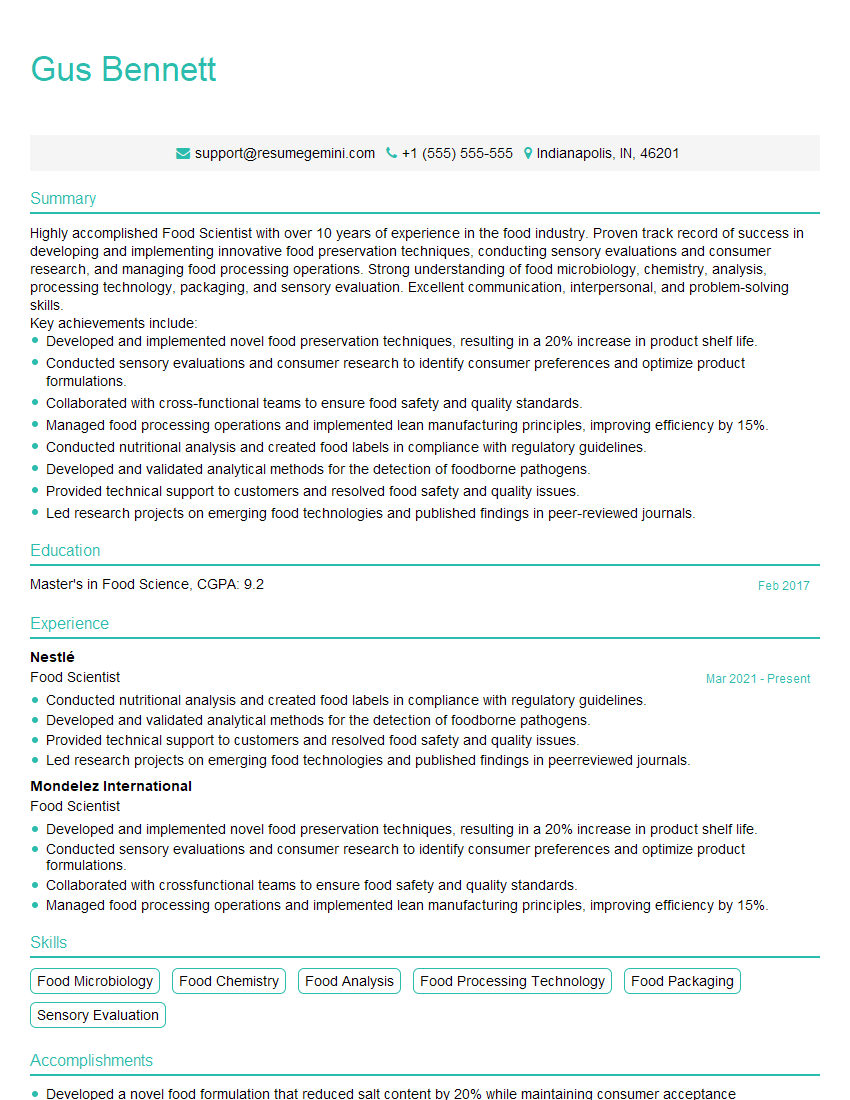

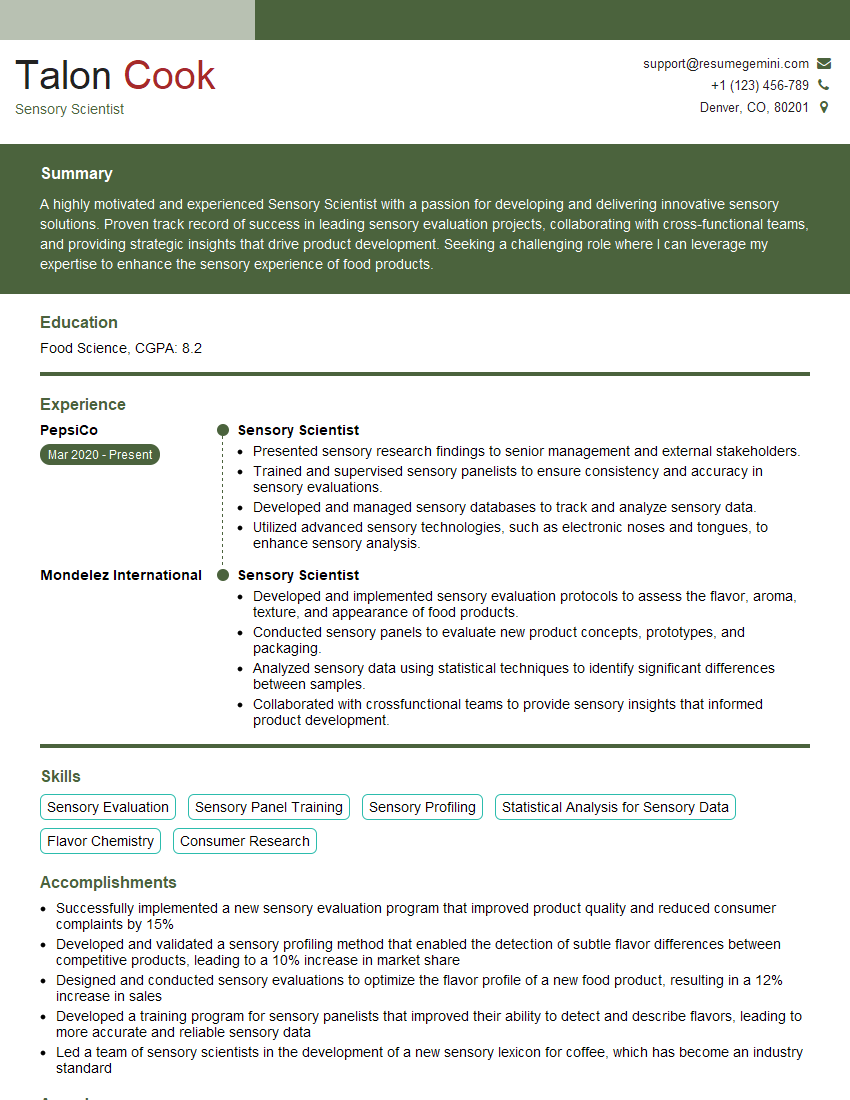

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with process optimization in a food production environment?

Process optimization in food production focuses on streamlining operations to enhance efficiency, reduce costs, and improve product quality. This involves analyzing every stage of the production line, from ingredient sourcing to packaging.

- Lean Manufacturing Principles: Identifying and eliminating waste (muda) in seven key areas – transportation, inventory, motion, waiting, overproduction, over-processing, and defects – is paramount. For example, optimizing the layout of a production line to minimize unnecessary movement of materials reduces waste and increases productivity.

- Statistical Process Control (SPC): Using statistical tools to monitor key process parameters and identify deviations helps maintain consistent quality. Control charts can help detect trends and prevent problems before they escalate.

- Data Analysis: Analyzing production data to pinpoint bottlenecks and areas for improvement is vital. This could involve tracking production times, yield rates, and defect rates to identify opportunities for optimization.

In a previous role at a dairy processing plant, I implemented a lean manufacturing program which reduced processing time by 15% and improved yield by 8% by optimizing the cleaning and sanitation procedures and improving material flow.

Q 17. Explain your understanding of different food preservation methods.

Food preservation methods aim to extend the shelf life of food products and prevent spoilage. They work by inhibiting the growth of microorganisms (bacteria, yeasts, molds) and slowing down enzymatic reactions that cause deterioration.

- Thermal Processing: This involves using heat to kill microorganisms. Methods include canning (high-temperature, short-time processing), pasteurization (moderate heat treatment), and sterilization (complete elimination of microorganisms).

- Low-Temperature Preservation: Refrigeration and freezing slow down microbial growth and enzymatic activity. Freezing is more effective at stopping spoilage than refrigeration.

- Water Activity Reduction: Methods such as drying (removing moisture), dehydration, and concentration reduce the availability of water for microbial growth. This is effective in preserving many fruits and vegetables.

- Chemical Preservation: Using preservatives like salt, sugar, vinegar, or chemical additives (e.g., sodium benzoate) inhibits microbial growth. These must be used within regulatory limits.

- Irradiation: Exposing food to ionizing radiation kills microorganisms and extends shelf life, although consumer acceptance can be a challenge.

- Modified Atmosphere Packaging (MAP): Altering the gas composition inside packaging (e.g., using high nitrogen, low oxygen) slows down spoilage.

Understanding the interplay of these methods is crucial in selecting the appropriate technique for a particular product and its target shelf life. For example, a canned product needs sterilization for long shelf life, while fresh produce may rely on refrigeration and MAP.

Q 18. How do you ensure compliance with food safety and quality standards?

Ensuring compliance with food safety and quality standards is paramount. This involves adherence to regulations, implementation of robust systems, and continuous monitoring.

- Hazard Analysis and Critical Control Points (HACCP): This preventative system identifies potential hazards and establishes critical control points (CCPs) where control measures are implemented to prevent or eliminate hazards.

- Good Manufacturing Practices (GMP): This set of guidelines covers hygiene, sanitation, personnel training, and facility maintenance to ensure a clean and safe production environment.

- Supplier Audits: Verifying the safety and quality of ingredients and packaging materials from suppliers is crucial. This often involves on-site audits or reviewing supplier documentation.

- Regular Testing and Monitoring: Conducting routine testing of products and environmental samples (e.g., swabs from equipment) helps identify and address potential contamination.

- Documentation and Traceability: Maintaining detailed records of all processes and ingredients allows for tracking products in case of a recall or contamination incident.

Implementing a comprehensive food safety management system, coupled with regular audits and staff training, is key to maintaining compliance and consumer trust. For instance, we used a documented system to track temperatures throughout the production process and were able to prevent a potential salmonella outbreak by proactively identifying a temperature control issue.

Q 19. Describe a situation where you had to resolve a food safety issue.

In a previous role, we experienced a case of Listeria monocytogenes contamination in a batch of ready-to-eat meat products.

Our immediate response followed a defined protocol:

- Immediate Isolation: The affected batch was immediately isolated and quarantined to prevent further distribution.

- Root Cause Analysis: A thorough investigation was launched to pinpoint the source of contamination, examining all stages of production, equipment sanitation procedures, and ingredient sources.

- Corrective Actions: Once the source (a faulty piece of equipment) was identified, corrective actions were implemented, including deep cleaning and sanitization, equipment repair, and enhanced sanitation protocols.

- Notification and Recall: We immediately notified relevant authorities and initiated a product recall to protect consumers.

- Preventative Measures: Implemented enhanced monitoring procedures and employee training to prevent future occurrences.

This situation highlighted the importance of robust food safety systems, thorough investigations, and effective communication during a crisis.

Q 20. What is your experience with ISO 22000 or other food safety management systems?

I have extensive experience working with ISO 22000, a globally recognized food safety management system standard. It provides a framework for managing food safety hazards throughout the entire food chain.

My experience includes:

- Implementation and Auditing: I’ve been involved in implementing ISO 22000 in multiple food processing facilities, conducting internal audits to ensure ongoing compliance, and participating in external audits by certification bodies.

- HACCP Plan Development: I’ve developed and maintained HACCP plans, identifying critical control points and implementing effective control measures.

- Documentation and Record Keeping: I’m proficient in maintaining the necessary documentation required by ISO 22000, including procedures, records, and traceability information.

- Management Review: I’ve participated in management review meetings, evaluating the effectiveness of the food safety management system and identifying areas for improvement.

Understanding and implementing ISO 22000 ensures consistent food safety practices and improves customer confidence. For example, using ISO 22000 allowed us to standardize our processes, simplify audits, and improve efficiency in our supply chain.

Q 21. How do you interpret and apply food safety legislation?

Interpreting and applying food safety legislation requires a thorough understanding of relevant laws and regulations at both national and international levels. This involves staying current with changes in legislation and ensuring compliance throughout the entire food production process.

- Legal Research and Compliance: Regularly reviewing and updating knowledge on all applicable regulations is crucial. This could involve using resources such as government websites, industry publications, and legal experts.

- Risk Assessment: Identifying potential legal risks based on the specific operations and products is a critical first step. This helps prioritise compliance efforts and resource allocation.

- Policy Development and Implementation: Translating legal requirements into clear policies and procedures for the organization is vital for compliance. This should include employee training and documentation.

- Monitoring and Reporting: Regularly monitoring compliance and reporting on any non-compliance issues allows for prompt corrective actions and improves overall food safety.

For example, when a new food safety regulation was implemented in our region, I led the effort to review the legislation, update company policies, train staff, and implement the necessary changes within our production process, ensuring seamless compliance.

Q 22. What is your experience with conducting food audits?

Throughout my career, I’ve conducted numerous food audits, encompassing various aspects of food safety and quality. My experience ranges from small-scale artisanal food producers to large-scale manufacturing facilities. These audits typically follow established standards like HACCP (Hazard Analysis and Critical Control Points) and GFSI (Global Food Safety Initiative) benchmarked schemes. I am proficient in using audit checklists, conducting on-site inspections, reviewing documentation (such as SSOPs – Sanitation Standard Operating Procedures, and traceability records), interviewing personnel, and identifying non-conformances. For example, during an audit at a bakery, I uncovered a gap in their allergen control program which led to the implementation of improved ingredient segregation and labeling procedures. Another experience involved auditing a seafood processing plant where I identified critical control points needing immediate attention related to temperature control during storage and transportation. The audits resulted in corrective action plans and significantly improved their safety practices.

Q 23. Explain the importance of proper sanitation in food production.

Proper sanitation in food production is paramount to preventing foodborne illnesses and ensuring product quality. It’s a fundamental pillar of food safety and directly impacts consumer health and a company’s reputation. Think of it like this: a clean kitchen is more likely to produce a delicious and safe meal than a dirty one. In the food industry, this means implementing and strictly adhering to rigorous cleaning and sanitizing procedures at every stage, from ingredient receiving to finished product packaging. This involves regular cleaning of equipment, surfaces, and the entire facility. Effective sanitation minimizes the presence of harmful bacteria, viruses, and parasites, preventing cross-contamination and extending the shelf life of products. Regular monitoring and validation of sanitation procedures through microbial testing and staff training are also vital for maintaining optimal sanitation levels. Neglecting sanitation can result in costly product recalls, legal repercussions, and irreparable damage to a brand’s reputation.

Q 24. Describe your experience with developing and implementing food safety plans.

I have extensive experience in developing and implementing food safety plans, predominantly based on the HACCP principles. This involves conducting hazard analyses, identifying critical control points (CCPs), establishing critical limits for each CCP, and developing monitoring procedures. I’ve worked with various food matrices, including fresh produce, processed meats, and bakery items. For instance, in a project with a fruit juice producer, we identified the pasteurization process as a crucial CCP and established critical limits for temperature and holding time. We developed a monitoring system involving automated temperature recording and regular microbial testing. Implementation included staff training on the procedures and establishing a robust record-keeping system. This systematic approach ensures that potential hazards are controlled at every stage of production, safeguarding consumer safety and complying with relevant regulations. The documented plan forms the basis for ongoing monitoring and improvement.

Q 25. How do you stay current with changes in food safety regulations?

Staying current with evolving food safety regulations is essential in this dynamic industry. I achieve this through a multi-pronged approach: actively subscribing to and reviewing publications from reputable organizations like the FDA, USDA, and EFSA; attending industry conferences and workshops; participating in professional development courses; and networking with other food safety professionals. I also leverage online resources, including governmental websites and industry-specific journals, to stay informed about new regulations, emerging hazards, and best practices. For example, I regularly monitor updates on allergen management guidelines and emerging pathogen concerns. This ongoing learning ensures that my knowledge and practices are aligned with the latest standards, safeguarding consumer health and ensuring compliance.

Q 26. What is your experience with food product development and testing?

My experience encompasses the entire food product development lifecycle, from initial concept to market launch. This includes ideation, formulation, sensory evaluation, pilot-scale production, shelf-life studies, and regulatory compliance testing. For example, I was involved in developing a new line of gluten-free baked goods. This entailed extensive formulation work to achieve the desired texture and taste while maintaining stability and ensuring compliance with allergen labeling regulations. We also conducted extensive sensory evaluation to optimize the product profile. Subsequent testing involved evaluating the shelf life and microbial stability. This collaborative approach, encompassing research and development, quality assurance, and regulatory affairs, results in the successful launch of safe and high-quality products that meet consumer expectations and regulatory requirements.

Q 27. Describe your understanding of different food processing techniques.

My understanding of food processing techniques is comprehensive, spanning various methods tailored to different food products and desired outcomes. These include thermal processing (pasteurization, sterilization, blanching), non-thermal processing (high pressure processing, irradiation, pulsed electric fields), drying (spray drying, freeze-drying, air drying), fermentation, and various preservation methods (pickling, canning, freezing). Each technique offers advantages and disadvantages depending on factors like product characteristics, safety requirements, and desired shelf life. For example, pasteurization is commonly used for liquid products to eliminate pathogens while retaining quality, while freeze-drying is suitable for preserving delicate food components like fruits and vegetables. A thorough understanding of these techniques is crucial for selecting the most appropriate method to ensure product safety, quality, and desired sensory attributes.

Q 28. What are some common food safety hazards and how do you mitigate them?

Common food safety hazards encompass biological (bacteria, viruses, parasites), chemical (pesticides, toxins, allergens), and physical (glass, metal, bone) contaminants. Mitigation strategies vary depending on the hazard. For biological hazards, implementing good hygiene practices, controlling temperature during storage and processing (refrigeration, freezing), and employing appropriate thermal treatments (pasteurization, sterilization) are key. Chemical hazards are mitigated through careful sourcing of ingredients, monitoring pesticide residues, and implementing allergen control programs. Physical hazards are minimized through effective metal detection, X-ray inspection, and thorough visual checks at various production stages. For example, implementing a robust cleaning and sanitizing program can reduce biological hazards, while using validated suppliers ensures that ingredients are free from chemical contaminants. A multi-faceted approach involving preventive measures, monitoring systems, and corrective actions is crucial for effectively mitigating these hazards.

Key Topics to Learn for Knowledge of Food and Beverage Industry Standards Interview

- Food Safety and Hygiene: Understanding and applying HACCP principles, GMPs (Good Manufacturing Practices), and allergen management protocols. This includes practical knowledge of sanitation procedures and preventing cross-contamination.

- Quality Control and Assurance: Knowing how to implement quality control checks throughout the food production process, from raw materials to finished product. This involves understanding quality standards, testing methodologies, and corrective actions for non-conformances.

- Food Labeling and Regulations: Familiarity with legal requirements for food labeling, including ingredient lists, nutritional information, and allergen declarations. Understanding variations across different jurisdictions is beneficial.

- Supply Chain Management: Understanding the flow of goods from farm to table, including sourcing, storage, transportation, and distribution. This encompasses issues of traceability and sustainability.

- Food Waste Reduction Strategies: Knowledge of effective methods for minimizing food waste throughout the supply chain, including strategies for inventory management and efficient production processes.

- Beverage-Specific Standards: Depending on the role, detailed knowledge of brewing, winemaking, or other beverage production processes, including relevant quality control and safety standards.

- Industry Best Practices: Staying updated on emerging trends, technologies, and best practices in the food and beverage industry, demonstrating continuous professional development.

- Problem-Solving and Decision-Making: Ability to identify and resolve food safety or quality issues effectively, demonstrating critical thinking and problem-solving skills.

Next Steps

Mastering Knowledge of Food and Beverage Industry Standards is crucial for career advancement in this dynamic sector. A strong understanding of these standards demonstrates your commitment to quality, safety, and compliance – highly valued attributes by employers. To significantly boost your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the food and beverage industry. We provide examples of resumes specifically designed for candidates with expertise in Food and Beverage Industry Standards to help guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good