Are you ready to stand out in your next interview? Understanding and preparing for Knowledge of Mining Industry Standards interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Knowledge of Mining Industry Standards Interview

Q 1. Explain the importance of adhering to ISO 45001 in mining operations.

ISO 45001 is the internationally recognized standard for occupational health and safety (OHS) management systems. In the mining industry, its importance is paramount because of the inherent risks involved. Adhering to ISO 45001 demonstrates a commitment to proactively identifying, assessing, and controlling hazards, ultimately minimizing the risk of workplace injuries, illnesses, and fatalities. This translates to a safer work environment, improved worker morale, reduced costs associated with accidents, and enhanced regulatory compliance.

Specifically, ISO 45001 provides a framework for:

- Risk assessment and control: Systematically identifying and managing hazards specific to mining operations, such as ground control issues, explosives handling, and confined space entry.

- Emergency preparedness and response: Establishing clear procedures for dealing with emergencies like mine collapses or equipment malfunctions.

- Worker participation and consultation: Ensuring worker involvement in health and safety decisions, empowering them to identify and report hazards.

- Continuous improvement: Regularly reviewing and improving the OHS management system based on performance data and feedback.

For example, a mine adhering to ISO 45001 might implement a comprehensive training program for all employees on hazard identification and safe work practices, conduct regular safety inspections, and maintain detailed records of all incidents and near misses. This proactive approach significantly reduces the likelihood of serious accidents and promotes a culture of safety.

Q 2. Describe your experience with the implementation of a Mine Safety Management System.

In my previous role at [Previous Company Name], I was instrumental in the implementation of a Mine Safety Management System (MSMS) based on the principles of ISO 45001. This involved a multi-phased approach:

- Gap Analysis: We initially assessed the existing safety procedures against the ISO 45001 requirements, identifying areas for improvement.

- Policy Development: A comprehensive health and safety policy was developed, clearly defining roles, responsibilities, and objectives.

- Risk Assessment & Control: We conducted thorough risk assessments for all mining operations, identifying potential hazards and implementing control measures, including engineering controls, administrative controls, and personal protective equipment (PPE).

- Training and Communication: Comprehensive training programs were developed and delivered to all employees on hazard identification, risk control, and emergency procedures. Regular safety meetings and toolbox talks were also implemented to reinforce safety messages.

- Incident Reporting and Investigation: We implemented a robust system for reporting and investigating all incidents, near misses, and accidents to identify root causes and prevent recurrence.

- Auditing and Monitoring: Regular internal audits and management reviews were conducted to ensure the effectiveness of the MSMS.

This project led to a significant reduction in lost-time injuries (LTIs) and a demonstrable improvement in overall safety performance. The success was attributed to strong leadership commitment, employee engagement, and continuous improvement through data analysis and feedback.

Q 3. What are the key aspects of environmental regulations (e.g., permitting) relevant to mining projects?

Environmental regulations governing mining projects are stringent and vary depending on the jurisdiction. Key aspects typically include:

- Environmental Impact Assessments (EIAs): Thorough EIAs are usually required before a mining project can proceed, evaluating potential environmental impacts such as water pollution, air emissions, and habitat destruction.

- Permitting: Obtaining various permits from relevant authorities is crucial, covering aspects like water use, air emissions, waste disposal, and land reclamation.

- Water Management: Strict regulations govern water usage and discharge, often requiring measures to minimize water consumption, prevent pollution, and manage wastewater effectively.

- Waste Management: Regulations dictate how mining waste (tailings, overburden) must be handled, emphasizing safe storage, reclamation, and minimization of environmental impact.

- Air Quality: Controls are usually imposed on air emissions, particularly particulate matter and greenhouse gases, often requiring the use of air pollution control technologies.

- Biodiversity Conservation: Protecting biodiversity and minimizing impacts on ecosystems is a key consideration, sometimes requiring habitat restoration or mitigation measures.

- Rehabilitation and Closure Planning: Mine operators are typically required to develop detailed plans for land reclamation and mine closure, ensuring the site is returned to a safe and environmentally acceptable state after mining ceases.

Non-compliance can lead to significant penalties, operational disruptions, and reputational damage. Engaging experienced environmental consultants and adhering to best practices are crucial for navigating these complex regulatory requirements.

Q 4. How do you ensure compliance with relevant health and safety regulations on a mining site?

Ensuring compliance with health and safety regulations on a mining site requires a multi-faceted approach:

- Proactive Hazard Identification and Risk Assessment: Regular safety inspections, hazard identification checklists, and job safety analyses (JSAs) are used to proactively identify potential hazards.

- Implementation of Control Measures: Appropriate control measures (engineering controls, administrative controls, PPE) are implemented to mitigate identified risks.

- Training and Competency Assurance: All personnel are trained to a high standard on safe work practices specific to their roles. Competency is regularly assessed.

- Emergency Preparedness and Response: Emergency response plans are developed and regularly tested, ensuring personnel are adequately prepared to deal with emergencies.

- Incident Reporting and Investigation: A robust system for reporting and investigating accidents, incidents, and near misses is essential to learn from past events and prevent future occurrences.

- Compliance Monitoring and Auditing: Regular internal audits and compliance checks are conducted to ensure adherence to relevant regulations and company policies.

- Data Analysis and Continuous Improvement: Accident data is analyzed to identify trends and areas for improvement. This data is used to refine safety procedures and enhance the overall safety management system.

Ultimately, a strong safety culture, fostered by leadership commitment and employee engagement, is critical for maintaining a safe work environment.

Q 5. Detail your experience with mine ventilation standards and best practices.

Mine ventilation is crucial for ensuring the health and safety of miners by controlling the levels of harmful airborne contaminants and maintaining a comfortable and breathable atmosphere. My experience involves a deep understanding of relevant standards (e.g., MSHA regulations in the US, similar standards in other jurisdictions) and best practices. This includes:

- Ventilation Planning and Design: This involves using specialized software to model airflow and predict contaminant concentrations within a mine.

- Monitoring and Control: Continuous monitoring of air quality parameters (e.g., methane, carbon monoxide, respirable dust) is essential. Control measures include adjusting ventilation systems and implementing local exhaust ventilation.

- Emergency Ventilation Systems: Backup ventilation systems are crucial in case of equipment failure or emergencies, ensuring safe evacuation of personnel.

- Ventilation Surveys and Audits: Regular surveys and audits are vital to confirm that the ventilation system is operating effectively and that air quality standards are being met.

- Maintenance and Upkeep: Regular maintenance and upkeep of ventilation equipment are vital to ensure its continued functionality and prevent failures.

For example, in a coal mine, effective ventilation is critical to controlling methane levels and preventing explosions. This might involve implementing a sophisticated network of ventilation fans, monitoring methane levels with advanced sensors, and employing emergency ventilation systems to ensure safe evacuation in the event of a methane buildup.

Q 6. Describe your understanding of ground control principles and how they relate to mine safety.

Ground control principles are fundamental to mine safety. They encompass the techniques and strategies used to manage the stability of the ground surrounding mining operations, preventing ground falls, roof collapses, and other geotechnical hazards. Understanding these principles is paramount because ground instability is a leading cause of accidents in underground mining.

Key aspects include:

- Geological Characterization: A thorough understanding of the geological conditions of the mine is essential to predict potential instability.

- Support Systems: Implementing appropriate ground support systems, such as rock bolts, steel sets, and ground reinforcement, is vital to maintain stability.

- Monitoring and Instrumentation: Using instruments such as extensometers and convergence meters to monitor ground movements allows for early detection of instability.

- Stress Analysis: Understanding the stress conditions in the rock mass is crucial for designing effective ground support systems.

- Mine Planning and Design: The mine design itself should consider ground stability, with consideration given to extraction sequences and pillar layouts.

Failing to address ground control effectively can result in catastrophic consequences, such as mine collapses that can lead to injuries or fatalities. Therefore, rigorous ground control programs, guided by experienced geotechnical engineers, are essential in all mining operations.

Q 7. How do you manage risks associated with blasting operations, according to industry standards?

Managing risks associated with blasting operations requires strict adherence to industry standards and best practices, focusing on safety at every stage:

- Pre-blast Planning: This involves detailed planning, including geological surveys, blast design, and risk assessments to determine the appropriate quantity and type of explosives, blast patterns, and safety procedures.

- Drilling and Charging: Strict procedures must be followed during drilling and charging operations, ensuring proper hole spacing, stemming, and detonation techniques. This minimizes the risk of misfires or premature detonations.

- Initiation and Monitoring: Blast initiation must be performed by trained and qualified personnel using appropriate initiation systems. Post-blast monitoring is critical to ensure the blast conformed to the plan and caused no unexpected damage.

- Safety Procedures and Training: Comprehensive training and awareness programs must be implemented to educate all personnel involved in blasting operations about the hazards and safe procedures.

- Emergency Response Plan: A detailed emergency response plan must be in place to handle unexpected events such as misfires, premature detonations, or injuries.

- Post-Blast Inspections: Thorough inspections after each blast are required to check for any unexpected ground movement, flyrock, or damage to surrounding structures.

Compliance with regulatory requirements and best practices, combined with a strong safety culture, is fundamental to mitigating the risks associated with blasting operations. Failure to adhere to these standards can result in serious accidents, environmental damage, and significant legal consequences.

Q 8. Explain your knowledge of mine water management and its environmental impact.

Mine water management is crucial for both environmental protection and operational efficiency. It encompasses all aspects of controlling, treating, and disposing of water associated with mining activities. This includes managing surface water runoff, groundwater inflow, and water used in processing. Failure to properly manage mine water can lead to severe environmental consequences.

Environmental Impacts: Improperly managed mine water can cause significant pollution. Acid mine drainage (AMD), for example, occurs when sulfide minerals in exposed rock react with air and water, producing acidic runoff containing heavy metals like arsenic, lead, and mercury. This acidic water can contaminate surface and groundwater sources, harming aquatic life and potentially posing risks to human health. Other impacts include:

- Water contamination: Heavy metals and other pollutants can leach into water sources, making them unsafe for drinking, irrigation, and recreation.

- Habitat destruction: Changes in water quality and quantity can negatively impact aquatic ecosystems.

- Soil erosion: Water can erode exposed mine sites, leading to further pollution and land degradation.

- Greenhouse gas emissions: Certain mine water treatment processes can generate greenhouse gases.

Effective mine water management involves careful planning, including implementing water treatment plants, constructing dams and diversion channels, and monitoring water quality regularly. This often requires collaboration with regulatory agencies and local communities.

For instance, in one project I worked on, we implemented a multi-stage water treatment system that reduced heavy metal concentrations by over 95%, significantly mitigating the risk of AMD.

Q 9. How do you ensure proper disposal of mine tailings according to environmental regulations?

Tailings, the waste material left over after ore processing, require careful management to prevent environmental harm. Proper disposal involves adhering strictly to environmental regulations, which vary by location but generally emphasize minimizing environmental impact and long-term stability.

Ensuring Proper Disposal: The key is a multi-faceted approach:

- Tailings Storage Facility (TSF) Design: TSFs must be engineered to withstand various conditions, including seismic activity and potential rainfall events. This includes careful consideration of the tailings’ physical and chemical properties, as well as the surrounding geology and hydrology.

- Water Management: Effective water management within the TSF is crucial to prevent seepage and surface runoff. This often involves lined facilities, water recirculation systems, and careful monitoring of water quality.

- Environmental Monitoring: Regular monitoring of water, air, and soil quality in and around the TSF is essential to detect any potential pollution issues early on. This involves collecting samples, analyzing them in a certified lab, and reporting the results to regulatory agencies.

- Closure Planning: A comprehensive closure plan must be developed well in advance of mine closure. This plan details how the TSF will be reclaimed and stabilized after operations cease. This might involve covering the tailings, revegetating the area, and implementing long-term monitoring.

- Compliance with Regulations: All aspects of tailings management must comply with all relevant environmental regulations and permits. This includes obtaining necessary approvals, submitting regular reports, and responding promptly to any regulatory inquiries or concerns.

For example, in a previous role, I helped develop a TSF design that incorporated a geosynthetic liner and a sophisticated drainage system, significantly reducing the risk of groundwater contamination. We also implemented a rigorous environmental monitoring program that identified and addressed a minor seepage issue before it could escalate.

Q 10. Describe your experience with mine closure planning and its compliance aspects.

Mine closure planning is a critical aspect of responsible mining, ensuring the long-term environmental and social well-being of the affected area. It’s not simply a matter of shutting down operations; it’s a comprehensive process that begins during the early stages of mine development and continues throughout the mine’s lifespan.

Compliance Aspects: Mine closure planning must comply with numerous regulations and guidelines, varying by jurisdiction. Common elements include:

- Environmental Remediation: This involves restoring the site to a safe and stable condition, minimizing environmental impact and addressing any pollution.

- Water Management: Developing strategies for long-term management of mine water, including water treatment and monitoring, is crucial.

- Waste Management: Secure disposal or reclamation of tailings, waste rock, and other mine wastes is vital to protect human health and the environment.

- Site Stabilization: Steps to stabilize the site to prevent erosion, landslides, and other hazards, including backfilling, contouring, and revegetation, are critical.

- Community Consultation: Engaging with local communities and stakeholders is crucial to ensure their concerns are addressed and that the closure plan aligns with their needs and expectations.

- Financial Assurance: Adequate financial resources must be secured to cover the costs of mine closure, ensuring there are funds available for post-closure monitoring and maintenance.

A well-developed closure plan requires detailed feasibility studies, environmental impact assessments, and risk assessments. It must be approved by regulatory authorities and undergo continuous review and updates throughout the mine’s operational life. Failure to adequately plan for mine closure can lead to significant environmental liabilities and legal consequences.

I have been involved in several projects where we developed detailed closure plans, securing financial assurances and achieving regulatory approvals, leaving sites ready for post-mining land use.

Q 11. What are the key elements of a robust mine emergency response plan?

A robust mine emergency response plan is paramount for ensuring the safety and well-being of personnel and the protection of the environment during unexpected events. It should be a dynamic document, regularly reviewed and updated based on operational changes and lessons learned.

Key Elements:

- Hazard Identification and Risk Assessment: A comprehensive analysis of potential hazards (e.g., ground control issues, flooding, fires, equipment malfunctions) and their associated risks.

- Emergency Procedures: Clear and concise procedures for various emergency scenarios, including evacuation plans, communication protocols, and first aid response.

- Emergency Communication System: A reliable communication system to ensure effective communication between personnel, emergency services, and management during an emergency.

- Emergency Response Teams: Well-trained and equipped emergency response teams with clearly defined roles and responsibilities.

- Emergency Equipment and Supplies: Adequate emergency equipment and supplies (e.g., first aid kits, rescue equipment, communication devices) readily accessible at strategic locations.

- Training and Drills: Regular training and drills to ensure that personnel are familiar with emergency procedures and know how to react effectively.

- Post-Incident Review: A thorough review of every incident, identifying areas for improvement in the emergency response plan.

- Environmental Protection Procedures: Measures to mitigate the environmental impact of an emergency, such as preventing pollution or containing spills.

A well-structured emergency response plan utilizes a clear chain of command, integrates effectively with external emergency services, and prioritizes the safety of all personnel involved.

For example, I have firsthand experience developing and implementing emergency response plans for underground and open-pit mines, incorporating elements such as emergency shelters, dedicated communication systems, and regular training programs.

Q 12. Explain your understanding of mine rescue procedures and regulations.

Mine rescue procedures and regulations are designed to minimize casualties and injuries during mine emergencies. These procedures and regulations are crucial for the safety of miners and are typically governed by strict national and/or international standards.

Understanding Mine Rescue: Mine rescue involves specialized training, equipment, and procedures focused on locating, rescuing, and providing medical assistance to trapped or injured miners. Key aspects include:

- Training: Rigorous training for mine rescue teams, covering techniques such as self-rescue, search and rescue, first aid, and emergency communication.

- Equipment: Specialized equipment, including self-contained breathing apparatus (SCBA), communication systems, rescue tools, and medical supplies.

- Procedures: Established procedures for responding to different types of emergencies, including ground control incidents, fires, and flooding.

- Regulations: Adherence to strict regulations regarding training, equipment, and procedures, often mandated by government agencies.

- Emergency Communication: Efficient communication systems between the mine, emergency services, and rescue teams are essential for effective response.

Effective mine rescue procedures involve a coordinated effort between mine personnel, emergency services, and specialized rescue teams, often requiring detailed knowledge of the mine layout and potential hazards. Regular drills and training are essential to maintain readiness and ensure the effectiveness of rescue operations.

My experience includes participation in numerous mine rescue training programs and familiarity with various national and international standards and regulations related to mine rescue, ensuring I understand best practices and regulatory requirements.

Q 13. How familiar are you with the use of MineCAD or similar software for mine planning and design?

MineCAD and similar software packages (e.g., Datamine, Vulcan) are indispensable tools for mine planning and design. My experience with MineCAD is extensive, encompassing various aspects of mine design, from initial exploration data interpretation to long-term mine planning and optimization.

Applications of MineCAD:

- Geological Modeling: Creating 3D geological models using drillhole data, geological maps, and geophysical surveys.

- Resource Estimation: Estimating ore reserves and resources using geostatistical techniques.

- Mine Design: Designing open-pit and underground mines, including pit optimization, stope design, and haulage routes.

- Production Scheduling: Developing production schedules to maximize profitability and efficiency.

- Simulation and Optimization: Simulating mining operations and optimizing various parameters such as production rates, costs, and environmental impact.

- Visualisation and Reporting: Creating visualizations and reports to communicate findings to stakeholders.

Proficiency in MineCAD allows for more efficient and accurate mine planning, reducing costs, optimizing production, and minimizing environmental impact. The software’s capabilities contribute to data-driven decision-making, improving overall mine performance.

In previous roles, I have used MineCAD to optimize pit designs, resulting in significant increases in ore recovery and reductions in waste material handling. I’ve also used it extensively in resource estimation and production scheduling, leading to better resource allocation and production targets.

Q 14. How do you utilize geological data to optimize mining operations and maintain safety?

Geological data is the cornerstone of safe and efficient mining operations. It’s crucial for understanding the subsurface conditions, identifying ore deposits, predicting potential hazards, and optimizing mining strategies.

Utilizing Geological Data:

- Geotechnical Assessments: Geological data helps assess the geotechnical properties of the rock mass, allowing for the design of stable mine workings and predicting potential ground control problems (e.g., rockfalls, subsidence).

- Orebody Modeling: Accurate geological models are essential for resource estimation, mine planning, and production scheduling. This involves integrating various data sources, including drillhole data, geophysical surveys, and geological mapping.

- Hazard Prediction: Geological data can help predict potential hazards, such as groundwater inflow, gas emissions, and seismic activity, allowing for proactive risk mitigation strategies.

- Mine Planning and Design: Geological data informs decisions on mine layout, extraction methods, and infrastructure development, ensuring efficient and safe operations.

- Environmental Management: Geological data aids in understanding potential environmental impacts, such as acid mine drainage and groundwater contamination, allowing for effective environmental management plans.

Effective utilization of geological data requires expertise in geological interpretation, geostatistics, and mine planning software. It also involves integrating data from various sources and applying appropriate geological models to guide decision-making throughout the mining lifecycle.

For instance, I have leveraged geological data to identify areas of potential instability in an underground mine, leading to the implementation of proactive support measures that prevented a major ground control incident. In another project, geological modeling helped optimize the blast design, improving ore fragmentation and reducing operating costs.

Q 15. Explain your understanding of different mining methods and their associated risks.

Mining methods are broadly categorized based on the deposit’s location and characteristics. Understanding these methods and their inherent risks is crucial for safe and efficient operations.

- Open-pit mining: This involves excavating a large open pit to extract ore. Risks include slope instability, ground collapse, heavy equipment accidents, and dust inhalation.

- Underground mining: This involves extracting ore from tunnels and shafts beneath the surface. Risks include roof falls, explosions (methane, coal dust), ground control issues, flooding, and limited ventilation.

- Placer mining: This method extracts minerals from alluvial deposits using water and gravity separation. Environmental risks are significant, including water pollution and habitat destruction.

- In-situ leaching: This involves dissolving minerals in place using chemicals, and then extracting the solution. Risks include groundwater contamination, chemical spills, and potential for induced seismicity.

For example, during open-pit mining, meticulous slope design and stability analysis are critical to preventing catastrophic landslides. In underground mining, rigorous ventilation planning and methane monitoring are essential to prevent explosions. Each method requires a tailored risk management strategy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with conducting risk assessments in mining environments.

My experience with risk assessments in mining environments involves a multi-stage process adhering to industry best practices. It starts with hazard identification through site inspections, review of operational procedures, and consultations with workers. This is followed by risk analysis, quantifying the likelihood and severity of identified hazards using methods like HAZOP (Hazard and Operability Study) or bow-tie analysis. We then develop control measures to mitigate these risks, prioritizing those with the highest risk ratings. These measures are documented in a risk register, regularly reviewed, and updated as needed. For instance, I’ve been involved in risk assessments for an underground mine where we identified a risk of methane build-up. This led to implementing enhanced ventilation systems, gas monitoring procedures, and strict lockout/tagout protocols for equipment maintenance near potential methane sources.

Q 17. How do you interpret and apply relevant mining legislation and regulations?

Interpreting and applying mining legislation and regulations requires a thorough understanding of both the overarching principles and the specific requirements for the type of mine and its location. This involves staying updated on amendments, reviewing the relevant legislation (e.g., the Mine Safety and Health Administration (MSHA) regulations in the US, or equivalent regulations in other jurisdictions), and ensuring all operations are compliant. I actively participate in training sessions and workshops to maintain my knowledge. In practice, this translates into developing and implementing operational procedures that demonstrably meet legal requirements. For example, understanding the regulations related to dust control allows for the implementation of effective dust suppression methods, like water sprays and ventilation, and the monitoring of airborne dust levels to remain within legal limits.

Q 18. Explain your understanding of the importance of record-keeping in compliance with mining standards.

Meticulous record-keeping is paramount for compliance with mining standards. It provides evidence of adherence to regulations, supports investigations in case of accidents, and facilitates continuous improvement. This includes maintaining comprehensive records of inspections, safety meetings, training, maintenance, incident investigations, emergency response drills, and environmental monitoring data. Digital record-keeping systems enhance efficiency and accuracy. For instance, a well-maintained database documenting all equipment inspections and maintenance activities allows for proactive identification of potential failures and prevents breakdowns that might compromise safety. Lack of proper records can lead to non-compliance penalties, hindering operational licenses, and potentially jeopardizing employee safety.

Q 19. How do you ensure effective communication and collaboration to maintain safety standards on a mine site?

Effective communication and collaboration are fundamental to maintaining safety standards. This involves fostering a culture of open communication where all employees feel comfortable reporting hazards, near misses, and concerns without fear of retribution. Regular safety meetings, toolbox talks, and the use of communication tools like two-way radios are crucial. Collaboration extends beyond the mine site; it includes engaging with regulatory bodies, contractors, and other stakeholders. I’ve successfully implemented a system of daily safety huddles, where crews discuss potential risks, review the previous day’s incidents, and coordinate work tasks, fostering a strong sense of shared responsibility for safety.

Q 20. Describe your experience with conducting mine inspections and audits.

My experience with mine inspections and audits is extensive. Inspections focus on identifying immediate hazards and ensuring compliance with safety procedures. Audits, on the other hand, provide a more comprehensive review of the entire safety management system, including policies, procedures, training, and performance. I utilize checklists, observation techniques, and interviews to ensure thoroughness. During inspections, I’ve discovered numerous safety deficiencies, ranging from inadequate guarding on machinery to improper use of personal protective equipment (PPE). Corrective actions are documented, and follow-up inspections are carried out to ensure the issues are rectified. A well-structured audit report outlines the findings, recommendations, and areas for improvement.

Q 21. How do you identify and address potential safety hazards during mining operations?

Identifying and addressing potential safety hazards involves a proactive and systematic approach. This starts with regular safety inspections, observations of workers’ practices, and analysis of incident reports. Hazard identification tools such as Job Safety Analysis (JSA) and HAZOP are valuable. Once a hazard is identified, a risk assessment is conducted to determine its severity and likelihood, which informs the development of appropriate control measures. These measures might range from engineering controls (e.g., guarding machinery) to administrative controls (e.g., implementing work permits) and personal protective equipment (PPE). For example, if a high risk of slips, trips, and falls is identified, implementing improved housekeeping, providing adequate lighting, and training workers on safe walking practices are effective solutions.

Q 22. Explain your understanding of the role of a Mine Safety Officer.

A Mine Safety Officer (MSO) is a critical role in the mining industry, responsible for ensuring the health, safety, and well-being of all personnel and the protection of the environment at a mining operation. They are the primary advocate for safety, working to prevent accidents and injuries through proactive measures and incident response. This includes developing and implementing safety programs, conducting regular inspections, investigating accidents, and ensuring compliance with all relevant regulations and standards.

Their duties often involve:

- Developing and implementing safety policies and procedures.

- Conducting regular safety inspections and audits.

- Investigating accidents and incidents to identify root causes and prevent recurrence.

- Providing safety training and education to all personnel.

- Ensuring compliance with all relevant health, safety, and environmental regulations.

- Monitoring workplace hazards and implementing control measures.

- Working with management and employees to foster a strong safety culture.

For example, an MSO might develop a comprehensive fall protection program for an open-pit mine, ensuring proper training, equipment provision, and regular inspections to minimize the risk of falls from high places. They’re essentially the safety ‘police’ and ‘doctor’ combined, ensuring things are safe and remedying issues when they arise.

Q 23. Describe your experience with incident investigation and root cause analysis in mining accidents.

My experience in incident investigation and root cause analysis in mining accidents encompasses a multi-faceted approach, aligning with industry best practices such as the ‘Taproot’ methodology. This involves systematically investigating the contributing factors leading to an accident, going beyond simply identifying the immediate cause to uncover the underlying systemic issues. I’ve been involved in investigations spanning various types of mining accidents, including ground control failures, equipment malfunctions, and transportation incidents.

My approach follows a structured process:

- Data Gathering: This includes interviewing witnesses, reviewing documentation (safety reports, maintenance records, operational logs), examining the accident site, and analyzing any available data (e.g., sensor readings).

- Timeline Development: Creating a detailed timeline of events leading up to the accident provides a clear picture of the sequence of events.

- Root Cause Identification: Using techniques like fault tree analysis or ‘5 Whys,’ I delve into the underlying reasons for the accident, moving beyond superficial explanations.

- Corrective Actions: Once root causes are identified, corrective actions are developed and implemented to prevent similar incidents. This might involve changes to procedures, equipment upgrades, additional training, or improved supervision.

- Reporting and Documentation: Comprehensive reports are created, documenting the entire investigation process, findings, and implemented corrective actions.

For instance, in one case involving a haul truck rollover, initial investigation pointed to driver error. However, a deeper investigation revealed inadequate training on handling the vehicle in adverse weather conditions, leading to improved training programs and the implementation of a weather-dependent operating procedure.

Q 24. How familiar are you with the different types of mining permits and licenses?

My familiarity with mining permits and licenses is extensive. The specific types and requirements vary significantly depending on the jurisdiction and the type of mining operation (e.g., surface mining, underground mining, placer mining). However, common types include:

- Exploration Licenses: Permitting initial exploration activities to assess the presence and potential of mineral deposits.

- Mining Leases/Tenements: Granting the right to extract minerals from a specific area, usually after successful exploration.

- Environmental Permits: Addressing environmental impacts associated with mining operations, covering aspects such as water management, air quality, and waste disposal. These often involve obtaining separate permits for different aspects of environmental protection.

- Waste Disposal Permits: Specific permits for the management and disposal of mine tailings and other waste materials. These are crucial for ensuring the long-term environmental safety of the mine site.

- Water Use Permits: Authorizations for the use of water resources in mining operations, adhering to water conservation and protection regulations.

Understanding the specific requirements for each permit is critical for compliance. I’m experienced in navigating the complex regulatory landscape, ensuring all necessary permits are obtained and maintained throughout the lifecycle of a mining project. Failure to obtain and adhere to permit conditions can lead to significant penalties and operational disruptions.

Q 25. Explain your experience in managing stakeholder relationships regarding mining projects.

Managing stakeholder relationships in mining projects requires a proactive and collaborative approach. Stakeholders can range from local communities and Indigenous groups to government agencies, environmental organizations, and investors. Effective communication and engagement are paramount to fostering trust and ensuring the successful implementation of mining projects.

My experience includes:

- Community Engagement: Participating in community consultations, addressing concerns, and building relationships with local residents.

- Government Liaison: Working closely with regulatory bodies to ensure compliance and obtain necessary permits.

- Investor Relations: Communicating project updates, progress, and financial performance to investors.

- Environmental Advocacy Groups: Engaging with environmental groups to address their concerns and demonstrate commitment to environmental protection.

- Indigenous Consultation: Working collaboratively with Indigenous communities to respect their rights and traditional land use, obtaining free, prior, and informed consent (FPIC) where applicable.

For example, during a project near a sensitive ecosystem, we proactively engaged with local environmental groups, collaborating on an independent environmental impact assessment and committing to ongoing monitoring of biodiversity. This transparency built trust and mitigated potential conflicts.

Q 26. How do you maintain accurate records of mining activities for regulatory compliance?

Maintaining accurate records of mining activities is crucial for regulatory compliance, operational efficiency, and risk management. This involves a comprehensive system encompassing various aspects of the operation.

Key aspects of record-keeping include:

- Production Records: Tracking ore extraction, processing, and waste generation. This often involves specialized software for data capture and analysis.

- Safety Records: Documenting accidents, incidents, near misses, and safety training. This information is critical for identifying trends and implementing preventative measures.

- Environmental Monitoring Data: Recording data related to water quality, air emissions, and waste disposal, ensuring compliance with environmental regulations.

- Maintenance Logs: Tracking equipment maintenance, repairs, and inspections, crucial for preventing equipment failures and ensuring operational efficiency.

- Geological Data: Maintaining detailed geological records, including exploration data, resource estimates, and mining plans.

- Personnel Records: Tracking employee training, qualifications, and work hours. This data is vital for ensuring compliance with labor laws.

We use a combination of digital and physical record-keeping, leveraging database systems for efficient data storage and retrieval. Regular audits are conducted to ensure data accuracy and integrity. The system is designed to provide easy access to information for both internal and external stakeholders, including regulatory agencies.

Q 27. Describe your experience with the implementation and maintenance of a mine’s Quality Management System.

Implementing and maintaining a mine’s Quality Management System (QMS) typically involves adhering to international standards like ISO 9001. This framework focuses on continuous improvement and customer satisfaction, ensuring consistent delivery of products and services that meet or exceed expectations. In the mining context, the QMS encompasses all aspects of the operation, from exploration to closure.

My experience includes:

- Developing and Implementing QMS Procedures: Creating documented procedures for various aspects of the mining process, ensuring clarity and consistency in operations.

- Internal Audits: Conducting regular internal audits to evaluate compliance with QMS procedures and identify areas for improvement.

- Corrective and Preventative Actions: Developing and implementing corrective actions to address identified non-conformances and preventative actions to prevent future problems.

- Management Review: Participating in management reviews to assess the effectiveness of the QMS and identify opportunities for enhancement.

- Documentation Control: Implementing a robust system for documenting, controlling, and archiving QMS records.

For example, we implemented a QMS that improved our ore grading process. Through standardized procedures and regular monitoring, we were able to reduce ore dilution, leading to higher-grade product and increased profitability while minimizing environmental impact.

Q 28. How do you ensure the ongoing training and competence of personnel in relation to mining safety standards?

Ensuring ongoing training and competence of personnel in relation to mining safety standards is an ongoing process requiring a multi-pronged approach.

Key elements include:

- Needs Assessment: Regularly assessing the training needs of personnel based on job roles, identified risks, and changes in regulations or technology.

- Training Programs: Developing and delivering comprehensive training programs addressing specific safety hazards and operational procedures. This may include classroom instruction, hands-on training, and simulations.

- Competency Assessments: Regularly assessing the competency of personnel through practical assessments, written exams, or observation of on-the-job performance.

- Refresher Training: Providing regular refresher training to reinforce safety knowledge and skills and to address any changes in best practices or regulations.

- Record Keeping: Maintaining accurate records of training received by each employee, ensuring that all personnel have the necessary qualifications and certifications.

- Use of Technology: Incorporating technology such as online training modules, virtual reality simulations, and mobile safety apps to enhance training effectiveness and accessibility.

We emphasize practical, hands-on training, complemented by regular refresher courses and simulations. Furthermore, we create a safety-conscious culture where employees are encouraged to report hazards and participate actively in safety improvement initiatives.

Key Topics to Learn for Knowledge of Mining Industry Standards Interview

- Health and Safety Regulations: Understand key legislation, best practices, and risk management strategies within mining operations. Consider practical applications like incident reporting procedures and emergency response protocols.

- Environmental Compliance: Familiarize yourself with environmental impact assessments, permitting processes, and waste management techniques. Explore case studies demonstrating successful environmental stewardship in mining.

- Mine Planning and Design: Grasp the principles of mine design, geotechnical engineering, and resource estimation. Practice applying these concepts to hypothetical scenarios involving mine layout optimization or resource depletion strategies.

- Mining Methods and Technology: Explore various extraction techniques (open-pit, underground) and the application of modern technologies (automation, data analytics) to enhance efficiency and safety. Be prepared to discuss the advantages and disadvantages of different methods.

- Mine Closure and Reclamation: Understand the regulations and best practices surrounding mine closure, land reclamation, and environmental rehabilitation. Consider the long-term environmental and social responsibilities involved.

- Quality Control and Assurance: Learn about quality management systems in mining, including sampling, assaying, and data analysis. Be prepared to discuss how quality control impacts operational efficiency and profitability.

- Sustainable Mining Practices: Understand the principles of sustainable mining, including resource efficiency, water management, and reducing carbon footprint. Be ready to discuss how these principles are implemented in modern mining operations.

Next Steps

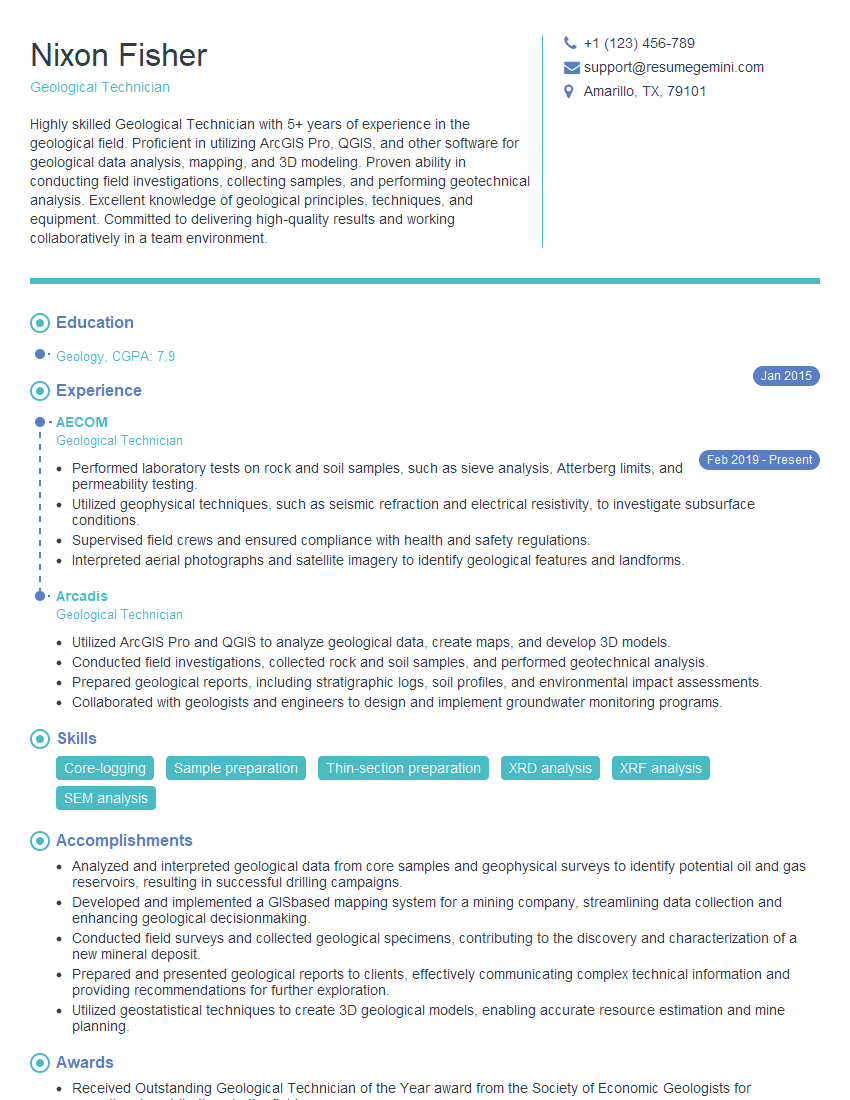

Mastering Knowledge of Mining Industry Standards is crucial for advancing your career in this dynamic field. A strong understanding of these standards showcases your commitment to safety, environmental responsibility, and operational excellence – qualities highly valued by employers. To maximize your job prospects, invest time in creating an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications are effectively communicated to potential employers. Examples of resumes tailored to showcasing expertise in Knowledge of Mining Industry Standards are available to further guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good