Unlock your full potential by mastering the most common Knowledge of Construction Industry Standards interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Knowledge of Construction Industry Standards Interview

Q 1. What are the key components of OSHA regulations relevant to construction?

OSHA (Occupational Safety and Health Administration) regulations for construction are extensive, focusing on preventing workplace hazards. Key components include fall protection, hazard communication, scaffolding safety, personal protective equipment (PPE) requirements, and lockout/tagout procedures.

- Fall Protection: This is paramount, encompassing the use of guardrails, safety nets, and personal fall arrest systems. Imagine working on a high-rise – these regulations are life-saving.

- Hazard Communication: Employers must clearly identify and communicate all potential hazards, including chemical safety data sheets (SDS) and proper training. Think about handling hazardous materials like asbestos – proper communication is crucial.

- Scaffolding Safety: OSHA provides strict guidelines on erecting, using, and disassembling scaffolding to prevent collapses. A poorly built scaffold can lead to catastrophic accidents.

- Personal Protective Equipment (PPE): Workers must use appropriate PPE, such as hard hats, safety glasses, gloves, and safety harnesses, depending on the task. It’s like wearing a suit of armor tailored for the specific job.

- Lockout/Tagout: This crucial procedure ensures that dangerous energy sources (electricity, machinery) are isolated and rendered inoperable before maintenance or repair. This prevents accidental start-ups that can cause serious injury.

Non-compliance with OSHA can result in hefty fines and potential legal action. Regular safety training, inspections, and incident reporting are vital for maintaining compliance.

Q 2. Explain the importance of building codes and their impact on construction projects.

Building codes are sets of rules and standards designed to ensure the safety, health, and welfare of building occupants and the public. They cover various aspects, from structural integrity to fire safety, accessibility, and energy efficiency. These codes directly impact construction projects by dictating design, material selection, construction methods, and inspection processes.

- Impact on Design: Codes dictate minimum requirements for structural strength, load-bearing capacity, and resistance to natural disasters like earthquakes and hurricanes. For example, the required number of exits in a building is directly specified in the building code.

- Material Selection: Codes often mandate specific materials or performance standards for things like fire resistance, insulation, and structural components. Choosing materials that meet the code ensures the building’s safety.

- Construction Methods: Construction techniques and processes are subject to code regulations, ensuring correct installation and quality workmanship. For instance, the depth of foundation footings is typically dictated by local codes.

- Inspections: Codes require regular inspections at different stages of construction to verify compliance. This assures building quality and conformity to standards.

Ignoring building codes can lead to project delays, legal issues, structural problems, and even collapse, posing significant risks to the project and the public.

Q 3. Describe your experience with LEED certification or other green building standards.

I’ve been involved in several projects seeking LEED (Leadership in Energy and Environmental Design) certification. LEED is a globally recognized green building rating system that assesses a building’s environmental performance across various criteria. My experience includes:

- Sustainable Site Development: This involves minimizing land disturbance, protecting existing vegetation, and promoting sustainable transportation options. For example, designing a building to minimize its ‘carbon footprint’ by using recycled materials and renewable energy.

- Water Efficiency: This focuses on reducing water consumption through efficient fixtures and landscaping. One example is incorporating rainwater harvesting systems.

- Energy Efficiency: This involves optimizing building design and systems to minimize energy usage. This might include the use of high-performance windows and energy-efficient HVAC systems.

- Materials and Resources: This emphasizes the use of recycled and regionally sourced materials to reduce embodied carbon and transportation impacts. For example, selecting locally sourced timber for construction.

- Indoor Environmental Quality: This prioritizes creating a healthy and comfortable interior environment with good air quality and daylighting. This includes the use of non-toxic paints and proper ventilation.

Achieving LEED certification requires meticulous documentation and adherence to rigorous standards throughout the project lifecycle. It adds complexity but greatly enhances the building’s value and sustainability profile.

Q 4. How do you ensure compliance with local, state, and federal building codes?

Ensuring compliance begins with a thorough understanding of all applicable codes – local, state, and federal. This involves:

- Code Research: This is a crucial first step, and I use online resources, building department websites, and consultation with code experts.

- Design Review: The project design must meticulously comply with all relevant codes from the outset. This avoids costly rework later on.

- Permitting: Submitting complete and accurate permit applications to the relevant authorities is essential.

- Inspections: Working closely with inspectors during all phases of construction to address any issues proactively.

- Documentation: Maintaining accurate and complete records of all inspections, materials used, and construction practices is key.

- Ongoing Monitoring: Regularly reviewing and updating knowledge of the codes to remain current.

Proactive compliance saves time, money, and prevents potential legal and safety problems. Ignoring codes can lead to costly corrections, delays, and legal ramifications.

Q 5. What are your strategies for managing risk related to construction industry standards?

Managing risk associated with construction industry standards requires a multi-pronged approach:

- Proactive Risk Assessment: Identifying potential risks related to code compliance, safety, and environmental regulations early in the project.

- Regular Safety Training: Providing comprehensive safety training to all workers to ensure they understand and follow all relevant standards.

- Quality Control Measures: Implementing strict quality control procedures throughout the construction process to detect and correct errors early on.

- Insurance: Securing appropriate insurance coverage to protect against potential liabilities.

- Contingency Planning: Developing plans to address potential problems or delays caused by code violations or unforeseen circumstances.

- Documentation: Meticulous record-keeping of all relevant aspects of the project from the initial design through to completion.

A proactive approach minimizes unexpected problems and ensures that the project is completed safely, efficiently, and within budget. This ensures a smooth project completion without unnecessary delays or financial penalties.

Q 6. How familiar are you with the International Building Code (IBC)?

I’m very familiar with the International Building Code (IBC). It’s a widely adopted model building code that provides a comprehensive set of minimum standards for building construction and safety. My familiarity extends to its various sections, including:

- Chapter 1: Administration: This covers permit processes, inspections, and general administrative requirements.

- Chapter 2: Definitions: Understanding the precise definitions of terms used within the IBC is critical.

- Chapter 3: General Provisions: This section addresses general requirements related to accessibility, fire safety, and other critical aspects.

- Chapter 4 through 33: Specific Construction Requirements: These chapters cover detailed regulations for various building systems like structural, plumbing, electrical, and mechanical systems.

The IBC serves as a foundation for many jurisdictions’ local codes, although specific requirements may vary based on location and local conditions. Understanding the IBC is essential for anyone involved in construction.

Q 7. Explain your understanding of different types of construction contracts and their implications.

Construction contracts define the legal agreement between the owner and the contractor. Different types of contracts have varying implications on risk allocation and responsibilities:

- Lump Sum (Fixed Price): The contractor agrees to complete the work for a pre-determined fixed price. Risk is largely borne by the contractor, while the owner has price certainty.

- Cost Plus Fee: The contractor is reimbursed for actual costs plus a predetermined fee. Risk is shared between the owner and contractor, but cost certainty is reduced. This is often used for projects with unclear scopes.

- Unit Price: Payment is based on the quantities of work performed (e.g., per square foot or cubic yard). This contract is suitable for projects where quantities can be accurately estimated.

- Design-Bid-Build: The owner hires a designer, who prepares plans and specifications, and then the project is bid out to a contractor. This is a traditional approach but can lead to potential communication issues between the design and construction phases.

- Design-Build: The owner contracts with a single entity responsible for both design and construction. This simplifies the process and can improve communication and coordination.

- Construction Management: A construction manager oversees the project on behalf of the owner, coordinating the various design and construction aspects. This method provides more control and flexibility for the owner.

Choosing the right contract type is crucial and depends on the project’s complexity, risk tolerance, and the owner’s and contractor’s preferences. Carefully reviewing and understanding the terms and conditions are vital to avoid potential disputes.

Q 8. Describe your experience with quality control procedures in construction.

Quality control (QC) in construction is a systematic process ensuring the project meets specified requirements, standards, and client expectations. My experience involves implementing and overseeing QC procedures at every stage, from initial design review to final project handover.

- Material Inspection: Verifying materials meet specifications through testing and documentation. For instance, I’ve personally overseen concrete testing to ensure compressive strength aligns with project requirements, preventing costly rework later.

- Workmanship Verification: Regularly inspecting work in progress to ensure adherence to drawings and specifications. This includes checking dimensions, levels, and finishes. I once identified a minor deviation in wall alignment during framing, allowing for early correction, avoiding significant issues during later stages.

- Documentation and Reporting: Maintaining detailed records of inspections, tests, and any non-conformances. This involves using checklists, photographic evidence, and generating reports that clearly highlight any issues and recommended corrective actions. These reports are critical for project transparency and accountability.

- Corrective Actions: Implementing corrective actions for any identified defects or non-conformances, ensuring these actions are documented and verified. This includes using a robust system for tracking and resolution of identified problems, ensuring no issue falls through the cracks.

I use a combination of visual inspections, sampling tests, and specialized equipment depending on the project requirements and stage. My goal is to proactively identify and address potential problems before they escalate, saving time, money, and ensuring a high-quality final product.

Q 9. How do you ensure that construction projects adhere to safety regulations?

Ensuring safety on construction sites is paramount. My approach integrates several strategies to maintain a safe working environment, adhering to OSHA (or relevant regional) regulations.

- Safety Training: Providing comprehensive safety training to all workers, covering topics such as hazard identification, personal protective equipment (PPE) usage, and emergency procedures. I frequently conduct toolbox talks to reinforce safety awareness and address specific job-site hazards.

- Hazard Identification and Risk Assessment: Proactively identifying potential hazards and implementing control measures to mitigate risks. This involves regular site inspections, conducting job hazard analyses (JHAs), and implementing appropriate safety protocols. For instance, I’ve implemented specific measures to prevent falls from heights, including the use of scaffolding and harnesses.

- Implementing Safety Protocols: Establishing and enforcing clear safety protocols, including procedures for working at heights, handling hazardous materials, and operating machinery. This often involves the use of signage, barriers, and designated safe zones.

- Regular Inspections: Conducting regular inspections of the site to ensure that safety protocols are being followed and that any hazards are promptly addressed. This includes both formal inspections and informal walkthroughs to maintain a constant awareness of site conditions.

- Incident Reporting and Investigation: Establishing a robust system for reporting and investigating any accidents or near misses. This ensures that lessons learned are incorporated into future practices to prevent similar incidents.

Safety is not just a policy but a culture. I believe in fostering a collaborative environment where everyone feels responsible for their own safety and the safety of their colleagues.

Q 10. How do you manage conflicts between project requirements and building codes?

Conflicts between project requirements and building codes are inevitable. My approach involves a collaborative and methodical resolution process.

- Clearly Define the Conflict: First, we meticulously identify the precise conflict, documenting the specific project requirement and the contradicting building code section. This clarity is crucial.

- Consult Relevant Codes and Standards: We conduct thorough research to understand the intent and rationale behind both the project requirement and the building code. Sometimes, a deeper understanding reveals a way to harmonize seemingly conflicting elements.

- Explore Alternatives: We brainstorm alternative solutions that meet both the project’s needs and comply with building codes. This might involve design modifications, material substitutions, or proposing alternative approaches.

- Consult with Stakeholders: We involve all relevant stakeholders, including the architect, engineer, contractor, and client, to discuss the alternatives and reach a consensus on the optimal solution. Open communication is paramount at this stage.

- Document the Decision: We carefully document the chosen solution, including the rationale, any waivers or exceptions obtained, and the impact on the project schedule and budget. Thorough documentation prevents future misunderstandings.

- Obtain Necessary Approvals: In cases requiring variance, we apply for necessary permits and approvals from the relevant authorities. We make sure to follow the appropriate channels and meet any requirements.

My experience has shown that proactive communication and collaboration are key to resolving these conflicts efficiently and effectively.

Q 11. Describe your experience with construction scheduling and its relation to industry standards.

Construction scheduling is a critical aspect of project management. It involves planning and sequencing activities to complete the project on time and within budget. My experience aligns with industry standards, utilizing methods like the Critical Path Method (CPM) and various software tools.

- CPM Scheduling: I’m proficient in developing CPM schedules, identifying critical paths, and analyzing float times to understand the project’s dependencies. This allows for effective resource allocation and risk management.

- Software Proficiency: I’m experienced using scheduling software such as Primavera P6 or MS Project to create, update, and analyze project schedules. These tools allow for detailed task breakdown, resource assignments, and progress tracking.

- Baseline Schedule Development: I develop a detailed baseline schedule at the project outset, including all activities, durations, and dependencies. This baseline serves as a benchmark for monitoring progress and identifying potential delays.

- Progress Monitoring and Reporting: Regularly monitor progress against the baseline schedule, using earned value management (EVM) principles to assess performance and identify variances. I prepare regular progress reports for stakeholders, highlighting any potential schedule risks and proposed mitigation strategies.

- Schedule Updates and Revisions: I proactively update and revise the schedule as needed, incorporating changes in project scope, resource availability, and unforeseen delays. Transparency and regular communication are key to successful schedule adjustments.

Adherence to industry standards in scheduling ensures accuracy, consistency, and effective communication across the project team. This directly impacts cost control and project success.

Q 12. How do you handle situations where industry standards conflict with project specifications?

When industry standards conflict with project specifications, a systematic approach is crucial to ensure both compliance and project goals are met.

- Document the Discrepancy: Clearly document the specific conflict, referencing both the relevant industry standard and the project specification. This creates a record for future reference.

- Evaluate the Implications: Assess the potential implications of each option – adhering to the industry standard versus following the project specification. Consider safety, functionality, cost, and legal compliance.

- Seek Clarification and Consultation: Consult with relevant experts, such as engineers, architects, or legal counsel, to understand the potential consequences of each approach. This step ensures informed decision-making.

- Negotiate and Compromise: Work collaboratively with stakeholders to find a mutually acceptable solution that addresses both safety and project goals. This might involve revisions to the specifications, obtaining waivers, or selecting alternative approaches.

- Document the Resolution: Thoroughly document the final decision, including the rationale, any compromises made, and the impact on the project. This transparent documentation safeguards against future disputes.

Often, the solution lies in finding a compromise that balances compliance with project requirements, ensuring both safety and functionality are maintained. Clear communication and transparency throughout the process are essential.

Q 13. Explain your understanding of sustainable construction practices and relevant standards.

Sustainable construction practices focus on minimizing environmental impact throughout a building’s lifecycle. My understanding encompasses various aspects and relevant standards, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method).

- Material Selection: Prioritizing the use of sustainable and locally sourced materials with lower embodied carbon. This reduces transportation emissions and supports local economies. For example, selecting reclaimed wood or recycled steel.

- Energy Efficiency: Designing buildings with high energy efficiency, utilizing passive design strategies and incorporating renewable energy sources, like solar panels. This includes proper insulation and efficient HVAC systems.

- Water Conservation: Implementing water-efficient fixtures and landscaping, minimizing water consumption. This might involve rainwater harvesting systems or drought-tolerant landscaping.

- Waste Management: Minimizing construction waste through careful planning, material selection, and recycling programs. We implement waste reduction strategies, from initial design to demolition, diverting waste from landfills.

- Indoor Environmental Quality: Prioritizing indoor air quality through material selection and ventilation systems. This ensures a healthier and more productive environment for occupants.

Adherence to standards like LEED or BREEAM provides a framework for measuring and verifying the sustainability performance of a project, helping to achieve environmentally responsible outcomes. I believe in incorporating sustainable practices throughout the entire lifecycle of a project, creating environmentally friendly buildings.

Q 14. What are some common construction defects and how are they prevented?

Common construction defects range from minor issues to significant structural problems. Preventing these defects requires a proactive approach.

- Cracking: Foundation cracks, wall cracks, or concrete cracking can result from inadequate foundation design, poor workmanship, or shrinkage. Prevention involves proper soil testing, reinforced concrete, and appropriate curing procedures.

- Water Leakage: Roof leaks, window leaks, or plumbing leaks often stem from improper installation, lack of sealant, or faulty materials. Prevention necessitates careful installation, quality materials, and proper waterproofing.

- Settlement Issues: Uneven settlement can cause cracks and damage. Preventing this requires proper site preparation, suitable foundation design, and compaction of soil.

- Defective Materials: Using low-quality or unsuitable materials can lead to various defects. Prevention involves stringent material testing and verification before use.

- Poor Workmanship: Improper installation or negligent practices can cause a wide range of issues. Prevention requires thorough training of workers, regular inspections, and quality control measures.

A comprehensive quality control program, thorough inspections at each stage of construction, and the use of qualified and experienced tradespeople are key to preventing these defects. Addressing issues early is significantly more cost-effective than dealing with them after project completion.

Q 15. Describe your experience with document control and its role in maintaining compliance.

Document control is the cornerstone of maintaining compliance in construction. It’s a systematic process of creating, reviewing, approving, distributing, storing, and disposing of project documents. Think of it as the central nervous system of a project, ensuring everyone is working from the same, approved information. My experience spans over 10 years, where I’ve implemented and managed document control systems using both paper-based and electronic methods (like SharePoint and dedicated document management software).

Maintaining compliance involves ensuring that all documents, from contracts and specifications to shop drawings and inspection reports, are current, accurate, and readily available. A robust document control system helps prevent costly errors, delays, and legal disputes. For instance, a failure to control the latest approved drawings can lead to construction of elements that do not comply with the design, resulting in rework and financial penalties. My approach always involves clear version control, defined approval workflows, and regular audits to maintain the integrity of the system.

I’ve successfully used a combination of ISO 9001 compliant document control systems and bespoke solutions tailored to specific project needs. Key aspects of my approach are establishing clear ownership and responsibility for each document, using a consistent naming convention, and employing a robust change management process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key differences between various types of building materials and their compliance standards?

Building materials vary significantly in their properties, applications, and, critically, their compliance standards. The differences stem from factors like their composition, strength, durability, fire resistance, and environmental impact. For example, steel, concrete, timber, and masonry each have distinct standards.

Steel: Complies with standards like ASTM A992 (for structural steel) and requires certifications proving its properties meet specified yield strength and other critical parameters.

Concrete: Its compliance is dictated by standards specifying compressive strength (e.g., ACI 318 for concrete structures in the US) and mix design, requiring rigorous testing to ensure it meets the project’s requirements.

Timber: Standards govern its grading, treatment (e.g., for fire or pest resistance), and moisture content. Certification bodies ensure lumber meets the specified grade and treatment requirements.

Masonry: Compliance focuses on the type and strength of the bricks or blocks, the mortar used, and the construction techniques employed. Specific standards address masonry wall design and stability.

Ensuring compliance involves verifying that the materials used on site have the necessary certifications and test reports, often checking these against the approved submittals. Failing to do so can lead to structural issues, safety hazards, and legal liabilities.

Q 17. How do you integrate technology, such as BIM, to improve compliance with construction standards?

Building Information Modeling (BIM) is a revolutionary technology that significantly improves compliance with construction standards. BIM creates a digital representation of the physical and functional characteristics of a facility. This digital model becomes a single source of truth for all project stakeholders.

By integrating BIM, we can achieve compliance in several ways:

Clash detection: BIM allows for early identification and resolution of clashes between different building services and structural elements, preventing costly rework on-site.

Accurate quantity takeoff: BIM provides precise material quantities, reducing waste and ensuring the correct materials are ordered, minimizing risks related to material substitutions or shortages.

Enhanced visualization and communication: BIM models facilitate clear communication and understanding of design intent, minimizing the risk of misinterpretations leading to non-compliance.

Automated compliance checks: BIM software can automatically check designs for compliance with relevant codes and standards, identifying potential issues before construction begins.

For example, during a recent project, we used BIM software to detect a clash between ductwork and structural steel before construction began. This saved significant time and cost by avoiding expensive on-site modifications. BIM software can also generate reports that automatically demonstrate compliance with building codes and standards.

Q 18. What is your experience with change management within the context of construction standards?

Change management is a critical aspect of construction, especially when dealing with compliance. Changes to designs, specifications, or materials must be carefully managed to ensure continued compliance with all standards. My approach involves a structured process, typically including:

Formal change request process: All changes must be submitted through a formal process, documenting the reason for the change, the impact on the project, and the proposed solution.

Impact assessment: A thorough assessment is performed to evaluate the impact of the change on cost, schedule, and compliance with relevant standards and regulations. This may involve consulting with engineers, architects, and other relevant specialists.

Approval workflow: Changes require approval from relevant stakeholders, with clear documentation of approval and authorization.

Updated documentation: All relevant documents, including drawings, specifications, and the project schedule, are updated to reflect approved changes. Version control is key.

Failing to manage changes effectively can lead to significant risks including rework, delays, cost overruns, and non-compliance leading to legal challenges. A well-defined change management process, diligently followed by all project stakeholders, is essential for project success and compliance.

Q 19. How do you ensure that subcontractors are complying with industry standards?

Ensuring subcontractor compliance is paramount for overall project success and legal protection. My strategy is proactive and multifaceted:

Pre-qualification process: Subcontractors undergo a rigorous pre-qualification process, verifying their experience, qualifications, insurance coverage, and commitment to safety and quality standards. This includes reviewing their safety records and past project performance.

Contractual obligations: Contracts clearly outline the subcontractor’s responsibilities regarding compliance with relevant industry standards, including providing certifications, insurance, and necessary documentation. The contract should clearly state consequences for non-compliance.

Regular inspections and audits: Regular inspections and audits of the subcontractor’s work are conducted to monitor their adherence to the project’s specifications and compliance with industry standards. This involves reviewing their work practices, documentation, and safety procedures.

Communication and collaboration: Open and consistent communication is maintained with subcontractors to address concerns, clarify requirements, and provide support in achieving compliance. Regular meetings and progress updates are crucial.

A strong subcontractor management plan, coupled with transparent communication and a robust enforcement mechanism, is crucial for maintaining a compliant and high-performing project team.

Q 20. Explain your approach to investigating and resolving non-compliance issues on a construction site.

Investigating and resolving non-compliance issues requires a systematic and thorough approach. My process involves the following steps:

Identification and documentation: Clearly identify the non-compliance issue, documenting its nature, location, and potential impact. Gather photographic and video evidence, if necessary.

Root cause analysis: Determine the underlying causes of the non-compliance. This might involve interviewing relevant personnel, reviewing documents, and analyzing construction records.

Corrective actions: Develop and implement corrective actions to address the non-compliance issue and prevent its recurrence. This could involve rework, material replacement, or process adjustments.

Preventive actions: Implement preventive actions to prevent similar non-compliance issues from occurring in the future. This could involve revising procedures, improving training, or strengthening communication.

Documentation and reporting: Meticulously document all aspects of the investigation, corrective actions, and preventive actions. This often involves generating a formal report outlining the issue, its resolution, and recommendations for future prevention.

For instance, if a non-compliant weld is discovered, we’d investigate the welder’s qualifications, review the welding procedures, and assess the quality of the welding materials. Corrective actions would involve rectifying the faulty weld, and preventive actions might include additional welder training or stricter inspection protocols.

Q 21. Describe your understanding of construction waste management and its environmental implications.

Construction waste management is critical for environmental sustainability and cost-effectiveness. It encompasses the planning, collection, processing, and disposal of waste generated during the construction process. The environmental implications are significant, ranging from greenhouse gas emissions associated with landfill disposal to pollution from improper waste handling.

My approach to construction waste management emphasizes:

Waste reduction strategies: Prioritizing waste reduction through careful planning, material selection, and efficient construction techniques. This involves using modular construction, prefabrication, and optimizing material quantities based on accurate BIM models.

Waste segregation: Implementing effective waste segregation at source, separating materials like timber, concrete, metals, and plastics to facilitate recycling and reuse.

Recycling and reuse: Maximizing the recycling and reuse of construction materials, diverting them from landfills and minimizing the need for new materials.

Responsible disposal: Ensuring that waste that cannot be recycled or reused is disposed of responsibly and in accordance with all environmental regulations, using licensed waste disposal facilities.

Documentation and reporting: Maintaining detailed records of waste generation, recycling, and disposal, compiling reports to track progress and identify areas for improvement.

Failing to manage construction waste properly can result in environmental damage, regulatory fines, and reputational harm. A proactive and well-planned waste management strategy is crucial for both environmental responsibility and economic efficiency.

Q 22. How familiar are you with accessibility standards, such as the ADA?

The Americans with Disabilities Act (ADA) is paramount in my work. I’m intimately familiar with its accessibility guidelines, particularly as they relate to building design and construction. This includes understanding requirements for ramps, elevators, accessible restrooms, signage, and clear pathways free of obstructions. For instance, I’ve ensured proper ramp slopes (following ADA’s 1:12 ratio), implemented tactile paving at intersections, and verified that door handles are appropriately sized and placed. Beyond the basics, I’m also aware of the nuances involving things like accessible parking spaces, appropriate door widths for wheelchairs, and provisions for people with visual or auditory impairments. I regularly consult the ADA Standards for Accessible Design to ensure complete compliance in all projects I oversee. In short, ADA compliance is not just a box to tick, but a core principle integrated into every stage of my project planning and execution.

Q 23. How do you stay updated on changes and revisions to relevant construction industry standards?

Staying current with construction industry standards is crucial. I actively subscribe to publications like the Journal of Construction Engineering and Management, and I’m a member of professional organizations such as the Associated General Contractors of America (AGC). These memberships provide access to regular updates, webinars, and conferences highlighting changes in codes and best practices. I also regularly check the websites of relevant standard-setting bodies, including the International Code Council (ICC) for building codes, OSHA for safety regulations, and ASTM International for materials standards. Finally, I actively engage with industry colleagues, attending workshops and networking events to learn about emerging trends and regulatory modifications. Keeping informed is an ongoing process, ensuring I always apply the most up-to-date and compliant methods.

Q 24. Explain your experience with project closeout procedures and final inspections.

Project closeout is a meticulously documented process I approach systematically. It begins well before the project’s completion, with a focus on comprehensive documentation of every aspect of the construction, from permits and inspections to change orders and material certifications. Final inspections involve a thorough walk-through with all relevant stakeholders – including clients, inspectors, and subcontractors – to identify and address any outstanding issues. This includes verifying that all work meets the approved plans and specifications and that the site is clean and safe. As-built drawings are meticulously updated to reflect any changes from the original plans. Once all inspections are completed and approvals received, the final payment is processed, and all relevant contracts and documentation are archived. I consider this phase as critical as any other, ensuring a smooth project handover and minimizing potential future disputes.

Q 25. What is your approach to risk assessment related to construction safety?

My approach to risk assessment for construction safety is proactive and multi-faceted. It starts with a thorough site analysis, identifying potential hazards like trench collapses, falls from heights, electrical hazards, and the presence of hazardous materials. This is followed by a detailed review of the project plans, focusing on identifying potential risks inherent in the construction methodology. We use a combination of quantitative and qualitative risk assessment tools, such as hazard and operability studies (HAZOP) and bow-tie analysis. The identified risks are then prioritized based on their likelihood and potential severity. From there, we develop control measures to mitigate these risks – these could range from providing personal protective equipment (PPE) to implementing specific work procedures and safety training. Regular safety meetings are held to discuss any emerging risks and to reinforce safety protocols.

Q 26. Describe your experience with conducting site safety inspections.

Conducting site safety inspections is a regular part of my routine. I utilize a checklist-based approach to ensure consistency and thoroughness, focusing on areas like proper use of PPE, adherence to safety regulations, housekeeping practices, and the condition of equipment. I look for potential hazards, such as exposed wiring, unsafe scaffolding, or obstructed pathways. During inspections, I take photos and notes documenting findings, and I immediately address any immediate hazards. Any more significant issues are communicated to the relevant contractors and supervisors, with corrective actions documented and verified. These inspections aren’t just about finding violations; they’re about fostering a proactive safety culture on the site, reminding everyone of the importance of safety and promoting a culture of hazard identification and prevention. Regular, thorough inspections are key to minimizing incidents and creating a safe working environment.

Q 27. How do you use industry standards to improve project efficiency and cost-effectiveness?

Industry standards are integral to improving project efficiency and cost-effectiveness. Using standardized design and construction methods streamlines the process, reducing material waste and labor costs. For example, employing prefabricated components often reduces on-site construction time and minimizes errors. Adhering to Lean Construction principles, often guided by industry best practices, improves workflow, minimizing delays and reducing unnecessary expenses. Adopting Building Information Modeling (BIM) helps visualize and coordinate the project effectively, preventing clashes and rework. Finally, careful adherence to codes and standards reduces the likelihood of costly rework stemming from regulatory non-compliance. In essence, leveraging industry standards helps avoid costly mistakes, allowing us to execute projects efficiently and within budget.

Q 28. Describe a time you had to enforce compliance with a construction standard despite challenges.

On a recent high-rise project, a subcontractor attempted to deviate from the specified fireproofing methods outlined in the project specifications and relevant building codes. While they argued their method was faster and cheaper, it compromised the integrity of the fire safety system. Despite the initial pushback and the potential for project delays, I stood firm. I presented them with the relevant codes and specifications, clearly demonstrating the safety risks associated with their proposed changes. We held a meeting with all relevant stakeholders, presenting a thorough risk assessment. Ultimately, they agreed to adhere to the original specifications. Although it caused temporary delays, adhering to the safety standards prevented potential catastrophes and upheld our commitment to building safe and compliant structures. This experience reinforced the importance of uncompromising safety compliance, regardless of external pressures.

Key Topics to Learn for Knowledge of Construction Industry Standards Interview

- Safety Regulations and Compliance: Understand OSHA standards, local building codes, and common safety protocols. Consider practical applications like hazard identification, risk mitigation, and incident reporting procedures.

- Building Codes and Standards: Familiarize yourself with relevant building codes (e.g., IBC, IRC) and their practical application in project planning and execution. Explore how these codes ensure structural integrity and safety.

- Quality Control and Assurance: Learn about quality management systems (QMS) and their role in ensuring projects meet specifications. Consider practical examples of quality checks at various stages of construction.

- Contract Administration and Management: Understand different contract types (e.g., lump sum, cost-plus) and their implications. Explore dispute resolution methods and best practices for contract management.

- Sustainable Construction Practices: Learn about LEED certification, green building materials, and energy-efficient design. Discuss how sustainable practices impact project cost and environmental responsibility.

- Project Management Methodologies: Familiarize yourself with methodologies like Agile, Lean Construction, and traditional project management approaches. Explore their application in managing construction projects effectively.

- Material Specifications and Selection: Understand the importance of specifying appropriate materials based on project requirements and industry best practices. Consider the impact of material selection on cost, durability, and sustainability.

Next Steps

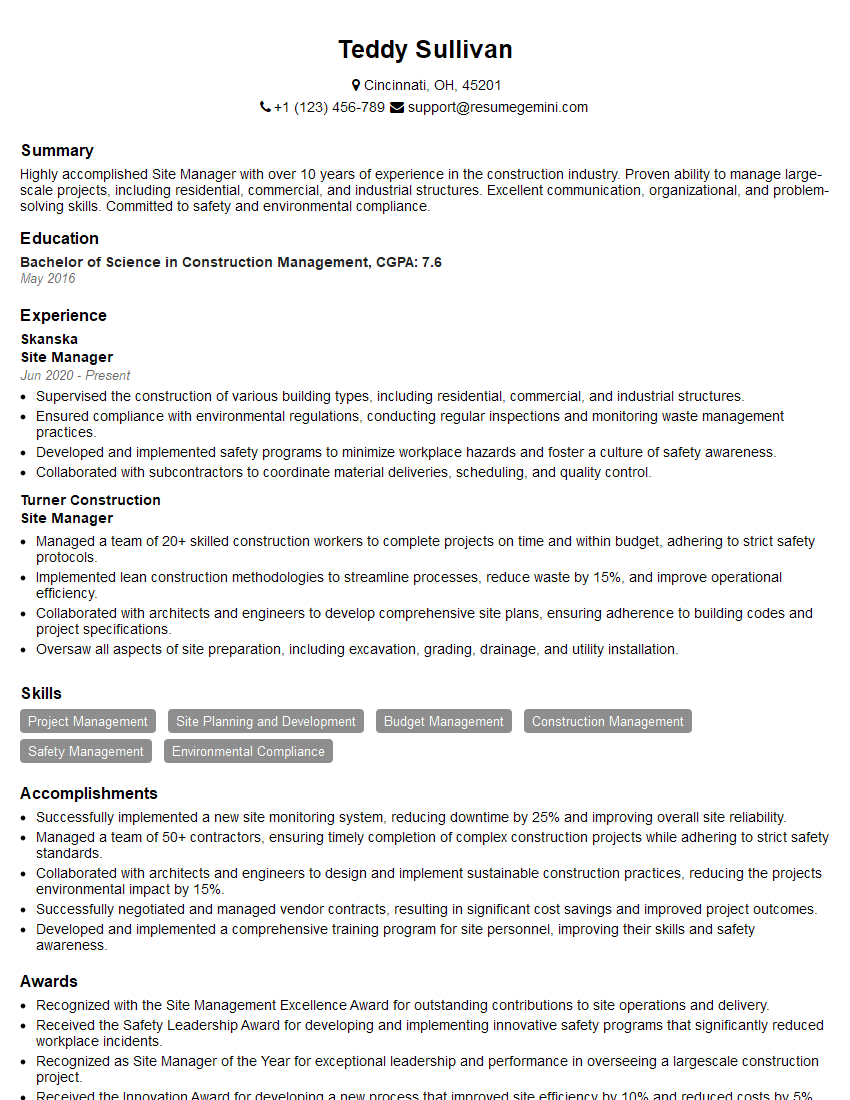

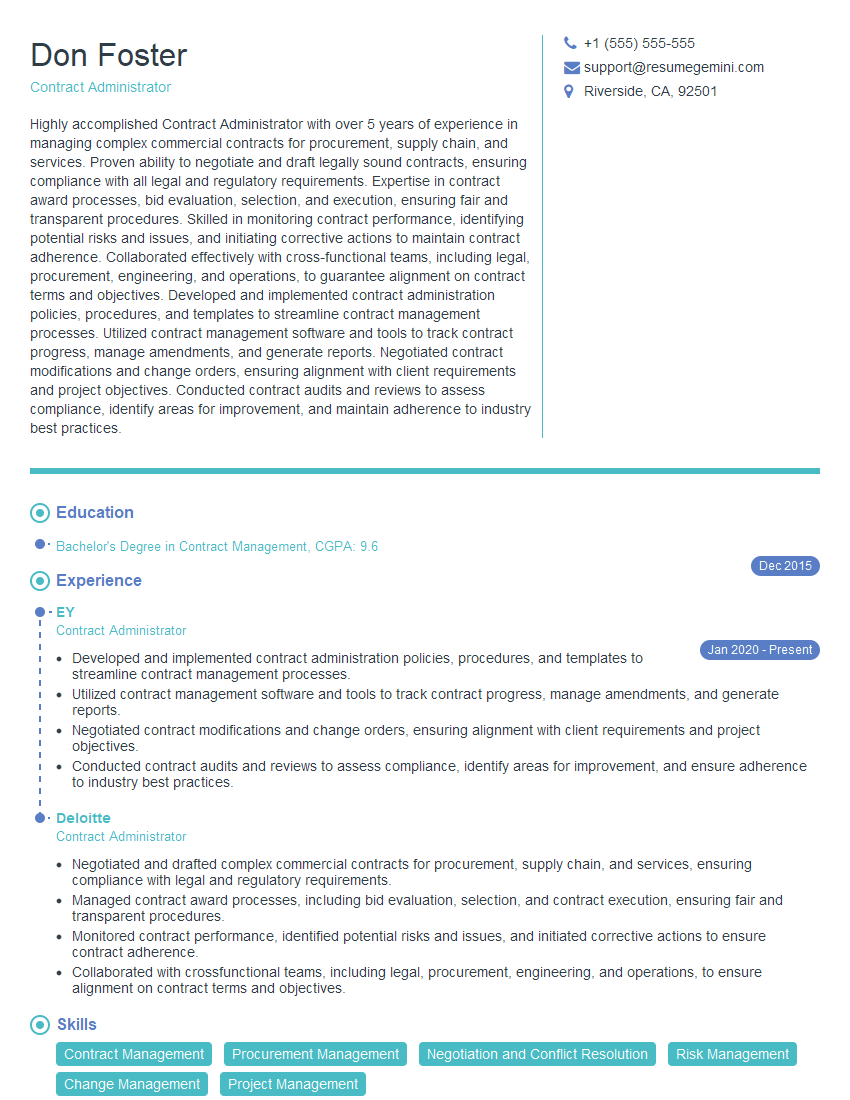

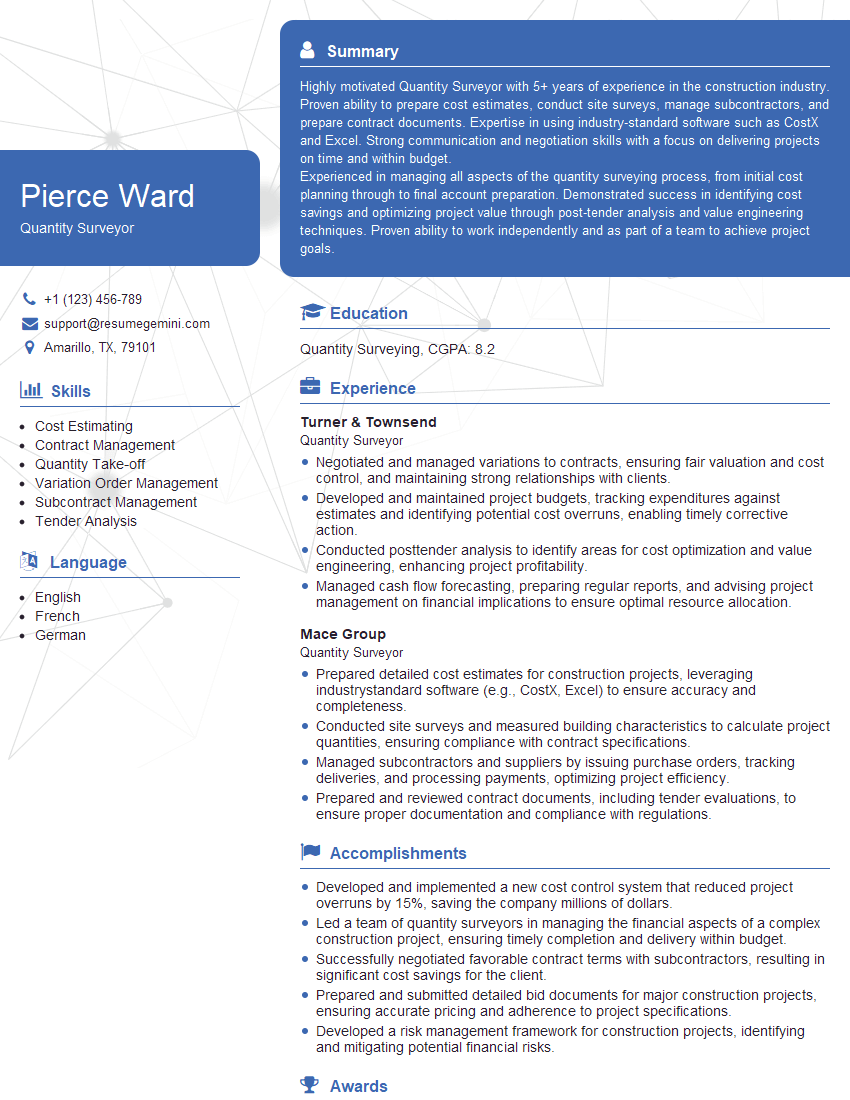

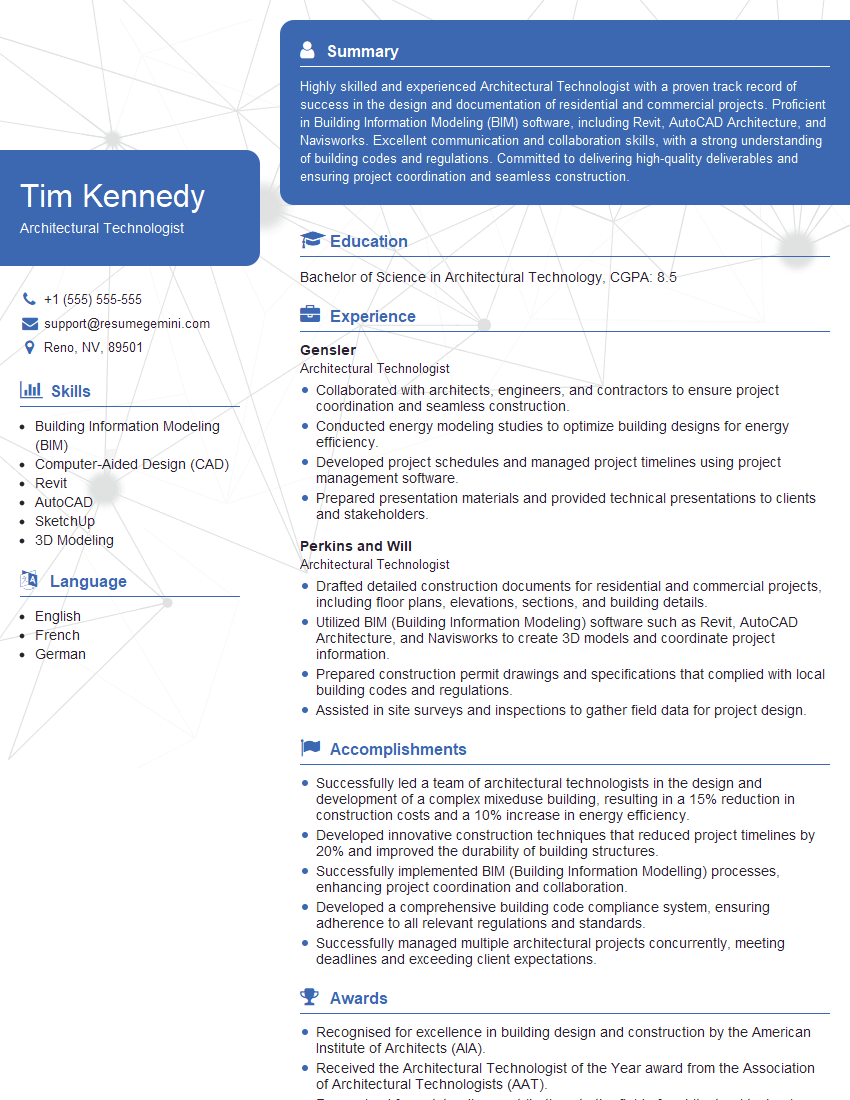

Mastering Knowledge of Construction Industry Standards is crucial for career advancement in this dynamic field. A strong understanding of these standards demonstrates your competence and commitment to quality and safety, opening doors to higher-level positions and increased earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource for building professional resumes that get noticed. They offer examples of resumes tailored to the Knowledge of Construction Industry Standards, helping you showcase your expertise effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good